Rolling rotor compressor oblique vane groove structure

A rolling rotor type, blade groove technology, applied in the field of blade groove structure, can solve problems such as suboptimal, and achieve the effects of improving work reliability, improving efficiency, and reducing the possibility of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

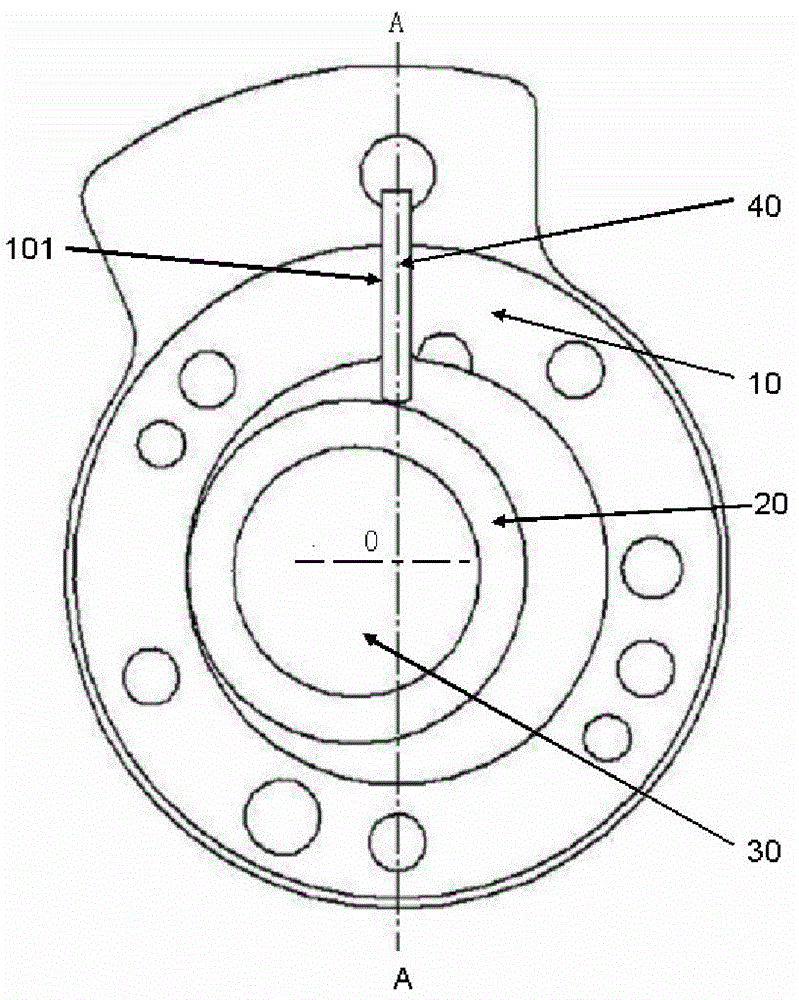

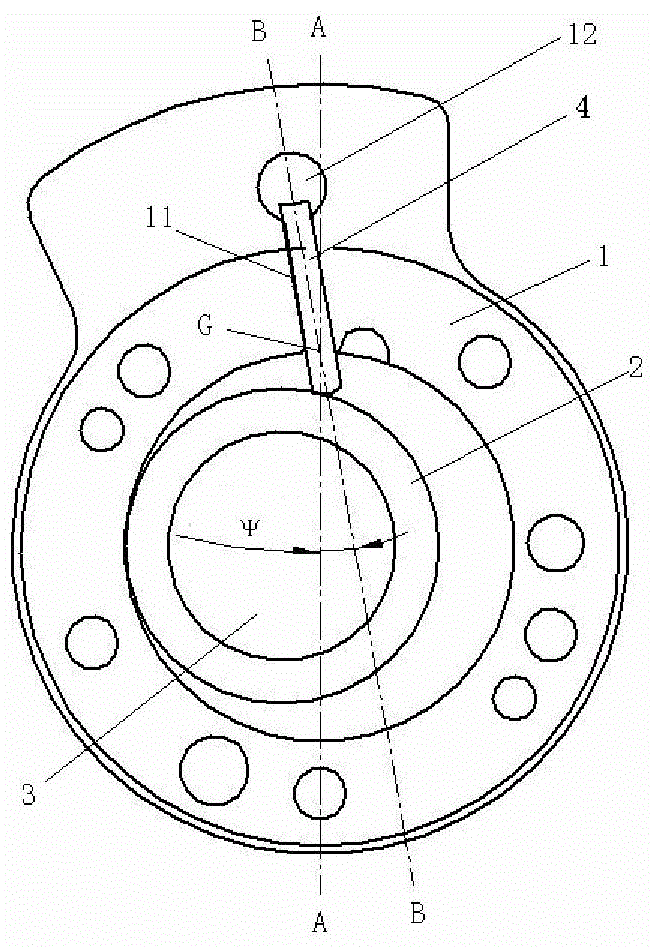

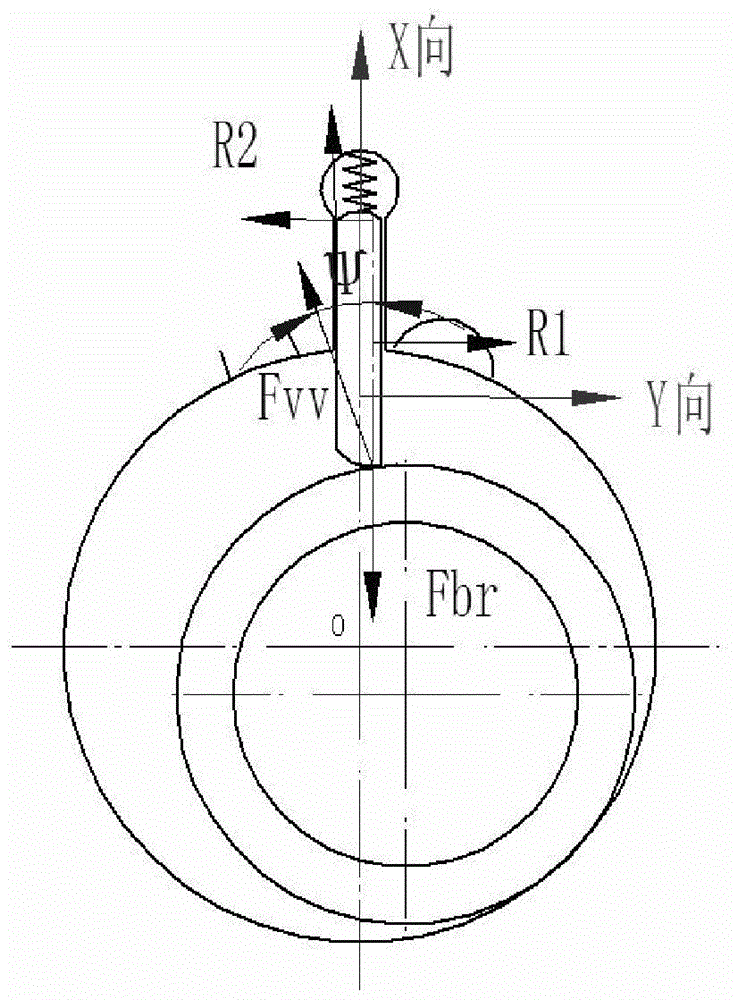

[0013] see figure 2 The oblique vane groove structure of the rolling rotor compressor includes a cylinder 1, a piston 2, a crankshaft 3, and a vane 4, wherein the cylinder 1 is provided with a vane groove 11 that can slide in the groove and closely fits the piston 2 and the cylinder 1 Connected guide seat 12. The vane groove rotates counterclockwise at an angle around the inner diameter of the cylinder and the intersection point G of the centerline AA of the original vane groove passing through the center O of the cylinder on the inner wall of the cylinder, forming an angle that is inclined relative to the centerline AA of the original vane groove, that is, the center The line is the blade groove 11 of BB, and the inclination angle is Ψ, Ψ is not greater than 22°. Preferably, the inclination angle Ψ is between 5° and 15°. The guide seat 12 is located on the vane slot 11 in a communication manner. And comprise the spring that is installed in its cylindrical inner hole, beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com