Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce the moment of inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

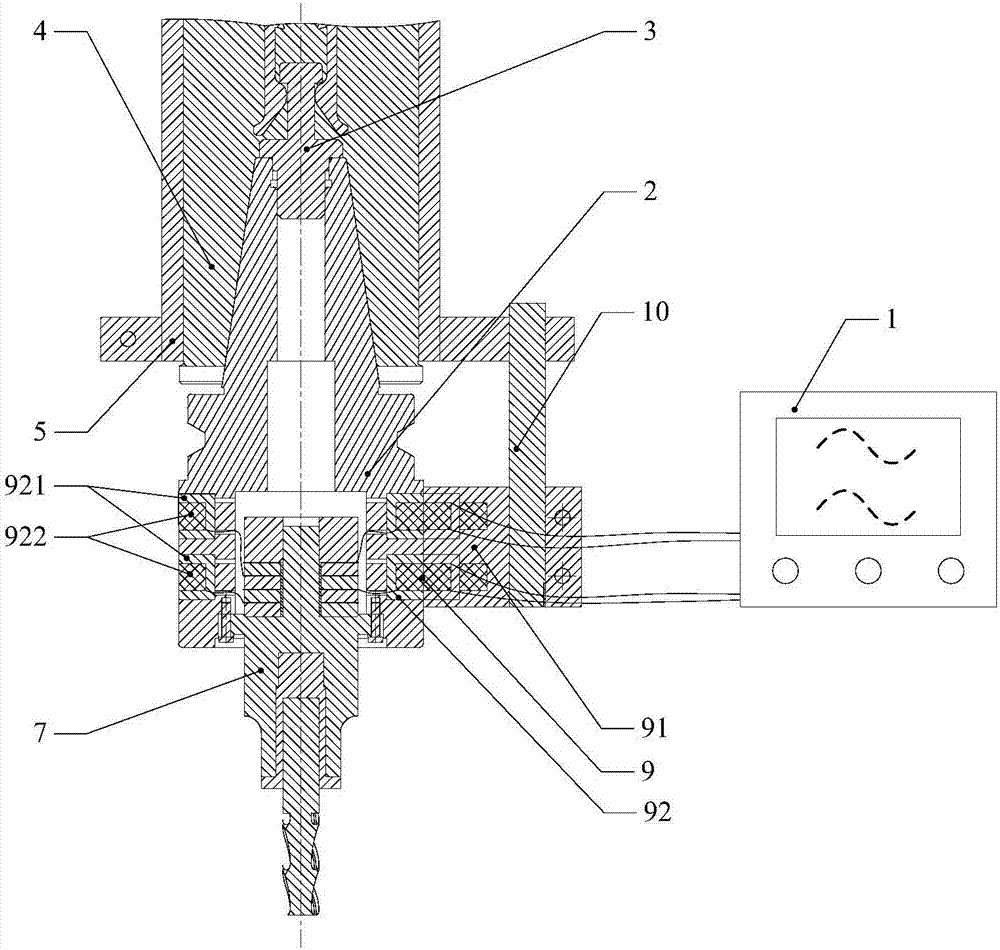

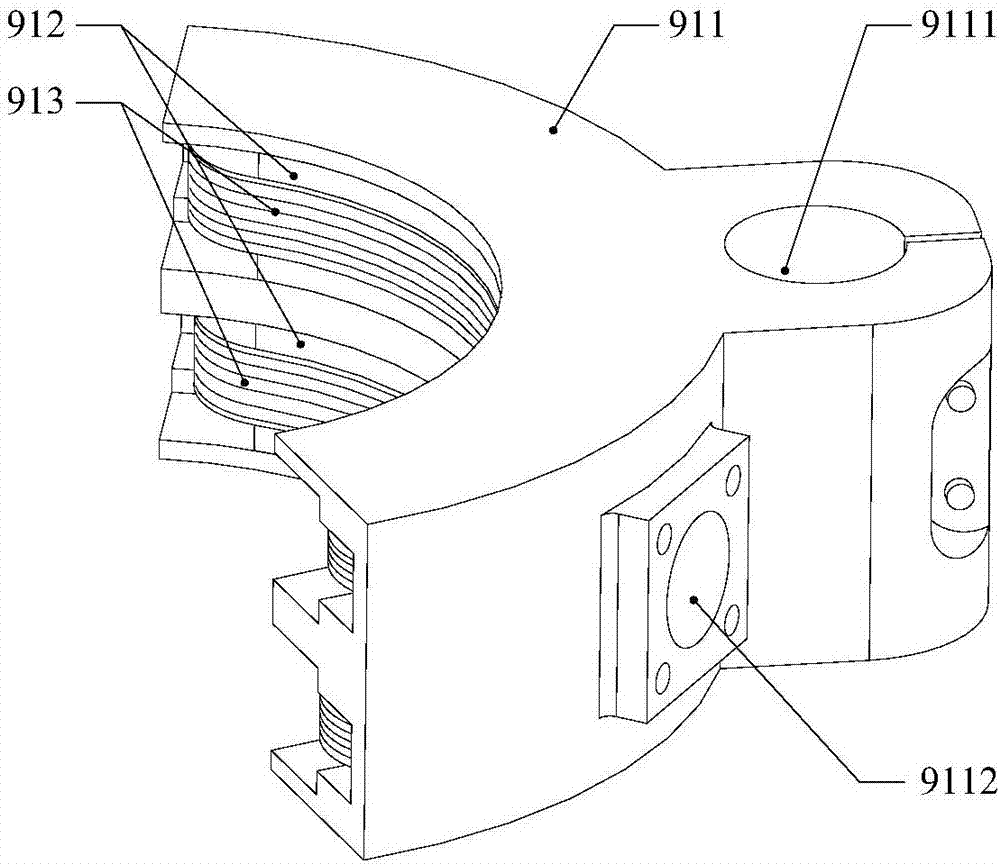

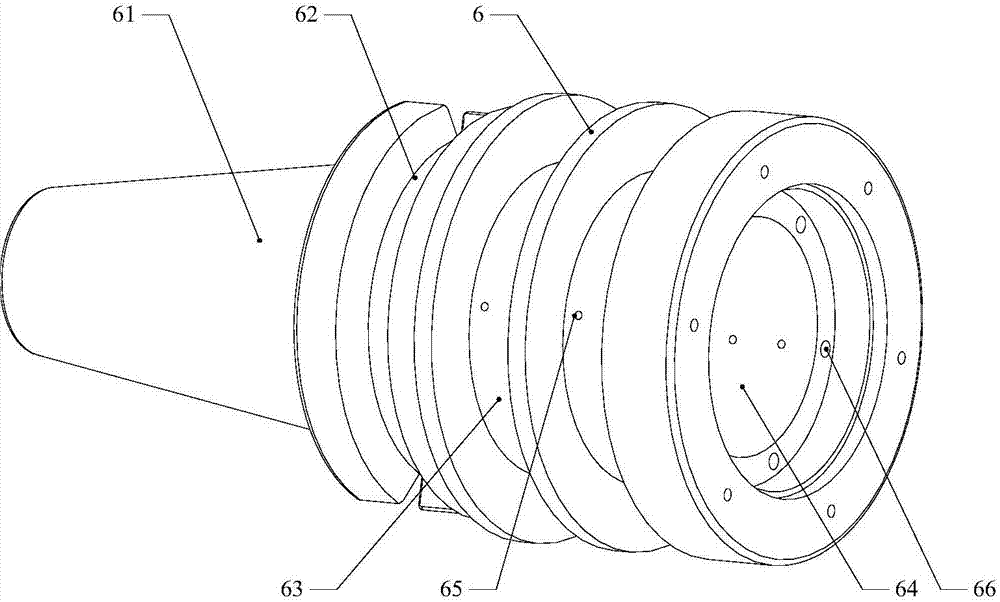

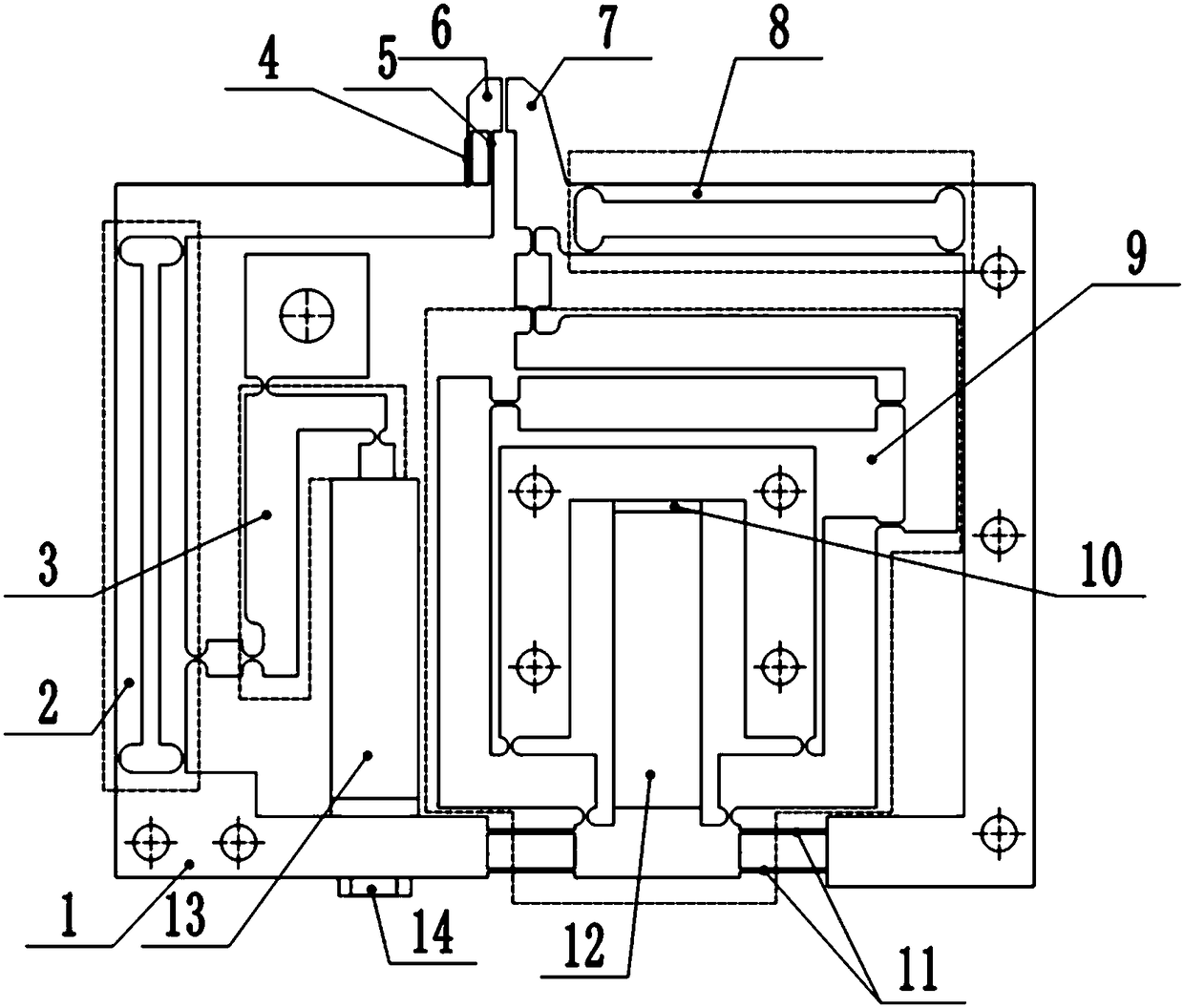

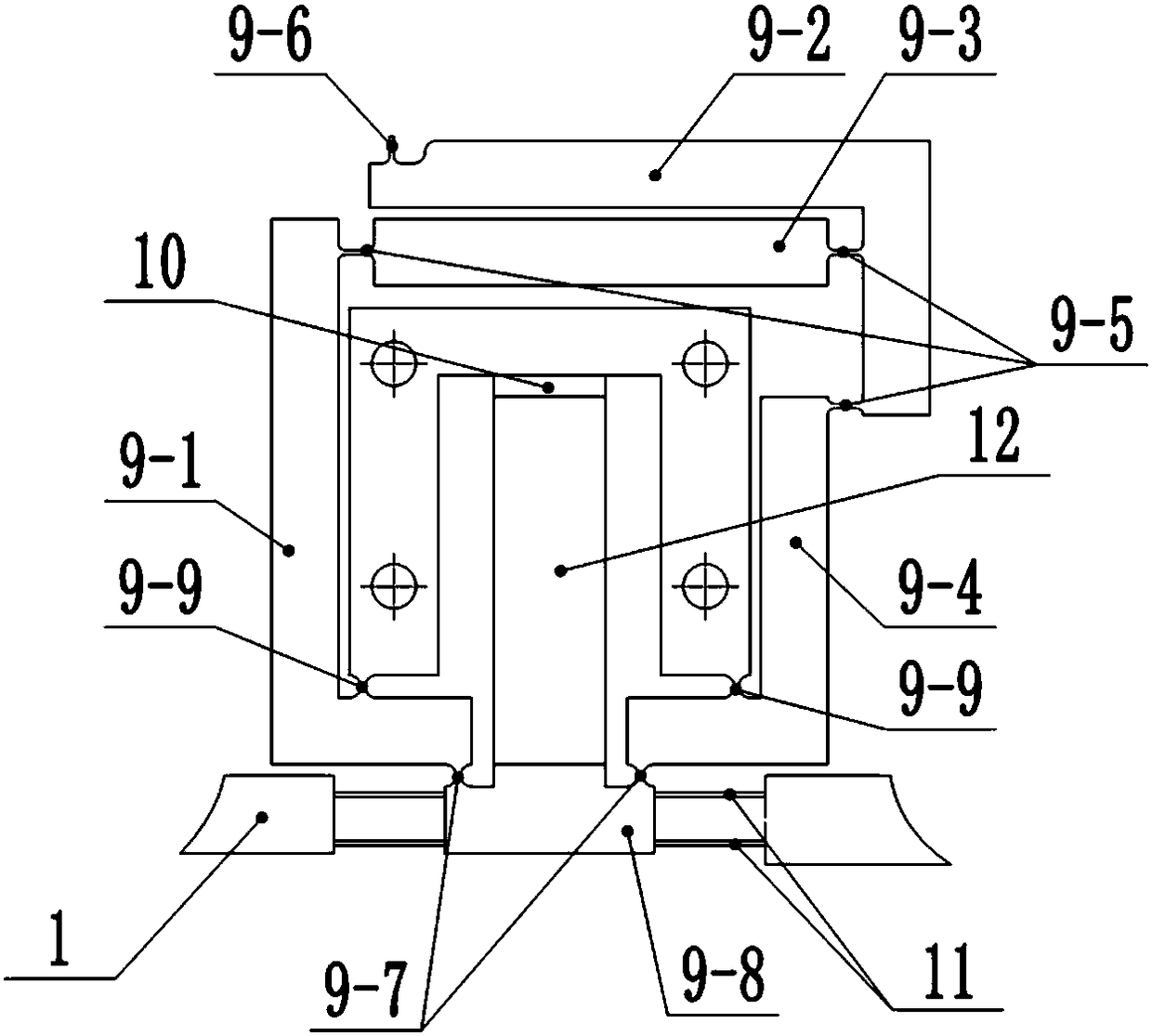

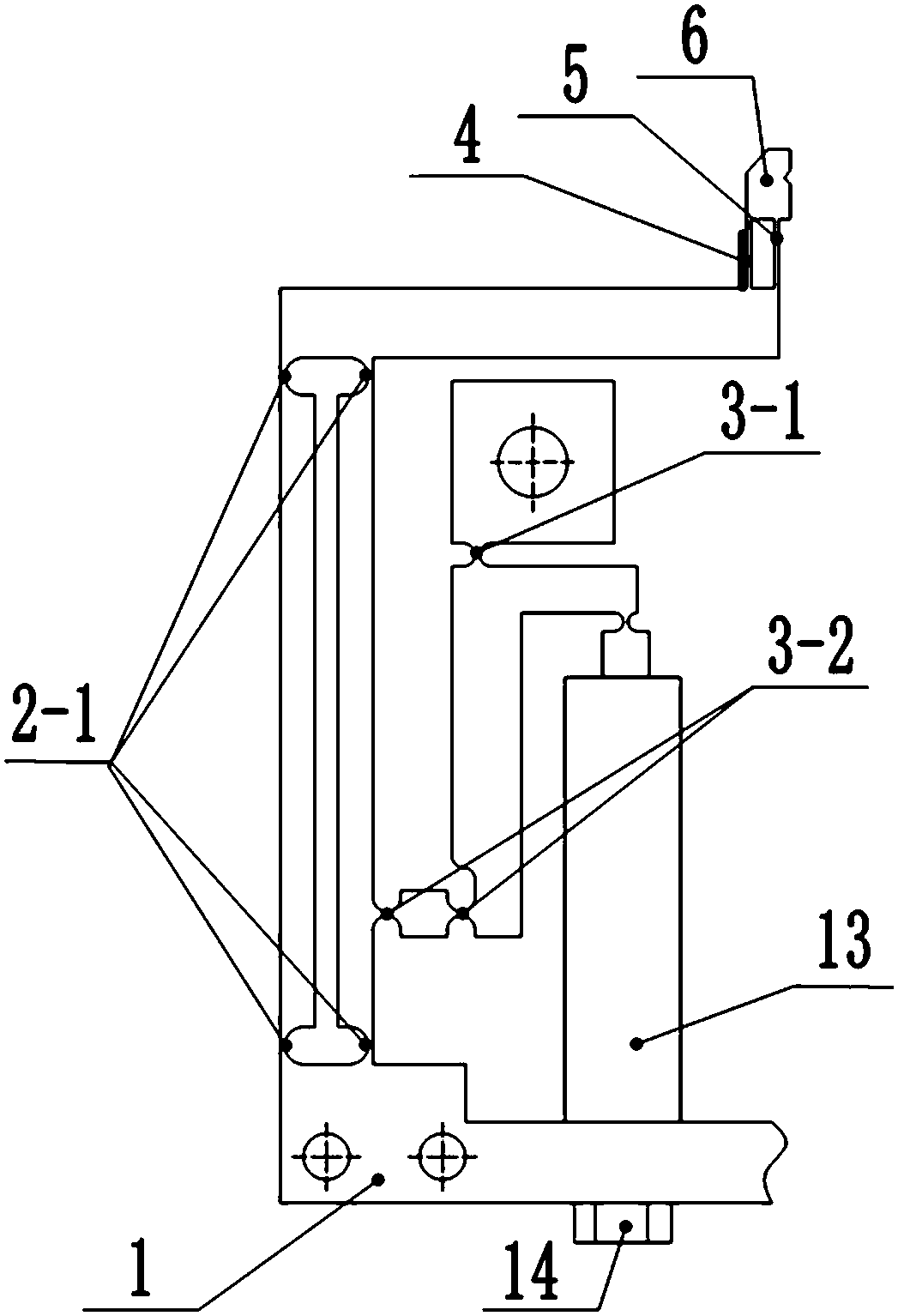

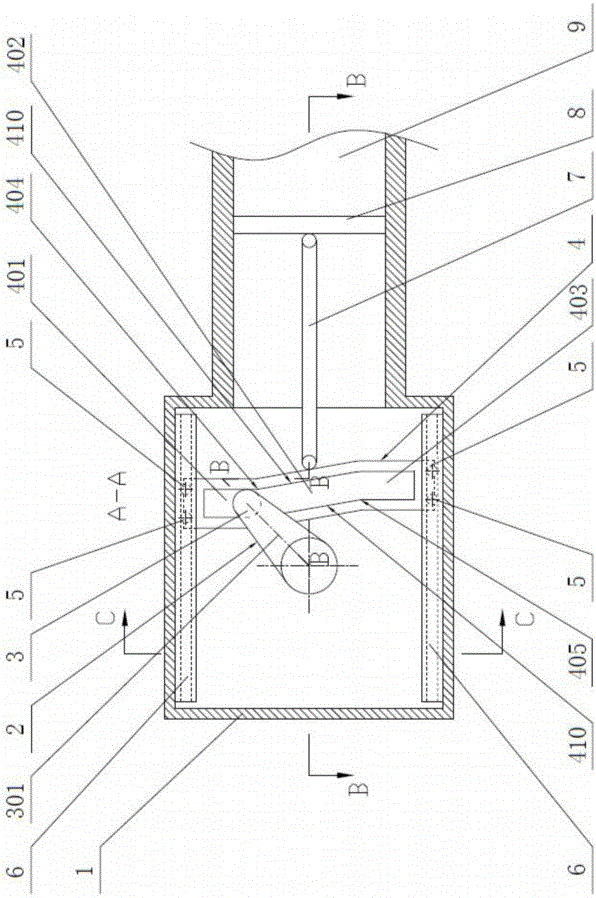

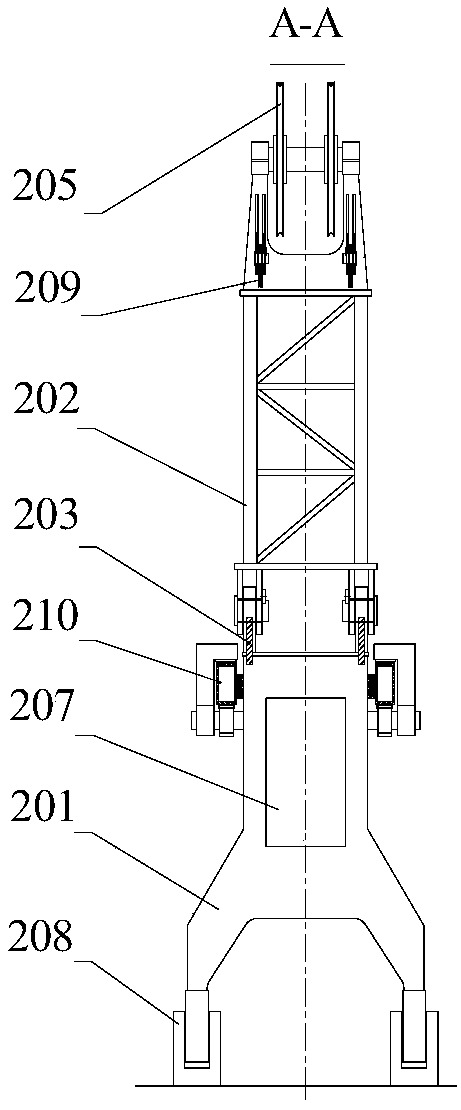

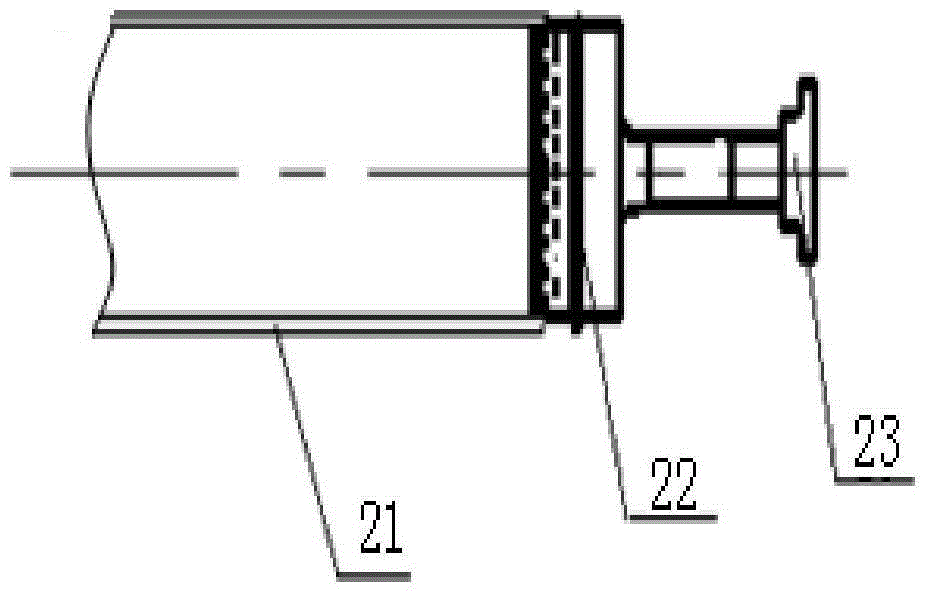

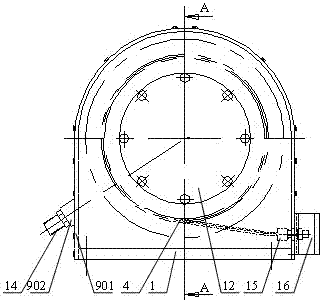

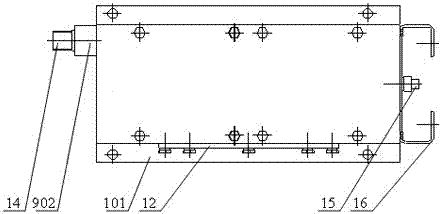

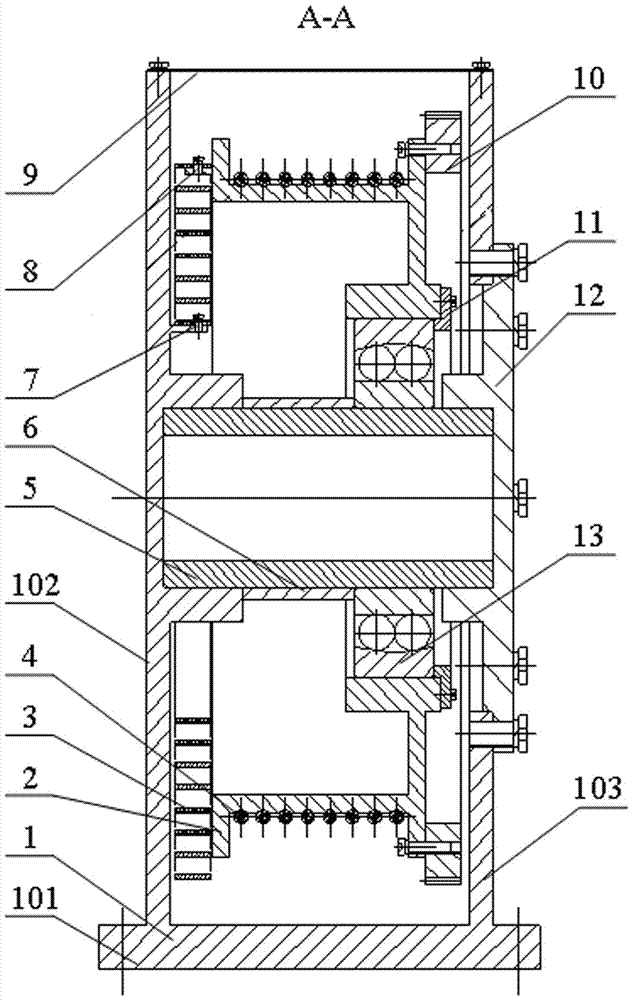

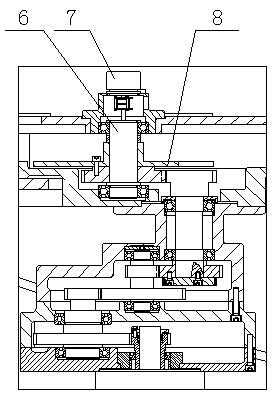

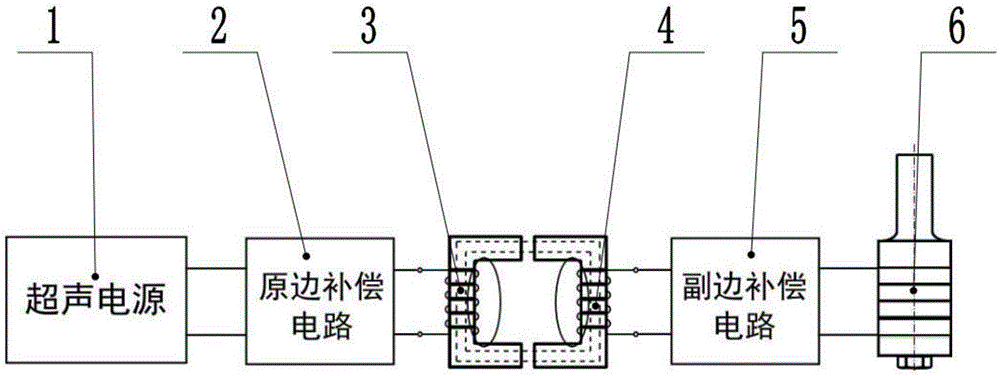

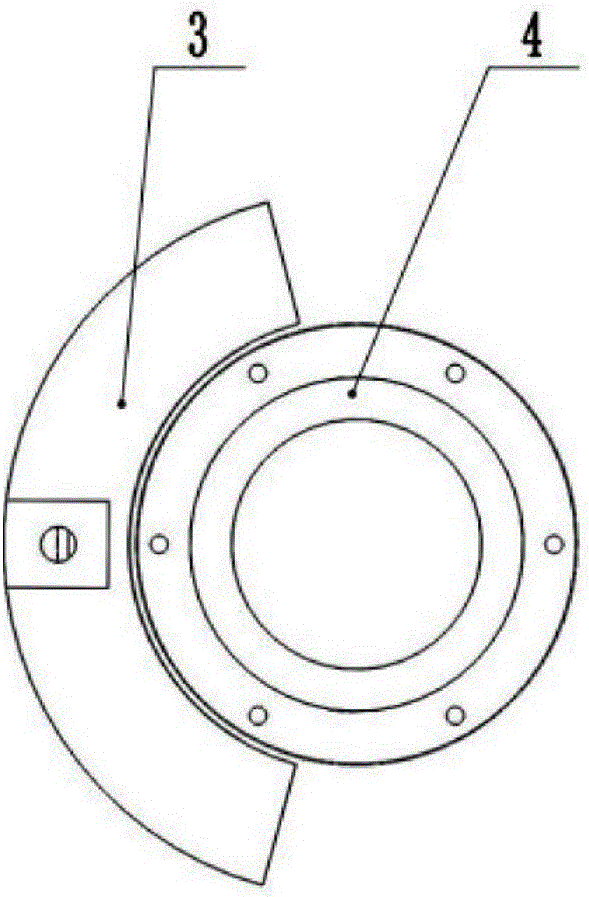

Oval ultrasonic machining device with non-contact induction power supply function

ActiveCN107008959ASmall turning radiusImprove rotational stabilityMachine tool componentsMilling cuttersNumerical controlUltrasonic machining

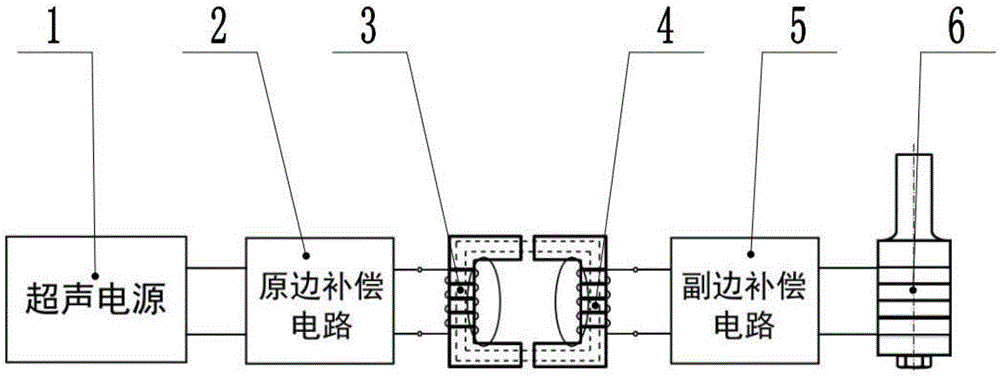

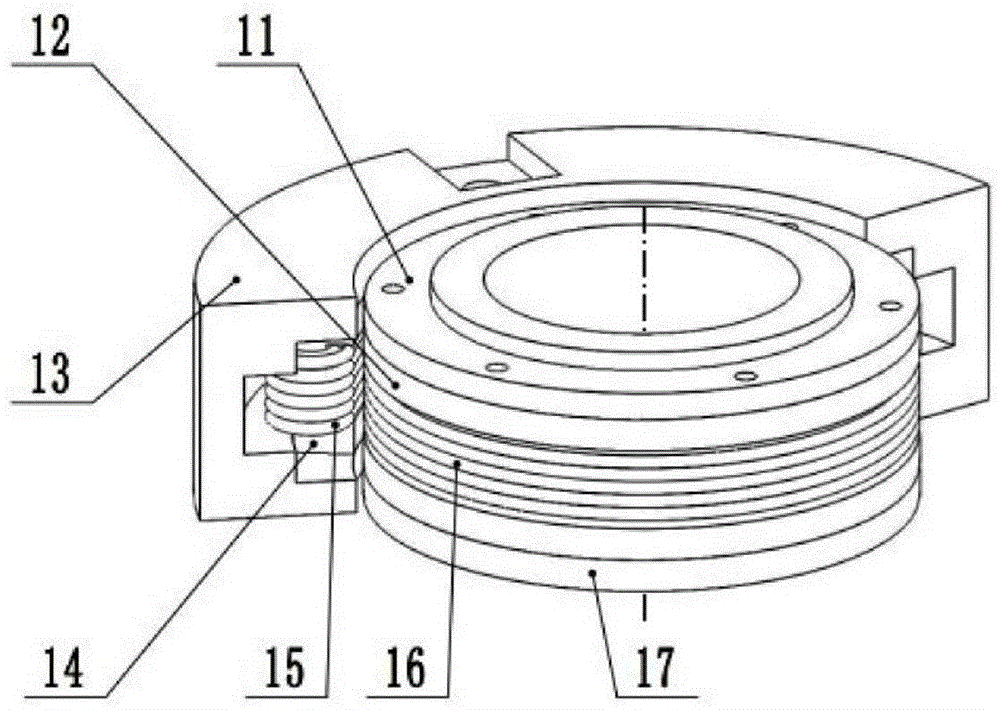

The invention provides an oval ultrasonic machining device with a non-contact induction power supply function. The oval ultrasonic machining device is composed of an induction power supply device and an oval ultrasonic tool handle. The induction power supply vice sides of the induction power supply device are fixed to a BT tool handle shell of the oval ultrasonic tool handle. The induction power supply primary sides of the induction power supply device are arranged on the outer side of the oval ultrasonic tool handle and are arranged in an internal-external concentric circle mode. The gap between the two induction power supply primary sides is kept small. The induction power supply primary sides are fixed to a spindle seat of a numerical control machining center machine tool through a bracket and kept static. The oval ultrasonic tool handle is fixed a spindle of the numerical control machining center spindle through a taper shank and rotates at a high speed along with the spindle. By adoption of the oval ultrasonic machining device, the rotary radius of the oval ultrasonic tool handle is decreased, the rotary inertia of the oval ultrasonic tool handle is lowered, rotary stability of the oval ultrasonic tool handle is improved, and the oval ultrasonic machining device can avoid the working space of a tool replacing manipulator and meet the automatic tool replacing condition under the condition that the structure of the spindle of the numerical control machining machine tool is not changed. The structure is simple, and operation and use are convenient.

