Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Rich three-dimensional sense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing enamel painted porcelain

InactiveCN102602216ARich layersRich three-dimensional senseDecorative surface effectsSpecial ornamental structuresEnamel paintEngineering

The invention discloses a method for manufacturing enamel painted porcelain. The method includes steps: manufacturing ornamental patterns, color enamel ornamental portions and color enamel ornamental pattern images with golden edges, and outputting films of the ornamental patterns, the color enamel ornamental portions and the color enamel ornamental pattern images with the golden edges; printing a color enamel ornamental layer on an ornamental pattern image; covering surface sealing oil on the ornamental pattern image and a color enamel ornamental layer and manufacturing ceramic transfer paper; adhering the ceramic transfer paper on porcelain; naturally cooling the porcelain after color baking of the porcelain; and preparing color enamel ornamental pattern stained paper with golden edges, attaching the color enamel ornamental pattern stained paper with the golden edges onto the porcelain, and naturally cooling the porcelain after color baking of the porcelain. The method can be used for manufacturing the enamel painted porcelain in a batch in a standardized manner, and the manufactured color enamel porcelain is rich in layered impression, stereoscopic impression and texture, does not contain lead and cadmium heavy metal, not only can be used as display artwork, but also can be used as a practical utensil for daily life.

Owner:斯达高瓷艺发展(深圳)有限公司

Three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology and aluminum veneer thereof

ActiveCN103394453AHigh degree of simulationRich three-dimensional senseCovering/liningsPretreated surfacesThree dimensional simulationManufacturing technology

The invention discloses a three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology. The three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology comprises the steps of spraying a fluorocarbon base coating, spraying a fluorocarbon facial coating, carrying out high-temperature solidification treatment, spraying a water-in-water type simulation mineral varnish layer, spraying a fluorocarbon varnish layer, and carrying out solidification treatment. The invention discloses aluminum veneer at the same time. The aluminum veneer comprises an aluminum base plate, the fluorocarbon base coating, the fluorocarbon facial coating, the water-in-water type simulation mineral varnish layer and the fluorocarbon varnish layer, wherein the surface of the water-in-water type simulation mineral varnish layer and the surface of the fluorocarbon varnish layer are uneven. According to the aluminum veneer and the three-dimensional fluorocarbon simulation mineral varnish aluminum veneer manufacturing technology, water containing ingredients in water-in-water multicolor paint are utilized ingeniously, the characteristics that the water multicolor paint is boiled and evaporated in high temperature are utilized, and thus an extreme good uneven three-dimensional simulation mineral varnish effect is formed in the surfaces of plates through unique paint distribution and a solidification technology. Meanwhile, the weather-proof, self-cleaning, easy cleaning, outdoor gloss loss free advantages of fluorocarbon paint are combined.

Owner:SHANGHAI YARET IND GROUP

Grainy paper printing production method

InactiveCN104354487ARich three-dimensional senseIntegrity guaranteedDuplicating/marking methodsPulp and paper industryDigital printing

The invention discloses a grainy paper printing production method which comprises steps as follows: firstly, various characters or patterns are input into a computer, and the characters or patterns are directly printed on the grainy paper by the computer. Various characters or patterns are printed on the grainy paper in a digital printing manner in an ink jet form, novel decorative paper is formed, and the patterns are clear, vivid and stereoscopic.

Owner:邱有英

Method for making woven picture as traditional Chinese picture

ActiveCN102582348AUnique artistic charmIntegrity guaranteedDecorative surface effectsSpecial artistic techniquesEngineeringLight transmission

The invention relates to a method for making a woven picture as a traditional Chinese picture, comprising the following steps: (1) drawing a picture: wherein a selected a piece of picture drawing paper is provided with a peripheral part and a middle part, the peripheral parts of the picture drawing paper are at the peripheral sides of the picture drawing paper and are connected in a closed way, and the middle part of the picture drawing paper is surrounded by the peripheral parts; (2) cutting the picture drawing paper: wherein the middle part of the picture drawing paper is cut into a plurality of strips, and the two ends of each paper strip are connected with the peripheral parts of the picture drawing paper; (3) making woven strips: wherein a piece of light-transmission paper provided with the same shape as the picture drawing paper is segmented into a plurality of woven strips; and (4) weaving, wherein the woven strips and the paper strips of the middle part of the picture drawing paper are weaved into a stereographic picture, and the two ends of each woven strip are adhered onto the peripheral parts of the picture drawing paper so as to form a picture body. The method for making the traditional Chinese picture is easy and convenient to operate, and the woven picture made by adopting the method has strong stereographic effect and attractive visual effect and presents a sense of spaciousness, so that the art enjoyment is enhanced.

Owner:汇立装备制造有限公司

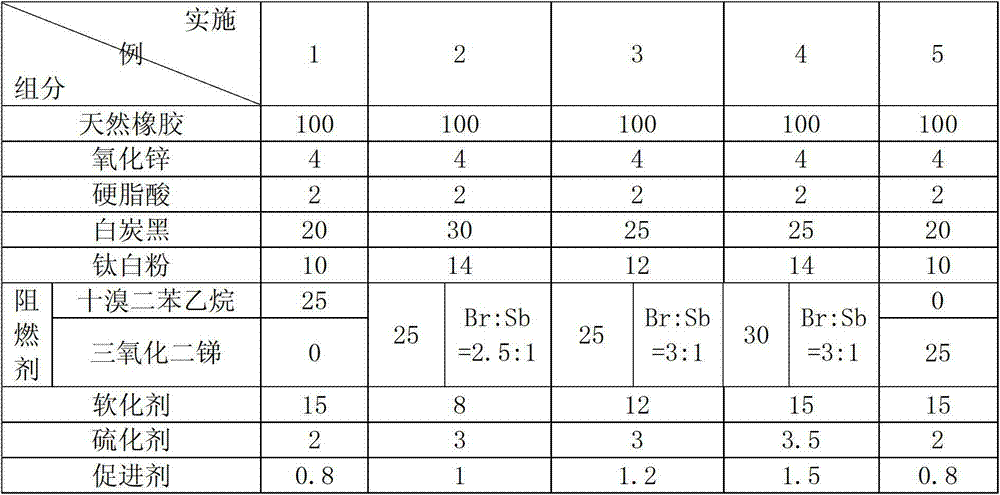

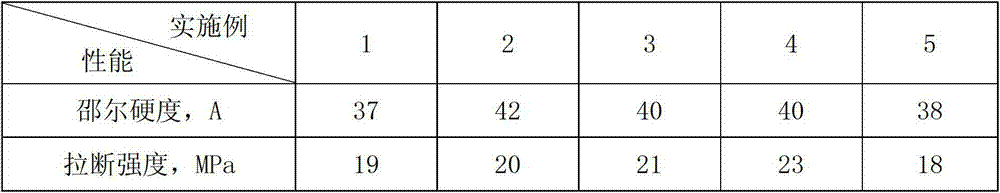

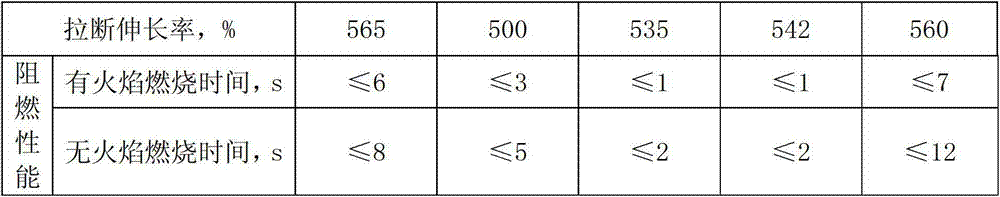

Flexible flame-retardant rubber curtain with high strength, long service life and good visual effect and preparation method thereof

