Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduced likelihood of wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

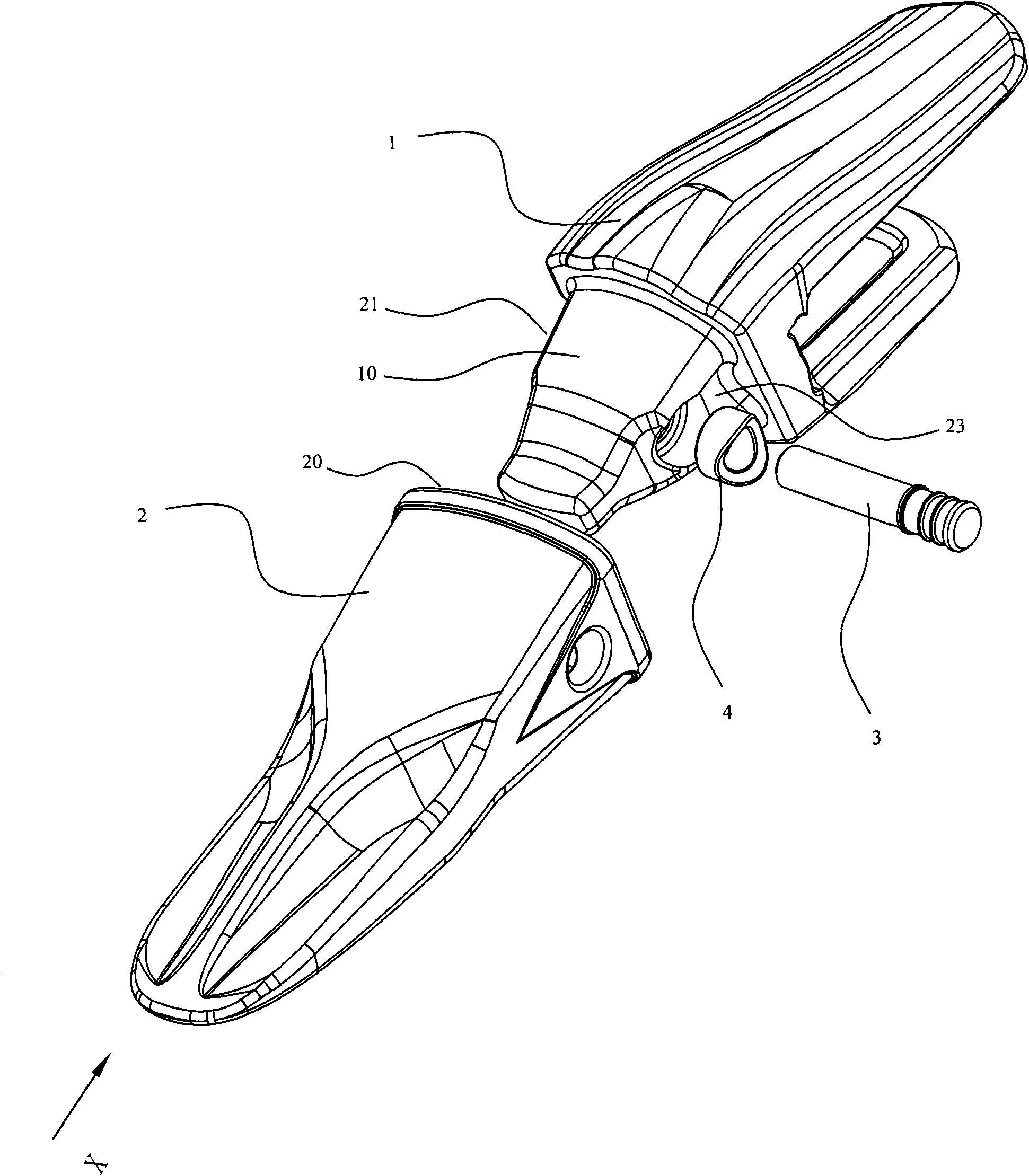

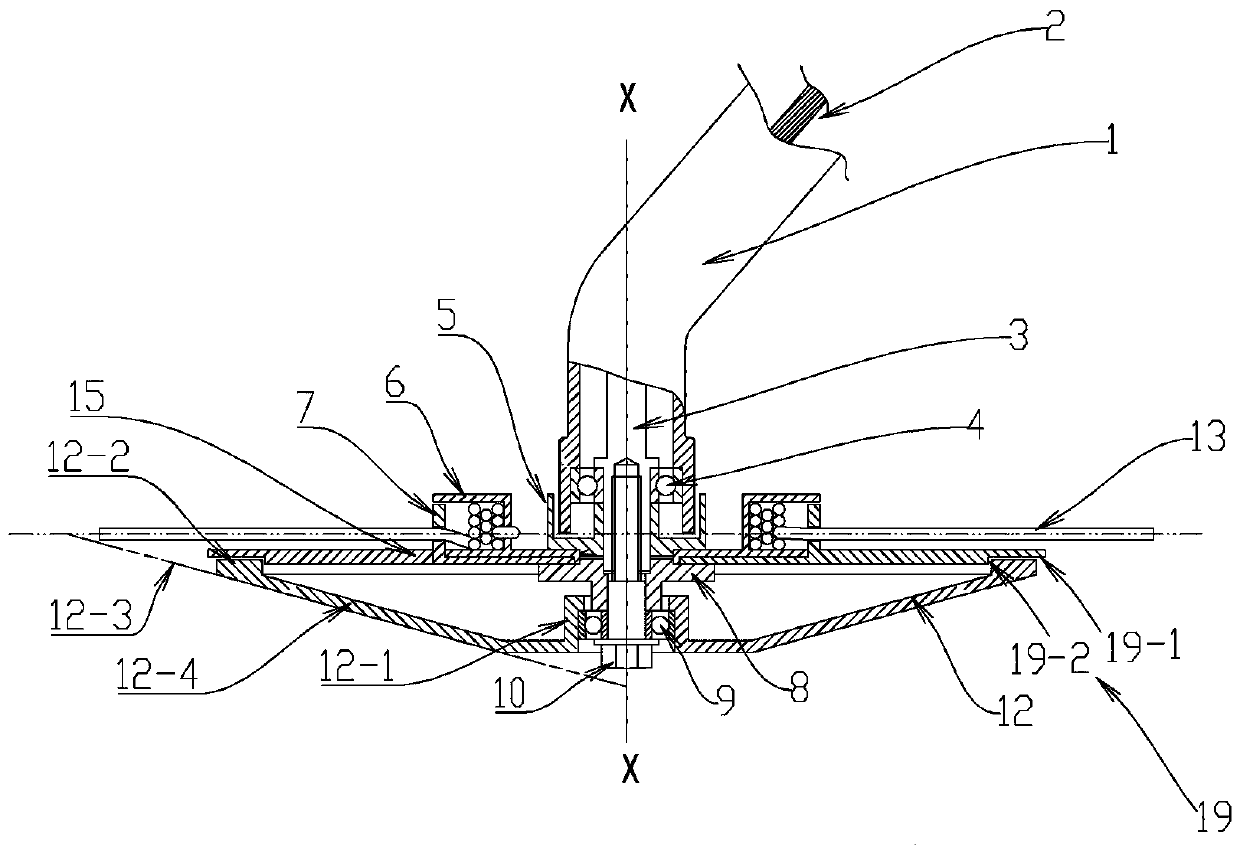

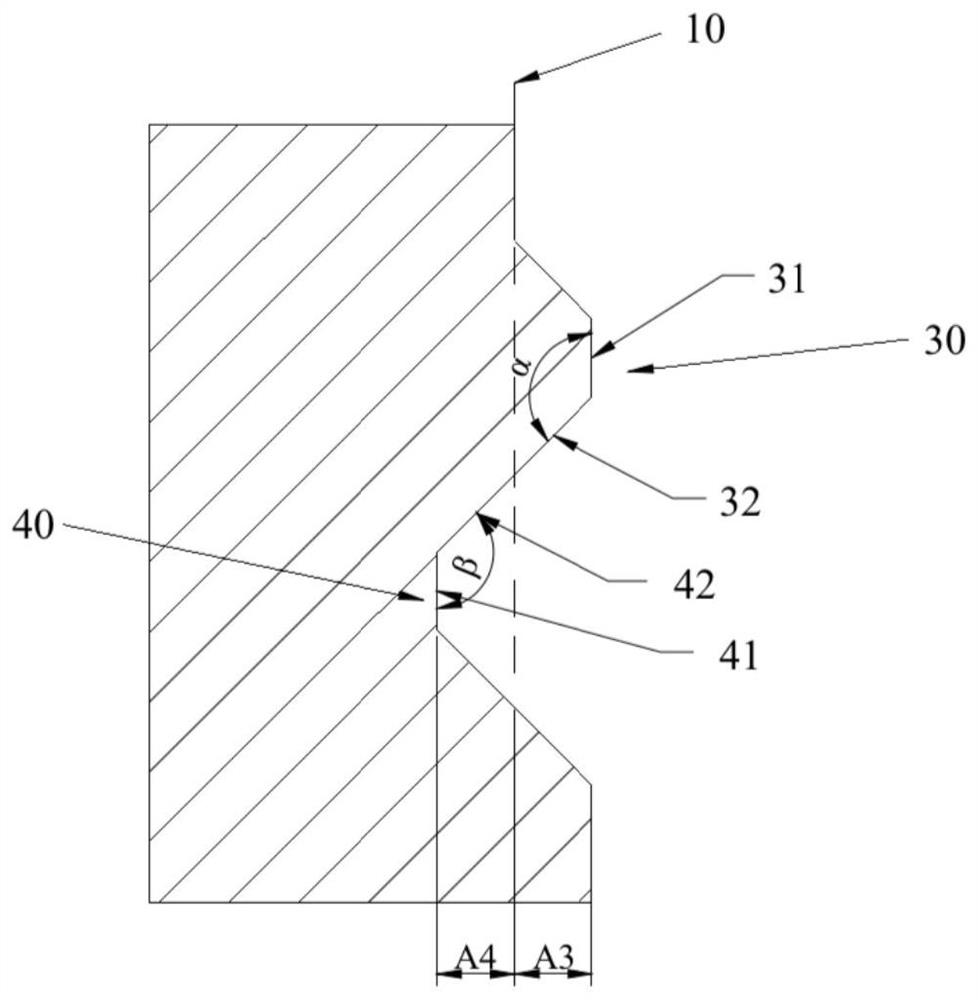

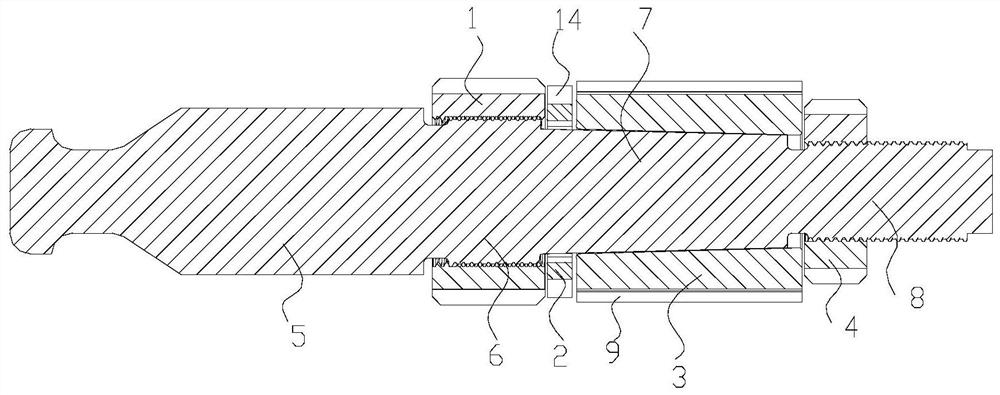

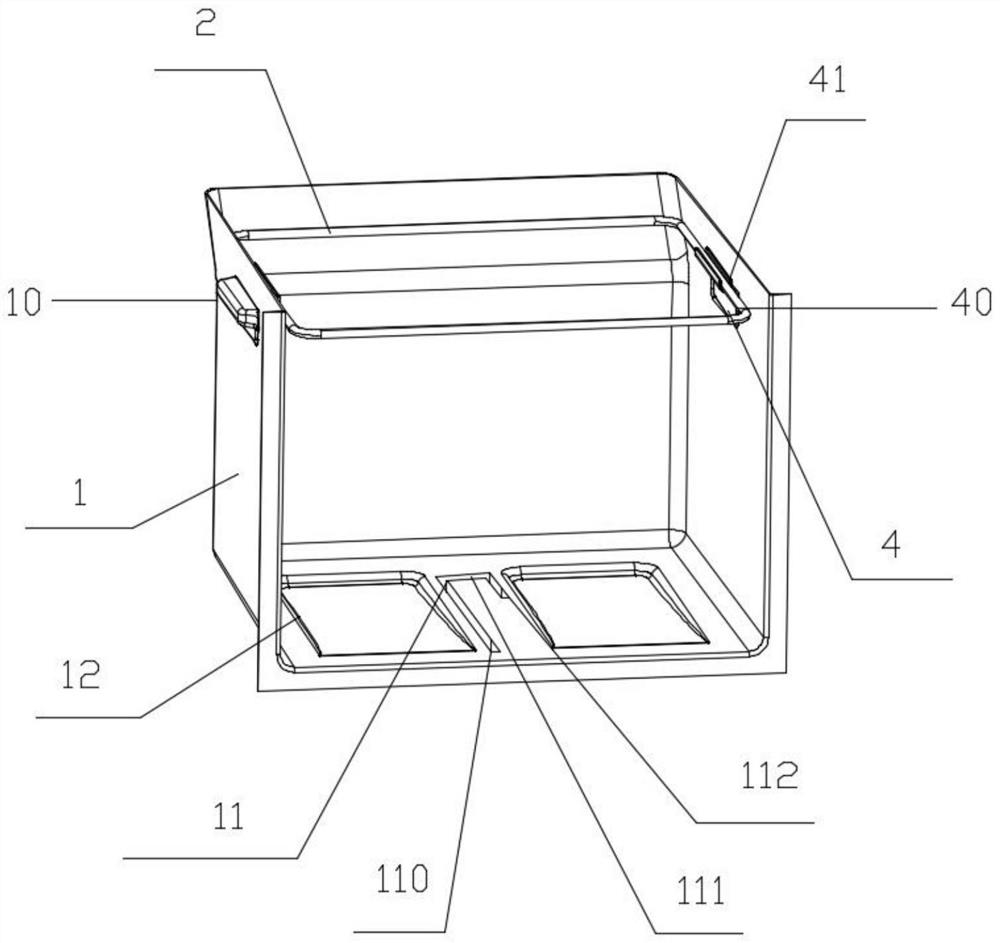

Excavating tooth component, tooth holder and bucket teeth

ActiveCN101768992AGuaranteed stabilityGuarantee the safety of useSoil-shifting machines/dredgersEngineeringTooth Component

The invention discloses an excavating teeth component, a tooth holder and bucket teeth. The excavating tooth component comprises the tooth holder, the bucket teeth, and a locking piece. The rear part of the bucket teeth is provided with a cavity and the front end of the tooth holder is provided with a tooth holder head. The cavity of the bucket teeth and the tooth holder head are firmly combined together through the locking piece. The upper part of the tooth holder head is provided with a first transition connecting surface, a first matching surface and a third matching surface, and the lower part of the tooth holder head is provided with a second transition connecting surface, a second matching surface and a fourth matching surface. The first matching surface and the third matching surface are connected through the first transition connecting surface, and the second matching surface and the fourth matching surface are connected through the second transition connecting surface. The first matching surface and the second matching surface form a predetermined angle with a central axis of the tooth holder head respectively, and the third matching surface and the fourth matching surface are parallel to the central axis of the tooth holder head respectively. An inner surface of the cavity of the bucket teeth is provided with a plurality of matching surfaces which are contacted with the matching surfaces.

Owner:NINGBO ZHEDONG PRECISION CASTING

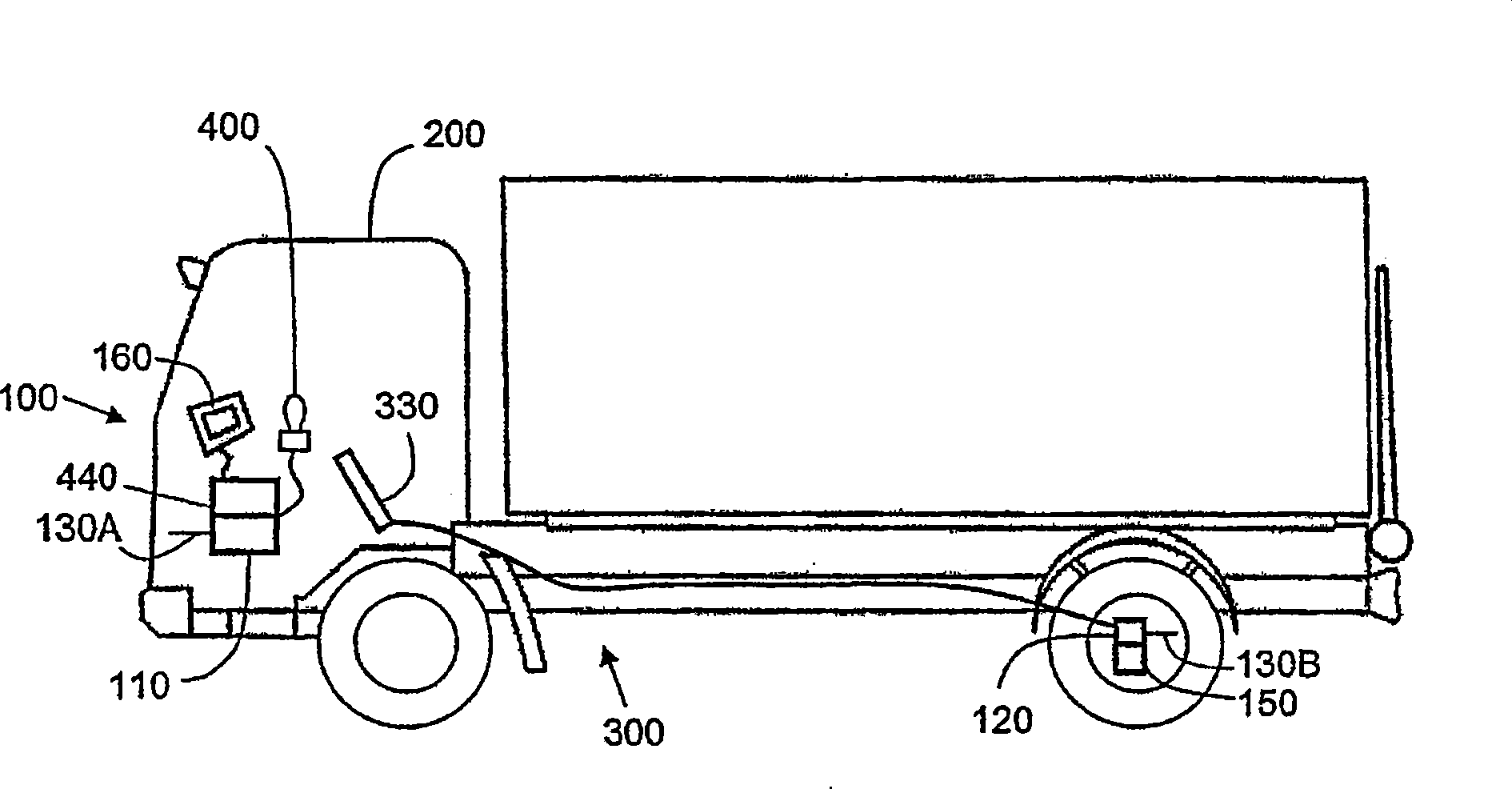

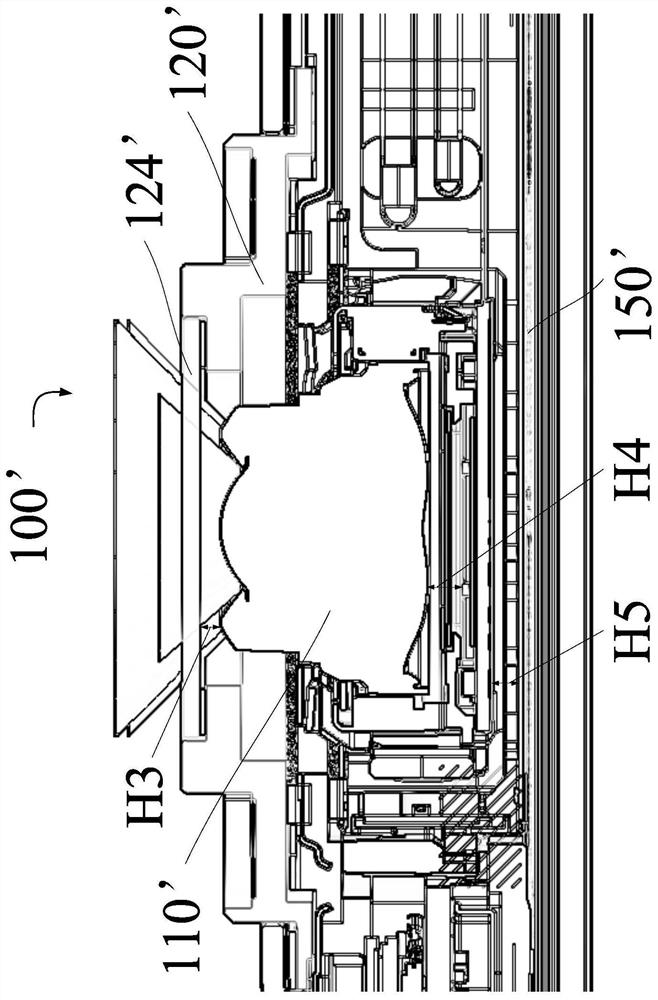

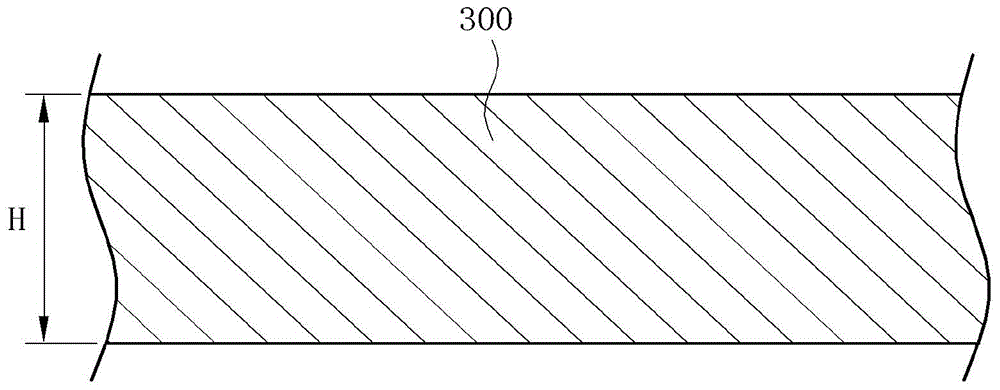

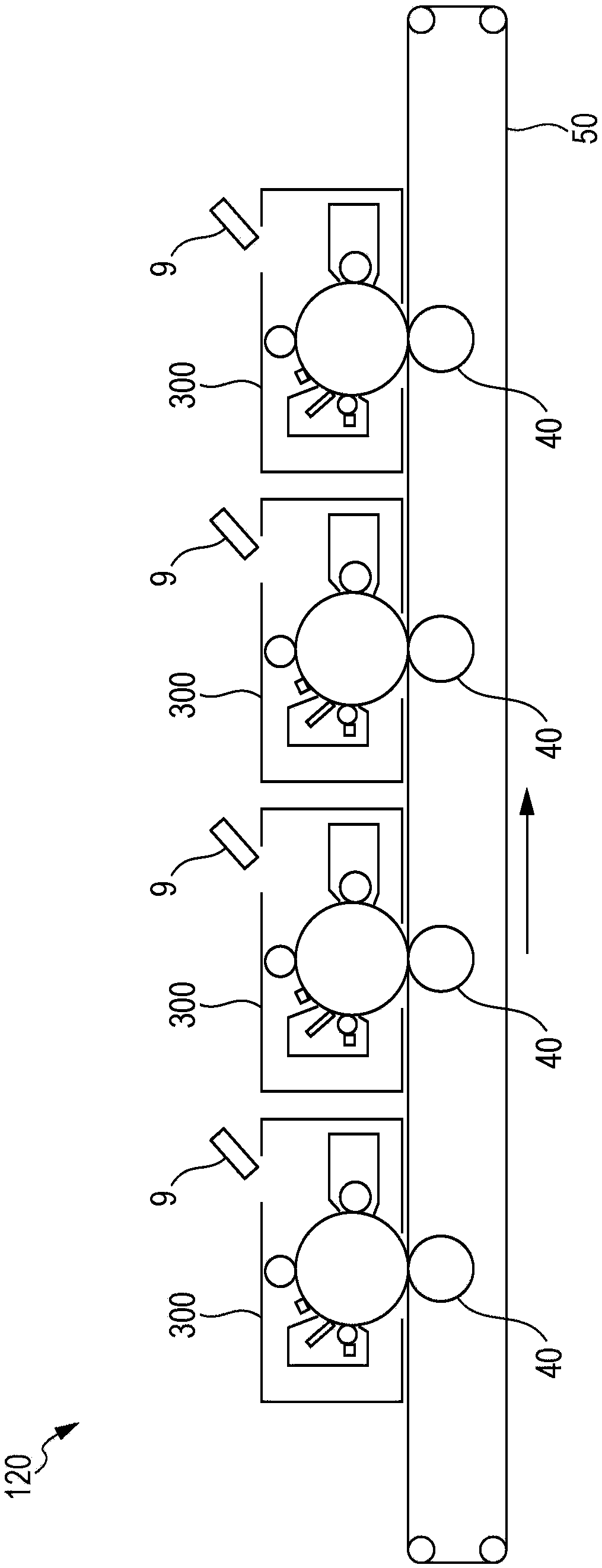

A system for automatically actuating the parking brake on a vehicle

The present invention concerns a system (100) for automatically actuating the parking brake (300) on a vehicle, such as a truck (200), comprising a parking brake (300) and at least a driver's door lock (400). Said system (100) comprises means for applying said parking brake (300) to an active position as a response to at least said driver's door lock (400) being locked in an active position. Preferably, said system comprises lock response means (110) which is operable for at least providing a first signal indicating that at least said driver's door lock (400) is locked in an active position; and hold means (120) for actuating the parking brake (300) to an active position based on said first signal. Thus, it is no longer necessary for a driver to remember to actuate the parking brake, when he or she parks the vehicle, as long as at least the driver's door lock on the vehicle is locked. By the invention, it has been realized that the manual locking action of the driver's door lock may be further utilized for automatic actuation of the parking brake, i.e. the same manual action may induce two separate functions at the same time. Further, it has been realized that the system is increasing the effect of the locking the vehicle door by effectively locking the wheels of the vehicle when the parking brake is on, which further reduces the possibility of a vehicle thief removing said vehicle, e.g. by towing it away. As a consequence, the system may be perceived to further provide an improved anti-theft device.

