Testing device

A test device and guide rod technology, which is applied in the direction of measurement device, circuit breaker test, measurement of electricity, etc., can solve problems such as affecting test accuracy, difficulty in unified positioning, and inconsistent pressing strokes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

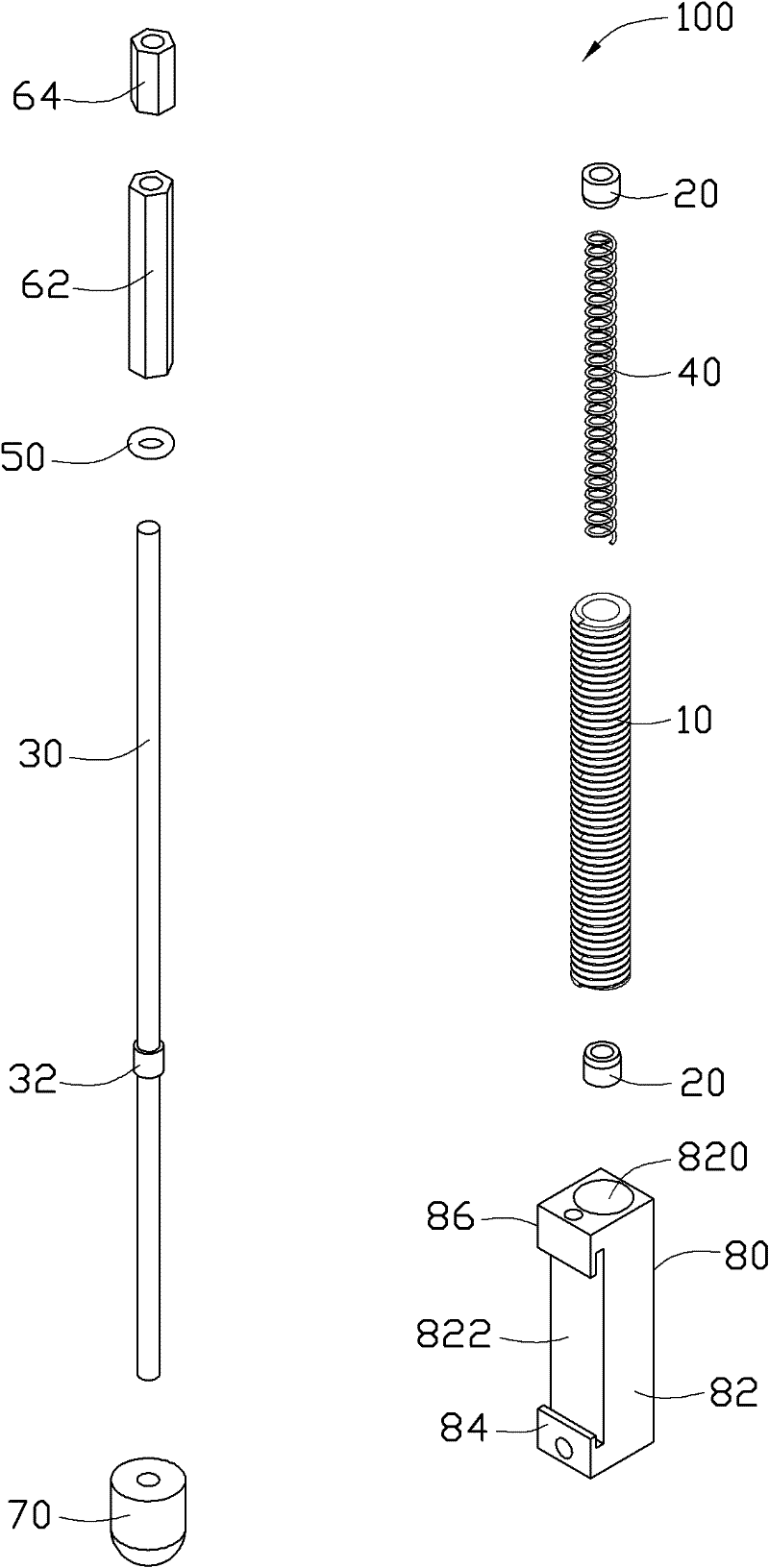

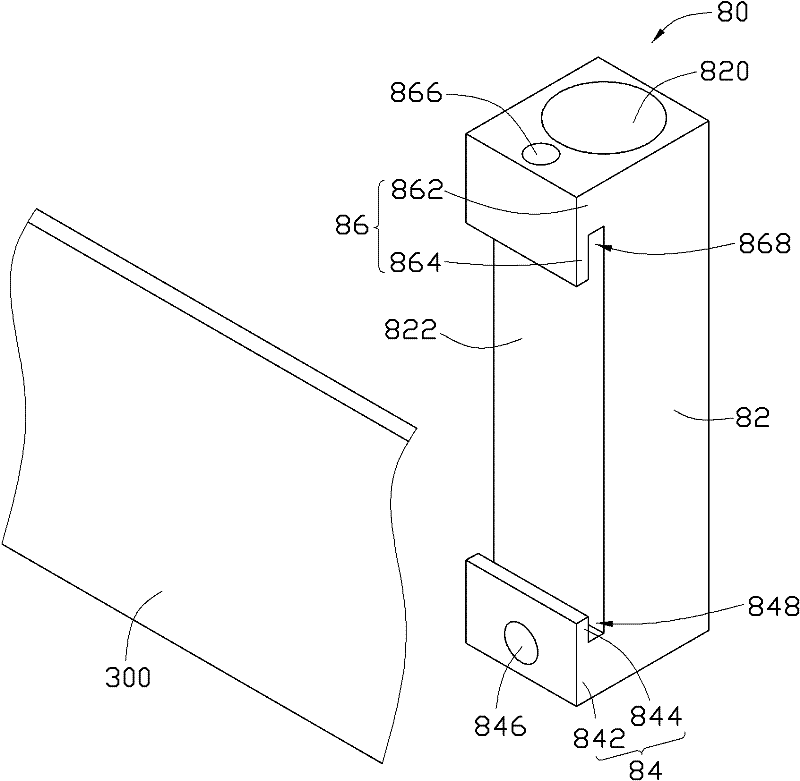

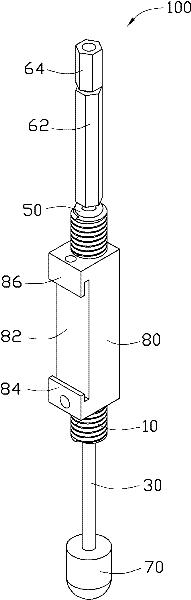

[0038] see figure 1 , the present invention discloses a test device 100, which is used to test a keyboard 200 (see Figure 4 ) reliability and service life. The testing device 100 includes a sleeve 10 , two stoppers 20 , a guide rod 30 , an elastic member 40 , a washer 50 , a first adjustment member 62 , a second adjustment member 64 , a pressure head 70 and a fixing member 80 .

[0039] The sleeve 10 is a hollow structure, and its outer peripheral wall is provided with several annular protrusions arranged at equal intervals. The two stoppers 20 are hollow cylinders, which are respectively fixed on the inner peripheral walls of the two ends of the sleeve 10 .

[0040] The guide rod 30 is slidably passed through the sleeve 10 , and a flange 32 is arranged around a substantially middle and lower portion of the guide rod 30 . The diameter of the flange 32 is slightly larger than that of the guide rod 30 . When the guide rod 30 passes through the sleeve 10 , the flange 32 abuts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com