Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Relative position adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

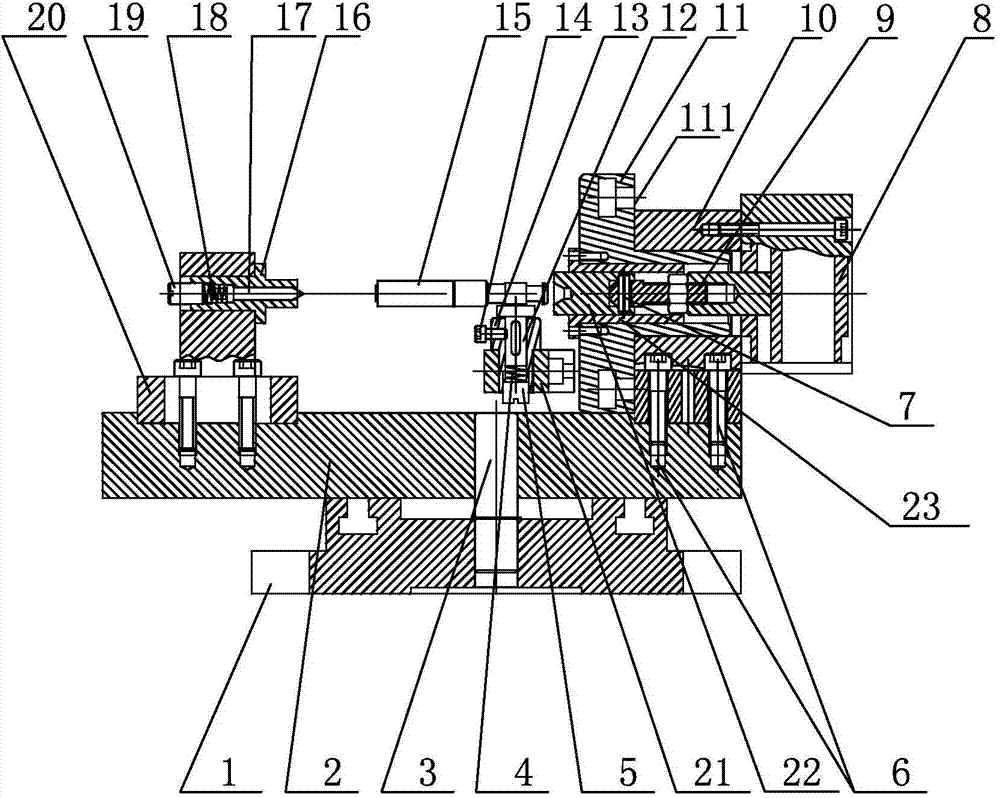

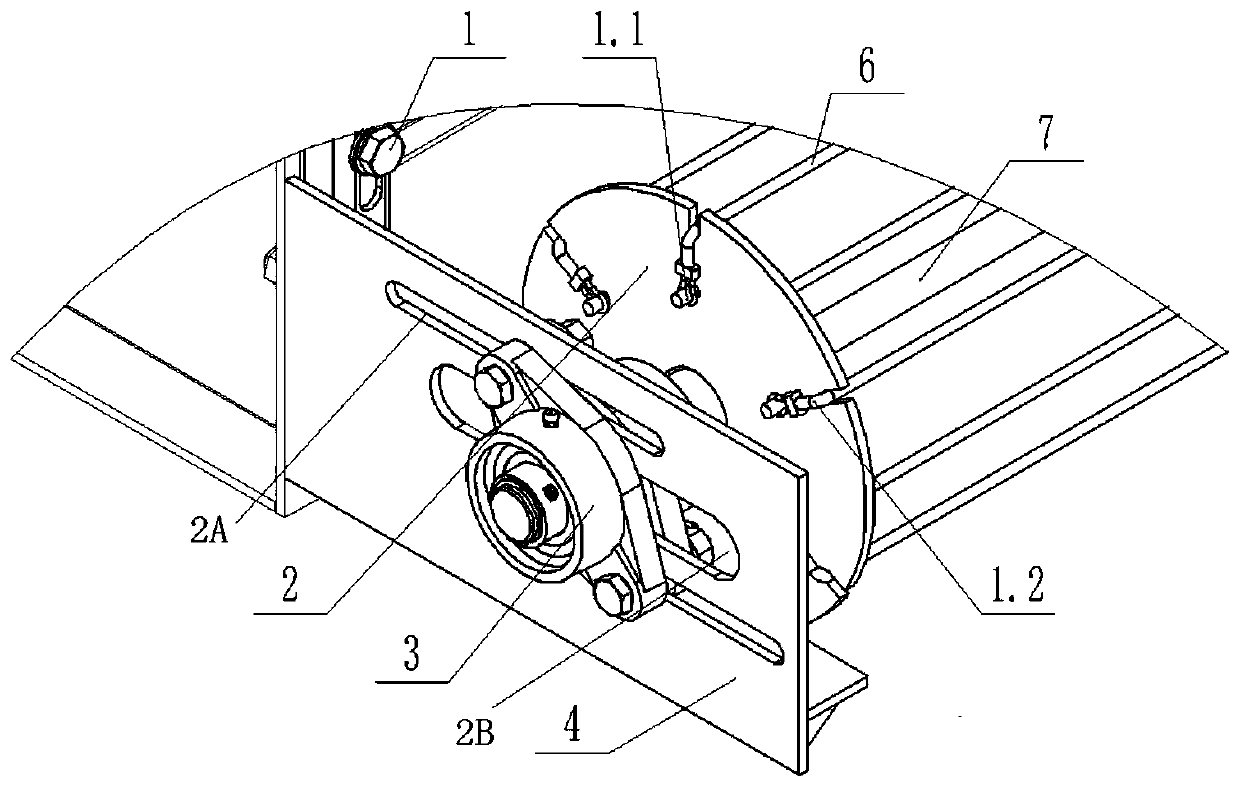

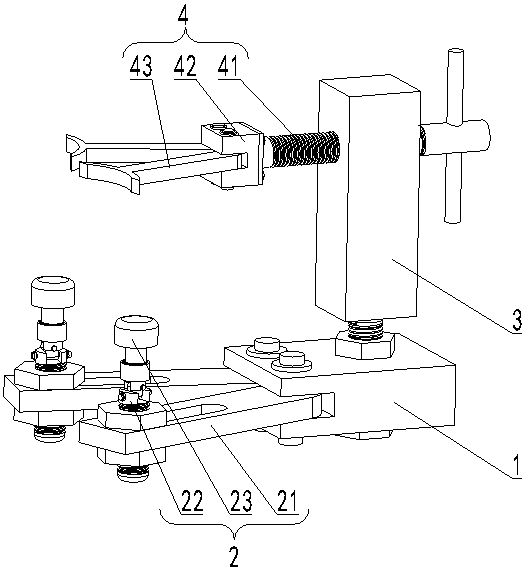

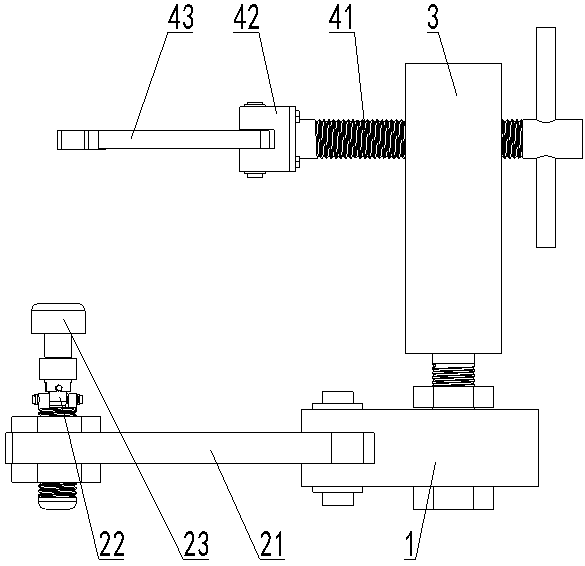

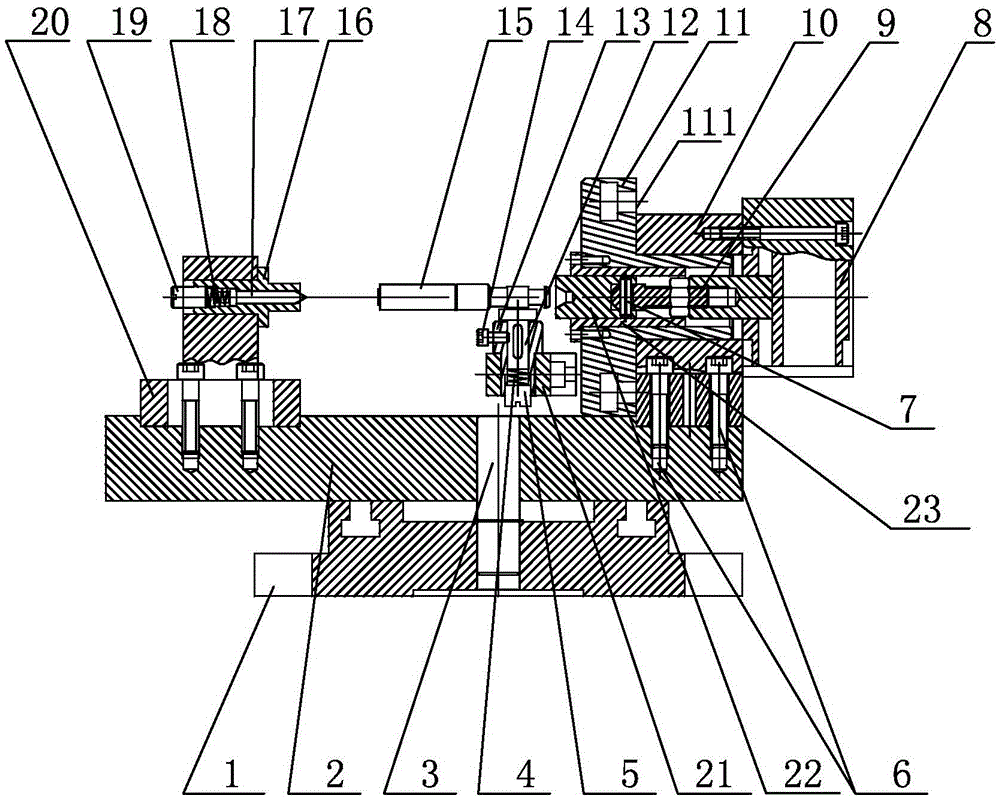

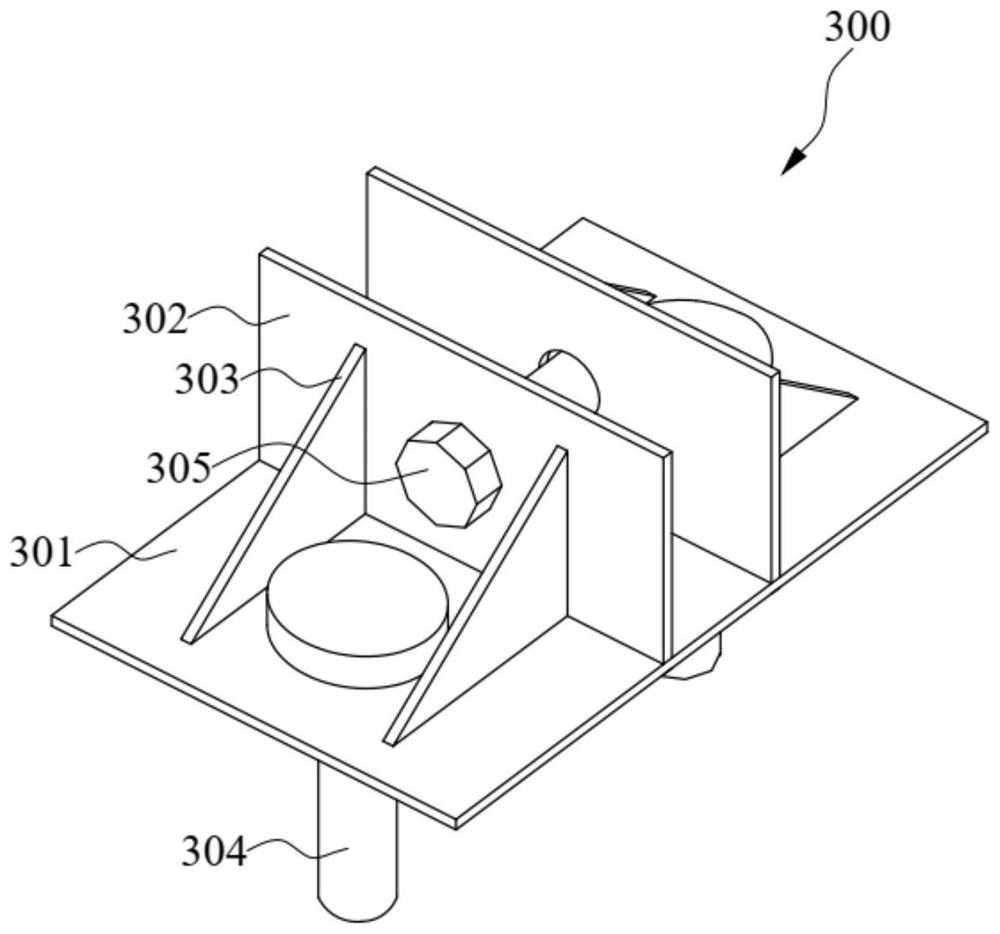

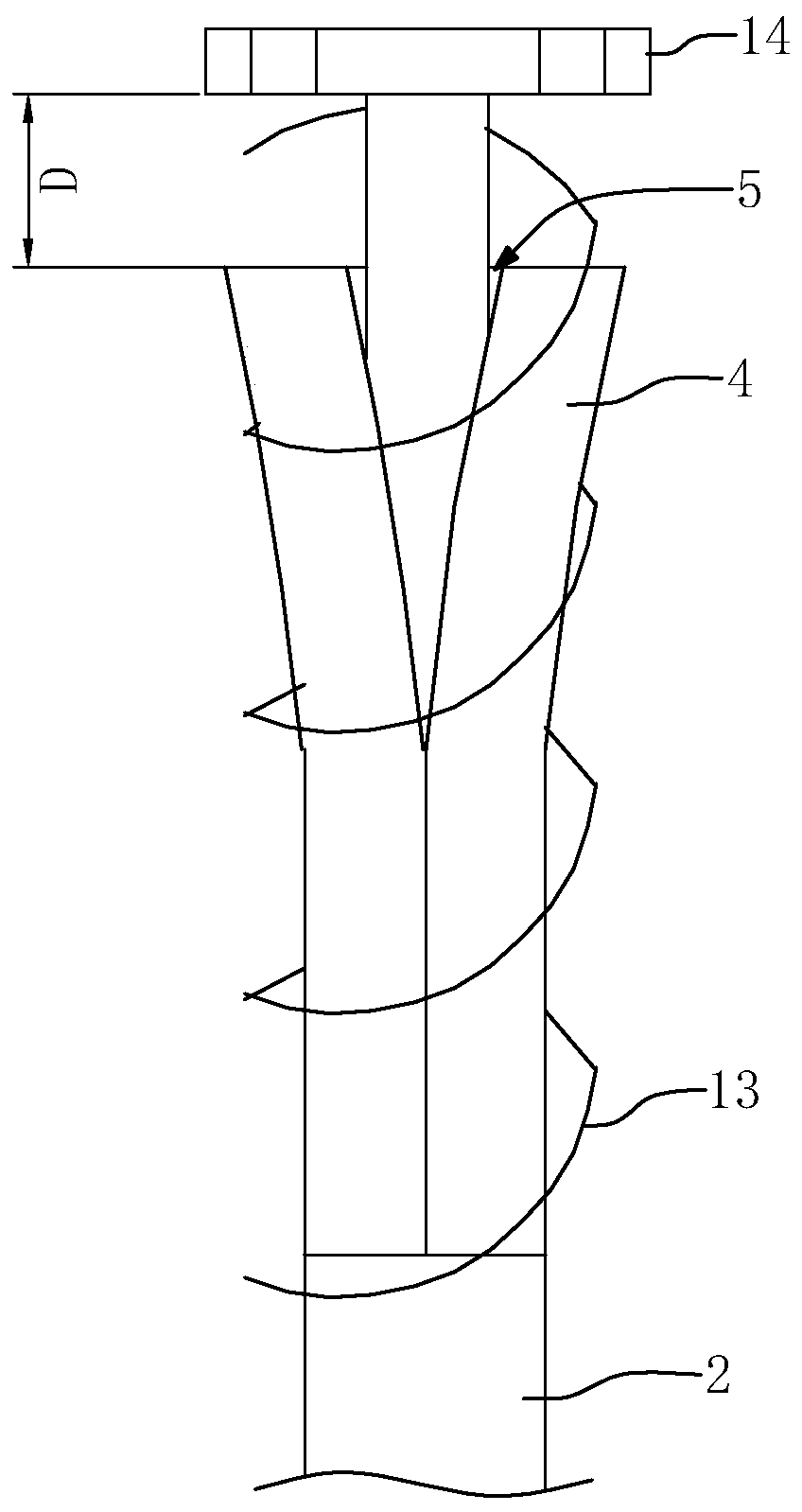

Clamping structure for machining plunger inclined grooves

ActiveCN103753317ARealize the positioning of the center of the circleEasy to adjustAutomatic control devicesFeeding apparatusMechanical engineeringPlunger

The invention relates to a clamping structure for machining plunger inclined grooves. The clamping structure comprises base disc which in location connection with a location round pin of a bottom plate. A first center mechanism and a clamp mechanism are fixedly connected onto the bottom plate respectively. A second center mechanism is arranged in the clamp mechanism, and a location mechanism is arranged on the clamp mechanism. According to the clamping structure, a center hole of one end and a cap of the other end of the plunger are clamped through a yin center and a yang center respectively, so that the circle center location of the two ends of the plunger is achieved, and the location reference is consistent with the design reference; the location mechanism is use, a location block of the location mechanism used for being attached to the plunger flat surface, the relative position of the plunger axis direction is adjustable through the yin center and the yang center, and the adjustability of the rotation direction and the machining angle is achieved through a dial.

Owner:WUXI CITY PEIJI MACHINERY

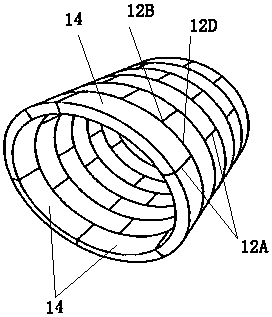

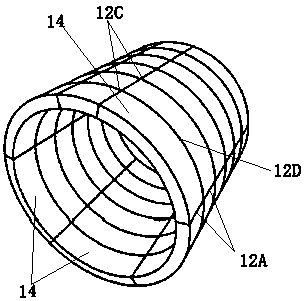

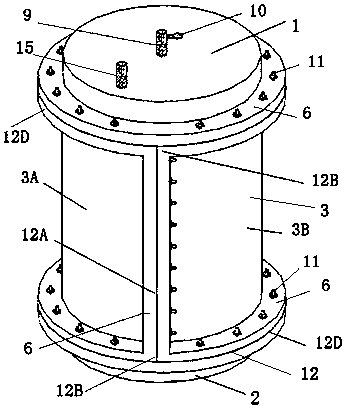

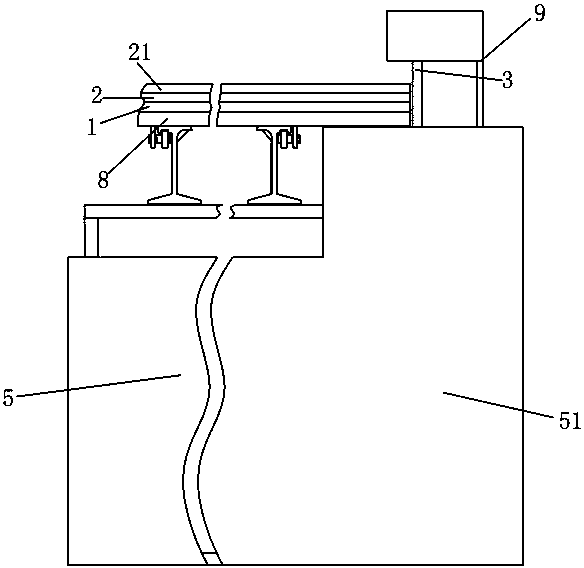

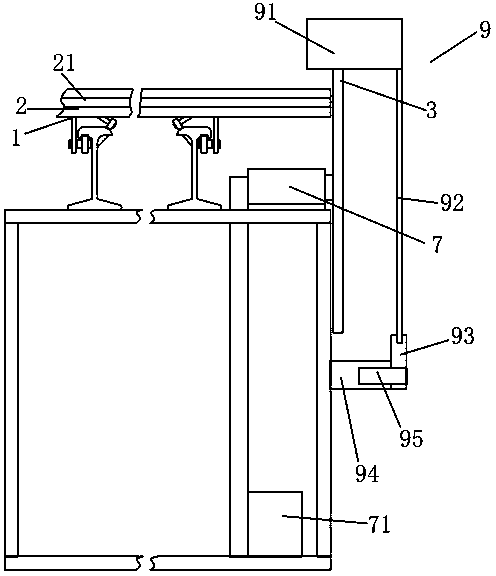

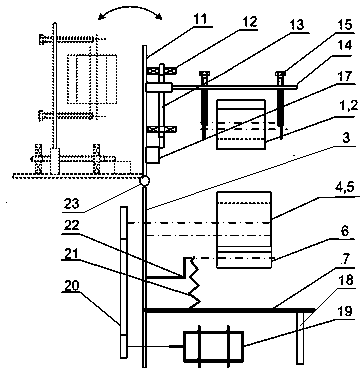

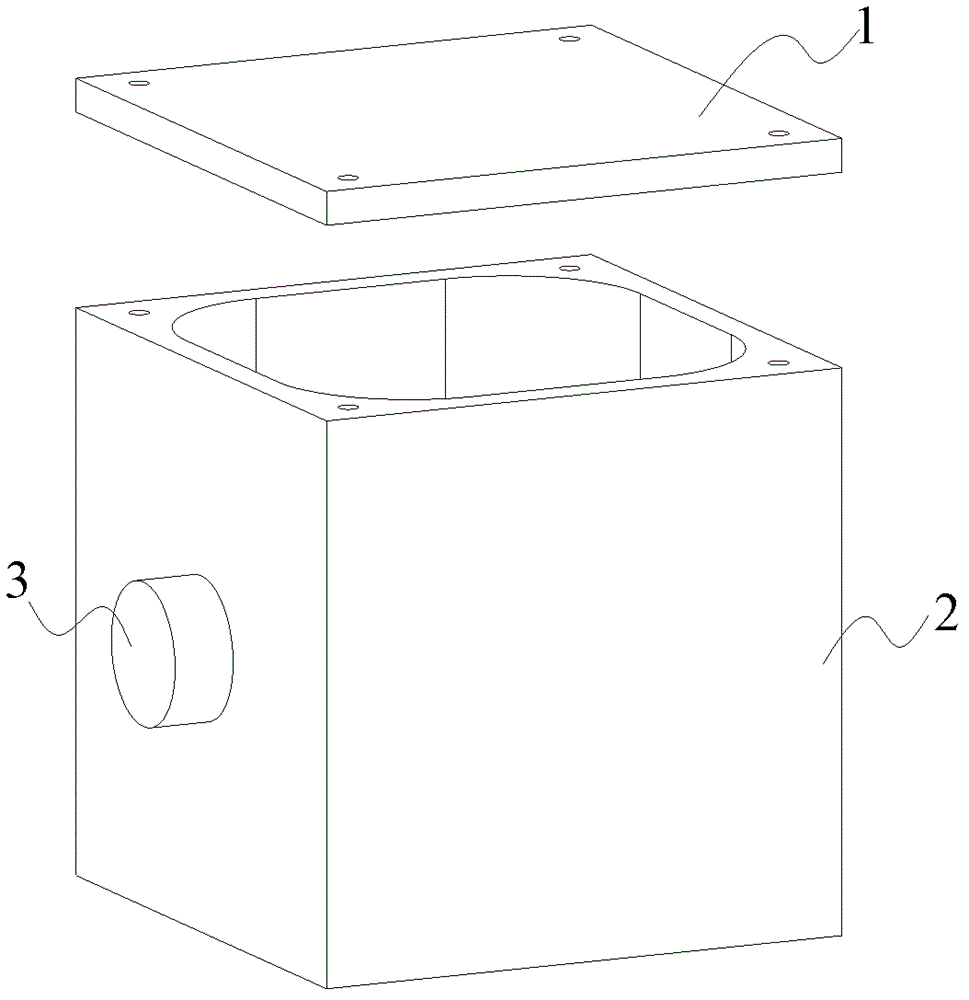

Test device and test method for testing waterproof performance of pipe segment joint sealing gaskets

InactiveCN107817078ARelative position adjustableWaterproofMeasurement of fluid loss/gain rateExperimental methodsEngineering

The invention relates to the technical field of tunnel engineering, and particularly relates to a test device and a test method for testing the waterproof performance of pipe segment joint sealing gaskets. The test device of the invention includes a sleeve with openings at both ends, and sealing covers installed at the two ends of the sleeve. The sleeve includes a plurality of sleeve blocks, and the sleeve blocks are spliced into an overall sleeve structure. Sealing gaskets are installed on the sleeve blocks on the two sides of a joint, and sealing gaskets are also arranged in the positions ofthe sleeve where the sealing covers are installed. The test device can simulate the actual condition that there are various types of joints after pipe segment splicing in actual projects. The experimental data of the waterproof performance of sealing gaskets is consistent with reality. Reliable reference and data support are provided for the construction of actual projects. The construction quality and the waterproof safety are ensured.