Owner:BEIHANG UNIV

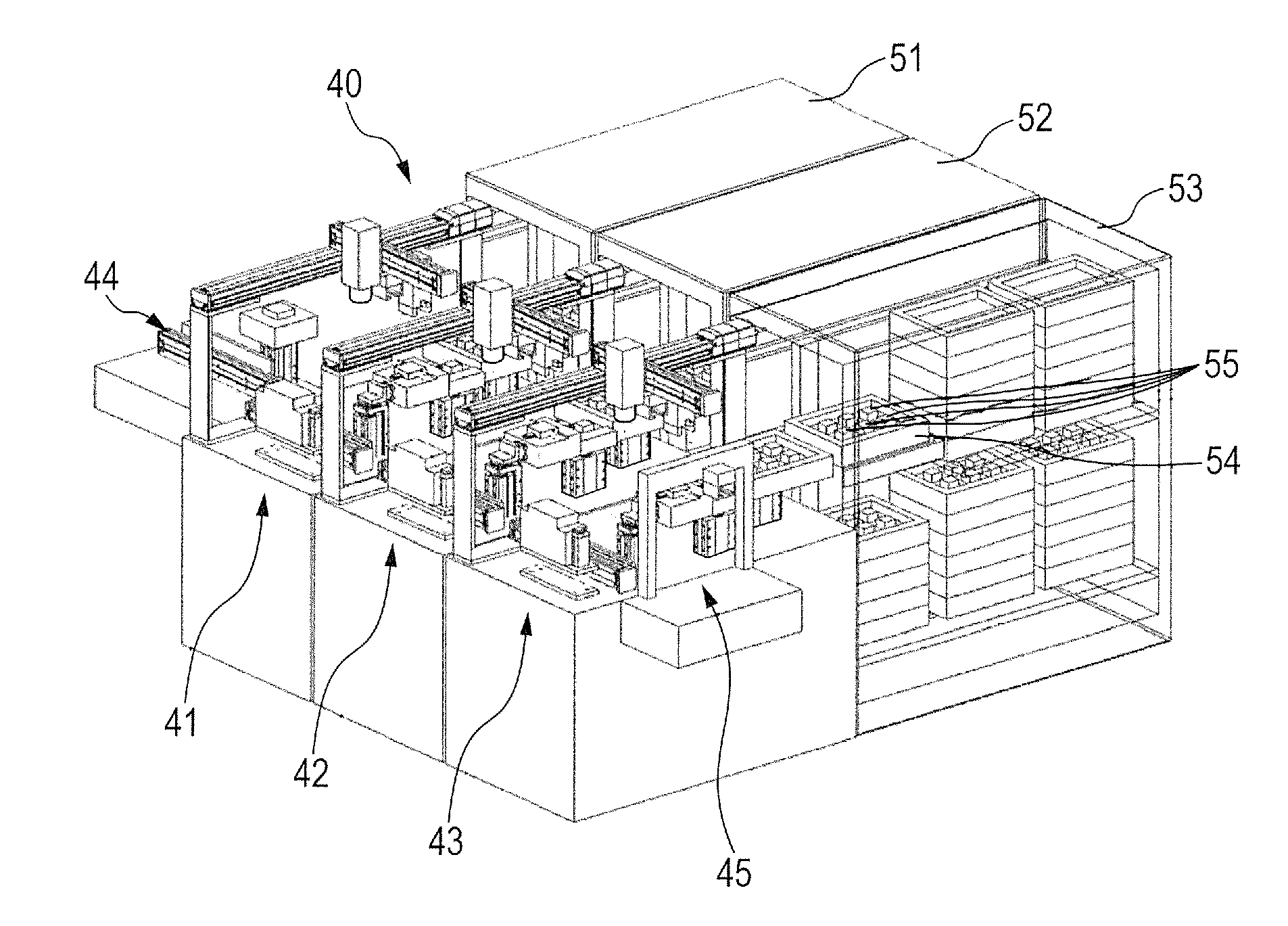

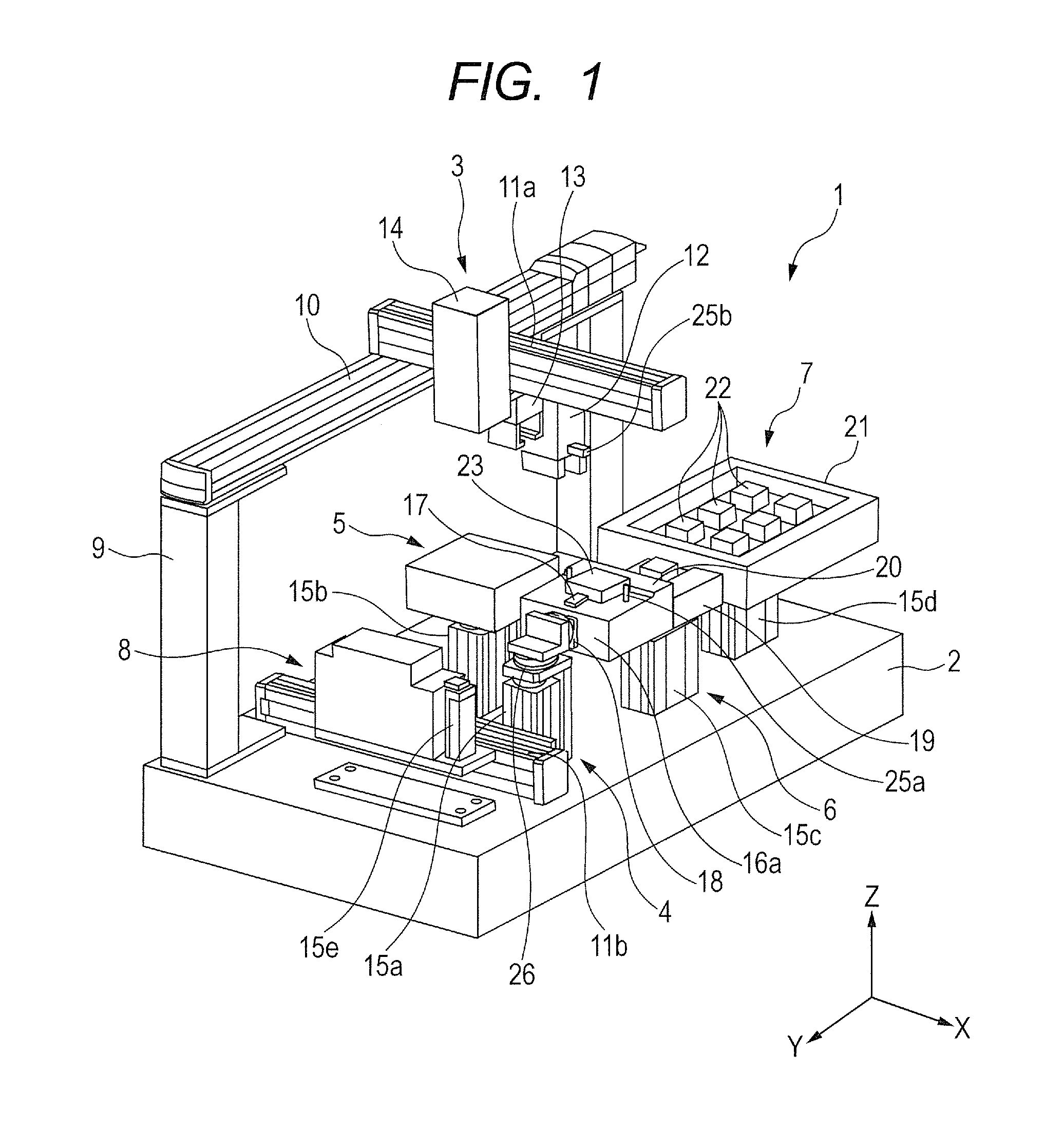

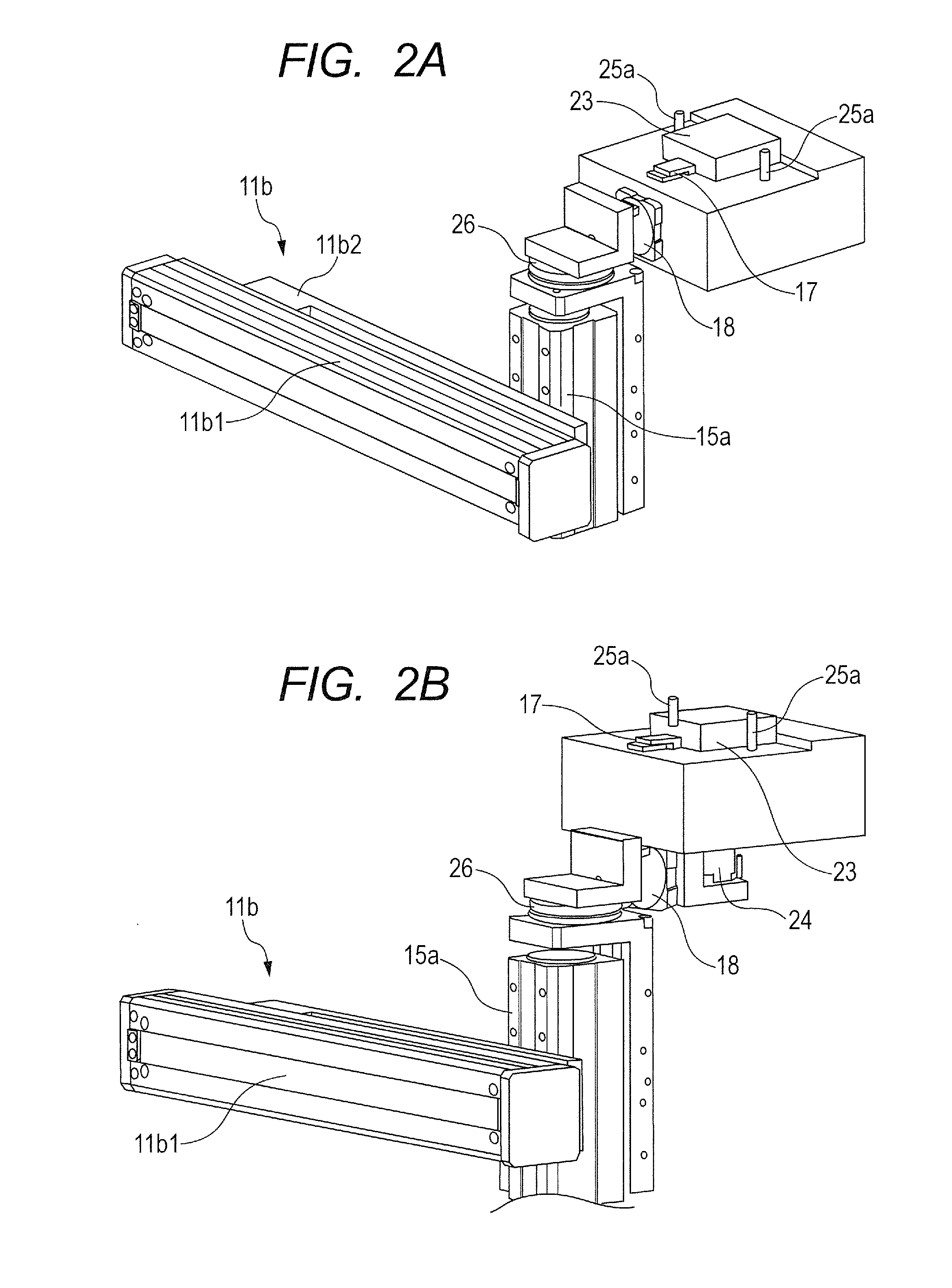

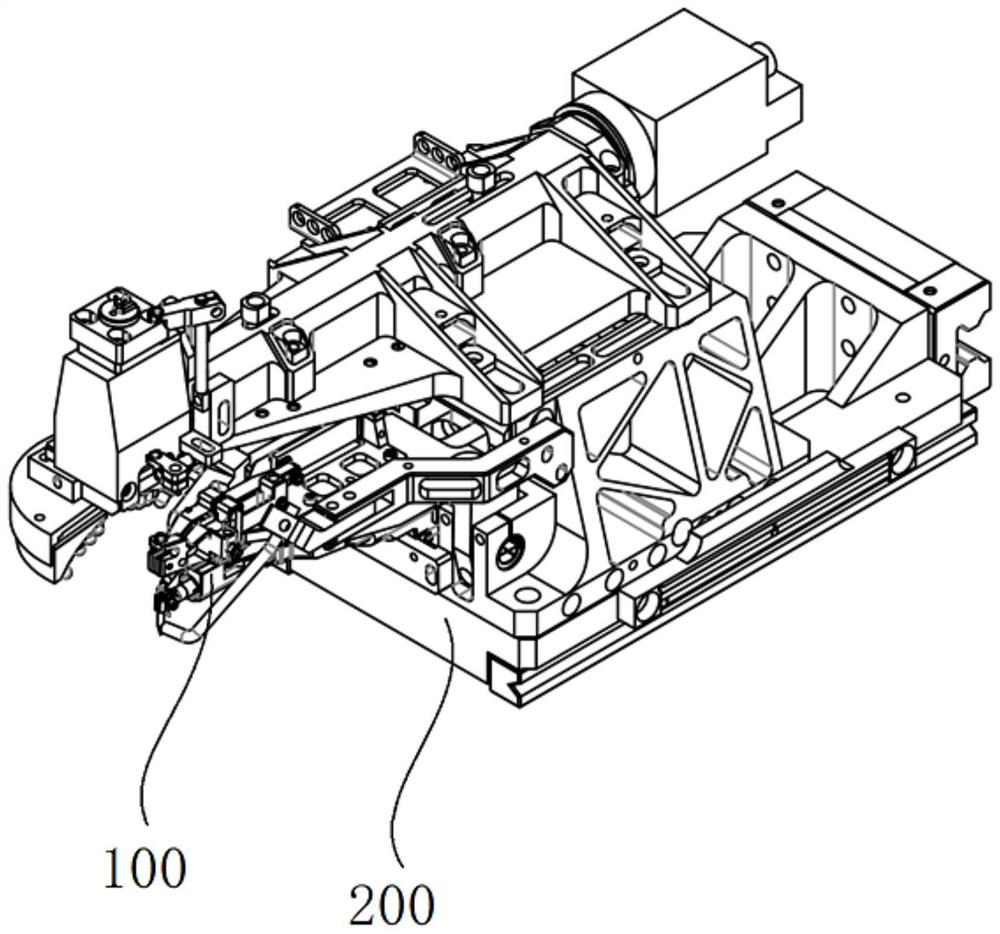

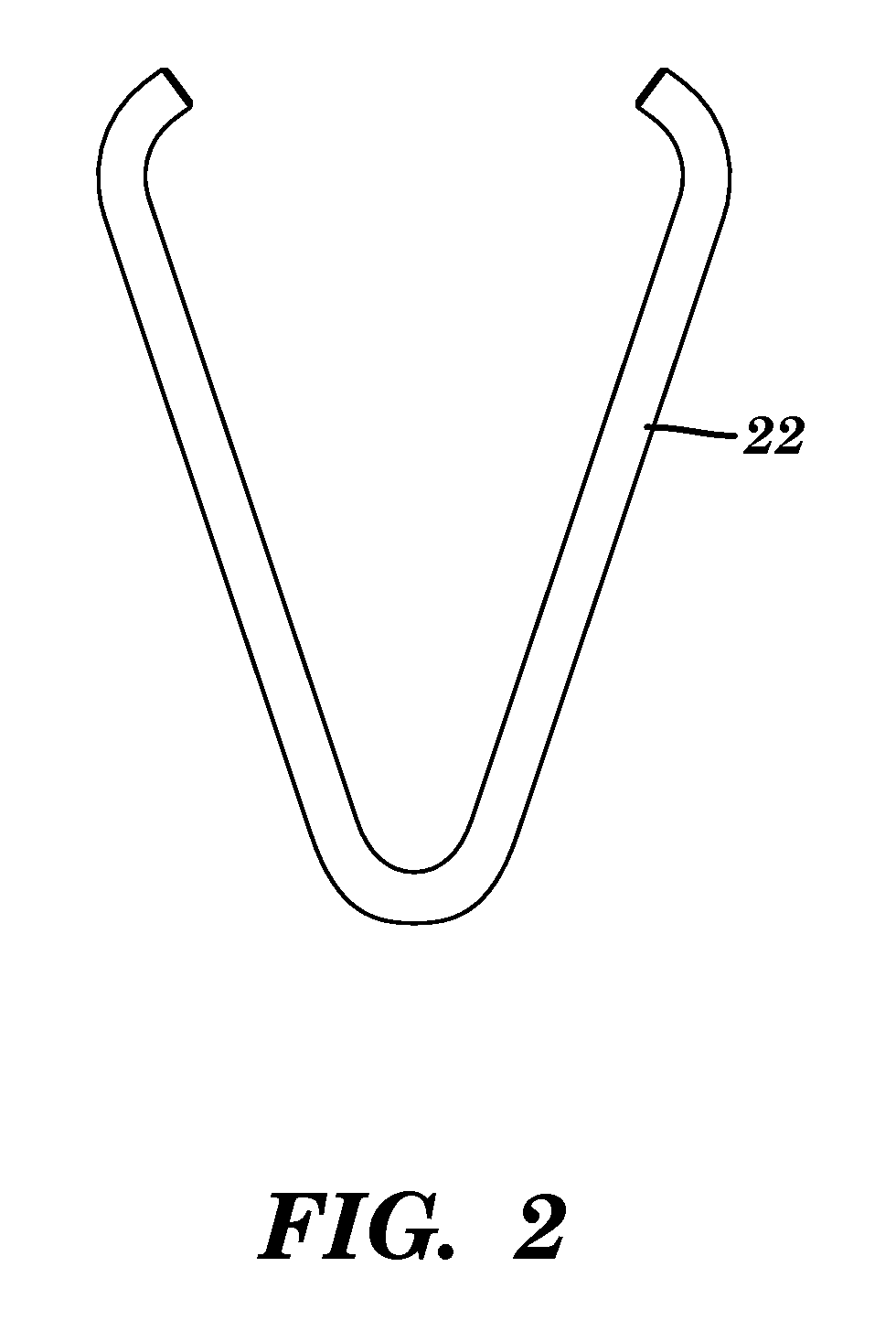

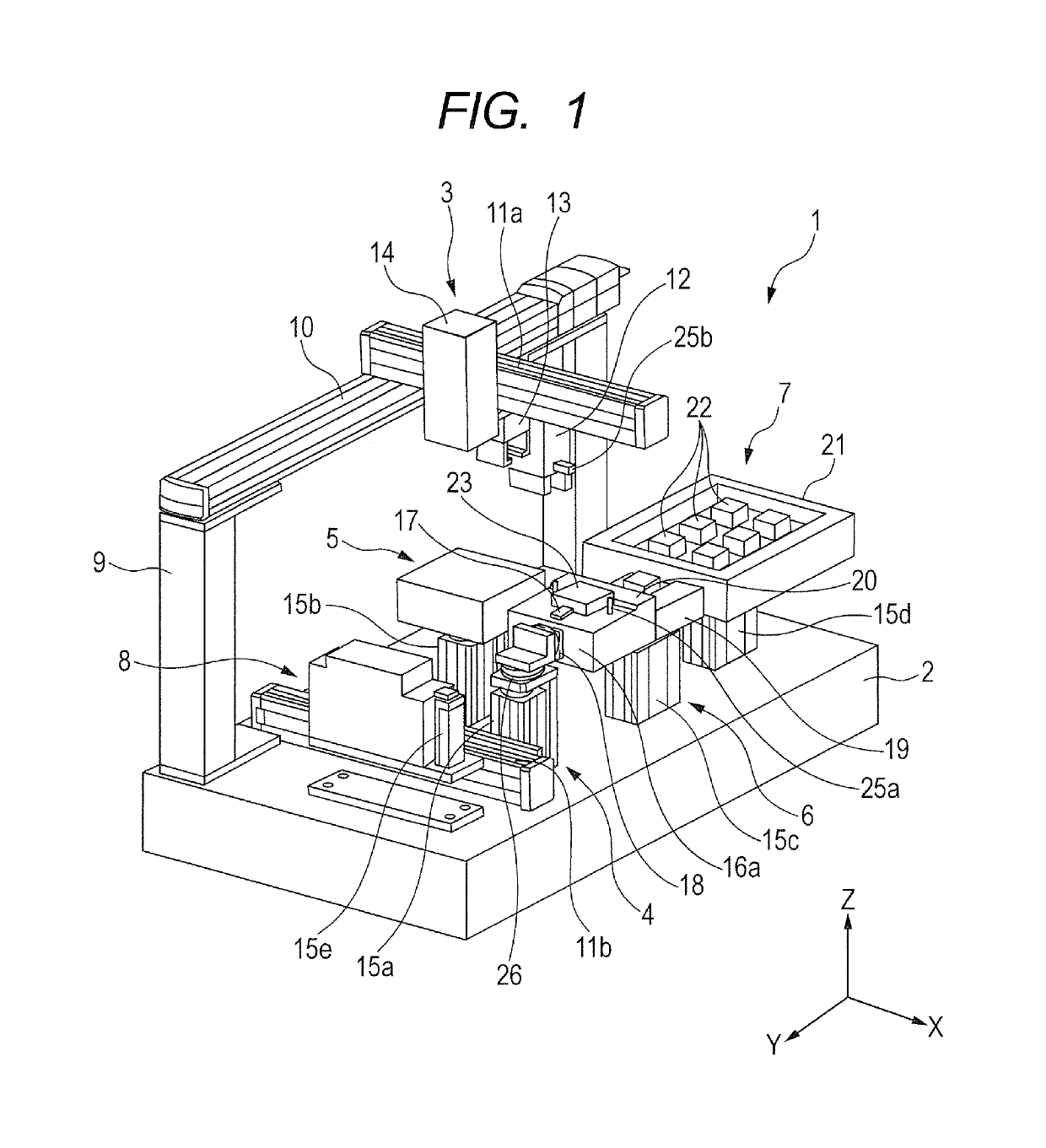

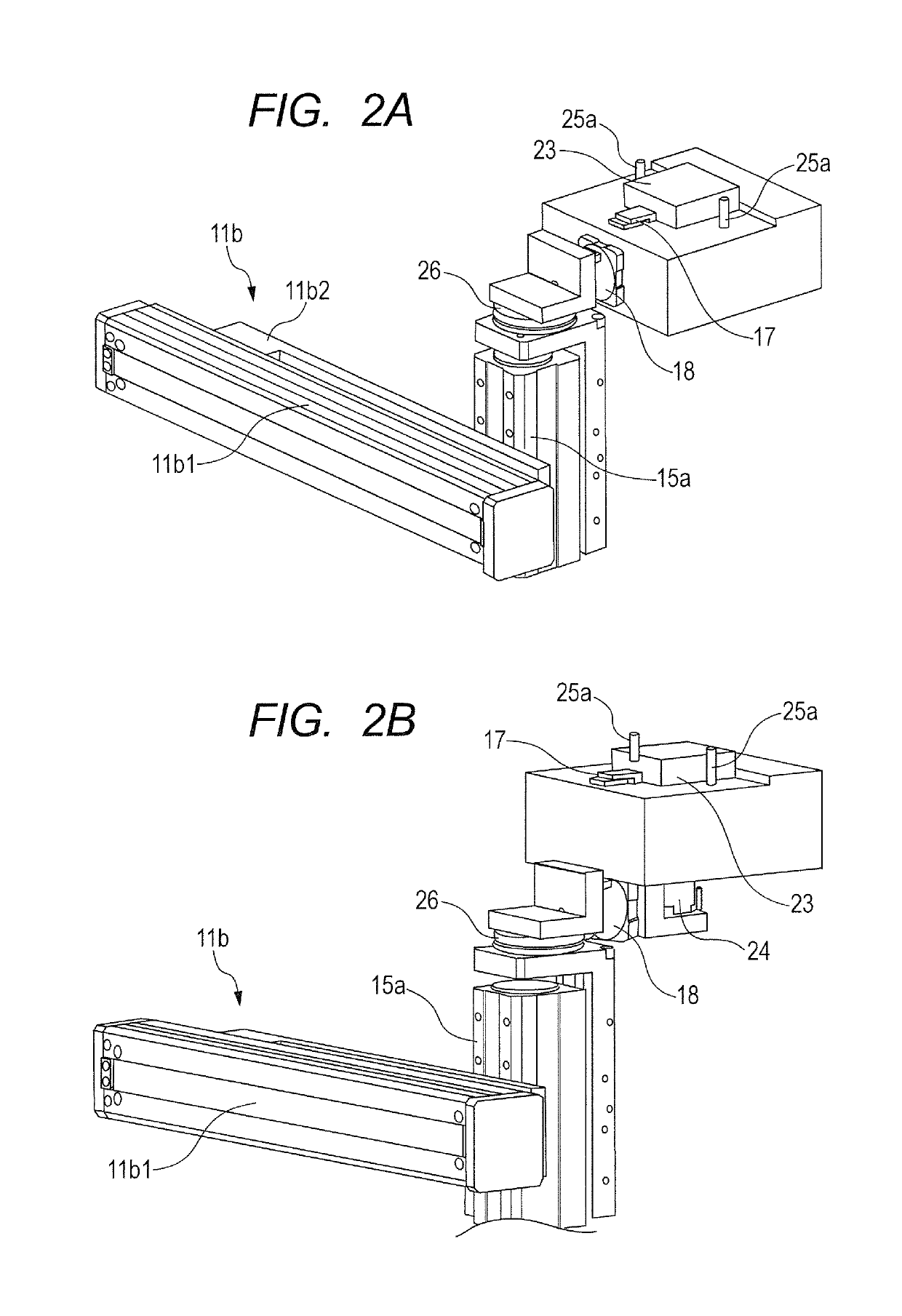

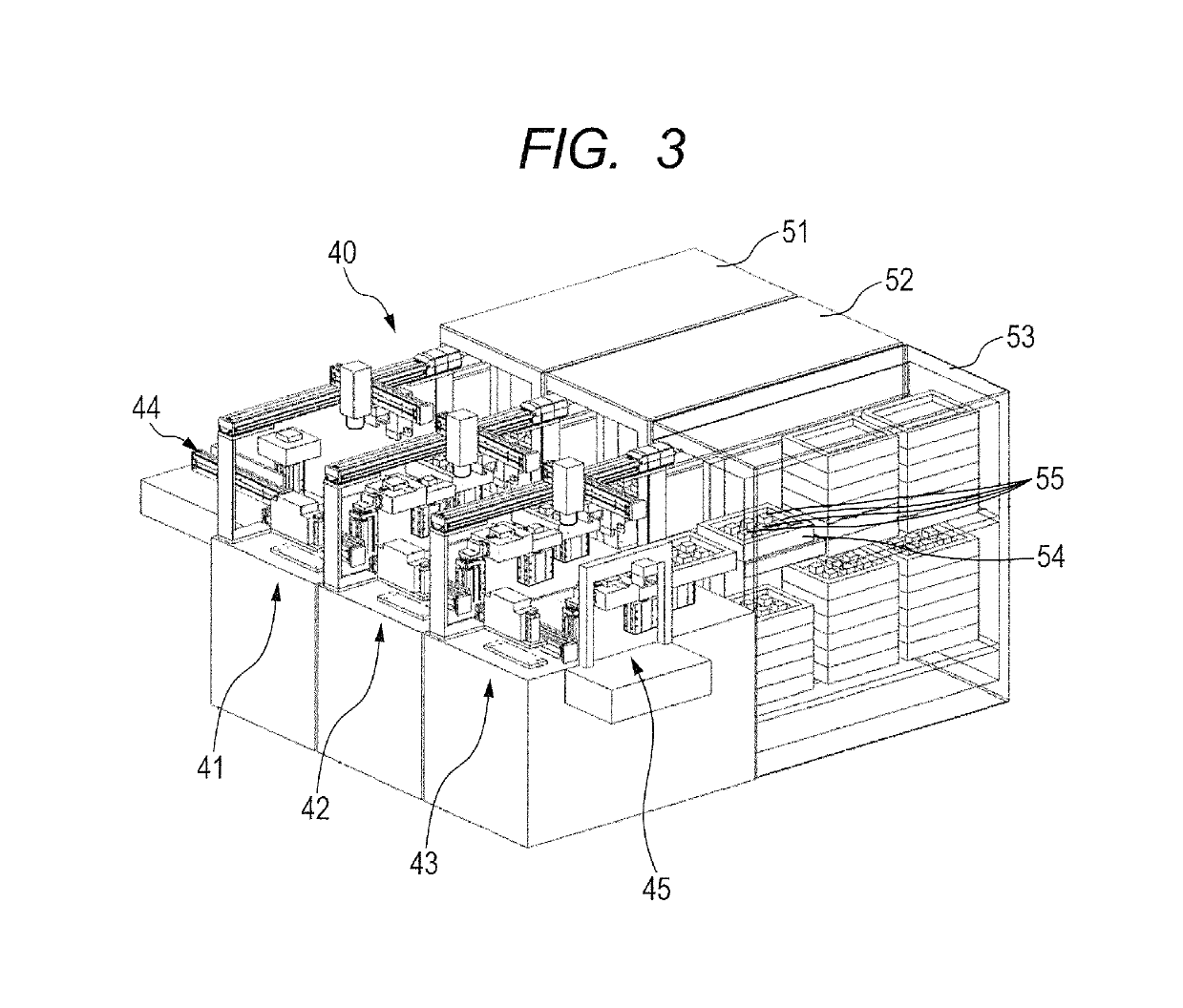

Automated assembly apparatus, automated assembly system and automated assembly method

ActiveUS20160089755A1Accurate assembly operationAccurate operationProgramme-controlled manipulatorAssembly machinesEngineeringMechanical engineering

An automated assembly apparatus comprises an assembly robot that includes a Y-axis movement unit, a first X-axis movement unit movable in a Y-axis direction along the Y-axis movement unit, and a grip unit movable in an X-axis direction along the X-axis movement unit, and a workbench