Owner:VOLVO LASTVAGNAR AB

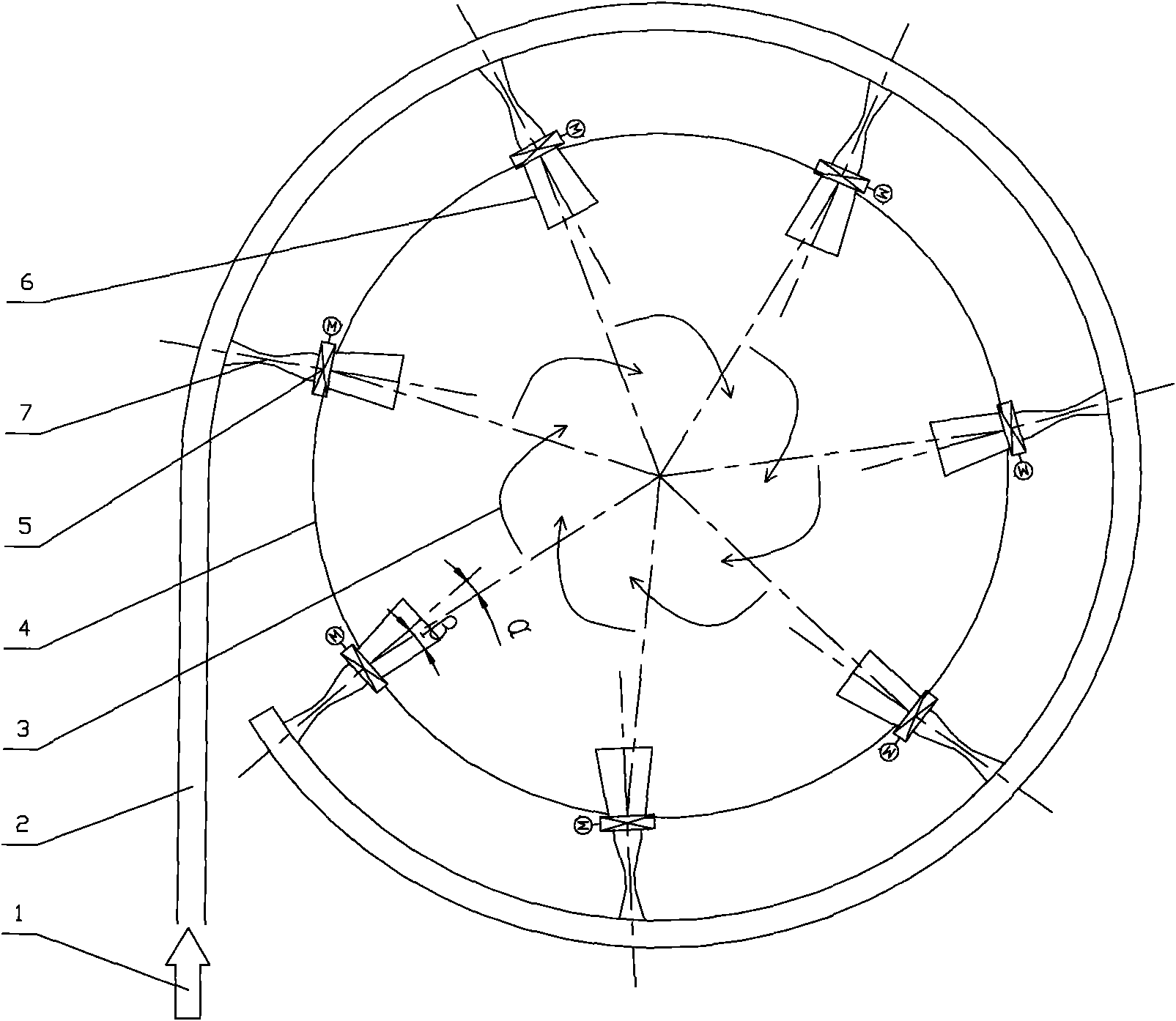

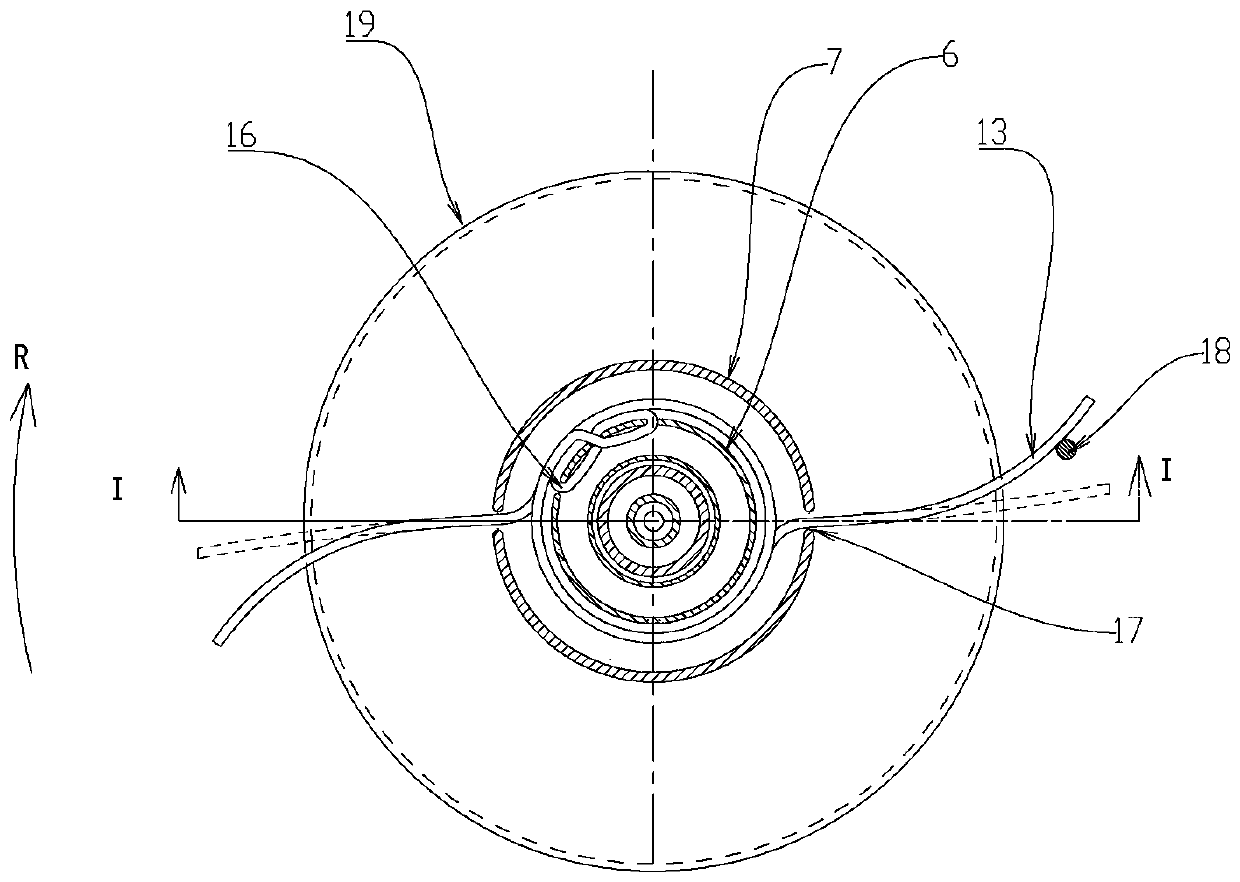

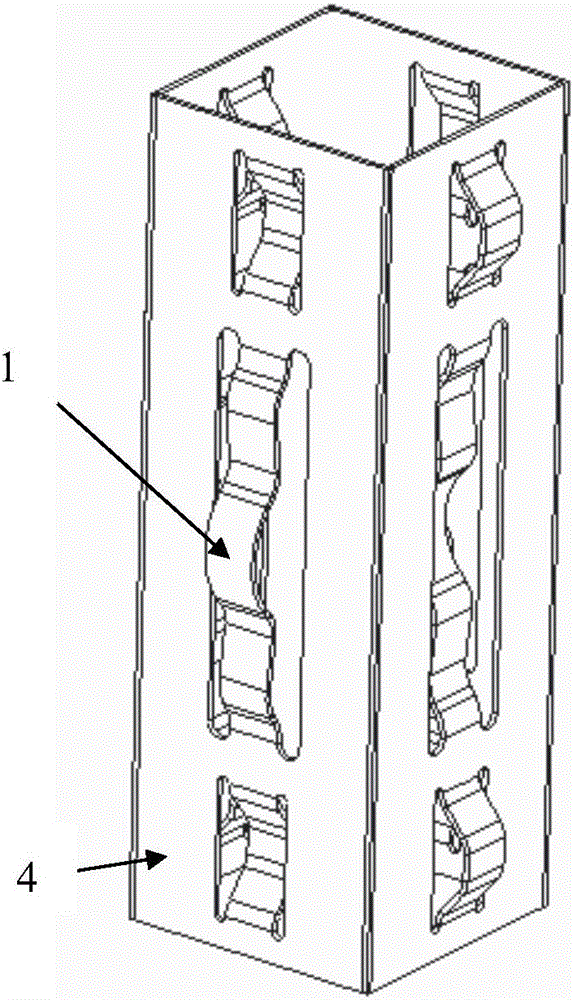

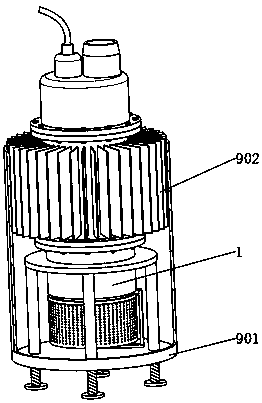

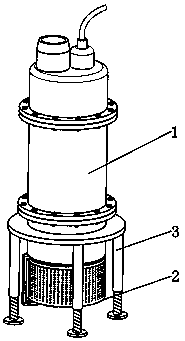

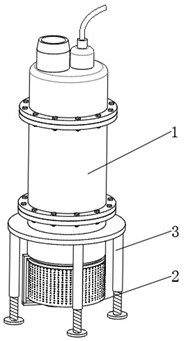

LAVAL pipe jet air stirring device

InactiveCN101670249AReduced likelihood of wearHigh componentTransportation and packagingMixersSlurryDistributor

The invention relates to an LAVAL pipe jet air stirring device used in a wet-process flue gas desulfurization system (WFGD) or similar fields for preventing sediment in a size tank. The device comprises a size tank, a plurality of eddy flow pipes arranged on the inner wall of the size tank, an air distributor, an LAVAL jet pipe and a valve, wherein the air outlet end of the LAVAL jet pipe is connected with the air inlet ends of the eddy flow pipes, the air inlet end of the LAVAL jet pipe is connected with the air outlet end of the air distributor, and the valve is arranged between the eddy flow pipes and the LAVAL jet pipe. The LAVAL jet pipe is used for accelerating jetting air with a certain pressure into the size, under the initial velocity and floatage, the air overturns and rises to drive size around to overturn so as to achieve the effect of stirring.

Owner:中建中环新能源有限公司

Extruder screw, extruder, and method for producing an extruder screw

ActiveCN103764368AIncrease torqueNo need to change other designsCouplings for rigid shaftsEngineeringPolymer science