Owner:SOUTHWEST PETROLEUM UNIV

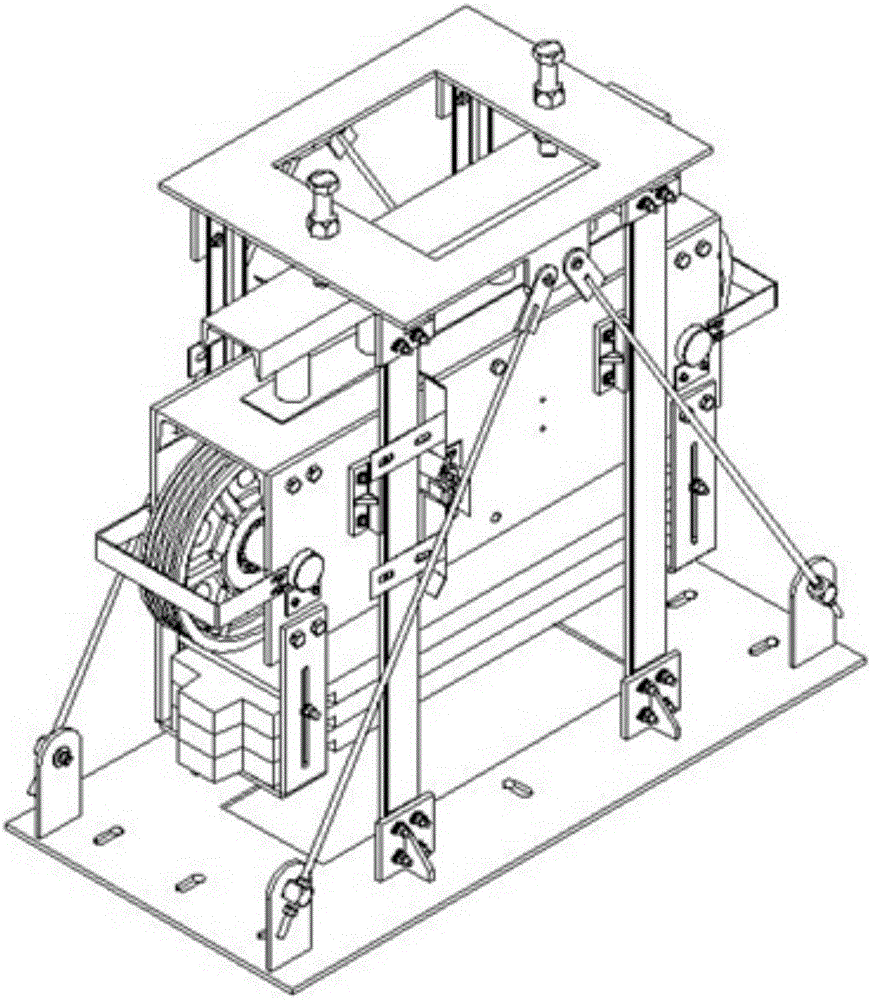

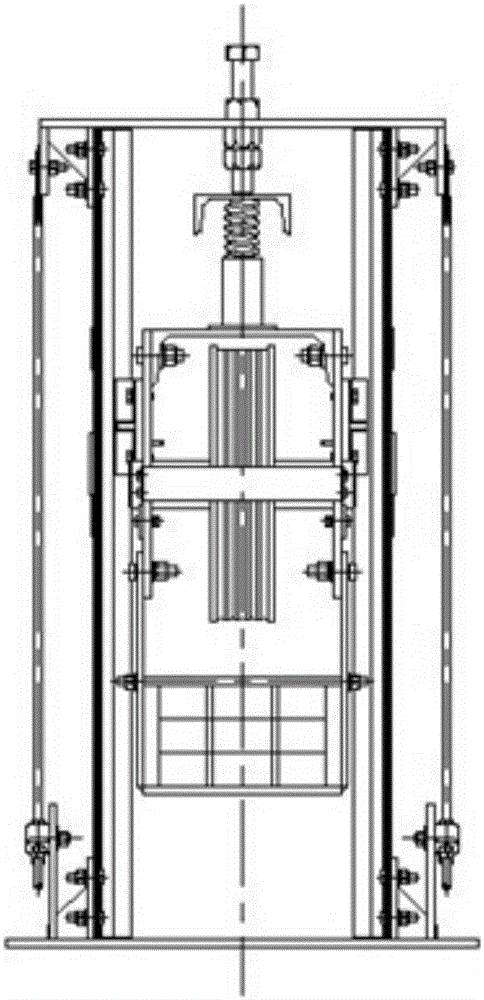

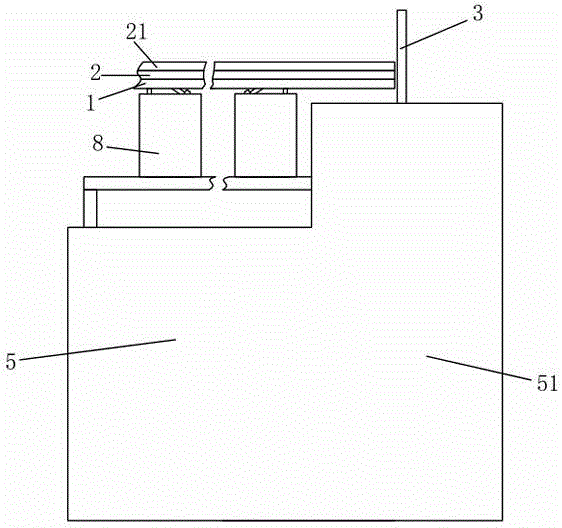

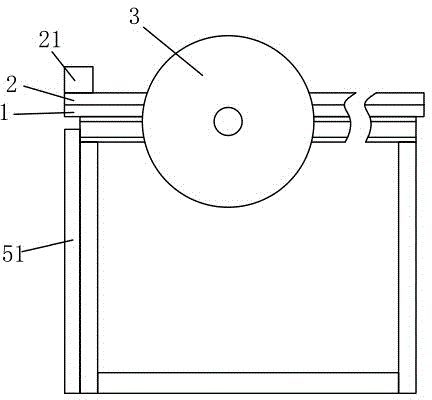

High-speed elevator compensating rope tensioning device and application thereof

The invention relates to a high-speed elevator compensating rope tensioning device and application thereof. The high-speed elevator compensating rope tensioning device comprises a base, fixed guide rails symmetrically arranged on the two sides of the base, and a balance baffle arranged above the base; a tensioning mechanism is arranged between the base and the balance baffle, is positioned between the fixed guide rails on the two sides, is connected with the fixed guide rails in a sliding manner, and comprises a tightening wheel fixing device, tightening wheels arranged on the two sides of the tightening wheel fixing device, and a balancing weight arranged at the bottom of the tightening wheel fixing device; the top part of the tightening wheel fixing device is connected with the balance baffle through an elastic component. Compared with the prior art, the elevator tensioning device is directly mounted on a pit floor, so that the occupied area is small, and the mounting is flexible. A pair of safety tongs is replaced with a flexible balance device, so that the operation of an elevator is more comfortable. In addition, the weight of an original steel plate is replaced with the additionally arranged balancing weight, so that the device is not only more flexible, but also convenient to mount, and meanwhile, the cost is reduced.

Owner:SHANDONG HONGYUNDA ELEVATOR CO LTD

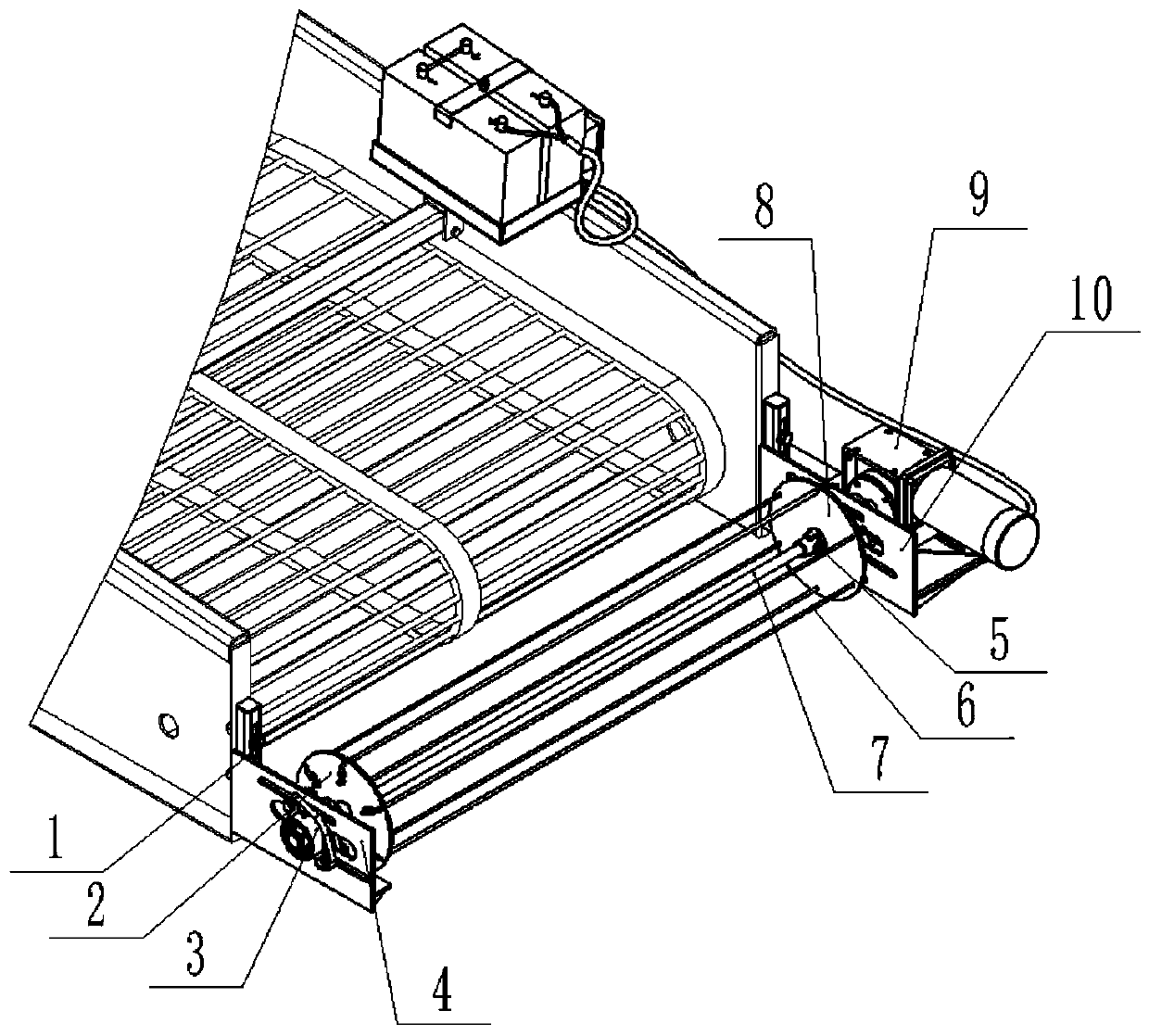

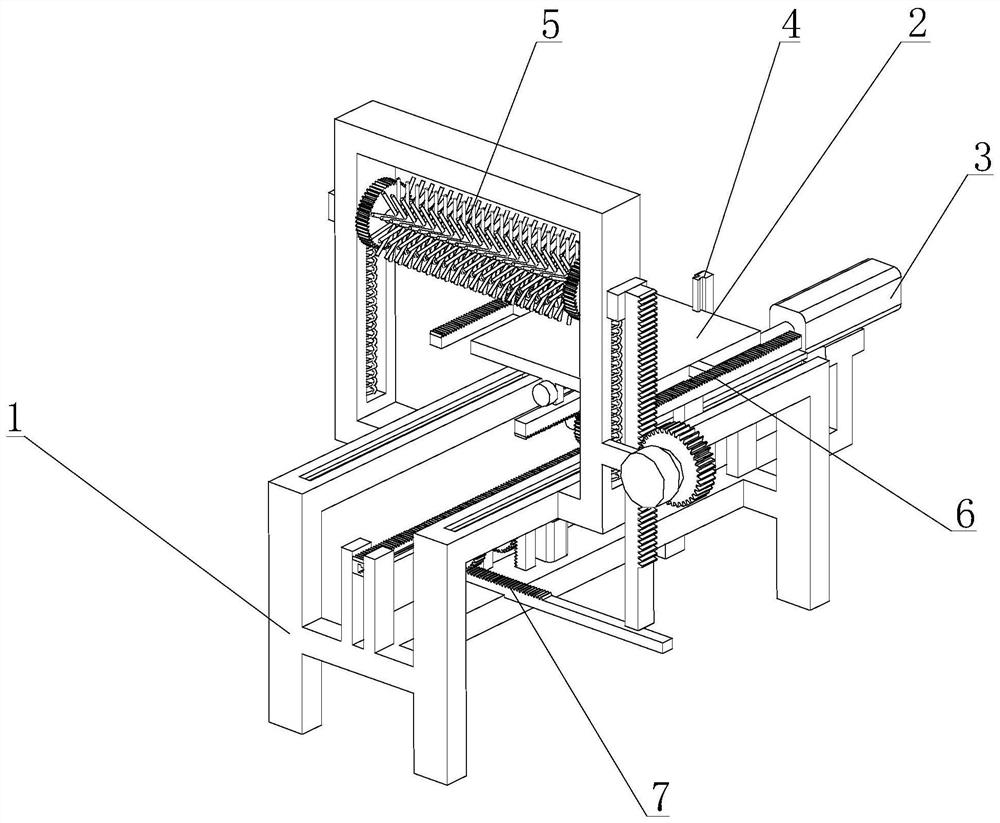

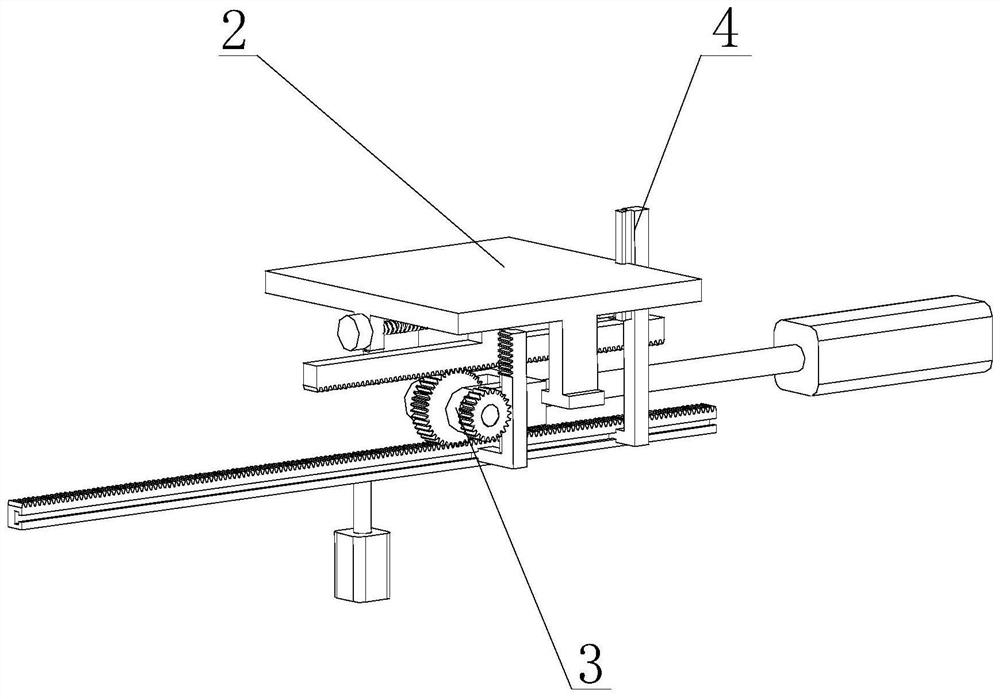

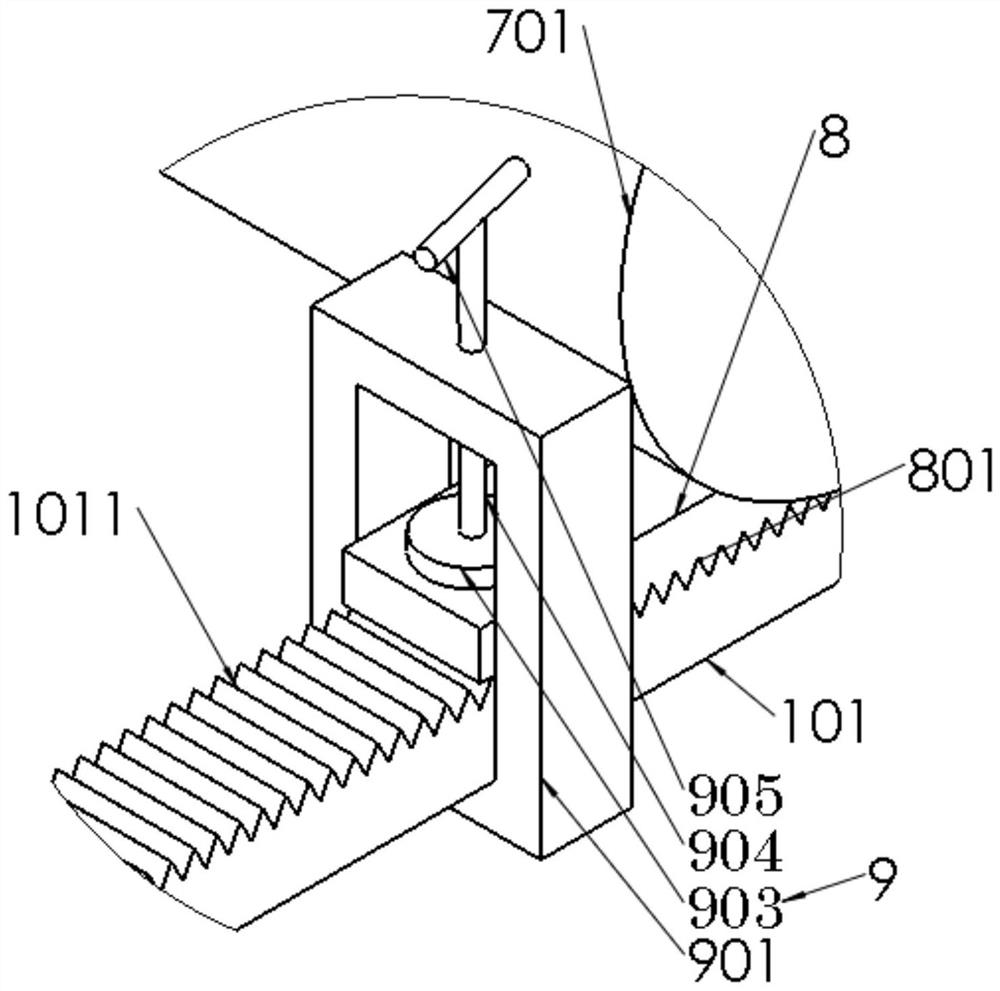

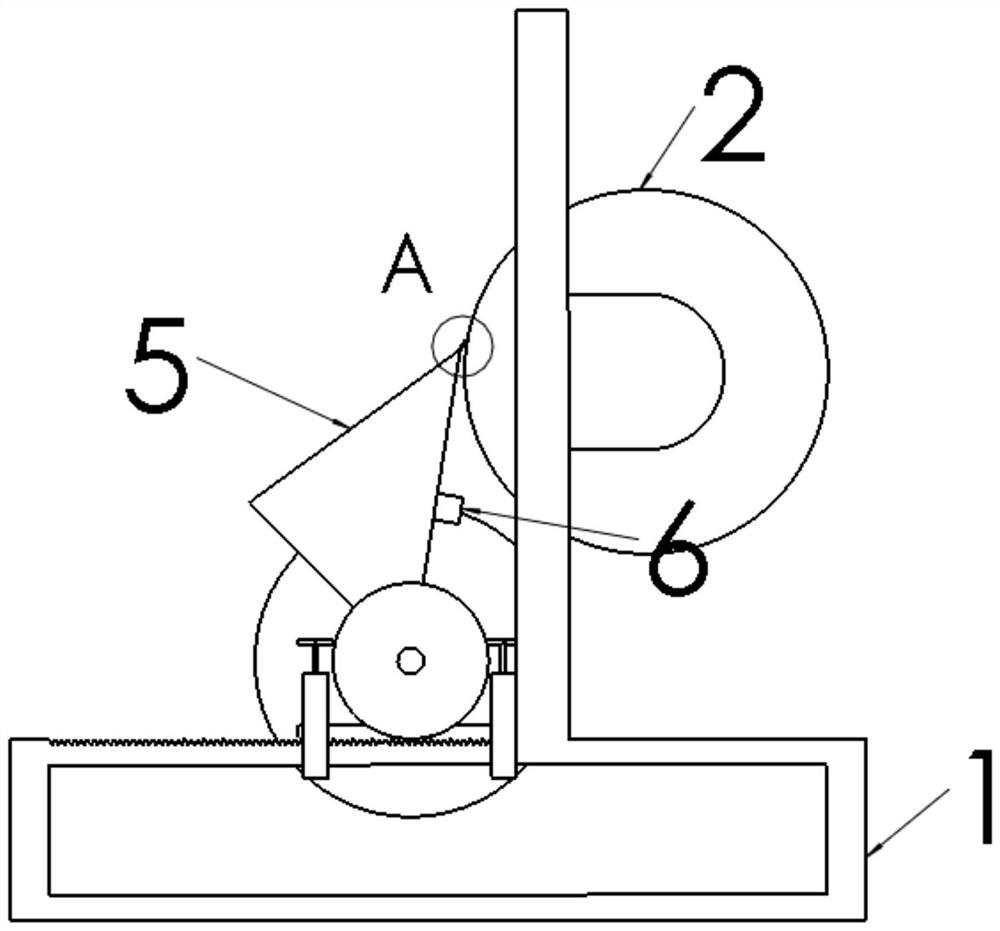

Portable small sawing machine

InactiveCN104290140AOperational securityEasy to cleanCircular sawsBark-zones/chip/dust/waste removalMechanical engineeringEngineering

The invention belongs to the field of plate sawing machines and particularly relates to a simple portable small sawing machine easy to disassemble and assemble and simple in operation. The sawing machine comprises a machine frame, a guide rail, a push table frame and a disk saw. A protection scrap guide cover is arranged above the disk saw, the push table frame comprises a push frame and a push table plate, and a location baffle and a limit block are arranged on the upper surface of the push table plate. A guide rail comprises a base plate and a frame rail with a T-shaped section and arranged on the base plate. The frame rail comprises a support strip and a rail ejection strip. An inclined rail face is arranged on the upper surface of the rail ejection strip, the lower surface on one side of the rail ejection strip is a bottom rail face, a rolling part comprises an upper roller and a lower roller, a plate is firmly clamped on the push table plate through matching of the location baffle and the limit block, then the pushing frame is pushed and is erected on the guide rail through the upper roller pressed on the inclined rail face, the whole pushing frame is located by means of matching of the upper roller and the lower roller fastened on the bottom rail face, and the pushing frame can only slide along the guide rail. The sawing machine facilitates matching, is small in roller and guide rail contact face, small in friction and free to operate.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