unit including a Z-axis movement unit arranged below the assembly robot with respect to an Z-axis and a workbench movable in the Z-axis direction along the Z-axis movement unit, wherein an assembly operation for a first assembly component gripped by the grip unit and a second assembly component mounted on the workbench unit is performed through movement in the Z-axis direction by the workbench unit.

Owner:CANON KK

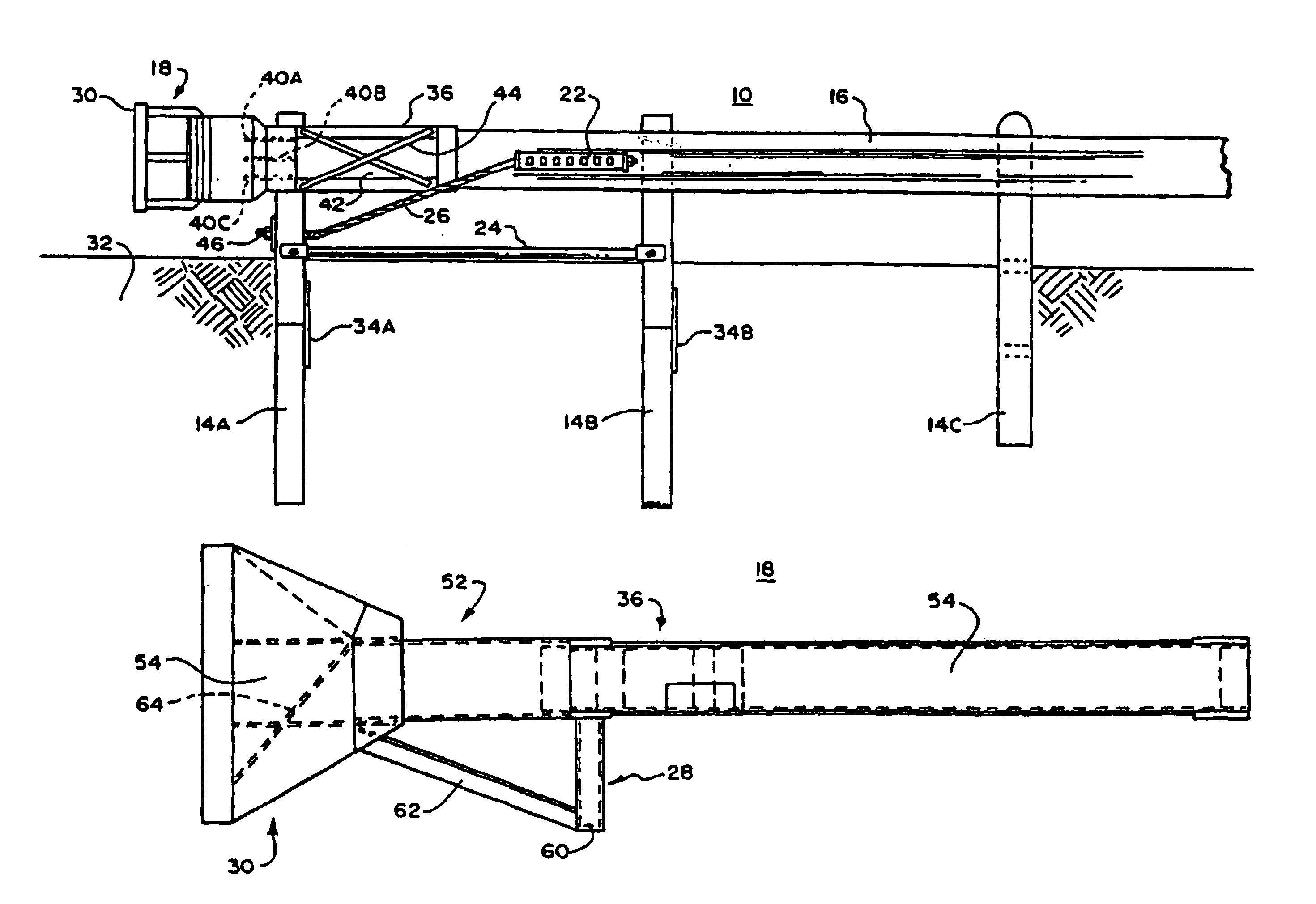

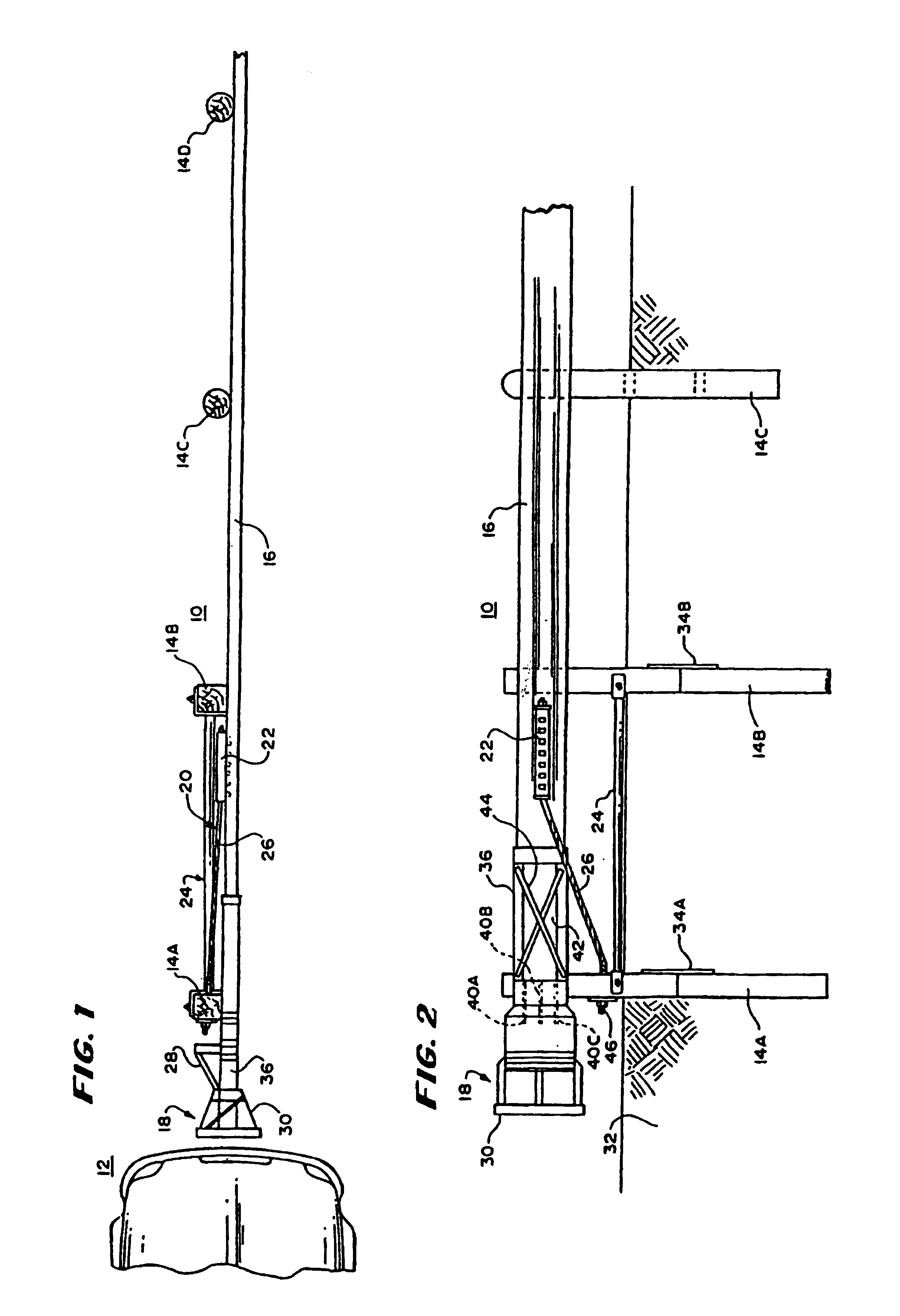

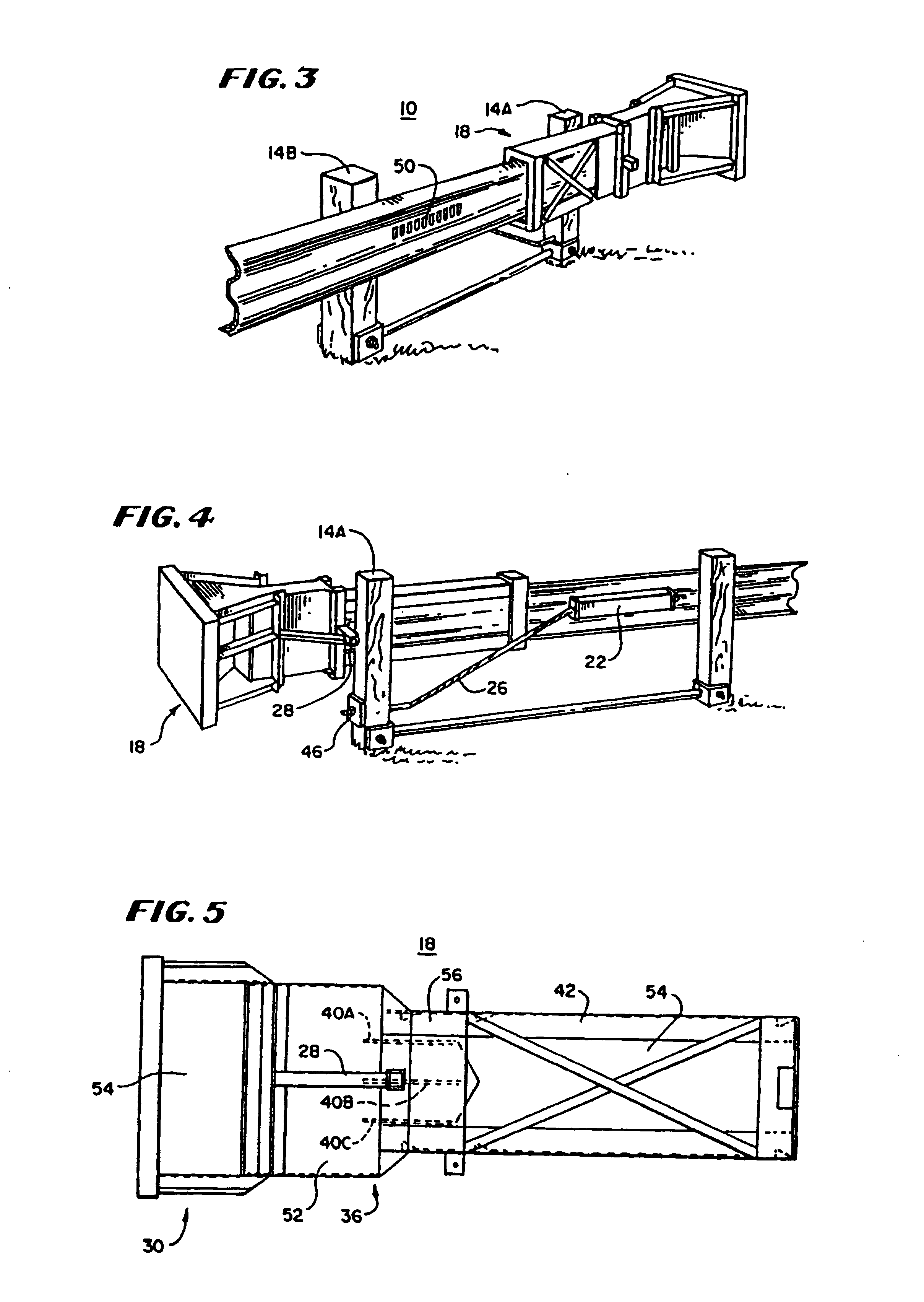

Energy-absorption system

To reduce the danger of bodily harm to occupants of vehicles that leave a roadway, a guardrail system includes an energy-absorption system is provided. The energy-absorption system including a cutting mechanism positioned to cut a guardrail section upon impact by a vehicle to decelerate the vehicle.