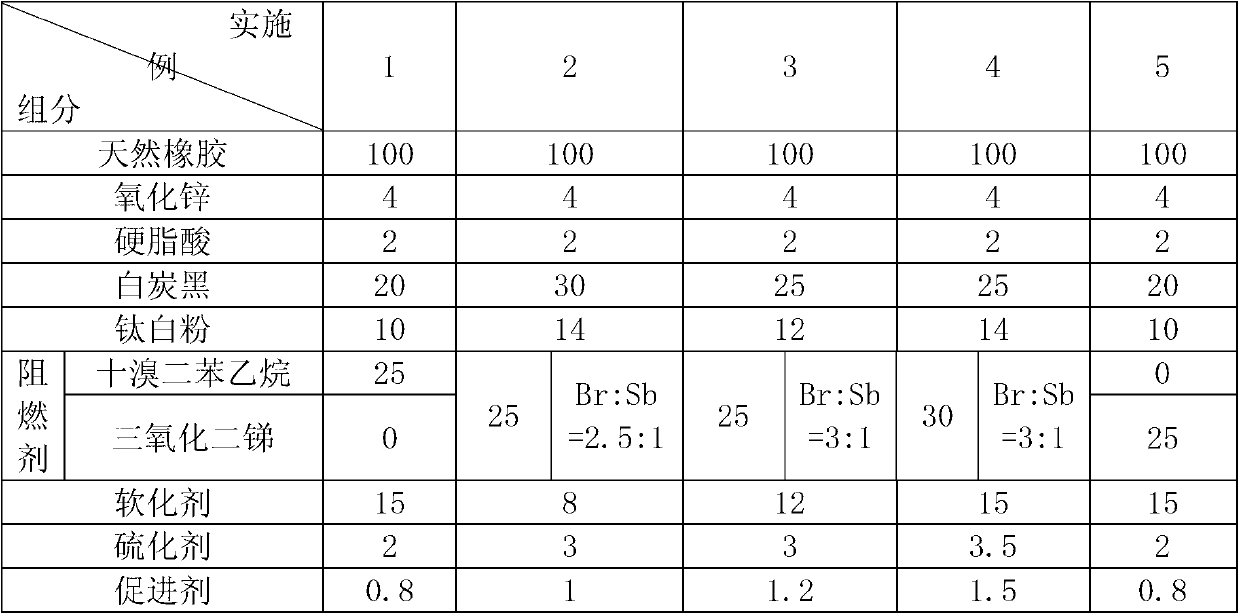

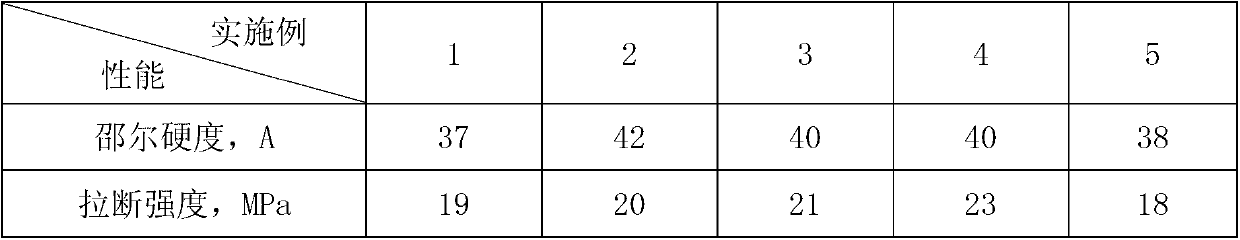

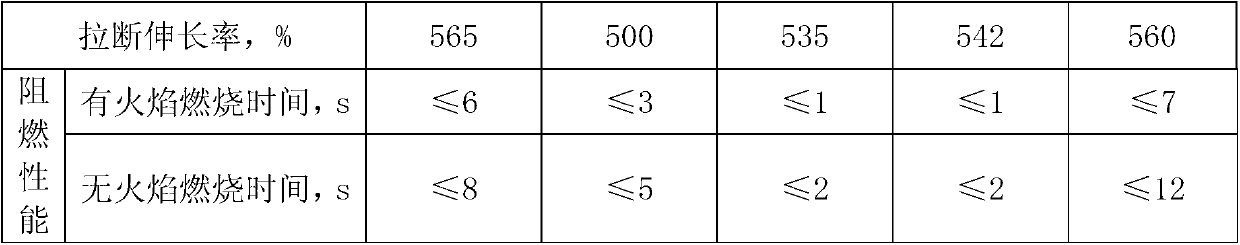

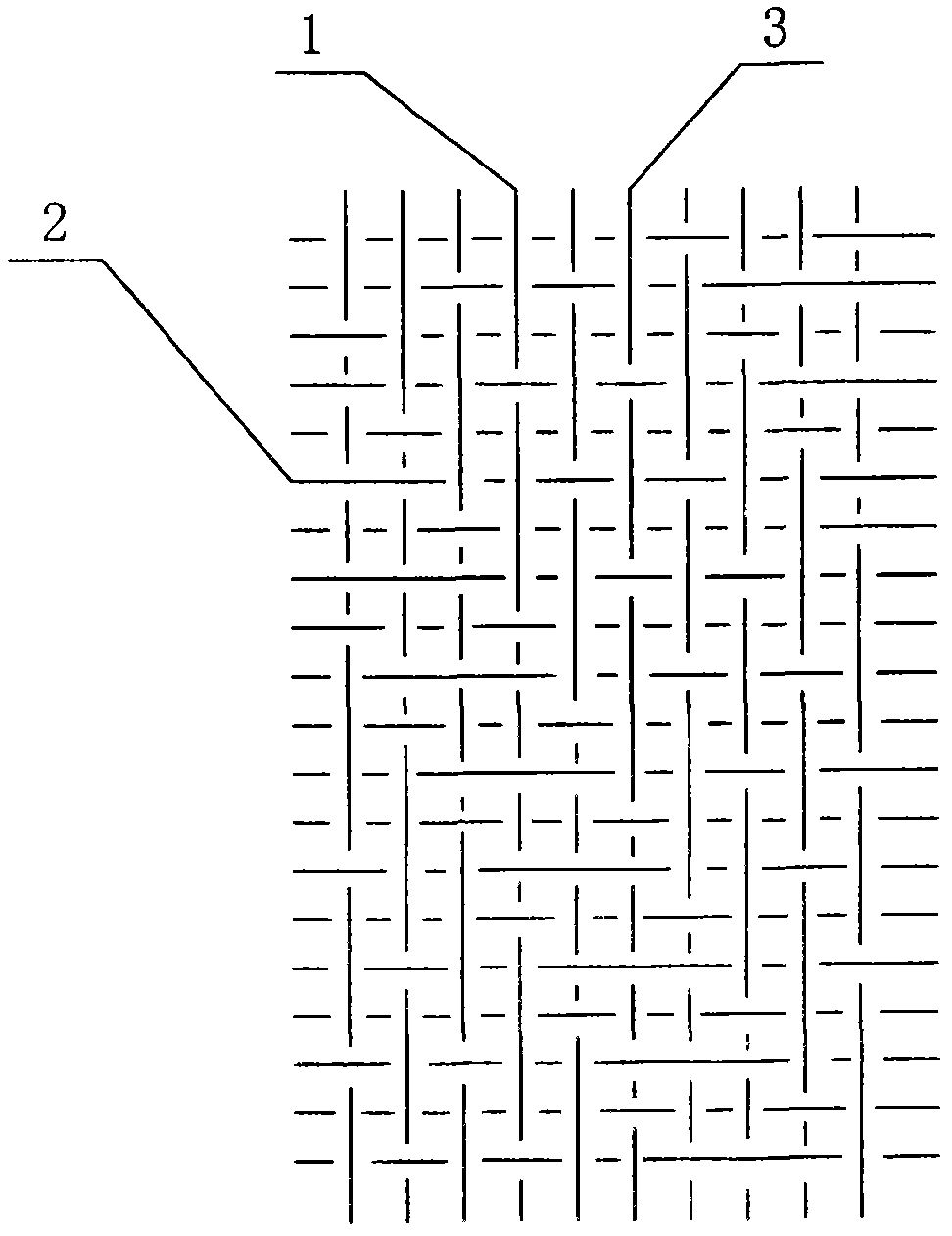

The invention provides a flexible flame-retardant rubber curtain with high strength, long service life and good visual effect, which realizes good flame retardance, high strength, long service life, good flattening performance, rich stereoscopic impression of pictures and bright and gentle picture quality, is easy to clean and convenient to prepare and does not need a curtain base for support. The flexible flame-retardant rubber curtain consists of the following components in parts by weight: 100 parts of natural rubber, 2-3.5 parts of vulcanizing agent, 0.8-1.5 parts of accelerant, 4-6 parts of zinc oxide, 2-3 parts of stearic acid, 20-30 parts of white carbon black, 10-15 parts of titanium dioxide, 25-35 parts of flame retardant and 8-30 parts of softener, and preferentially 3-3.5 parts of vulcanizing agent, 1-1.5 parts of accelerant, 4-5 parts of zinc oxide, 25-30 parts of white carbon black, 12-14 parts of titanium dioxide, 25-30 parts of flame retardant and 8-15 parts of softener. A preparation method comprises the following steps of: putting the natural rubber, zinc oxide, stearic acid, white carbon black, titanium dioxide, flame retardant and softener in a closed rubber mixing machine; performing rubber mixing at 95-105 DEG C for 13-17 minutes to obtain a rubber compound; adding the vulcanizing agent and the accelerant into the rubber compound; remilling in an open rubber mixing machine for 4-6 times and discharging sheet; and vulcanizing the rubber compound after the remilling in a vulcanizing machine.

Owner:NANJING DONGRUN SPECIAL RUBBER

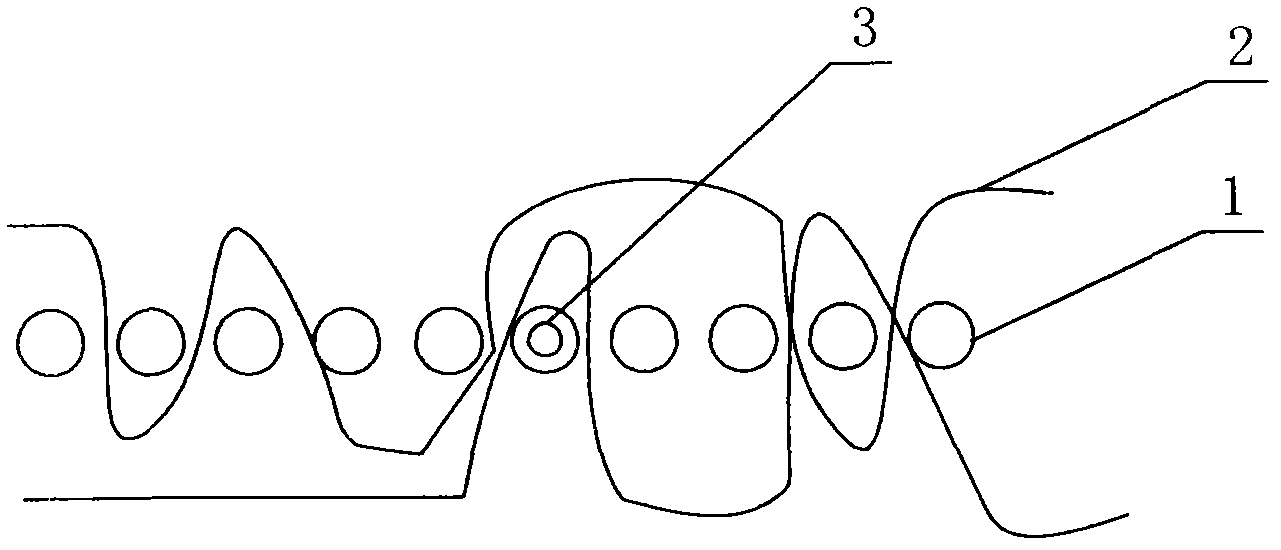

Anti-electrostatic shell fabric in calvary twill weave

The invention discloses an anti-electrostatic shell fabric in calvary twill weave. The shell fabric is characterized in that a fabric base interwoven with warps and wefts is in the composite twill weave with structures of exposed weaving four times and embedded weaving once, exposed weaving three times and embedded weaving once, exposed weaving four times and embedded weaving twice, exposed weaving once and embedded weaving once and exposed weaving once and embedded weaving twice, twills are clear and highly stereoscopic. The warps and the wefts are high in arraying density and compactness, so that the anti-electrostatic shell fabric is thick, compact, fine in wear resistance and high in dust filtering efficiency and generates no dust. Further, anti-electrostatic yarns are uniformly embedded in the fabric base body and concealed between the warps and the wefts, so that anti-electrostatic performance cannot be reduced evidently by common washing and friction. In addition, the anti-electrostatic shell fabric is capable of completely meeting the requirements of anti-electrostatic clothing on the aspects of anti-electrostatic performance and dustproof performance.

Owner:ANHUI HUAMAO TEXTILE +1

Making method of embossment type color metal etchings

ActiveCN102774219ARich three-dimensional senseRich visual senseDecorative surface effectsSpecial artistic techniquesEtchingPrinting ink

The invention discloses a making method of embossment type color metal etchings. The method comprises the following steps: firstly, grinding metal plates; then making canvas shadings and image films according to pictures, etching back on grinded metal plates to making the canvas shadings and image films; then mixing photosensitive printing ink with thickness texture according to color separation photographic plates of pictures; then making thickness photographic films capable of acquiring picture stroke and thickness texture effects according to picture effect; carrying out sensitization to obtain bottom slabs with abundant stroke texture; finally, making 4-color photographic films; spraying colorful photosensitive printing ink on the metal plates by a spraying method; and performing sensitization by using the 4-color photographic films respectively, so as to obtain the embossment type color metal etchings. By means of the making method of the embossment type color metal etchings, the thickness feeling and volume feeling of the pictures can be made on the metal plates, so that colorful metal printmaking has more abundant stereoscopic impression and texture is more close to vivid oil painting in visual effect and abundant visual impression of people is met.