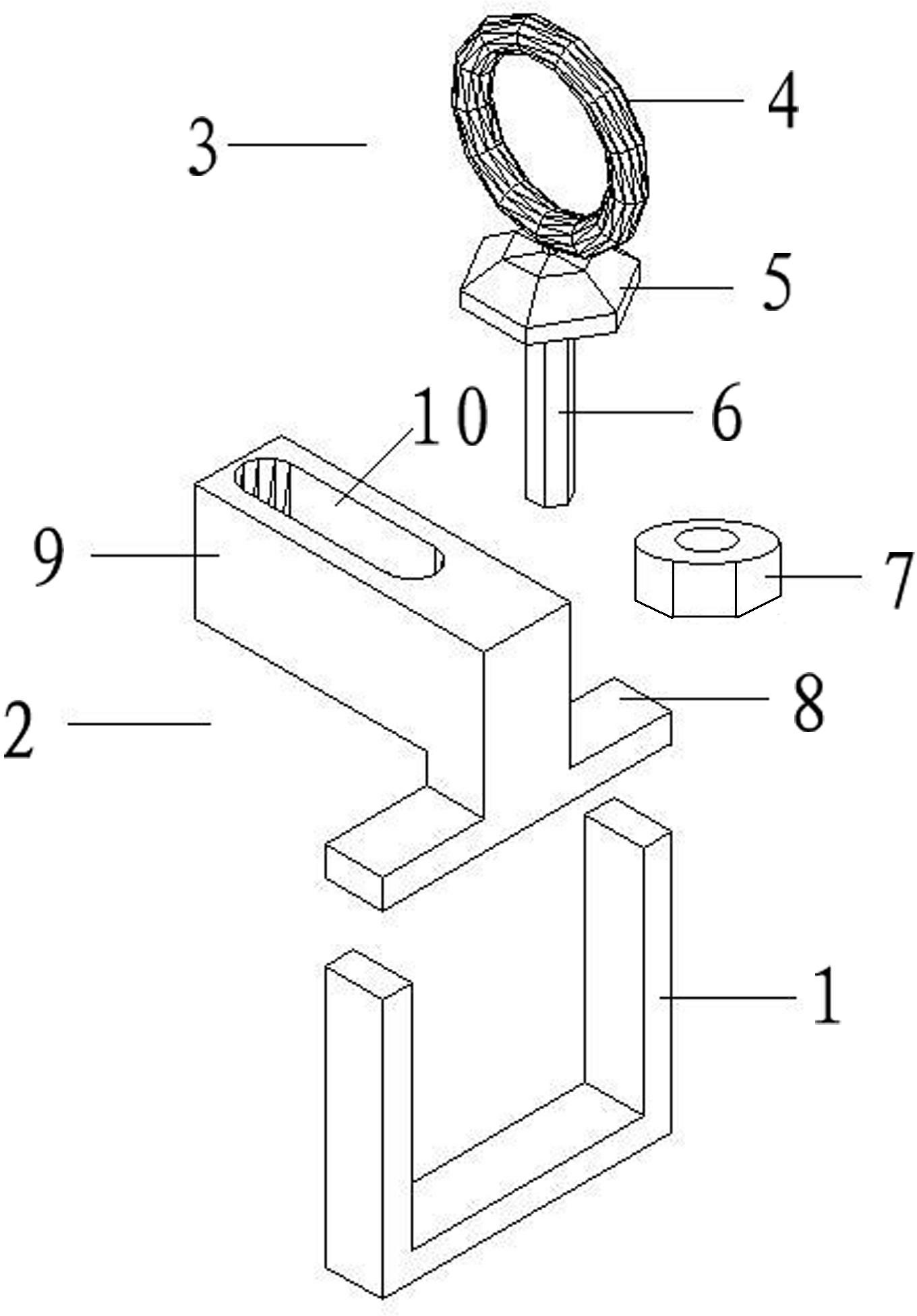

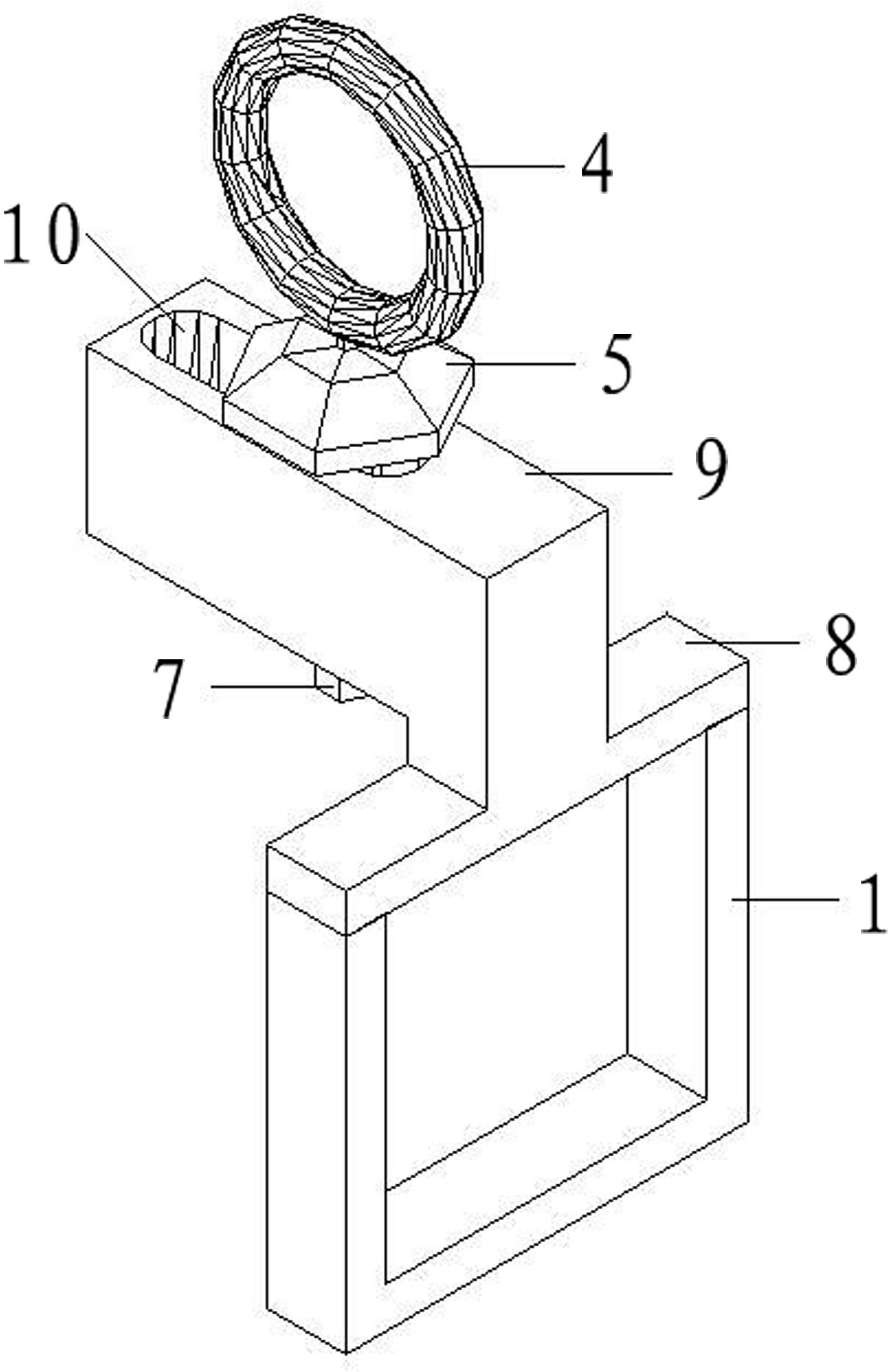

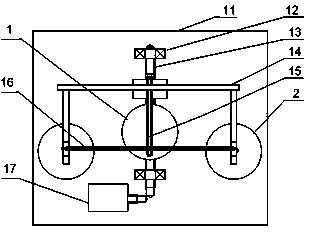

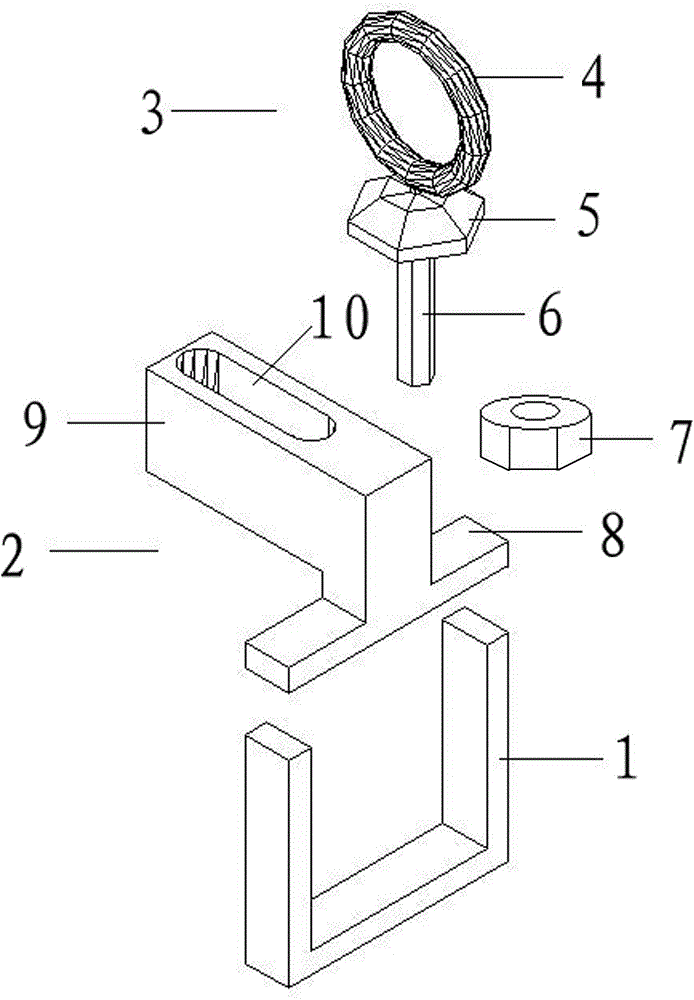

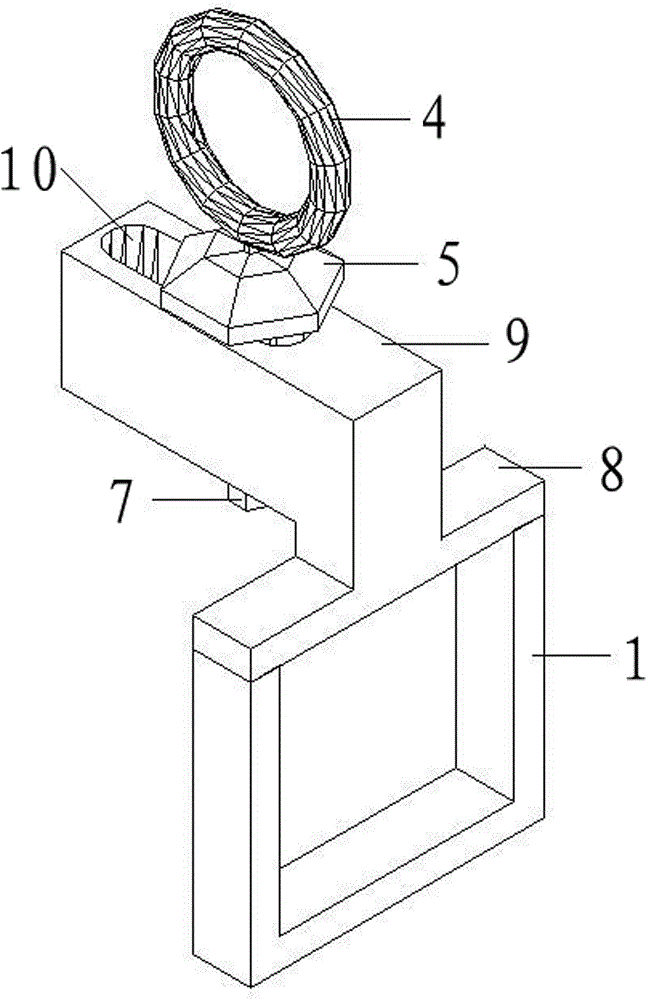

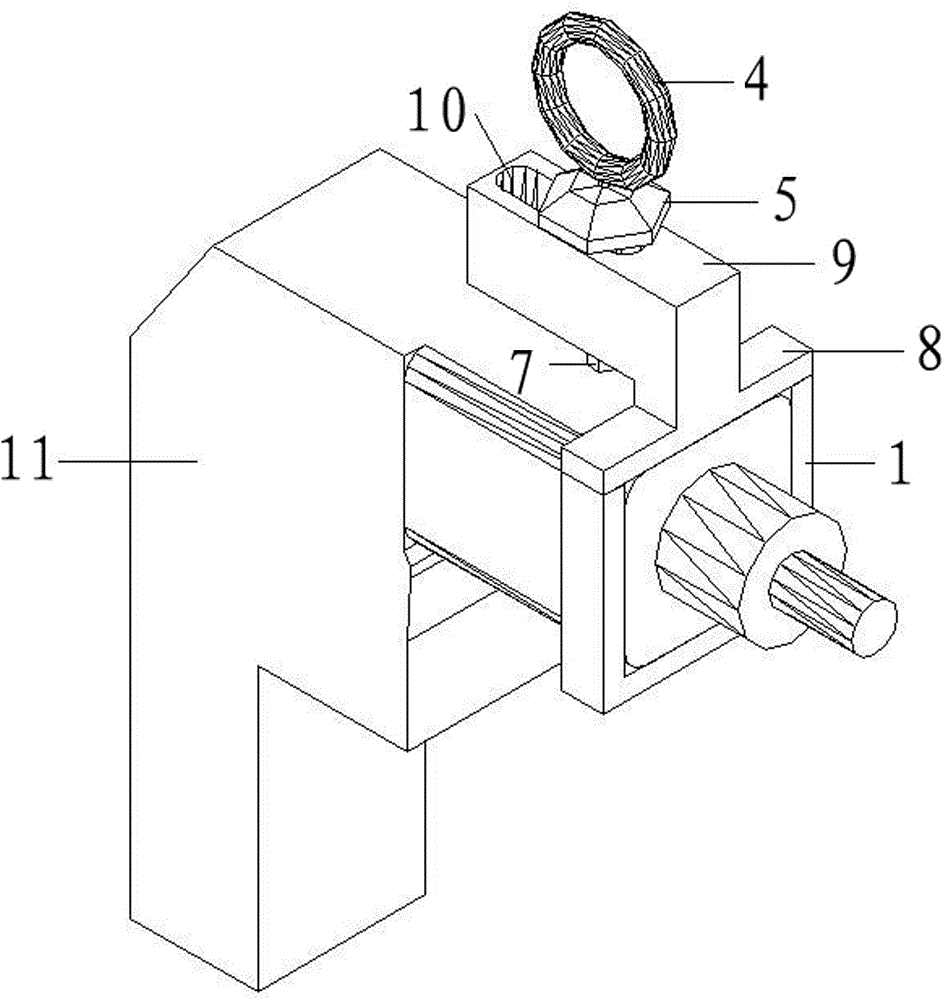

Hoisting tool for electric torque spanner

ActiveCN102672697ARelative position adjustableImprove balanceWork tools storageBraced frameAssembly line

The invention discloses a hoisting tool for an electric torque spanner, which is characterized by comprising a support framework, a hoisting beam used for being fixedly connected with the support framework by a screw and fastening the electric torque spanner, and a hoisting ring used for being movably connected with the hoisting beam and suspending the hoisting beam, wherein the support framework has a U-shaped section and is used for clamping the electric torque spanner; and the hoisting ring comprises a ring for providing a hooking position, a limit gasket for limiting the position of the ring, a screw rod for connecting the hoisting beam, and a fastening piece provided with an internal screw thread and used for fastening the screw rod on the hoisting beam. The hoisting tool for the electric torque spanner has the benefitsthat the hoisting beam is provided with a regulation slideway, so that the relative positions of the hoisting ring and the hoisting beam can be regulated, and the balance of the tool provided with the electric torque spanner can be conveniently regulated; the hosting tool is simple in structure, small in size and convenient to manufacture and use; and the hoisting tool is suitable for a progressive assembly line and is beneficial to improve the working efficiency.