Owner:KRAUSSMAFFEI BERSTORFF GMBH

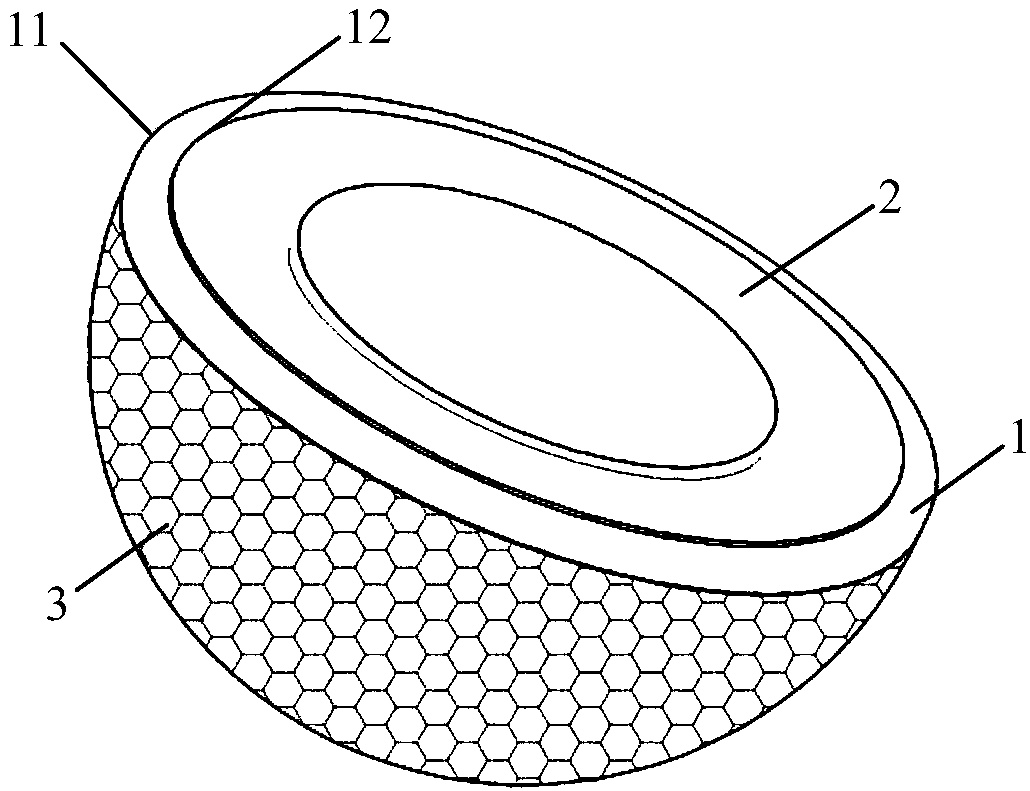

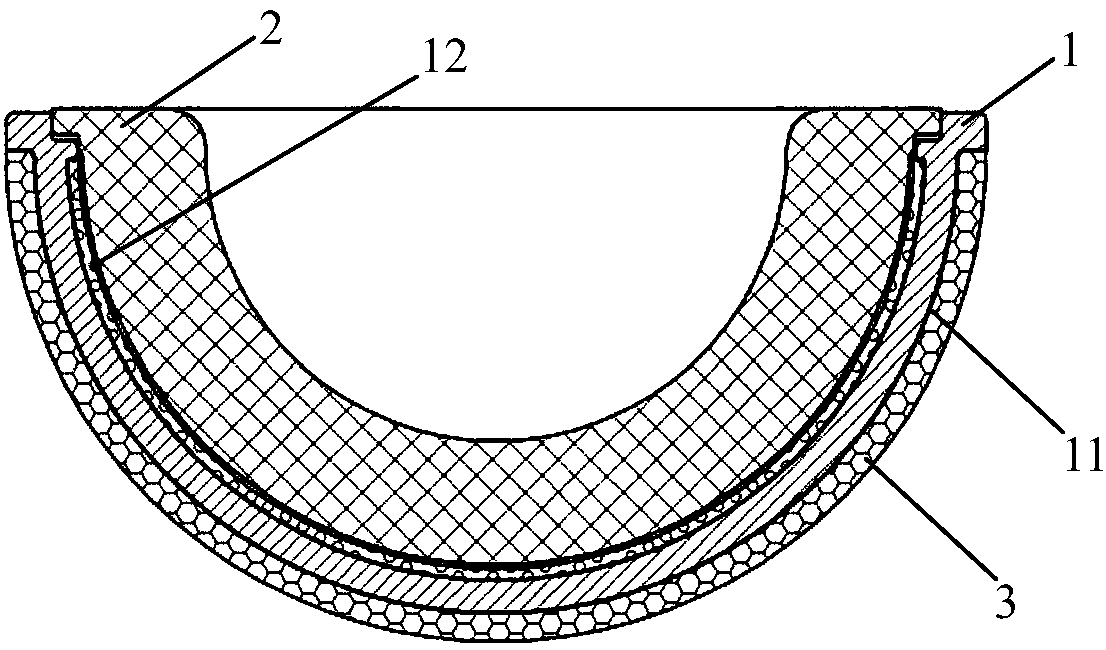

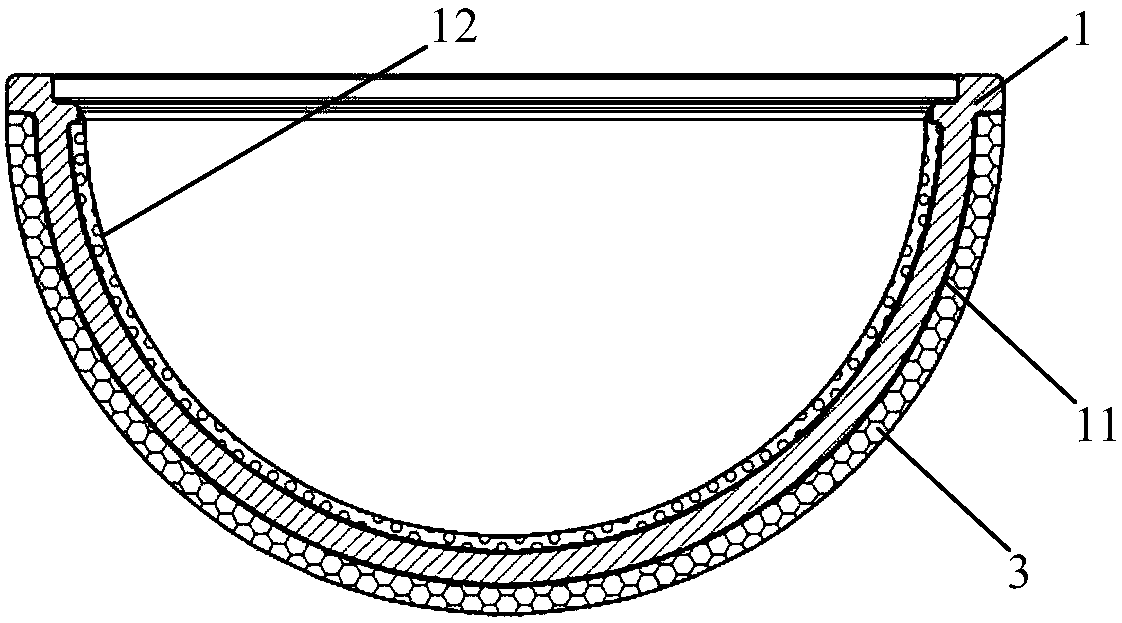

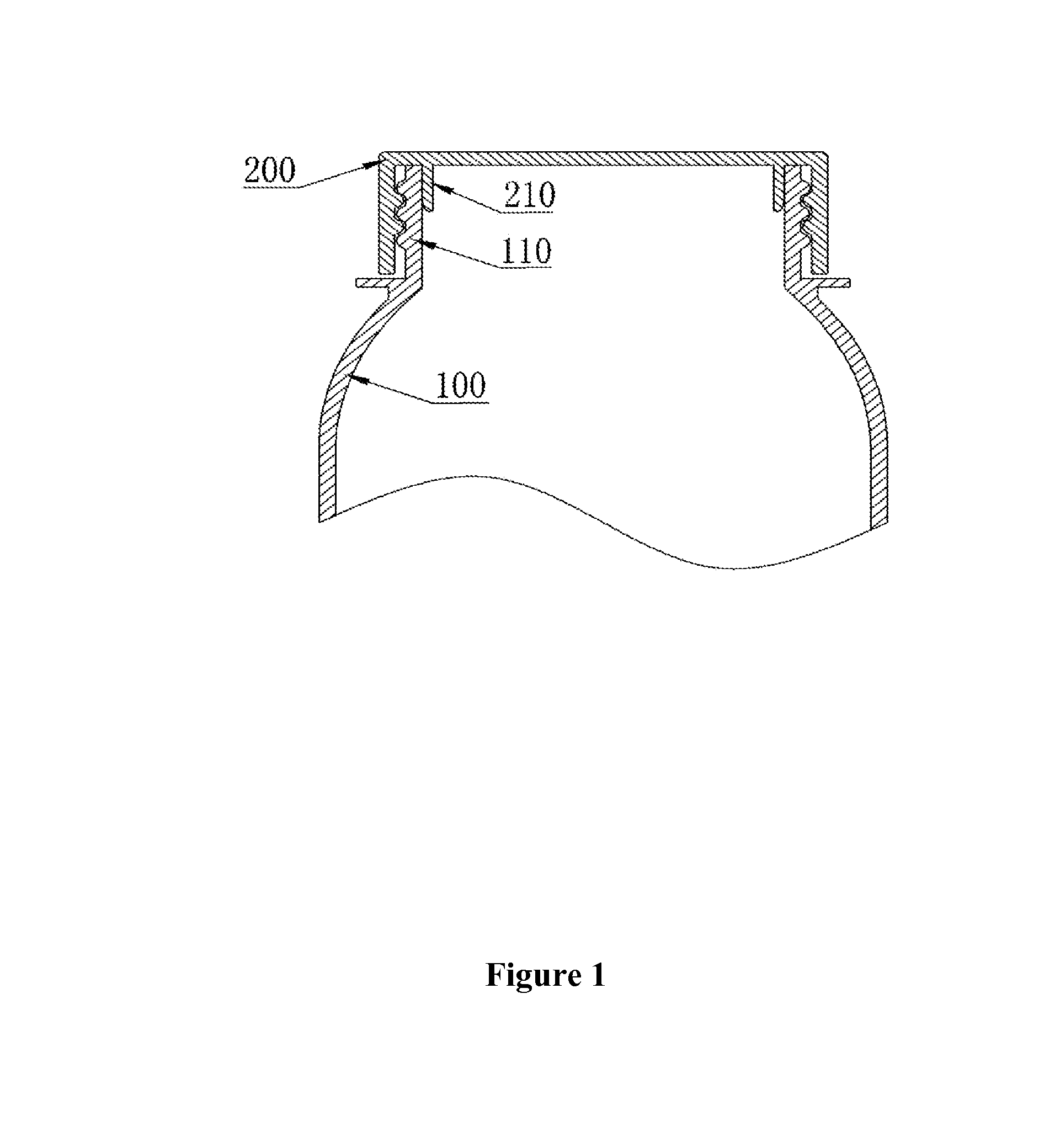

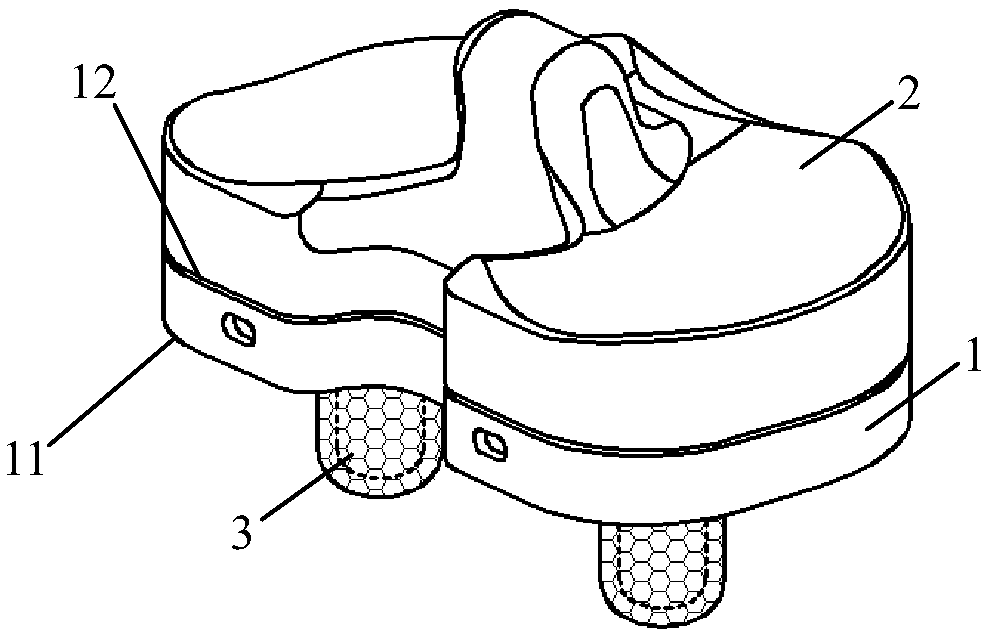

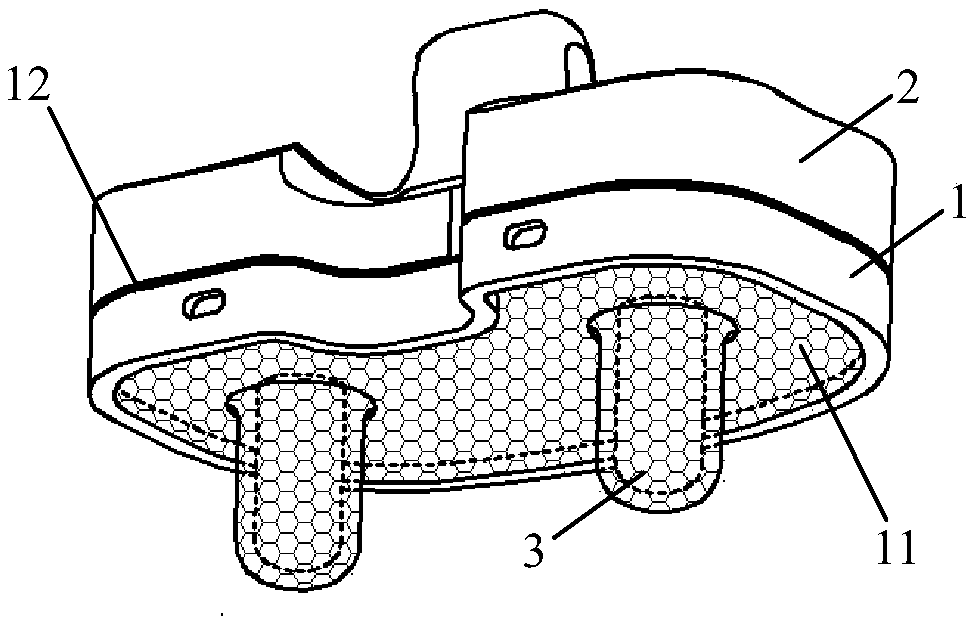

Cup and liner integrated acetabulum component and preparation method thereof

InactiveCN108042243AReduce installation stepsReduced likelihood of wearJoint implantsAcetabular cupsRough surfaceAcetabular liner

The invention provides a cup and liner integrated acetabulum component and a preparation method thereof. The cup and liner integrated acetabulum component comprises an acetabulum cup, an acetabulum liner and a bone trabecula structure. The bone trabecula structure is arranged on the outer surface of the acetabulum cup, the acetabulum cup and the bone trabecula structure are formed integrally, theacetabulum liner is in melt connection with the inner surface of the acetabulum cup, and the inner surface of the acetabulum cup is a rough surface with a microporous structure. Preferably, the porosity of the bone trabecula structure is 50%-65%, the pore diameter of the bone trabecula structure is 300-800micron, the acetabulum cup is a metal acetabulum cup, the bone trabecula structure is a metalbone trabecula structure, and the acetabulum liner is a nonmetal acetabulum liner. The cup and liner integrated acetabulum component is structurally firm and stable, capable of improving post-surgical early-stage fixing effects and long-term stability, safe, simple and convenient to use, long in service life, ingenious in design, simple in structure and convenient and simple in manufacturing.

