Plastic film unfolding frame

A technology of plastic film and unfolding rack, applied in thin material processing, sending objects, transportation and packaging, etc., can solve the problems of uneven film thickness, film tearing, and sliding resistance, so as to reduce the contact area and improve the film quality level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

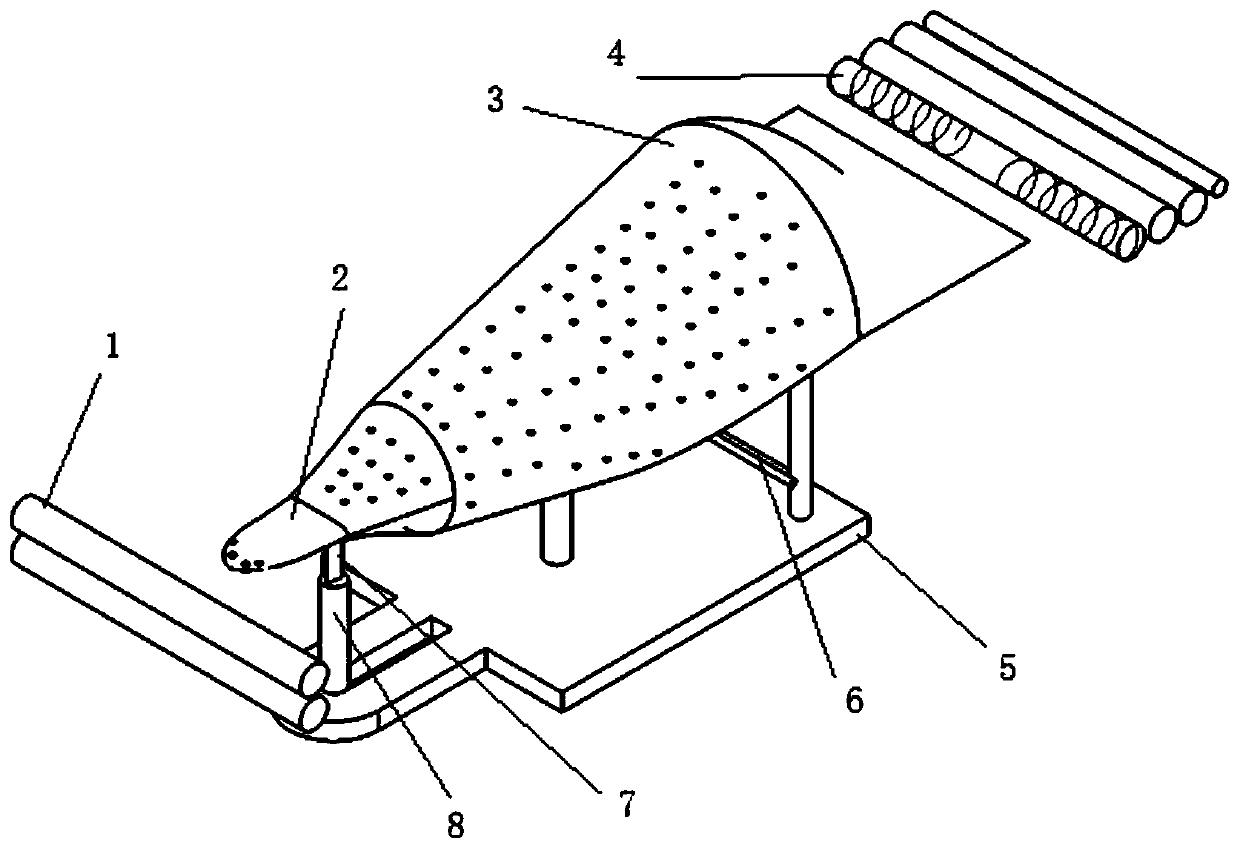

[0015] A kind of plastic film unfolding frame of the present invention, as figure 1 As shown, it includes an unwinding roller 1, an opener 2, a round table spreader 3, a winding roller 4, a support frame 5, an air intake pipe 6, a cutter 7 and a cutter support column 8.

[0016] The plastic film is drawn into the opening device 2 by the unwinding roller 1 . The opening device 2 is solidly connected with the circular platform expander 3, and its width is narrower than the diameter of the film. The airflow is blown out to the front, and the two-layer bonded film is blown apart during the film pulling process to realize the opening.

[0017] The present invention is a plastic film unfolding frame. The cutter 7 is fixed on the cutter supporting column 8, and the cutter 7 is located in the lower part of the opener 2 and close to the opener 2. When the film passes through, the film is cut open for subsequent unfolding operation. Cutter support post 8 can slide along the slide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com