Owner:PINGHU LIDEFU HYDRAULIC TOOLS

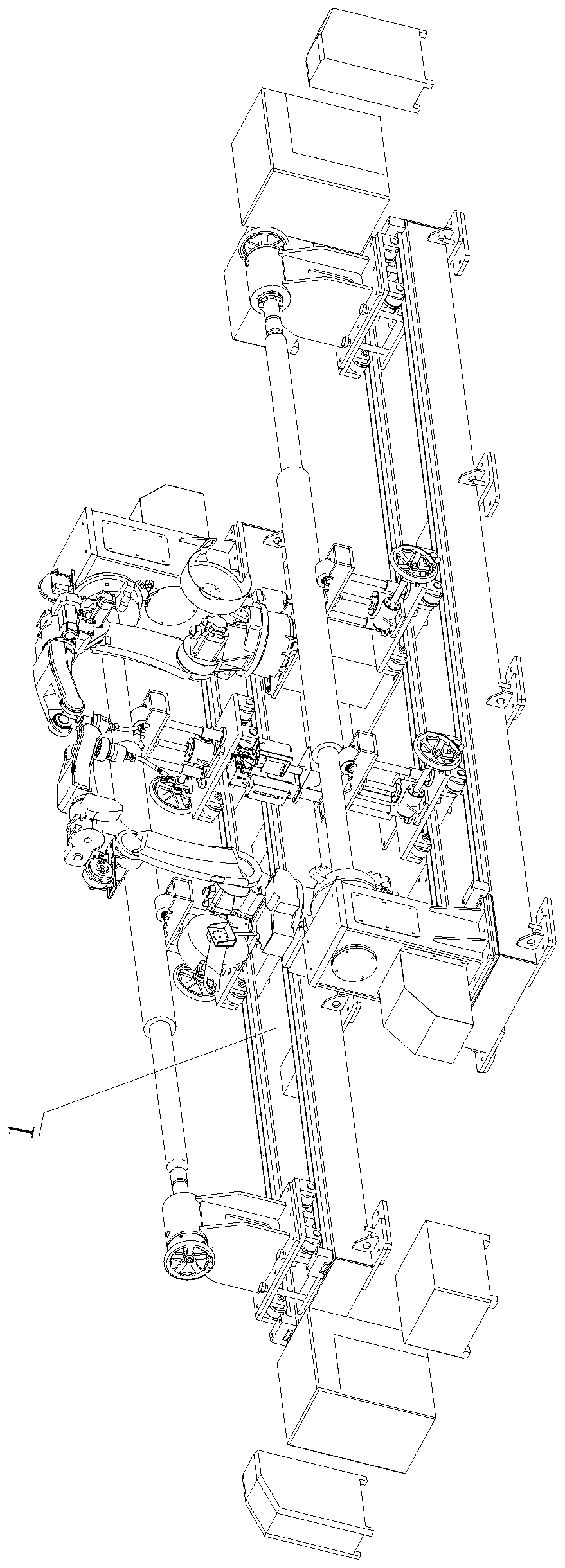

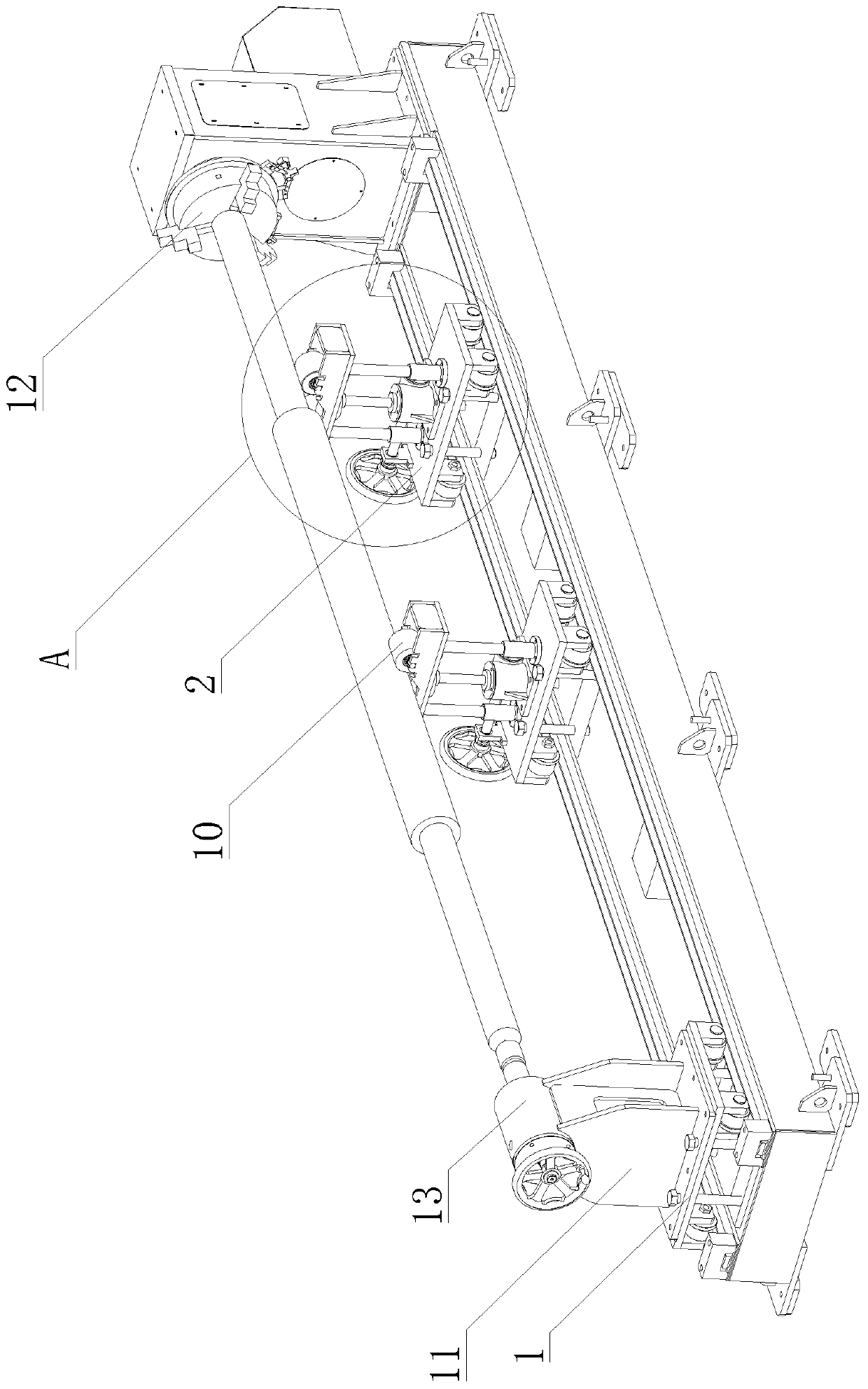

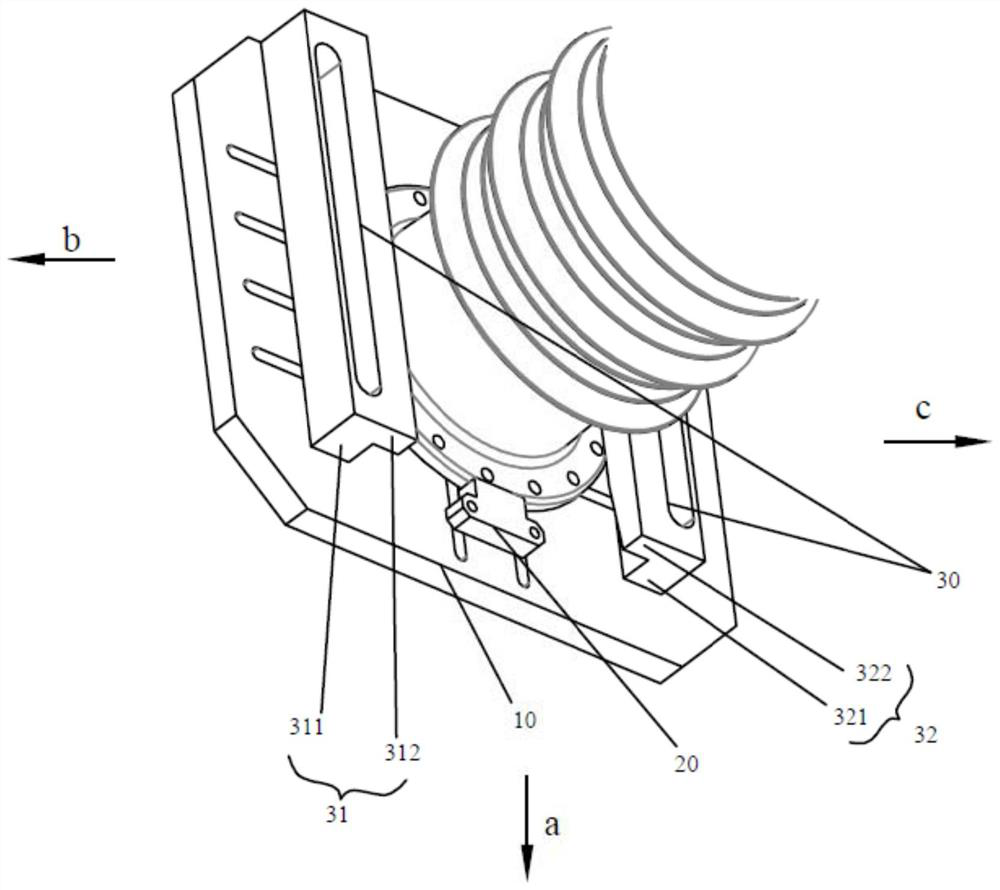

Long-axis circular seam welding device

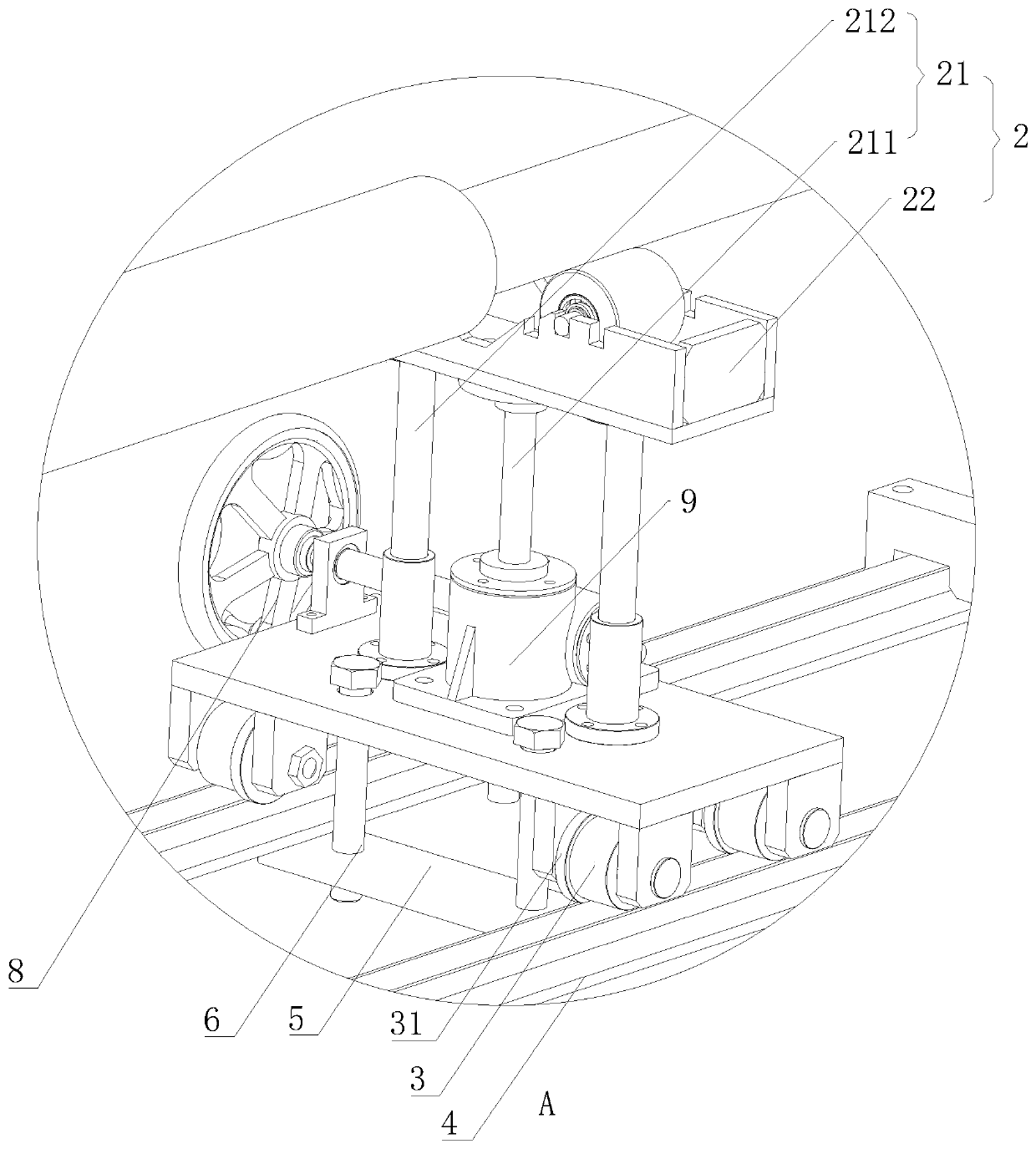

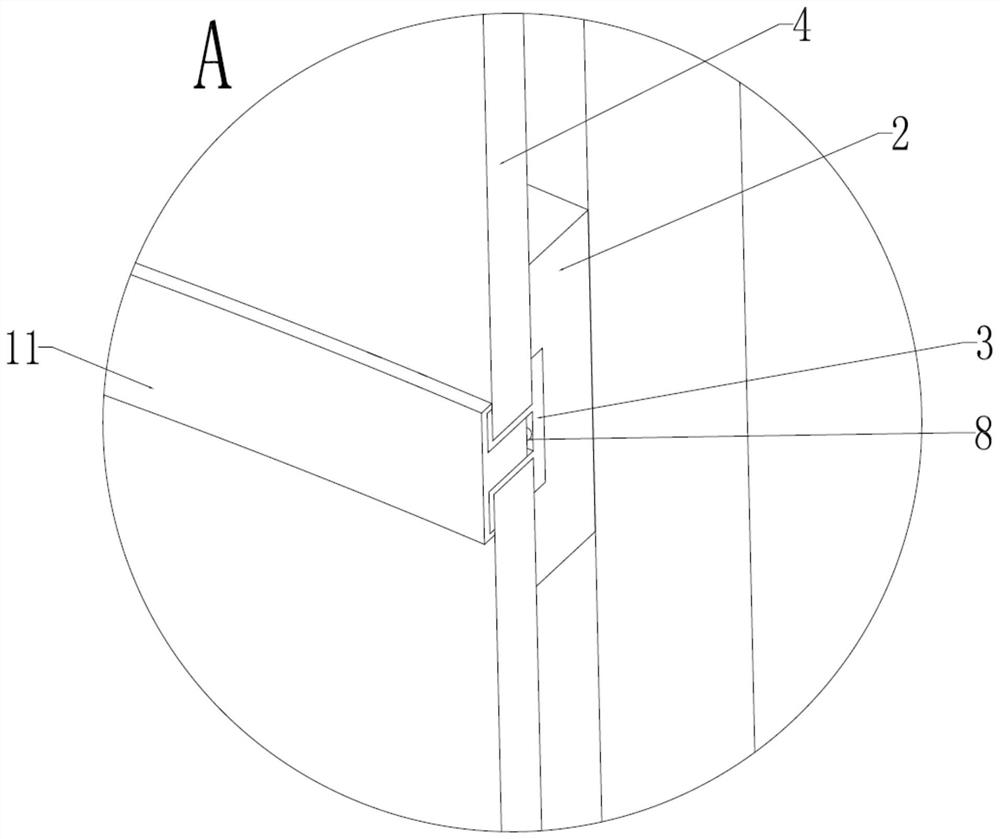

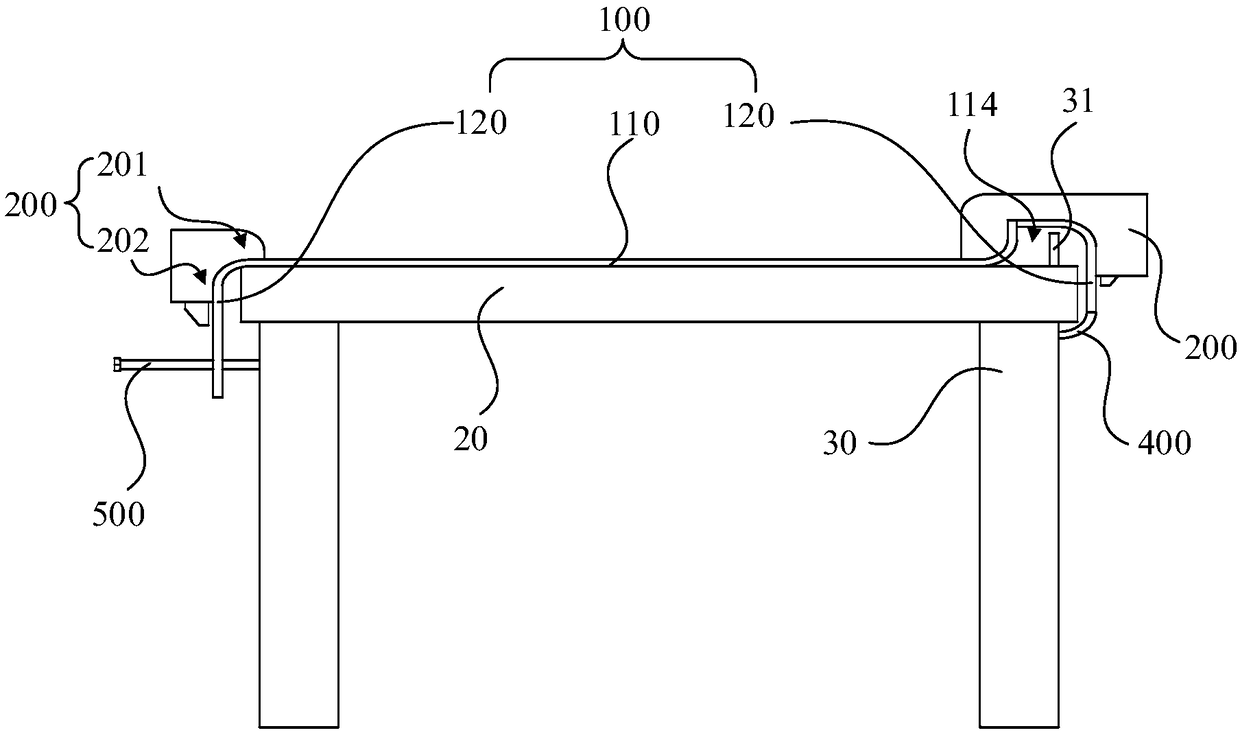

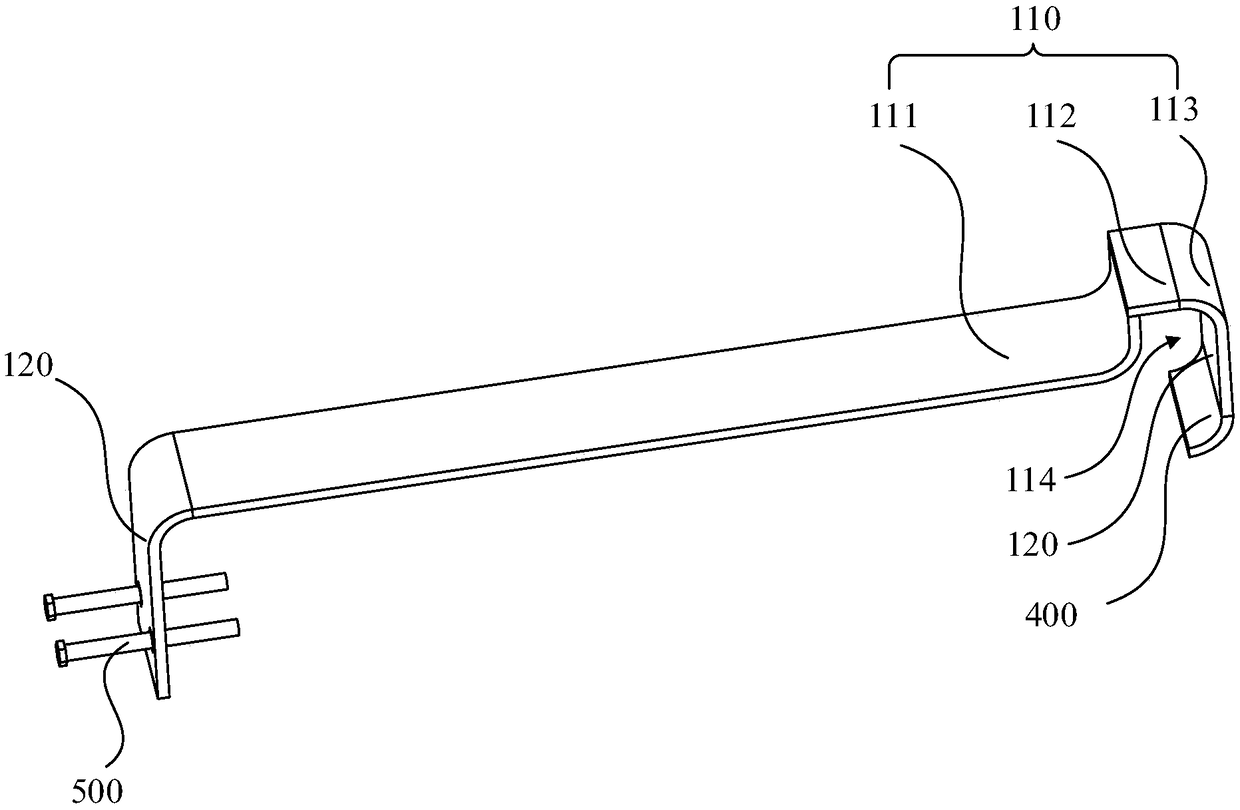

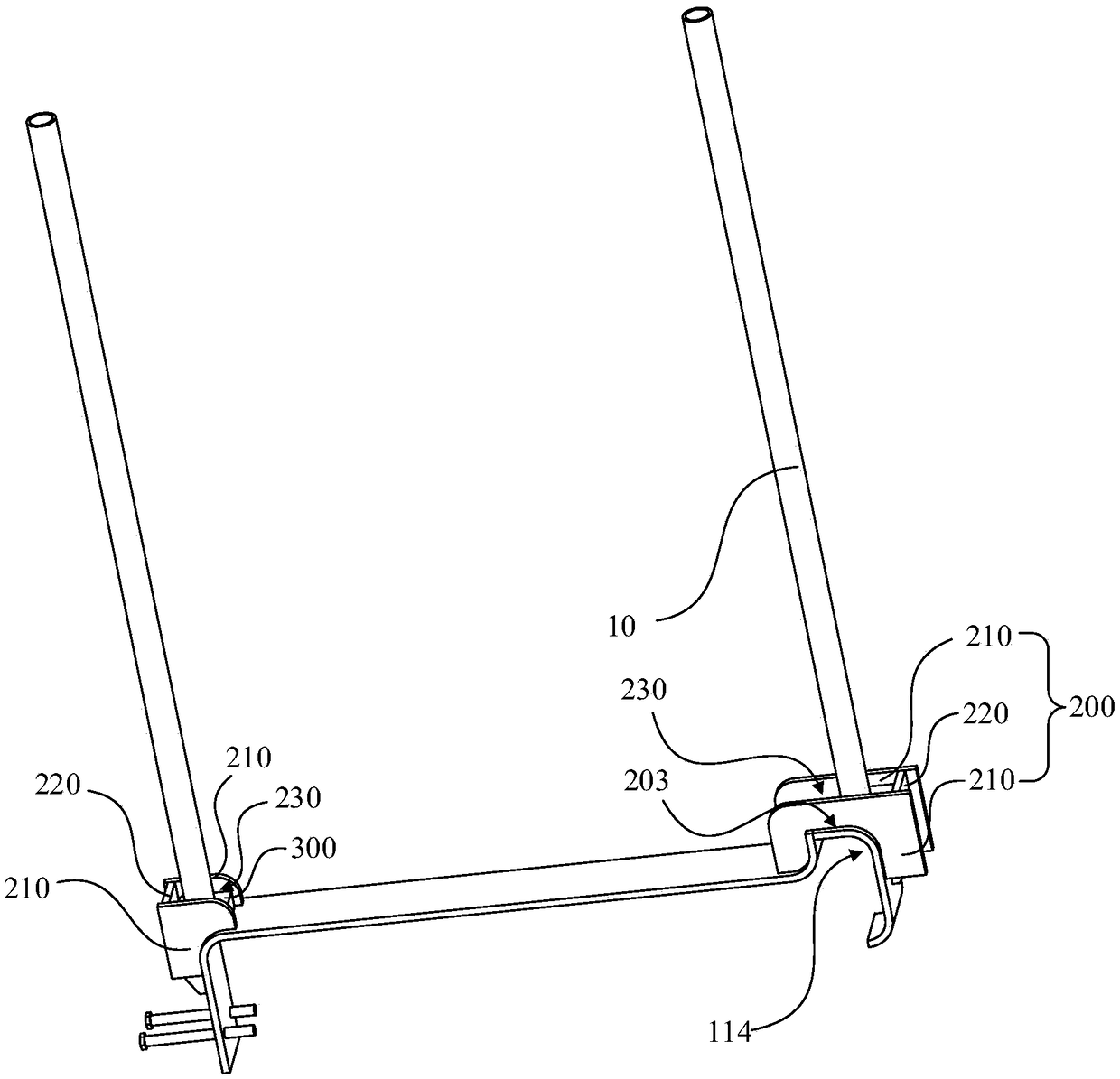

PendingCN109894795ARelative position adjustableWelding/cutting auxillary devicesAuxillary welding devicesLong axisSeam welding

The invention belongs to the field of welding equipment, and aims to provide a long-axis circular seam welding device. The long-axis circular seam welding device comprises a limiting tool, the limiting tool comprises a clamping frame used for limiting an end part of a shaft part, a clamping disc and a top column are arranged at the two ends of the clamping frame correspondingly, a supporting frameused for supporting the shaft part is further slidably connected to the middle position of the clamping frame; and the supporting frame comprises a lifting rod set which can vertically ascend and descend and an abutting base which is positioned at the top of the lifting rod set.

Owner:无锡金红鹰工业自动化有限公司

Plugging fixture

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

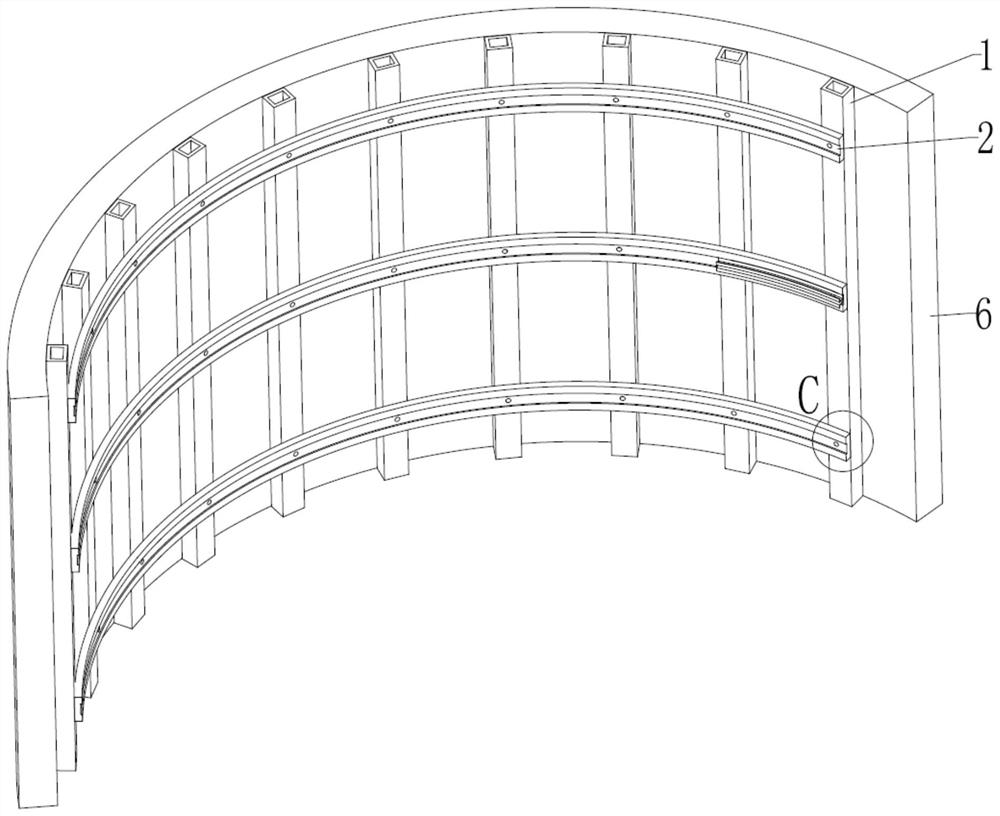

Lightweight modeling design structure of metal wallboard of arc-shaped curtain wall

The invention provides a lightweight modeling design structure of a metal wallboard of an arc-shaped curtain wall. The structure comprises a plurality of main keels, a plurality of arc-shaped keels, clamping pieces, an arc-shaped wallboard and a stretching mechanism, the plurality of main keels are fixedly connected to an arc-shaped wall surface, the main keels are vertically arranged, the arc-shaped keels are sequentially connected with the plurality of main keels, the arc-shaped keels are horizontally arranged, grooves are formed in the outer side faces of the arc-shaped keels, the clampingpieces are clamped in the grooves, and first bolts sequentially penetrate through the clamping pieces and the arc-shaped keels to be connected with the main keels. The upper and lower ends of the arc-shaped wallboard are clamped into the clamping pieces with the same radian, so that the arc-shaped wallboard is stressed uniformly, a stable connecting structure is formed, and the structural stability is good. Back ribs are connected with shaping plates to limit deformation of the arc-shaped wallboard, the distances between the back ribs and the shaping plates are adjusted to adapt to arc-shapedwallboards with different radians, and the universality is high.

Owner:GOLD MANTIS CONSTR DECORATION

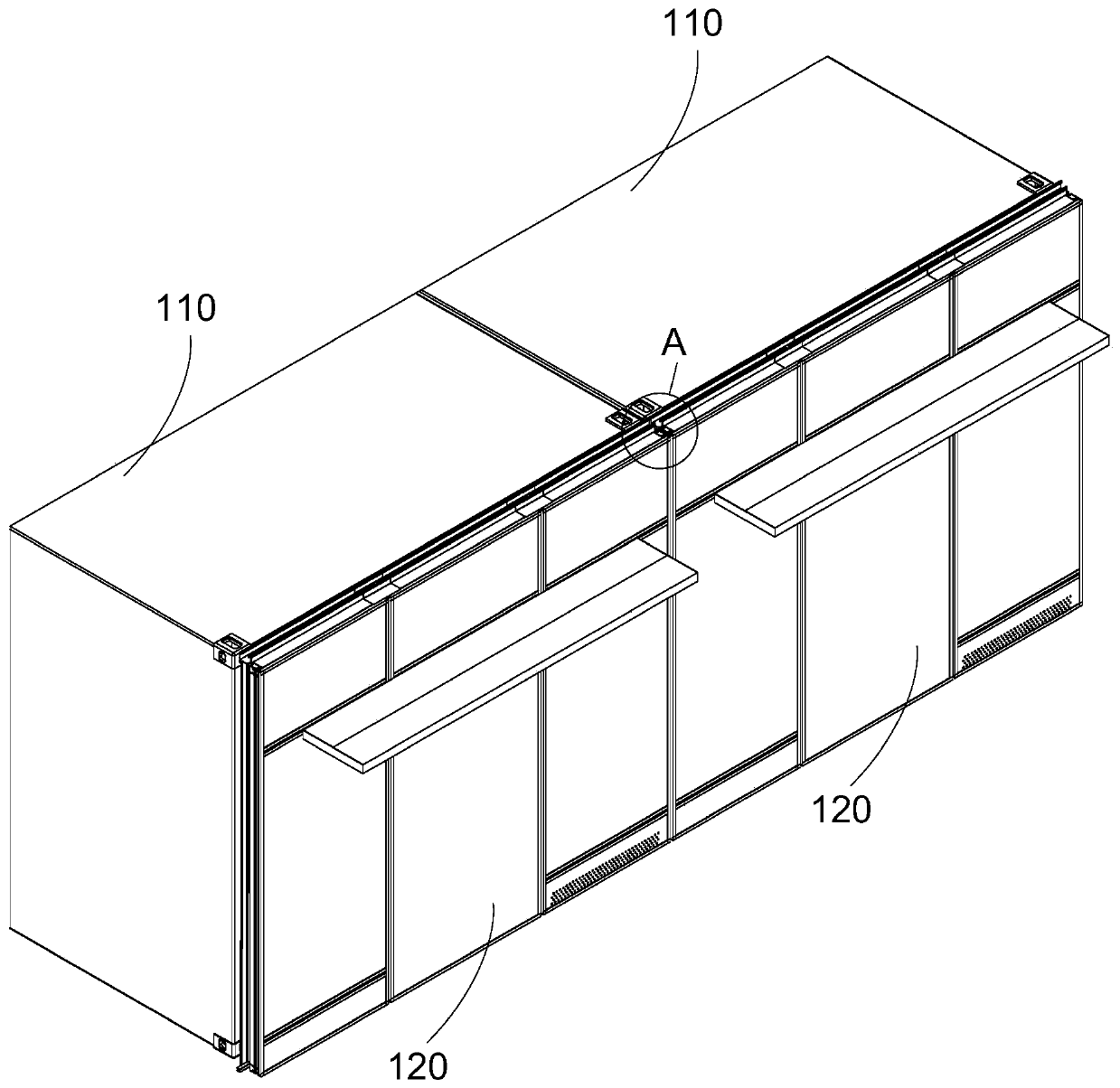

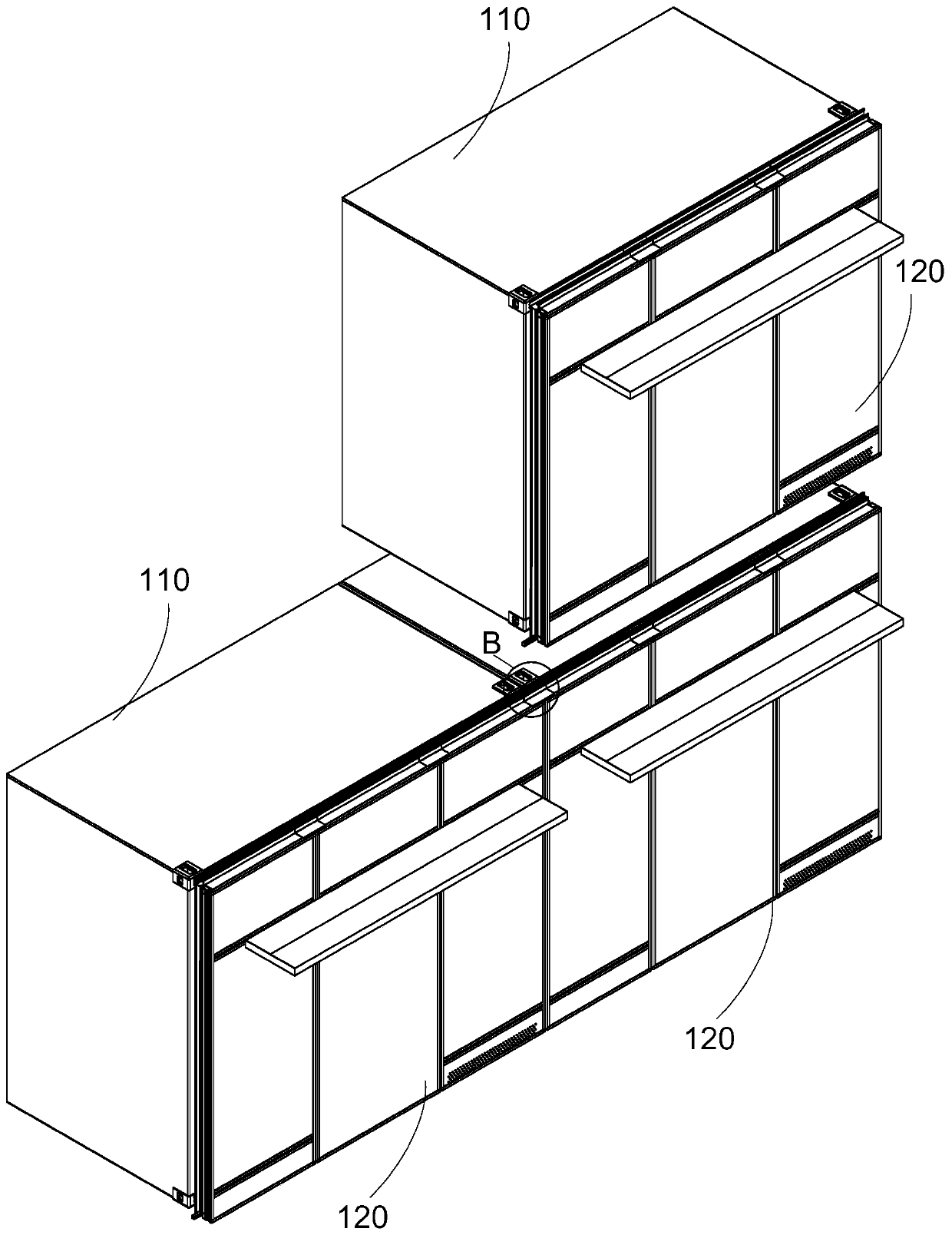

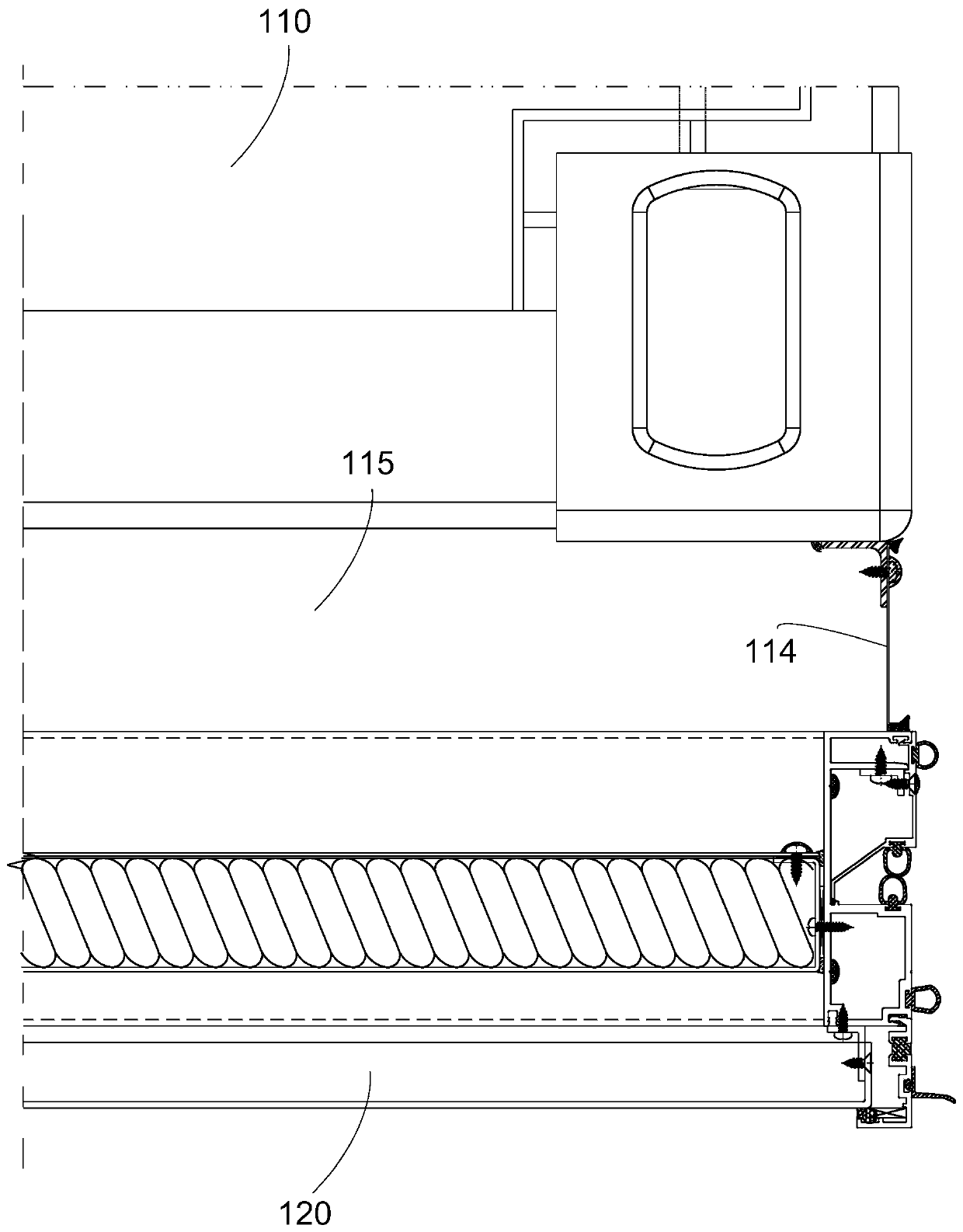

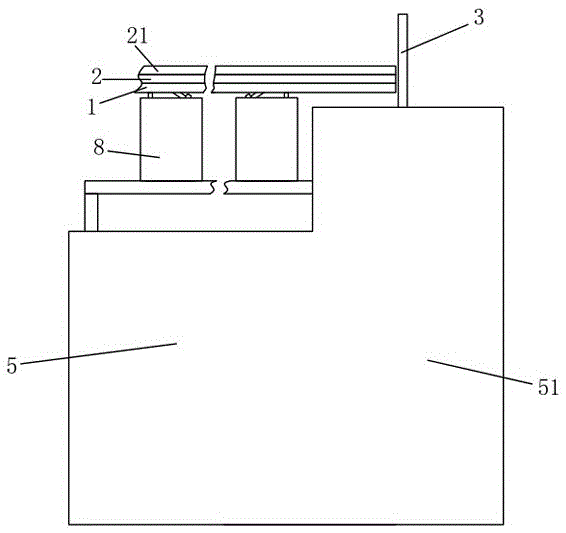

Modular curtain wall and installation method of modular curtain wall

PendingCN110886415AShorten the construction periodReduce construction costsWallsBuilding insulationsMechanical engineeringIndustrial engineering

The invention provides a modular curtain wall and an installation method of the modular curtain wall. The modular curtain wall comprises steel structure modules, curtain wall modules and first waterproof parts; each steel structure module comprises a steel structure body and a mounting base; and each curtain wall module comprises a curtain wall body, hooks and first sealing parts, wherein the hooks are used for being hung on the corresponding mounting base, so that each curtain wall body is fixed on the corresponding steel structure body, and the first sealing parts are arranged at the left end and the right end of each curtain wall body. When at least two curtain wall modules are spliced in the left-right direction of the corresponding steel structure body, the first waterproof parts areused for being arranged in a splicing seam between the adjacent curtain wall modules, and the first sealing parts abut against the first waterproof parts; and when the hooks are hung on the mounting bases, the relative positions of each curtain wall body and the corresponding steel structure body can be adjusted in the front-back direction, the left-right direction and the up-down direction of thesteel structure body. Therefore, the construction period can be shortened, the construction cost can be reduced, the full preassembly of the steel structure modules and the curtain wall modules of the modular curtain wall can be realized, and the installation is convenient.