Owner:上海科太迈迪医疗器械有限公司

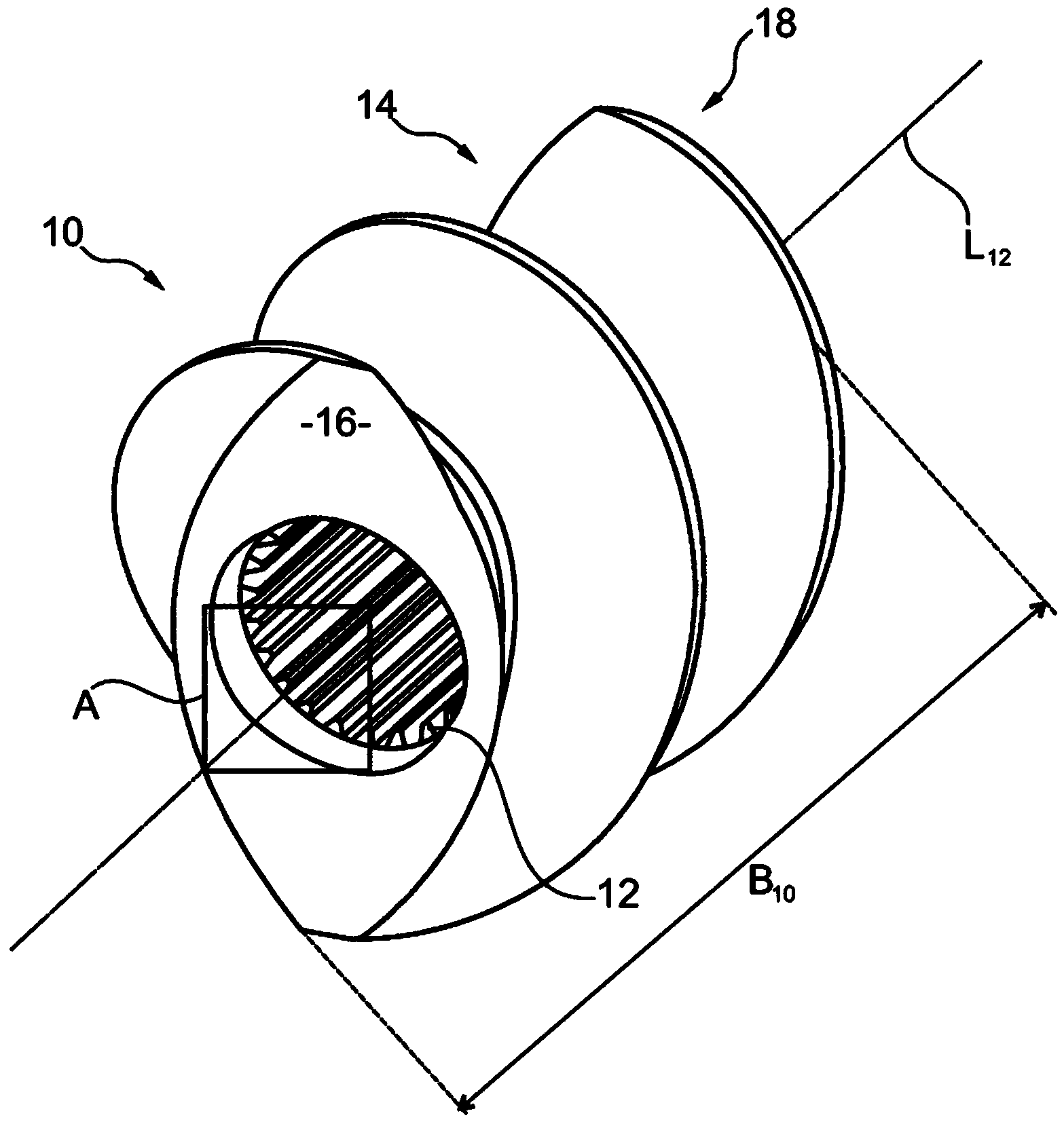

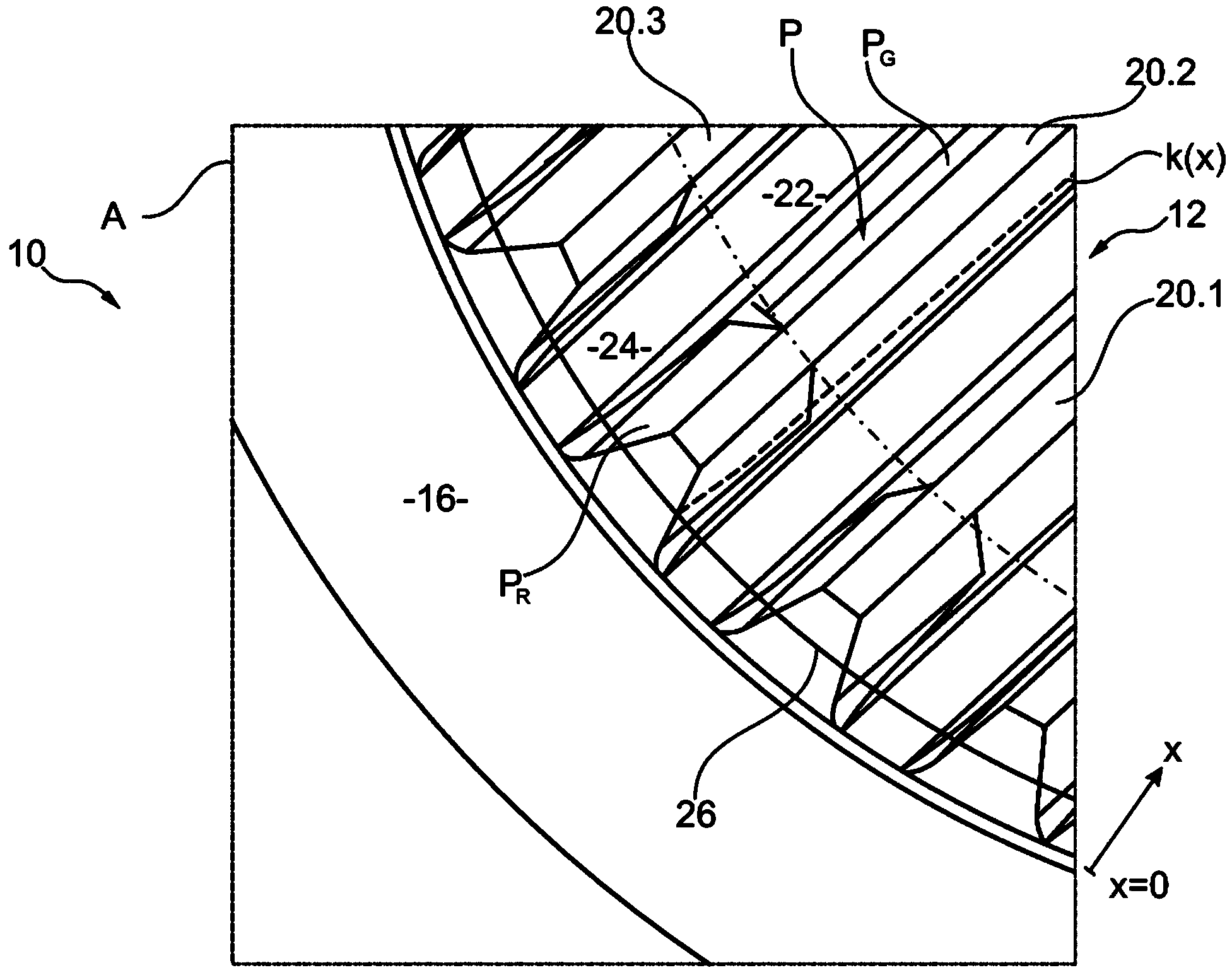

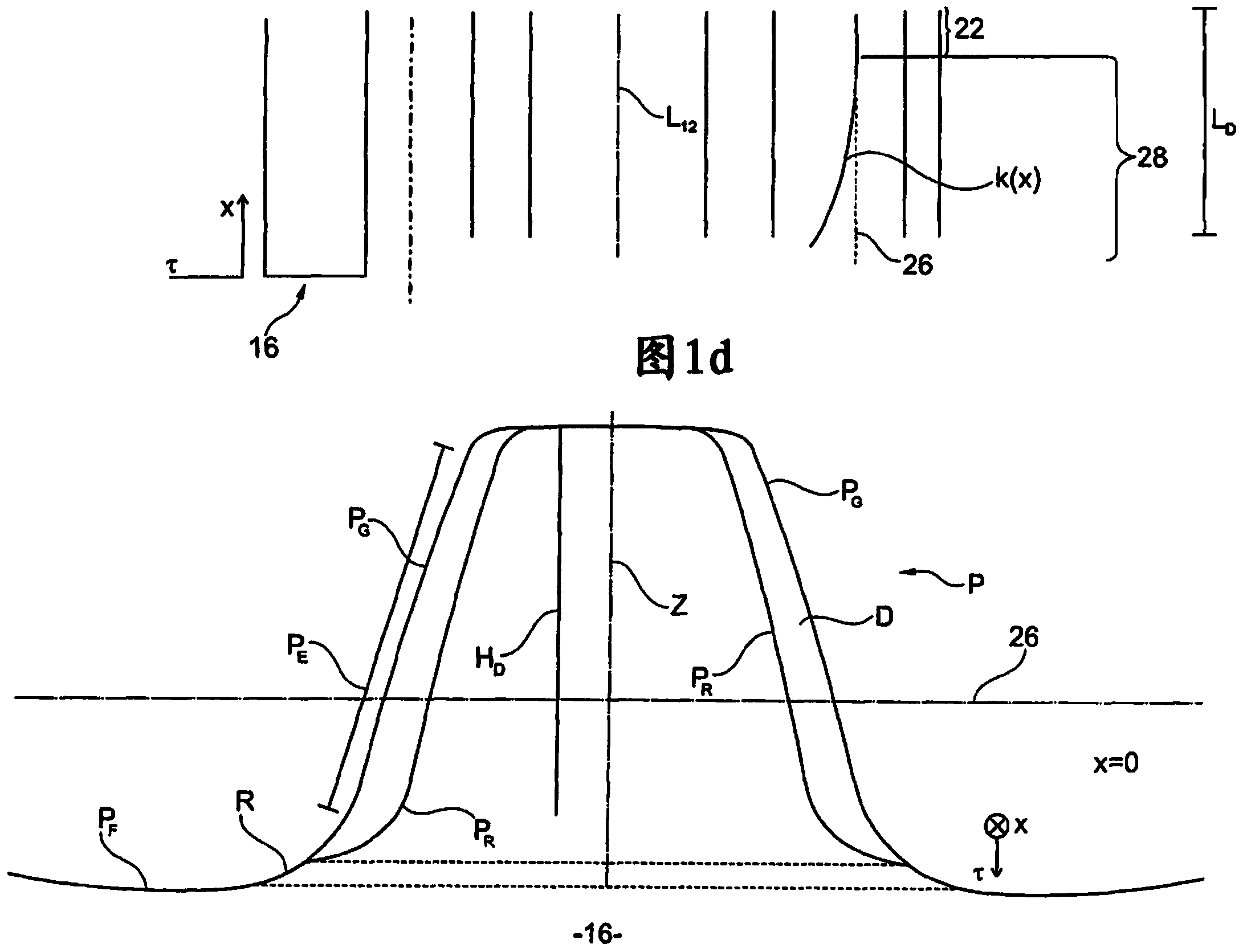

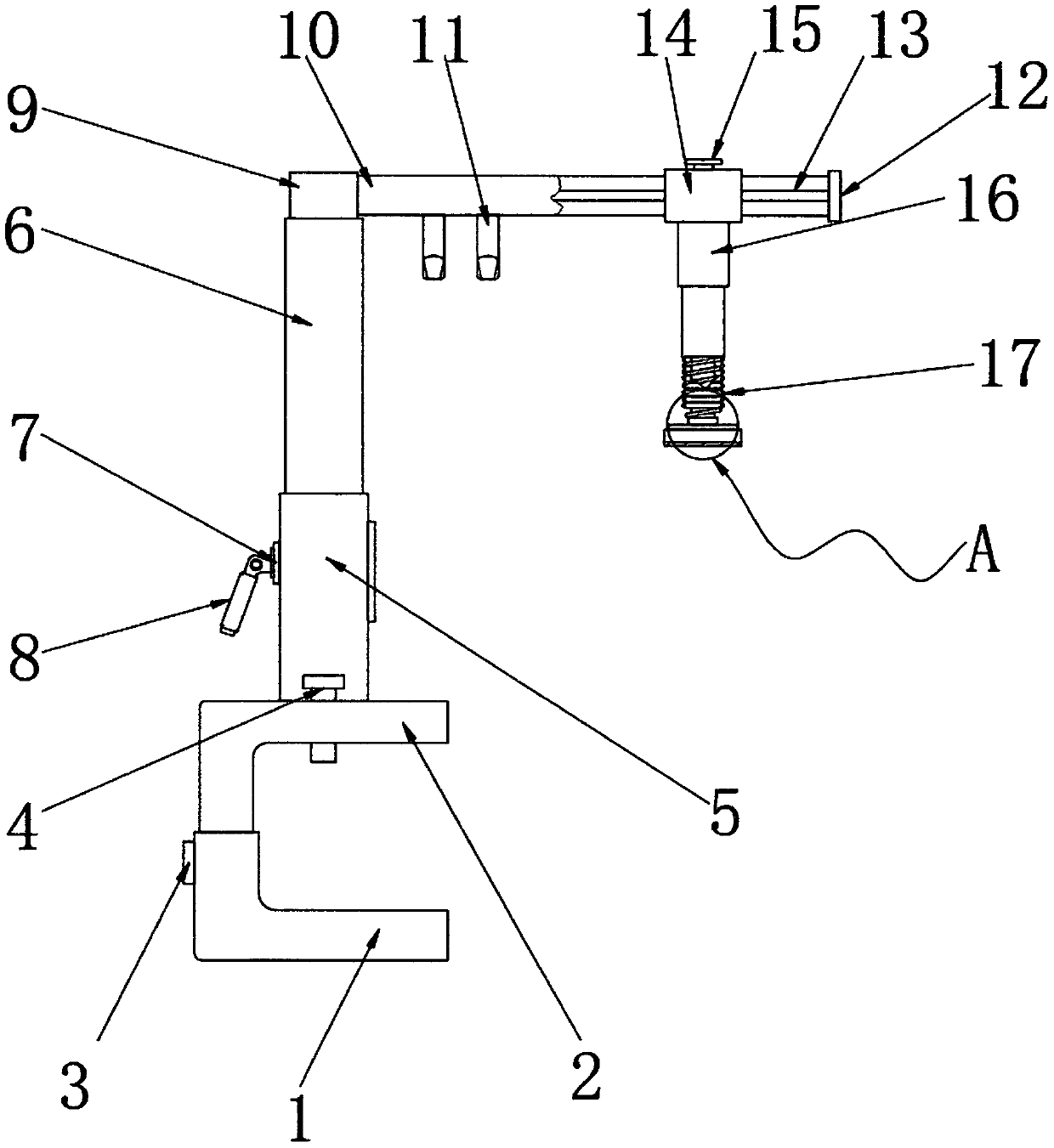

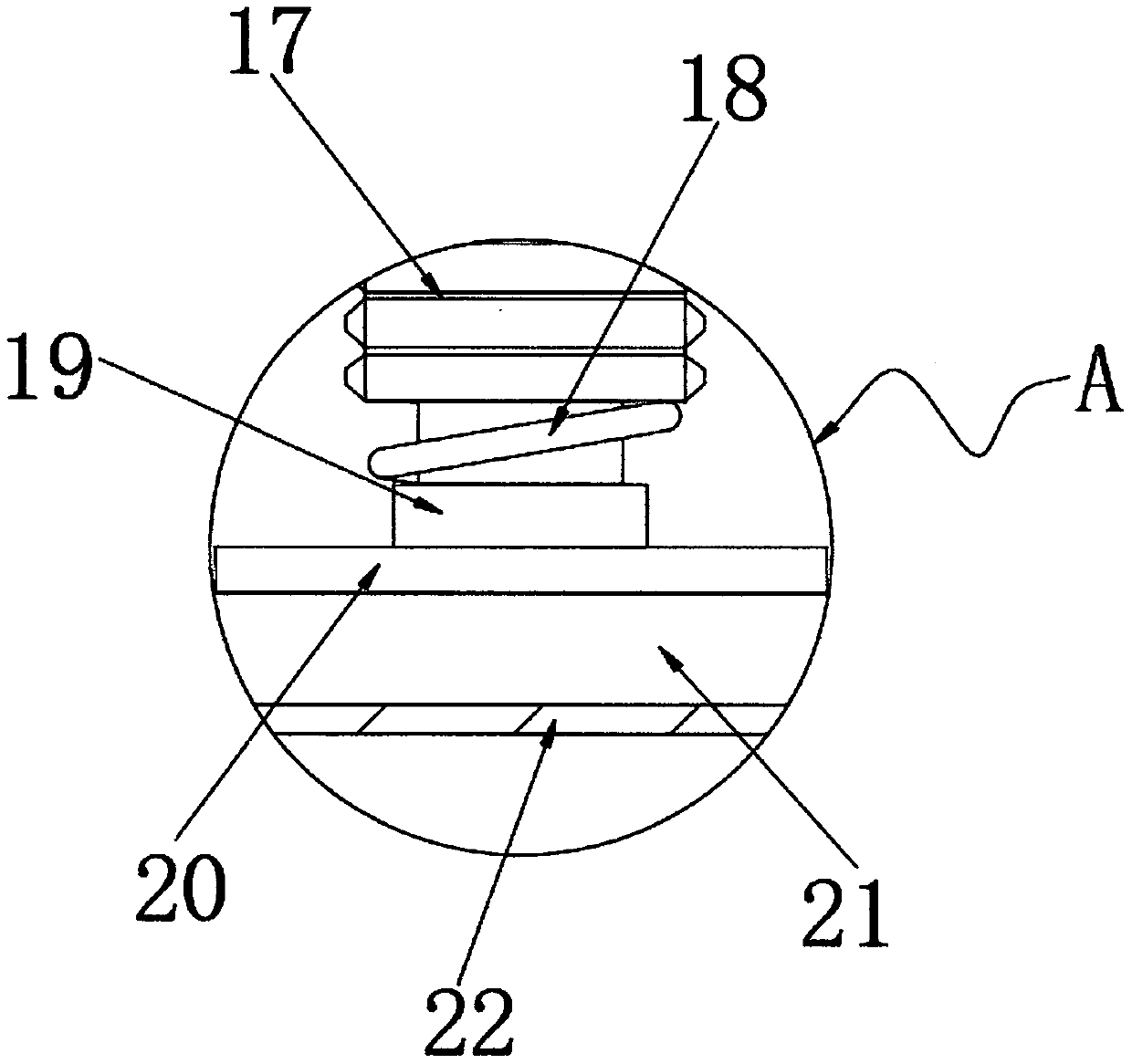

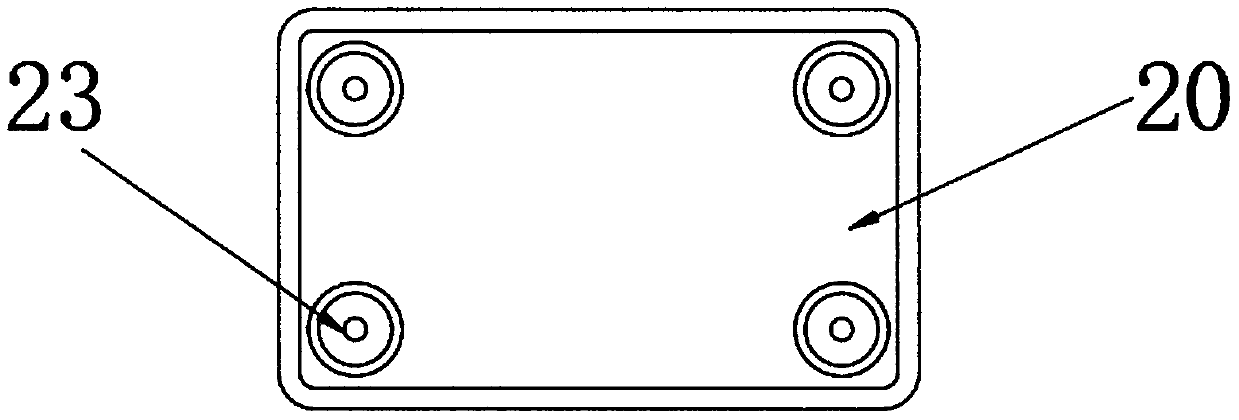

Rotary cutter for lawn mower and portable lawn mower using same

The invention discloses a rotary cutter for a lawn mower and a portable lawn mower using the same, which belong to the field of garden tools and are used for cleaning weeds during the greening processof gardens. The rotary cutter at least comprises a cutting tool installing shaft which is provided with a cutting tool rotating about the central axis of the installing shaft; a guiding member material which rotates with respective to the cutting tool installing shaft through a central part A is installed under the cutting tool; the central part A is connected with an edge A of the guiding membermaterial through a rotating surface A; the rotating surface A is formed by a ridge A rotating about the central axis of the cutting tool installing shaft and the ridge A is positioned outside a member rotating about the cutting tool installing shaft outside the cutting tool. In view of the above technical solution, the present invention can provide a rotary cutter for a lawn mower that is safe, efficient, and easy to adjust and maintain, and a portable mower using the same.

Owner:YITIANJI POWER MACHINERY RES DEV LINYI

Clinical hemostasis rescue device for cardiology department

InactiveCN109620336AAvoid direct contactReduced likelihood of wearSurgeryNursing bedsHospital bedMedical staff

The invention belongs to the technical field of medical apparatuses, and particularly discloses a clinical hemostasis rescue device for the cardiology department. The clinical hemostasis rescue devicecomprises a first clamping plate of an L-shaped structure. A second clamping plate is installed on the upper surface of the first clamping plate. A second bolt is rotationally connected with the upper surface of the second clamping plate. The second bolt penetrates through the second clamping plate and extends to the outside. The rear side, close to the second bolt, of the second clamping plate is fixedly provided with a sleeve. The inner side wall of the sleeve is slidingly connected with a stand column. If the distance between the first clamping plate and the second clamping plate is largerthan the width of a hospital bed or a tabletop, the first clamping plate downwards slides, and the width of the second clamping plate is increased through a welding plate; when the widths of the first clamping plate, the second clamping plate and the welding plate are larger than the width of the hospital bed or the tabletop, medical staff make the first bolt penetrate through the first clampingplate and make contact with the welding plate, the welding plate and the first clamping plate are fixed, and the device can be conveniently fixed by the medical staff according to different fixing occasions.