Owner:刘明祥 +1

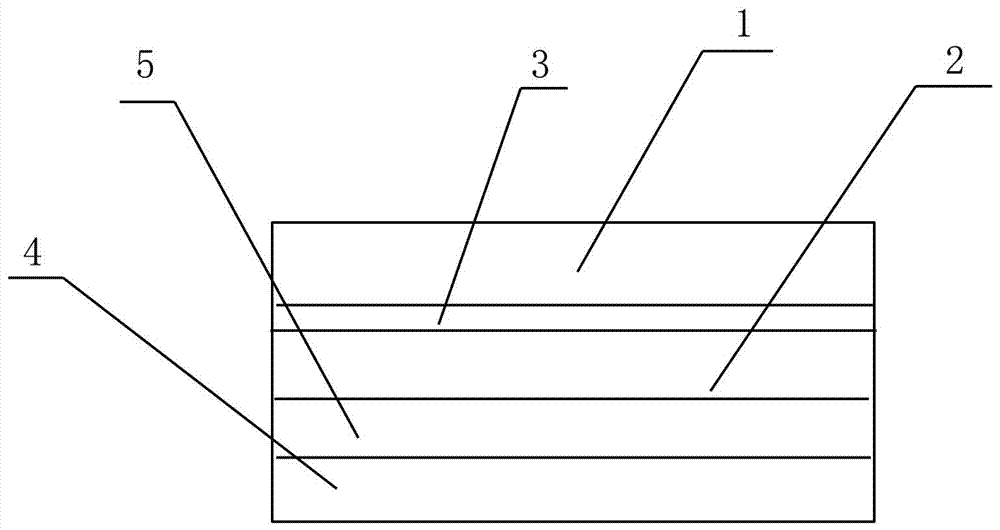

Aluminum alloy plate with woodgrained paper

InactiveCN107060251AStrong fastnessIntegrity guaranteedCovering/liningsSynthetic resin layered productsSurface layerAlloy

The invention discloses an aluminum alloy plate with wood-grain paper, which comprises a surface layer (1) and a bottom layer (2), wherein the surface layer (1) is a wood-grain paper layer, and the bottom layer (2) is a non-woven fabric layer. A bonding layer (3) is provided between the surface layer (1) and the bottom layer (2), and the surface layer (1) and the bottom layer (2) are connected through the bonding layer (3) to form a composite paper layer, and the composite paper layer and The decorative aluminum plate (4) is connected, and a reinforcing plate surface (5) is provided between the composite paper layer and the decorative aluminum plate (4). The invention makes the fastness of the decorative aluminum alloy plate stronger and tougher, and the surface tension increases.

Owner:王兆进

Surface pattern making process of glass fiber reinforced plastic

InactiveCN102673289ARich three-dimensional senseImprove aestheticsDecorative surface effectsSurface patternGlass fiber

The invention discloses a surface pattern making process of a glass fiber reinforced plastic. The process comprises the following steps of: spraying a first layer of transparent gel coat resin on a glass fiber reinforced plastic base material; after the first layer of gel coat resin is naturally dried and completely dried, brushing a second layer of transparent gel coat resin on the first layer of gel coat resin; before the second layer of gel coat resin is dried, laying a plastic film with wrinkles or patterns at the surface of the second layer of gel coat resin; after the plastic film is solidified, tearing off the plastic film; and then coating a packaging gel coat resin with a color on the second layer of gel coat resin; as the plastic film with the wrinkles is laid on the undried gel coat resin, uneven pattern marks are left at the surface of the gel coat resin after the plastic film is solidified and torn off; and after the packaging gel coat resin with the color is coated, the pattern of the surface of the glass fiber reinforced plastic shows rich three-dimensional sense and is greatly improved in sense of beauty.

Owner:杨泉辉

Calligraphy and painting pigment and preparation method thereof

InactiveCN107151476ARich three-dimensional senseIncrease artistic senseArtist's paintsPaperboardAcrylic paint

The invention provides calligraphy and painting pigment. The calligraphy and painting pigment consists of the following components: acrylic paint, diatom ooze, sandalwood powder, glue and clear water. Diatom ooze, sandalwood powder, glue and clear water are mixed in conventional acrylic paint to form the calligraphy and painting pigment with certain shape features, so that after the calligraphy and painting pigment provided by the invention is adopted, calligraphy and painting works with bump features are formed on a paperboard or a sheet. The invention further provides a preparation method for the calligraphy and painting pigment, and the preparation method comprises the steps of soaking and water-swelling of glue, heating and dissolving of glue, adding and cooling of mixed components comprising acrylic paint, diatom ooze, sandalwood powder, and the like. The preparation method is simple and easy to operate, can flexibly prepare the calligraphy and painting pigment according to practical calligraphy and painting creation quantity demanded; and the calligraphy and painting pigment prepared by the method keeps activity of the sandalwood powder.

Owner:宜都市晶典艺术品有限公司

Writing method for color register and reiterative locution on Chinese art paper

InactiveCN101318442ALow costStrong contrastSpecial artistic techniquesArtistic renderingPulp and paper industry

A writing method of colour process and reiterative locution on rice paper is characterized in that a calligraphy creation technique for writing the effects of colour process and reiterative locution on rice paper is provided by the invention, the technique is characterized in that ink and the dyes of other colors are adopted to be confected with water into a tinge liquid according to a proportion of 1 to 50 percent to be used as the writing material of background characters; the tinge characters which are written and arranged on the rice paper are taken as the background color; then large characters with mass tone distinguished from the styles and colors of the background color are selected on the same piece of rice paper which takes the small tinge characters as the background color to write, cover and overlap on the small characters in the background color, so as to create the calligraphy works with different sizes, different styles, overlapped fonts, proper color difference or concentration, strong contrast sense as well as abundant third dimension and hierarchy. The method can also be applied to the manufacturing of other artworks, is a technical innovation to the traditional calligraphy works and is simple, convenient and easy for operation.

Owner:张凝

Preparation method of ceramic tile with geometric textures and ceramic tile

The invention discloses a preparation method of a ceramic tile with geometrical textures and the ceramic tile, and the preparation method comprises the following steps: A, mixing a ceramic backing material raw material and a black pigment to prepare a black backing material with the water content of 13-15%, and carrying out pressure granulation on the ceramic backing material raw material and a white pigment to prepare a white granular material, adding a part of the black backing material into the white granules, and uniformly mixing to obtain a mixture; b, distributing the remaining black backing material to obtain a backing material layer, distributing the mixture on the surface of the backing material layer to obtain a surface material layer, and pressing and drying to obtain a spot green body; and C, printing concave-convex geometric texture patterns on the whole surface of the spot green body through roller printing. According to the preparation method of the ceramic tile with thegeometric textures, the texture of the green body can be presented while the bright effect and the matte effect are combined and presented on the tile surface, and the ceramic tile prepared through the preparation method of the ceramic tile with the geometric textures is good in overall texture, high in stereoscopic impression and rich in layering sense.

Owner:FOSHAN PINWEIXIAN CERAMICS CO LTD

Decorative aluminium alloy plate

InactiveCN106427132AIncrease surface tensionAvoid pollutionPaper/cardboard layered productsMetal layered productsSurface roughnessPaper sheet

The invention discloses a decorative aluminium alloy plate. The decorative aluminium alloy plate comprises a composite paper layer and a decorative aluminium plate (4); the composite paper layer comprises a stone paper layer (1) and a non-woven cloth layer (2); the stone paper layer (1) is connected with the non-woven cloth layer (2) through a bonding layer (3); the composite paper layer is connected with the decorative aluminium plate (4). According to the decorative aluminium alloy plate, stone paper is high in surface tension and is tougher and firmer; the surface roughness of non-woven cloth on a bottom layer is easier to be bonded to the aluminium alloy plate.

