Portable small sawing machine

A portable and small-scale technology, which is applied in the direction of circular saws, sawing equipment, wood processing equipment, etc., can solve the problems of large contact area, short service life, and less safety protection, so as to achieve a clean working environment, long service life, and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

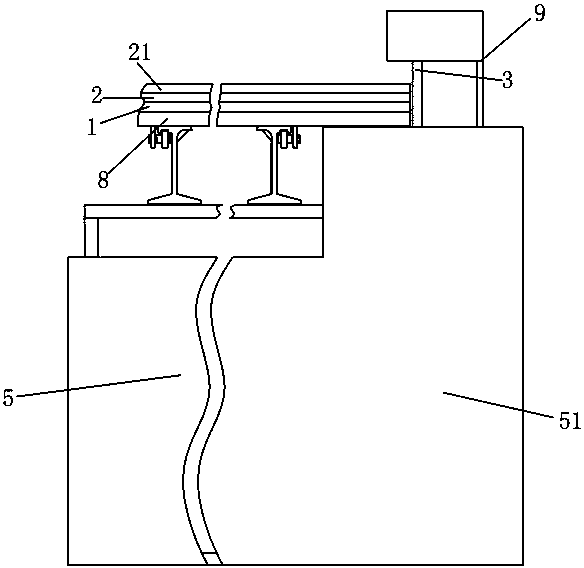

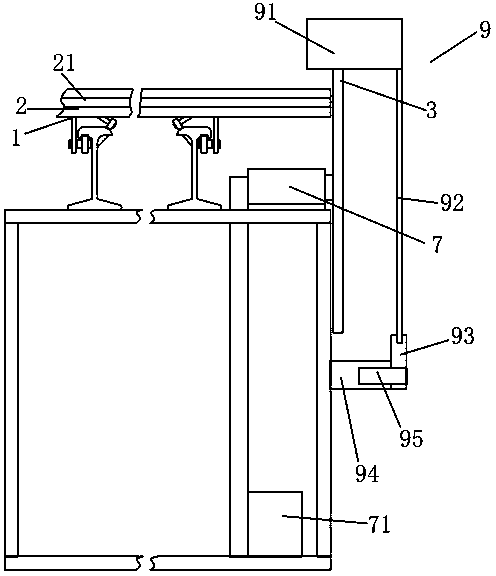

Embodiment 1

[0047] A portable small saw machine is characterized in that it includes a frame, at least two symmetrically arranged guide rails arranged on the top of the frame, and a pusher that is erected on the two guide rails and moves back and forth along the guide rails and has rolling parts that cooperate with the guide rails. A platform and a circular saw 3 whose disk surface is parallel to the length direction of the guide rail, the push platform includes a push frame 1 erected on the guide rail and a push plate 2 detachably arranged on the push frame, on the push plate The surface is provided with a positioning baffle 21 perpendicular to the length direction of the guide rail and a limit block 22 that can move back and forth along the length direction of the guide rail for cooperating with the positioning baffle. Type rack rail, the rack rail includes a support bar 41 arranged on the bottom plate and a top rail bar 42 arranged on the upper end of the support bar, and one side of th...

Embodiment 2

[0055] The difference from the above-mentioned embodiment is that the middle part of the wheel surface of the upper roller and the lower roller is provided with an auxiliary pulley cavity 64 formed in a concave shape. The two locking bars are respectively arranged on the side surfaces on both sides of the outer end of the fixing rod.

Embodiment 3

[0057] The difference from the above-mentioned embodiment is that the middle part of the wheel surface of the upper roller and the lower roller is provided with an auxiliary pulley cavity 64 formed in a concave shape. The inclined rail surface and the bottom rail surface are provided with a roller limiting protrusion 65 that cooperates with the auxiliary pulley cavity.

[0058] When in use, the limit block is opened, the board to be sawed leans against the positioning baffle, and then the limit block is moved to cooperate with the positioning baffle to clamp the board to be sawed, the bolts are tightened, the limit block is fixed, and the push table is pushed to saw the board. When the circular saw needs to be replaced, the protective chip guide cover can be turned down to facilitate the disassembly and assembly of the circular saw.

[0059] A positioning baffle for leaning against the board is set on the push table, and a limit block is provided to clamp the board between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com