Owner:李玉耕

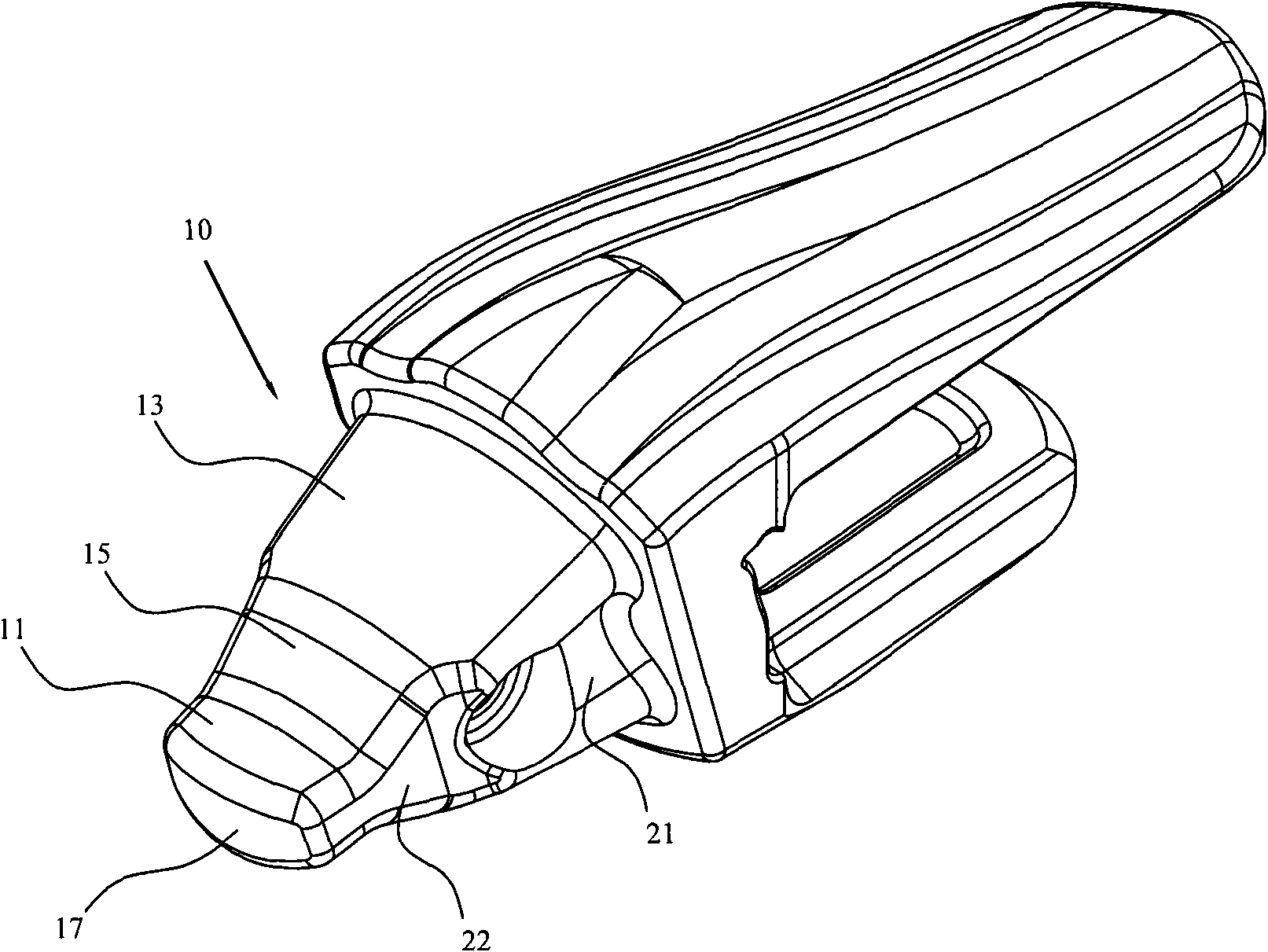

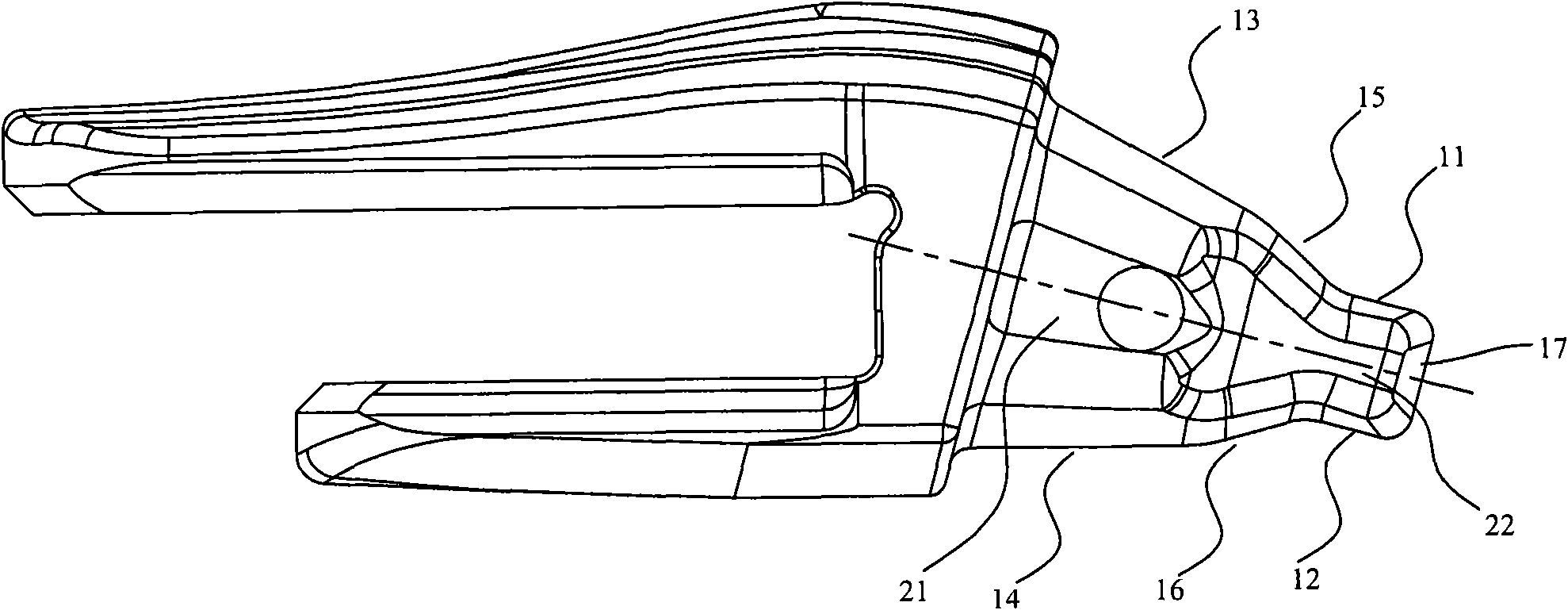

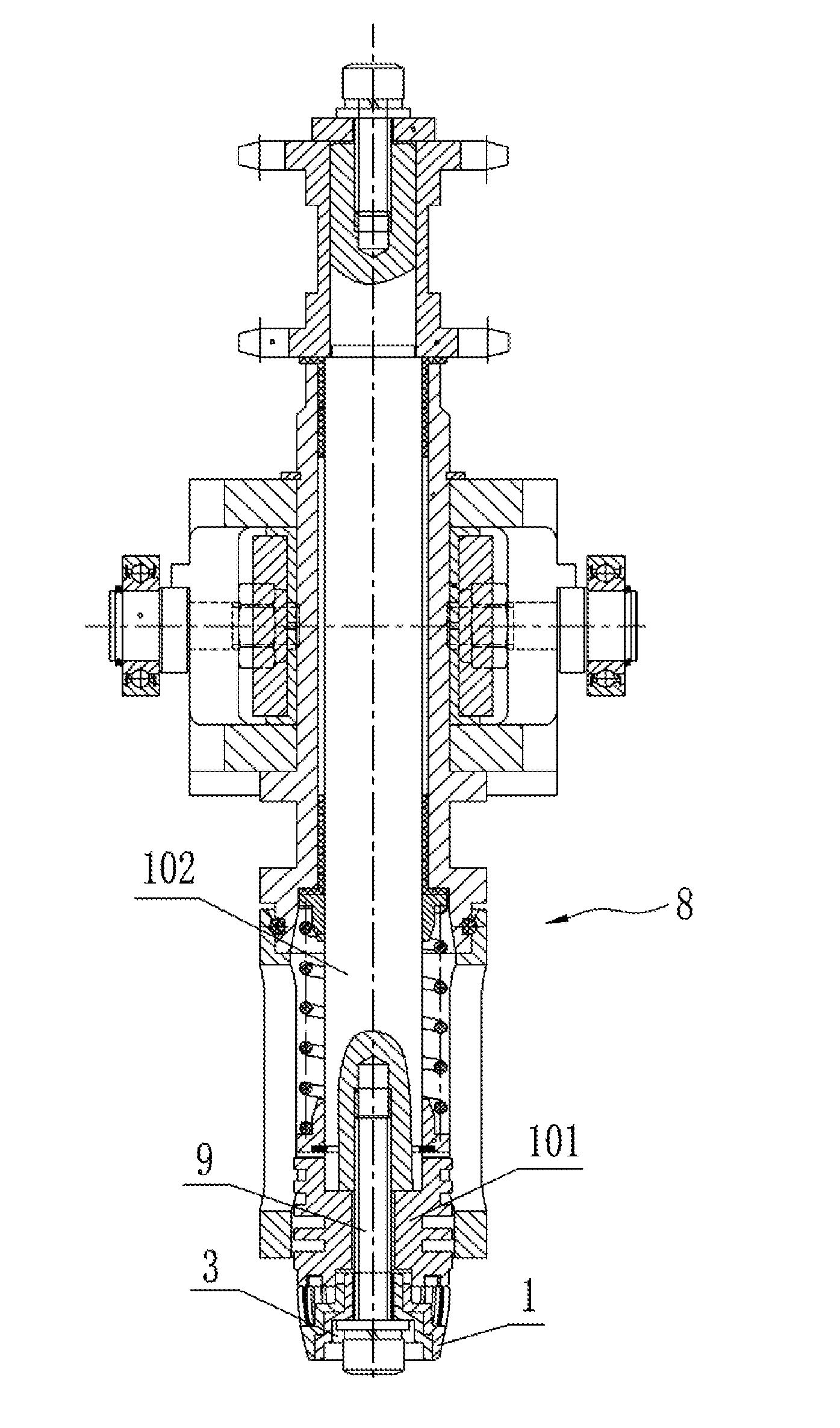

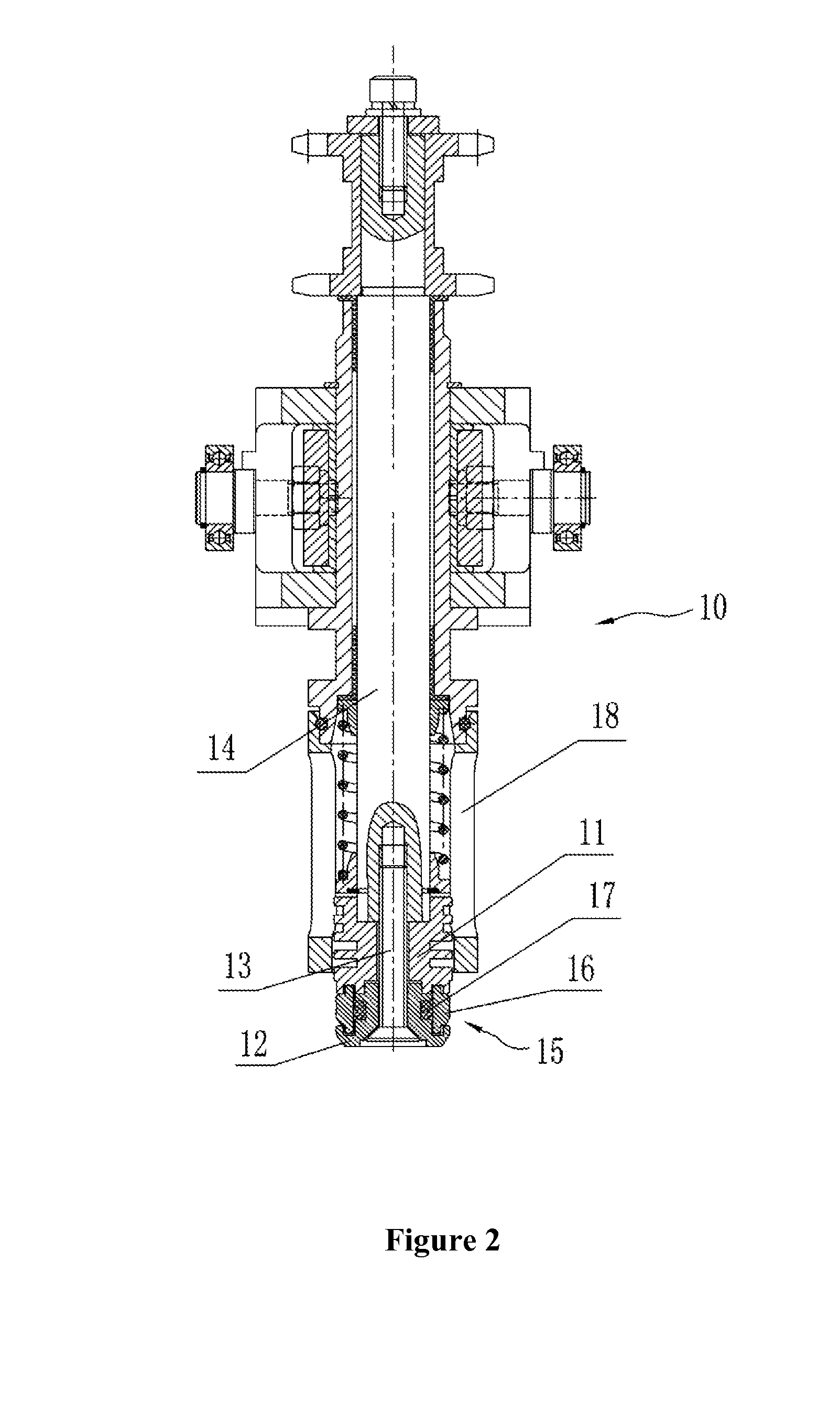

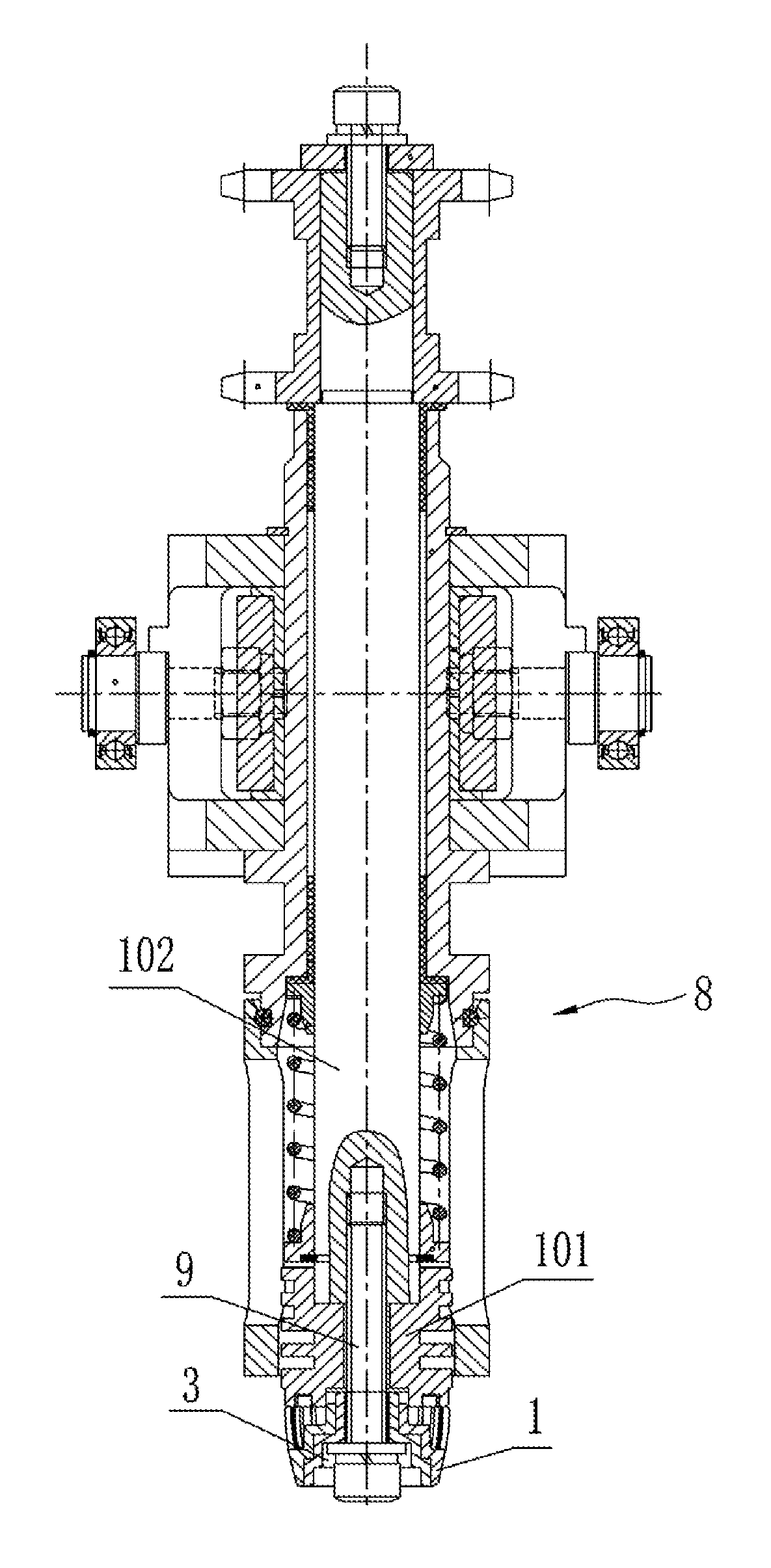

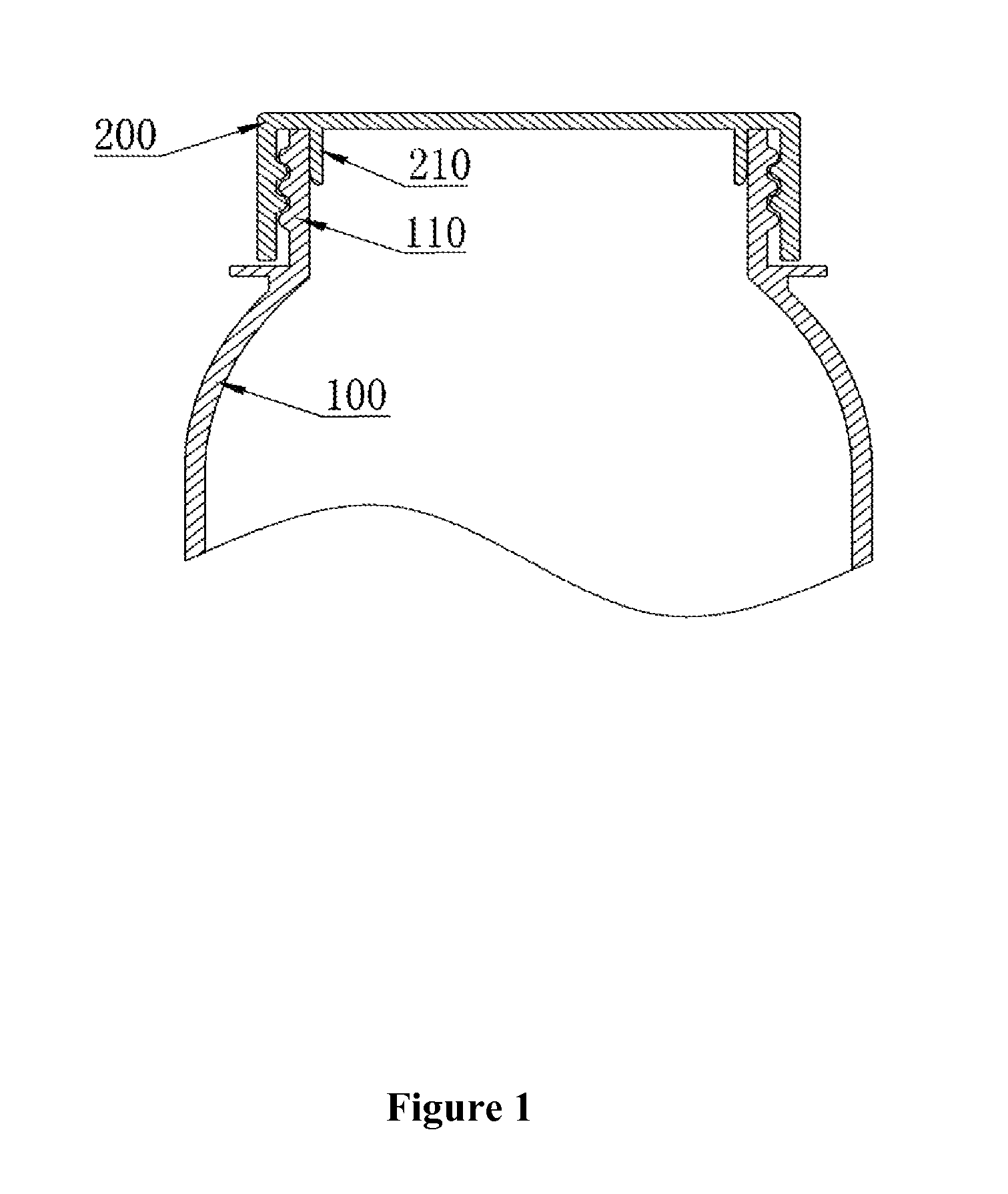

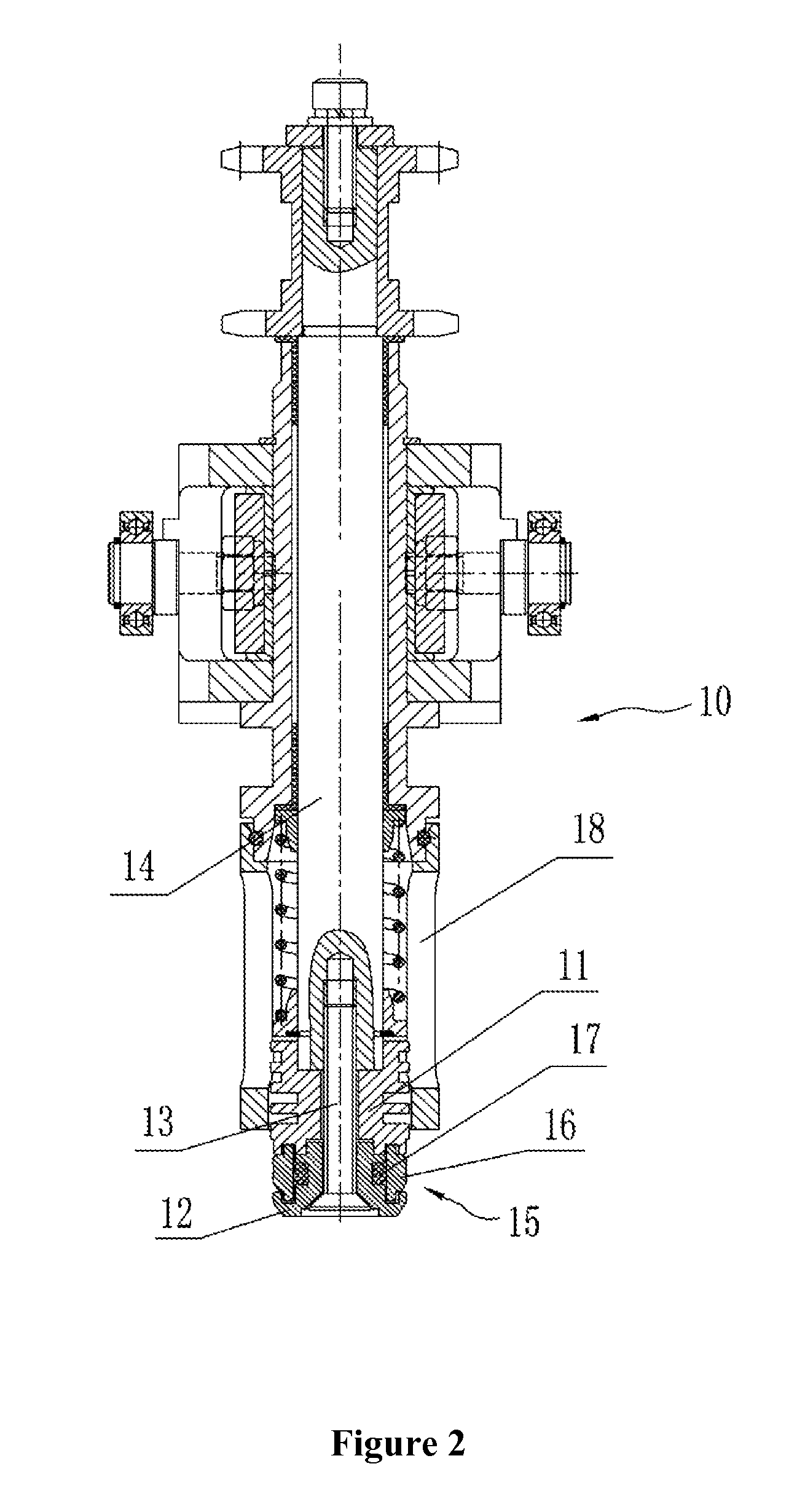

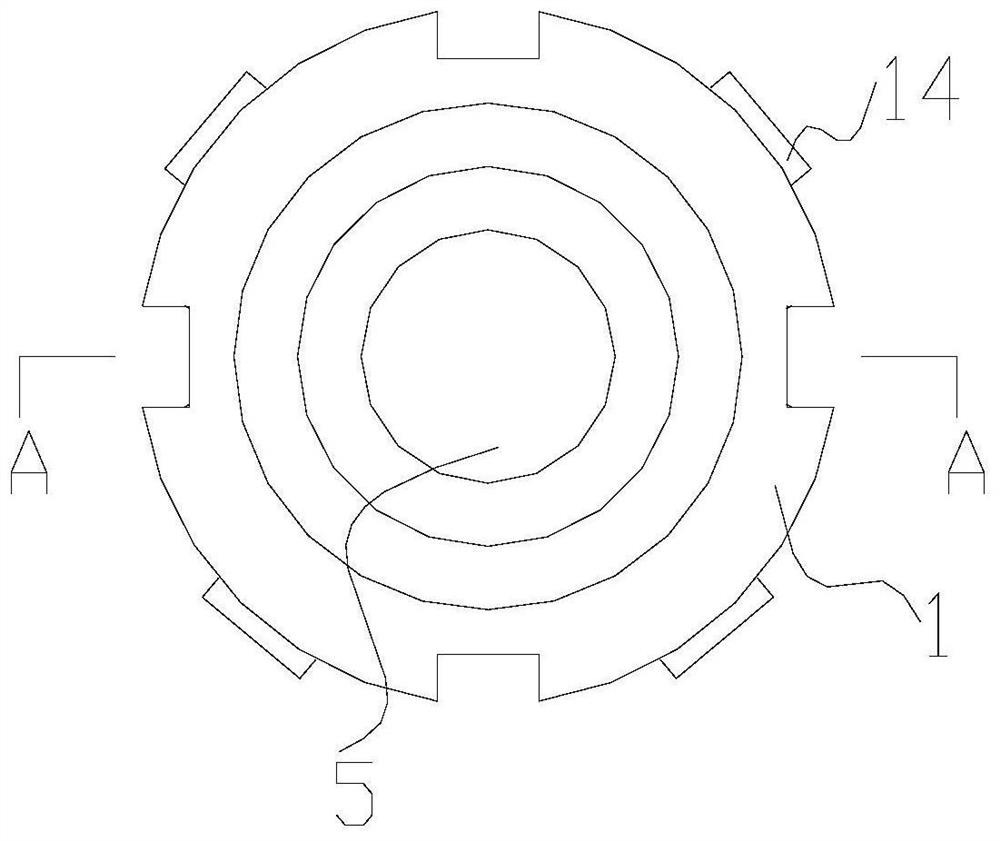

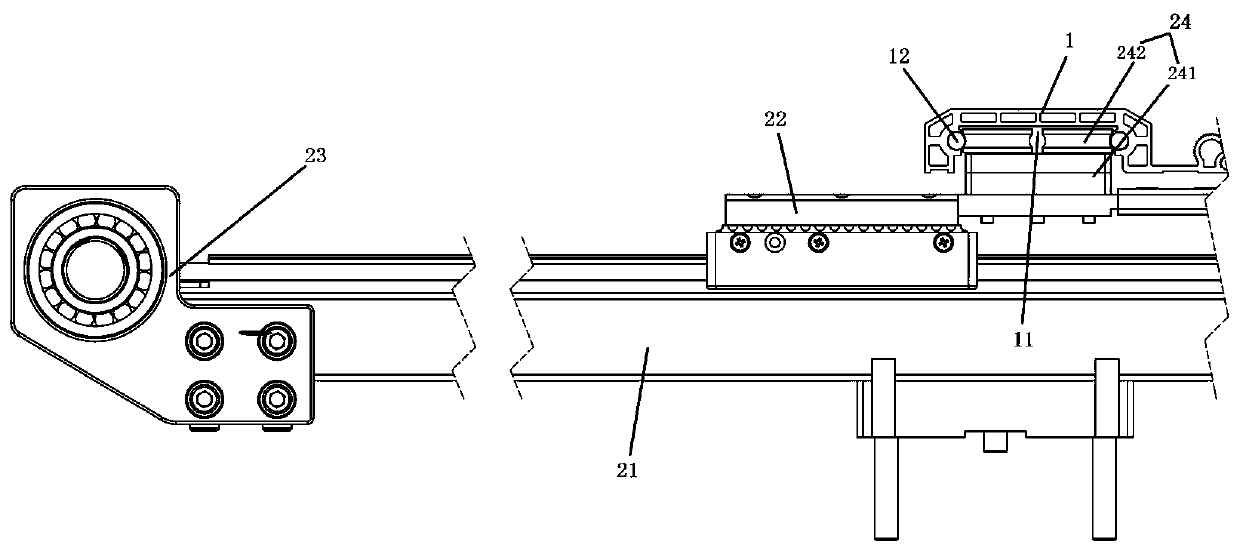

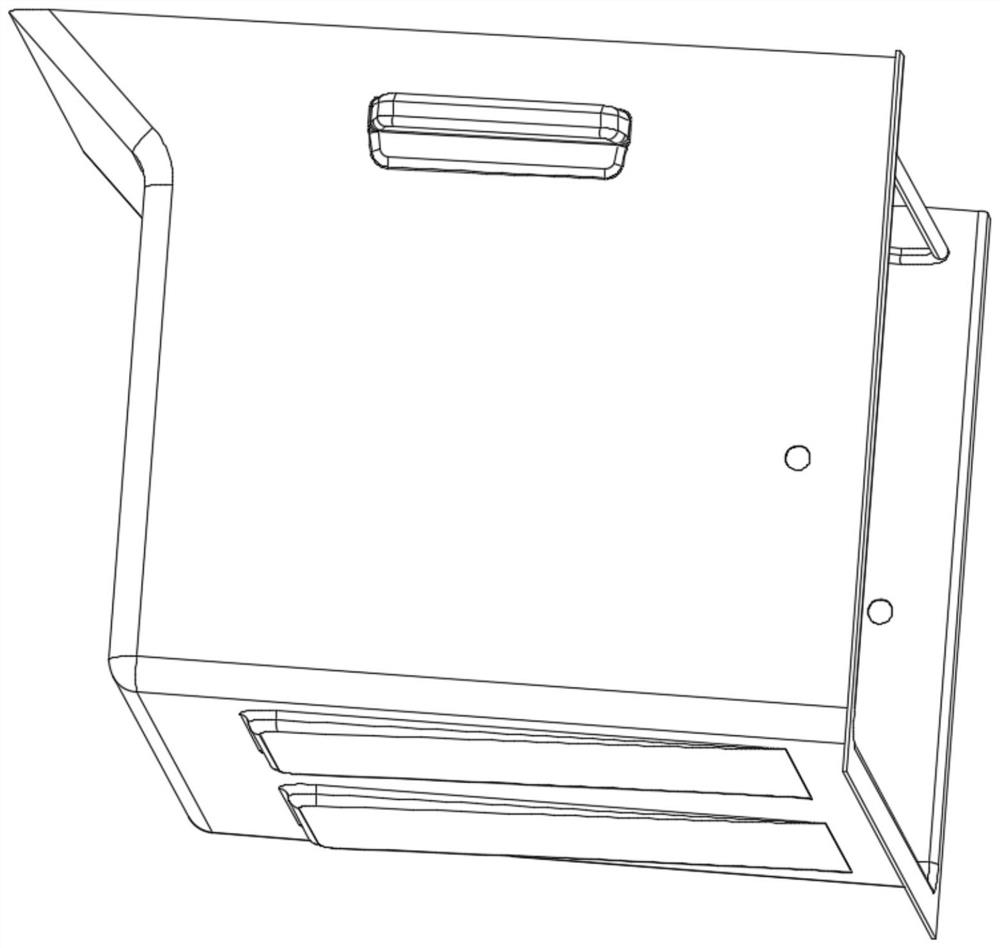

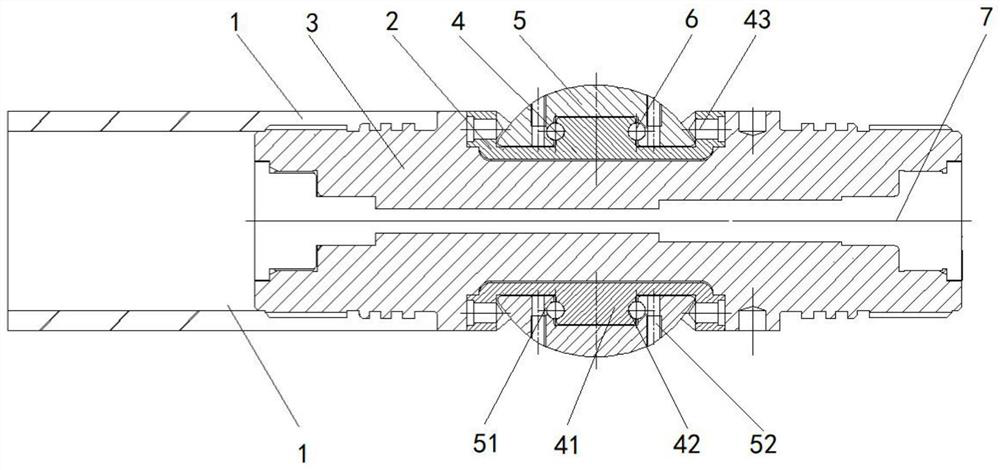

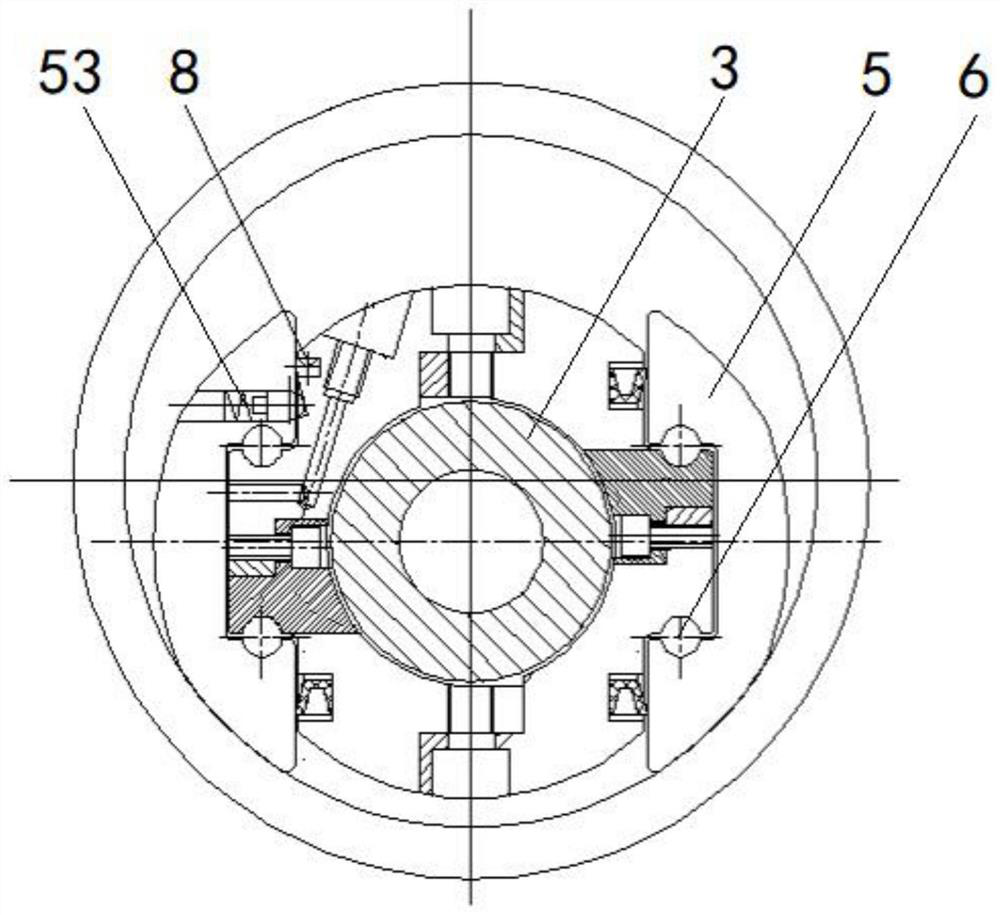

Preform Clamping Head

InactiveUS20130087964A1Reduce probability of abrasionStably rotatePositioning apparatusMetal-working holdersEngineeringBottle

A preform clamping head which is mounted at the lower part of a heating chain (8) includes an integral annular sleeve body (1), the outer surface of which inclines outwardly from bottom to top and the upper part of which is provided with a retracting space (2) for the inward retracting of the annular sleeve body when it is pressed. The invention has simple manufacture process and low manufacture cost. By means of the integral molding mode, the axial requirement of the preform clamping head is easier to satisfy, so that the bottle preform clamped on the outer surface of the sleeve body is capable of rotating stably along the heating chain and can be heated more uniformly during the heating process.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

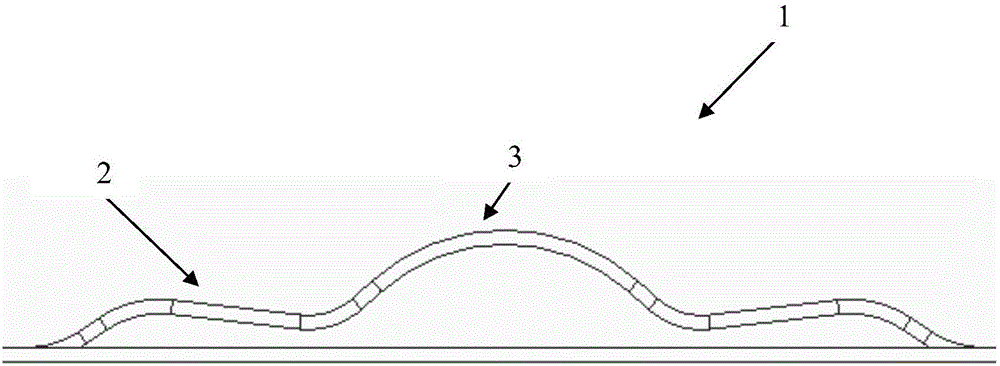

Three-arc spring for grid positioning and utilization method of three-arc spring

ActiveCN106251913AAvoid damageMeet the clamping force requirementsNuclear energy generationReactor fuel elementsNuclear reactorNuclear reactor core

The invention relates to nuclear reactor core fuel components and discloses a three-arc spring for grid positioning and a utilization method of the three-arc spring. The three-arc spring which is composed of three waved arcs is used for grid positioning and longitudinally arranged in a grid, the length direction of the three-arc spring is parallel to that of a to-be-positioned object, and the three arcs are in two heights. Contact surfaces of the arcs of the three-arc spring and the to-be-positioned object are arc, one side of each of the first arcs 2 on two sides is connected with the grid, and the other side of each of the first arcs 2 are connected with the second arc 3 in the middle. When the three-arc spring is used, the three-arc spring for grid positioning is arranged in the grid longitudinally, outer sides of the first arcs 2 on two sides of the three-arc spring formed by the three arcs are enabled to connect with the grid, and the arcs having arc contact surfaces with the to-be-positioned object are enabled to contact with the to-be-positioned object.

Owner:上海核工程研究设计院股份有限公司

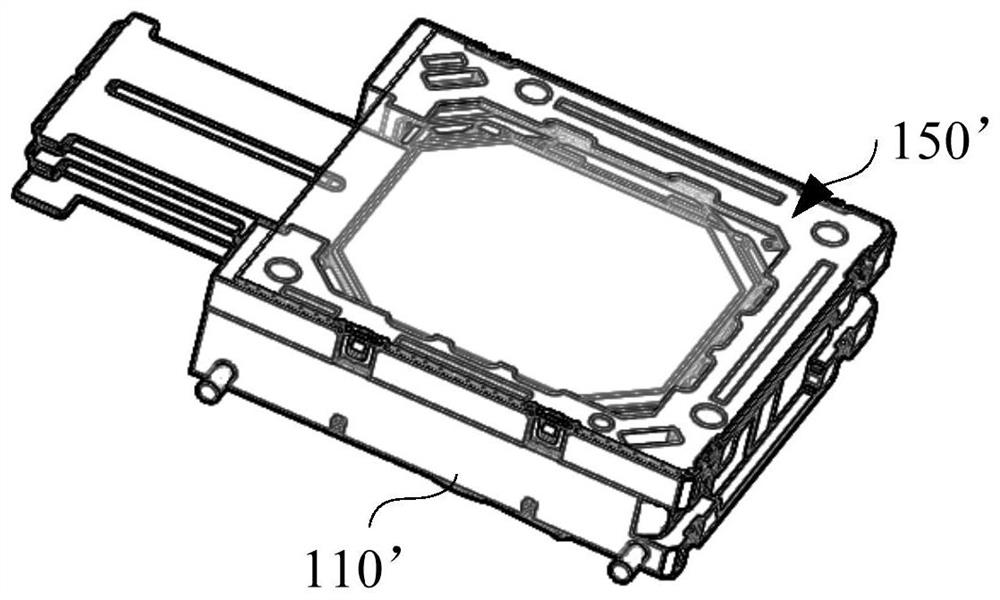

Camera module and electronic equipment

ActiveCN113079289ALower protrusion heightHigh mechanical reliabilityTelevision system detailsColor television detailsEngineeringCamera module

The invention provides a camera module and electronic equipment. The camera module comprises a camera assembly; a decoration assembly which movably covers the camera assembly; and a telescopic mechanism component which is arranged on the peripheral sides of the camera assembly and the decoration assembly, wherein the telescopic mechanism component comprises a first guide part, the decoration assembly is movably arranged on the first guide part, and the decoration assembly can move close to or away from the camera assembly along with movement of the telescopic mechanism component. According to the embodiment of the invention, while the excellent performance of the camera module is ensured, the protruding height of the camera module on the electronic equipment can be reduced when the camera module is not used, so that on one hand, the aesthetic degree of the appearance of the electronic equipment is improved, and on the other hand, the mechanical reliability of the camera module on the electronic equipment is improved; and the possibility that the camera module is broken or worn is reduced.