Owner:王兆进

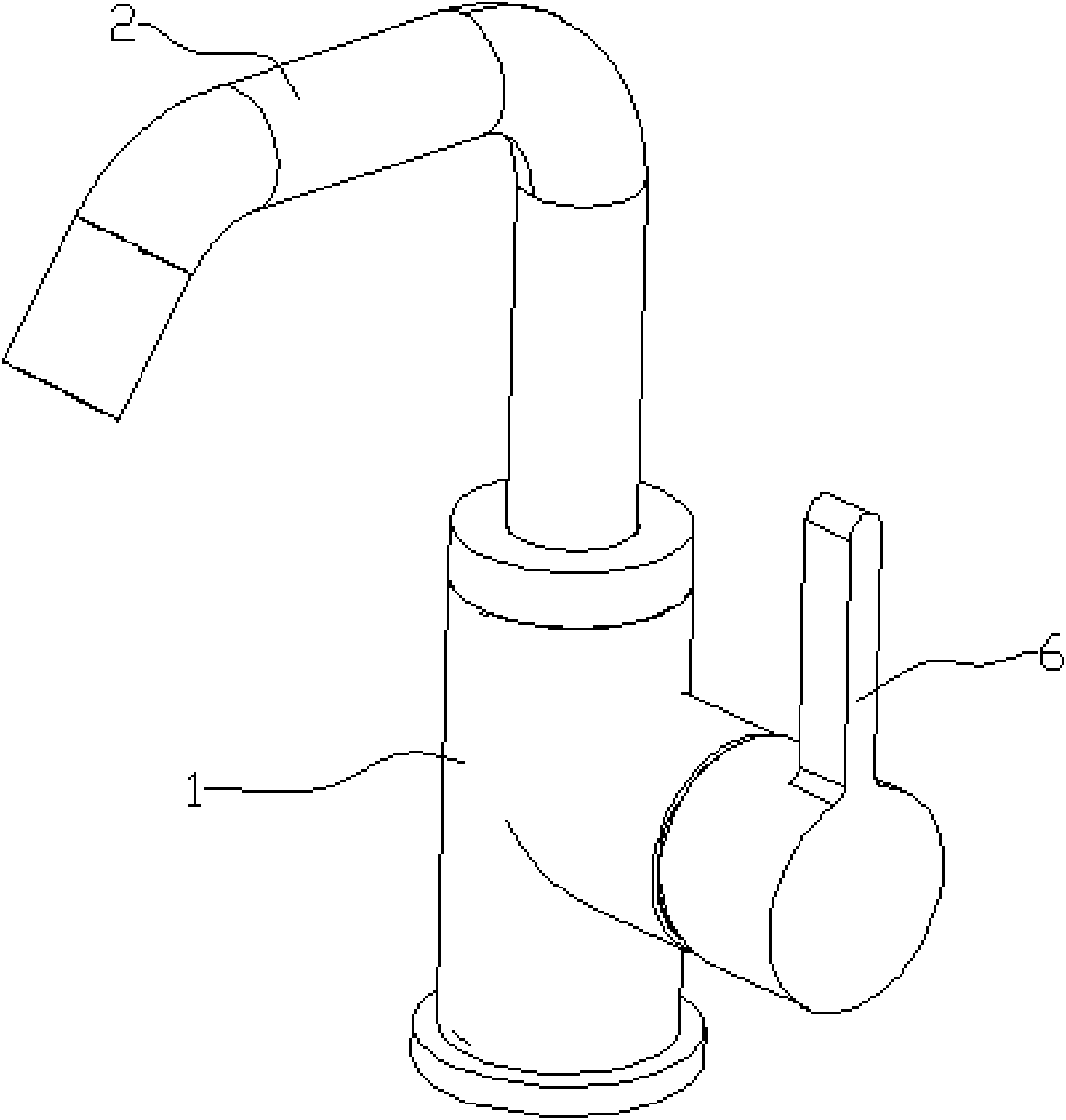

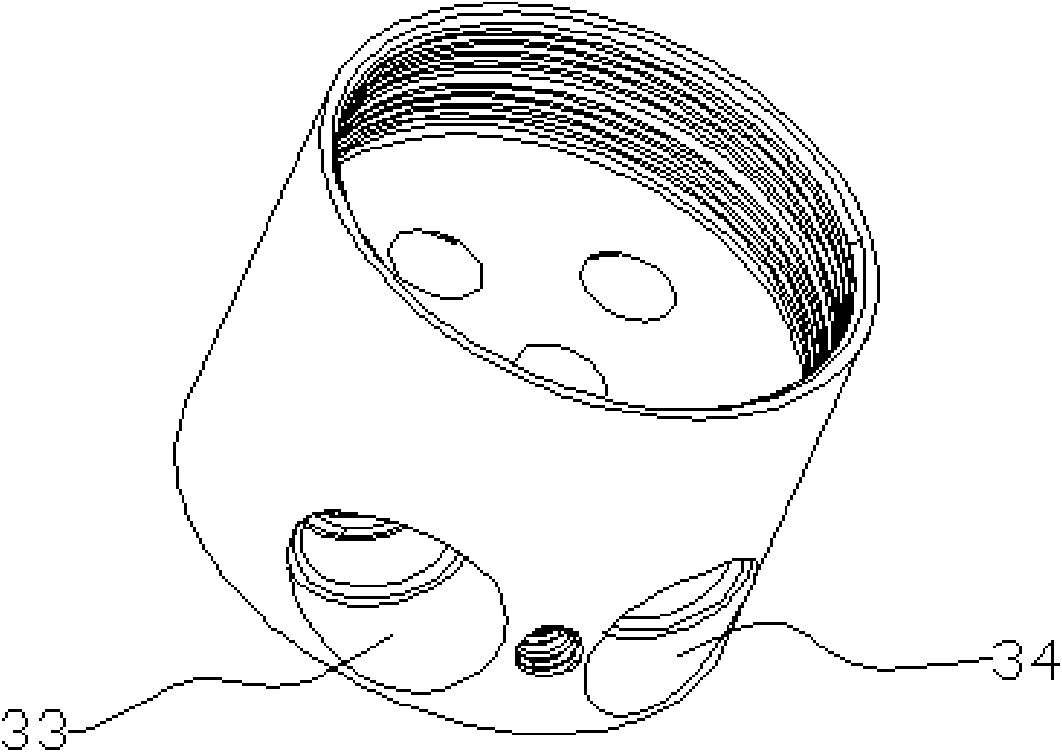

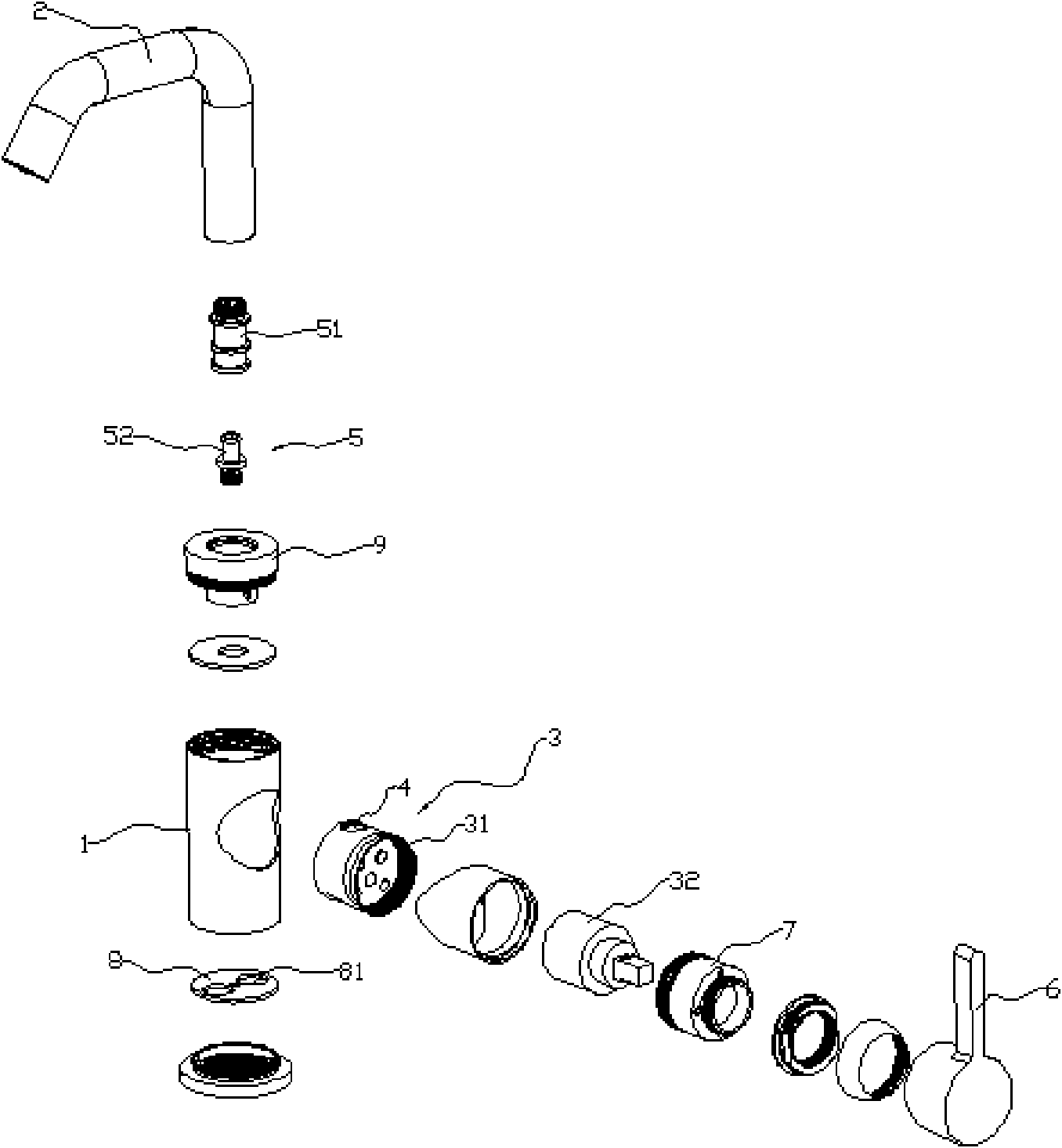

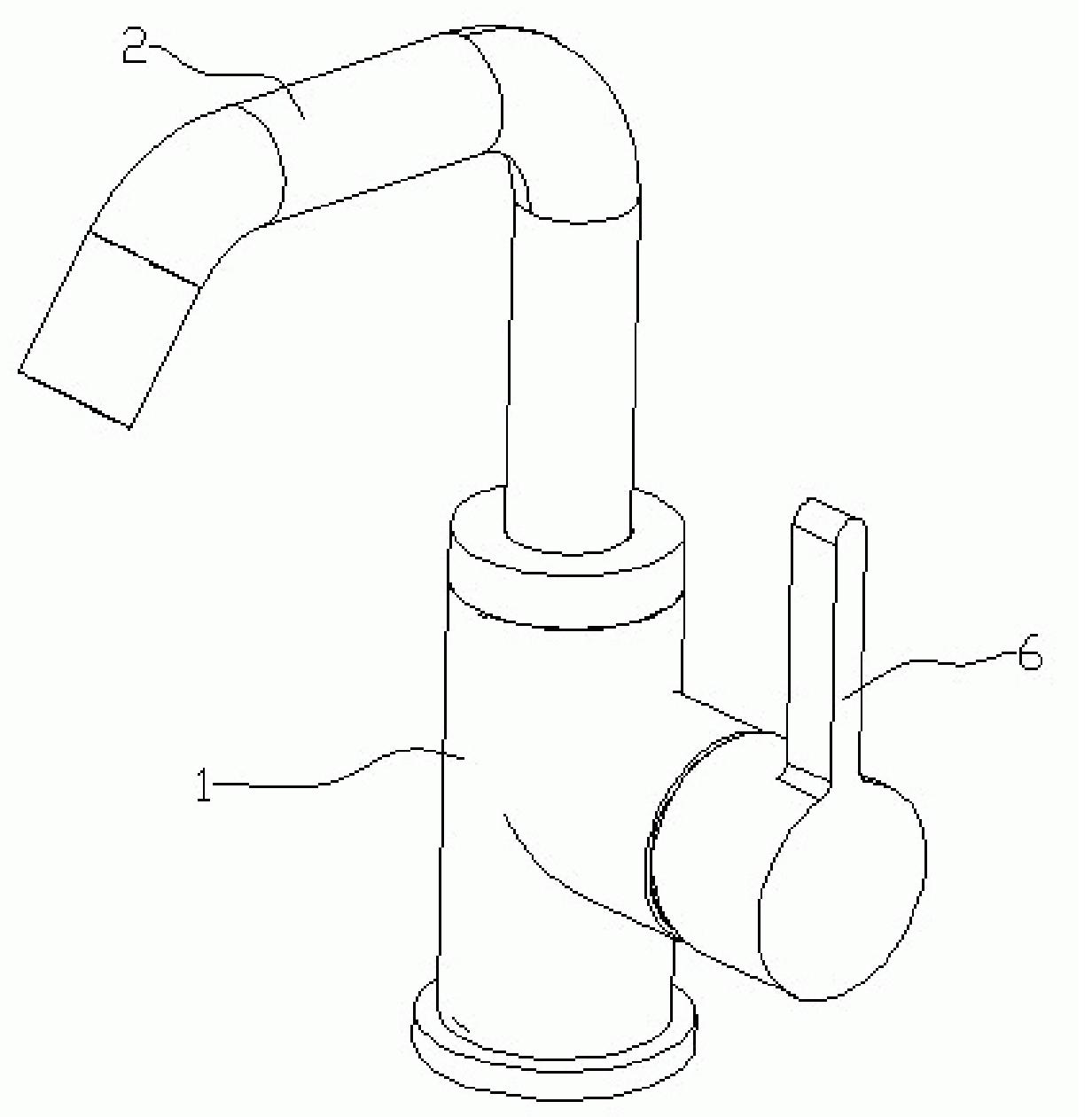

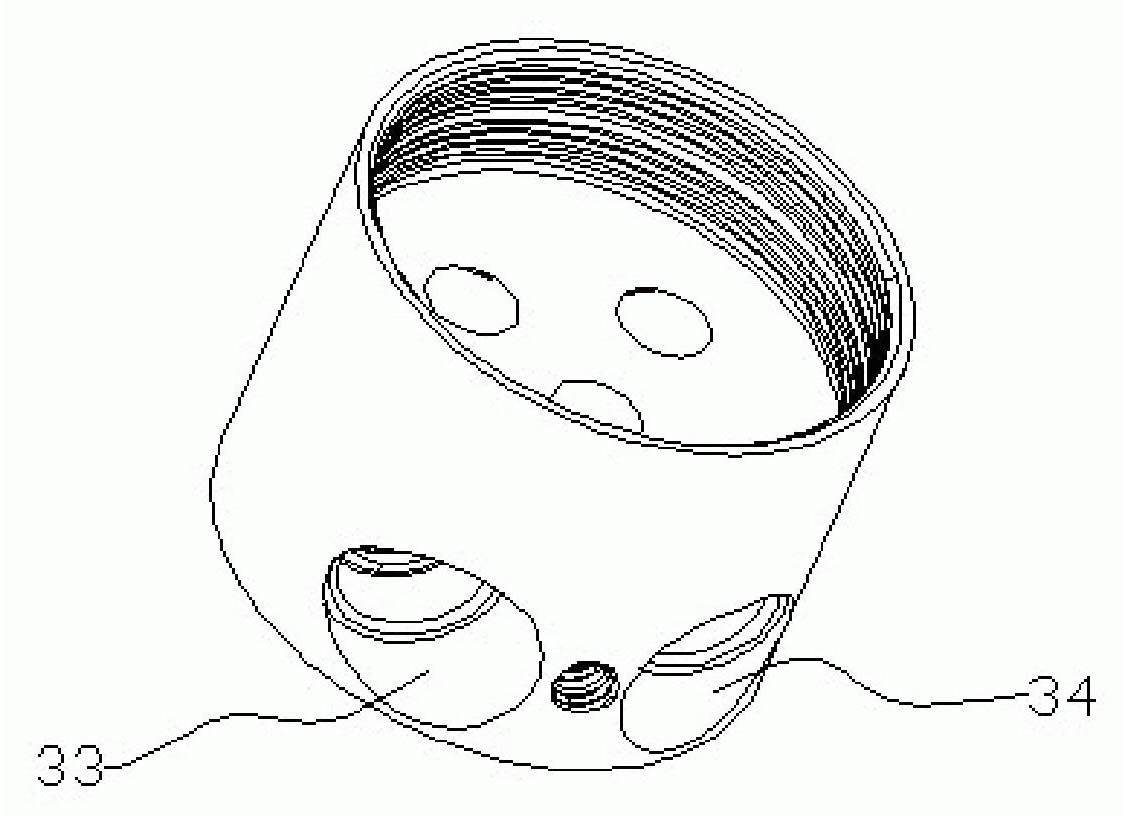

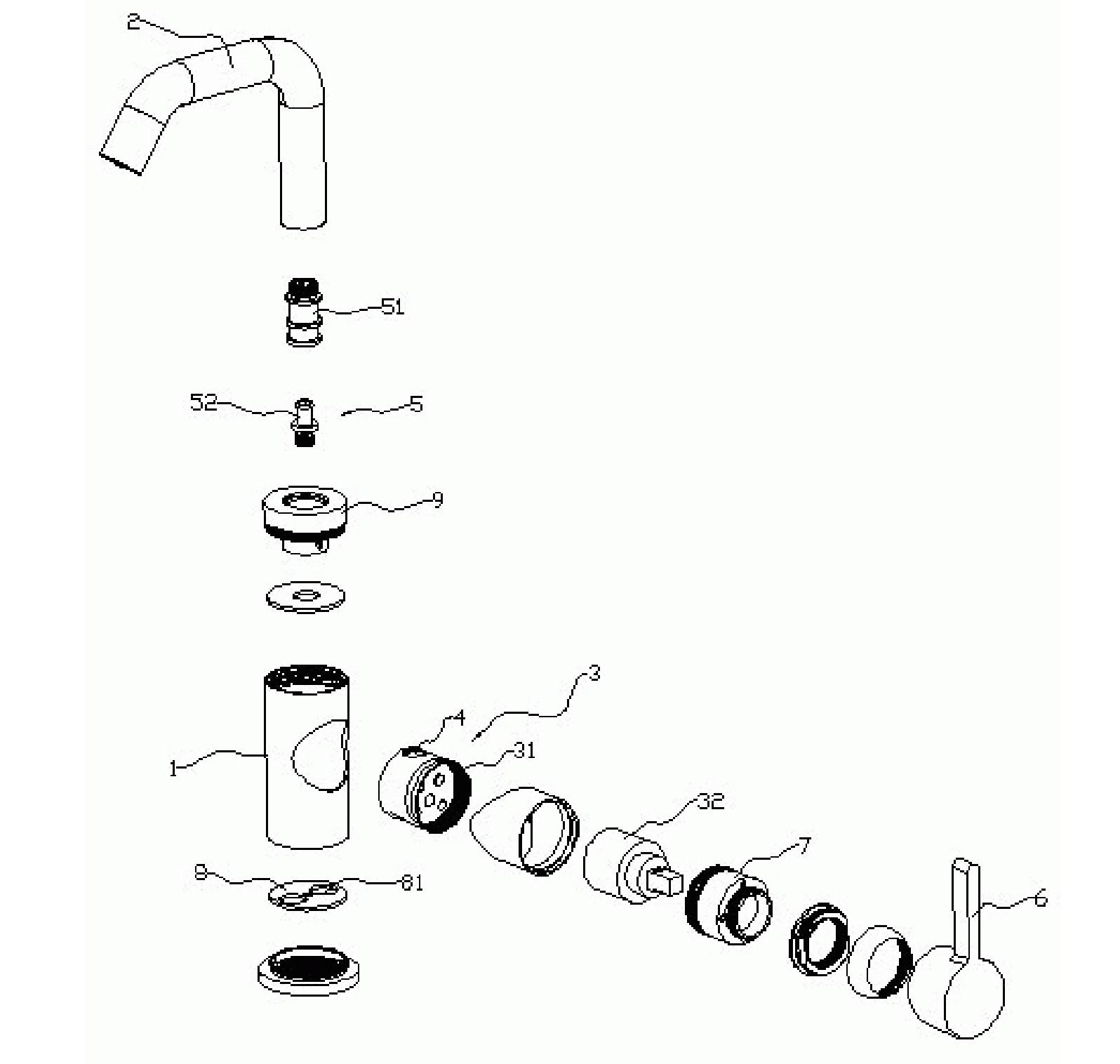

Combined type water tap

InactiveCN101581377ASimple processingEasy to manufacture and controlOperating means/releasing devices for valvesMultiple way valvesWater pipeEngineering

The invention discloses a combined type water tap comprising a valve body, a water outlet pipe and a valve core. The valve core is arranged in the valve body and is provided with a thread hole. A connector is arranged in the thread hole. One end of the connector is connected with the water outlet pipe by threads. A handle for controlling the opening and closing of the valve core is arranged outside the valve body. As the combined type water tap adopts the structure, all components are connected and combined by threads, the processing is simple, the production and the product quality control are facilitated, and the production cost of the product is reduced. As the components are connected by the threads, the production process of the water tap requires no casting or welding, thereby causing no chemical pollution; in addition, such connection causes the appearance outline of the valve body to be clearer and have more three dimensional effect; and when one component is damaged, the component can be independently replaced, thereby reducing waste.

Owner:陈级利

DuiJin artware making method

PendingCN111421995ARich in detailsRich three-dimensional senseDecorative surface effectsOrnamental structuresFiberStructural engineering

The invention relates to a DuiJin artware making method, which solves a problem that a conventional handcraft of DuiJin is poor in stereo perception and texture and is not easy to produce in large scale. A technical scheme comprises steps of blank making, sheet making and shaping of a whole artware; and specifically comprises the following steps: making a blank master mask and a female die according to a pattern, and forming each local blank through injection molding and blank stripping; wrapping the local blank with a fiber material to form a sheet; and adhering the different made sheets on corresponding position of a drawing board according to the pattern to complete the artware. The sheet made according to the invention has a concave and convex curved surface, so that the whole DuiJin artware has more abundant detail and stereo perception; product consistency is excellent, quality is controllable, the artware is more approximate to a designed pattern, and massive and efficient high-quality making of the DuiJin artware is facilitated.

Owner:长治市类通堆锦工艺有限公司

Production method of decorative aluminum alloy plate

InactiveCN106739414AIncrease surface tensionAvoid pollutionLamination ancillary operationsDomestic upholsteryRough surfaceAlloy

