Multifunctional sample stage for measuring block-shaped solid sample in X-ray diffractometer

A diffractometer and X-ray technology, applied in the field of detection equipment, can solve the problems of sample cutting damage, troublesome adjustment, and high production requirements, and achieve the effects of easy preparation, easy installation and disassembly, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

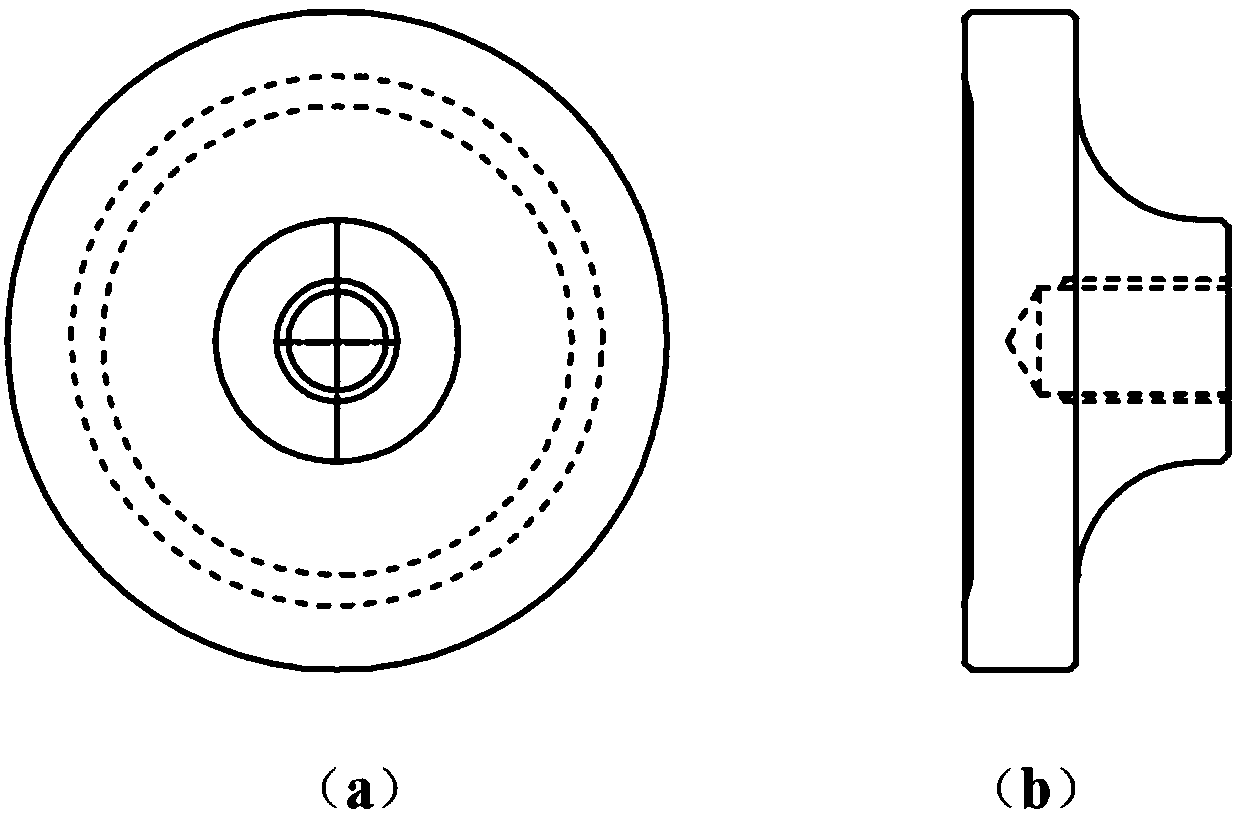

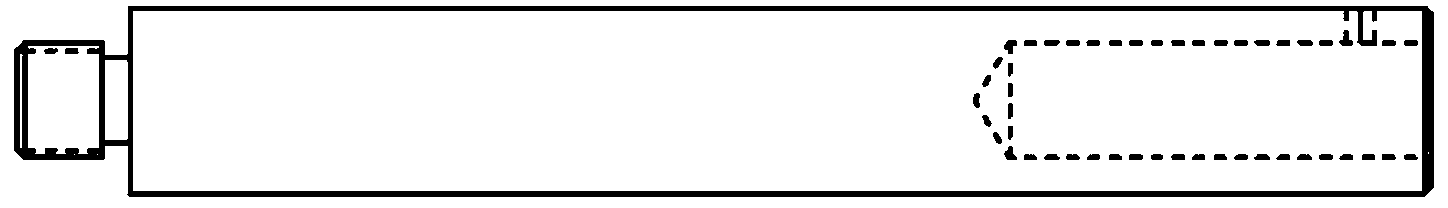

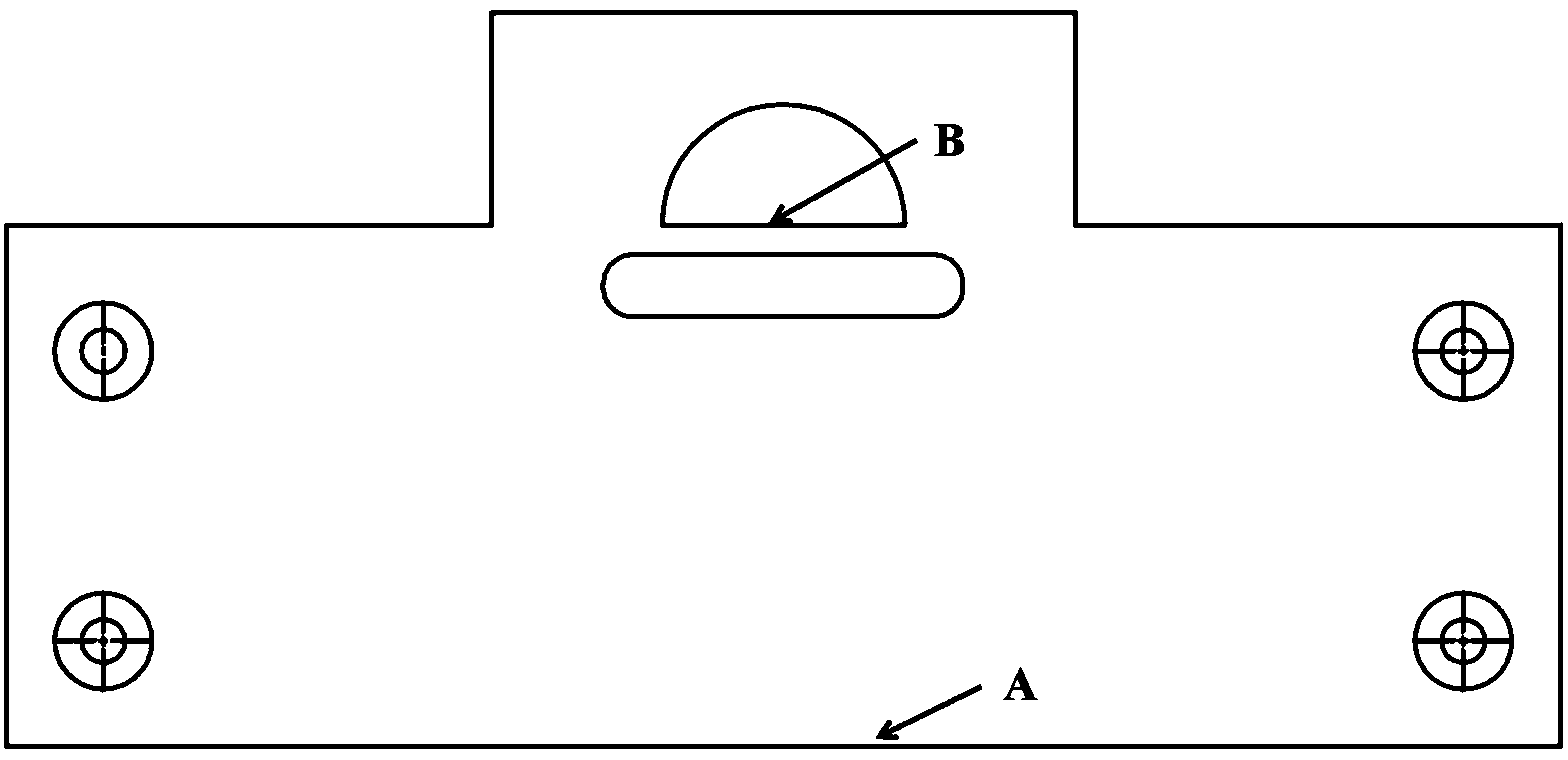

[0039] A multifunctional sample stage for X-ray diffractometer to measure bulk solid samples, including a base bracket and a sample tank arranged on the base bracket; The shaft and two base brackets serve as support points to fix and adjust the position of the sample well.

[0040] The base bracket is composed of a base, a guide rod and an inner diameter micrometer; the base and the guide rod are connected by threads, and the inner diameter micrometer is fixed in the guide rod by screws.

[0041] The measurement range of the inner diameter micrometer is 250-275mm, the scale value is 0.01mm, and the accuracy level is grade 1; the main function of the inner diameter micrometer is to adjust the balance position of the sample tank.

[0042] The sample slot includes a positioning mask, a sample pool and a mask which are connected sequentially by screws.

[0043] A central axis clamping hole is arranged on the positioning mask, and the size of the central axis clamping hole matches t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| division value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com