Owner:GUANGDONG CIMC BUILDING CONSTR CO LTD

Plug-in connection tool

PendingCN108747922AStable structureNo deformationWork holdersEngineeringElectrical and Electronics engineering

The invention discloses a plug-in connection tool which is used for connecting safety handrails to a hatch coaming panel. The plug-in connection tool comprises locating plates. Each locating plate comprises a body and bending bodies connected to the two ends of the body, and the two bending bodies are clamped to the hatch coaming panel. The plug-in connection tool further comprises reinforcers, arotary locating part and a translational motion locating part. Each reinforcer comprises a first part and a second part, the first part abuts against the corresponding body. The safety handrails are fixedly arranged on the surfaces, far away from the bodies, of the first parts. The second parts abut against the surfaces, far away from the locating plates, of the bending bodies. The rotary locatingpart is connected to the corresponding bending body. The translational motion locating part penetrates through the corresponding bending body. Through the plug-in connection tool, the problem of deformation and fracture of a locating plate is solved well, so that the safety handrails fixedly arranged on the locating plate are stable relatively, and security of working staff is ensured.

Owner:楼佳琪

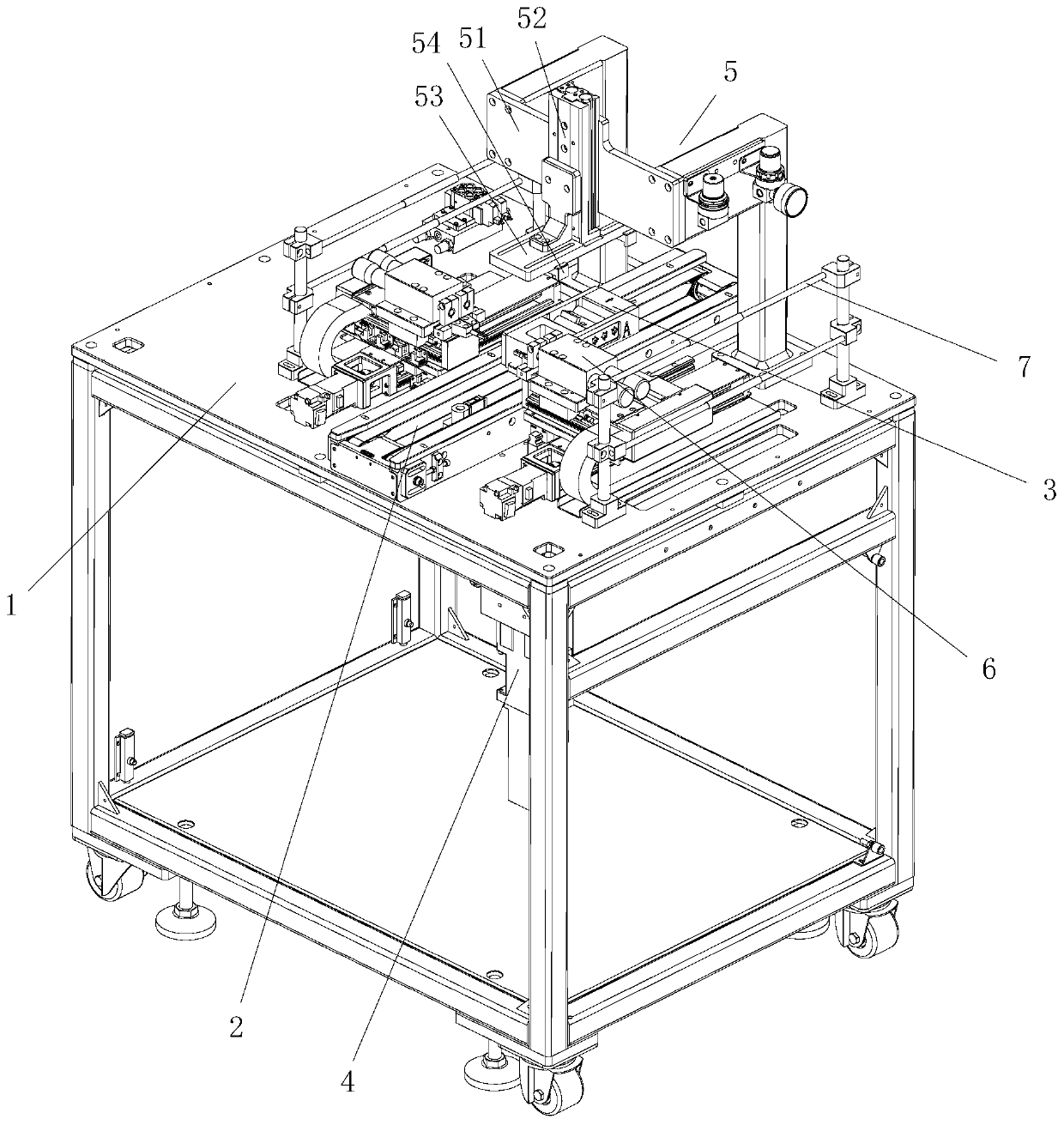

Resistance welding mechanism for floor mopping robot battery

PendingCN111014918AWide applicabilityAvoid wire frayingResistance electrode holdersEngineeringBattery cell

The invention discloses a resistance welding mechanism for a floor mopping robot battery. The resistance welding mechanism comprises a machine frame, a conveyor, a resistance welding jig, a jacking assembly, a pressing-down assembly, a welding assembly and a wire follow-up assembly. The conveyor is arranged on the machine frame and conveys the resistance welding jig. The bottom of the machine frame is provided with the jacking assembly matched with the resistance welding jig. The pressing-down assembly is arranged on the upper side of the resistance welding jig. The welding assembly and the wire follow-up assembly are arranged at the positions, on the front side and the rear side of the resistance welding jig, of the machine frame. In this way, the resistance welding mechanism is compact in structure and stable in operation, can rapidly position and install the battery and a connector and weld the battery and the connector together, and is high in work efficiency.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

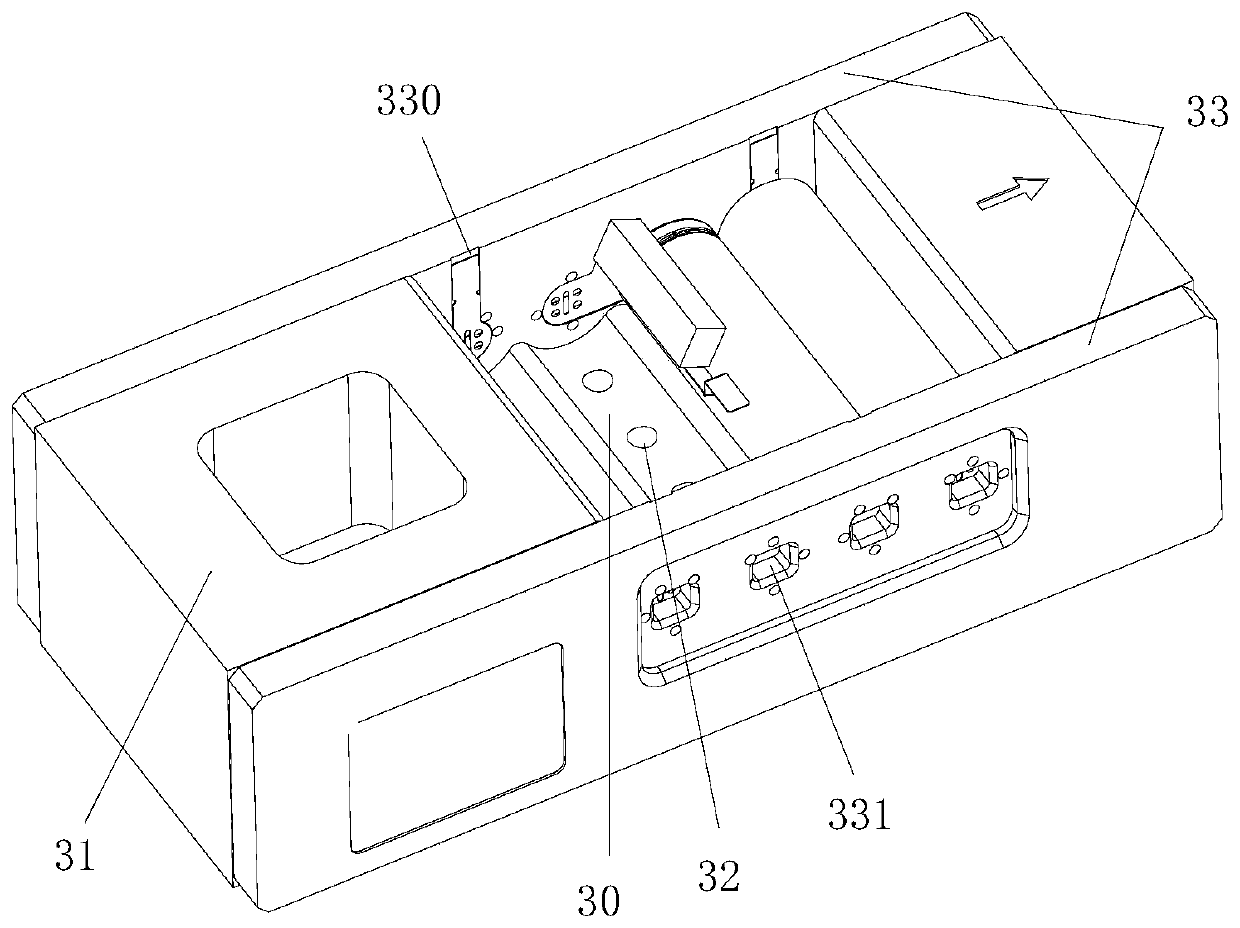

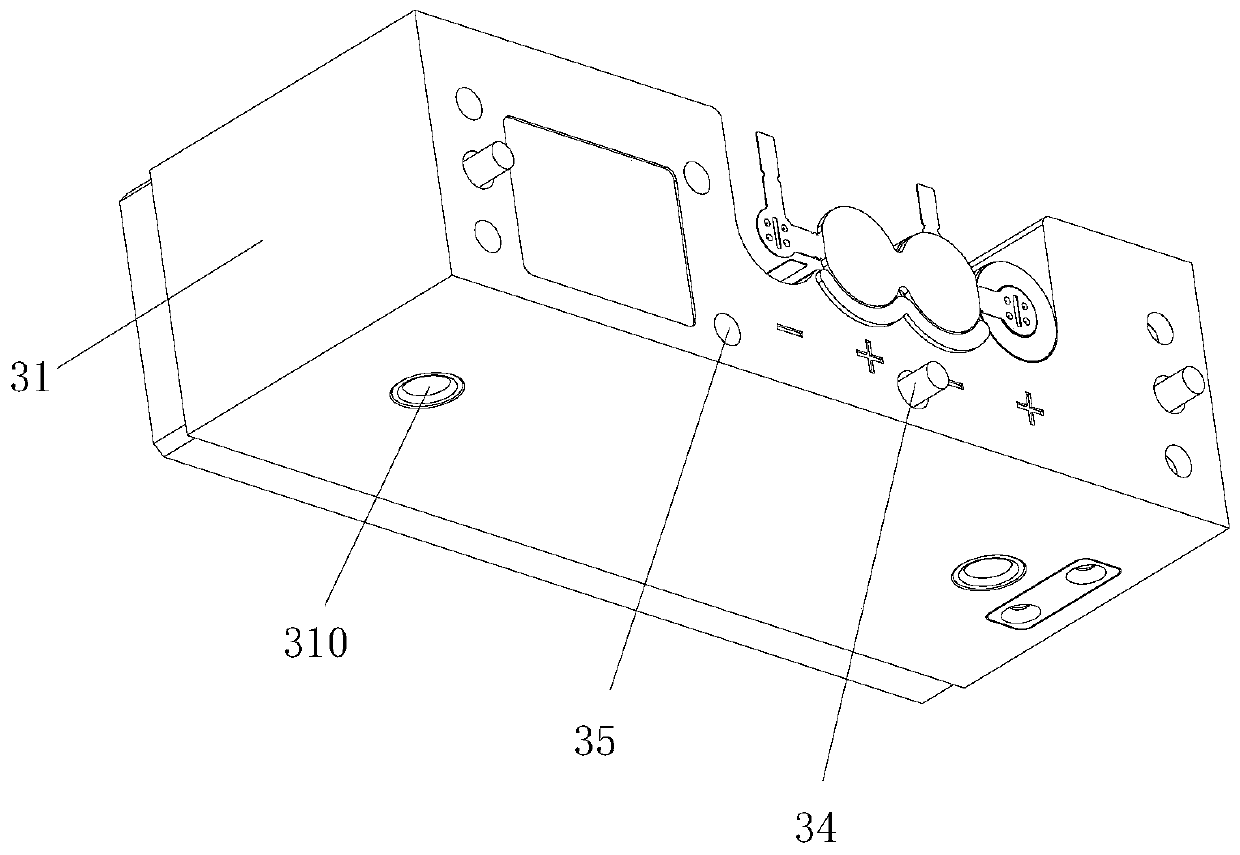

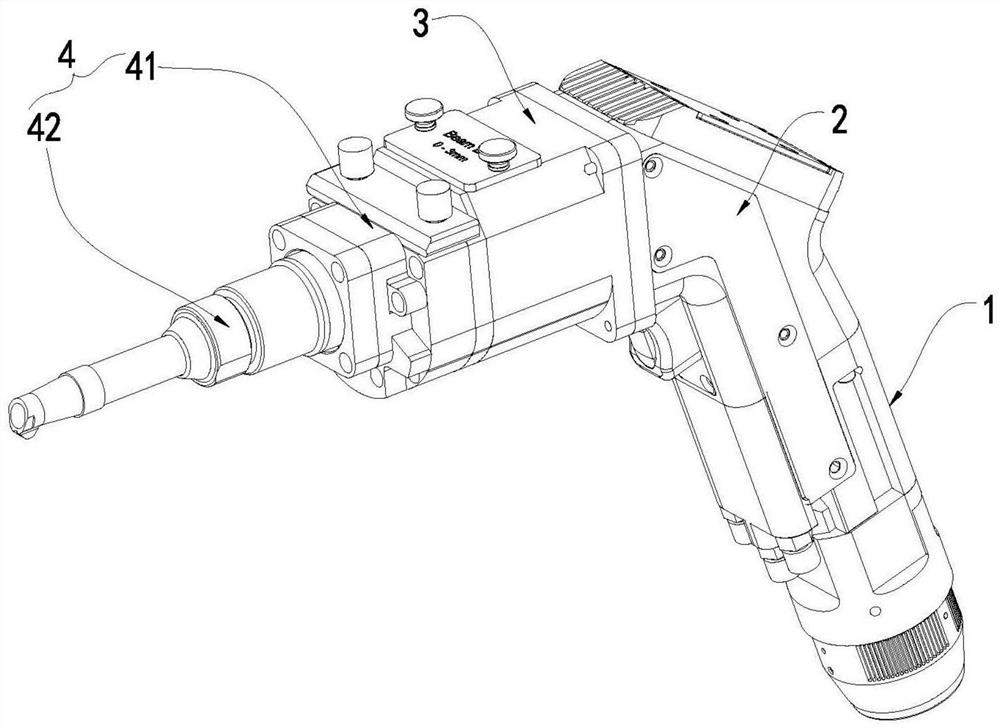

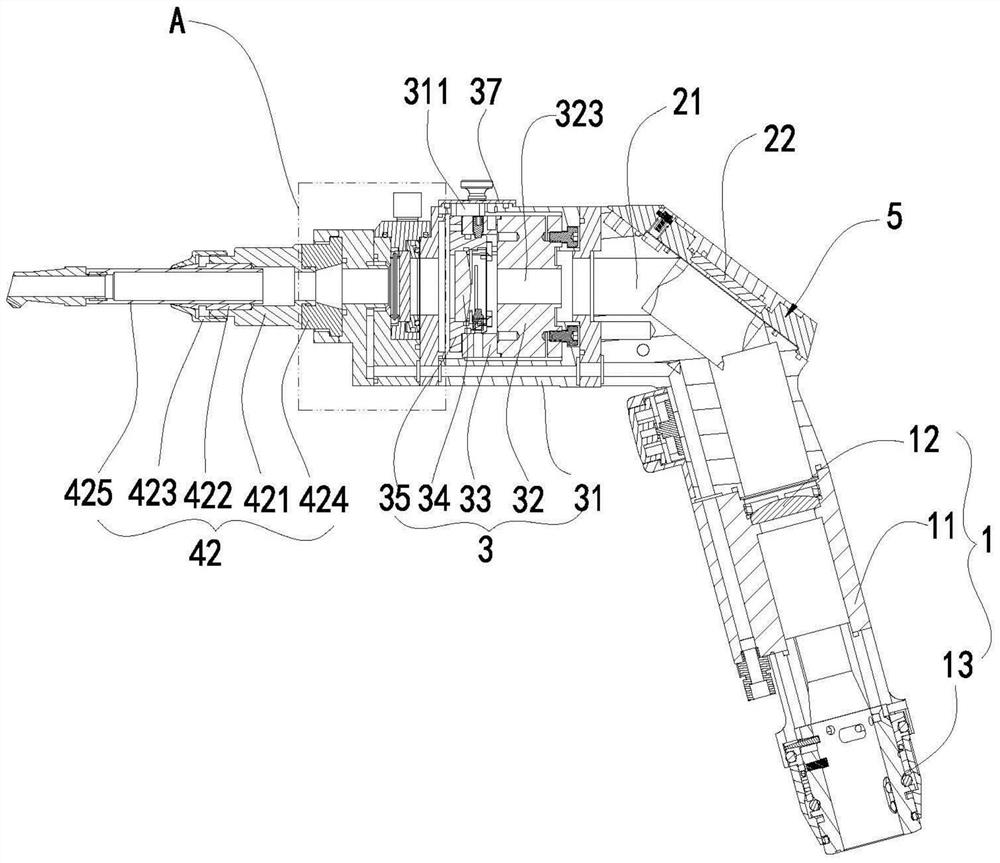

Hand-held laser welding head with adjustable light spots

PendingCN114160963ARelative position adjustableSpot Size AdjustmentLaser beam welding apparatusLight spotElectric machinery

The handheld laser welding head comprises a collimation assembly, a reflection assembly, an adjusting assembly and an emitting assembly which are connected in sequence, the adjusting assembly comprises a shell, a holder motor, an adapter disc, a mirror box and a focusing mirror, the holder motor, the adapter disc, the mirror box and the focusing mirror are arranged in the shell, a light through hole is formed in the center of the holder motor, and the holder motor comprises a stator and a rotor; one end of the switching disc is coaxially and fixedly connected with the rotor, a through hole is eccentrically formed in the switching disc, the distance from the center axis of the through hole to the center axis of the light through hole is a first preset value, the lens box is rotationally arranged at the other end of the switching disc, a through groove is eccentrically formed in the lens box, and the focus lens is coaxially and fixedly arranged in the through groove. The distance between the center axis of the through groove and the center axis of the through hole is a second preset value, the second preset value is smaller than or equal to the first preset value, and the mirror box is rotated around the center of the through hole in the transfer disc by rotating the mirror box, so that the relative position of the focus lens is adjustable, the emergent laser rotates with the center of the rotor as the center axis, and an adjustable circular light spot is formed.

