Residual film recovery and rapid-detachment device and method, and harvesting machine

A technology of residual film recovery and recovery device, applied in collectors, agricultural machinery and implements, plant protection covers, etc., can solve the problems of low recovery efficiency of residual film, difficulty in unloading film, etc., so as to improve the recovery efficiency of residual film and facilitate debugging. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

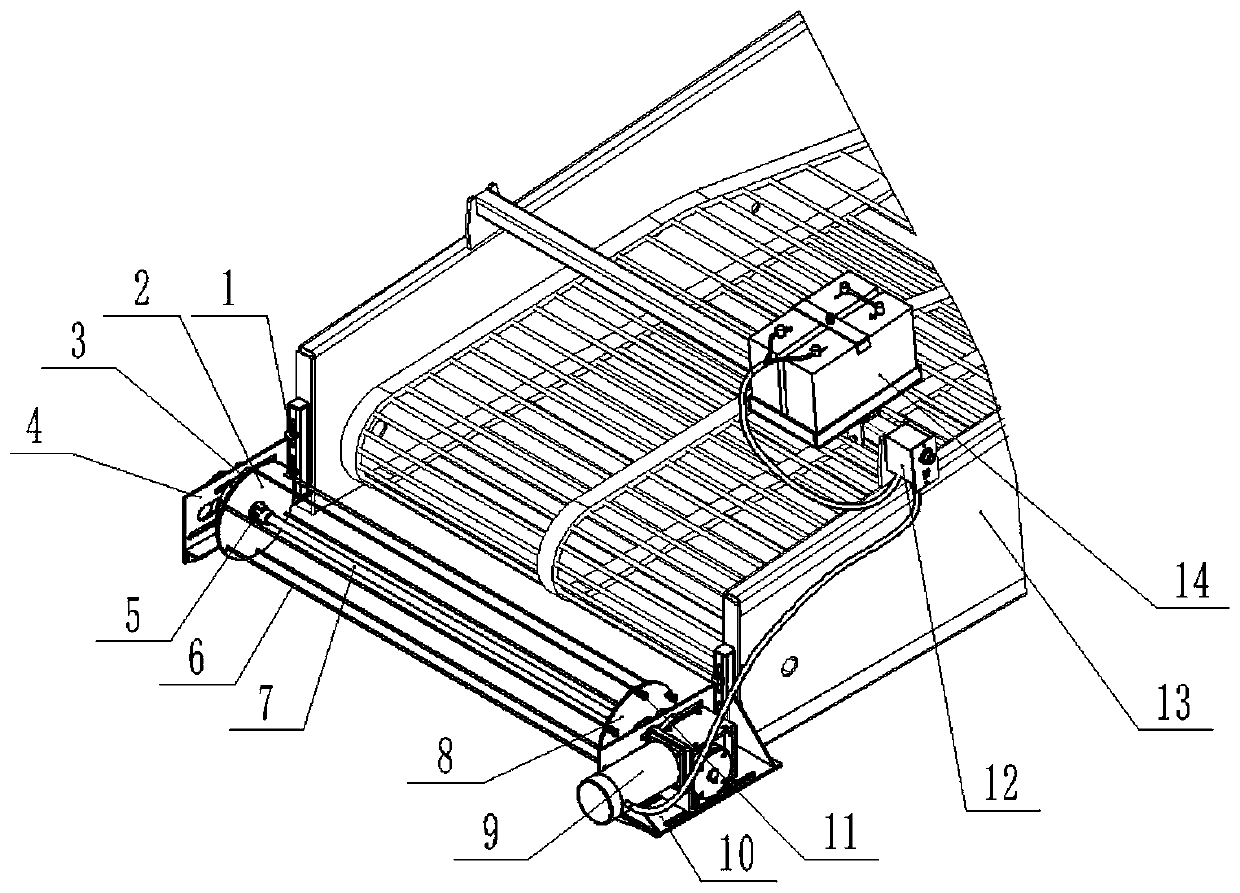

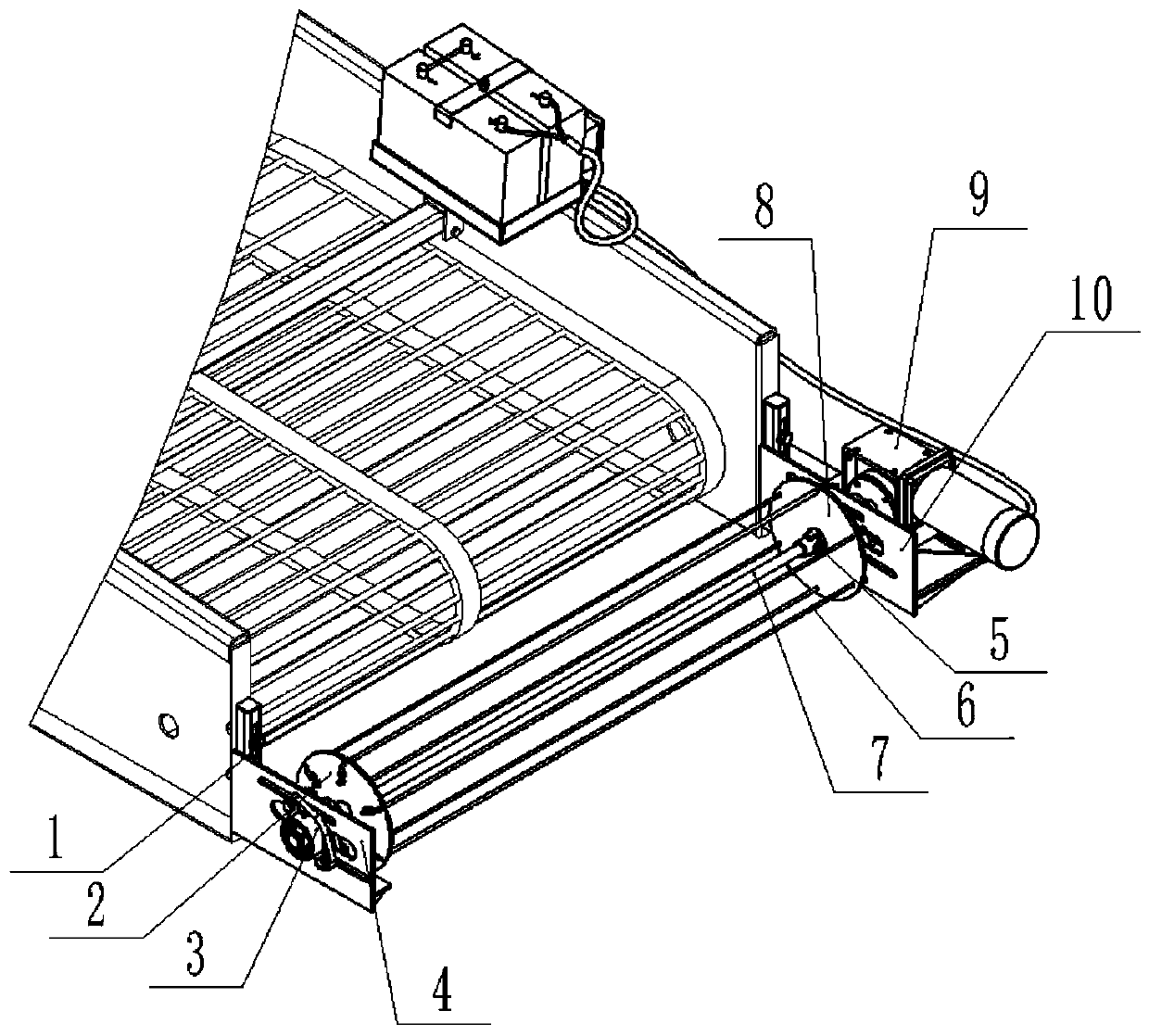

[0050] Example 1, such as Figure 1-4 As shown, the present embodiment provides a quick-release device for recycling residual film, including a first frame assembly and a second frame assembly installed on both sides of the end of the harvester 13, the first frame assembly and the second frame A rotating recovery device is installed between the components, and the rotating recovery device can rotate along its own axis to wind the residual film;

[0051] Specifically, the first frame assembly and the second frame assembly are respectively installed on the frame at the end of the conveying chain of the harvester 13, and the rotating recovery device is facing the conveying chain.

