Flange Alignment Tool and Operation Method

An operation method and flange technology, applied in the field of flange alignment tools, can solve the problems of fragile components, sealing rings and gaskets, difficult insertion of bolts, and difficult alignment work, and achieve flexible adjustment and accurate alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

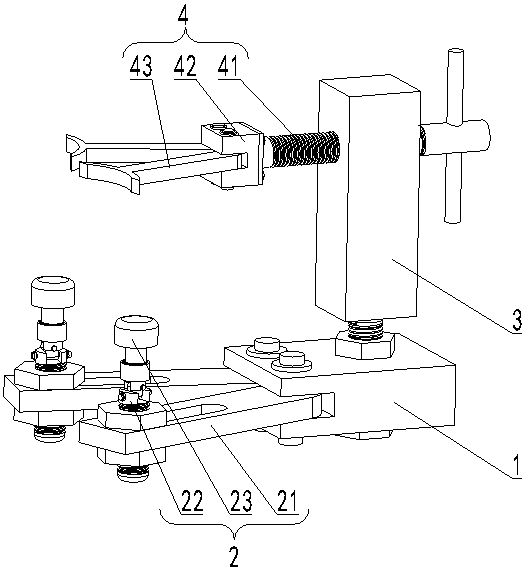

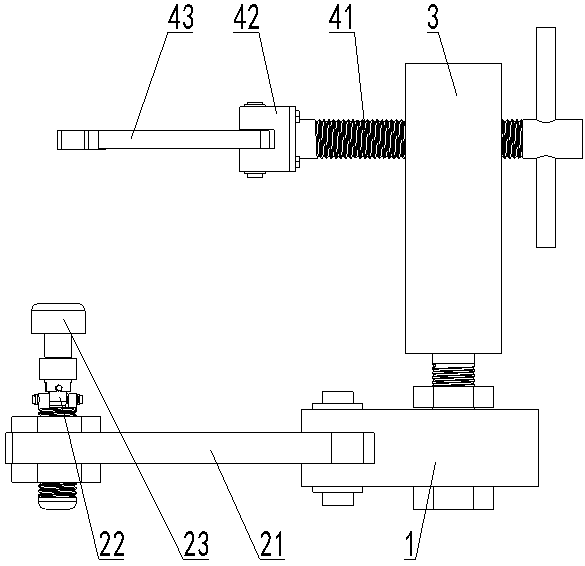

[0076] A flange alignment tool includes a base 1 , a positioning mechanism 2 , a connecting rod 3 and an alignment mechanism 4 . One end of the positioning mechanism 2 is connected to the base 1 , and the other end is suitable for connecting to the bolt hole of the first flange 5 . The connecting rod 3 is vertically connected to the base 1 , and the connecting rod 3 can be adjusted up and down relative to the base 1 . One end of the alignment mechanism 4 is disposed on the connecting rod 3 , and the other end can abut against the second flange 6 . The alignment mechanism 4 can be adjusted in an axial direction perpendicular to the second flange 6 relative to the connecting rod 3 . The alignment mechanism 4 is arranged parallel to the positioning mechanism 2 .

[0077] The positioning mechanism 2 includes a pull rod 21 , a connecting mechanism 22 and a column hook 23 . One end of the pull rod 21 is connected to the base 1, and the other end is provided with a sliding groove....

Embodiment 2

[0085] A flange alignment tool includes a base 1 , a positioning mechanism 2 , a connecting rod 3 and an alignment mechanism 4 . One end of the positioning mechanism 2 is connected to the base 1 , and the other end is suitable for connecting to the bolt hole of the first flange 5 . The connecting rod 3 is vertically connected to the base 1 , and the connecting rod 3 can be adjusted up and down relative to the base 1 . One end of the alignment mechanism 4 is disposed on the connecting rod 3 , and the other end can abut against the second flange 6 . The alignment mechanism 4 can be adjusted in an axial direction perpendicular to the second flange 6 relative to the connecting rod 3 . The alignment mechanism 4 is arranged parallel to the positioning mechanism 2 .

[0086] The positioning mechanism 2 includes a pull rod 21 , a connecting mechanism 22 and a column hook 23 . One end of the pull rod 21 is connected to the base 1, and the other end is provided with a sliding groove....

Embodiment 3

[0091] A flange alignment tool includes a base 1 , a positioning mechanism 2 , a connecting rod 3 and an alignment mechanism 4 . One end of the positioning mechanism 2 is connected to the base 1 , and the other end is suitable for connecting to the bolt hole of the first flange 5 . The connecting rod 3 is vertically connected to the base 1 , and the connecting rod 3 can be adjusted up and down relative to the base 1 . One end of the alignment mechanism 4 is disposed on the connecting rod 3 , and the other end can abut against the second flange 6 . The alignment mechanism 4 can be adjusted in an axial direction perpendicular to the second flange 6 relative to the connecting rod 3 . The alignment mechanism 4 is arranged parallel to the positioning mechanism 2 .

[0092] The connecting rod 3 is located on one side of the base 1, the base 1 is provided with a first threaded through hole, and the end of the connecting rod 3 close to the base 1 is provided with a threaded through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com