The invention discloses a production method of a decorative aluminum alloy plate. The production method comprises the following steps: bonding stone paper with non-woven fabric through a bonding agent to form composite paper, digitally printing the composite paper into wood-grain paper, stone-grain paper or other decorative paper with various patterns, and bonding the decorative paper onto an aluminum plate by a compositing technology to obtain the decorative aluminum plate. By the production method, the stone paper has higher surface tension and is more tough and firm, and the bottom non-woven fabric layer has a rough surface and can be easily glued to the aluminum alloy plate.

Owner:王兆进

Manufacturing process of gold wire color drawing painting

InactiveCN111806138AImprove toughnessImprove aestheticsSpecial ornamental structuresColored whitePolishing

The invention discloses a manufacturing process of a gold wire color drawing painting. The process comprises the following steps of material selection, wherein a selected material is a metal plate; pre-processing, wherein the selected plate is subjected to pre-shearing, and polishing or wire drawing is carried out; first-time cleaning, wherein the plate after wire drawing is subjected to oil contamination removal, and an oxide layer is removed; coloring processing, wherein one face of the plate is coated with a layer of white ink; first-time drying; pattern printing, wherein a set pattern is printed on a white coating; secondary drying, wherein the printed pattern is dried; engraving, wherein through an engraving machine, an outside outline of the pattern can be engraved; secondary cleaning, wherein metal chips generated by engraving and all colors of the previous steps are cleaned; polishing, wherein the plate pattern after cleaning is polished; third-time drying, wherein the treatedplate is dried; electroplating coloring; three-dimensional metal decoration pasting; and mounting and packaging. The metal plate is subjected to wire drawing and antioxidant treatment, and the toughness and the attractive degree of the metal plate can be effectively increased, and the third dimension is higher.

Owner:江苏辰宇文化艺术品有限公司

Preparation method of decorative calcium silicate board

InactiveCN106739223AEasy to replaceIncrease surface tensionPaper/cardboard layered productsCalcium silicateSurface layer

The invention discloses a preparation method of a decorative calcium silicate board. The preparation method comprises the following steps of: employing a calcium silicate board as a substrate, and pasting a decorative composite layer on one surface of a calcium carbonate board, wherein the decorative composite layer comprises a surface layer and a bottom layer; the surface layer is stone paper; the bottom layer is non-woven fabric; and the stone paper and the non-woven fabric are bonded by a bonding layer to form the decorative composite layer. The board is simple in structure and low in manufacturing cost, and the decorative layer is relatively convenient to replace.