Owner:KOTHMANN ENTERPRISES

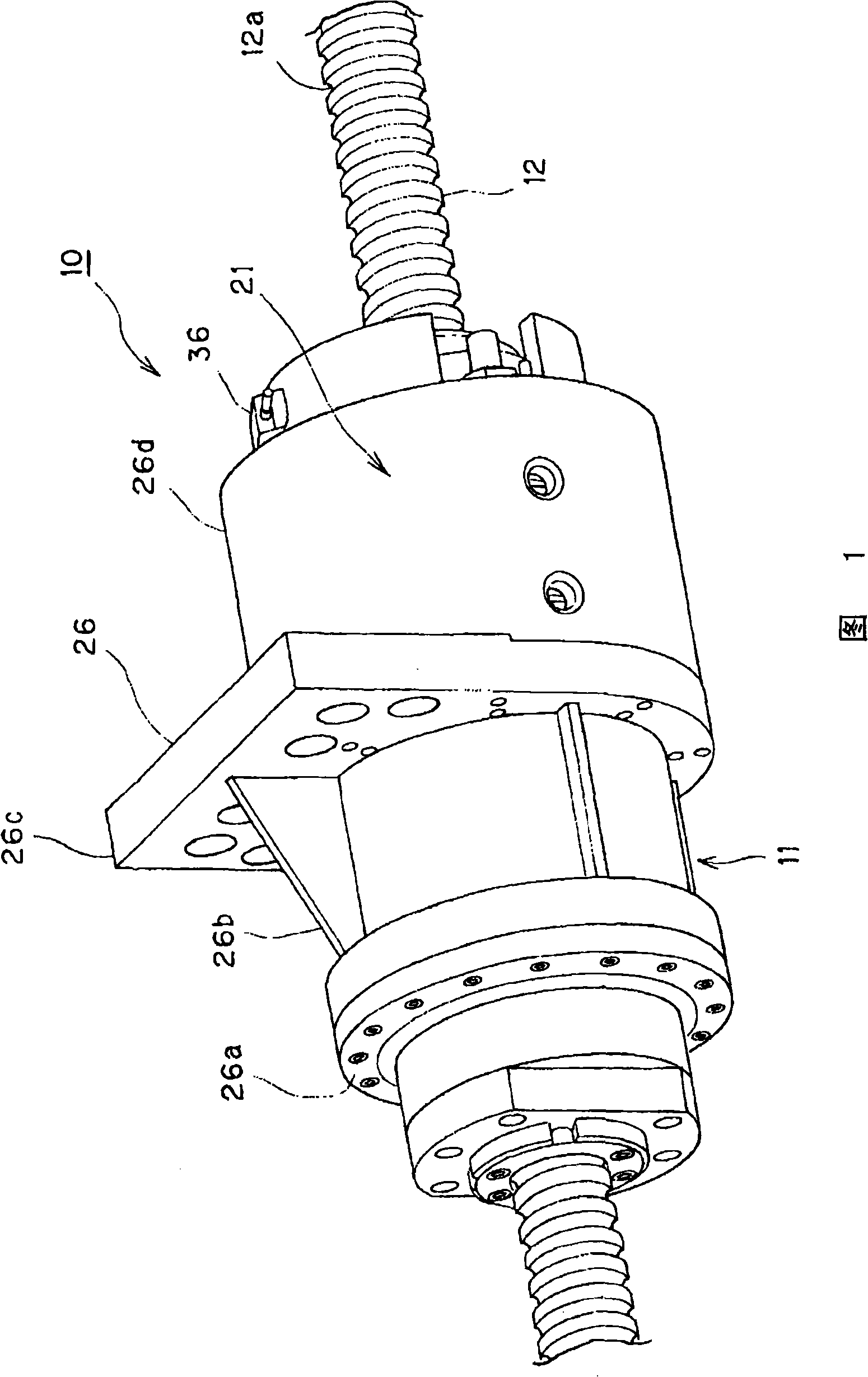

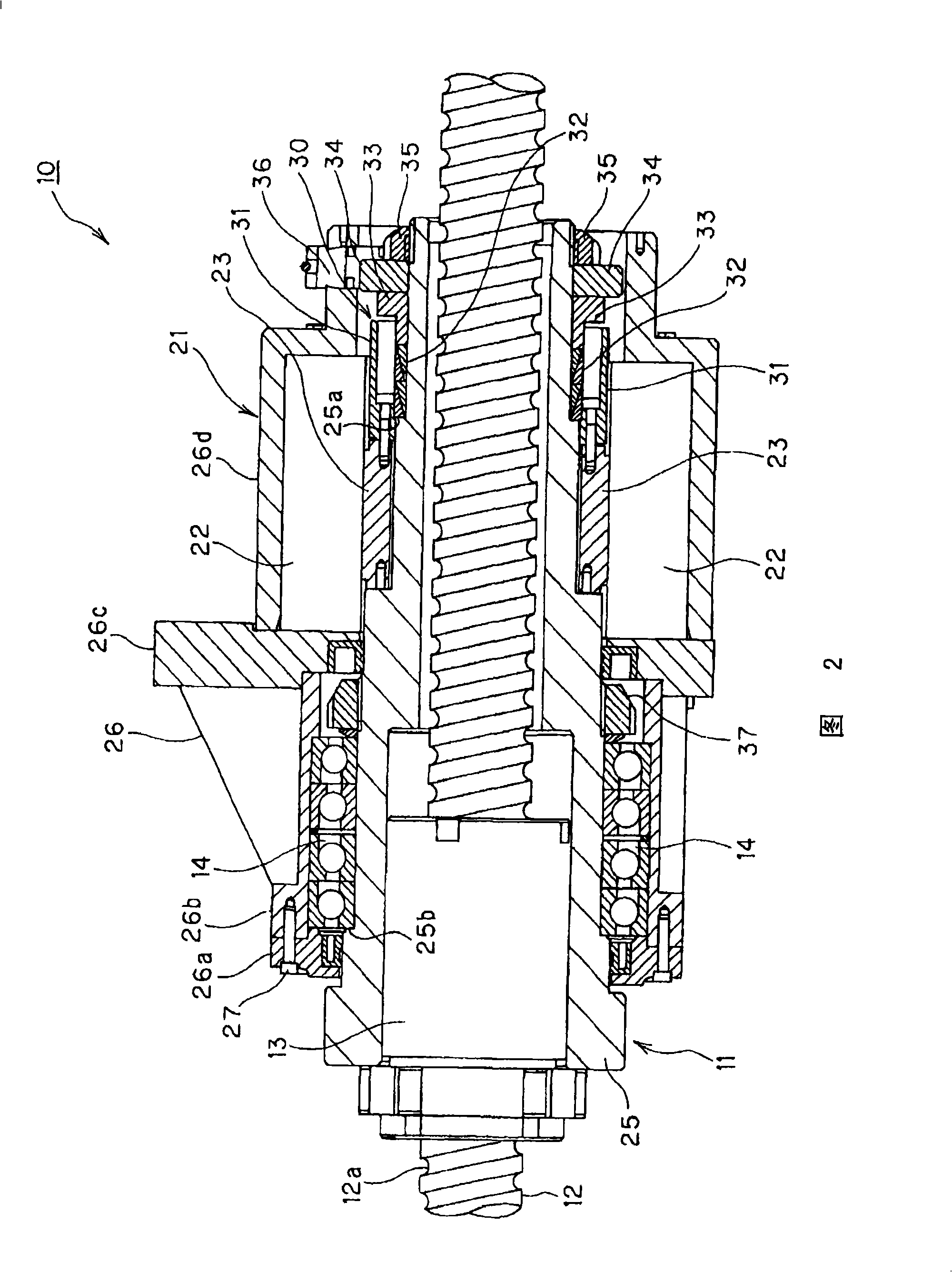

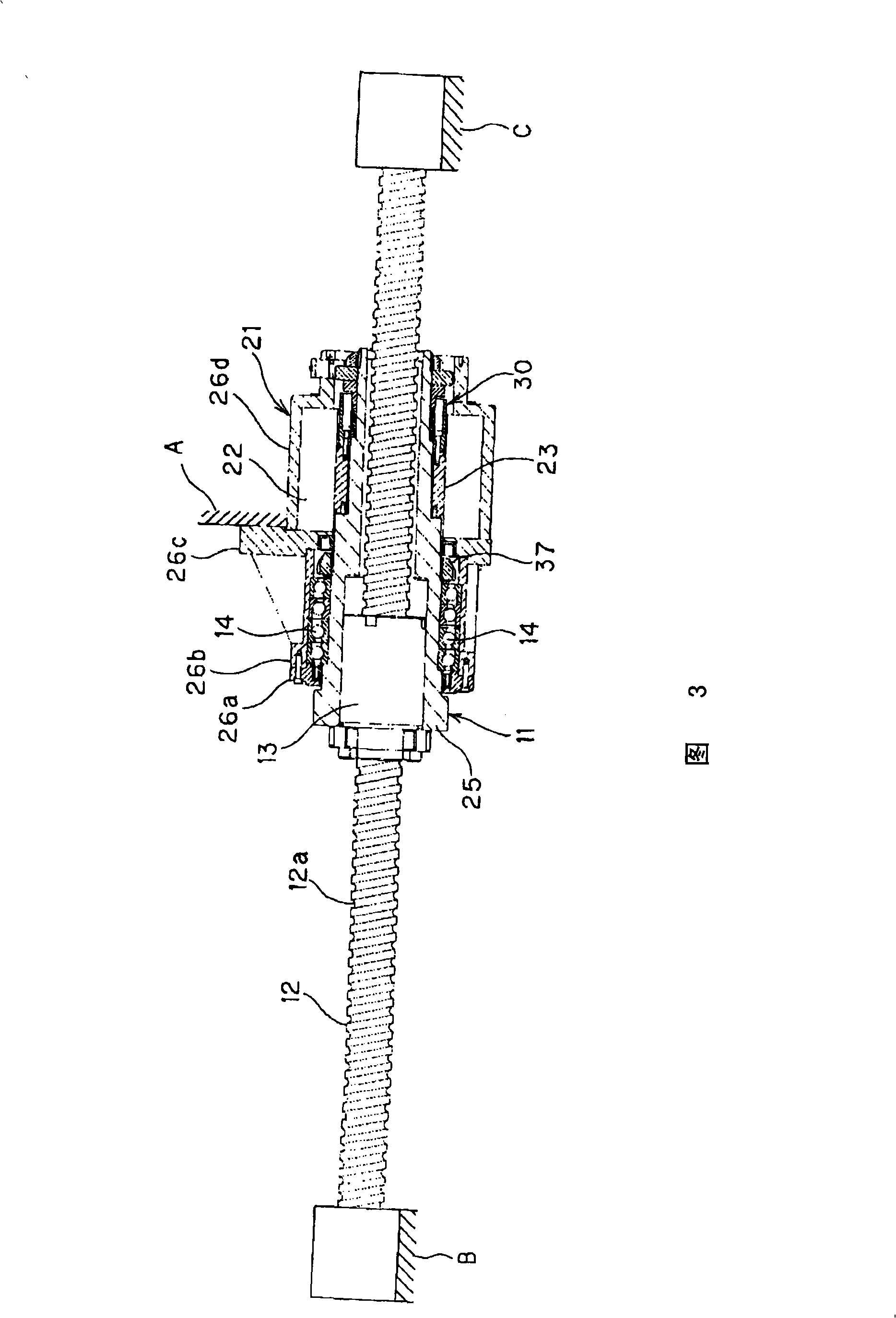

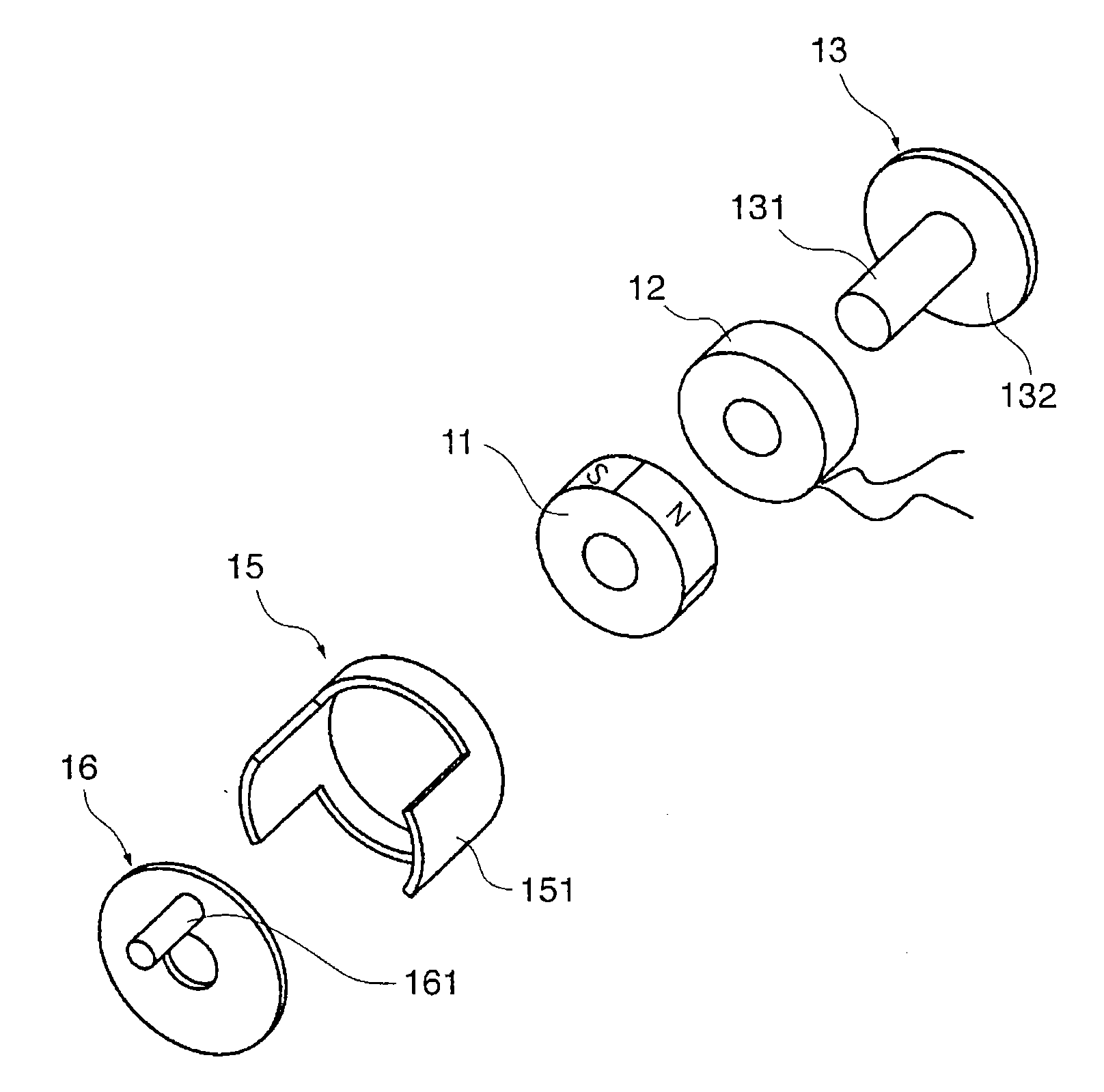

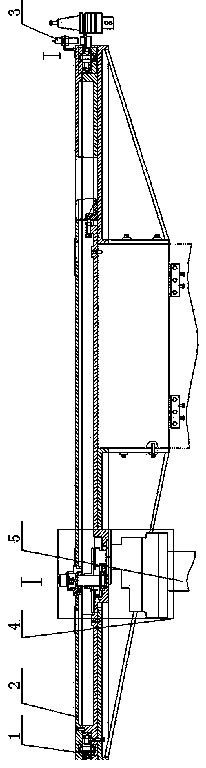

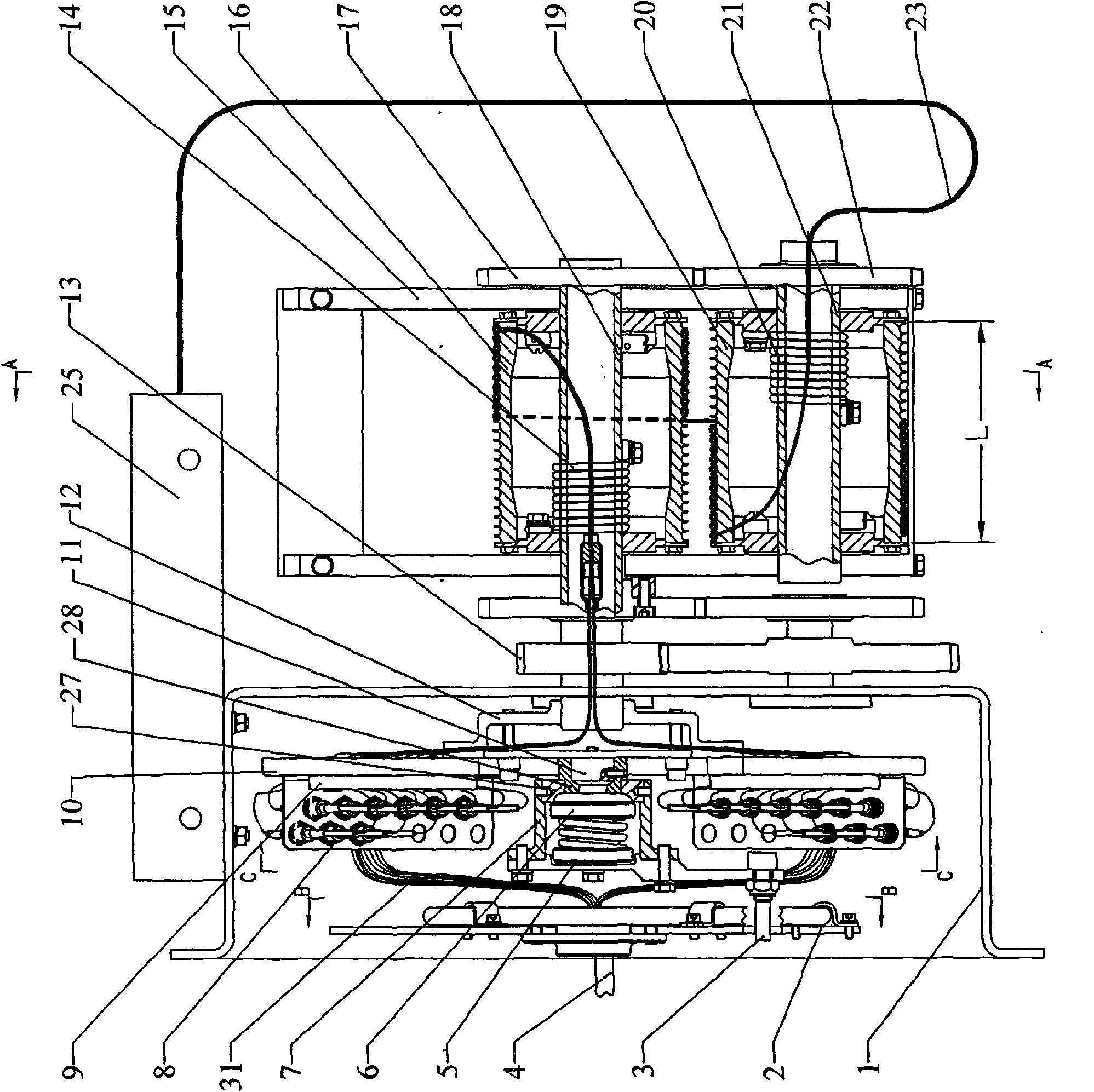

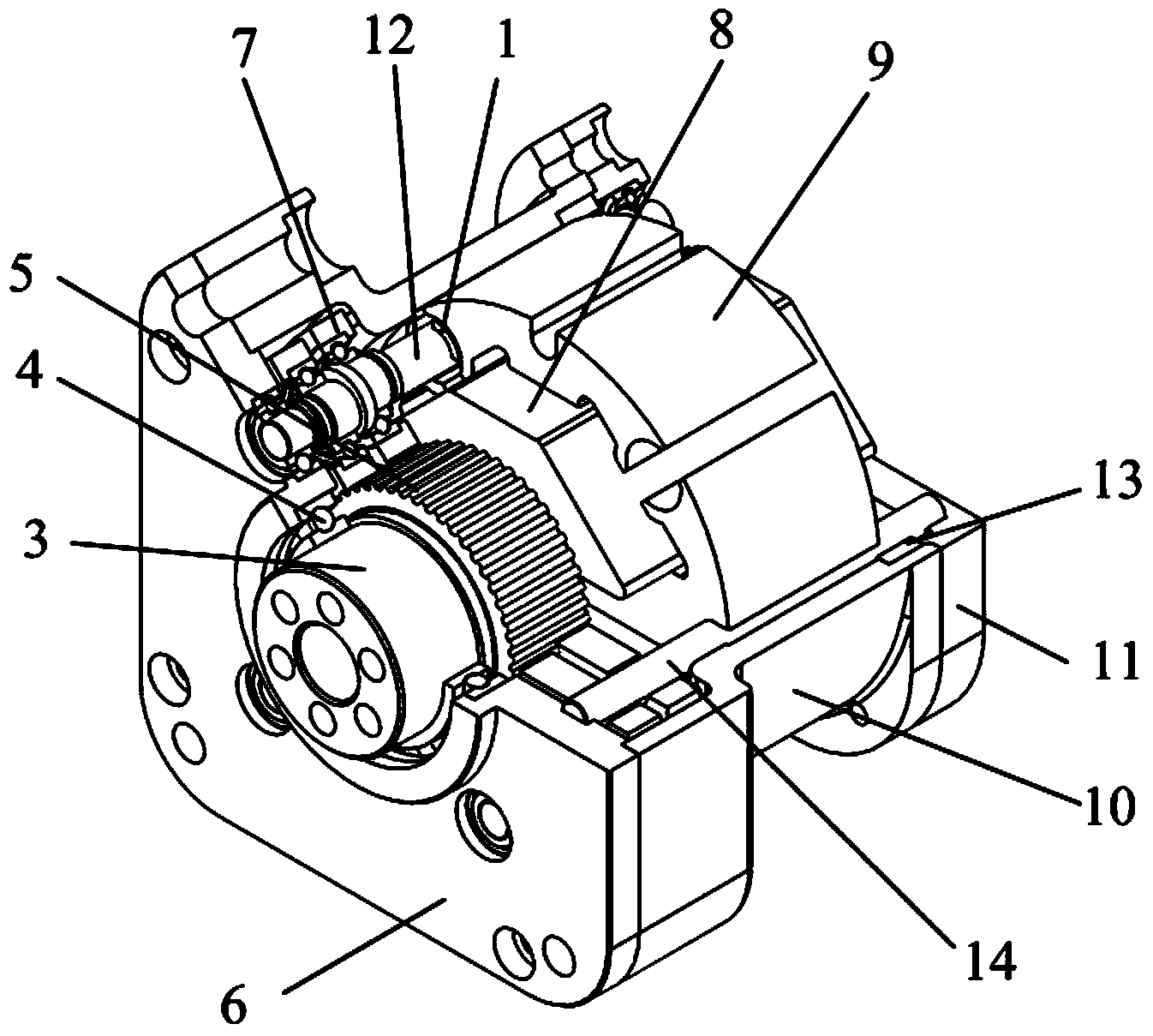

Hollow motor drive device

ActiveCN101336507AReduce the moment of inertiaGood stop responsivenessGearingMechanical energy handlingMotor driveDrive shaft

A hollow motor drive device (10) comprises a screw shaft (12) with a spiral screw groove (12a) formed in the outer peripheral surface, a nut member (13) threaded with the screw groove (12a), a hollow drive shaft (25) with the nut member (13) fixedly fitted to its inner peripheral side and a permanent magnet (23) fitted to its outer peripheral side, and a housing (26) having a bearing part (14) rotatively supporting the hollow drive shaft (25) and a coil part (22). In the hollow drive shaft (25), the nut member (13) and the permanent magnet (23) are so disposed that they are not overlapped with each other in the direction perpendicular to the axial direction of the hollow drive shaft (25). In the housing (26), the bearing part (14) is disposed at a position corresponding to the nut member (13), and the coil part (22) is disposed at a position corresponding to the permanent magnet (23). By adopting this constitution, it is possible to provide a hollow motor drive device having a high rigidity, excellent stop-responsive performance, excellent maintainability and compact shape.

