Plugging fixture

A technology for tooling and hatch enclosures, applied in transportation and packaging, ship parts, ships, etc., can solve the problems of positioning plate deformation, safety railings cannot be fixed, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

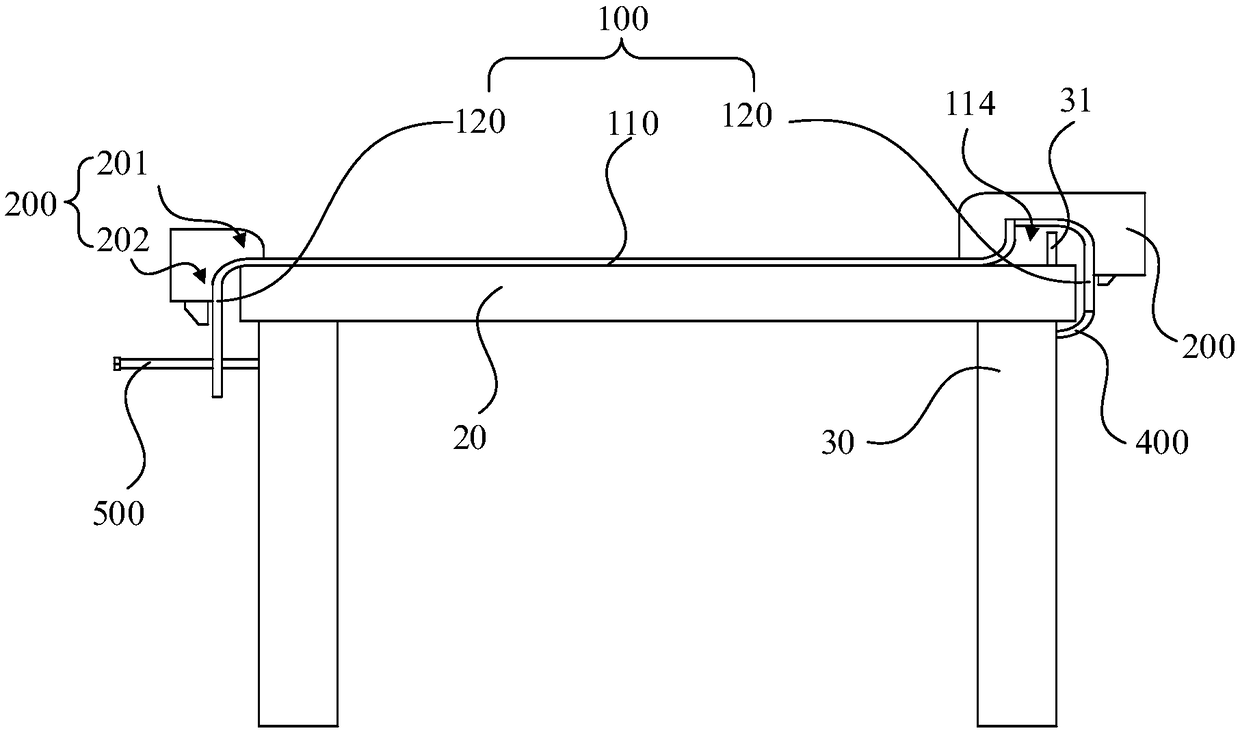

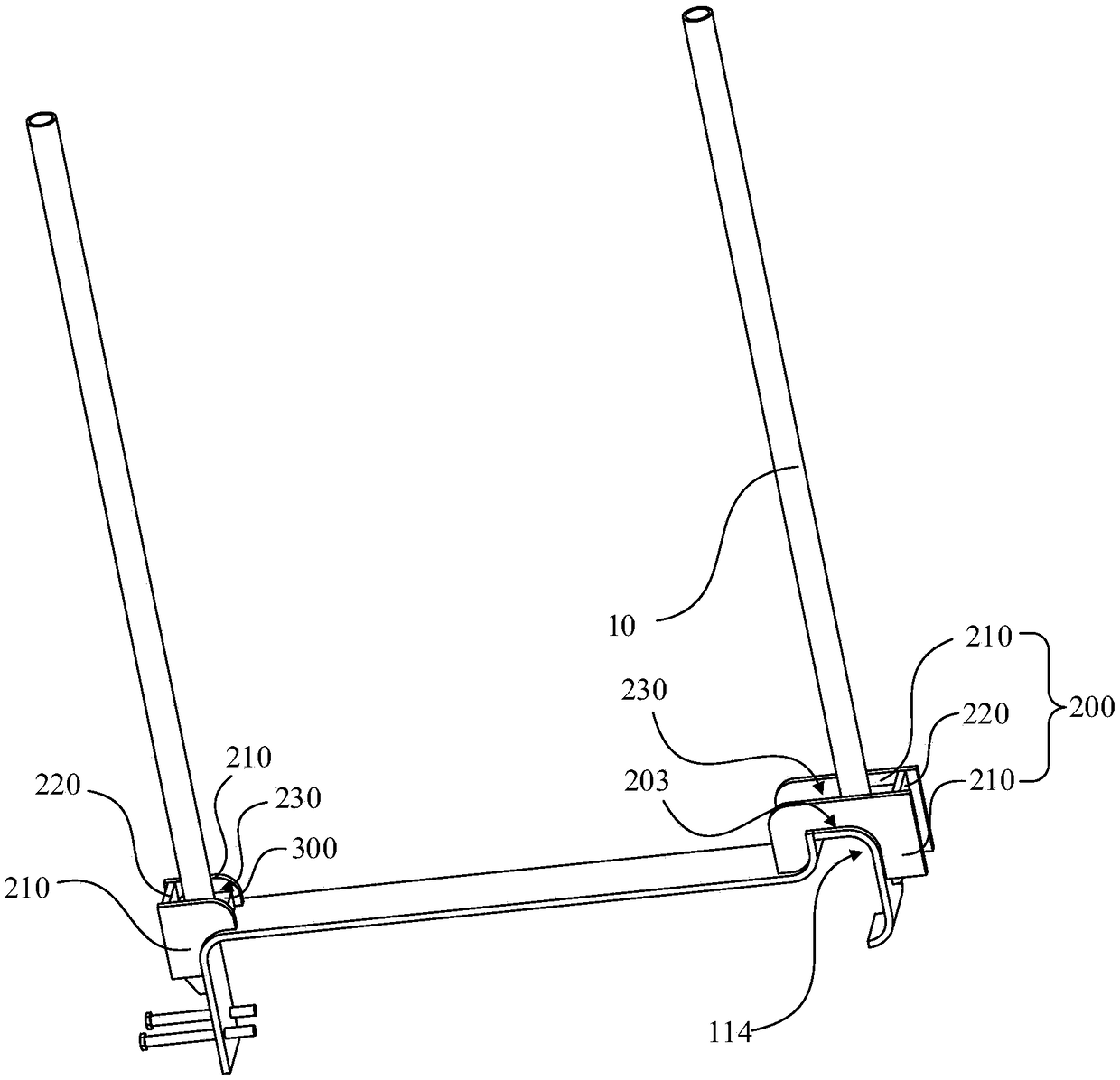

[0056] Such as Figure 1-Figure 3 As shown, the invention discloses a plug-in tooling. The plug-in tool is used to connect the safety railing 10 to the hatch coaming panel 20 , and the hatch coaming panel 20 covers the opening of the ship's hatch coaming 30 . Such as figure 1 and image 3 As shown, the plug-in tooling includes a positioning plate 100 and a reinforcing member 200 .

[0057] Such as Figure 1-Figure 3 As shown, the positioning plate 100 includes a body 110 and bent bodies 120 connected to two ends of the body 110 , and the two bent bodies 120 are clamped on the hatch coaming panel 20 . A rib 31 is usually provided on the hatch coaming panel 20 , so a receiving space 114 is defined on the surface of the body 110 abutting against the hatch coaming panel 20 , and the rib 31 is located in the receiving space 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com