Owner:王兆进

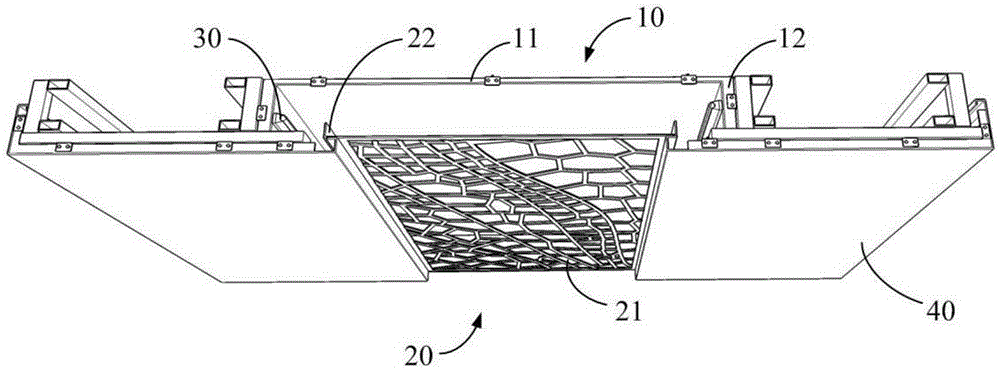

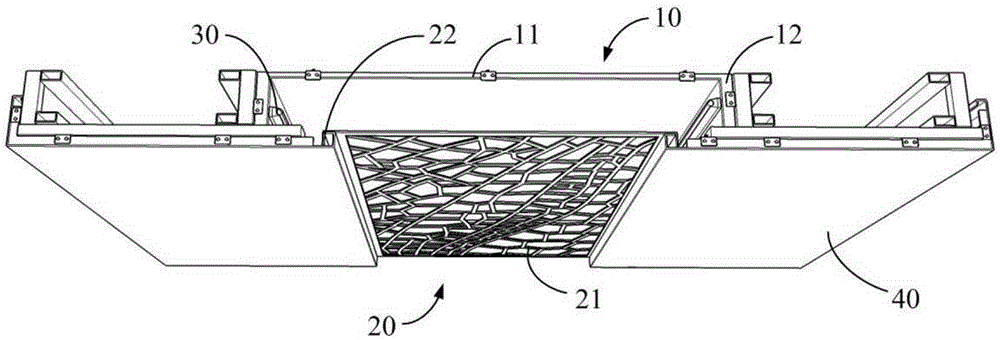

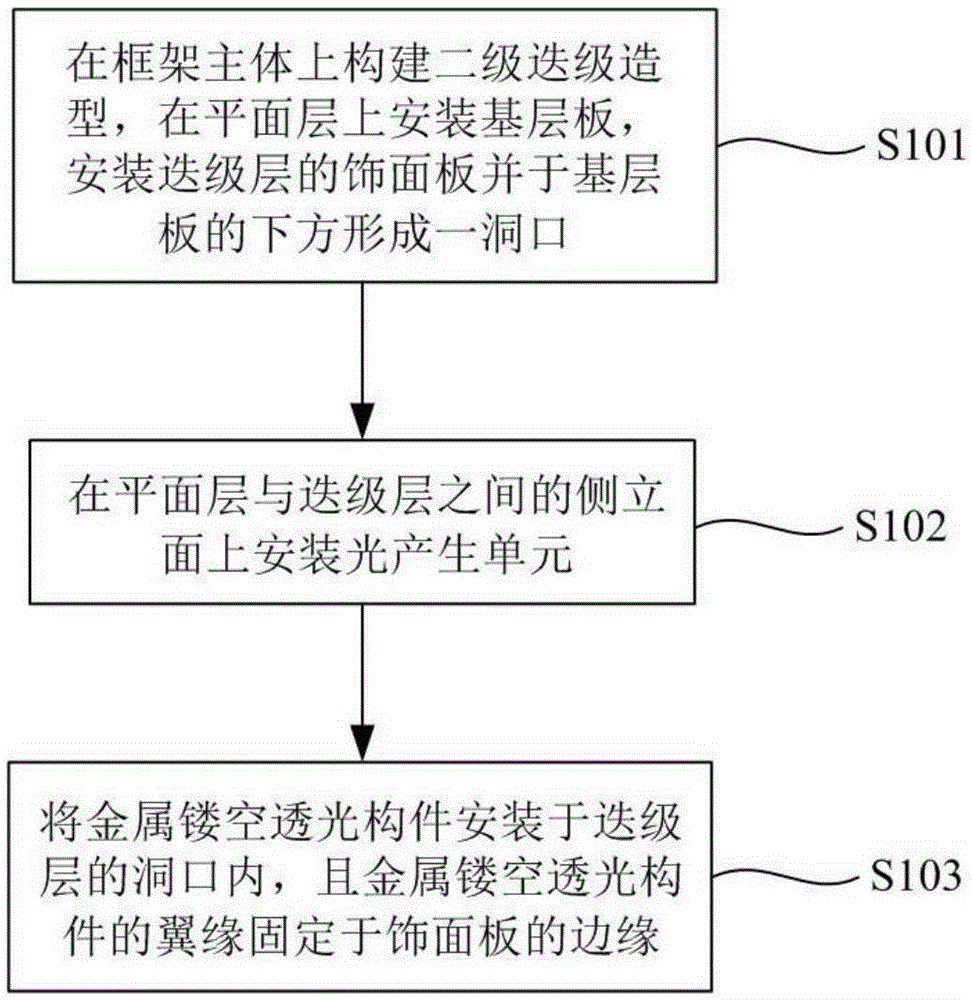

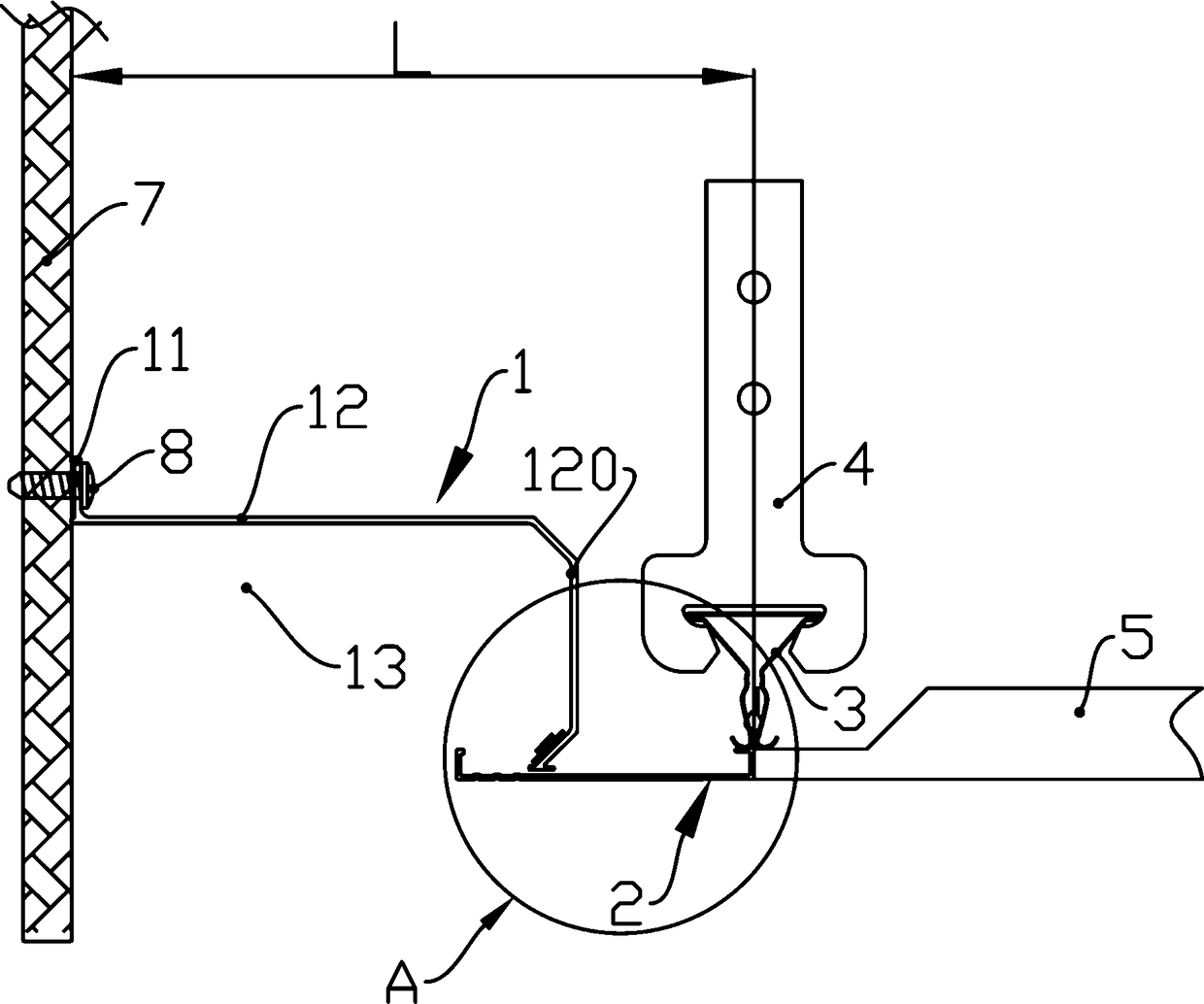

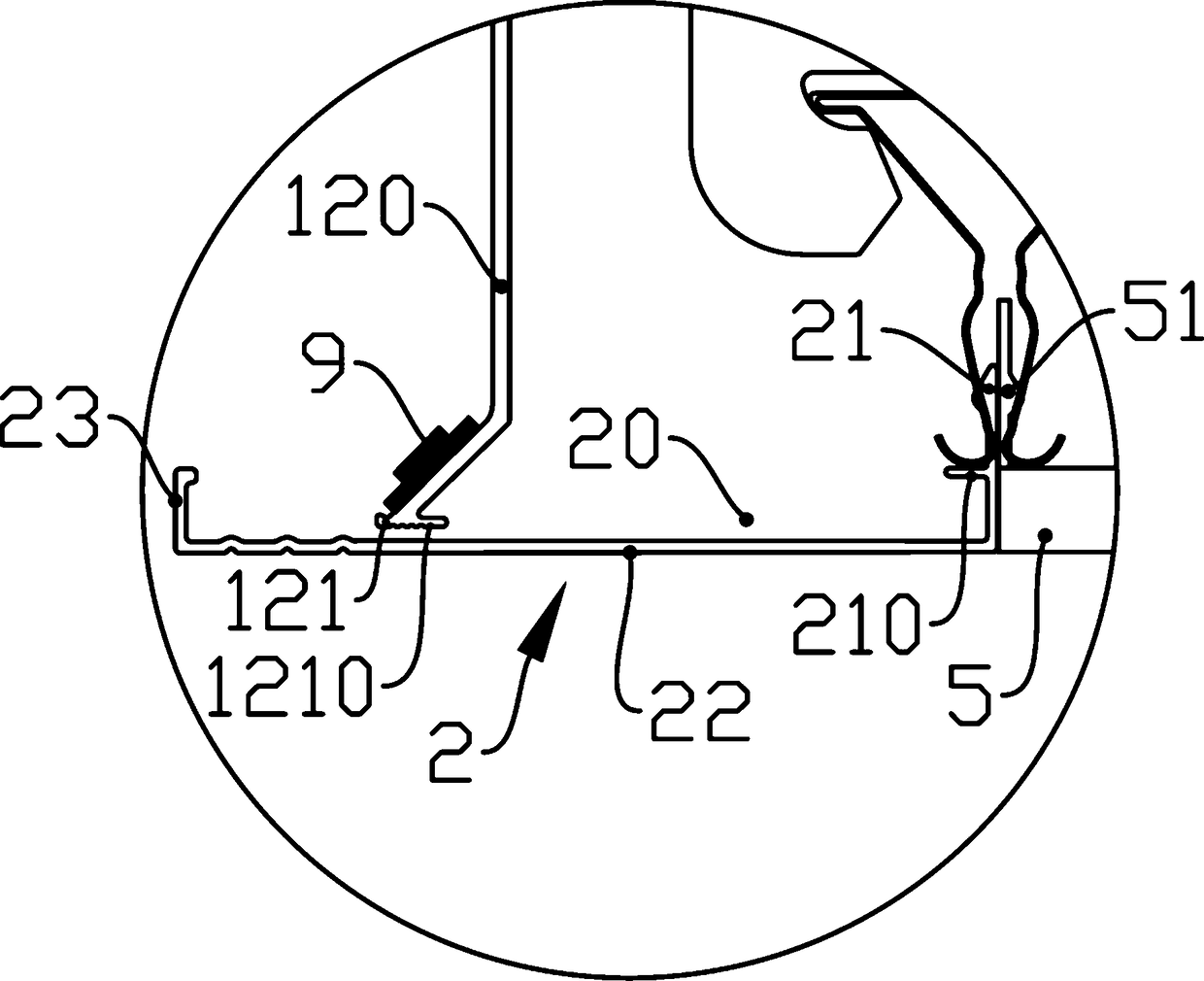

Hollow light-transmitting finish structure and its installation method

ActiveCN103993695BIncreased durabilityImprove cooling effectCeilingsCovering/liningsEngineeringPlane layer

The invention discloses a hollow-out light-pervious veneer structure and a mounting method thereof, and relates to the field of indoor and outdoor decoration. The hollow-out light-pervious veneer structure and the mounting method thereof aim to solve the problems that an existing light-pervious film suspended ceiling is poor in durability and heat dissipation performance, a surface is prone to being contaminated through static electricity, multiple pieces of shadows appear after contamination and decoration effects are influenced. The veneer structure is a secondary overlapped shape, base layer plates are arranged on a plane layer, metal hollow-out light-pervious components are connected in openings of an overlapped layer, and light generating units are arranged on a side vertical face between the plane layer and the overlapped layer. According to the mounting method, firstly, the base layer plates are arranged on the plane layer, veneers of the overlapped layer are mounted, and the openings are formed in the lower portions of the base layer plates; secondly, the light generating units are mounted on the side vertical face between the plane layer and the overlapped layer; thirdly, the metal hollow-out light-pervious components are mounted in the openings. The veneer structure can prevent static electricity contamination, is not prone to accumulating dirt, the light generating units can be cooled naturally, and the service life of the veneer structure can be prolonged. A-level inflaming retarding and fireproof materials are adopted by the components, the durability and the heat dissipation performance are good, dismounting and mounting are convenient to carry out, and the shaping of the suspended ceiling and later cleaning and maintenance work are facilitated.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Combined type water tap

InactiveCN101581377BClear outlineRich three-dimensional senseOperating means/releasing devices for valvesMultiple way valvesChemical contaminantsMechanical engineering

Owner:陈级利

Writing method for color register and reiterative locution on Chinese art paper

InactiveCN101318442BLow costStrong contrastSpecial artistic techniquesArtistic renderingPulp and paper industry

A writing method of colour process and reiterative locution on rice paper is characterized in that a calligraphy creation technique for writing the effects of colour process and reiterative locution on rice paper is provided by the invention, the technique is characterized in that ink and the dyes of other colors are adopted to be confected with water into a tinge liquid according to a proportionof 1 to 50 percent to be used as the writing material of background characters; the tinge characters which are written and arranged on the rice paper are taken as the background color; then large