High-speed elevator compensating rope tensioning device and application thereof

A tensioning device and high-speed elevator technology, which is applied in the field of elevators, can solve the problems of small adjustable range and achieve the effects of large adjustable range, comfortable elevator operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

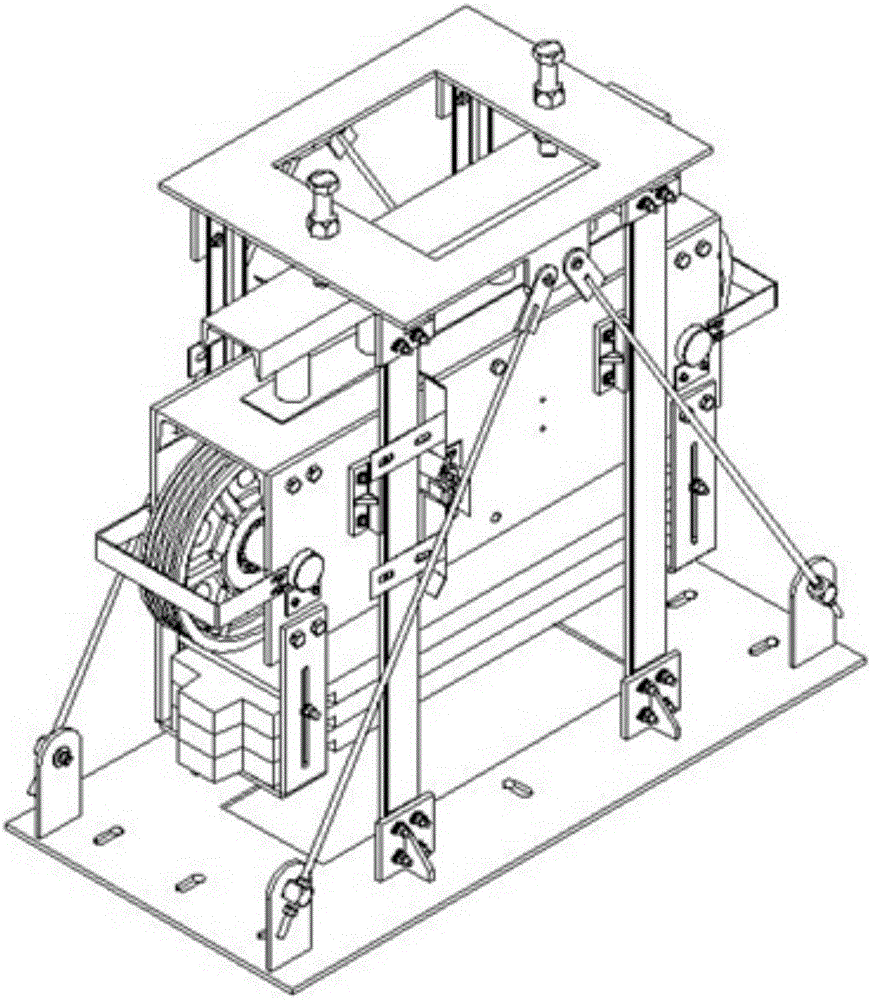

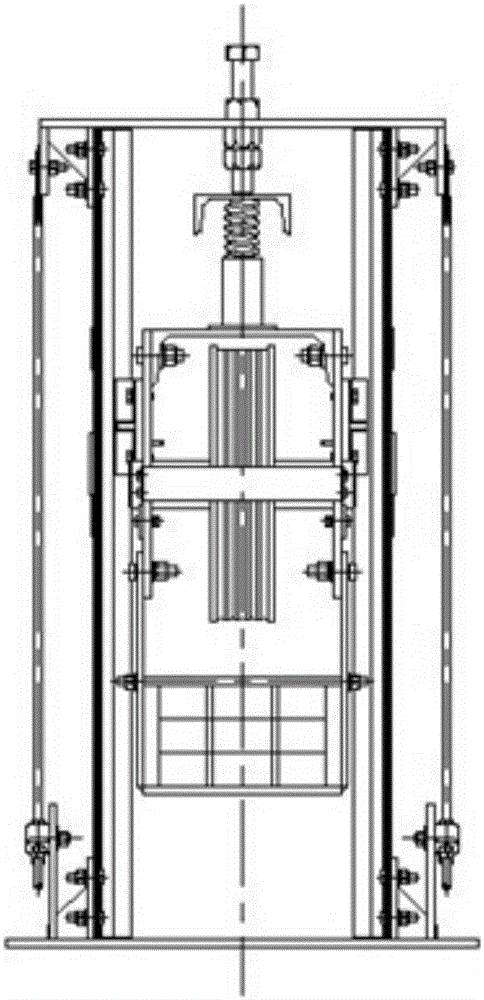

[0038] This embodiment provides a high-speed elevator compensation rope tensioning device, including a base 6, fixed guide rails 7 symmetrically arranged on both sides of the base, and a balance baffle 17 arranged above the base, between the base 6 and the balance baffle 17 There is a tensioning mechanism, which is located between the fixed guide rails on both sides and is slidably connected with the fixed guide rails on both sides; The wheel 2 and the counterweight 8 arranged at the bottom of the tensioning wheel fixing device 1, the counterweight 8 is made of cement material, and the top of the tensioning wheel fixing device 1 passes through the spring 16 and the balance baffle 17 through the spring guide 15 to connect. In this embodiment, the spring guide device 15 is a cylinder, which runs through the spring 16 to play a guiding role, preventing the spring 16 from shifting when it is compressed.

[0039] Wherein, the tensioning mechanism also includes a counterweight hange...

Embodiment 2

[0047] A method for installing a high-speed elevator compensating rope tensioning device, comprising the following steps,

[0048] (1) Drill holes on the ground of the well pit, fix the base 6 of the tensioning device on the ground of the well pit through expansion screws, and the tension pulleys 2 on both sides correspond to the positions of the car and the counterweight vertical suspension compensation wire rope respectively;

[0049] (2) Adjust the position of the diagonal tie rod 12 through the bolts on the diagonal tie rod seat 11, so that the axes of the tension pulleys 2 on both sides are on the same plane, pass the compensation wire rope through the tension pulley 2 on both sides, and compensate one end of the wire rope It is connected to the center of gravity of the car, and the other end is connected to the center of gravity of the counterweight frame;

[0050] (3) Adjust the tension of the spring 16 by turning the adjusting screw 18 to drive the balance baffle 17 up...

Embodiment 3

[0054] A high-speed elevator, including the high-speed elevator compensating rope tensioning device described in embodiment 1, the high-speed elevator compensating rope tensioning device described in embodiment 1 is installed and connected according to the method described in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com