Tandem type brake master cylinder with adjustable pre-tightening force for electric control brake system

A technology of electronically controlled braking and brake master cylinder, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problem of large volume, vacuum booster that cannot meet the braking requirements of new energy vehicles, and the structure of the brake master cylinder Complicated and other issues, to reduce the difficulty of processing and installation, convenient production, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

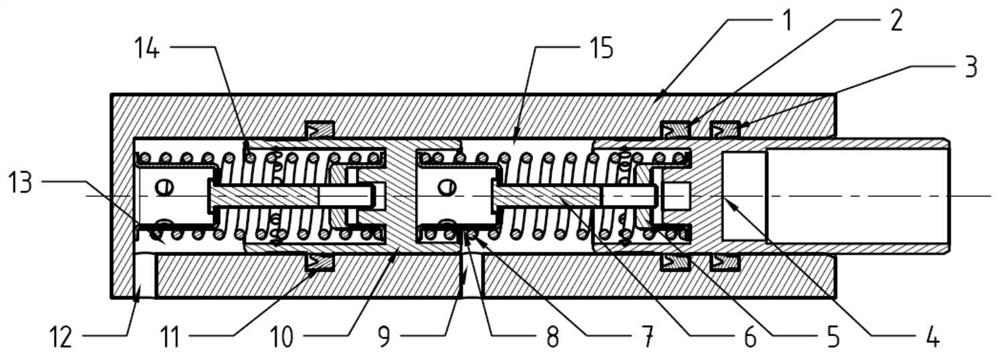

[0027] Example one, as figure 1 As shown, a tandem brake master cylinder with adjustable pre-tightening force for an electronically controlled brake system includes a housing 1 with a primary piston 4 and a secondary piston 10 in the housing 1. The primary piston 4 and the secondary piston 10 are arranged in parallel. The front ends of the primary piston 4 and the secondary piston 10 are respectively equipped with a primary spring 7 and a secondary spring 14. The sealing ring 3 is sealed, the secondary piston 10 is sealed by the third sealing ring 11, the primary spring 7 is fixed and preloaded by the first spring holder 5 and the second spring holder 8, and the first spring holder The second spring holder 8 is connected with the guide rod 6 through threads, and the fixing structure of the secondary spring 14 is the same as that of the primary spring 4 .

[0028] During normal movement, when the driver steps on the pedal, the first-stage piston 4 starts to move, and the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com