Owner:VIVO MOBILE COMM CO LTD

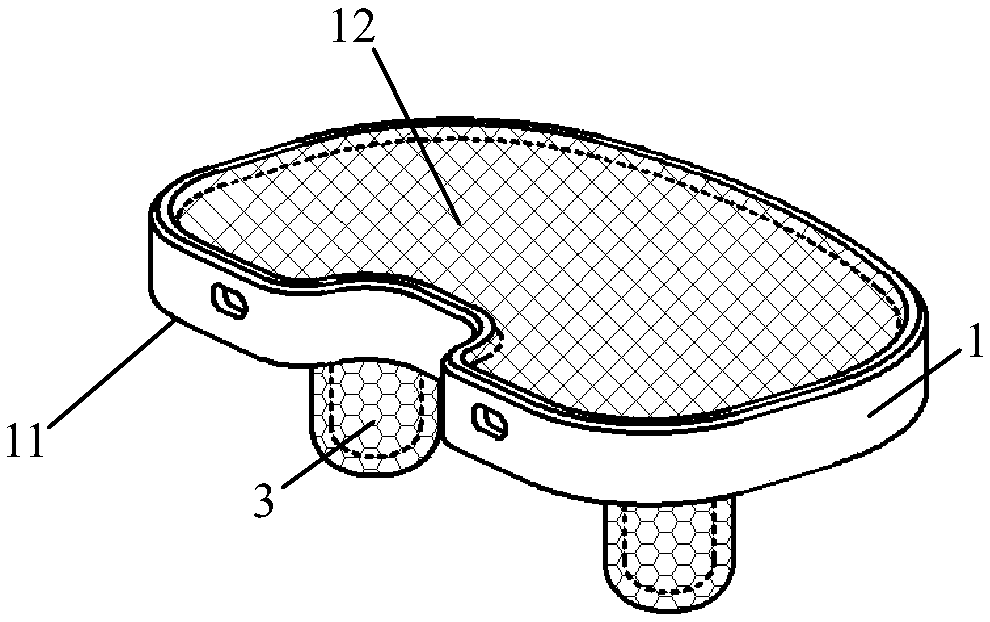

Uncemented tibial component of trabecular structure and making method of uncemented tibial component

The invention provides an uncemented tibial component of a trabecular structure. The uncemented tibial component comprises a tibial plateau, a liner and the trabecular structure, wherein the trabecular structure is arranged on the lower surface of the tibial plateau; the tibial plateau and the trabecular structure are integrally molded; the liner is melted on the upper surface of the tibial plateau; and the upper surface of the tibial plateau is a rough surface having a micro-porous structure. Preferably, the porosity of the trabecular structure is 50-65%. The aperture of the trabecular structure is 300-800[mu]m. The tibial plateau is a metal tibial plateau. The trabecular structure is a metal trabecular structure. The liner is a non-metal liner. The invention also provides a making methodof the uncemented tibial component of the trabecular structure. The uncemented tibial component of the trabecular structure provided by the invention is firm and stable in structure, and a postoperative early fixing effect and long-term stabilization can be improved; and the uncemented tibial component is simple and convenient to use, long in service life, skillful in design, concise in structureand simple and convenient to make.

Owner:上海科太迈迪医疗器械有限公司

Vacuum hard coating water needle plate and manufacturing method thereof

ActiveCN104975435AReduced likelihood of wearExtended service lifeVacuum evaporation coatingSputtering coatingWater sprayMaterials science

The invention discloses a vacuum hard coating water needle plate and a manufacturing method thereof. The water needle plate comprises a strip and multiple water spraying holes arranged on the strip, and the water spraying holes are provided with coatings which are formed by a chemical vapor deposition method, a physical vapor deposition method or a plasma-enhanced chemical vapor deposition method. According to the vacuum hard coating water needle plate and the manufacturing method thereof, the wear-resisting performance of the surface of the water needle plate and the water spraying holes can be significantly improved.

Owner:NAXAU NEW MATERIALS CORP +1

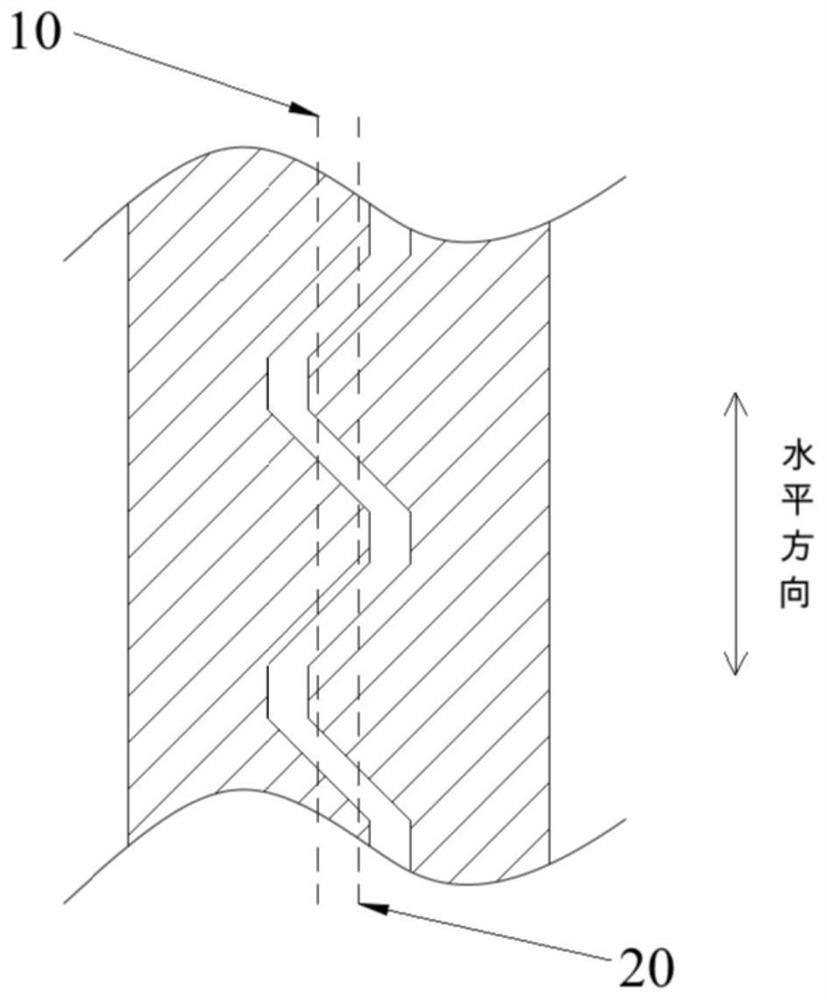

Tire with three-dimensional steel sheet pattern arranged on tread

ActiveCN112248721AReduce sharpnessReduce wearTyre tread bands/patternsStructural engineeringMechanical engineering

The invention discloses a tire with a three-dimensional steel sheet pattern arranged on a tread. The three-dimensional steel sheet pattern comprises a first pattern surface and a second pattern surface which are vertically and oppositely arranged and spaced by a pattern gap, and the first pattern surface and the second pattern surface are alternately provided with grooves and convex blocks in thehorizontal direction and the vertical direction; each convex block on any pattern surface has a groove corresponding to the convex block on the other pattern surface; each convex block comprises a round or oval convex block top face which is vertically arranged and a convex block inclined face which transits from the convex block top face to the pattern face where the convex block inclined face islocated; the intersection lines of the convex block inclined surface of one convex block and the pattern surface where the convex block is located form a first polygon; each groove comprises a circular or oval groove bottom face which is vertically arranged and a groove inclined face which is in transition from the groove bottom face to the pattern surface where the groove inclined face is located, and the intersecting lines of the groove inclined face of one groove and the pattern surface where the groove inclined face is located form a second polygon.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

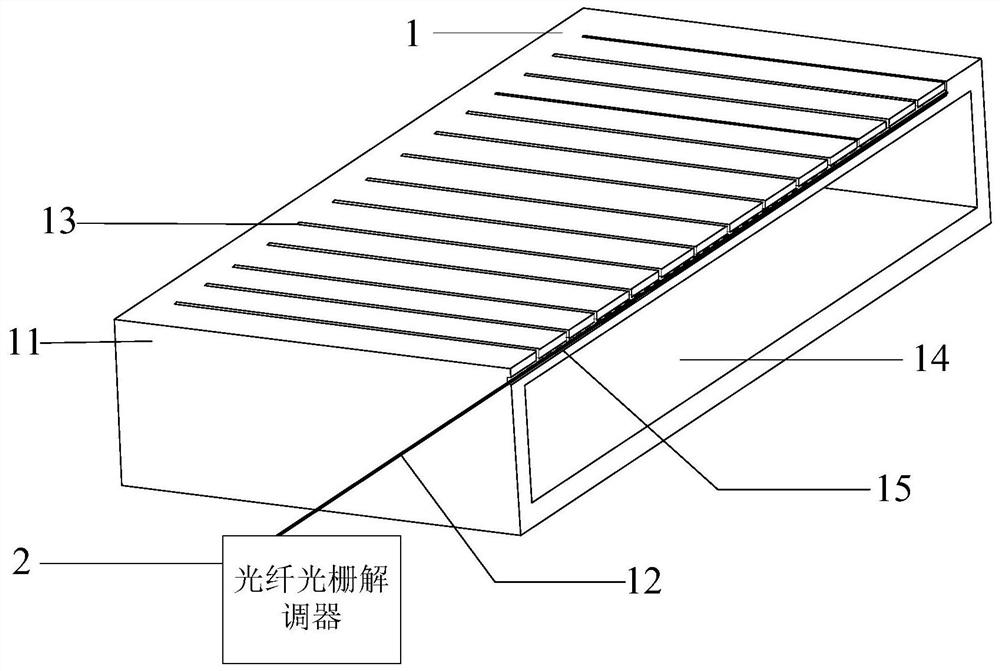

Crystallizer, method for measuring height of liquid level of molten steel in crystallizer and related device

The embodiment of the invention provides a crystallizer, a method for measuring the height of the liquid level of molten steel in the crystallizer and a related device. The crystallizer comprises a crystallizer body and a plurality of optical fibers. A plurality of parallel first grooves are formed in at least one side wall of the crystallizer body, and the same ends of the first grooves in the length direction extend to an upper opening of the crystallizer. One end of each optical fiber is independently arranged in the corresponding first groove, and the other ends of the optical fibers extend out of the corresponding first grooves and are used for being connected with a fiber grating demodulator. The accuracy and stability of crystallizer temperature measurement can be effectively improved, and then the accuracy and efficiency of acquiring the molten steel liquid level fluctuation state in the crystallizer through the crystallizer temperature measurement result can be effectively improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

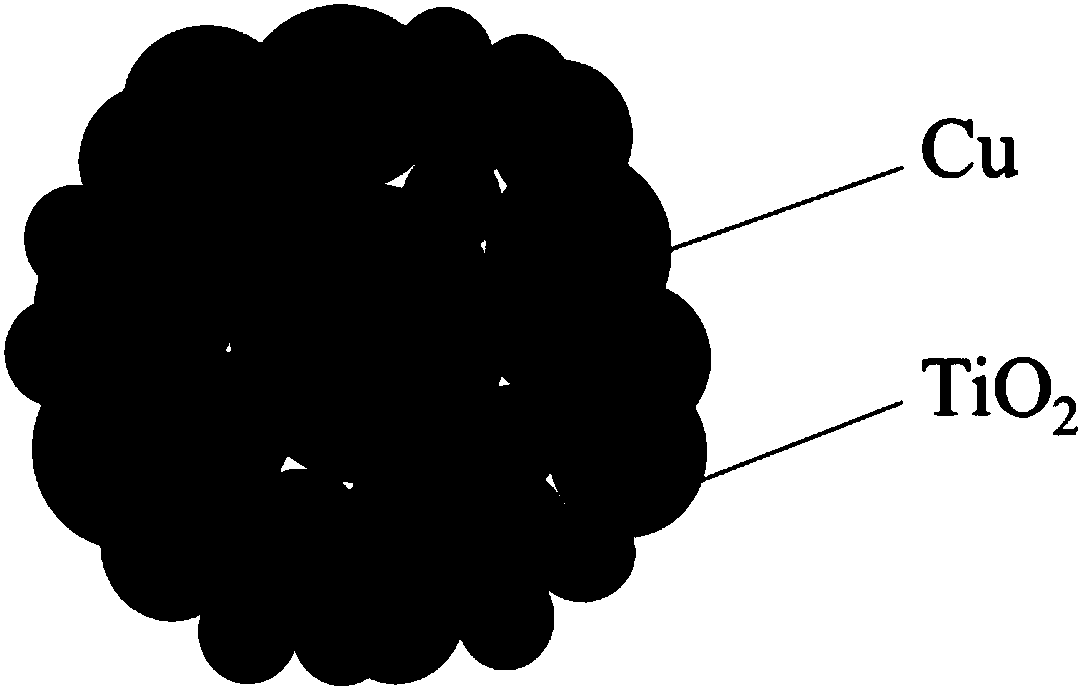

High-performance and long-service-life space equipment precise conductive slip ring and preparing method thereof

ActiveCN107794486APrevent oxidationReduce contact areaMolten spray coatingRotary current collectorCore shellPlasma sprayed

The invention relates to a high-performance and long-service-life space equipment precise conductive slip ring and a preparing method thereof. The conductive slip ring is composed of a single metal base body and a conductive abrasion resisting, corrosion preventing and self-lubricating integrated coating. The surface coating is formed in the manner that Cu-TiO2 composite powder of a core-shell structure is directly subjected to plasma spraying to a slip ring base body. The coating comprises components including, by mass percent, 62%-75% of Ti4O7, 12%-20% of Cu, 10%-15% of TixO2x-1 and 3%-10% of TiO2, wherein x is larger than or equal to 5 and smaller than or equal to 10. The surface multifunctional composite coating serves as a work layer of the conductive slip ring, good abrasion resistance of the composite coating is utilized, the metal base body of the conductive slip ring is protected, accordingly, the service life of the conductive slip ring is greatly prolonged, and long-time stable work reliability is improved. Meanwhile, the proportion of Ti4O7 in the composite coating is small, lightweight of the conductive slip ring is facilitated, the specific energy is improved, and good application prospects are achieved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

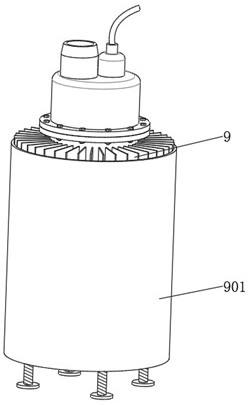

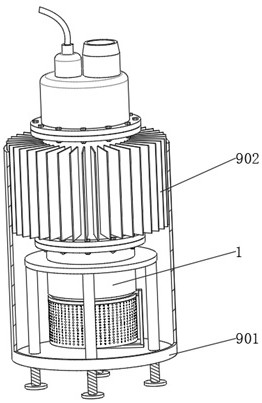

Oil pump with anti-blocking function

ActiveCN110821841AImprove the stability of useImprove stabilityPump componentsPump installationsHeat conductingElectric machinery

The invention relates to the technical field of oil pumps, in particular to an oil pump with an anti-blocking function. The oil pump main body with the anti-blocking function is characterized by comprising an oil pump body; the surface of the oil pump body is sleeved with a heat conducting device; a filter screen is arranged on the surface of the oil pump body in a sleeving mode and positioned inside the heat conducting device; a supporting device penetrating through the heat conducting device is arranged at the top of the filter screen; a cleaning device capable of rotating in a sliding groove is arranged inside the filter screen; a speed regulating device is arranged at an input end of the cleaning device; a connecting column is arranged between the top of the speed regulating device andthe inner wall of the oil pump body; and two ends of the connecting column are fixedly connected with the speed regulating device and the oil pump main body respectively. By means of the oil pump main body with the anti-blocking function, the use stability and cleanliness of the oil pump are improved, overload work of a motor in the oil pump is reduced, and the service life of the motor is prolonged; and moreover, the filter screen is further cleaned, so that on the one hand, the filter screen is prevented from being blocked, and on the other hand, the service life of the filter screen is prolonged.

Owner:惠州市正康实业有限公司

Excavation tooth components, tooth holders and bucket teeth

ActiveCN101768992BGuaranteed stabilityGuarantee the safety of useSoil-shifting machines/dredgersEngineeringTooth cavity

An excavation tooth assembly, a tooth seat and a bucket tooth. The excavation tooth assembly includes the tooth seat and the bucket tooth, and includes a locking member. A cavity is provided at the rear of the bucket tooth, and a tooth seat head is provided at the front end of the tooth seat. The cavity and the adapter head are firmly combined through the locking piece. The upper part of the adapter head is provided with a first transition connection surface, the first mating surface and the third mating surface, and the lower part of the adapter head is provided with a second transition connection surface , the second mating surface and the fourth mating surface, the first mating surface and the third mating surface are connected by the first transition connection surface, the second mating surface and the fourth mating surface are connected by the second transition connection surface, the first mating surface and the The second mating surface forms a predetermined angle with the central axis of the tooth seat head respectively, the third mating surface and the fourth mating surface are respectively parallel to the central axis of the tooth seat head, and the inner surface of the cavity of the bucket teeth provides Multiple mating surfaces in surface contact.

Owner:NINGBO ZHEDONG PRECISION CASTING

Preform clamping head

InactiveUS9327373B2Smooth rotationEasy to installPositioning apparatusMetal-working holdersEngineeringBottle

A preform clamping head which is mounted at the lower part of a heating chain (8) includes an integral annular sleeve body (1), the outer surface of which inclines outwardly from bottom to top and the upper part of which is provided with a retracting space (2) for the inward retracting of the annular sleeve body when it is pressed. The invention has simple manufacture process and low manufacture cost. By means of the integral molding mode, the axial requirement of the preform clamping head is easier to satisfy, so that the bottle preform clamped on the outer surface of the sleeve body is capable of rotating stably along the heating chain and can be heated more uniformly during the heating process.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

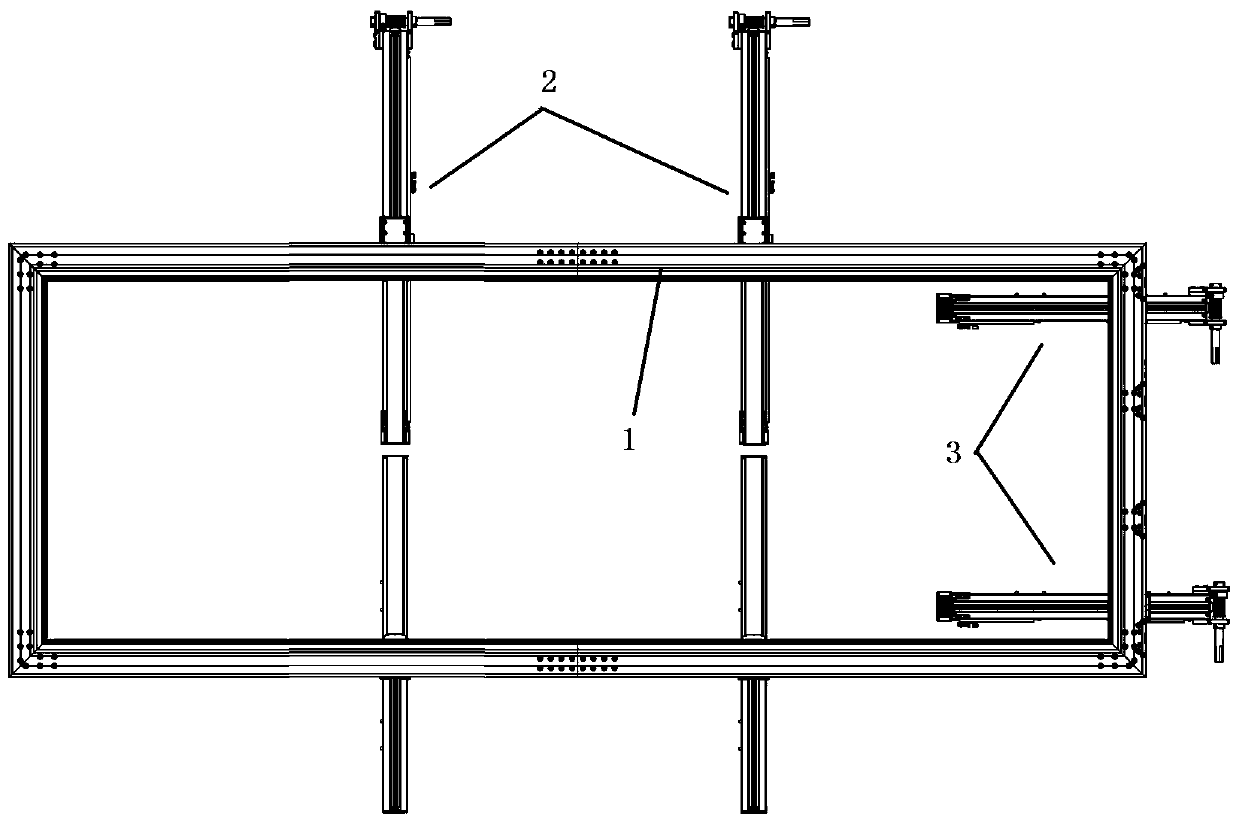

A gear grinding tool for internal spline gear

ActiveCN111715949BPossibility of inelastic deformationReduces the possibility of inelastic deformationGear-cutting machinesGear teethGear grindingGear wheel

The invention provides a tooth grinding tool for internal spline gears, which includes a tooth grinding mandrel, a first nut, an elastic metal ring, an expansion sleeve and a second nut. The shank, the first external thread section, the tapered section and the second external thread section, the tapered section is small in front and large in the rear, the first nut is screwed on the first external thread section, a tapered hole is arranged in the expansion sleeve, and the expansion sleeve Located on the tapered section, the outer wall of the expansion sleeve is arranged with a plurality of spline teeth, the outer surface of the expansion sleeve is arranged with a plurality of through grooves, and the side wall of the expansion sleeve is also provided with a first opening. Filled with sponge, the sponge is impregnated with lubricating oil, the second nut is screwed on the second external thread segment, the elastic metal ring is provided with a second opening, the elastic metal ring includes multiple convex plates, and the multiple convex plates pass through the screw It is fixedly connected to the rear end face of the expansion sleeve. Due to the adoption of the above technical solution, the present invention can improve the fixing stability and the machining accuracy of the internal spline gear.

