Tire with three-dimensional steel sheet pattern arranged on tread

A pattern and steel sheet technology, applied to tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problems of small geometric size of three-dimensional steel sheet patterns, wear of steel sheet molds, damage to pattern surfaces, etc., to achieve Less sharpness, less abrasion, less damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

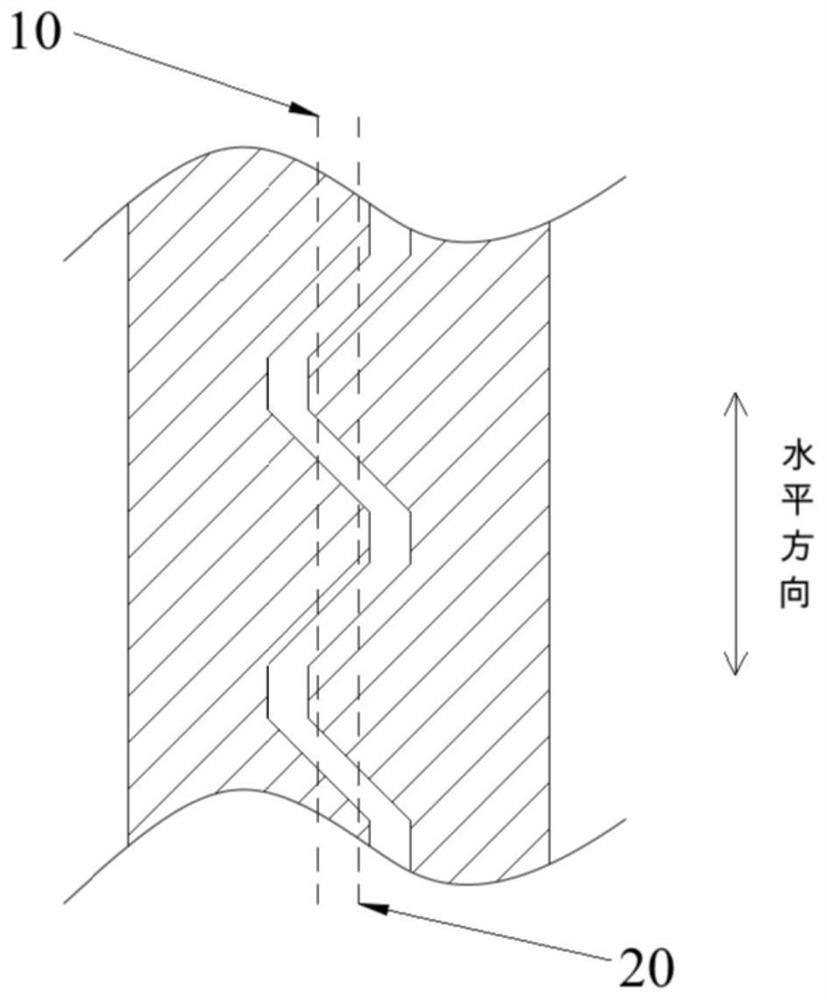

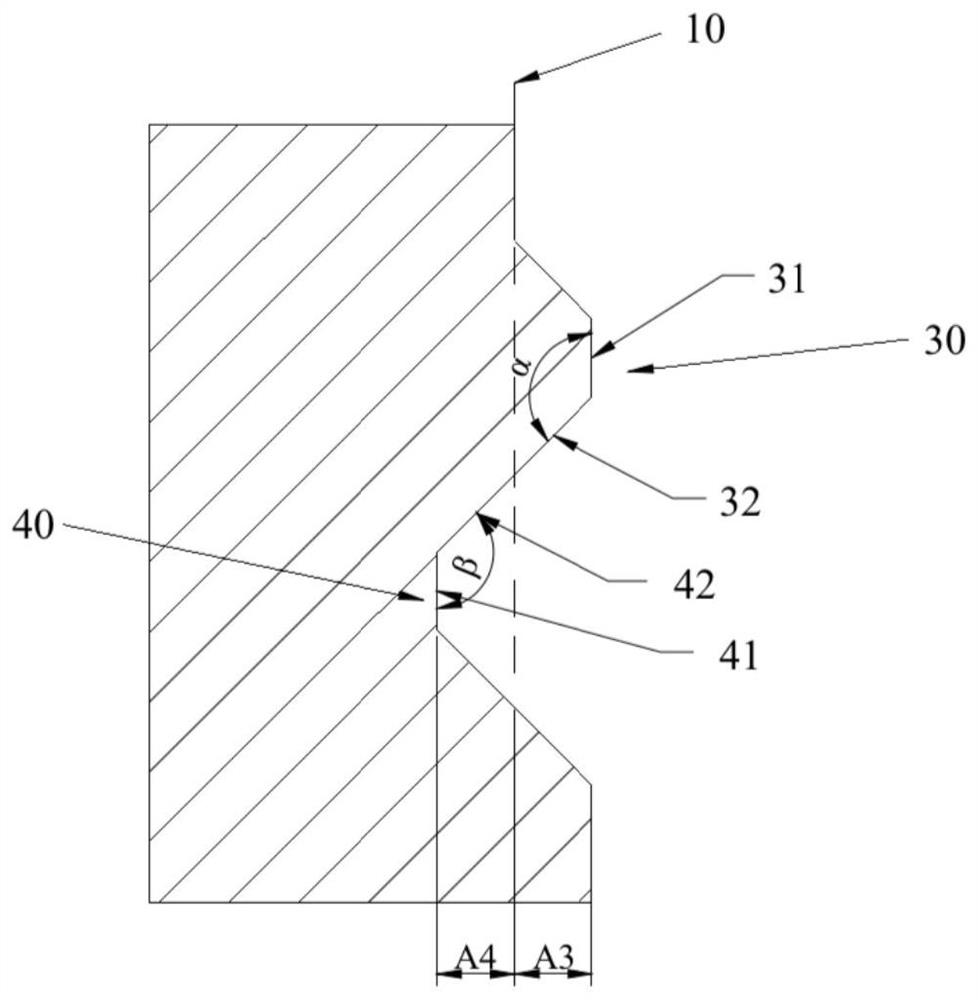

[0035] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0036] Due to the small geometric size of the pattern of the three-dimensional steel sheet, the three-dimensional steel sheet in the prior art may have difficulties in demoulding, damage to the pattern surface during the demoulding process, and wear of the steel sheet mold during actual processing and production.

[0037] For example, the patent CN104070937B discloses a three-dimensional steel pattern, at least a part of the depth direction of the pattern has a bent part, and the bent part is alternately bent to one side and the other side in the width direction of the steel pattern, And it extends continuously along the entire length of the transverse direction of the pattern to form a bending area; there are sharp straight lines at the maximum amplitude of these bending parts. These straight lines will cause greater damage to the pattern sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com