Full-automatic intelligent steel wire winding equipment

A steel wire winding and fully automatic technology, applied in the field of winding rubber hose linkage production equipment, can solve the problems of uncontrollable steel wire tension, affecting the production quality of high-pressure steel wire winding rubber hose, etc., achieve stable rotation track, stable tension, and solve the problems of unstable specifications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

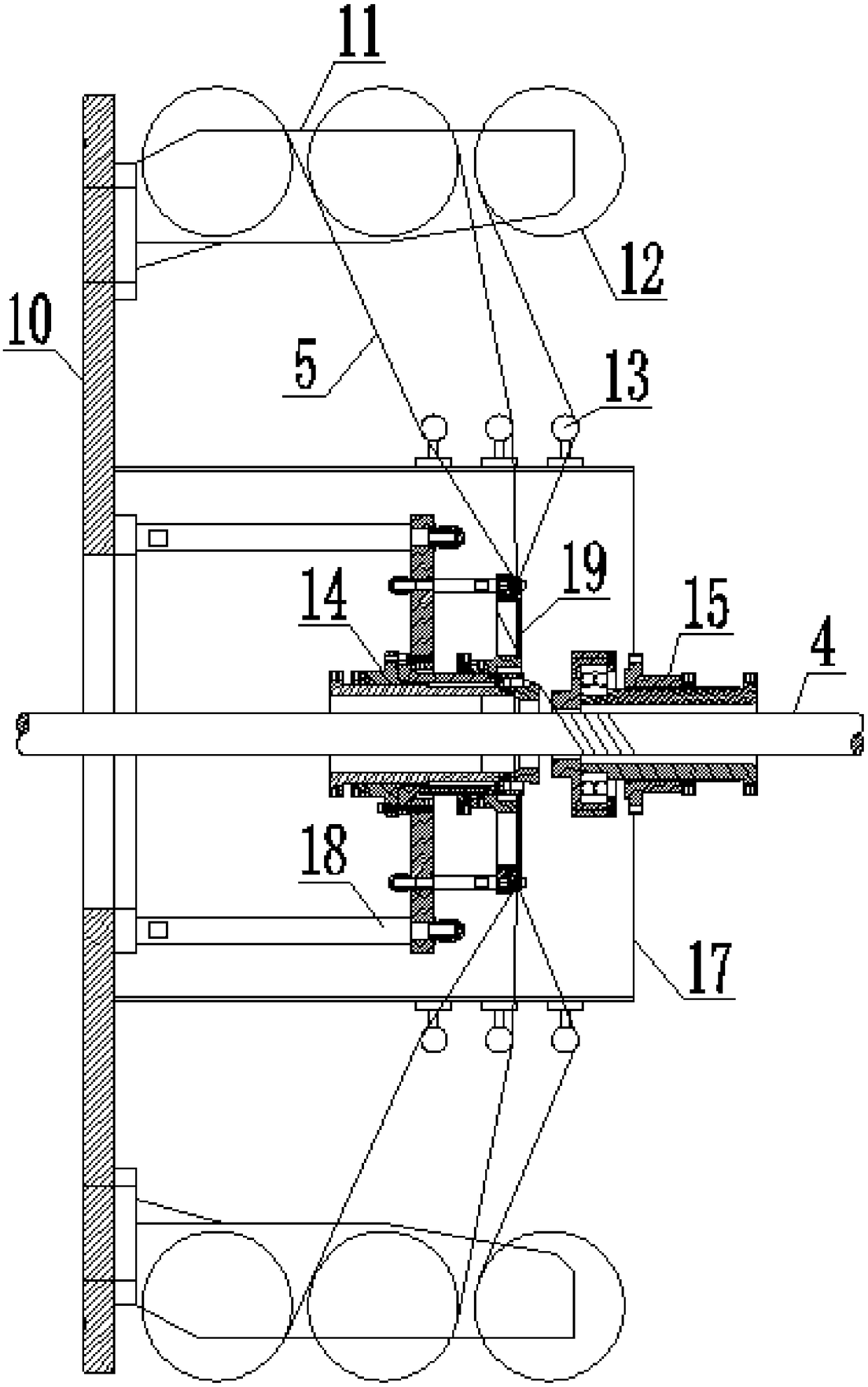

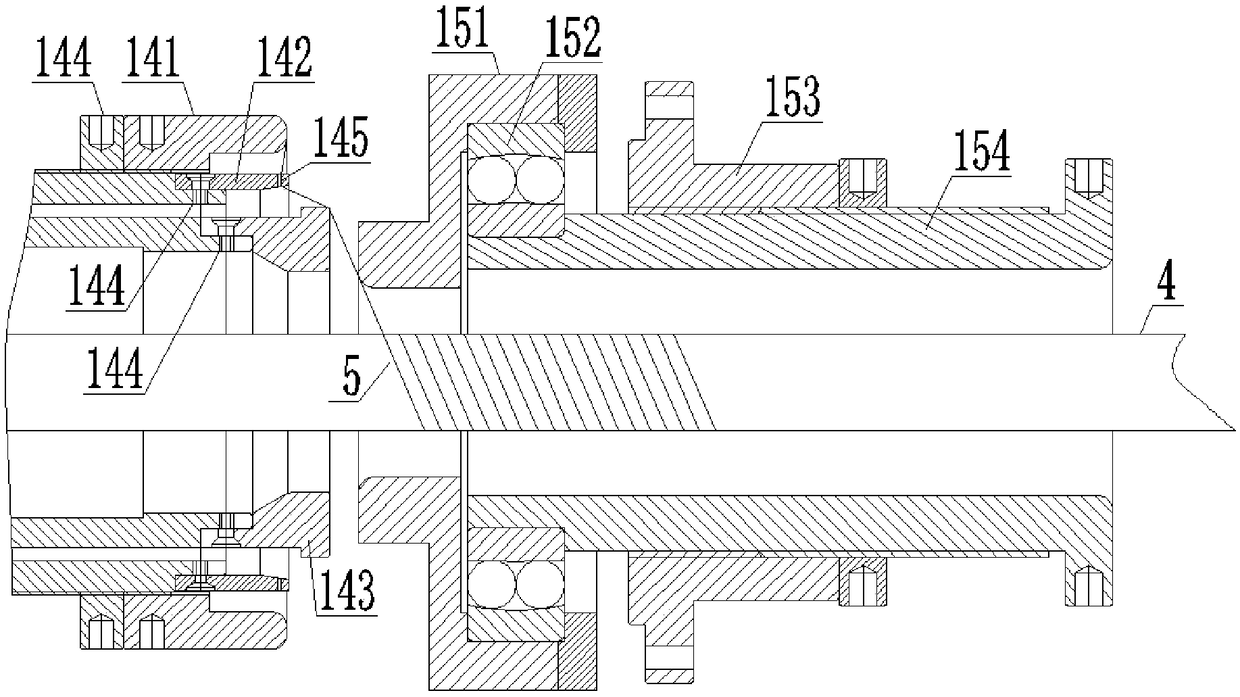

[0035] A fully automatic intelligent steel wire winding equipment, such as Figure 4 As shown, it includes a medium rubber winding machine 3, four steel wire preforming machines 1, a traction machine 2 and a PLC centralized control system. Connect for centralized control. The tube blank 4 processed by multiple processes is sequentially input into four steel wire preforming machines 1 through the rubber winding machine 3 under the traction of the tractor 2 to wind the steel wire 5 . The middle glue winding machine 3 is equipped with an infrared monitor to give an early warning of the remaining amount of the middle glue film, and adopts a photoelectric control method to automatically and smoothly stop the middle glue winding machine 3 when the middle glue film is about to run out. The tube blank 4 output from the guide roll frame on the middle glue winding machine 3 can be easily adjusted to the center of the revolving disk 10 on the steel wire preforming machine 1, so that the...