characters with mass tone distinguished from the styles and colors of the background color are selected on the same piece of rice paper which takes the small tinge characters as the background color to write, cover and overlap on the small characters in the background color, so as to create the calligraphy works with different sizes, different styles, overlapped fonts, proper color difference or concentration, strong contrast sense as well as abundant third dimension and hierarchy. The method can also be applied to the manufacturing of other artworks, is a technical innovation to the traditional calligraphy works and is simple, convenient and easy for operation.

Owner:张凝

Manufacturing method for flocked digital printing wallpaper

InactiveCN105856887ARich three-dimensional senseStrong three-dimensional senseSpecial paperDuplicating/marking methodsProduction lineColor image

The invention discloses a manufacturing method for flocked digital printing wallpaper. Non-woven paper is used as backing paper, and totally-environment-friendly upscale nylon wool is adopted for manufacturing flocked paper on electrostatic flocking production line equipment. A digital printing mode is adopted for rapidly forming images on the flocked face at a time, a high-speed printing mode is adopted, and the speed is up to 200 M / min, so that connection of the images is smooth, the high-fidelity color images can be rapidly printed, the novel wallpaper has more stereoscopic impression, and patterns are more realistic and attractive.

Owner:王兆进

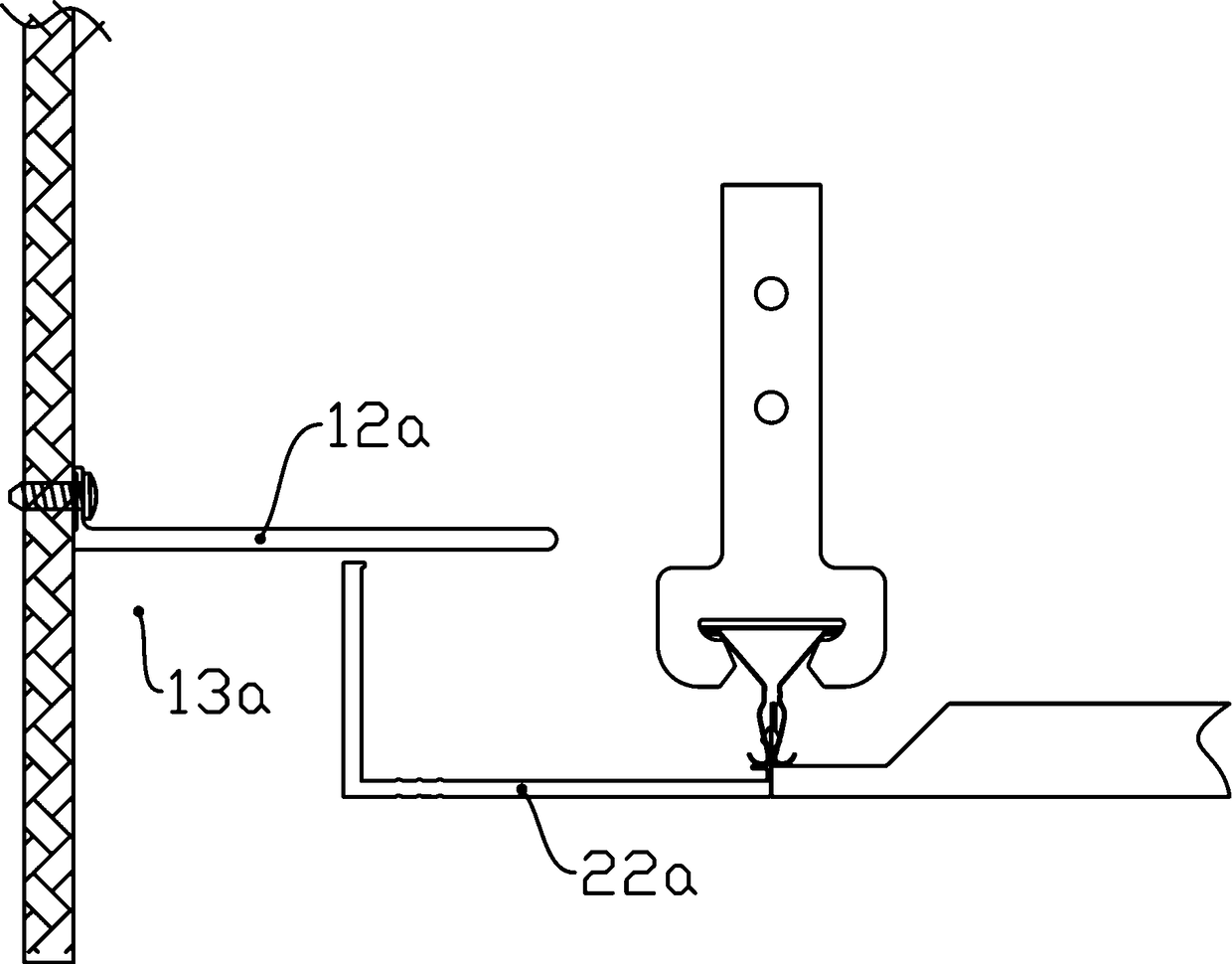

Furred ceiling edge closing method with combined structure, and combined furred ceiling edge closing section bar assembly

The invention relates to a furred ceiling edge closing method with a combined structure, and a combined furred ceiling edge closing section bar assembly. The combined furred ceiling edge closing section bar assembly comprises a first edge closing section bar and a second edge closing section bar. The first edge closing section bar has a fixing part and a first decorating part. The second edge closing section bar has a vertical socket arm and a second transverse decorating part. The first decorating part and the second transverse decorating part extend in opposite directions. An open space exists above the second transverse decorating part. The open space is used for stacking the first decorating part and the second transverse decorating part in a vertical direction for forming two edge closing layers with different heights, and furthermore makes the second transverse decorating part movably abut against or get close to the first decorating part when the second edge closing section baris assembled in a vertical direction, or makes the second transverse decorating part leave the first decorating part when the second edge closing section bar is detached in the vertical direction. Thesecond transverse decorating part is used for supplying a random abutting or getting-close position to the first decorating part based on different space distances which are defined between the fixing part and the vertical plugging arm, thereby facilitating mounting and detachment of the second edge closing section bar.