Owner:武汉奥森迪科智能科技股份有限公司

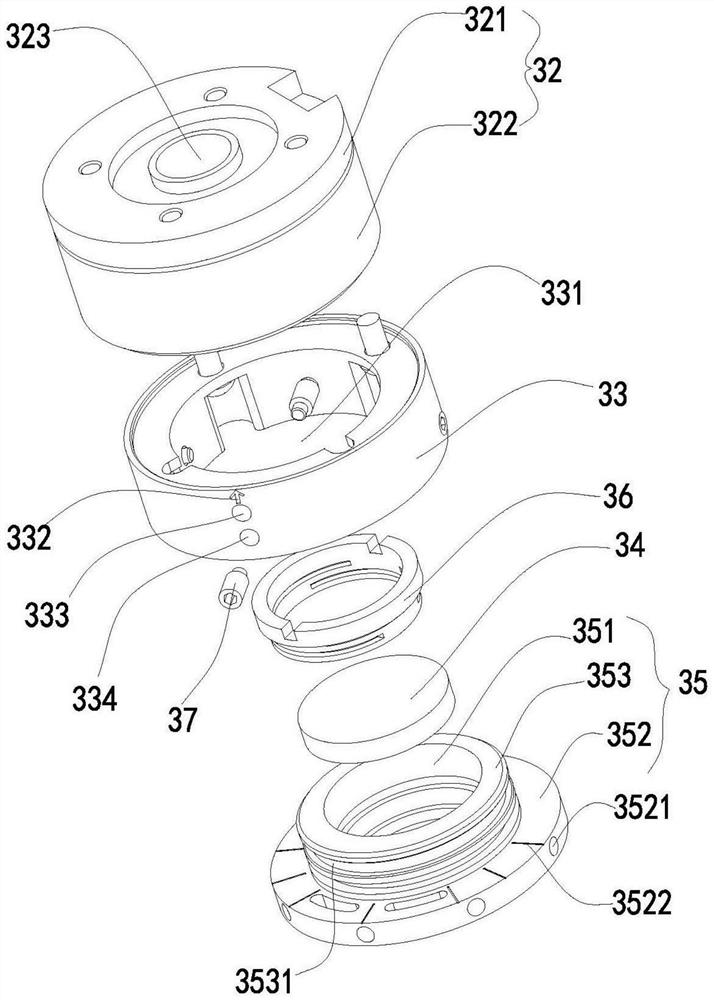

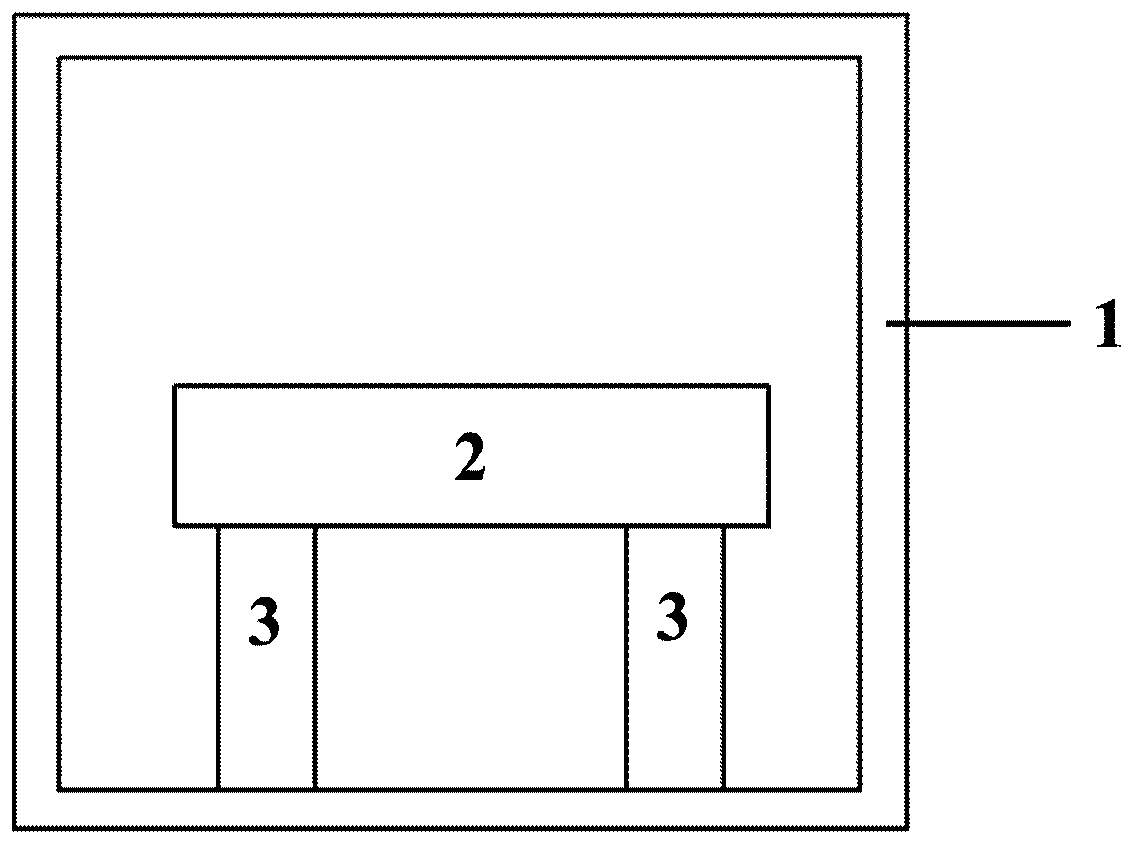

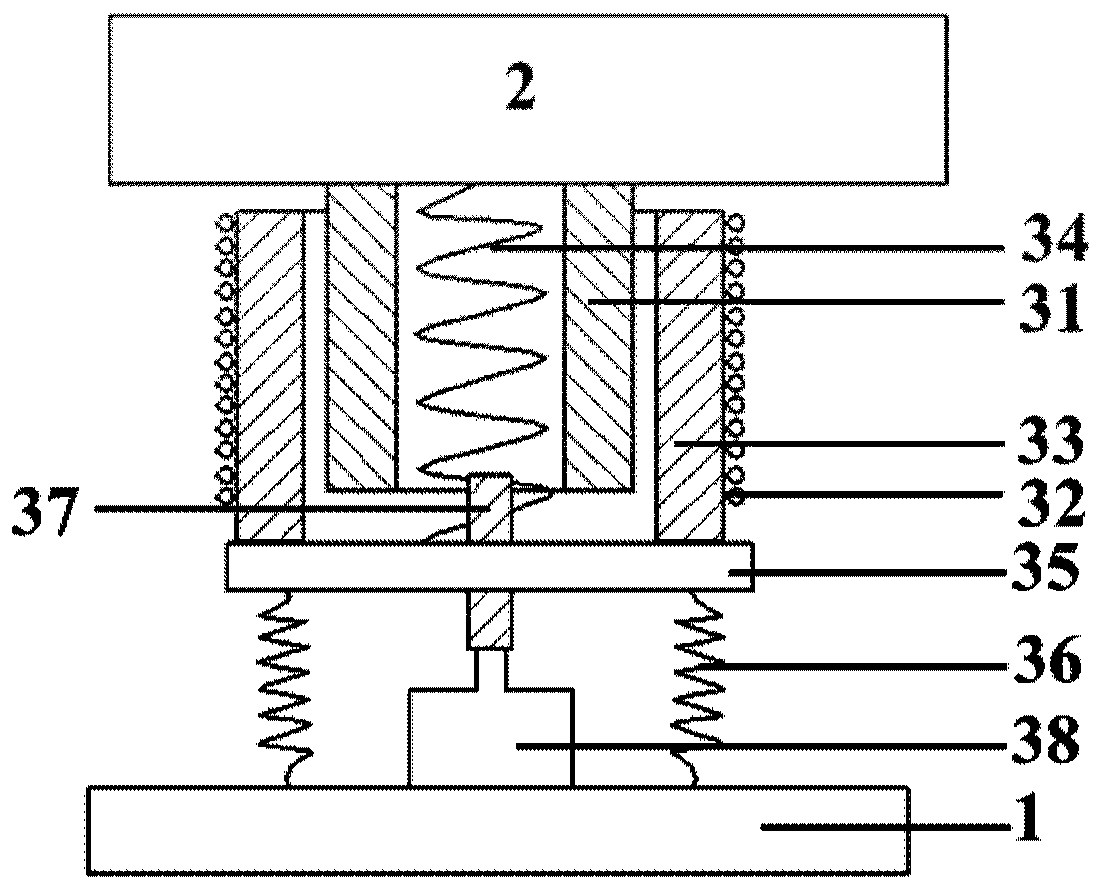

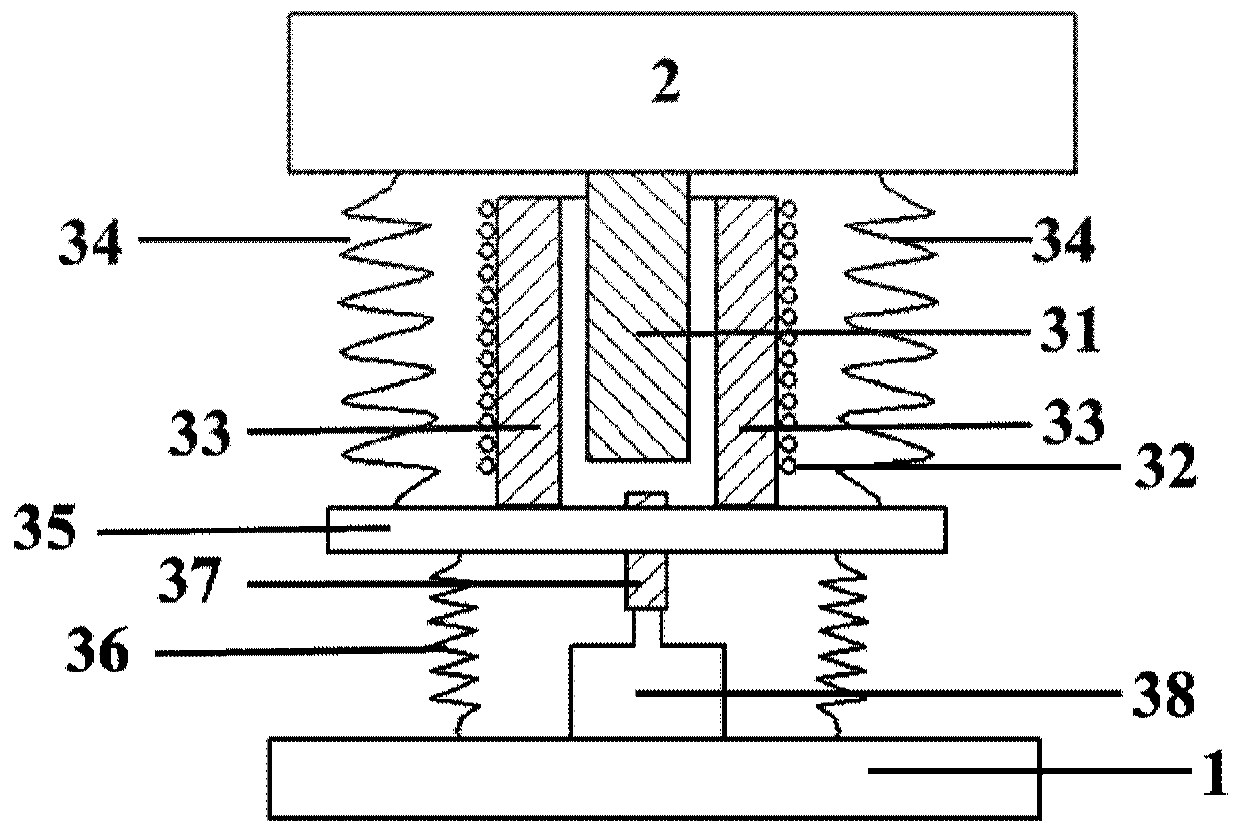

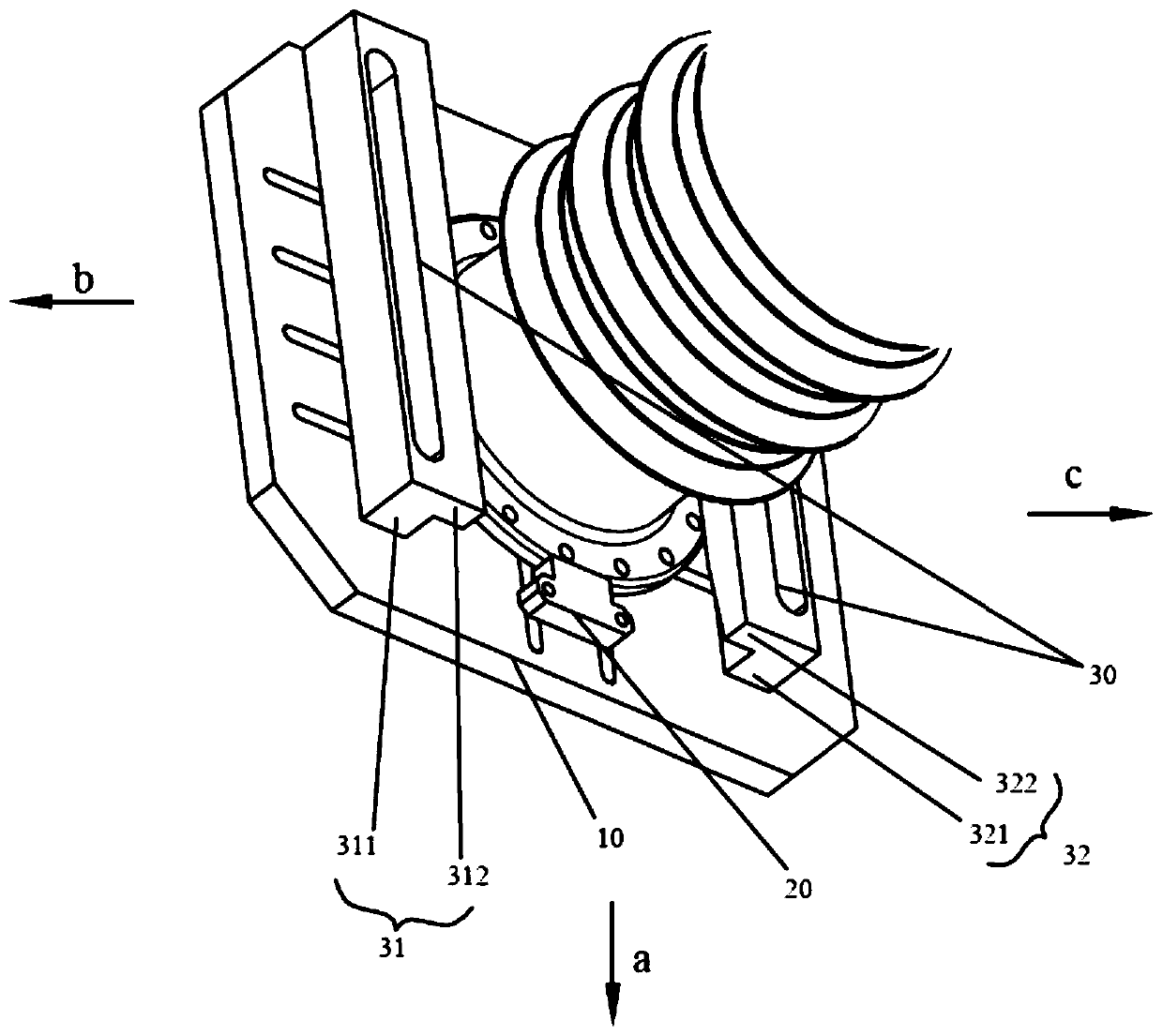

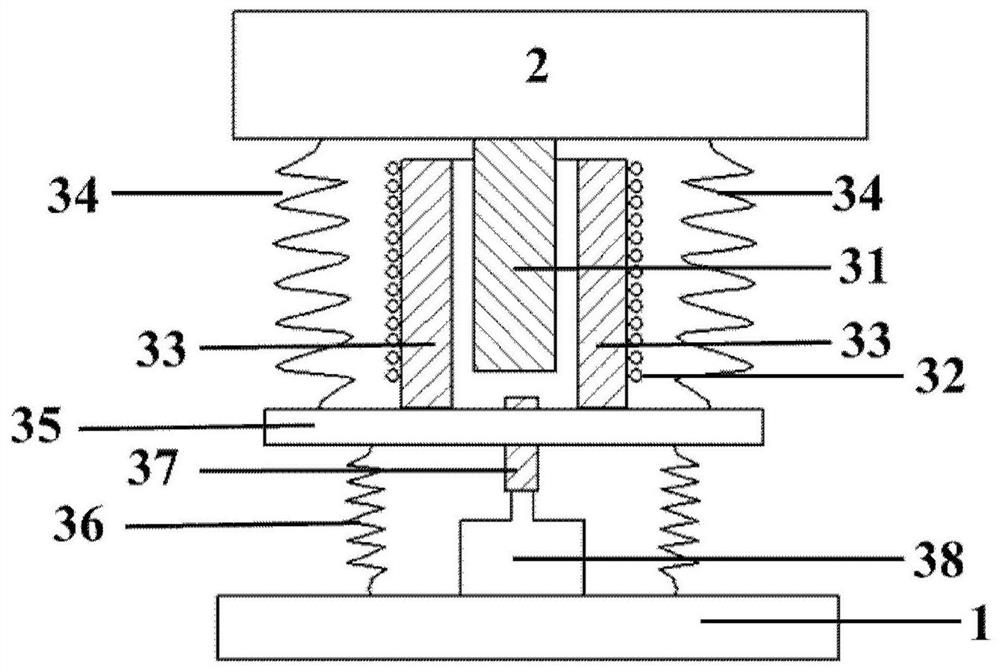

Vibration isolation device

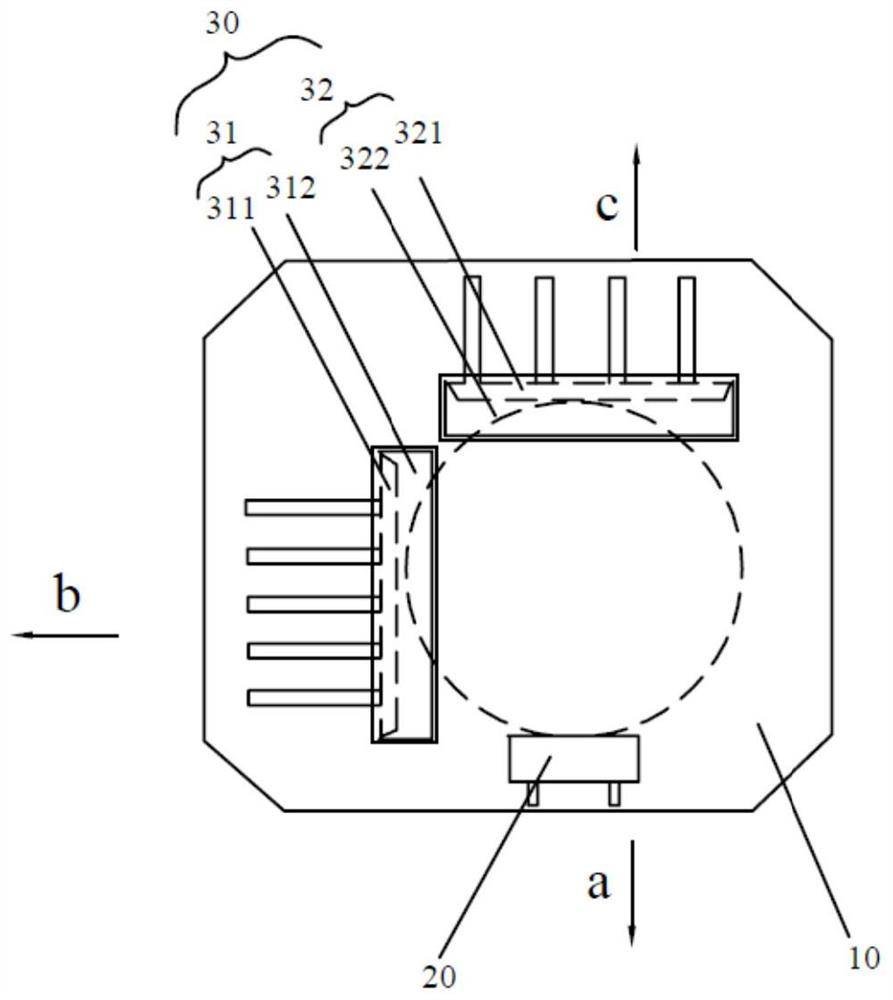

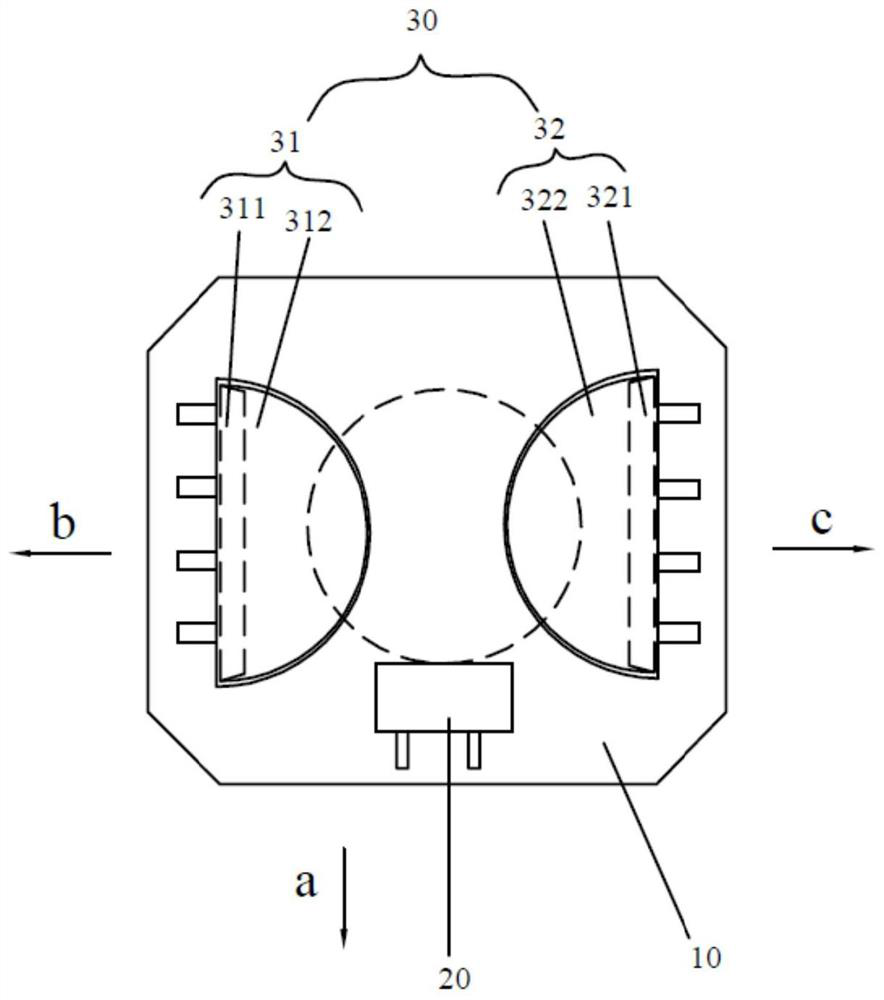

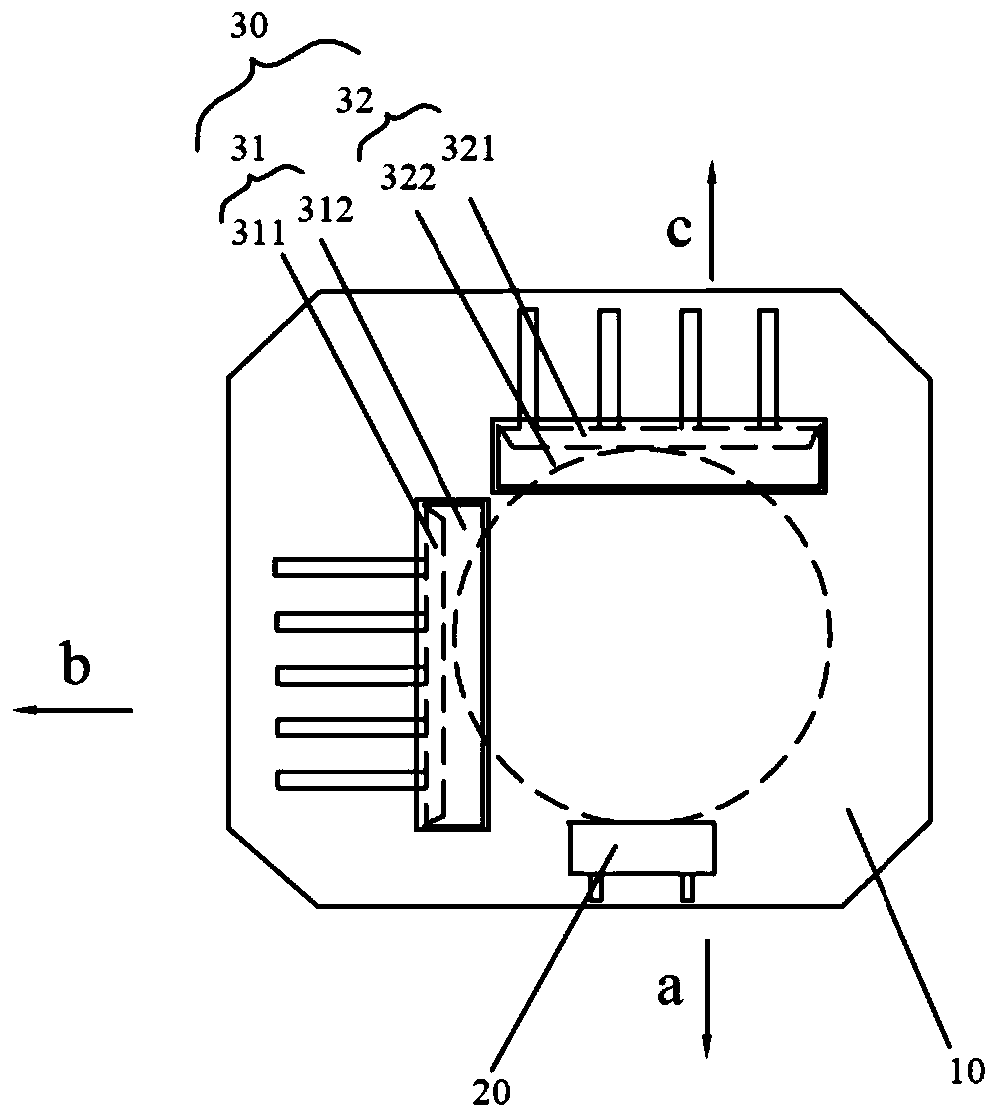

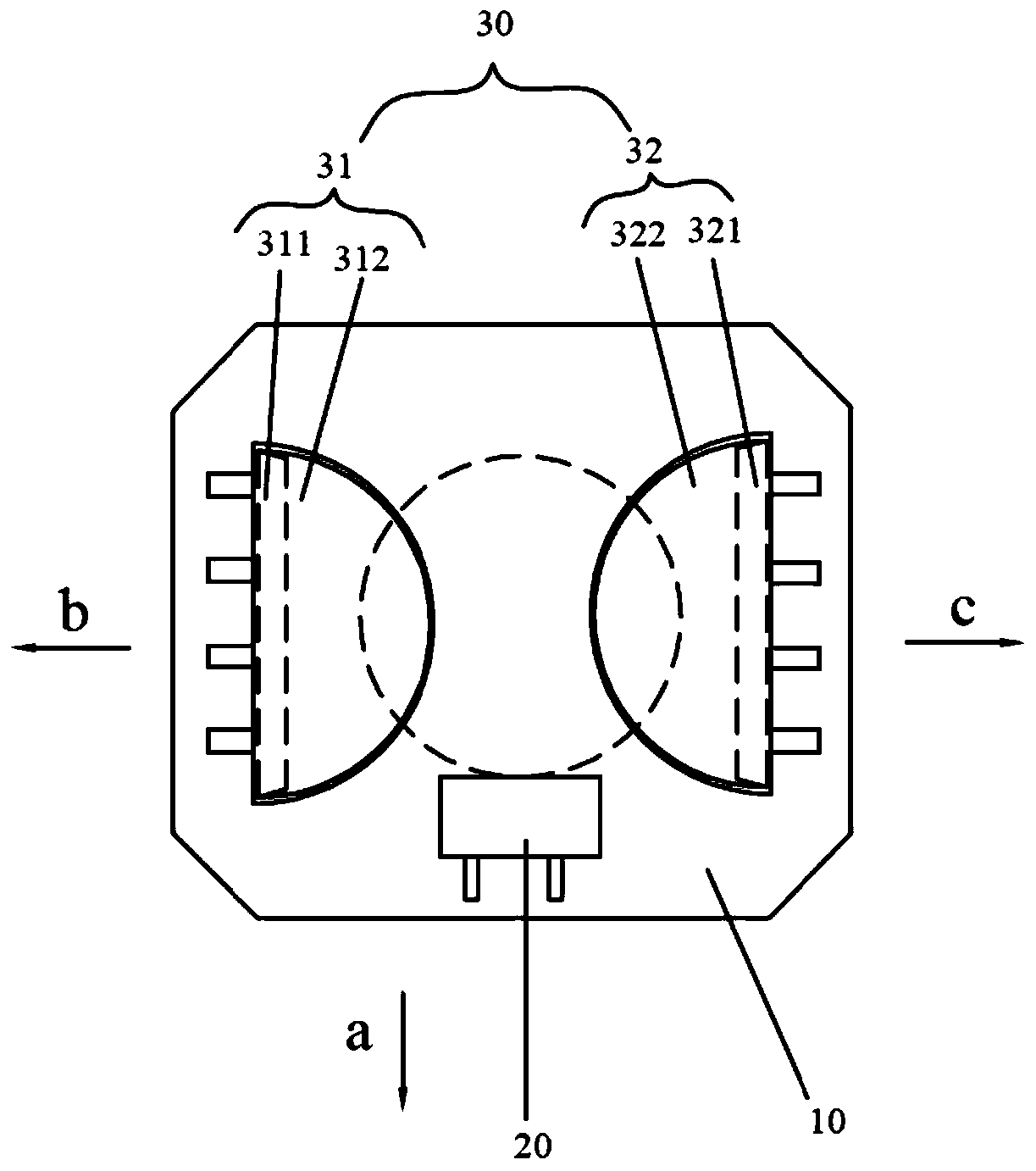

ActiveCN111059208ARelative position adjustableBalance disturbance forceNon-rotating vibration suppressionPhotomechanical exposure apparatusPhysicsMagnet

The invention provides a vibration isolation device. The vibration isolation device comprises a vacuum cavity (1); a main base plate (2) is arranged in the vacuum cavity (1); at least one vibration isolation system (3) is arranged between one inner wall of the vacuum cavity (1) and the main base plate (2); the vibration isolation system (3) comprises a permanent magnet (31), a coil frame (33), a main spring (34), a partition plate (35) and partition plate springs (36), wherein the coil frame (33) is provided with a coil (32); one end of the permanent magnet (31) is connected with the main baseplate (2); one end of the coil frame (33) is fixed on the partition plate (35); part of or the whole permanent magnet (31) is arranged in the coil frame (33); and the relative positions of the coil frame (33) and the permanent magnet (31) are adjustable; and the main base plate (2), the main spring (34), the partition plate (35), the partition plate springs (36) and the vacuum cavity (1) are connected with one another sequentially.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