Owner:THK CO LTD +1

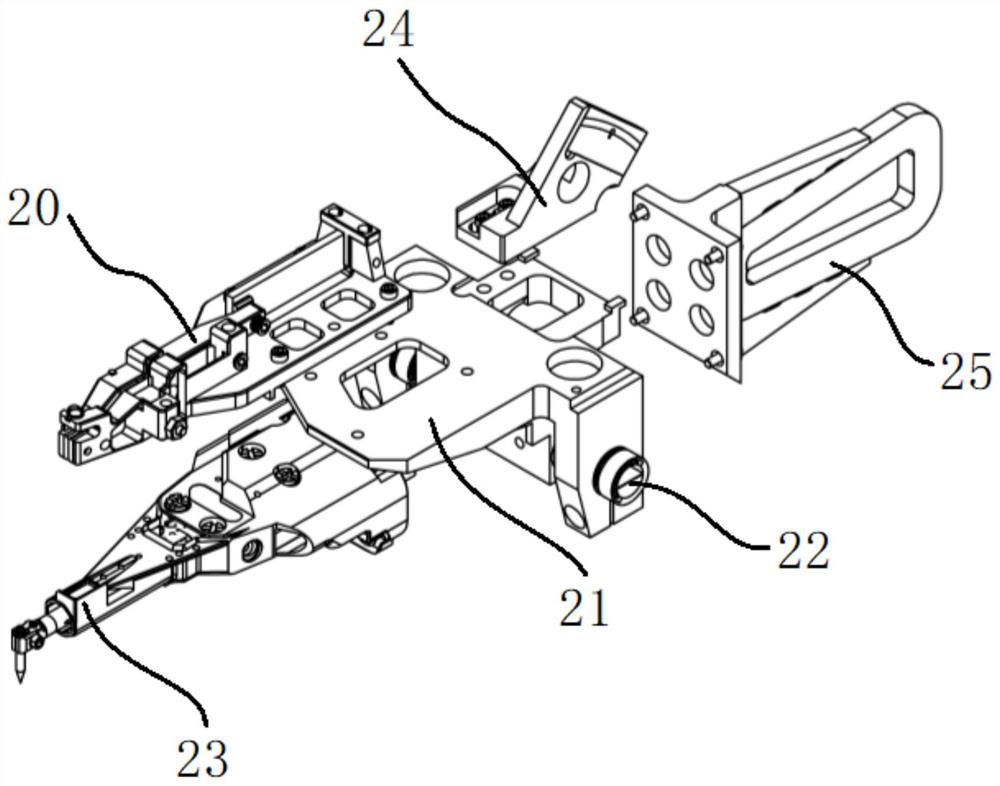

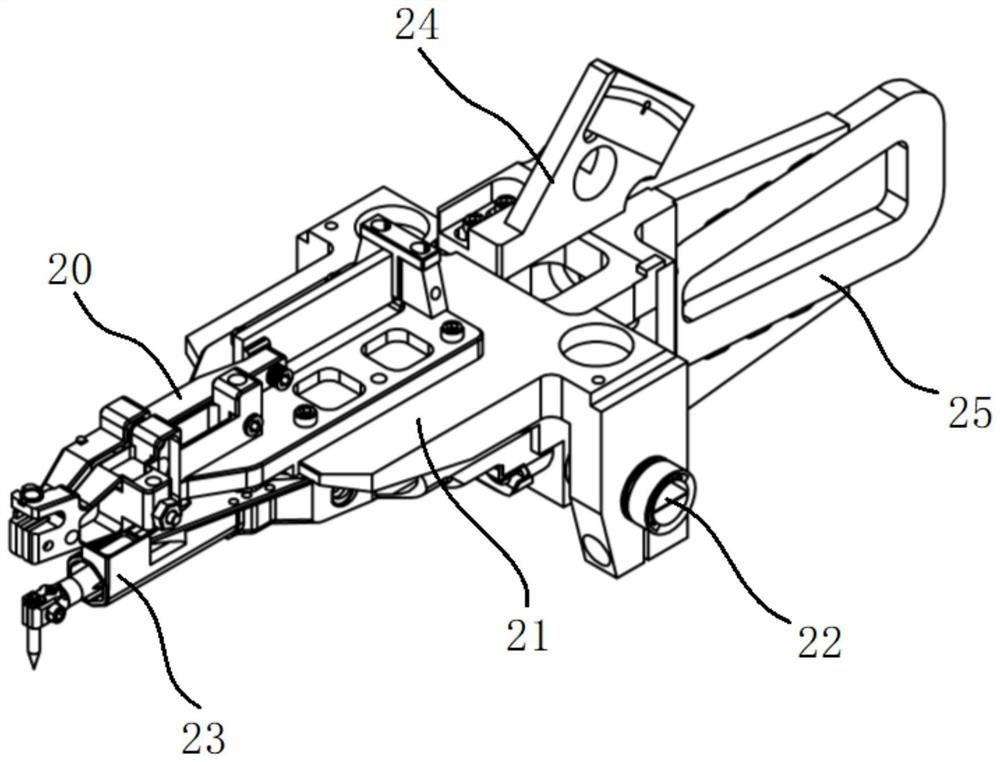

Two-degree-of-freedom microgripper

ActiveCN108406738AReduce quality problemsReduce the moment of inertiaMicromanipulatorGripping headsHinge angleTwo degrees of freedom

The invention discloses a two-degree-of-freedom microgripper. The microgripper is of an asymmetrical structure integrally formed by linearly cutting a panel, and comprises a differential displacementmagnifying mechanism, a lever displacement magnifying mechanism and a base body, wherein the differential displacement magnifying mechanism is arranged on the right side of a center line of the gripper; the lever displacement magnifying mechanism is arranged on the left side of the center line of the gripper; the differential displacement magnifying mechanism is provided with an L-shaped rod pieceI, an L-shaped rod piece II, an L-shaped rod piece III, an input rod piece and a horizontal rod piece; the lever displacement magnifying mechanism and the base body are connected by adopting a flexible hinge III; an input end and an output end are arranged at two ends of the lever displacement magnifying mechanism; and the input end of the lever displacement magnifying mechanism is driven througha piezoelectric ceramic actuator II. The two-degree-of-freedom microgripper provided by the invention is small in volume and compact in structure, has two degrees of freedom, low manufacturing cost,and larger displacement magnifying times, can realize clamping force measurement and feedback, and can be applicable to different application fields.

Owner:TIANJIN UNIV

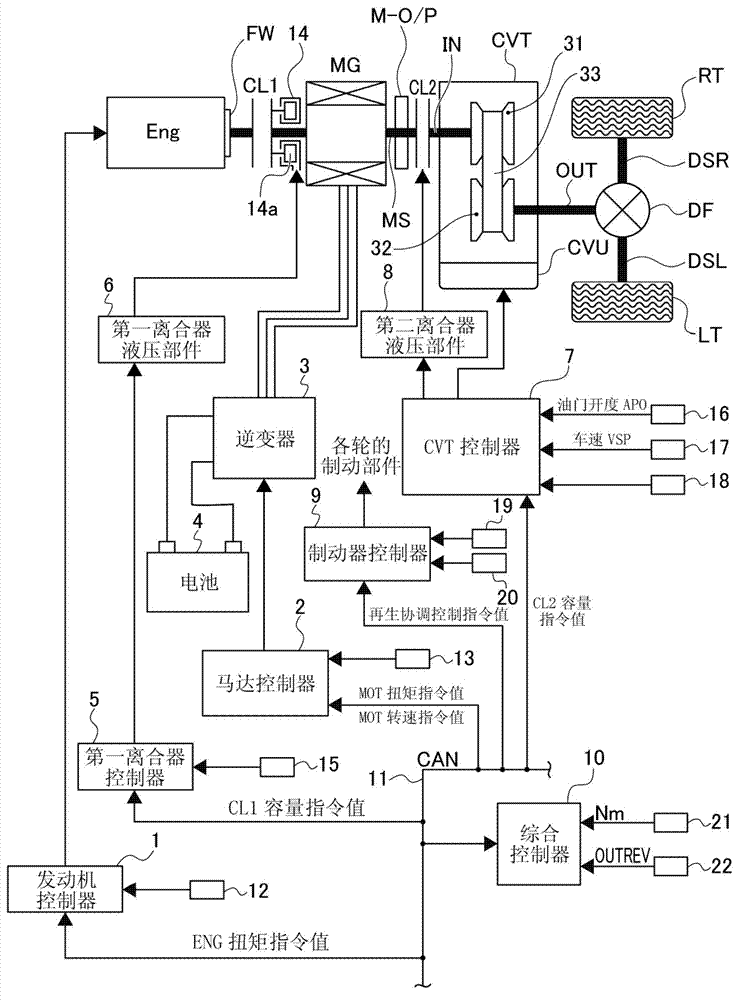

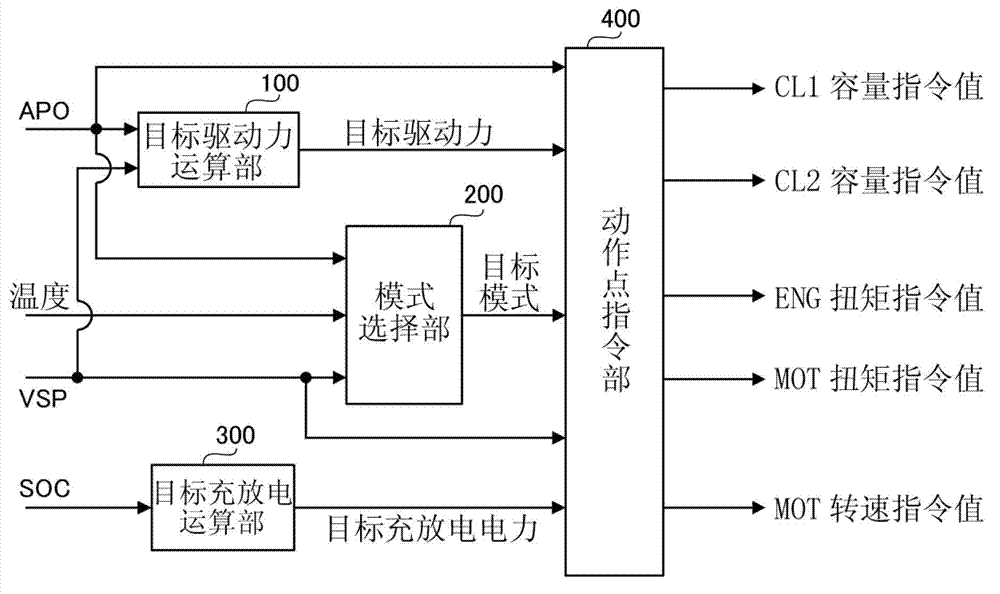

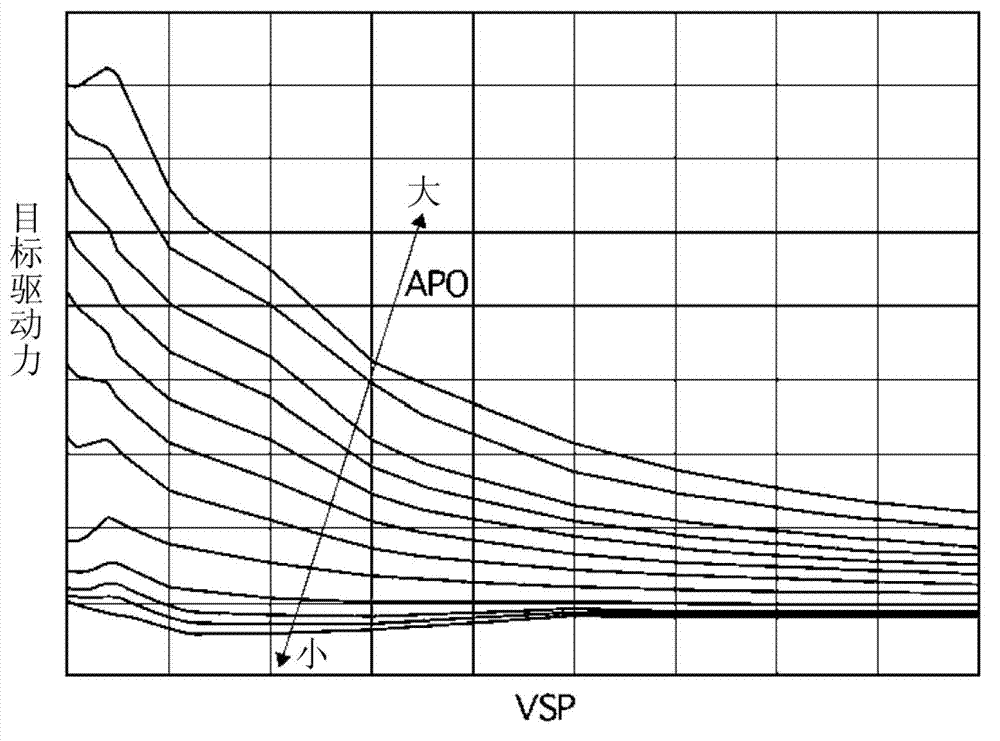

Vehicle control device

ActiveCN103373347AReduce the moment of inertiaSuppress changesRoad transportPropulsion using engine-driven generatorsDrive wheelControl theory

A vehicle control device suppresses change of torque output to driving wheels when a clutch is shifted from a full-joint state to a sliding joint state or from a sliding joint state to a full-joint state. The vehicle control device of a hybrid vehicle comprises a motor, an electric generator, a second clutch and an action instruction value calculating and processing structure, wherein the second clutch is arranged between the electric generator and left and right driving wheels, and the sliding joint WSC driving mode is shifted to a full joint HEV driving mode or vice versa. When the action instruction value calculating and processing structure is under an HEV driving mode, the ENG torque instruction value and MOT torque instruction value for the motor and the electric engine are set to a value obtained by adding a target transmission torque for the output shaft of the second clutch, namely T / M input target torque, to a torque of revolving rising inertial part (inertial torque) of the motor and the electric engine.

Owner:NISSAN MOTOR CO LTD

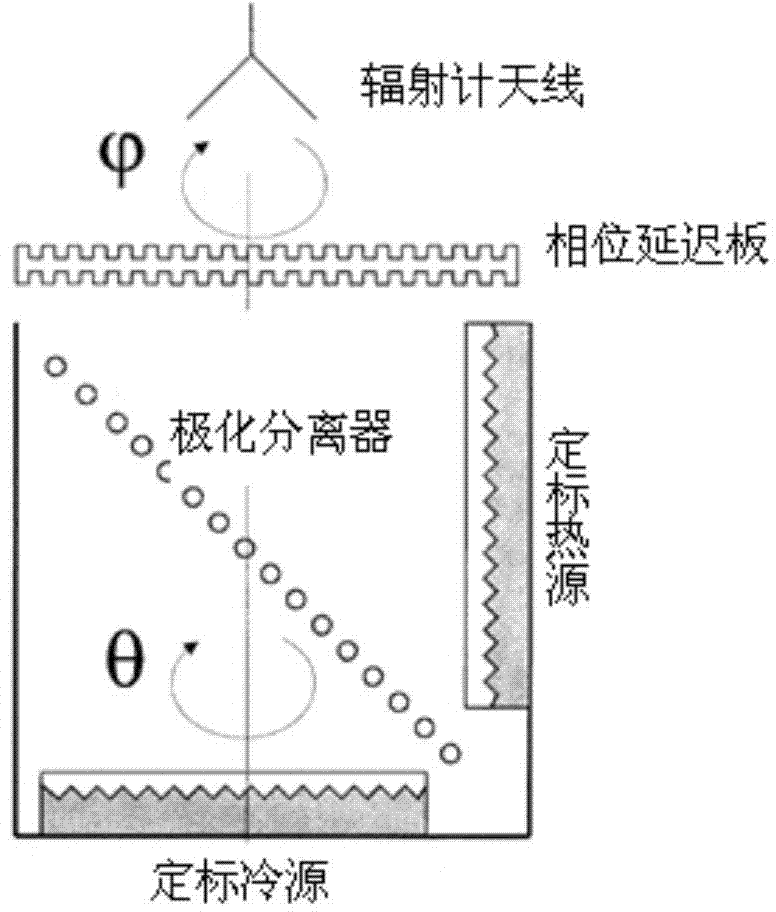

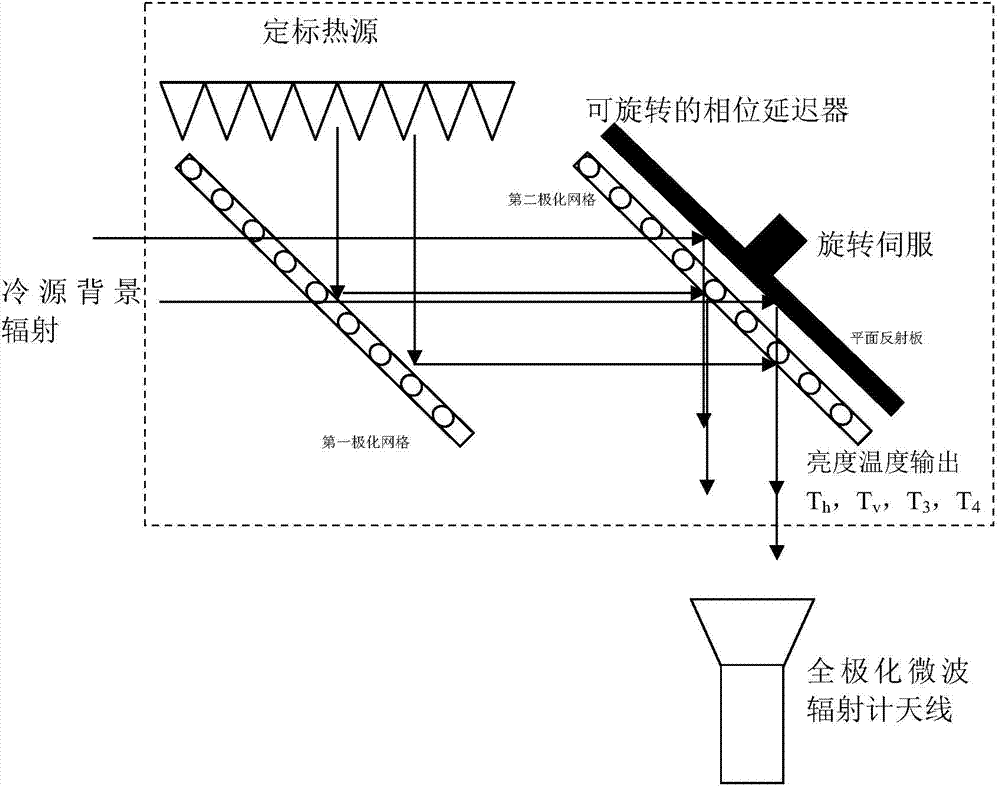

Novel complete polarization temperature-changing source device of microwave radiometer

ActiveCN104266768AContinuously variable output brightness temperatureShort temperature change timeRadiation pyrometryTemperature controlBrightness temperature

The invention provides a novel complete polarization temperature-changing source device of a microwave radiometer. The device comprises a calibrating heat source, a calibrating cold source, a first polarization grid and a phase delayer, wherein a plane where the calibrating heat source is located and a plane where the calibrating cold source is located are in perpendicular mutually, and the first polarization grid is located between the calibrating cold source and the calibrating heat source and forms an angle of 45 degrees with a horizontal plane; relative positions among the calibrating heat source, the calibrating cold source and the first polarization grid are fixed; the phase delayer is arranged in a rotating manner by using a center shaft perpendicular to a plane where the phase delayer is located as a center. Only through the rotation of the phase delayer which consists of a second polarization grid and a plane reflecting plate, the temperature-changing source device can achieve the purpose of changing and outputting brightness and temperature. The temperature of the calibrating heat source is fixed, the temperature is simple to control, the angle of the phase delayer is easy to control, and the precision is higher, so that the device has high temperature changing output stability, the purpose of changing the temperature can be achieved in a shorter time, and the complete polarization calibrating temperature-changing source has stable output.