Owner:广东省锦绣明天建材有限公司

Preparation method of ceramic brick with geometric texture and ceramic brick

Owner:FOSHAN PINWEIXIAN CERAMICS CO LTD

Jet printing process of fur fabric

InactiveCN107663797AEasy to cut uniformlyAvoid changeDecorative surface effectsSpecial ornamental structuresDark colorEngineering

A jet printing process of fur fabric comprises the steps as follows: (1) pattern design is performed; (2) a film is produced; (3) platemaking is performed; (4) multiple color sprays at different depths are blended; (5) a pattern plate is firstly positioned in a position where jet printing is to be performed as required and then fixed; (6) the blended spray in the lightest color is jet at patternsof the pattern plate according to required amount and position; (7) the second-layer darker color spray is jet on the required positions of the patterns; (8) colors are added to 3, 4, 5...layers according to aesthetic needs of different patterns until satisfaction through the steps; (9) fabric on which patterns are jet is steamed for 3-30 min by a steam box to reach the required color fastness; (10) the product steamed by the steam box is taken out and naturally aired, and a finished product is obtained. Washing is not needed, color loss, fading, change of fuzzy grains on the fur surface, shrinkage and other phenomena of the fabric are avoided, and original fur or fabric can be cut into clothes conveniently; a washing treatment procedure after printing is omitted, water pollution caused bywashing is effectively avoided, and environmental protection is facilitated.

Owner:海宁市皮仙努皮草保养有限公司

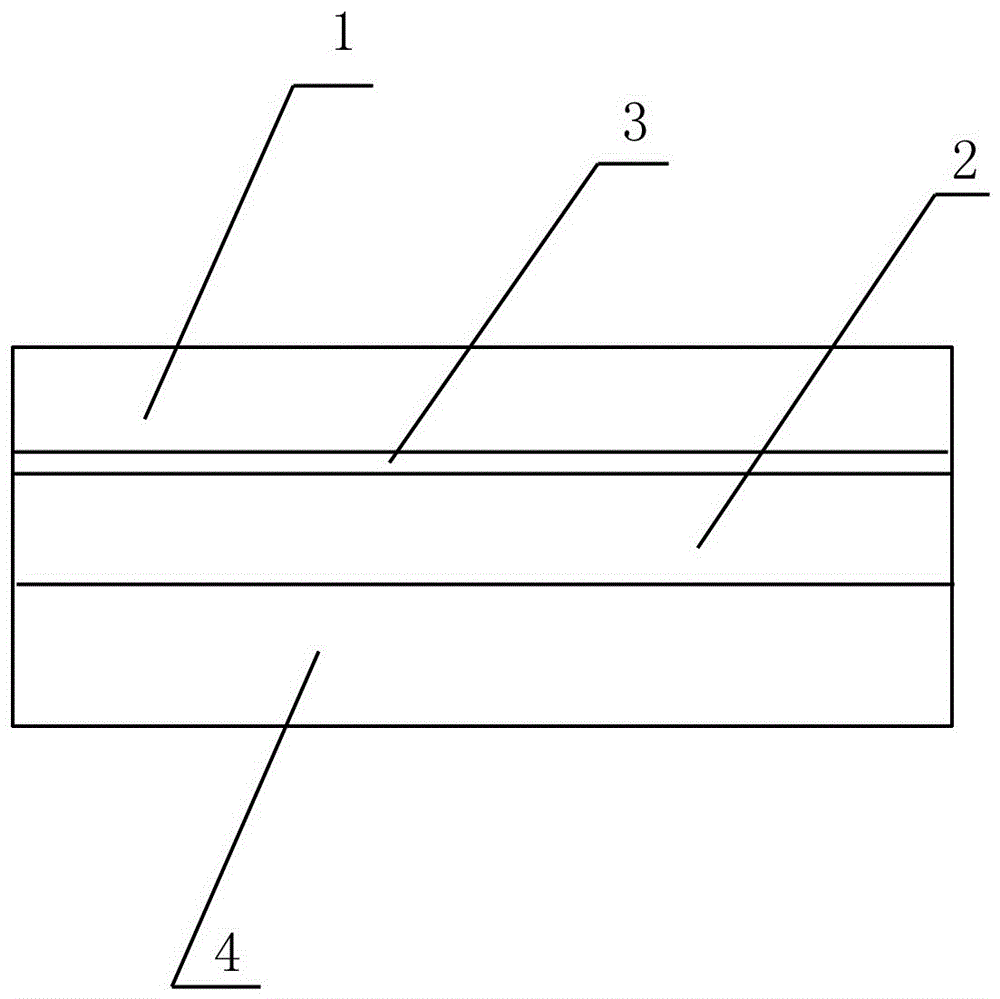

Manufacturing method of decorative aluminum-plastic composite plate

InactiveCN106739208AEasy to replaceLightweightConstructions elementsDomestic wallsSurface layerAdhesive

The invention discloses a manufacturing method of a decorative aluminum-plastic composite plate. The manufacturing method comprises the following steps: at first, preparing surface layer materials and a core layer material, adhering two surface layer materials on the two surfaces of the core layer material to form a three-layer composite plate, adhering non-woven cloth on the surface of one of the surface layer materials, and finally adhering stone decorative paper on the surface of non-woven cloth through an adhesive. The manufacturing is simple, and the manufacturing cost is low.

Owner:王兆进

A wood-grain wallpaper made from wood-plastic waste and its preparation method

ActiveCN109278391BRich three-dimensional senseVariety of colorsLamination ancillary operationsCovering/liningsFiberPolyvinyl chloride

The invention discloses wood-grain wallpaper made of wood-plastic garbage. The wood-grain wallpaper comprises the following components in percentage by weight: 40-68% of polyvinyl chloride (PVC) particles, 18-30% of modified wood flour, 10-16% of long fibers, 10-15% of modified stone powder, 3-6% of spar, and the balance of glue, wherein the PVC particles are recycled plastic, the modified wood flour is recycled wood chips, the long fibers are straw, the modified stone powder is recovered concrete garbage, and the spar material is recycled colorful pebbles or glass. The invention further provides a preparation method of the wood-grain wallpaper prepared from the wood plastic-garbage. The preparation method comprises the following steps: 1) removing organic matter; 2) carrying out modification treatment; 3) carrying out filament formation on the long fibers; 4) grinding the spar; 5) carrying out pulp mixing; 6) preparing a single-layer thin film; and 7) preparing the wallpaper. The invention provides a wide eliminating platform for various types of garbage which mainly contains white-pollution garbage, and the wallpaper with tree-dimensional impression and rich color and texture isobtained and is an advanced product taking wood-plastic garbage as a raw material. Meanwhile, the wallpaper is simply to lay and is high in laying quality, and edges do not warp easily.

Owner:铜陵市天峰汽车维修服务有限责任公司

Multilayer film primary formed plate plating method

InactiveCN111229570ARich three-dimensional senseReduce stressLiquid surface applicatorsLamination ancillary operationsVacuum dryingKiln

The invention discloses a multilayer film primary formed plate plating method. The multilayer film primary formed plate plating method comprises the following steps that a raw material is subjected topretreatment, specifically, the raw material is cut according to the required dimension and specification through a template; the raw material is cut into wood plates which are the same in proportion, then, the surface of the raw material is subjected to polishing treatment and impurity removal till the surface is smooth and clean, and the preprocessed wood plates are obtained; then, drying treatment is conducted, the cleaned wood plates are put into a vacuum drying machine to be dried, the water content of the dried plates is 30-35%, the plates are loaded into a drying kiln, steam is injected, the temperature of the interior of the kiln keeps to be 50 DEG C, the humidity keeps to be 42%, steam is injected every 2-3 hours, and the process lasts for 2-3 days till the water content of the dried plates is 10-125. According to the multilayer film primary formed plate plating method, during plating, a layer of environment-friendly paper is laid on the plate, then, plating is conducted, thus, the effect after plating is better, and the third dimension is higher.

Owner:JIANGSU DINGPIN FURNITURE CO LTD

Method for making woven picture as traditional Chinese picture

ActiveCN102582348BRich three-dimensional senseUnique artistic charmDecorative surface effectsSpecial artistic techniquesEngineeringLight transmission

The invention relates to a method for making a woven picture as a traditional Chinese picture, comprising the following steps: (1) drawing a picture: wherein a selected a piece of picture drawing paper is provided with a peripheral part and a middle part, the peripheral parts of the picture drawing paper are at the peripheral sides of the picture drawing paper and are connected in a closed way, and the middle part of the picture drawing paper is surrounded by the peripheral parts; (2) cutting the picture drawing paper: wherein the middle part of the picture drawing paper is cut into a plurality of strips, and the two ends of each paper strip are connected with the peripheral parts of the picture drawing paper; (3) making woven strips: wherein a piece of light-transmission paper provided with the same shape as the picture drawing paper is segmented into a plurality of woven strips; and (4) weaving, wherein the woven strips and the paper strips of the middle part of the picture drawing paper are weaved into a stereographic picture, and the two ends of each woven strip are adhered onto the peripheral parts of the picture drawing paper so as to form a picture body. The method for making the traditional Chinese picture is easy and convenient to operate, and the woven picture made by adopting the method has strong stereographic effect and attractive visual effect and presents a sense of spaciousness, so that the art enjoyment is enhanced.

Owner:汇立装备制造有限公司

Flexible flame-retardant rubber curtain with high strength, long service life and good visual effect and preparation method thereof

The invention provides a flexible flame-retardant rubber curtain with high strength, long service life and good visual effect, which realizes good flame retardance, high strength, long service life, good flattening performance, rich stereoscopic impression of pictures and bright and gentle picture quality, is easy to clean and convenient to prepare and does not need a curtain base for support. The flexible flame-retardant rubber curtain consists of the following components in parts by weight: 100 parts of natural rubber, 2-3.5 parts of vulcanizing agent, 0.8-1.5 parts of accelerant, 4-6 parts of zinc oxide, 2-3 parts of stearic acid, 20-30 parts of white carbon black, 10-15 parts of titanium dioxide, 25-35 parts of flame retardant and 8-30 parts of softener, and preferentially 3-3.5 parts of vulcanizing agent, 1-1.5 parts of accelerant, 4-5 parts of zinc oxide, 25-30 parts of white carbon black, 12-14 parts of titanium dioxide, 25-30 parts of flame retardant and 8-15 parts of softener. A preparation method comprises the following steps of: putting the natural rubber, zinc oxide, stearic acid, white carbon black, titanium dioxide, flame retardant and softener in a closed rubber mixing machine; performing rubber mixing at 95-105 DEG C for 13-17 minutes to obtain a rubber compound; adding the vulcanizing agent and the accelerant into the rubber compound; remilling in an open rubber mixing machine for 4-6 times and discharging sheet; and vulcanizing the rubber compound after the remilling in a vulcanizing machine.

Owner:NANJING DONGRUN SPECIAL RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com