Belt roller with packaged goods cleaning function and application method

A drum and belt technology, applied in the field of belt drums, can solve the problems of total pulverized coal loss, pulverized coal sticking to the belt, pulverized coal drifting, etc., to achieve less machine wear, less dust pollution, and less pulverized coal loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

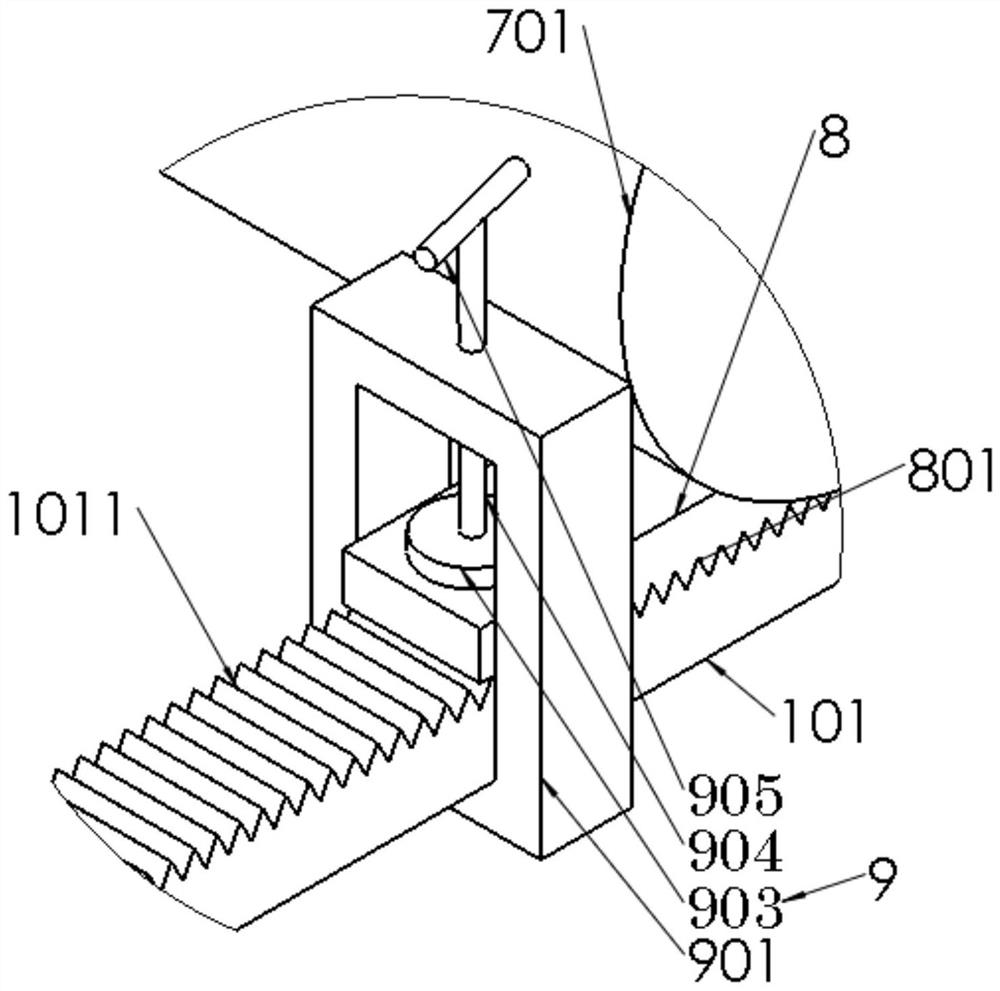

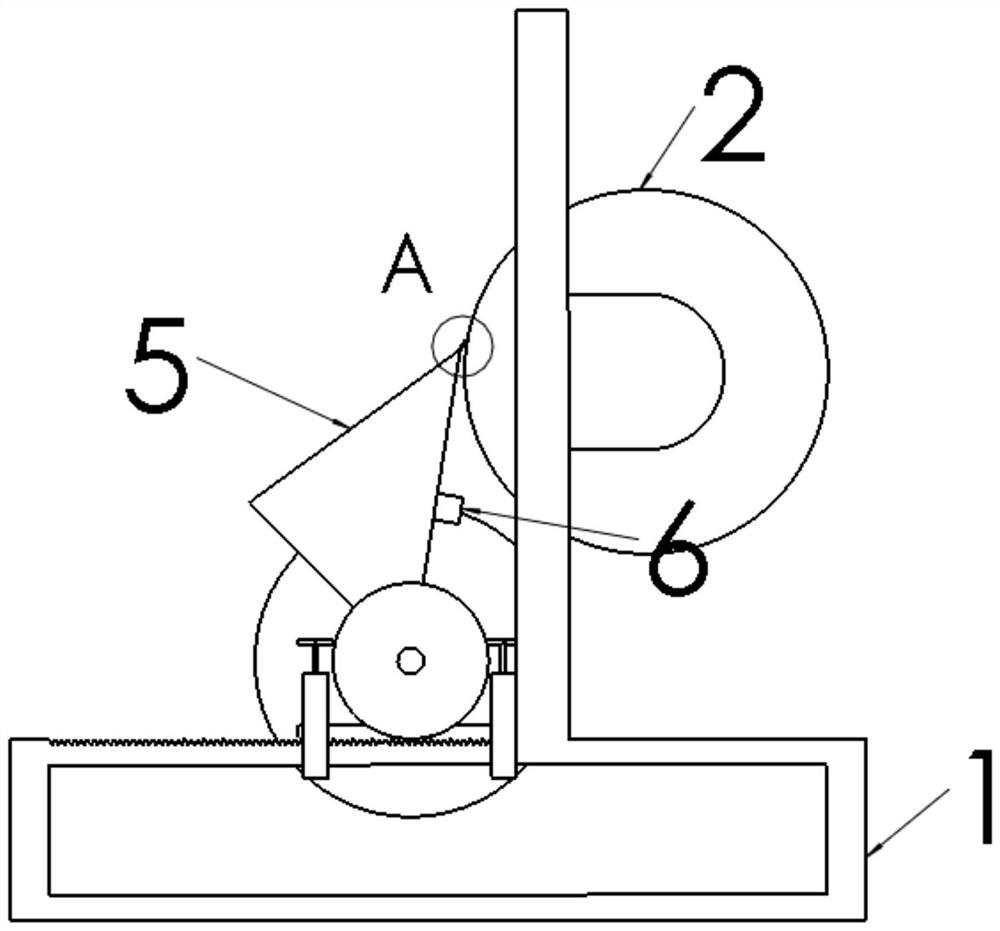

[0051] Implementation Example 1: Reference Figure 1 to Figure 4 , a kind of belt drum with package cleaning function in this embodiment, comprising: a base 1; Plate 4, the scraping edge 401 of the scraper 4 is parallel to the central axis of the drum 2, the distance between the scraping edge 401 of the scraper 4 and the surface of the drum 2 is greater than the thickness of the belt, and the clockwise clamping between the upper surface of the scraper 4 and the moving direction of the belt is The angle is greater than 90 degrees and less than 180 degrees, and the thickness of the scraper 4 gradually decreases from the side away from the scraping edge 401 to the side of the scraping edge 401 .

[0052] Further, it also includes: collection tank 5, one side of the collection tank 5 has the same length as the scraper 4 and is welded to the lower part of the scraper 4, and the outer surface of the collection tank 5 welded to the scraper 4 is welded or bolted to vibrate device6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com