Owner:QIJIANG HEAVY DUTY TRUCK GEAR

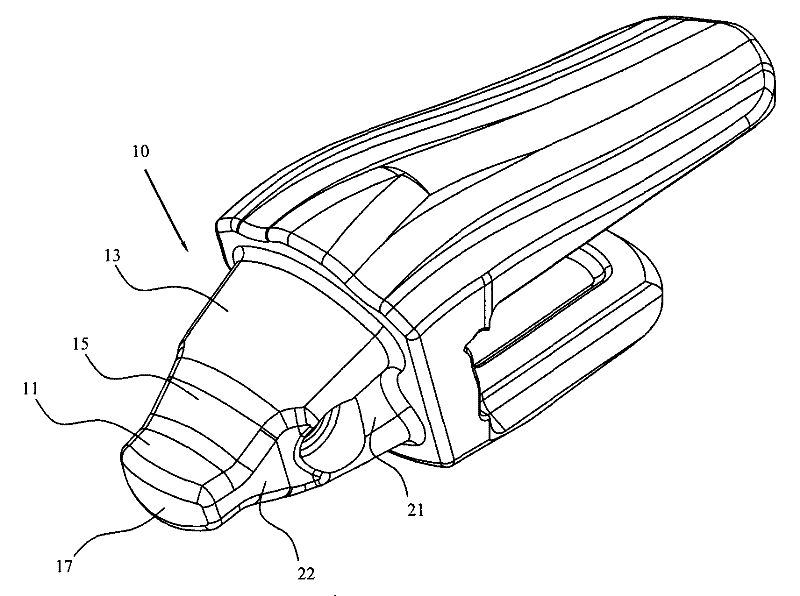

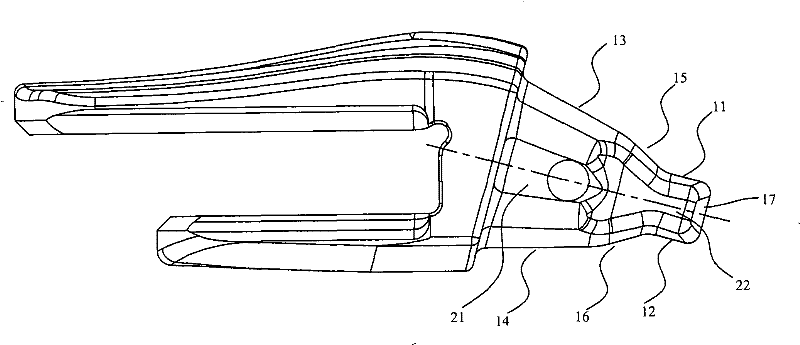

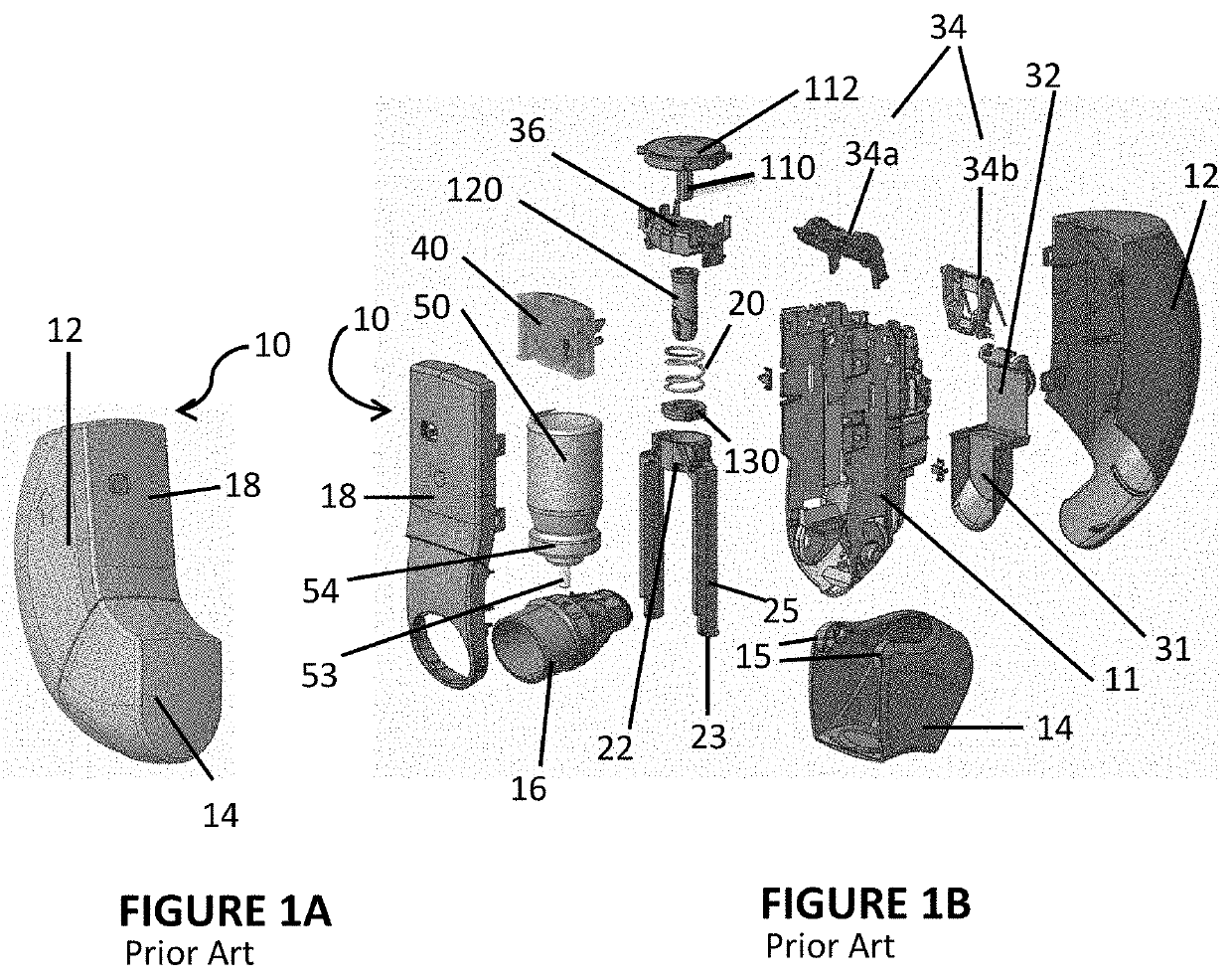

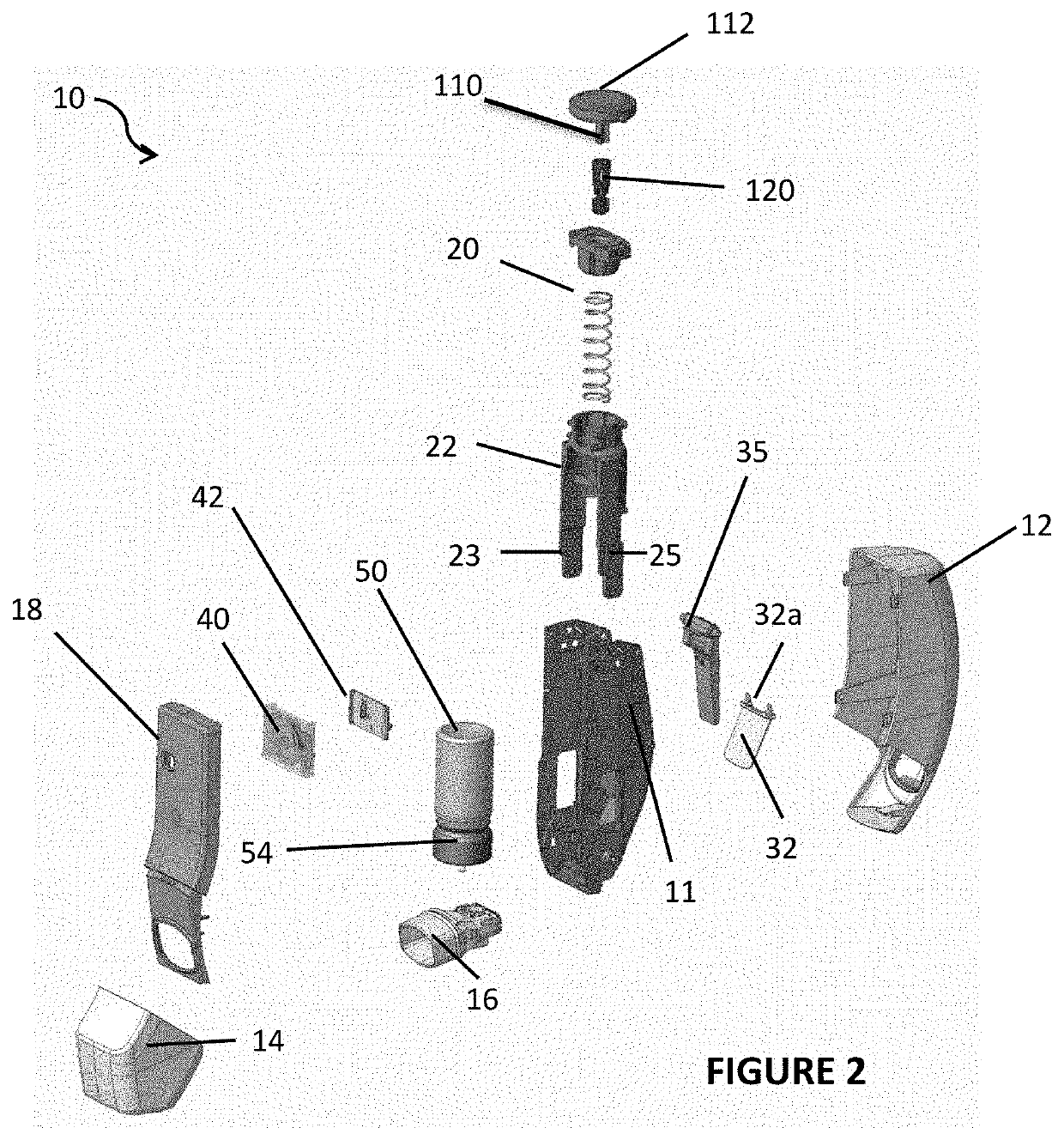

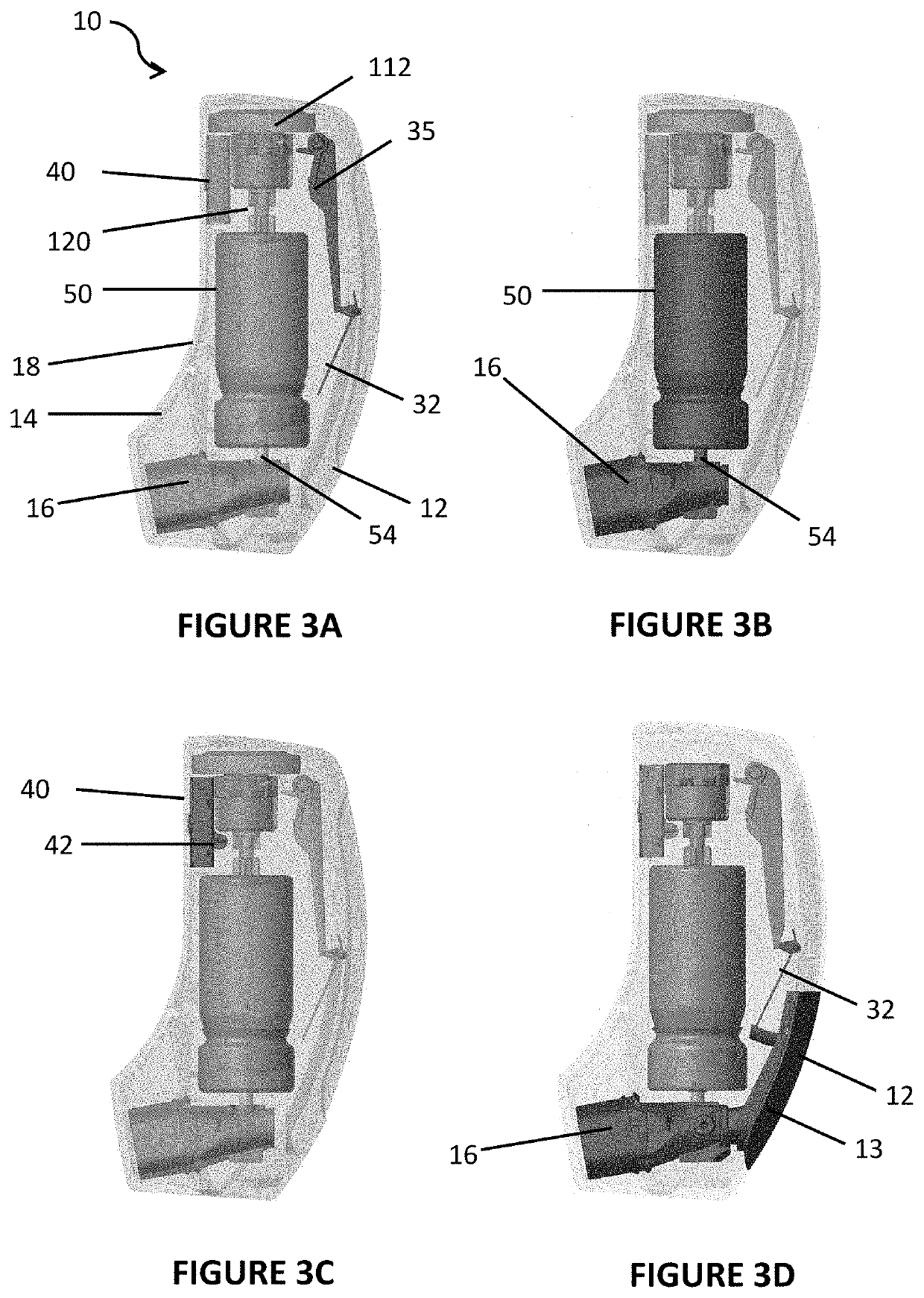

Inhaler

There is disclosed an inhaler 10 for delivery of a medicament by inhalation. The inhaler 10 comprises a drive mechanism comprising a canister drive 22 for receiving a canister 50 of medicament, a biasing means 20, and a trigger mechanism. The trigger mechanism comprises a latch 35. The latch 35 has a locked position in which it contacts the canister drive 22 to prevent linear movement of the canister drive 22 and holds the biasing means 20 in a loaded configuration; and an unlocked position in which the latch 35 is disengaged from the canister drive 22 and releases the biasing means 20 from the loaded configuration to drive the canister drive 22 from a rest position to an actuated position. The trigger mechanism comprises a blocker 32. The blocker 32 has a blocking position in which it contacts the latch 35 to block movement thereof from the locked position to the unlocked position; and a rotated position in which the blocker 32 is disengaged from the latch 35 and allows movement of the latch 35 from the locked position to the unlocked position. The blocker 32 is rotatable in response to a force applied to the blocker 32. A method of operation of an inhaler 10 is also disclosed.

Owner:ASTRAZENECA AB

Electrophotographic Photoreceptor, Process Cartridge, And Image-Forming Apparatus

The invention provides an electrophotographic photoreceptor, a process cartridge, and an image-forming apparatus. The electrophotographic photoreceptor includes a conductive substrate and a photosensitive layer disposed on the conductive substrate which serves as an outermost surface of the electrophotographic photoreceptor. The electrophotographic photoreceptor satisfies YC-YA>=0.1 MPa, YC-YB>=0.1 MPa, and YC<=4.5 MPa, where YA, YB, and YC (MPa) represent the Young's moduli of a surface of the photosensitive layer determined by nanoindentation at an indentation depth of 500 nm at end portionsA and B extending from a position 10 mm to a position 70 mm from the respective edges of the photosensitive layer toward the center of the photosensitive layer in an axial direction of the electrophotographic photoreceptor and a central portion C extending from a position 20 mm in front of and to a position 20 mm behind the center of the photosensitive layer in the axial direction of the electrophotographic photoreceptor, respectively.

Owner:FUJIFILM BUSINESS INNOVATION CORP

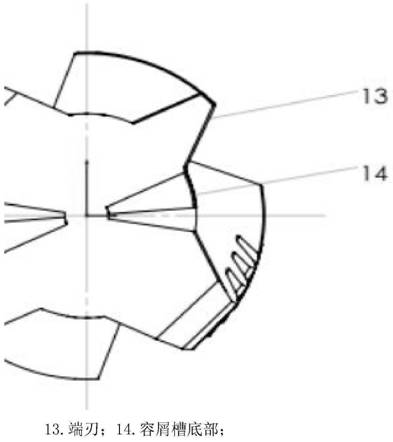

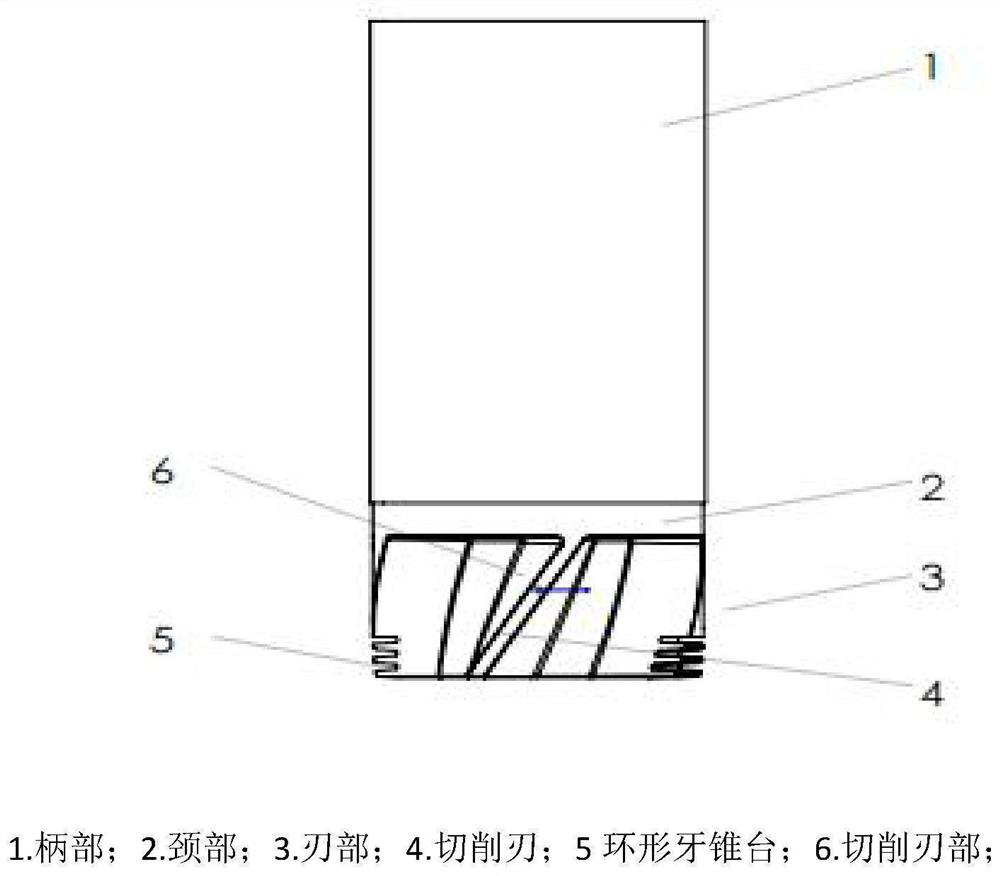

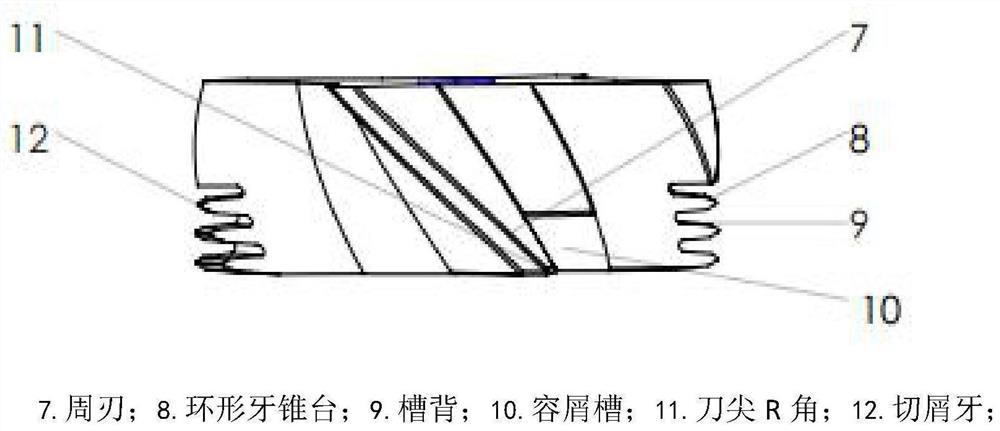

Ceramic milling cutter suitable for rough machining

The invention relates to a ceramic milling cutter suitable for rough machining. The milling cutter is made of AL2O3 / TiB2 metal ceramic materials and is mainly composed of a handle part, a neck part and a cutting edge part, the front end of the handle part is connected with the rear end of the neck part, the front end of the neck part is connected with the rear end of the cutting edge part, the handle part is used for installing the cutter and a cutter handle, the neck part is used for avoiding interference during cutting of the milling cutter, and the cutting edge part is a part, actually participating in cutting of a nickel-based high-temperature alloy workpiece, of the milling cutter. The cutting edge part is divided into two parts, the first part is a spiral cutting edge part which comprises a cutting edge and chip containing grooves, the cutting edge is composed of circumferential edges, end edges and tool nose R angles connecting the circumferential edges and the end edges, the tool nose R angles are used for connecting the circumferential edges and the end edges at the corresponding positions, and the two end edges are evenly distributed in the radial direction relative to the center of the front end face of the cutting edge part. Each end edge corresponds to one tool nose R angle and one circumferential edge, the circumferential edges are spirally arranged on the outer circumferential ring face of the cutting edge part at intervals, and the chip containing grooves are spirally arranged on the inner circumferential ring face of the cutting edge part at intervals (located behind an annular tooth frustum part and in front of the cutting edge part). The second part is the annular tooth frustum, at least three blades are arranged on the circumferential surface of the blade part, and a chip discharging groove is formed between every two adjacent blades. The blades are composed of cutting teeth which are arranged at equal intervals in the axial direction.

Owner:XIANGTAN UNIV

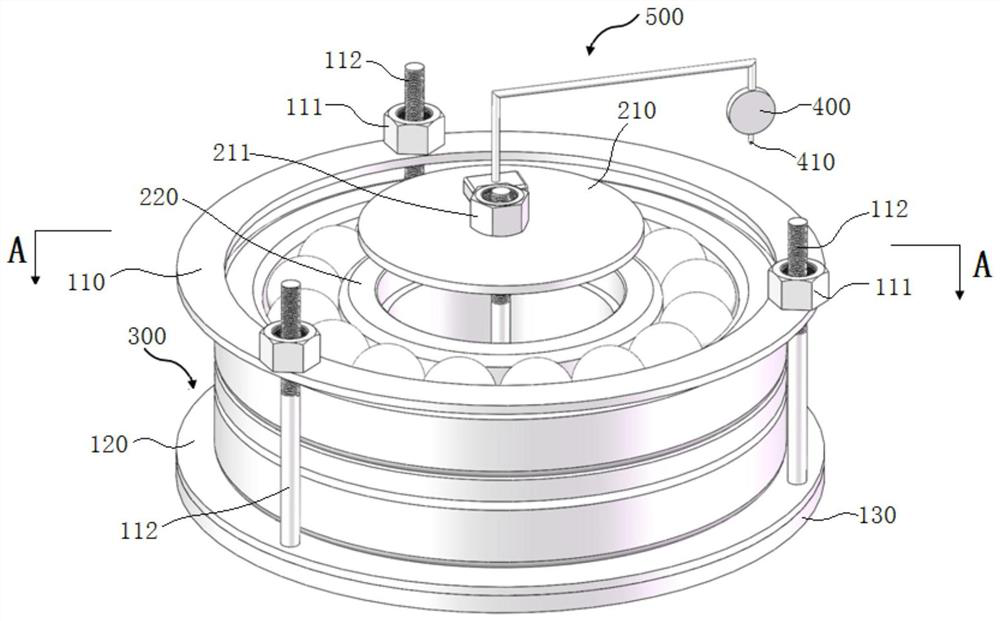

A device for measuring and adjusting thrust clearance of angular contact ball bearings

ActiveCN111571181BFast measurement speedIncrease the speed of adjustmentMetal working apparatusBall bearingPhysics

The invention discloses a thrust gap measurement and adjustment device of an angular contact ball bearing group, which belongs to the technical field of bearing measurement. The present invention includes an inner ring and an outer ring arranged sequentially from the inside to the outside. The outer ring is sheathed on the outer circumference of the inner ring, wherein the inner ring includes a hollow cylinder, and the upper and lower ends of the hollow cylinder are respectively provided with an inner ring pressure plate and an inner ring base. The inner ring pressure plate and the inner ring base are connected by an inner connecting column, and a dial indicator is arranged on the top of the inner ring pressure plate; The bases are connected by outer connecting columns, and the outer edge of the base of the outer ring is provided with supporting bosses around the circumference, and the supporting bosses extend in a direction away from the pressure ring of the outer ring. The purpose of the present invention is to overcome the disadvantages of complicated and laborious measurement and adjustment of the thrust gap during assembly of the existing angular contact ball bearings or the lack of accurate measurement, to speed up the measurement and adjustment speed, and to improve the accuracy of the measurement results.