Owner:NAT SPACE SCI CENT CAS

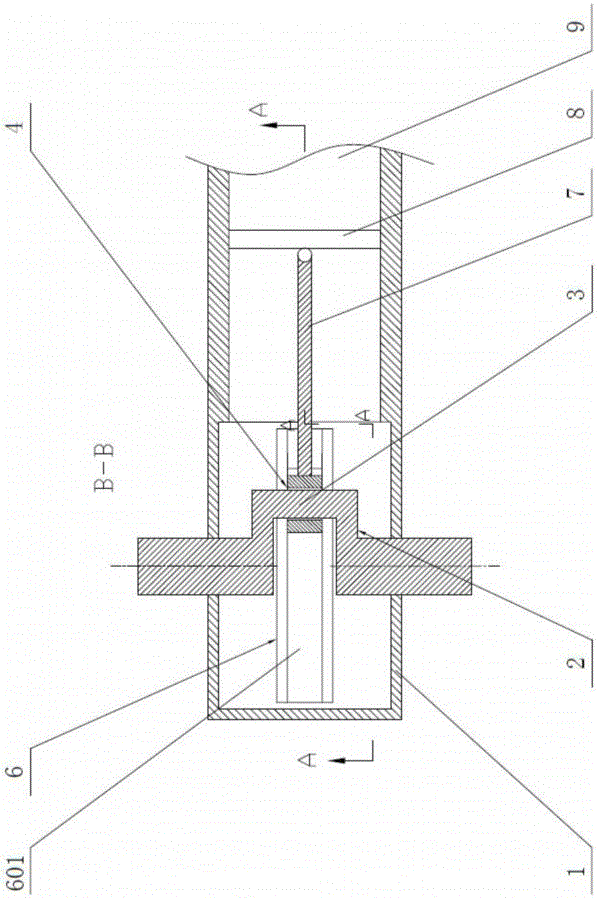

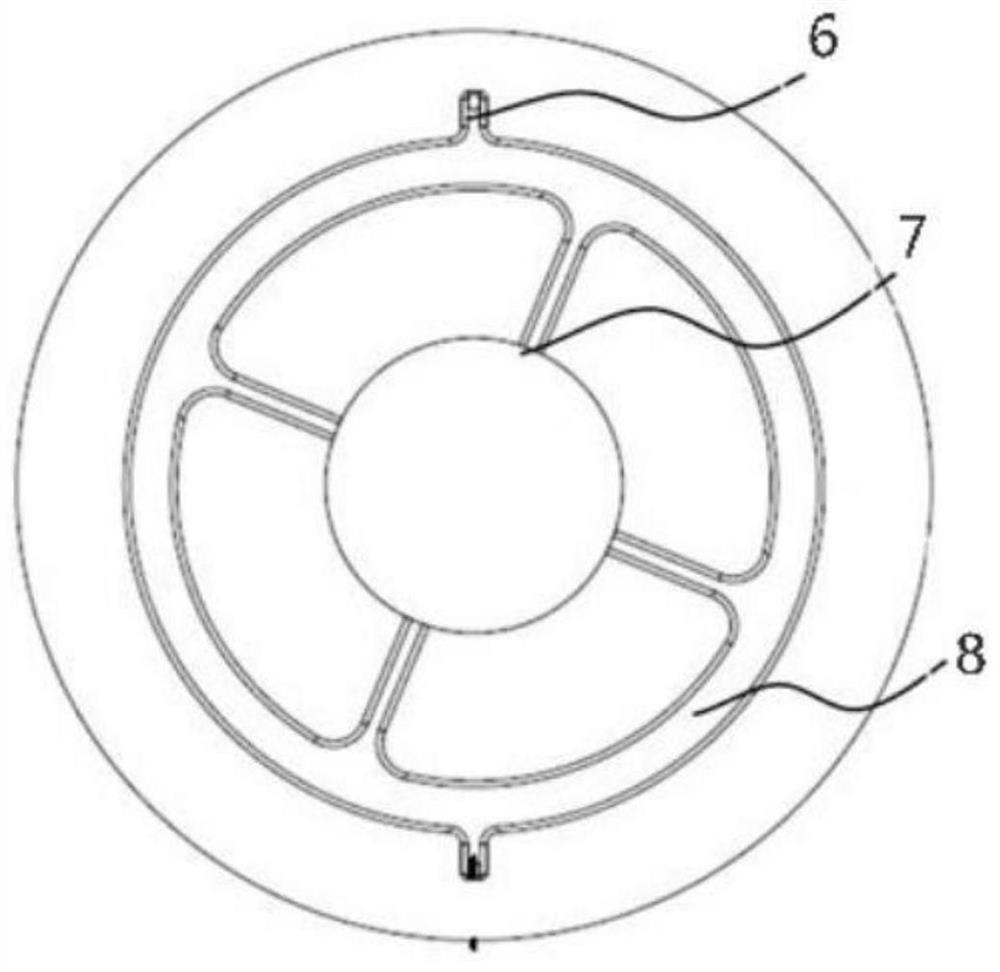

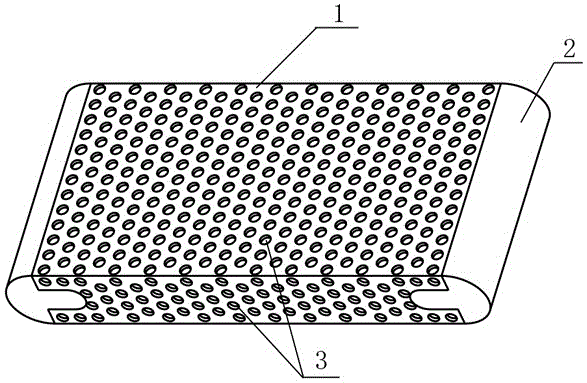

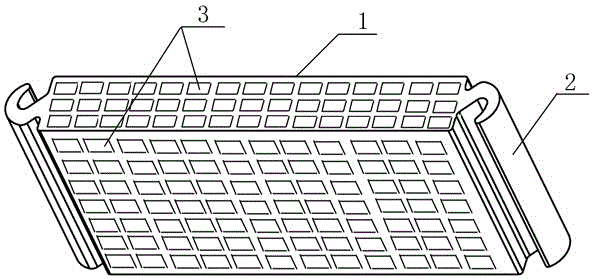

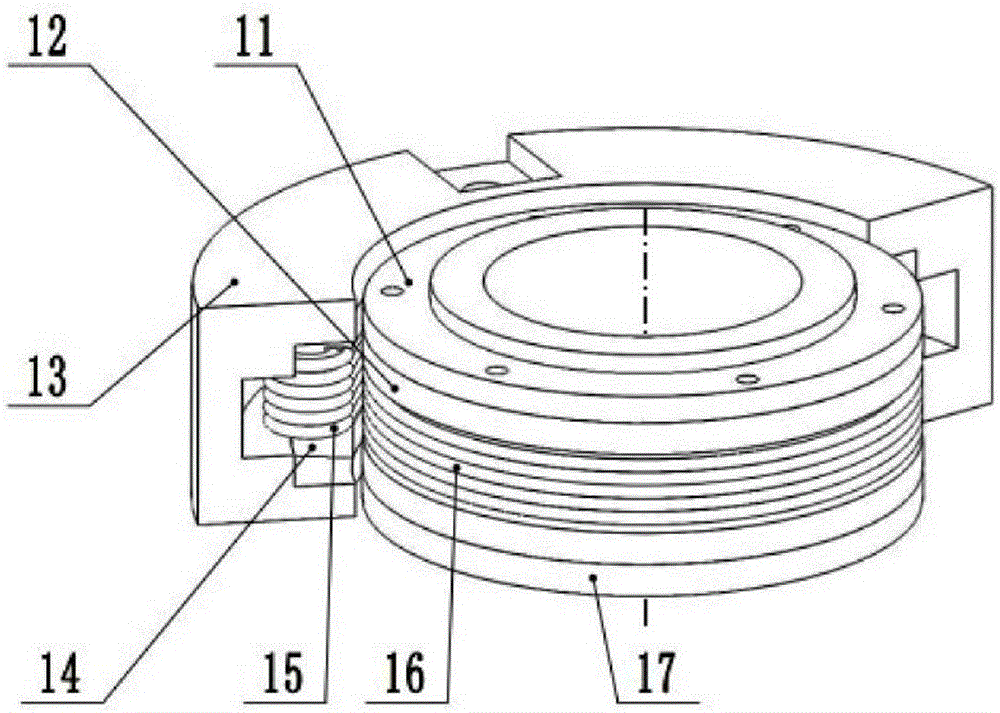

Non-contact induction power supply device used for ultrasonic milling processing

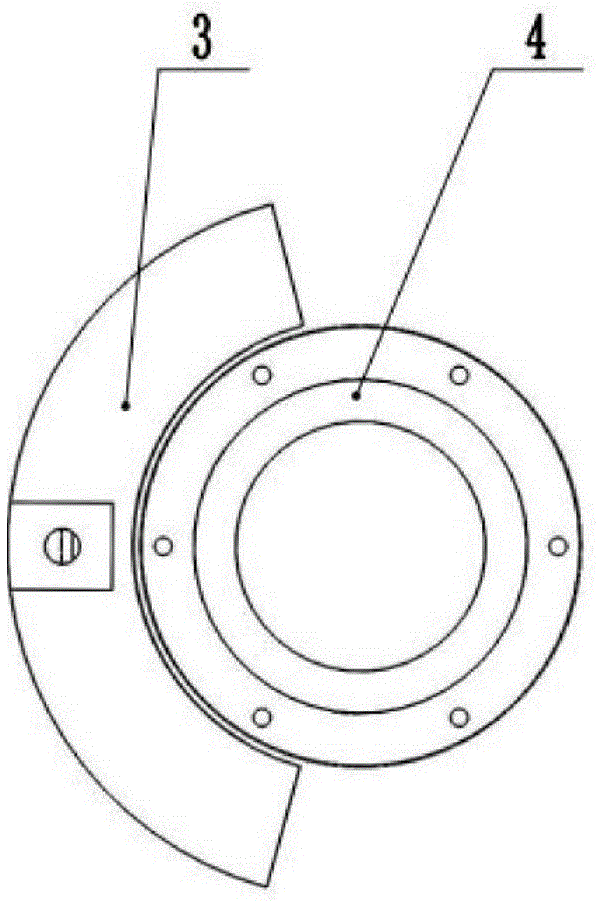

ActiveCN105529836ASmall turning radiusImprove rotational stabilityCircuit arrangementsUltrasonic vibrationEngineering

The invention discloses a non-contact induction power supply device used for ultrasonic milling processing. The non-contact induction power supply device mainly comprises a primary side and a secondary side, wherein the spatial position relationship of the primary side and the secondary side is arranged as an inner and outer concentric circle type, the primary side and the secondary side do not have any mechanical connection, and the primary side is of an incomplete-ring columnar structure which is only provided with 2 / 5 circumference on a circumferential direction. Through the optimal design of the secondary side, under a situation that no compensation components are additionally arranged, mutual compensation is realized under the working vibration frequency of an ultrasonic vibration system by the leak inductance of a secondary side coil and the equivalent capacitive reactance of an ultrasonic vibration system. The non-contact induction power supply device has the advantages of compact structure and small rotational inertia, can carry out expansion installation, and can meet the working requirements that the ultrasonic milling processing can automatically carry out tool change, a main shaft rotates at a high speed and the ultrasonic vibration system is large in power. The power supply requirements of elliptical ultrasonic milling processing also can be met if two groups of non-contact induction power supply devices are installed.