A simple cutting machine

InactiveCN104308902BOperational securityEasy to cleanGripping devicesClamping devicesCircular discEngineering

The invention belongs to the field of a plate cutting machine, and particularly relates to a simple plate cutting machine with the advantages that simplicity is realized, the dismounting and the mounting are convenient, and the operation is simple. The simple plate cutting machine comprises a machine frame, a guide rail, a pushing table frame and a circular disc saw, wherein the pushing table frame comprises a pushing frame and a pushing table plate, the upper surface of the pushing table plate is provided with a positioning baffle plate and a position limiting block, the guide rail comprises a bottom plate and a frame rail, the frame rail is arranged on the bottom plate, the cross section of the frame rail is in a T shape, the frame rail comprises a support strip and a top rail strip, an inclined rail surface is arranged at one side of the upper surface of the top rail strip, the lower surface, positioned at one side opposite to the inclined rail surface in the lower surface positioned at the two sides of the support strip, of the top rail strip is a bottom rail surface, a rolling component comprises an upper rolling wheel and a lower rolling wheel, the plate is fixedly clamped on the pushing table plate through the matching of the positioning baffle plate and the position limiting block, then, the whole pushing frame is pushed, the pushing frame is erected on the guide rail through an upper rolling wheel frame pressed on the inclined rail surface, and is then matched with the lower rolling wheel buckled on the bottom rail surface, so that the whole pushing frame is positioned and can only slide along the guide rail. The matching is convenient, the contact area of the rolling wheels and the guide rail is small, the friction force is small, and the operation and the control are free.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

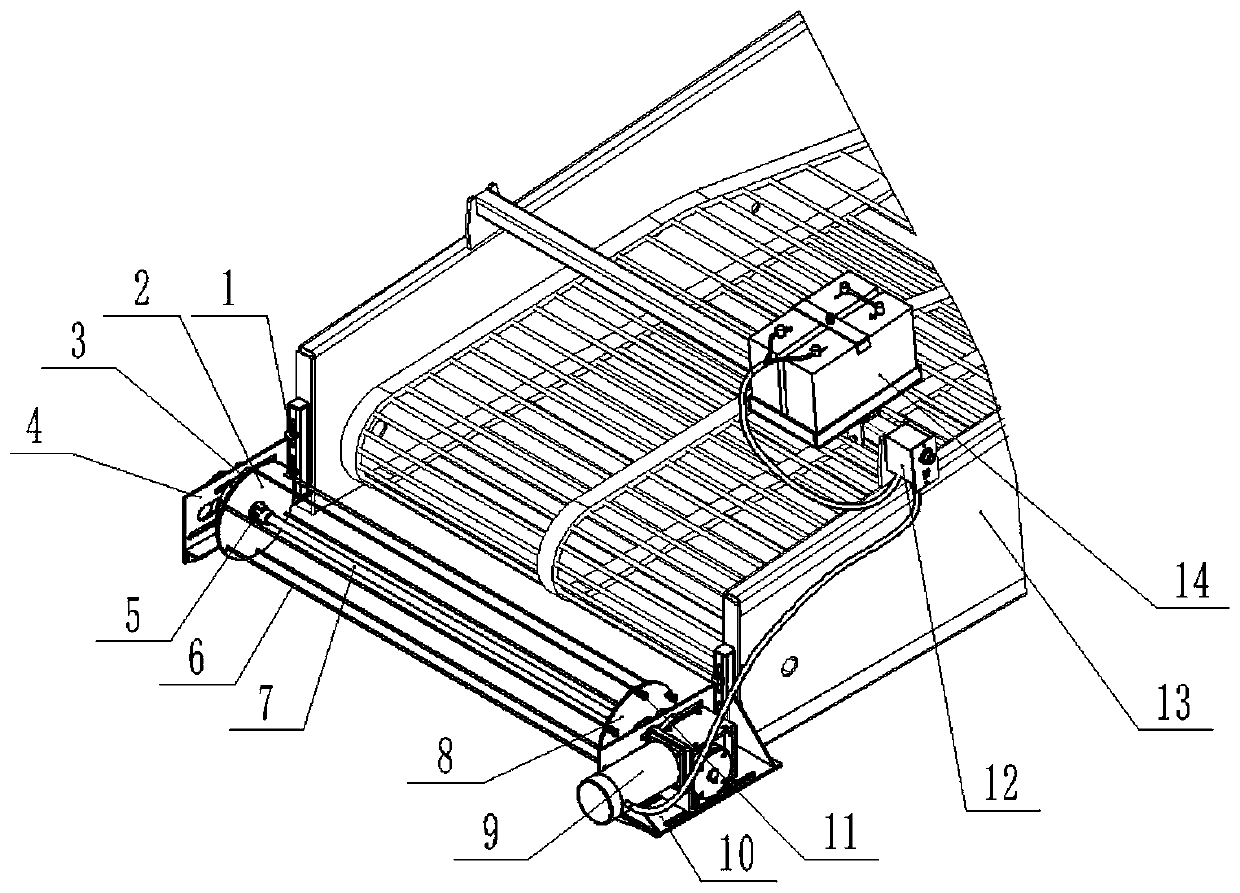

Residual film recovery and rapid-detachment device and method, and harvesting machine

PendingCN109699211AChange distanceRealize flexible adjustmentPlant protective coveringsGatherer machinesWire ropeMental detachment

The invention relates to a residual film recovery and rapid-detachment device and method, and a a harvesting machine. The residual film recovery and rapid-detachment device comprises a first rack assembly and a second rack assembly which are installed on the two sides of the tail end of the harvesting machine, and a rotary recovery device is installed between the first rack assembly and the secondrack assembly and can rotate around the axis of the rotary recovery device to wind residual films; the rotary recovery device comprises a first shaft disc connected with the first rack assembly rotatably and a second shaft disc rotatably connected with the second rack assembly, and the first shaft disc and the second shaft disc are fixedly connected through a connecting shaft; multiple round holes in the circumferential direction are formed in the second shaft disc, one end of a steel wire rope is connected into each round hole, and a snap ring is arranged at the other end of the steel wire rope. The efficiency of recovering the residual films can be improved through the residual film recovery and rapid-detachment device, and the operation of rapidly detaching the residual films can be realized.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

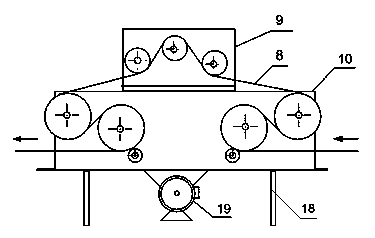

Small narrow band bending straightener

The invention relates to a small narrow-band stretch-bending straightening machine and belongs to the technical field of metal strip straightening equipment. It consists of a straightening roller set mechanism in the upper part, a bending roller set mechanism in the middle, a machine base, a power mechanism, and a control device in the lower part; the straightening roller set mechanism includes a straightening roller set and a support adjustment device. The straightening roller set consists of a The straightening roller is composed of a pair of lower pressing rollers; the bending roller group mechanism is composed of two pairs of main and driven bending rollers and pressing rollers; the power mechanism includes a main drive motor and a transmission mechanism; the main and driven bending rollers and pressing rollers The rotating shaft is cantilevered on the back plate of the machine base, and the straightening roller and the lower pressing roller are cantilevered on the supporting adjustment device via the rotating shaft; the main drive motor is connected to the active bending roller shaft through the transmission mechanism, and the main drive motor is under the workbench panel. , the transmission mechanism is located behind the back panel of the machine base; the two motors are controlled by the control device. It has the advantages of adjustable belt straightening speed and relative position of straightening rollers, simple and compact structure, convenient belt threading and operation, and good straightening effect.

Owner:KUNMING UNIV OF SCI & TECH

Flange Alignment Tool and Operation Method

ActiveCN107009304BEasy alignmentPlay the role of fixing the first flangeWork holdersEngineeringParallel arrangement

Owner:HEBEI IRON AND STEEL

A fixture structure for plunger chute machining

ActiveCN103753317BRealize the positioning of the center of the circleEasy to adjustAutomatic control devicesFeeding apparatusMechanical engineeringPlunger

Owner:WUXI CITY PEIJI MACHINERY

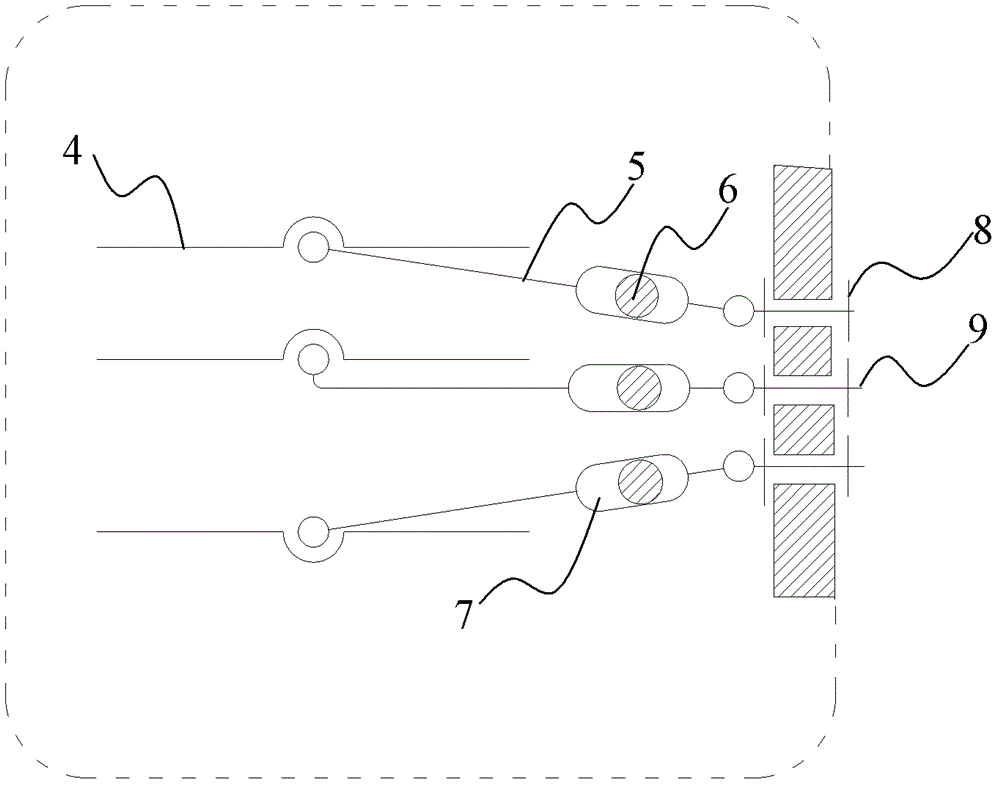

Resonant cavity

ActiveCN103000979BRelative position adjustableTo achieve the purpose of frequency reductionResonatorsResonant cavityRefractive index

Provided is a resonant cavity, including a cavity body, at least two metamaterial plates located inside the cavity body, each metamaterial plate including at least one metamaterial sheet, the cavity body being further installed thereon with an adjustment device for adjusting the relative position between the at least two metamaterial plates. The present invention realizes the purpose of frequency reduction by way of placing a metamaterial plate in a resonant cavity and using the high refractive index property of metamaterial, and further realizes trimming of the resonant frequency under the condition of reduced frequency by providing an adjustment device for the metamaterial plate to make the relative position between each metamaterial plate adjustable, which can meet more accurate filtering demands. In addition, also provided is a filter having said resonant cavity.

Owner:KUANG CHI INST OF ADVANCED TECH +1

Simple plate cutting machine

InactiveCN104308902AOperational securityEasy to cleanGripping devicesClamping devicesCircular discEngineering

The invention belongs to the field of a plate cutting machine, and particularly relates to a simple plate cutting machine with the advantages that simplicity is realized, the dismounting and the mounting are convenient, and the operation is simple. The simple plate cutting machine comprises a machine frame, a guide rail, a pushing table frame and a circular disc saw, wherein the pushing table frame comprises a pushing frame and a pushing table plate, the upper surface of the pushing table plate is provided with a positioning baffle plate and a position limiting block, the guide rail comprises a bottom plate and a frame rail, the frame rail is arranged on the bottom plate, the cross section of the frame rail is in a T shape, the frame rail comprises a support strip and a top rail strip, an inclined rail surface is arranged at one side of the upper surface of the top rail strip, the lower surface, positioned at one side opposite to the inclined rail surface in the lower surface positioned at the two sides of the support strip, of the top rail strip is a bottom rail surface, a rolling component comprises an upper rolling wheel and a lower rolling wheel, the plate is fixedly clamped on the pushing table plate through the matching of the positioning baffle plate and the position limiting block, then, the whole pushing frame is pushed, the pushing frame is erected on the guide rail through an upper rolling wheel frame pressed on the inclined rail surface, and is then matched with the lower rolling wheel buckled on the bottom rail surface, so that the whole pushing frame is positioned and can only slide along the guide rail. The matching is convenient, the contact area of the rolling wheels and the guide rail is small, the friction force is small, and the operation and the control are free.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

Combined sliding table driven by hydraulic cylinder and gear

ActiveCN114101145AConsistent sliding strokeConsistent speedCleaning using toolsHydraulic cylinderGear wheel

The invention discloses a combined sliding table driven by a hydraulic cylinder and a gear, and belongs to the field of sliding table structures. The combined sliding table driven by the hydraulic cylinder and the gear comprises a workbench, a sliding plate, a driving mechanism, the first gear, a first rack, a second rack, a first connecting rod and the hydraulic cylinder. The driving mechanism is arranged on the workbench to drive the sliding plate to slide, the first gear, the first rack and the second rack capable of ascending and descending are arranged in the driving mechanism, and the first connecting rod is arranged to limit rotation of the first gear, so that two driving states of the sliding plate are achieved; the sliding stroke and speed of the sliding plate can be kept consistent with those of the hydraulic cylinder, and the stroke and speed of the sliding plate can be larger than those of the hydraulic cylinder so as to adapt to complex and changeable use working conditions of the sliding table.

Owner:深圳市锐健电子有限公司

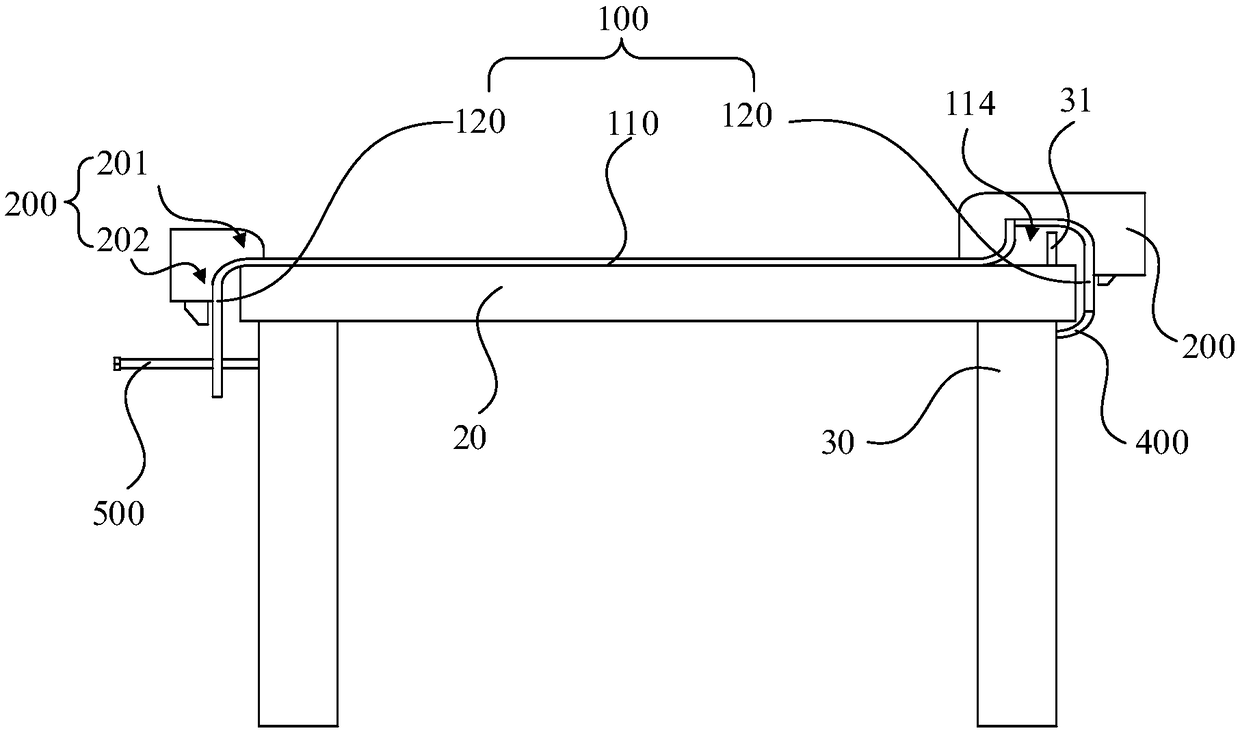

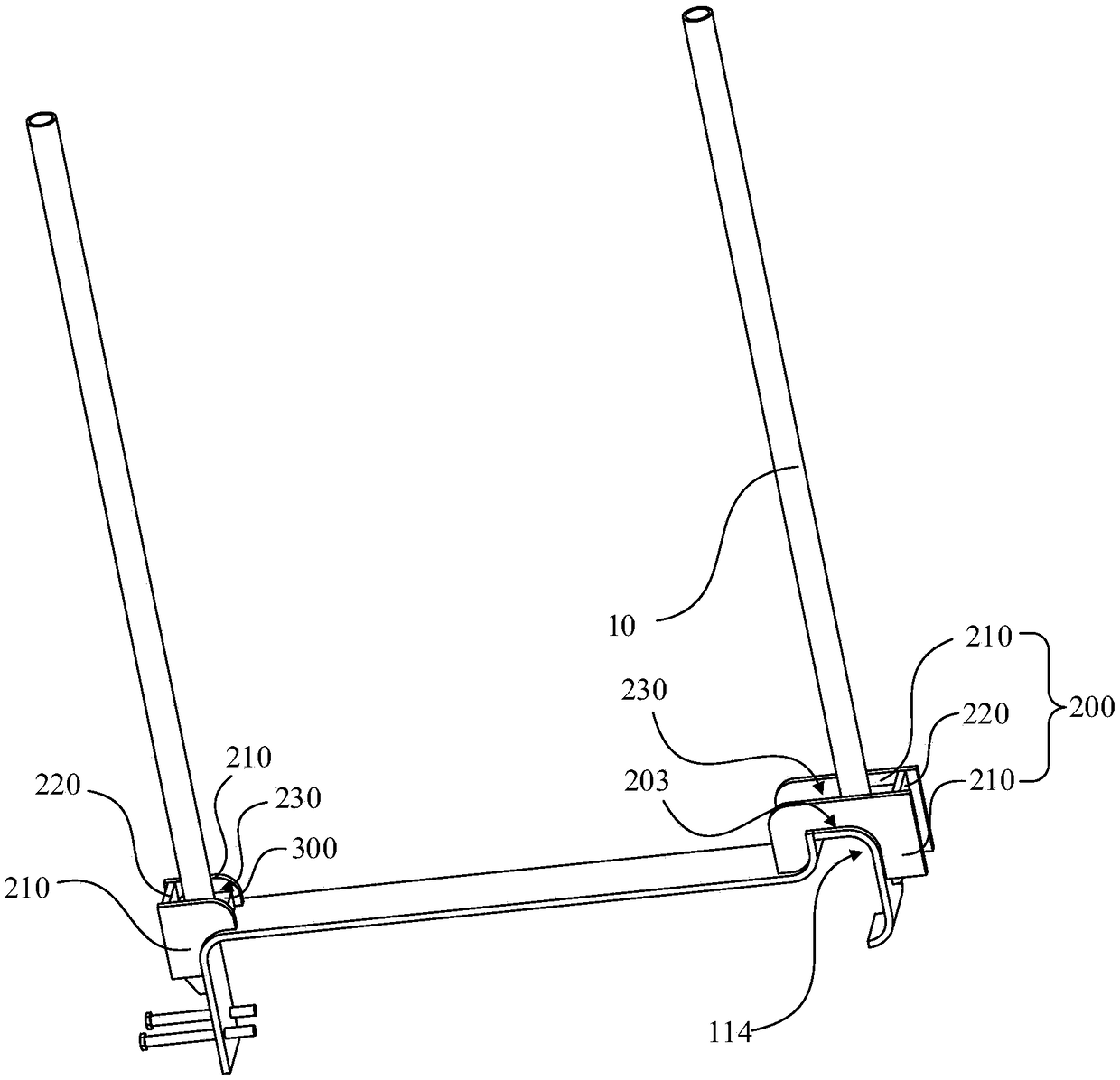

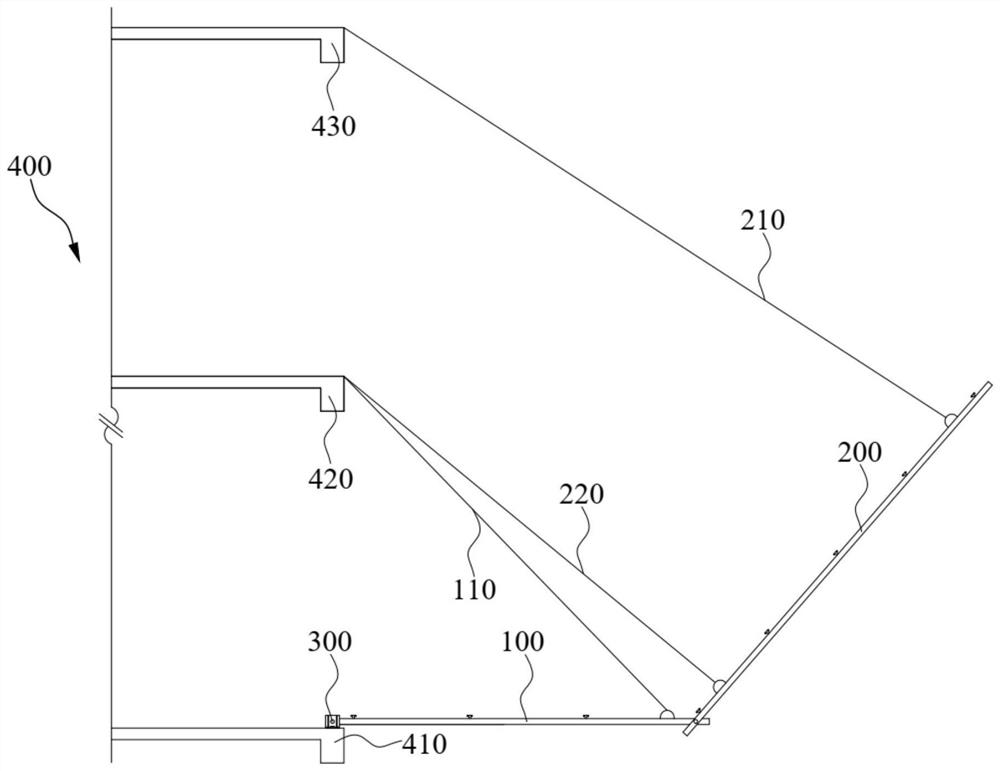

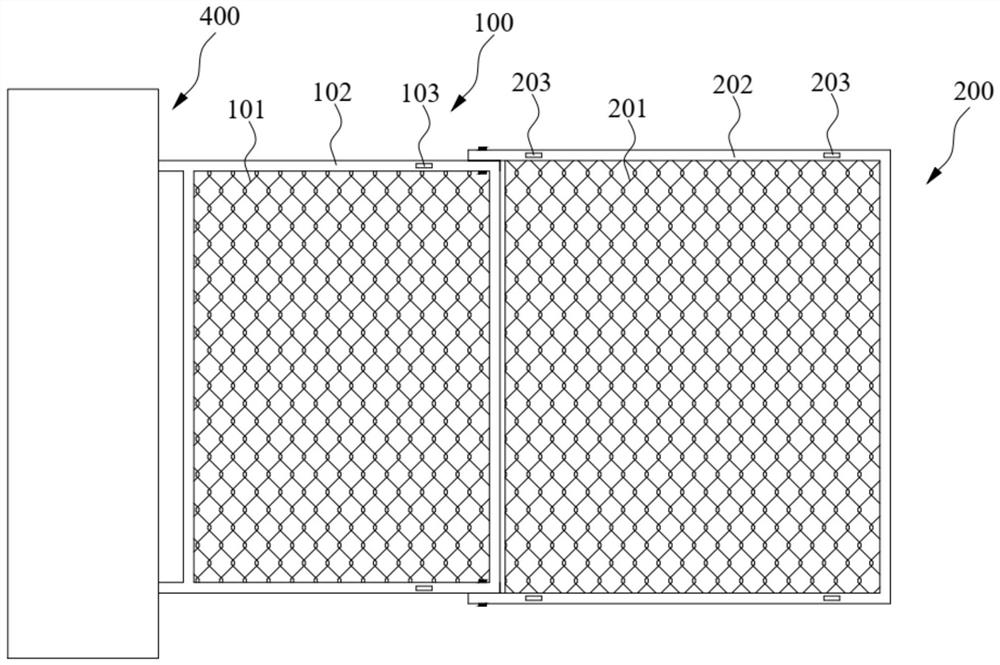

Net overhanging device, mounting method of net overhanging device, net overhanging system and mounting method of net overhanging system

InactiveCN113073867AOptimize the process of installation operationsImprove the protective effectBuilding material handlingStructural engineeringMechanical engineering

The invention relates to the technical field of constructional engineering, and particularly discloses a net overhanging device, a mounting method of the net overhanging device, a net overhanging system and a mounting method of the net overhanging system. The net overhanging device is mounted on an outer wall and comprises a first overhanging net and a second overhanging net. One end of the first overhanging net is rotationally connected with the outer wall; and one end of the second overhanging net is connected with the end, away from the outer wall, of the first overhanging net, a first rope is connected to the other end of the second overhanging net, the first rope enables the second overhanging net to be connected with the outer wall, and the second overhanging net is inclined upwards away from the outer wall. The first overhanging net and the second overhanging net are arranged in a split mode, so that the protection effect is improved, and the disassembly and assembly difficulty is reduced; and the first overhanging net is rotationally connected with the outer wall, so that high-altitude operation of an operator is avoided, the safety of disassembly and assembly operation is guaranteed, and the efficiency is improved. According to the net overhanging system, the density of the net overhanging devices can be reduced through a third wire net, the cost needed by the system is further reduced while the purpose is achieved, and the construction efficiency is improved.