Embodiment 2

[0041] As preferably, in order to realize the present invention better, optimize further on the basis of above-mentioned embodiment, especially adopt following setting structure:

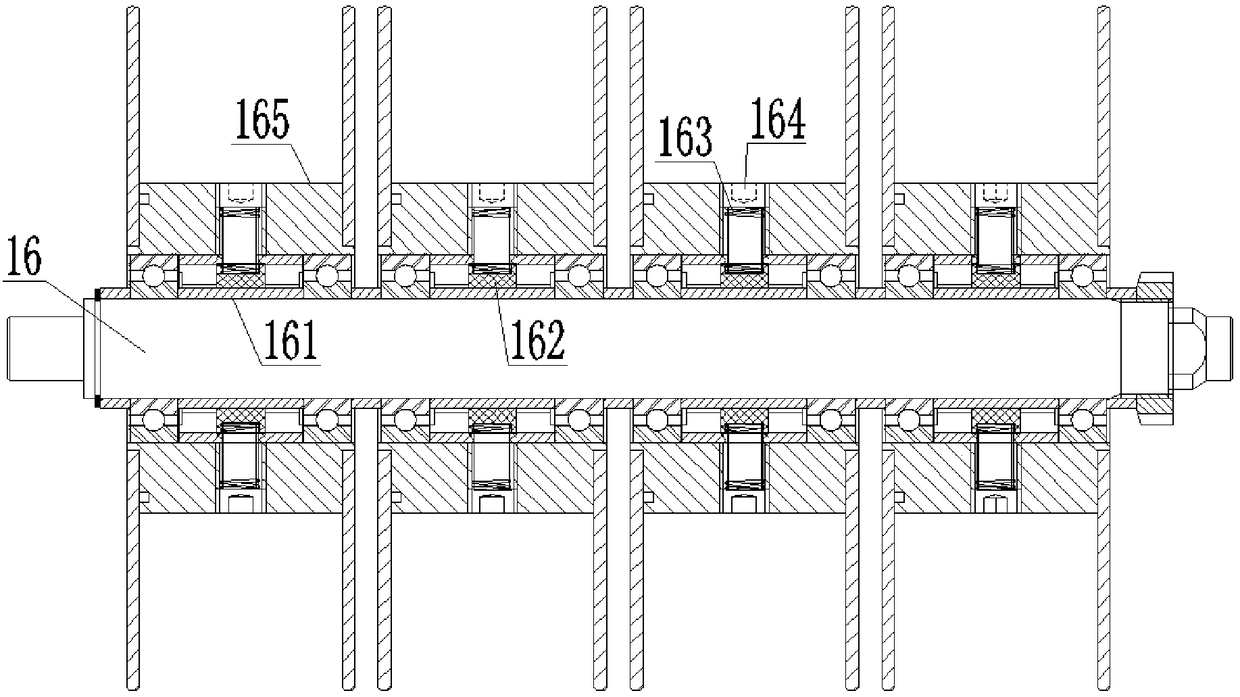

[0042] Such as image 3 As shown, the winding wheel 12 has a winding wheel mandrel 16, and a plurality of friction block assemblies are arranged on the winding wheel mandrel 16, and each friction block assembly includes a spacer 161, a friction block 162, a spring 163, and a top wire 164 And the bearing 165, the spacer 161 and the bearing 165 are all arranged on the surface of the winding wheel mandrel 16, the friction block 162 is installed on the spacer 161, the spring 164 and the top wire 165 are installed in the bearing 165, and the spacer 161 passes through the top wire 165 Adjust the pressure of the spring 164 on the friction block 162 to adjust the frictional force on the winding wheel mandrel 16 , and the friction block assembly is symmetrically distributed on both sides of the winding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com