Owner:BEIHANG UNIV

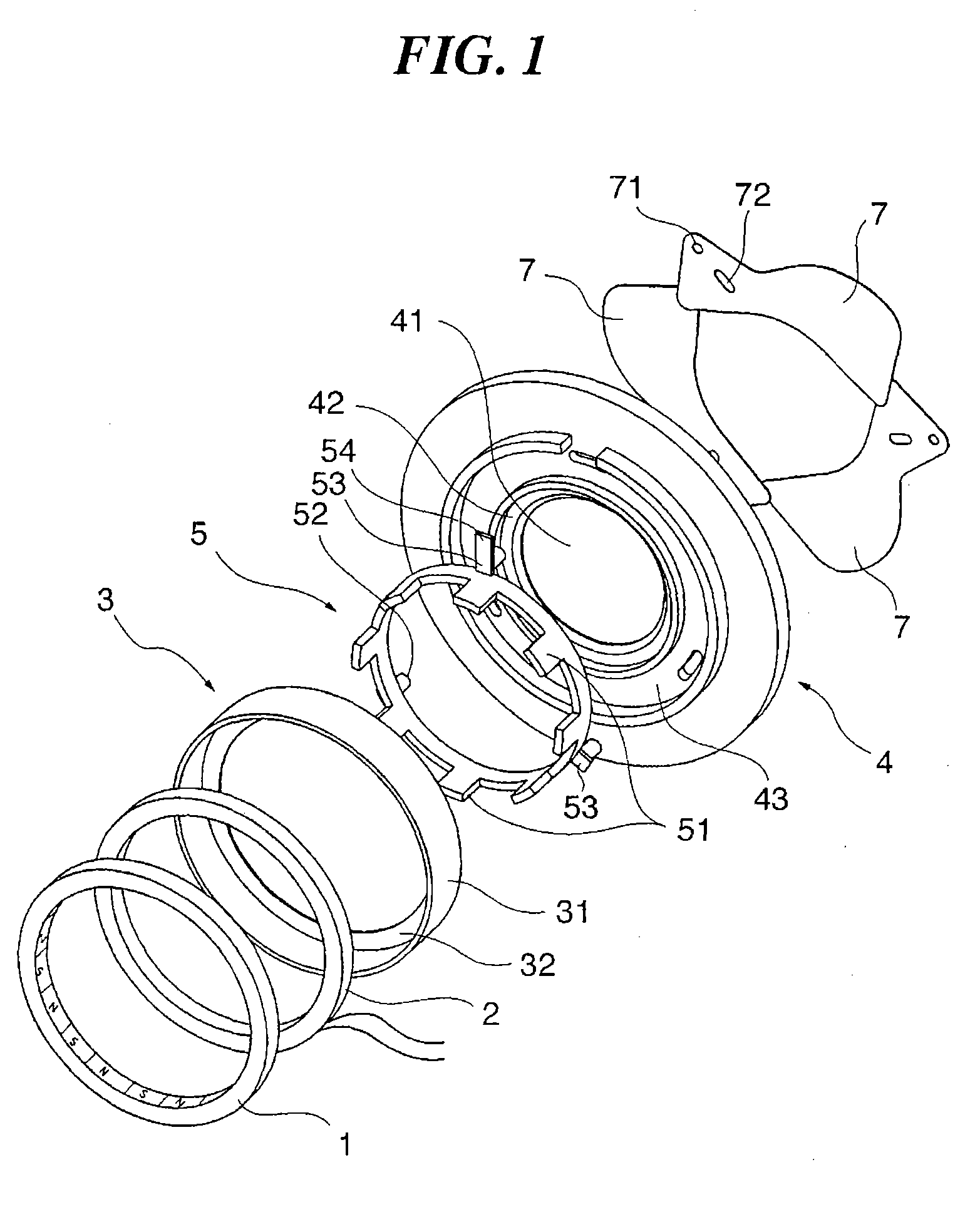

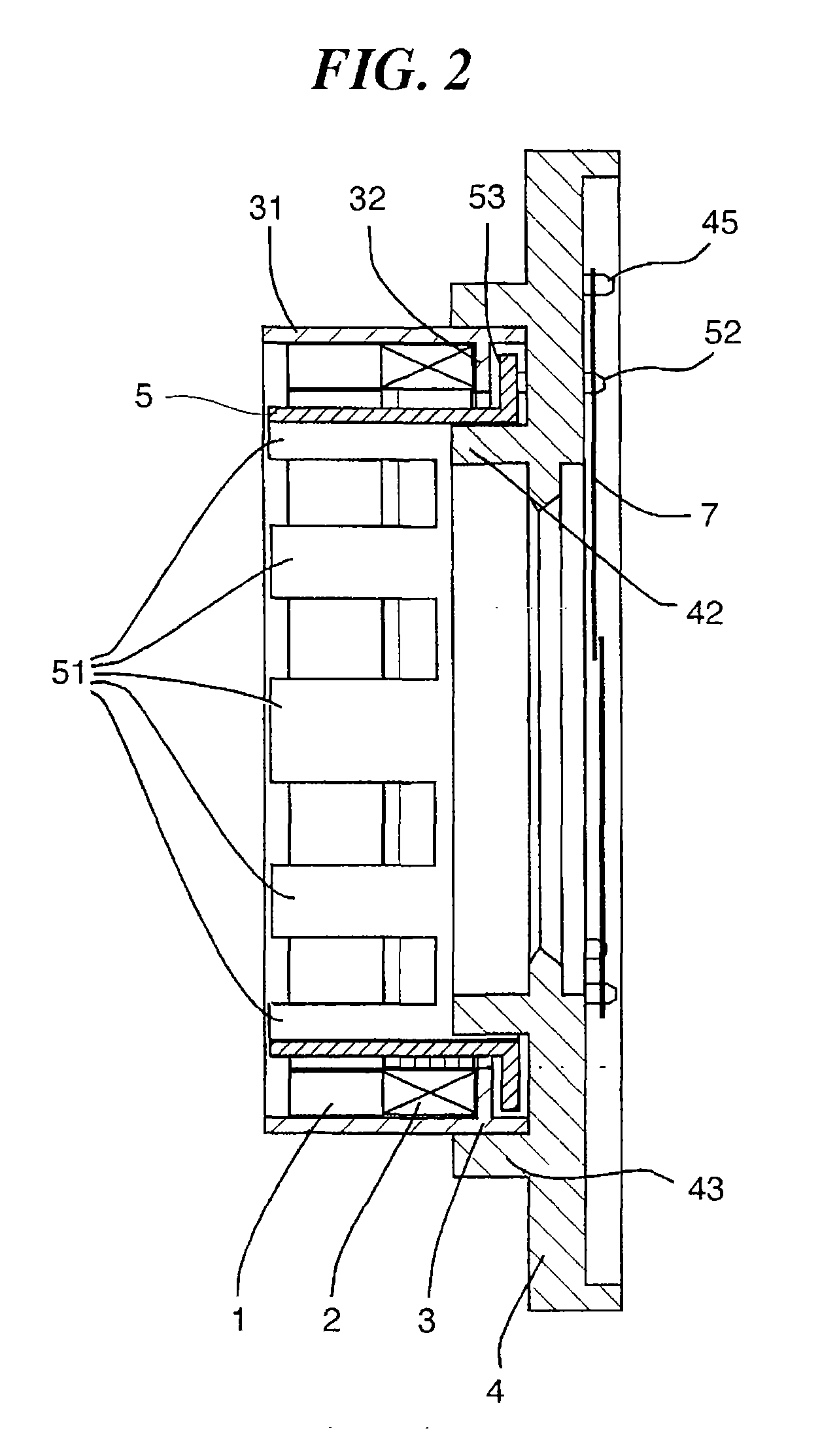

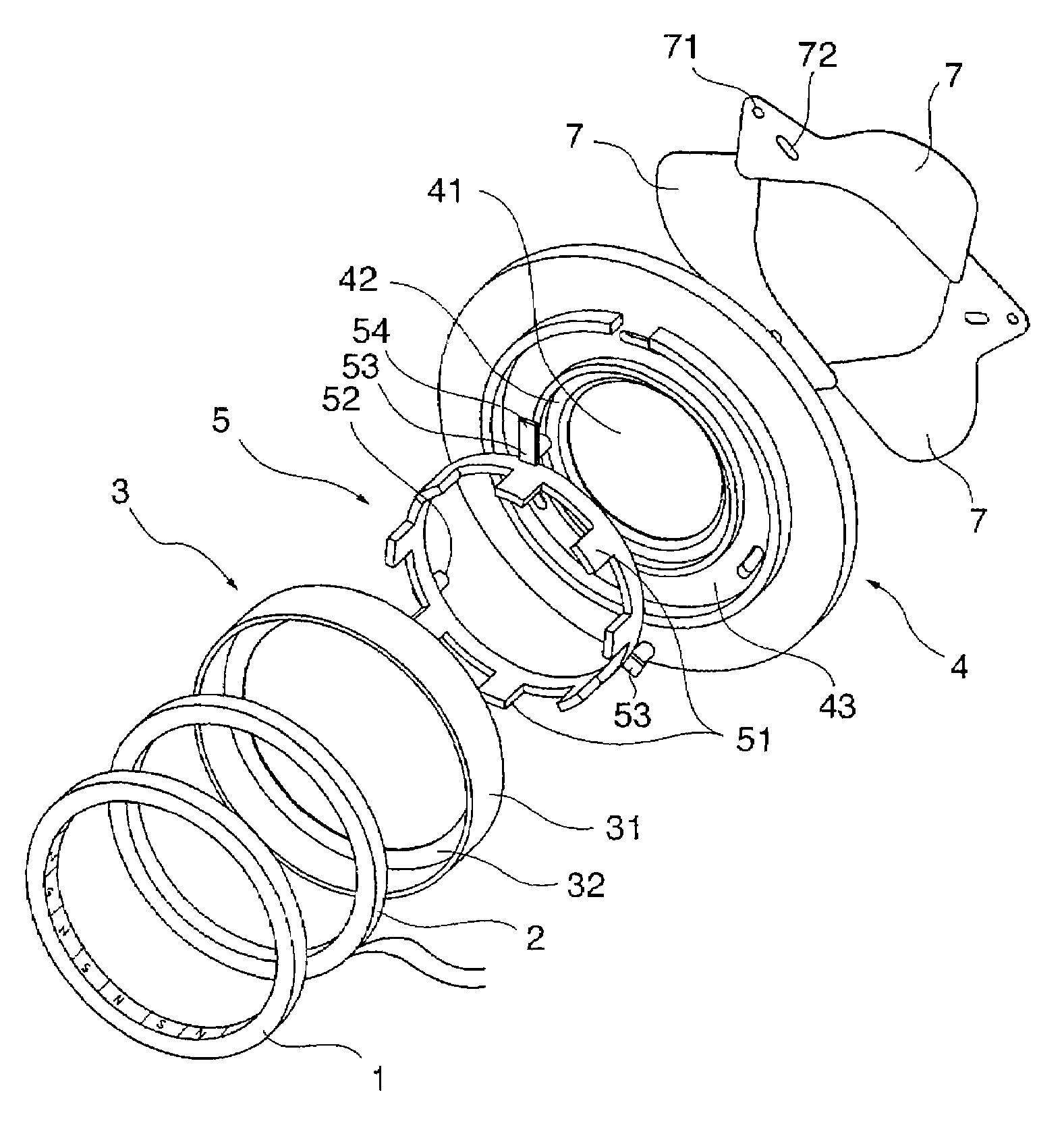

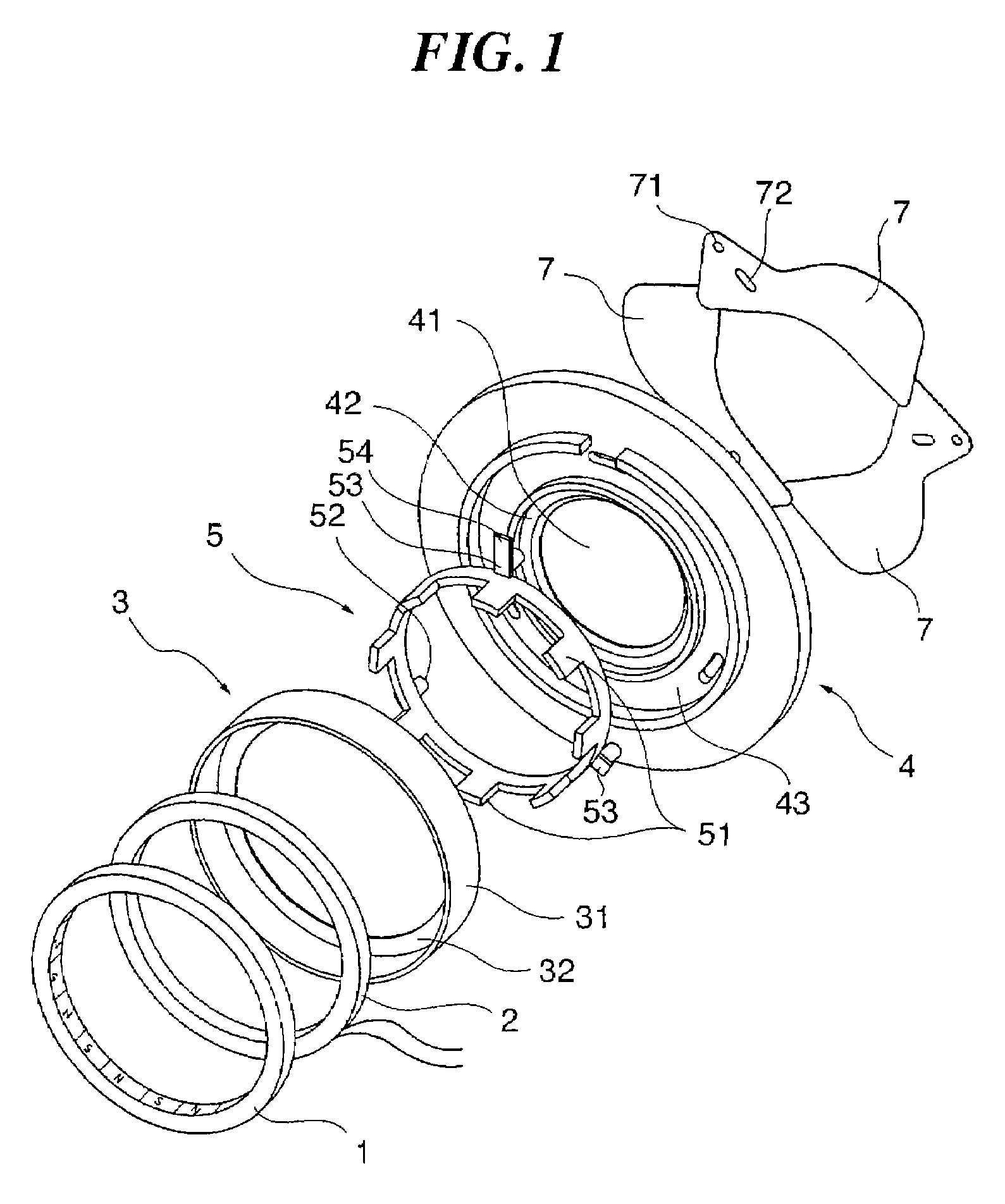

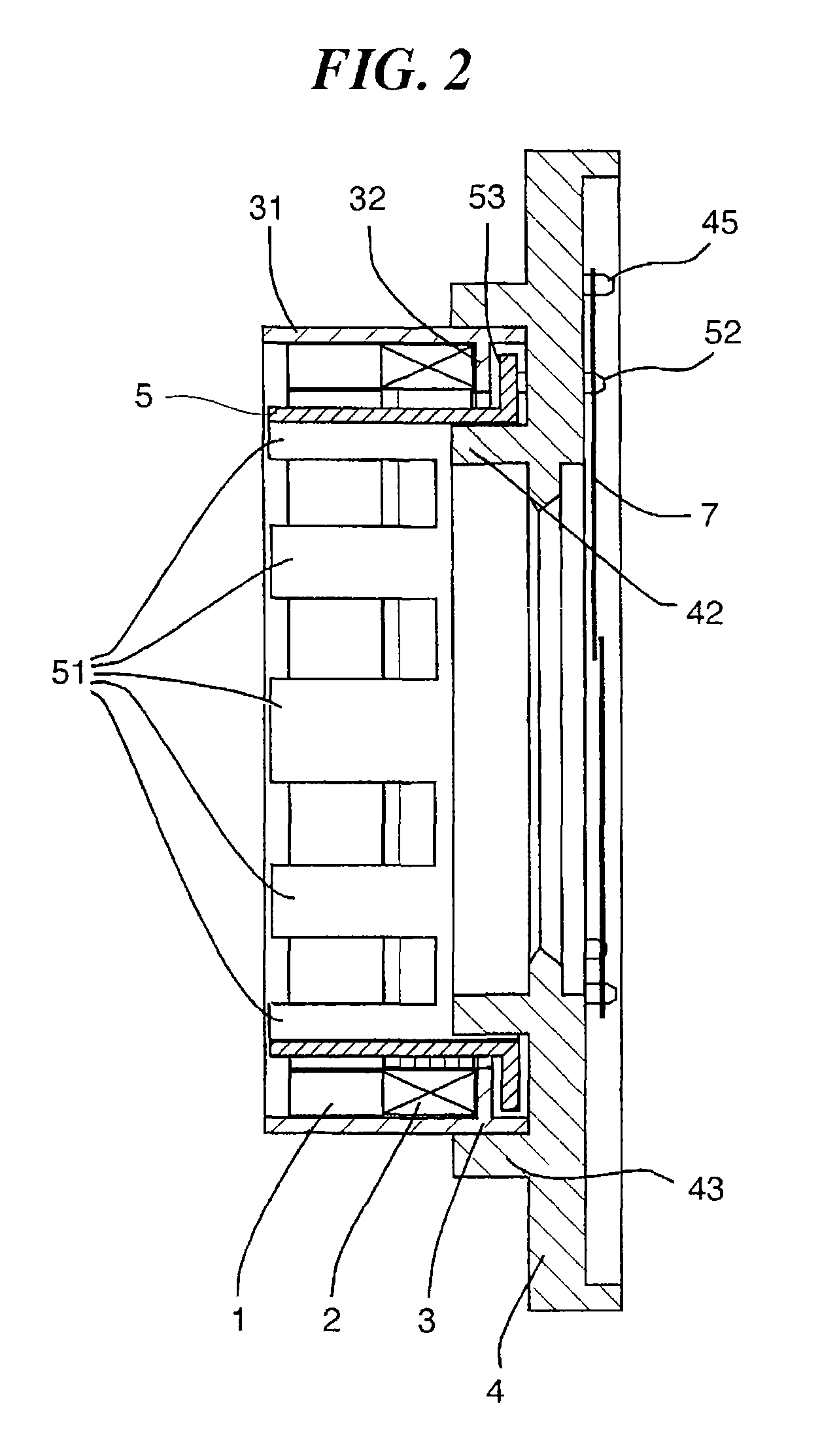

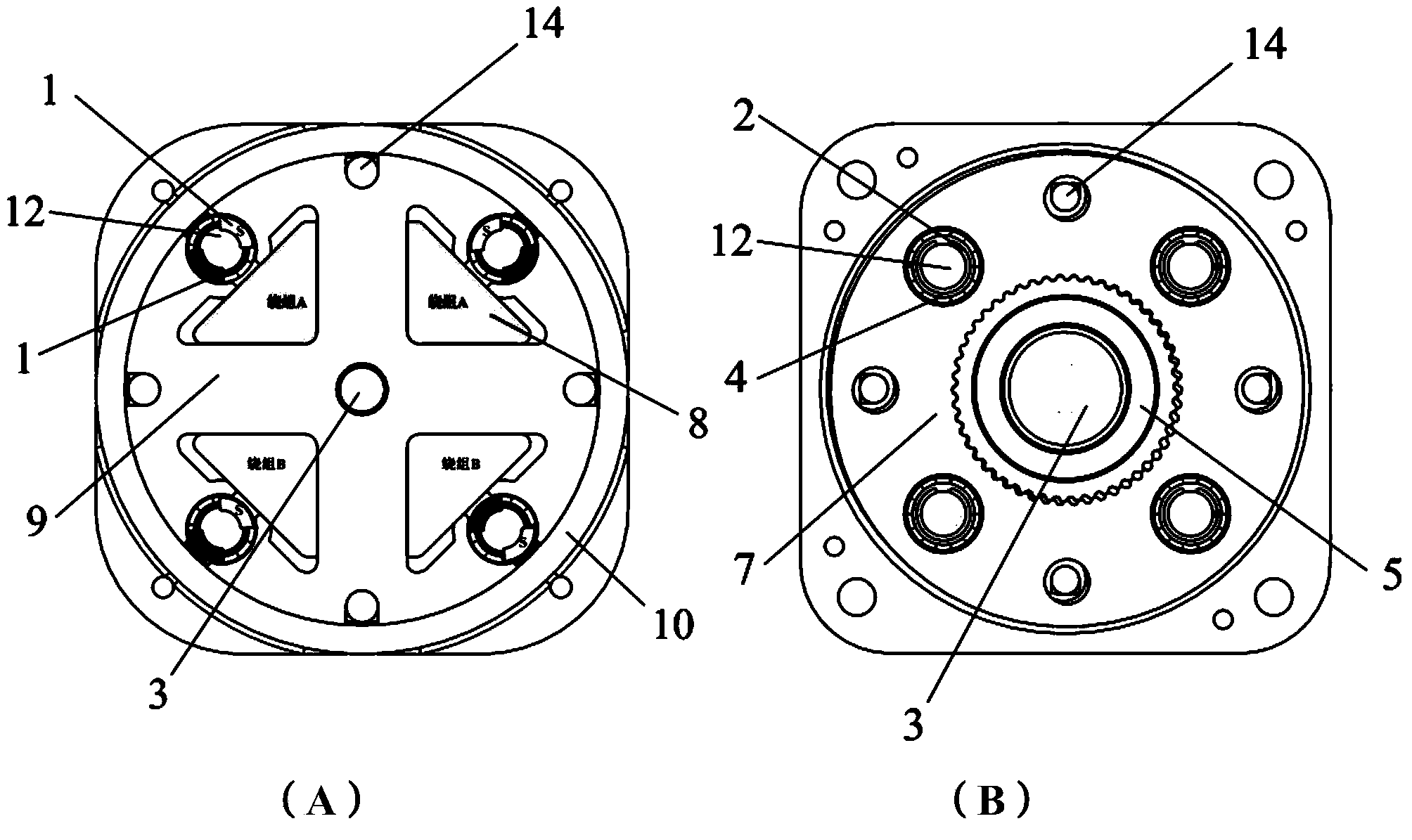

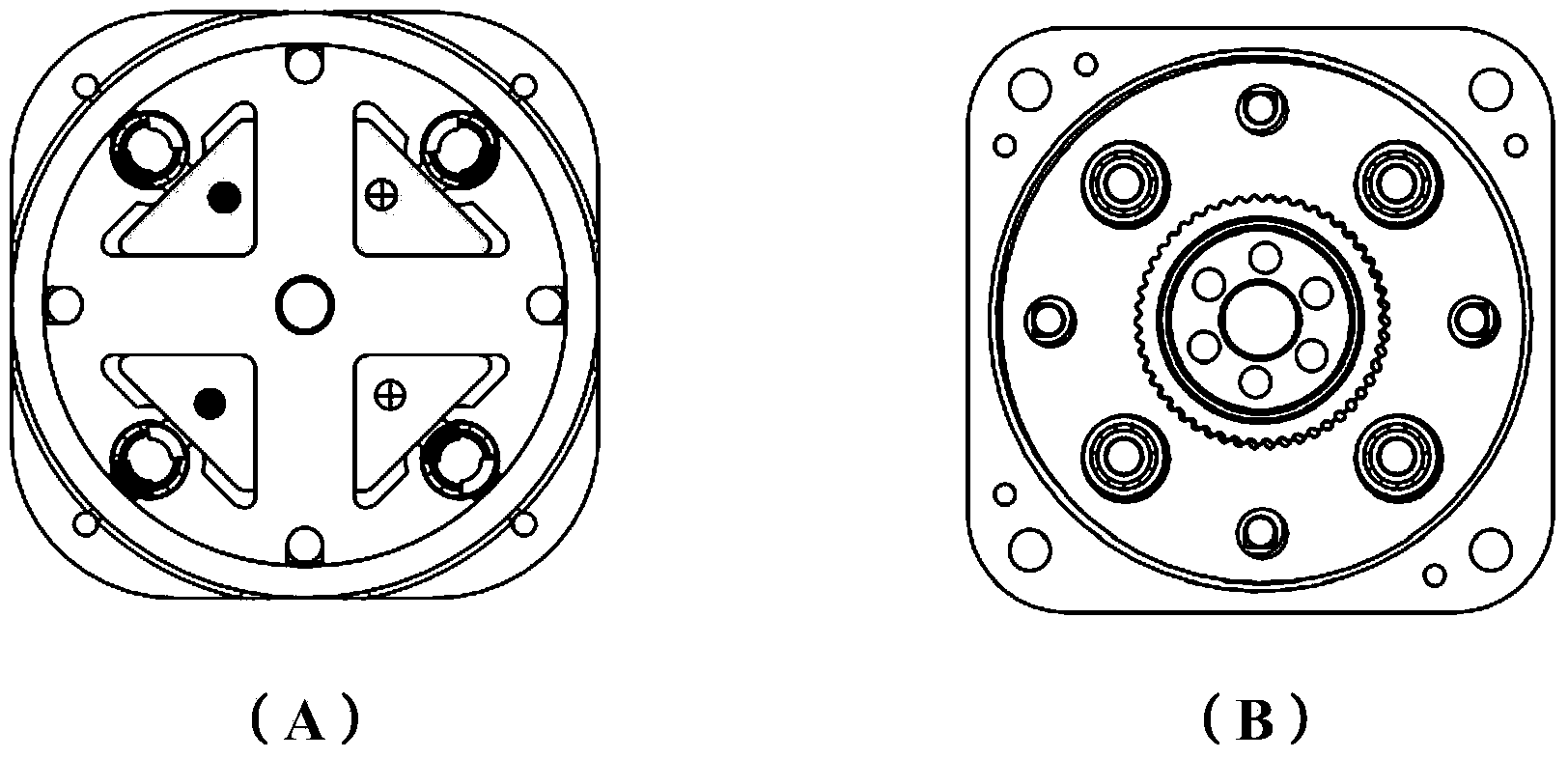

Driving device and light amount controller

InactiveUS20070063591A1Reduce moment of inertiaIncrease torqueTelevision system detailsColor television detailsMagnetic polesMoment of inertia

A driving device which makes it possible to reduce the moment of inertia of a rotor and increase torque. A magnet is formed to have a hollow cylindrical shape and has magnetized sections which are magnetized to have alternately different poles in a circumferential direction thereof. A coil is wound coaxially with the magnet and is disposed in axially side-by-side relation to the magnet. A stator yoke is formed of a soft magnetic material and fixes the magnet and the coil. A rotor yoke is formed of a soft magnetic material, and has magnetic pole portions formed in opposed relation to the magnetized sections, for being magnetized by the coil. The rotor yoke is supported in a manner rotatable with respect to the stator yoke. An rotation restricting part limits a range of rotation of the rotor yoke within a predetermined angle.

Owner:CANON KK

Sliding chute and crankshaft linked engine transmission mechanism

InactiveCN105840308AIncrease tangential forceImprove conversion efficiencyGearingMachines/enginesMechanical engineeringCrankshaft

The invention provides a sliding chute and crankshaft linked engine transmission mechanism. The sliding chute and crankshaft linked engine transmission mechanism comprises a crankshaft 2, a connecting rod sliding chute 4 with the two ends closed, drag reduction rollers 5 and guide sliding grooves 6, wherein the crankshaft 2 is mounted on the front sidewall and the rear sidewall of a shell 1; a journal 3 of the crankshaft 2 is sleeved with the connecting rod sliding chute 4; the drag reduction rollers 5 are arranged at the two ends of the connecting rod sliding chute 4; the upper inner wall and the lower inner wall of the shell 1 are provided with the guide sliding grooves 6 of the same shape correspondingly; the drag reduction rollers 5 are arranged in the two parallel guide sliding grooves 6 correspondingly; and the chute wall of one side or the chute walls of the two sides of the connecting rod sliding chute 4 are connected with one or more connecting rods 7 and a piston or more pistons 8 of one or more air cylinders 9 to form a single-cylinder or multi-cylinder engine unit. By adopting the transmission mechanism, the output torque of an engine is increased, the lateral pressure of the pistons 8 to the air cylinders 9 is eliminated, and the conversion efficiency of the engine is improved.

Owner:安里千

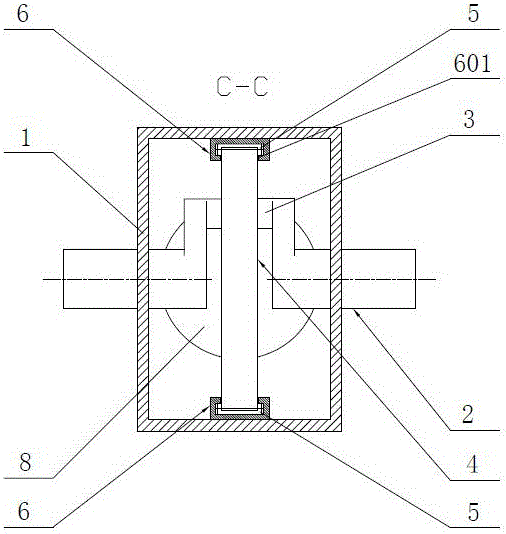

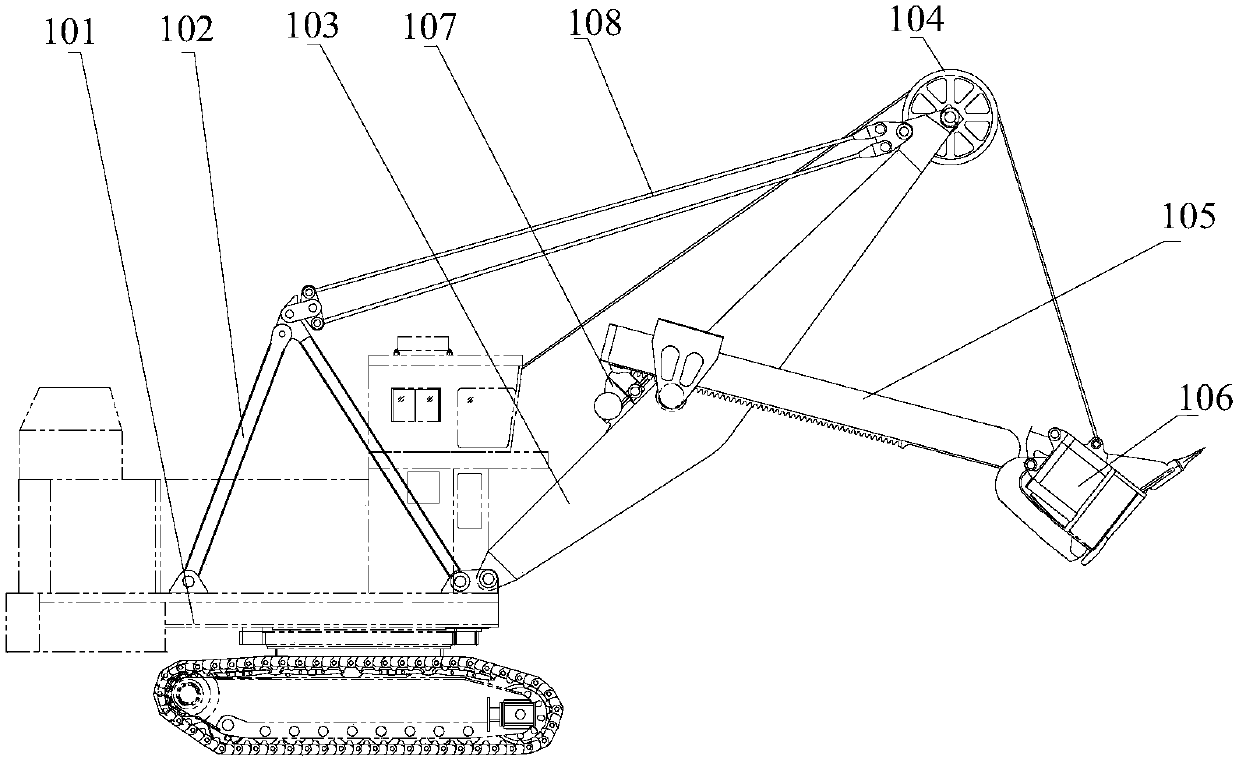

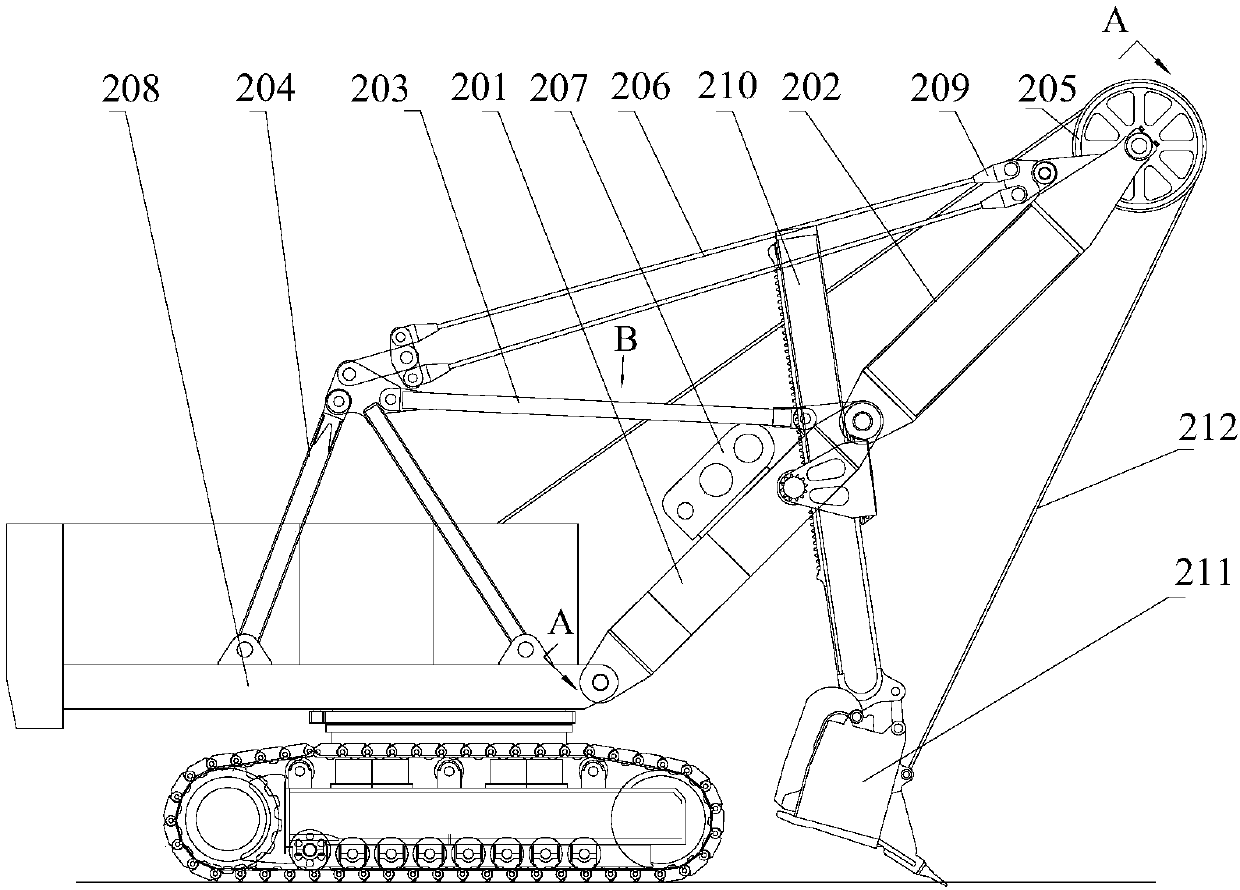

Working arm frame of excavator and excavator

ActiveCN107938736AStress structure is stableEliminate shockMechanical machines/dredgersMechanical shovelEngineering

The invention relates to the technical field of a mechanical shovel-like excavator which is special equipment for mining a large-scale open-pit mine, and particularly relates to a working arm frame ofan excavator and the excavator. The working arm frame comprises a lower arm frame, a support rod, an upper arm frame and a top pulley, wherein the lower end of the lower arm frame is hinged to a working platform, the upper end of the lower arm frame is hinged to one end of the support rod, the other end of the support rod is hinged to the top of an A-shaped frame, the lower arm frame, the supportrod and the A-shaped frame form a triangular support structure, the lower end of the upper arm frame is hinged to the upper end of the lower arm frame, the top pulley is arranged on the upper end ofthe upper arm frame, the upper end of the upper arm frame is connected with the top of the A-shaped frame by virtue of a pull rope, and a bucket rod and a pushing device are arranged on the lower armframe. According to the structure, the stressed structure of the working arm frame is optimized, the bending moment of the lower arm frame in the pushing process of the bucket rod is reduced, and theworking performance of the whole machine is improved; the support rod is additionally arranged on the arm frame, so that the possibility that the machine is damaged by the jacking of the working arm frame when a bucket is gnawing at the bottom is avoided.