Owner:BEIJING TIANRUN CONSTR +1

A test joint and test tooling

ActiveCN109916709BQuick installationThe function of reaching the stretch limitStrength propertiesTest sampleStructural engineering

The present invention relates to a test joint and a test tool, comprising an adapter seat, a support and a buckle assembly, the support and the buckle assembly are respectively arranged on the same side of the adapter seat; the support and the The adapter base is connected, the relative position of the support member and the adapter base is adjustable, and the support member can be adjusted and moved along a first direction to support the sample to be tested, wherein the first direction is in line with the The direction of gravity of the test joint in use is consistent; the buckle assembly is connected to the adapter base, the relative position of the buckle assembly and the adapter base is adjustable, and the buckle assembly is used for Clamp the sample to be tested. The present invention adopts the buckle assembly, on the one hand, the sample to be tested can be quickly installed and taken out, and the test efficiency is improved; The test sample reduces the time and cost of re-making the tooling, and saves the cost of the test.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

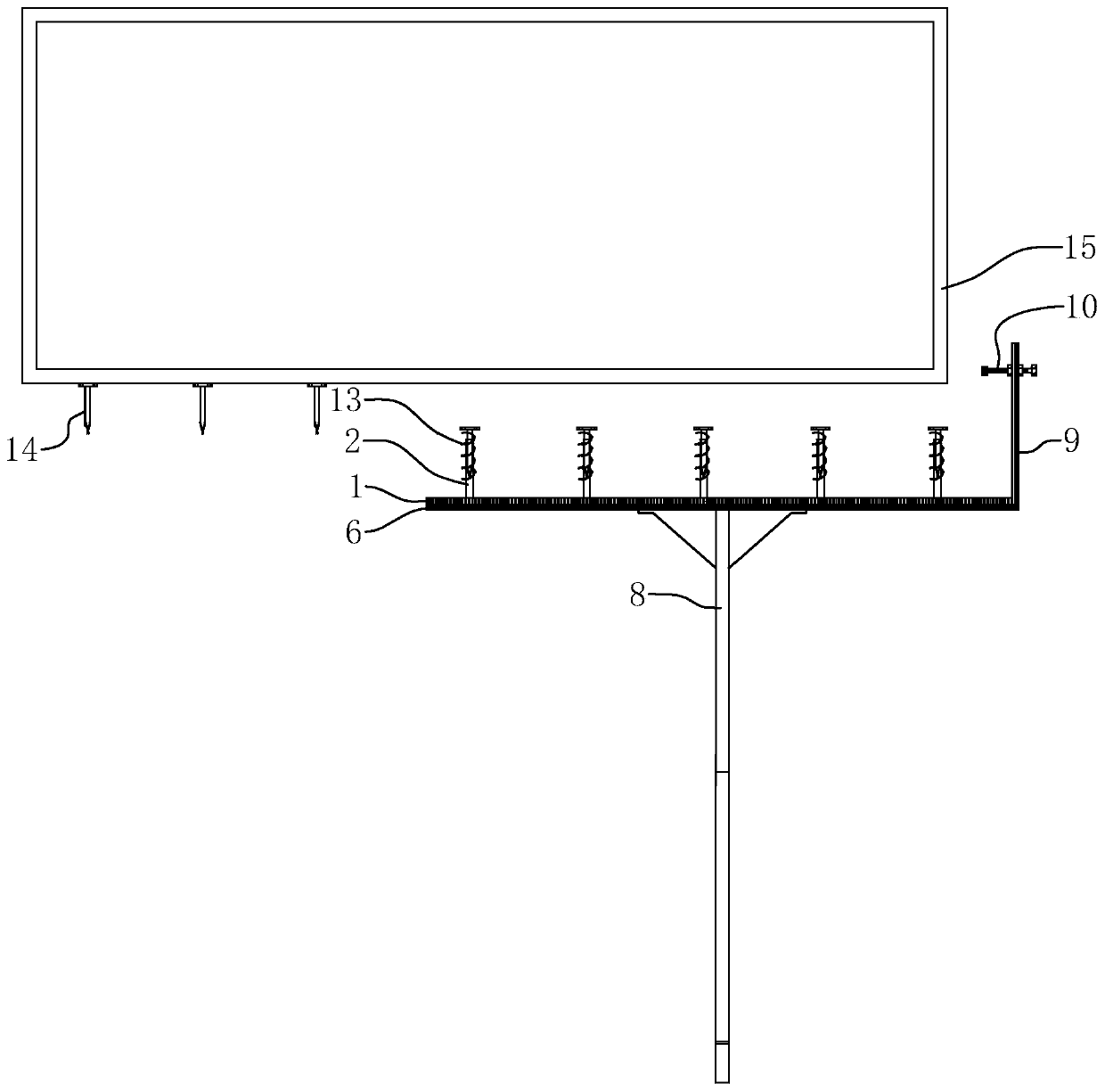

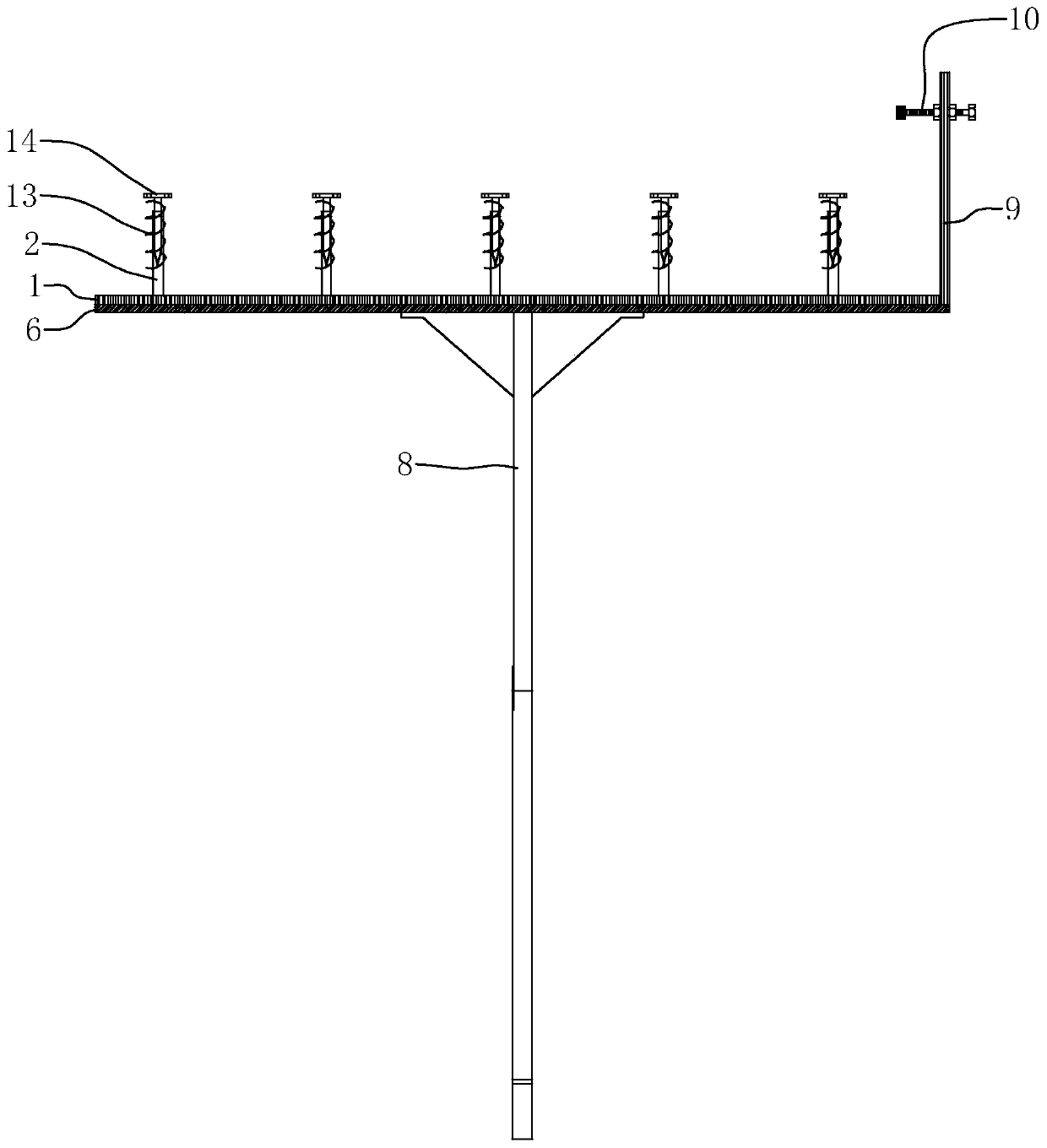

Insulation nail batch installation tool

PendingCN110985497AImproves bond strength consistencyHigh positioning accuracyMaterial gluingBonding strengthStructural engineering

The invention discloses an insulation nail batch installation tool. The insulation nail batch installation tool comprises a bottom plate provided with an installation surface, a plurality of sleeves and elastic elements; the sleeves are erected on the installation surface and are provided with inner holes and a plurality of supporting parts; the supporting parts are arranged around the peripheriesof the inner holes, and the supporting parts can be elastically gathered towards the inner holes; and the elastic elements are arranged on the supporting parts, and the distance between the end partsof the elastic elements and the end parts of the supporting parts can be elastically changed. The insulation nail batch installation tool has the beneficial effects that the elastic elements can elastically support insulation nails between the end surfaces of the supporting parts and the head parts of the insulation nails, so that the insulation nails are easily separated from the sleeves after being pushed and pressed and bonded; the bottom plate is provided with a plurality of sleeves, one-time pushing and pressing action can complete the bonding of a plurality of insulation nails, and theimprovement of the construction efficiency, the improvement of the consistency of the bonding strength between the insulation nails and the reduction of the number of positioning and alignment are facilitated. The invention relates to building mechanical and electrical installation.

Owner:GUANGDONG IND EQUIP INSTALLATION

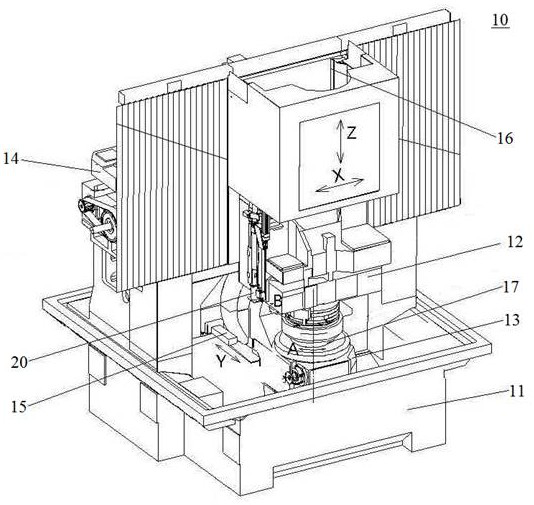

Gear grinding machine and indexing compensation method for gear machining

InactiveCN114799363AImprove accuracyPrevent deviationAutomatic control devicesFeeding apparatusGear grindingGear wheel

The invention discloses a gear grinding machine and an indexing compensation method for gear machining, the gear grinding machine comprises a lathe bed, a workpiece box, a grinding wheel box body and a Z-axis guide rail, the workpiece box, the grinding wheel box body and the Z-axis guide rail are installed on the lathe bed, the workpiece box is used for installing a gear workpiece, and the relative position between the grinding wheel box body and the workpiece box is adjustable; the grinding wheel box body can move along the Z-axis guide rail; the device is characterized in that an on-line measuring device is installed on the grinding wheel box body, the on-line measuring device comprises a probe, and the probe is used for measuring tooth pitch parameters of the gear workpiece. According to the gear grinding machine, the indexing error of the gear workpiece can be directly measured on the gear grinding machine through structural optimization, the gear workpiece does not need to be disassembled and assembled, deviation caused by different positioning is avoided, indexing error detection is relatively more accurate, and therefore the accuracy of gear indexing compensation is effectively improved.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Electric torque wrench lifting tooling

The invention discloses a hoisting tool for an electric torque spanner, which is characterized by comprising a support framework, a hoisting beam used for being fixedly connected with the support framework by a screw and fastening the electric torque spanner, and a hoisting ring used for being movably connected with the hoisting beam and suspending the hoisting beam, wherein the support framework has a U-shaped section and is used for clamping the electric torque spanner; and the hoisting ring comprises a ring for providing a hooking position, a limit gasket for limiting the position of the ring, a screw rod for connecting the hoisting beam, and a fastening piece provided with an internal screw thread and used for fastening the screw rod on the hoisting beam. The hoisting tool for the electric torque spanner has the benefitsthat the hoisting beam is provided with a regulation slideway, so that the relative positions of the hoisting ring and the hoisting beam can be regulated, and the balance of the tool provided with the electric torque spanner can be conveniently regulated; the hosting tool is simple in structure, small in size and convenient to manufacture and use; and the hoisting tool is suitable for a progressive assembly line and is beneficial to improve the working efficiency.

Owner:PINGHU LIDEFU HYDRAULIC TOOLS

Test joint and test tooling

ActiveCN109916709AQuick installationThe function of reaching the stretch limitStrength propertiesTest efficiencyEngineering

The invention relates to a test joint and a test tooling. An adapter, a support component and a buckle component are included. The support component and the buckle component are arranged on the same side of the adapter. The support component is connected to the adapter. The relative position of the support component and the adapter can be adjusted. The support component can be adjusted and moved along a first direction so as to support a sample to be tested. The first direction is consistent with a direction of gravity of the test joint under a usage state. The buckle component is connected tothe adapter. The relative position of the buckle component and the adapter can be adjusted. The buckle component is used for clamping the sample to be tested. By using the buckle component, on one hand, the sample to be tested can be rapidly installed and removed and test efficiency is increased; on the other hand, the relative position of the buckle component can be adjusted and versatility is achieved so as to satisfy the samples to be tested with different sizes, time and cost of remaking the tooling are reduced and test cost is decreased.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

Belt roller with packaged goods cleaning function and application method

PendingCN112124908AReduce resistanceLess loss of pulverized coalCleaningElectric machineryHigh energy

The invention discloses a belt roller with a packaged goods cleaning function. The belt roller comprises a base, a roller body, a motor and a scraping plate, wherein the roller body is mounted on thebase; the motor is rotationally connected with the roller body; and the scraping edge of the scraping plate is parallel to the central axis of the roller body, the distance between the scraping edge of the scraping plate and the surface of the roller body is greater than the thickness of a belt, the clockwise included angle between the upper surface of the scraping plate and the moving direction of the belt is greater than 90 degrees and smaller than 180 degrees, and the thickness of the scraping plate is gradually reduced from the side away from the scraping edge to the side at the scraping edge. The belt roller aims to solve the problems of loss of the total amount of pulverized coal, serious abrasion, high energy consumption and much dust in the prior art.

Owner:GUIZHOU PANJIANG REFINED COAL

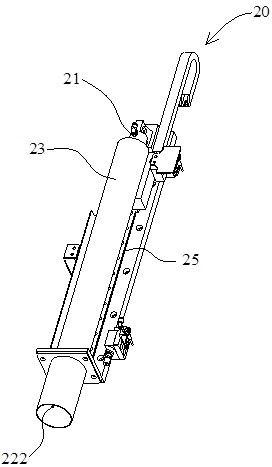

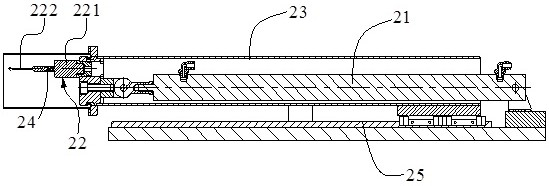

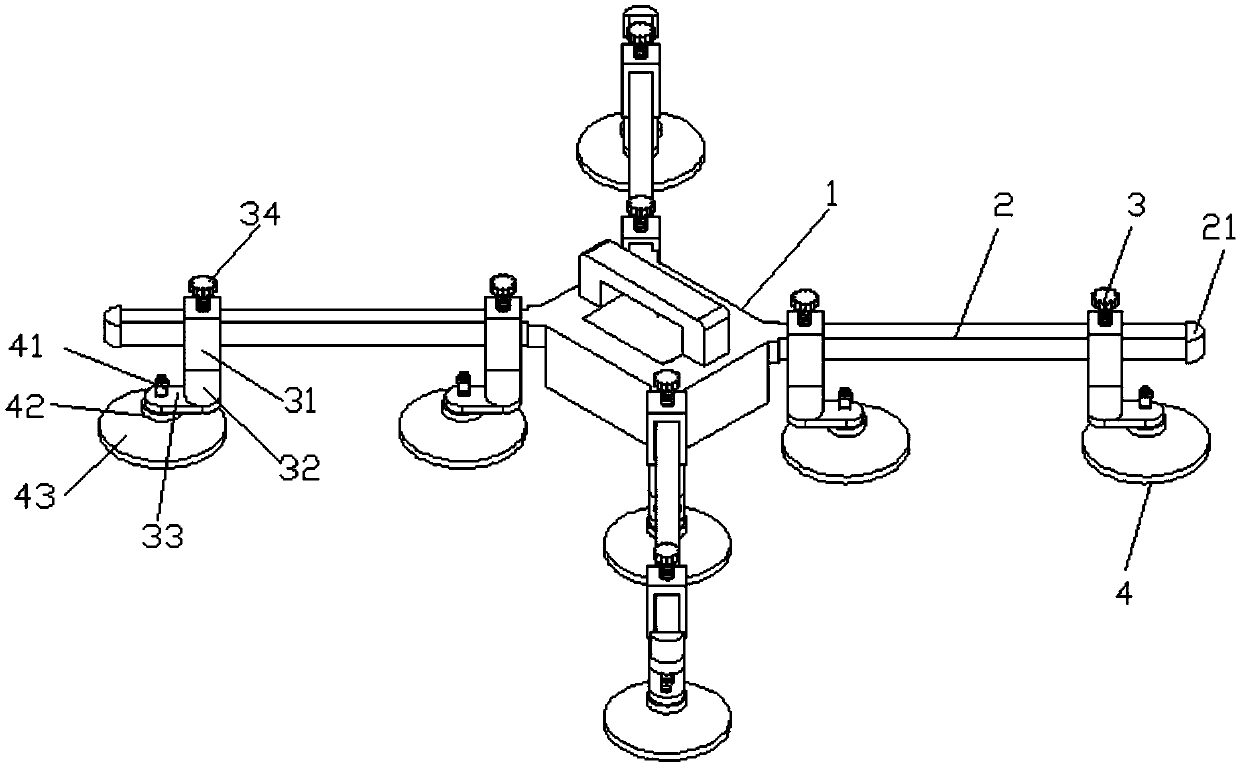

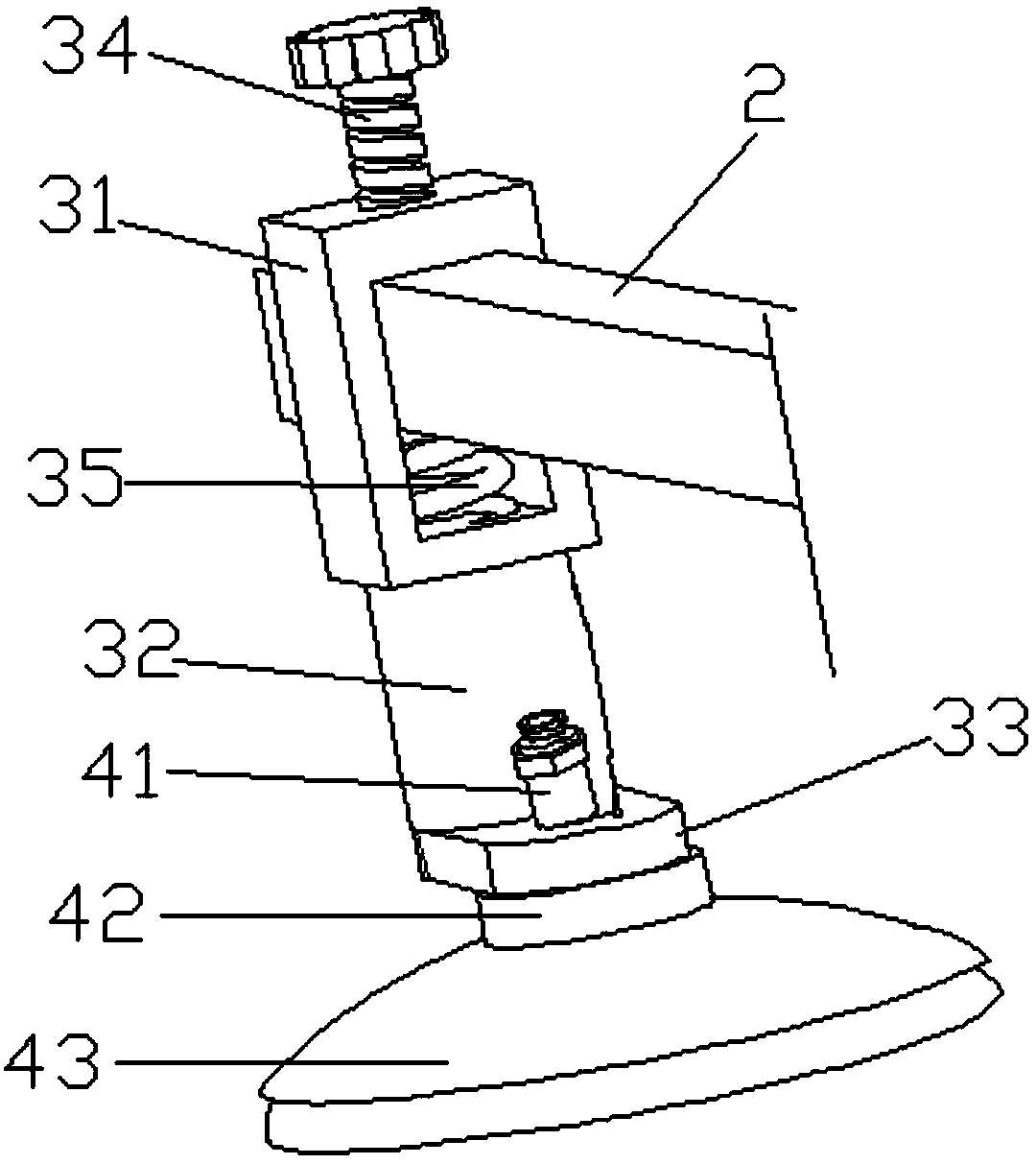

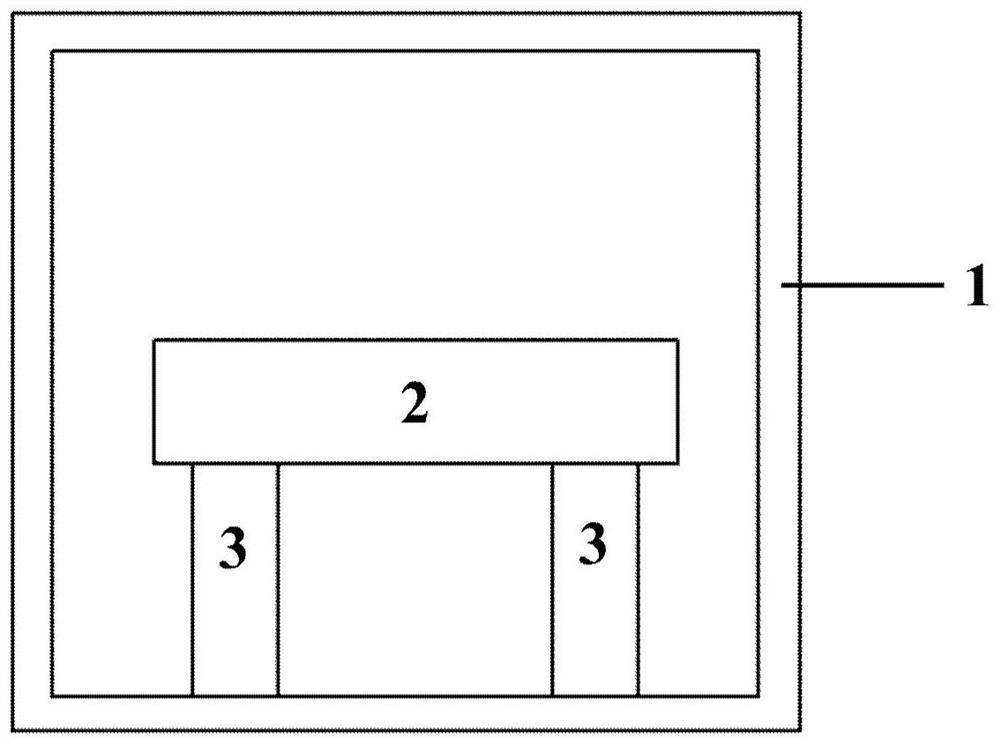

Hard adhesive film transfer equipment

PendingCN109592408AImprove stabilityRelative position adjustableConveyor partsDISC assemblyPositioning system

The invention discloses hard adhesive film transfer equipment. The hard adhesive film transfer equipment comprises a central frame, brackets, positioning assemblies and sucking disc assemblies, wherein the periphery of the central frame is integrally connected with the brackets; the positioning assemblies capable of moving and positioning relative to the brackets are arranged on each bracket; andone sucking disc assembly is arranged on the lower part of each positioning assembly. The hard adhesive film transfer equipment has the beneficial effects that: the positioning assemblies are arranged, so that the relative positions of the sucking disc assemblies and the brackets are adjustable, and therefore, the hard adhesive film transfer equipment can be suitable for transferring hard adhesivefilms of various models.

Owner:TIANJIN JINGDONG CHEM COMPOUND MATERIALS

A vibration isolation device

ActiveCN111059208BRelative position adjustableBalance disturbance forceNon-rotating vibration suppressionPhotomechanical exposure apparatusEngineeringVibration isolation

The invention provides a vibration isolation device, comprising: a vacuum cavity (1), a main substrate (2) inside the vacuum cavity (1), an inner wall of the vacuum cavity (1) and the main substrate (2) At least one vibration isolation system (3) is arranged between them; the vibration isolation system (3) includes: a permanent magnet (31), a coil frame (33) provided with a coil (32), a main spring (34), a partition (35) And the partition spring (36); one end of the permanent magnet (31) is connected to the main substrate (2), and one end of the coil frame (33) is fixed on the partition plate (35), and part or all of the permanent magnet (31) is placed on the coil frame (33) inside, the relative position between the bobbin (33) and the permanent magnet (31) is adjustable; The cavities (1) are connected sequentially.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com