Owner:MAANSHAN DANGTU POWER GENERATION

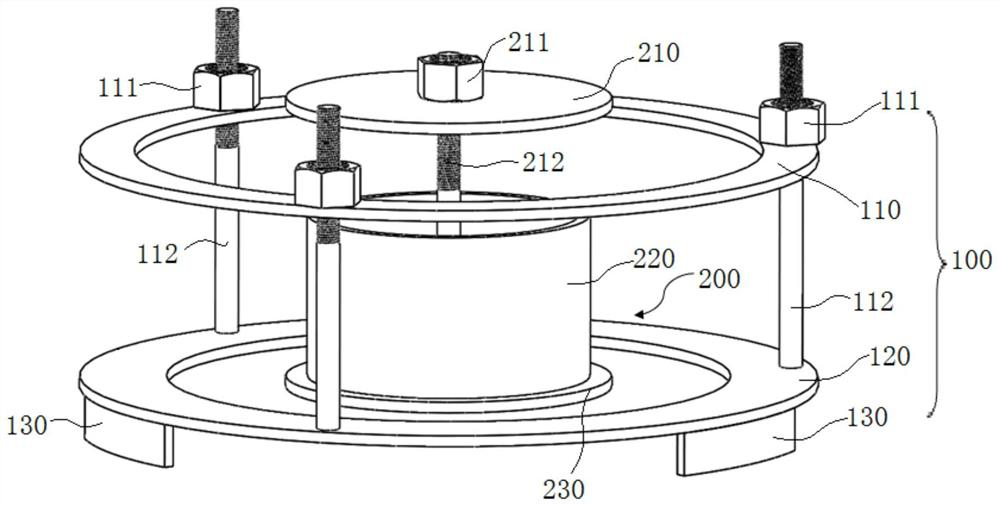

Suspension embroidery frame device of computerized embroidery machine

PendingCN110629421AAchieve levitationImprove running accuracyFeedersEngineeringOperational reliability

The invention discloses a suspension embroidery frame device of a computerized embroidery machine; the suspension embroidery frame device comprises: a frame, wherein a groove is formed in the lower surface of each framing member of the frame and extended along the length direction of the framing member, and each of two longer side surfaces of each groove is provided with a protruding part having acircular arc surface protruded towards the center of the groove; a Y-direction driving assembly, comprising a Y driving guide rail, a Y driving trolley, a Y transmission assembly and a Y frame connecting assembly, wherein the Y transmission assembly is connected with the Y driving guide rail and used for driving the Y driving trolley to slide along the Y driving guide rail, the Y frame connectingassembly comprises a connecting seat connected to the upper surface of the Y driving trolley and a U-shaped bearing connected to the connecting seat, and the concave part of the outer peripheral surface of the U-shaped bearing abuts against the arc surface protruding from the protruding part; and an X-direction driving assembly, comprising an X driving guide rail, an X driving trolley, an X transmission assembly and an X frame connecting assembly arranged on the X driving trolley and connected with the frame. The suspension embroidery frame device has the advantages of good disassembly and assembly convenience, no friction with a bedplate, low wear rate, good integral driving property and good operation reliability.

Owner:ZHEJIANG YUELONG SEWING EQUIP

Novel vehicle-mounted refrigerator

PendingCN114576898APrevent fallingReduce the possibility of spreadingVehicle arrangementsLighting and heating apparatusComputer hardwareIcebox

The invention provides a novel vehicle-mounted refrigerator which comprises a refrigerator body and a refrigerator door arranged at an opening of the refrigerator body. The food storage inner container is arranged in the box body, a storage rack and a storage box are arranged in the food storage inner container, the storage rack is connected with the inner wall of the food storage inner container in a clamping mode, the storage box is arranged below the storage rack, and the storage box is connected with the bottom face of the food storage inner container in a sliding mode; therefore, the vehicle-mounted refrigerator has the characteristic that the connectivity between the storage rack and the food storage inner container is improved, meanwhile, the storage box is arranged, food or fruits can be placed in the storage rack or the storage box according to the characteristics of the food or the fruits, and the situation that due to the fact that the vehicle-mounted refrigerator moves, the food or the fruits cannot be stored in the storage box is reduced. And meanwhile, the possibility that the food is easy to fall off after the refrigerator door is opened is also reduced.

Owner:青岛海力智能设备有限公司

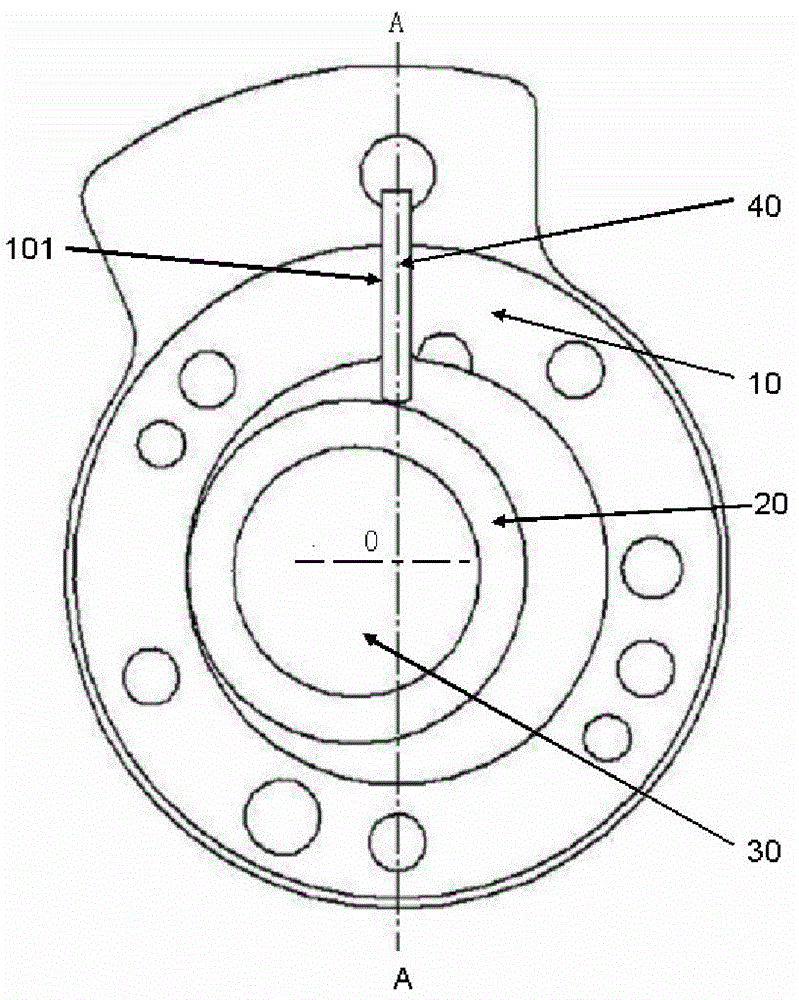

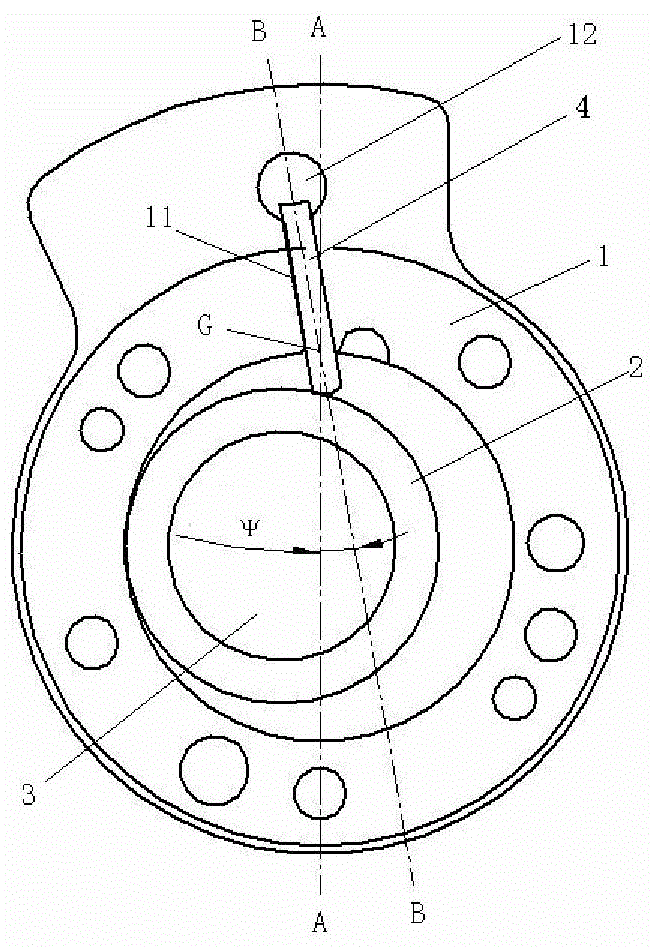

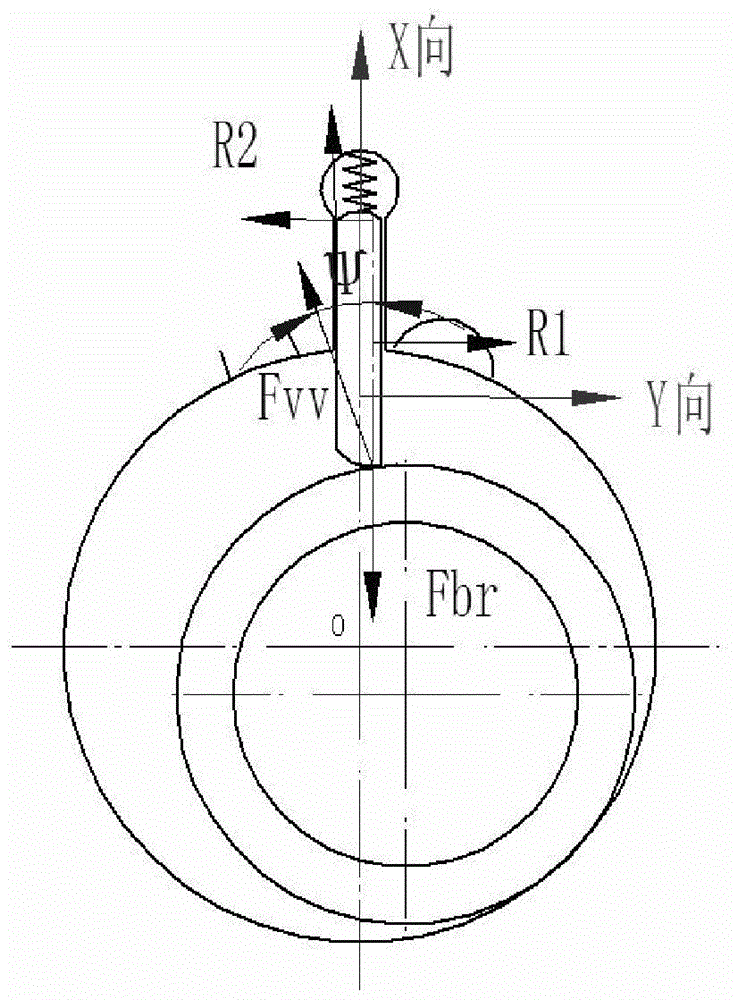

Rolling rotor compressor oblique vane groove structure

ActiveCN103629115BImprove the forceReduce input powerRotary piston pumpsRotary piston liquid enginesSurface reactionFriction loss

A rolling rotor compressor with an oblique vane groove structure, the compressor includes a cylinder, a piston, a crankshaft and vanes. The cylinder is provided with a vane groove and a guide seat. The vane groove is rotated counterclockwise at an angle based on the intersection point of the inner diameter of the cylinder and the center line of the original vane groove passing through the center of the cylinder on the inner wall of the cylinder to form a center relative to the original blade groove. For linearly inclined blade grooves, the inclination angle Ψ is greater than 0° and less than 22°. The present invention is an asymmetrical blade motion structure set for the asymmetrical load of the traditional compressor operating within 0~360°, which can greatly reduce the contact force between the blade and the blade groove of the cylinder and the tip of the piston, thereby reducing the pressure of the blade groove and the tip of the blade. And the friction loss of the eccentric part, improve the efficiency of the compressor; at the same time improve the force of the blade. After the present invention is used on a rotary compressor, its input power drops by up to 1.0%, and its efficiency is significantly improved; the side support reaction force of the blades drops by up to 17%, and the reduction in wear of the blades and blade grooves improves the working reliability.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

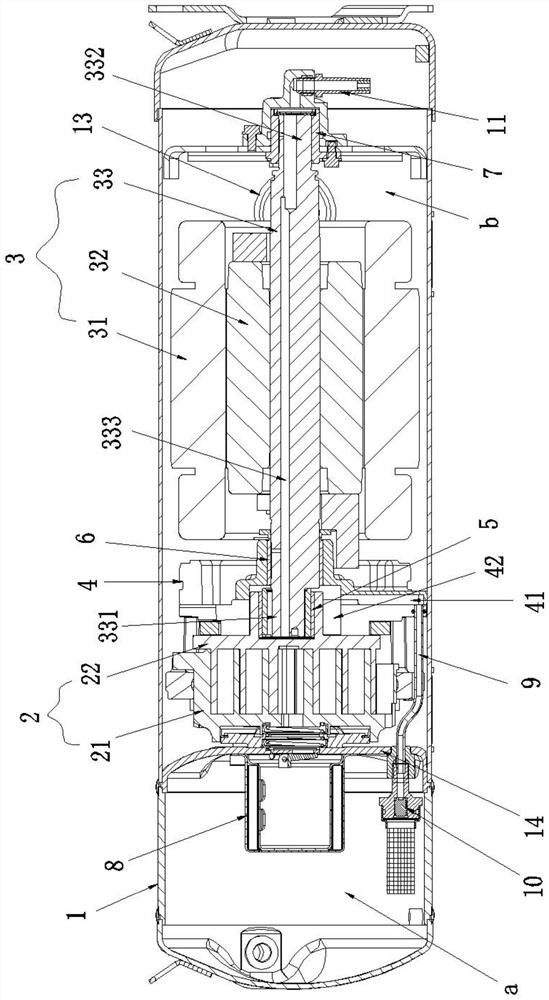

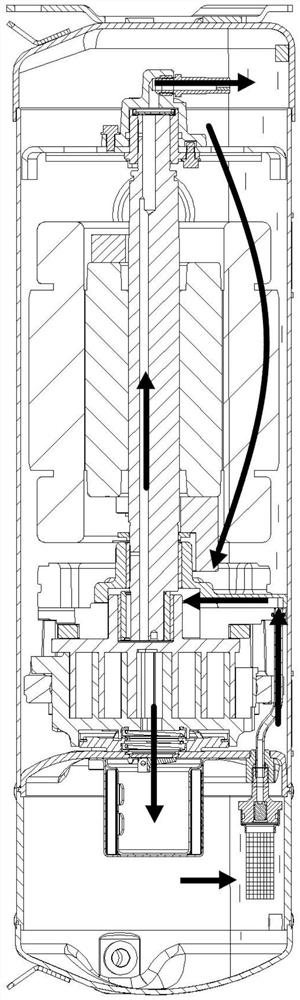

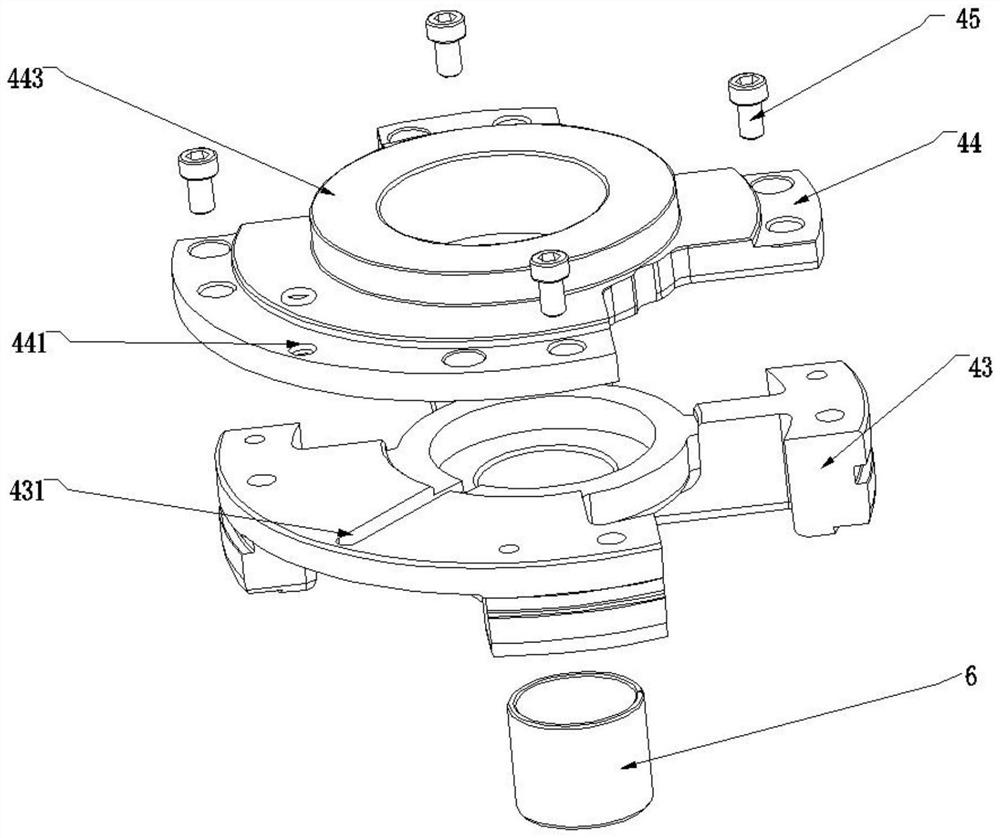

Differential pressure oil supply structure of horizontal scroll compressor

PendingCN114876807ALower overall pressure dropReduce leakageRotary piston pumpsRotary piston liquid enginesOil canBearing wear

The invention discloses a differential pressure oil supply structure of a horizontal scroll compressor, the differential pressure oil supply structure comprises an oil-gas separation device and an oil return pipe, the oil-gas separation device is arranged in a high-pressure cavity and is arranged on the exhaust port side of a compression mechanism, and the oil-gas separation device is used for separating lubricating oil in exhaust gas of the compression mechanism and storing the lubricating oil in a high-pressure cavity oil pool; one end of the oil return pipe is communicated with the high-pressure cavity oil pool, and the other opposite end is communicated with an internal oil path of the main bearing seat; the thrust surface of the main bearing seat is in close contact with the bottom surface of the movable scroll plate to form a closed bearing cavity, the bearing cavity is respectively communicated with an internal oil path of the main bearing seat and an internal oil path on the crankshaft, the internal oil path of the crankshaft is communicated with a shaft head of the crankshaft and a shaft tail of the crankshaft, and lubricating oil can be transmitted to a low-pressure cavity oil pool from a bottom bearing at the shaft tail of the crankshaft. According to the scroll compressor, an oil way is greatly shortened, pressure drop and leakage in the oil way are reduced, the movable scroll bearing is always soaked in lubricating oil, and the possibility that the bearing is abraded during heavy-load operation of the compressor is reduced.

Owner:常熟英华特环境科技有限公司

Rolling propelling device for perforating pipe string of horizontal well with upward inclination angle

PendingCN114876420ANo rolloverPrevent the phenomenon of detachment from the main body of the jointDrilling rodsFluid removalHorizontal wellsEngineering

The invention discloses a rolling propelling device for a perforating pipe string of a horizontal well with an upper dip angle, and relates to the technical field of perforating devices for perforation completion of oil fields. Comprising perforating gun barrels and a rolling propelling connector, and the rolling propelling connector is detachably connected between every two adjacent perforating gun barrels; the rolling propelling connector comprises a connector body, a rotating body, a rolling body, a steel ball and a conductive sealing communication assembly. The rotating body is connected to the side wall of the connector body. The rolling body is in rolling connection with the rotating body through the steel ball; the perforating gun barrel string is supported and eccentrically centralized by the rolling body; a conductive sealing communication assembly is installed in the connector body. The connection between the adjacent perforating gun barrels is stable, the friction resistance in the cable pumping and conveying process of the upper dip angle horizontal well perforating pipe string can be reduced, and gravity reversing can be prevented.

Owner:大庆华翰邦石油科技有限公司

An oil pump with anti-blocking function

ActiveCN110821841BImprove the stability of useImprove stabilityPump componentsPump installationsElectric machineryEngineering

The invention relates to the technical field of oil pumps, in particular to an oil pump with an anti-blocking function. A main body of an oil pump with an anti-blocking function. The surface of the main body of the oil pump is covered with a heat conduction device. There is a cleaning device that can rotate in the chute. A speed regulating device is installed at the input end of the cleaning device. There is a connecting column between the top of the speed regulating device and the inner wall of the main body of the oil pump. The two ends of the connecting column are respectively fixedly connected with the speed regulating device and the main body of the oil pump. . The device of the present invention improves the use stability of the oil pump and the cleanliness of the oil pump, reduces the overload of the internal motor of the oil pump, prolongs the service life of the motor, and further cleans the filter screen. The service life of the net.

Owner:惠州市正康实业有限公司

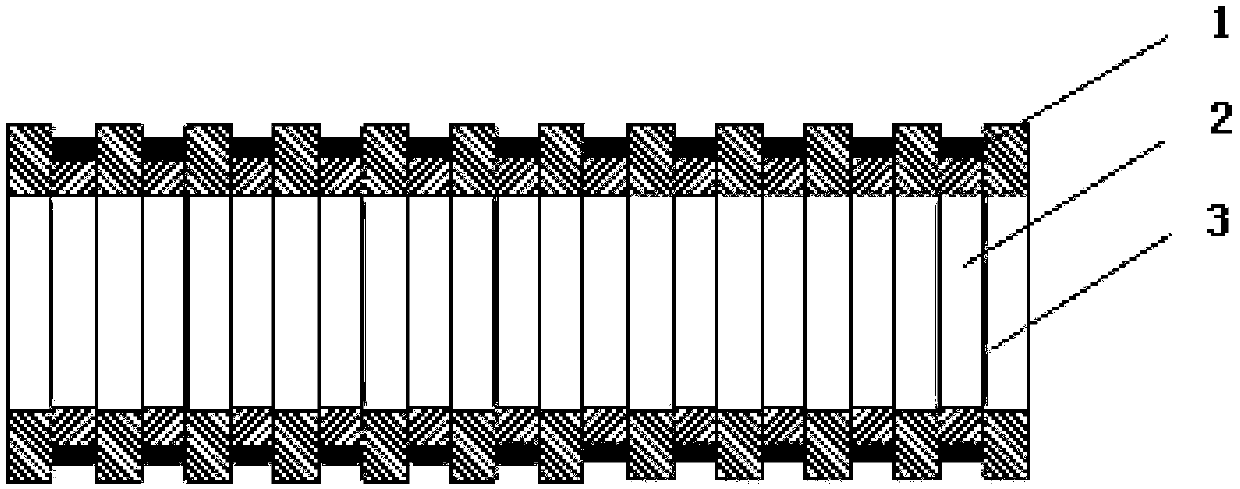

Improved fabric with reinforced interlaces

InactiveUS20160032502A1Improve integrityReduce potential for frayWarp knittingMedical devicesYarnUltimate tensile strength

A fabric having first section and having first pores created by the interlacings of yarn in a first pattern, and having a first average pore size. The fabric also includes a second fabric section having second fabric pores created by the interlacings of yarn in a second pattern, and a second average pore size. The number of first interlacings of yarn is greater than the number of second interlacings of yarn. The first fabric provides strength to the second fabric. The first fabric pattern designed to mitigate any unravel of a second pore yarn in the event it is severed.

Owner:ATEX TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com