Stop device of bending machine

A technology of a material stopper and a bending machine, which is applied in the directions of a feeding device, a positioning device, a storage device, etc., can solve the problems that the stroke of the stroke rod cannot be guaranteed to be consistent, the folding accuracy cannot be guaranteed, and the operation is complicated, and the structure is simple. , easy to operate and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

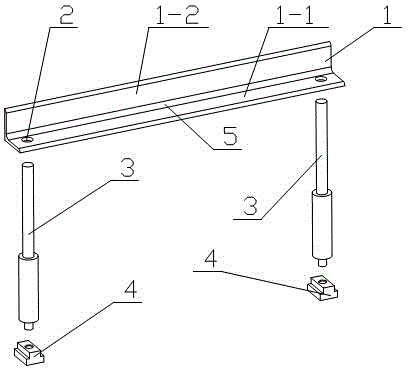

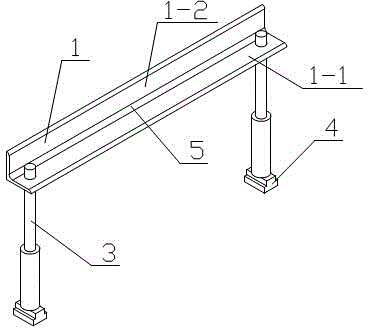

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0013] like figure 1 and figure 2 The material blocking device for the bending machine shown has a material blocking plate 1, the material blocking plate 1 includes a bottom plate 1-1 and a vertical plate 1-2 perpendicular to the bottom plate 1-1, and the left and right ends of the bottom plate 1-1 are respectively set There is a mounting hole 2, and each mounting hole 2 is fixedly connected with a stroke rod 3 by a fastening screw, and the bottom end of each stroke rod 3 is respectively equipped with a slide block 4, and the slide block 4 slides on the sliding track. A rounded corner 5 is provided at the connection between the base plate 1-1 and the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com