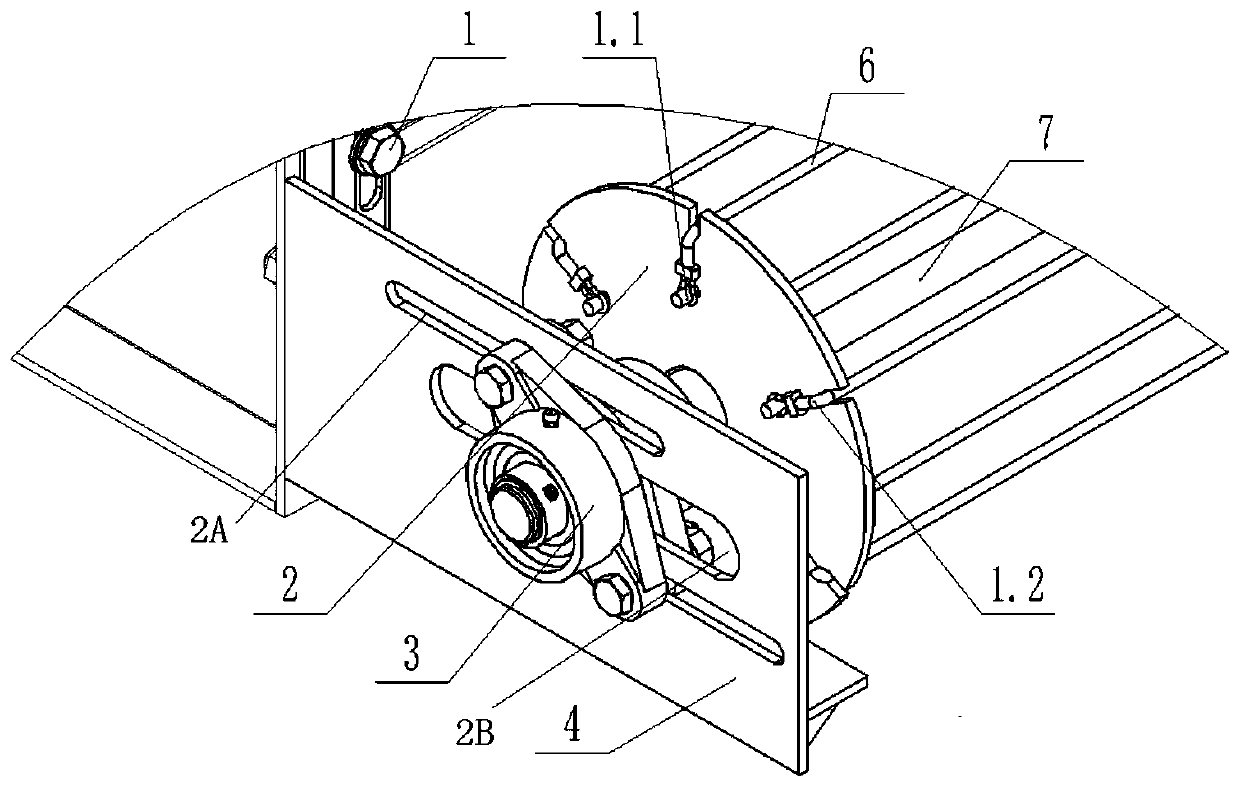

[0052] The rotary recovery device includes a first shaft disk 2 that is rotatably connected to the first frame assembly, and a second shaft disk 8 that is rotatably connected to the second frame assembly. The first shaft disk 2 and the second shaft disk 8 pass through The connecting shaft 7 is fixedly...

Embodiment 2

[0072] Example 2, such as Figure 1-4 As shown, this embodiment provides a quick-release method for recycling residual film, using a quick-release device for recycling residual film, including the following steps:

[0073] Step 1, start the harvester 13, the controller 12 controls the rotation of the DC motor, the DC motor drives the first shaft disk 2 and the second shaft disk 8 to rotate, and the rotation of the first shaft disk 2 and the second shaft disk 8 drives a plurality of steel wire ropes 6 Rotate with the connecting shaft 7 as the rotation center, and the residual film is wrapped around the outside of the steel wire rope 6;

[0074] Step 2, when the thickness of the residual film wrapped around the wire rope 6 meets the set requirements, the harvester 13 stops moving forward, and the DC motor stops rotating;

[0075] Step 3, separate the buckle 1.2 at the end of the wire rope 6 from the hook 1.1 on the first reel 2, the wire rope 6 changes from a tensioned state to...

Embodiment 3

[0077] Embodiment 3, a harvester, utilizes the residual film recovery quick-release device, and the residual film recovery quick-release device is installed at the end of the conveyor chain of the harvester 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com