Owner:TAIYUAN HEAVY IND

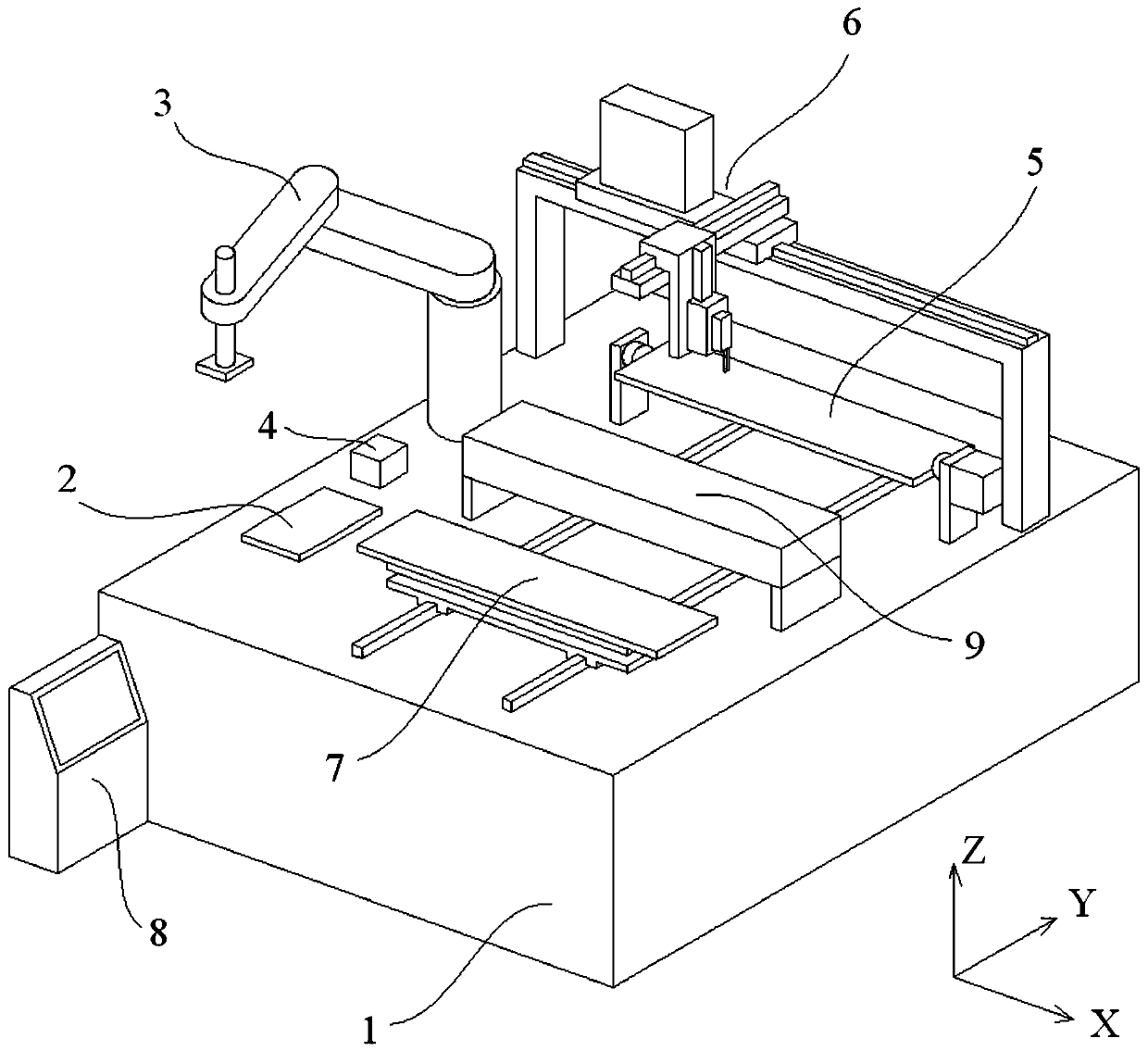

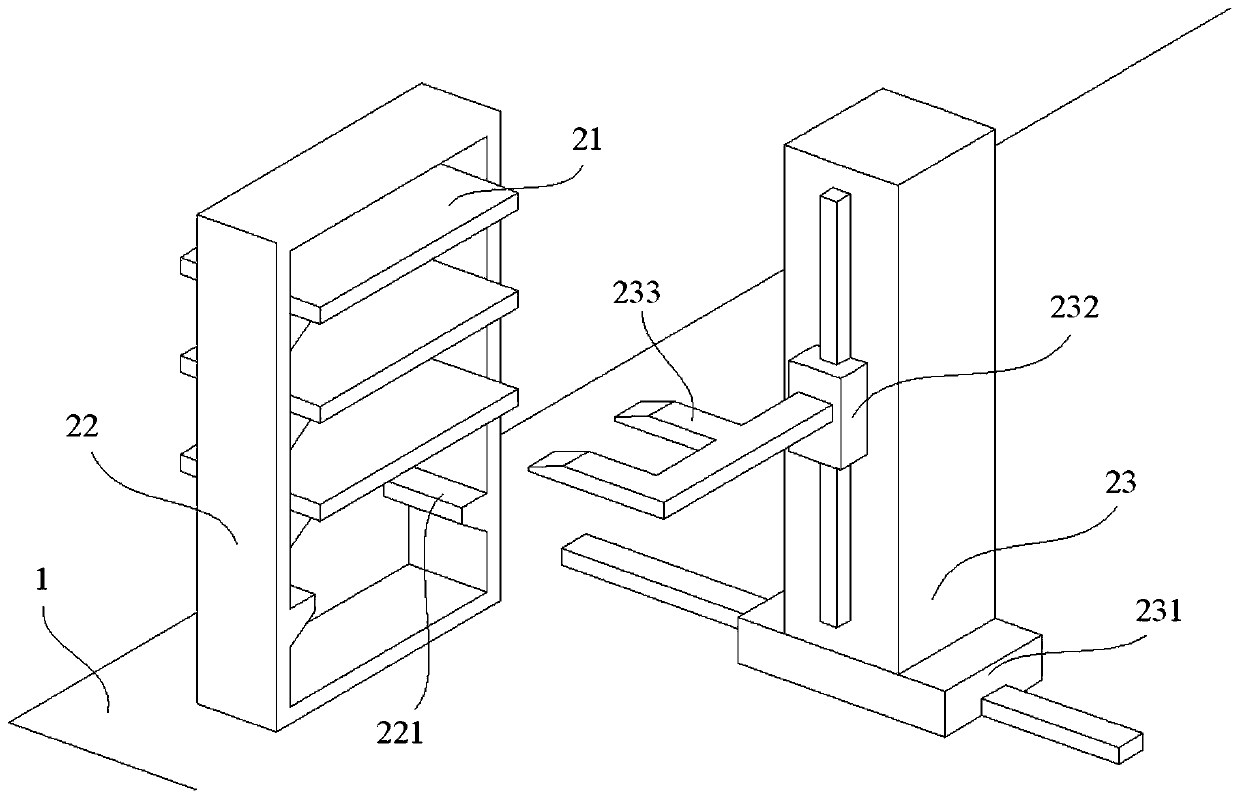

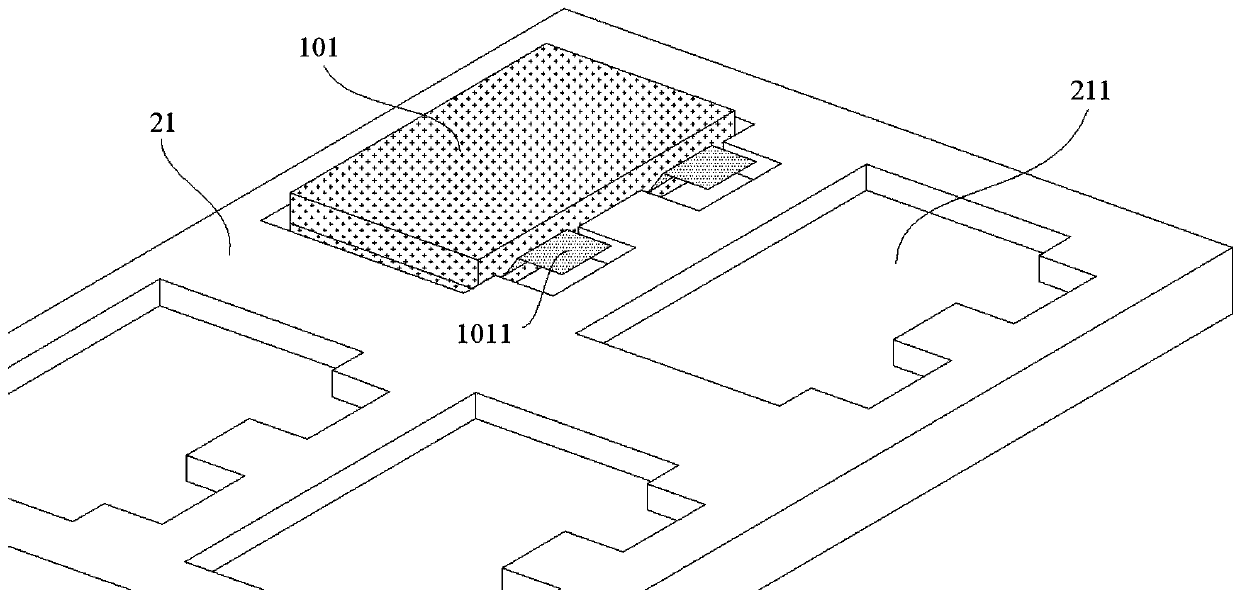

Solar battery series welding equipment and using method thereof

ActiveCN111375876ARealize fully automatic operationIncrease productivityMetal working apparatusElectrode maintenanceComputer control systemElectrical battery

The invention discloses solar battery series welding equipment and a using method thereof. The welding equipment comprises a base, a battery carrying system, a positioning camera, a welding platform,a welding system, a discharging system and a computer control system, wherein the battery carrying system is used for carrying stacked solar batteries to be welded; the positioning camera is used forshooting images of the stacked solar batteries to obtain position information of the stacked solar batteries; the welding platform can be turned over by 180 degrees after series welding is completed;the welding system is a resistance welding system capable of moving in the three-dimensional direction; the discharging system is used for transferring and / or storing welded solar battery modules; andthe computer control system is used for receiving the series welding requirements of the solar battery modules and controlling the operation of the battery carrying system, the positioning camera, the welding platform, the welding system and the discharging system according to the requirements. The solar battery series welding equipment achieves full-automatic series welding of the solar batteries for a space, and has the advantages of being high in production efficiency, high in precision, high in reliability and good in applicability.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

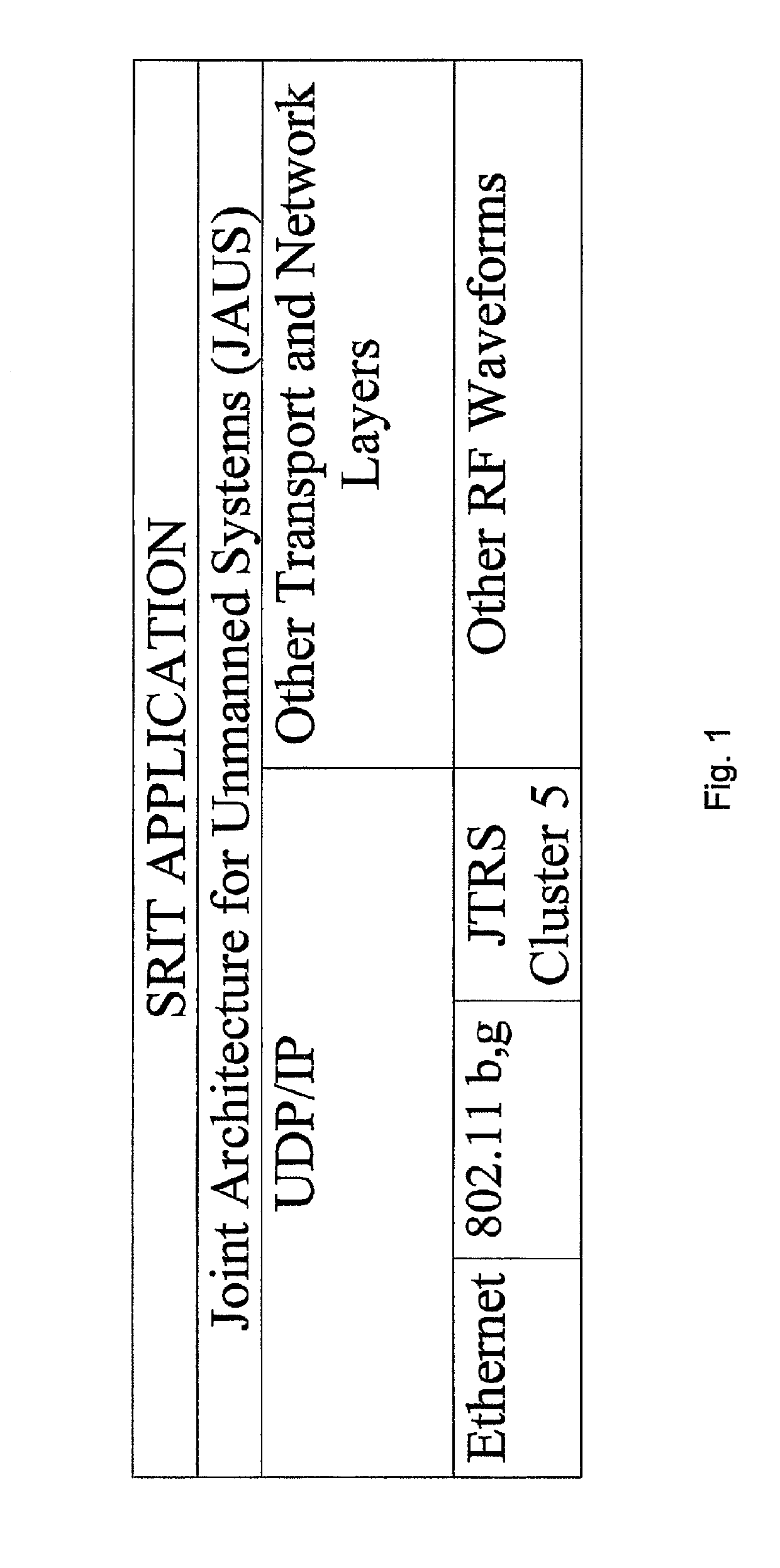

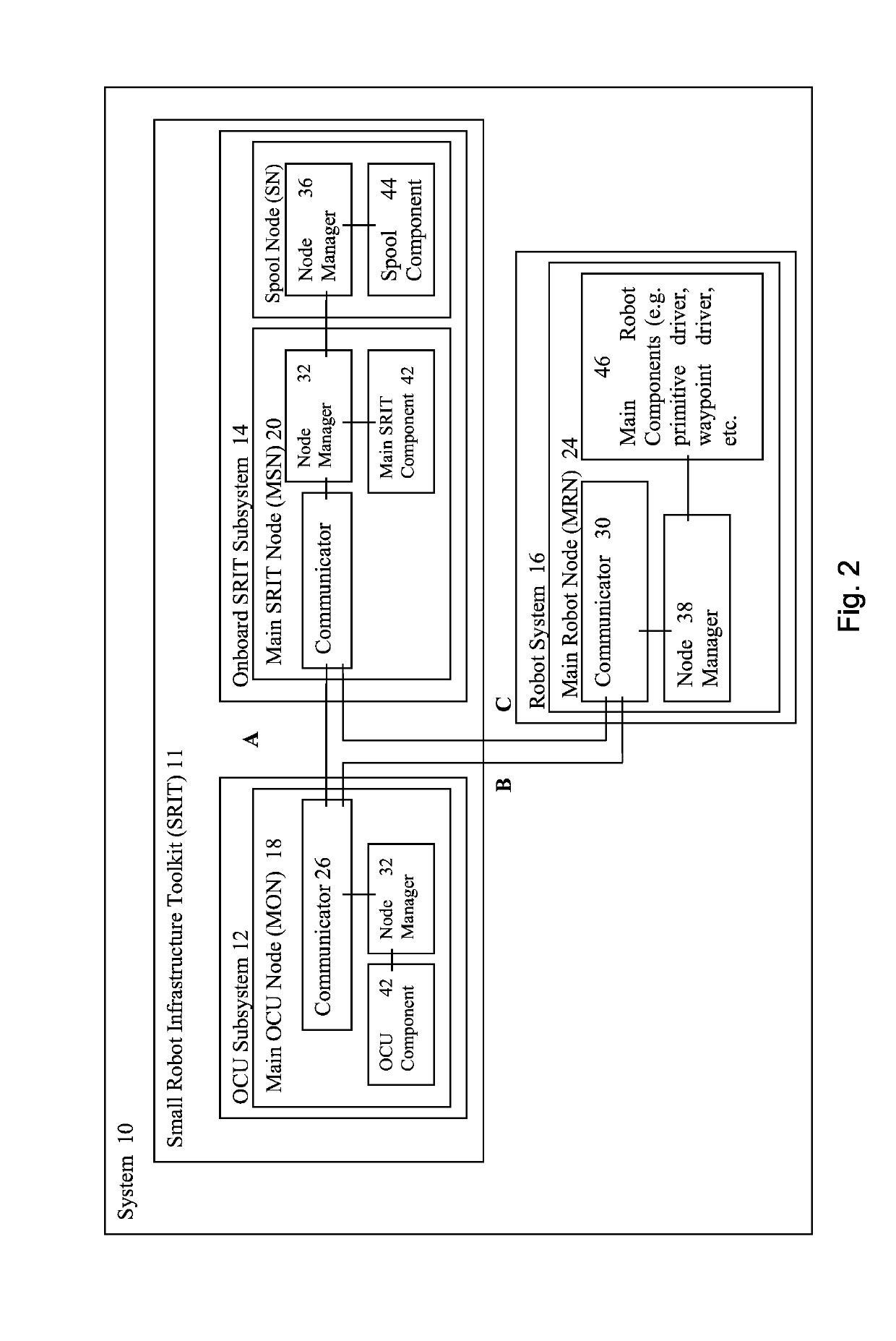

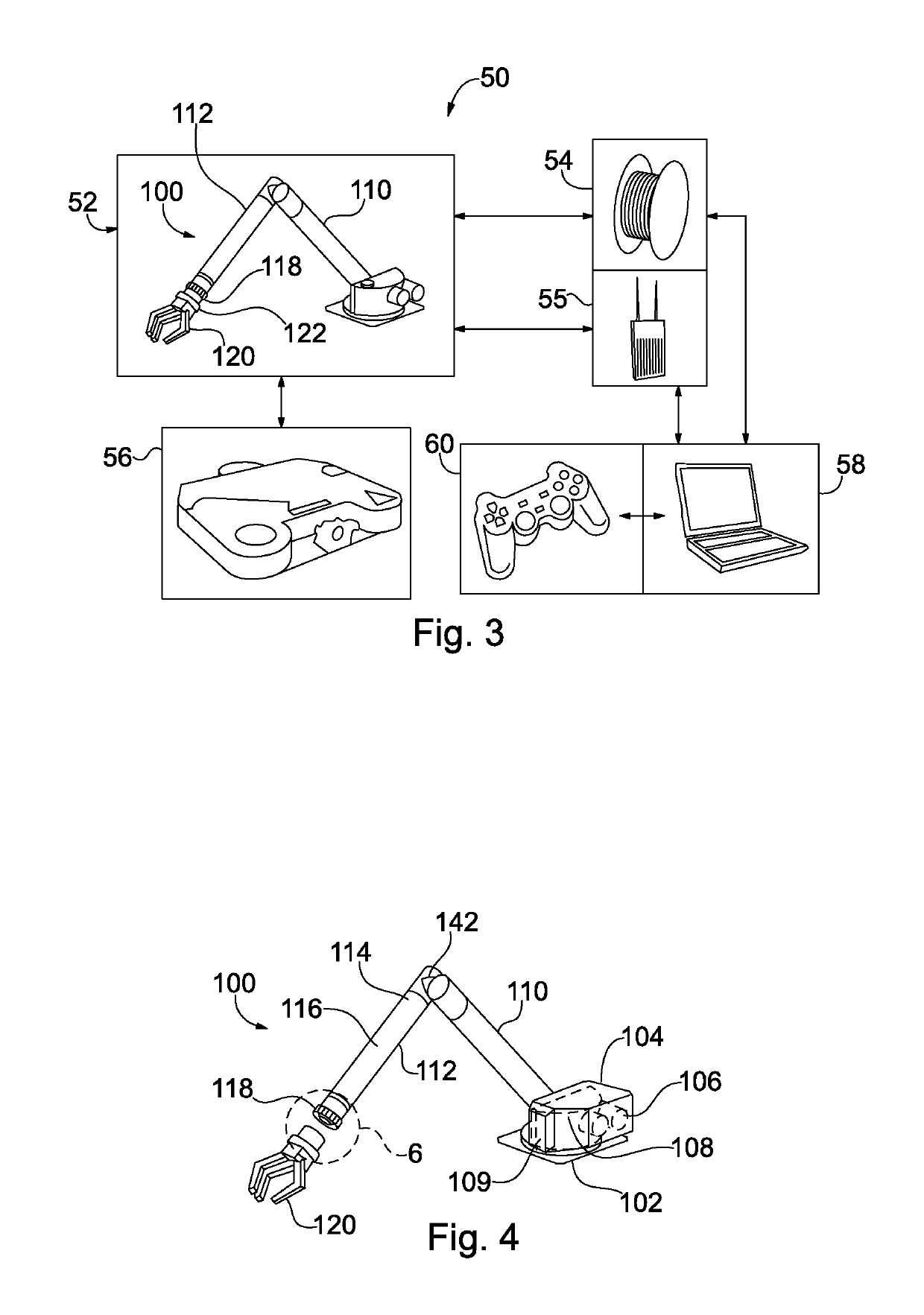

Defense related robotic systems

InactiveUS10272575B2Reduce moment of inertiaLarge forceJointsGripping headsJoint componentRobotic systems

A robot quick-release assembly has a first joint member and a robot component mounted thereon, the first joint member has a first coupler and a second joint member, a robot arm mounted thereon, has a second coupler, a clamp, and a locking collar. The first coupler can be coaxially aligned with the second coupler and pressed into the second joint member, and detachably connected to the second joint member. The first mechanical coupler is detachably connected to the second mechanical coupler for transferring power across the quick-release assembly. The robot component can receive an additional electrical connector, the additional electrical connector supplying power to the robot component. The quick-release assembly coupling assembly further exerts large forces with the application of a relatively small torque to the locking collar by applying a two stage wedge engagement and can further include a sequencing system.

Owner:RE2

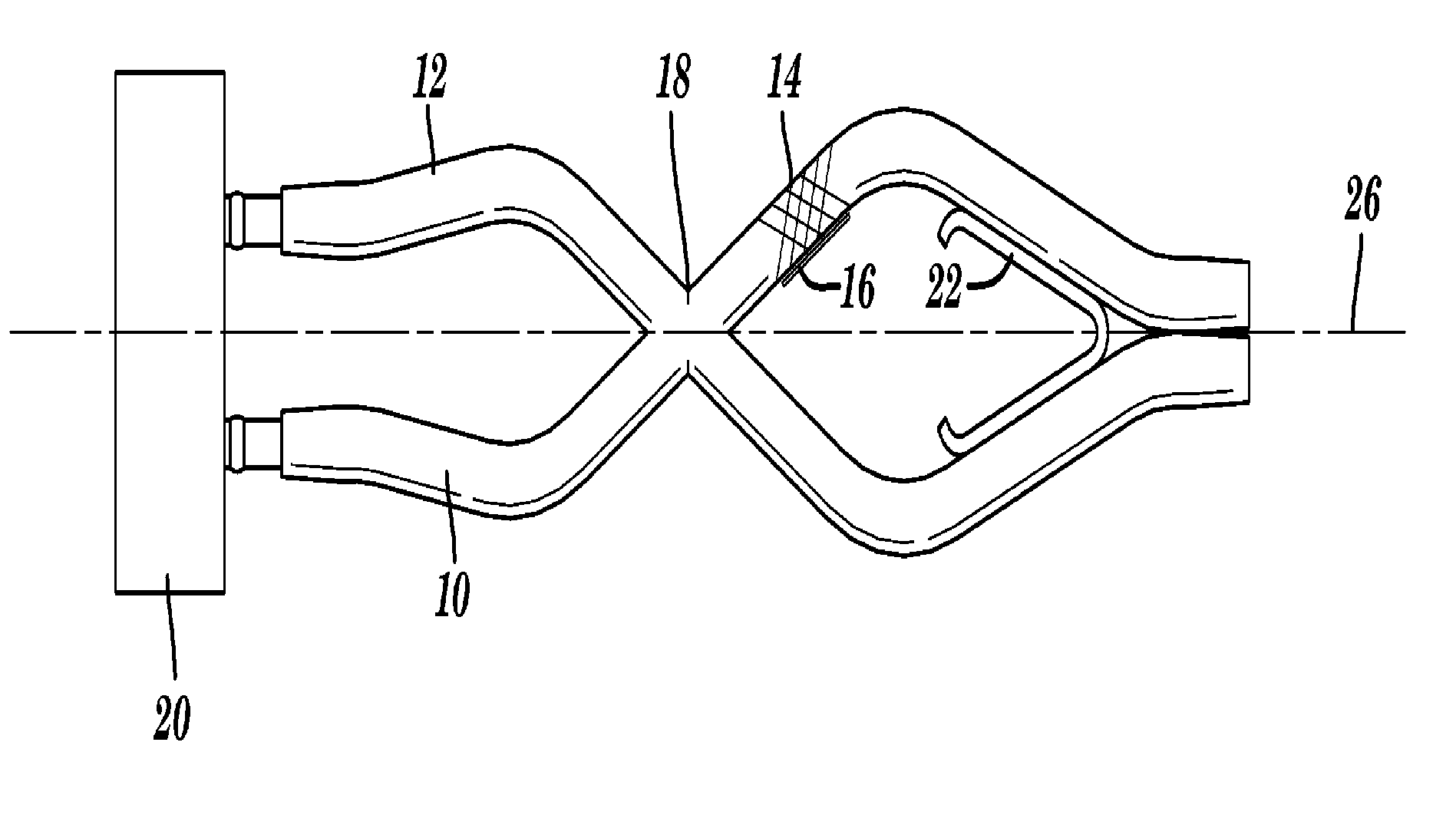

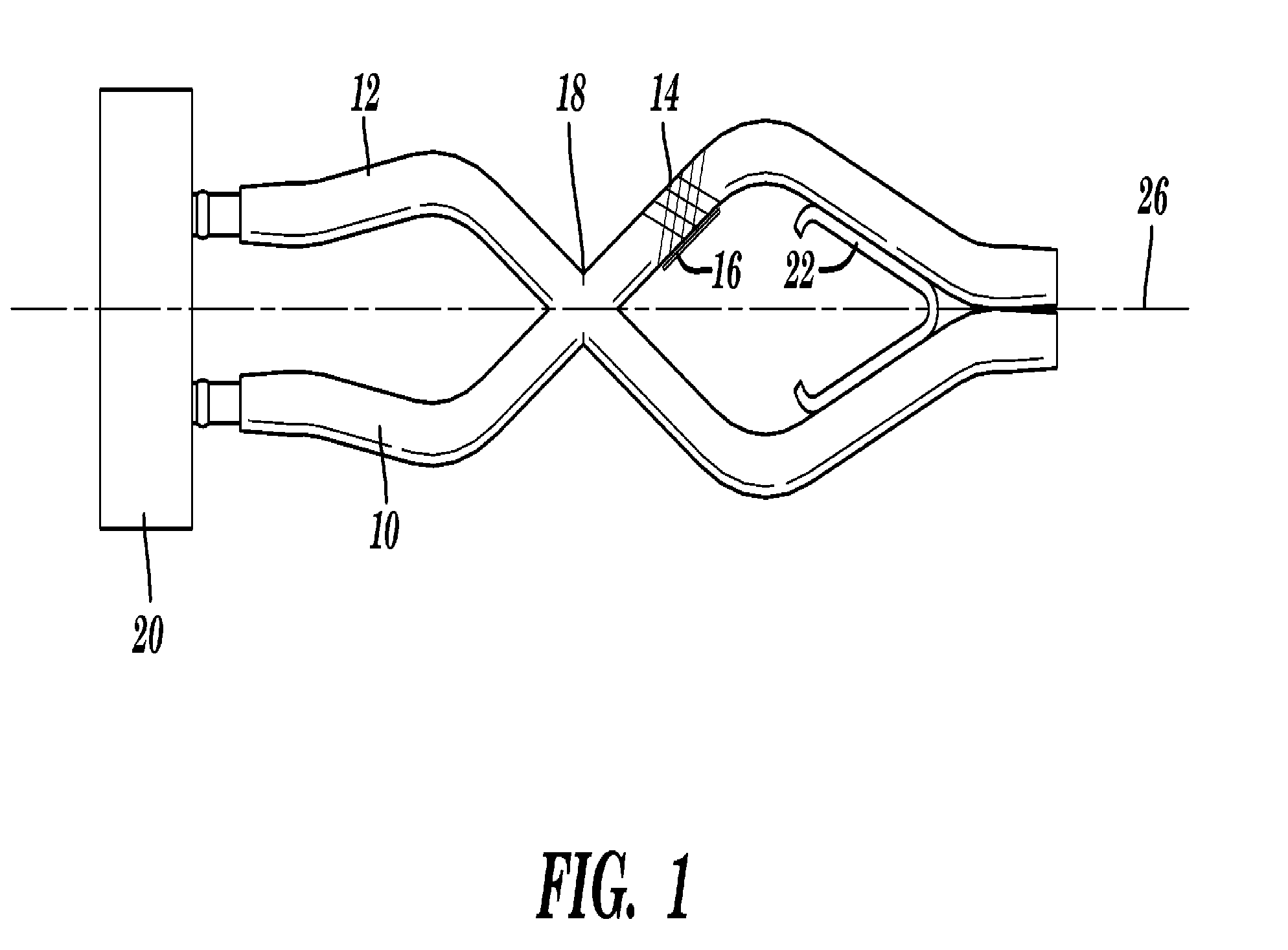

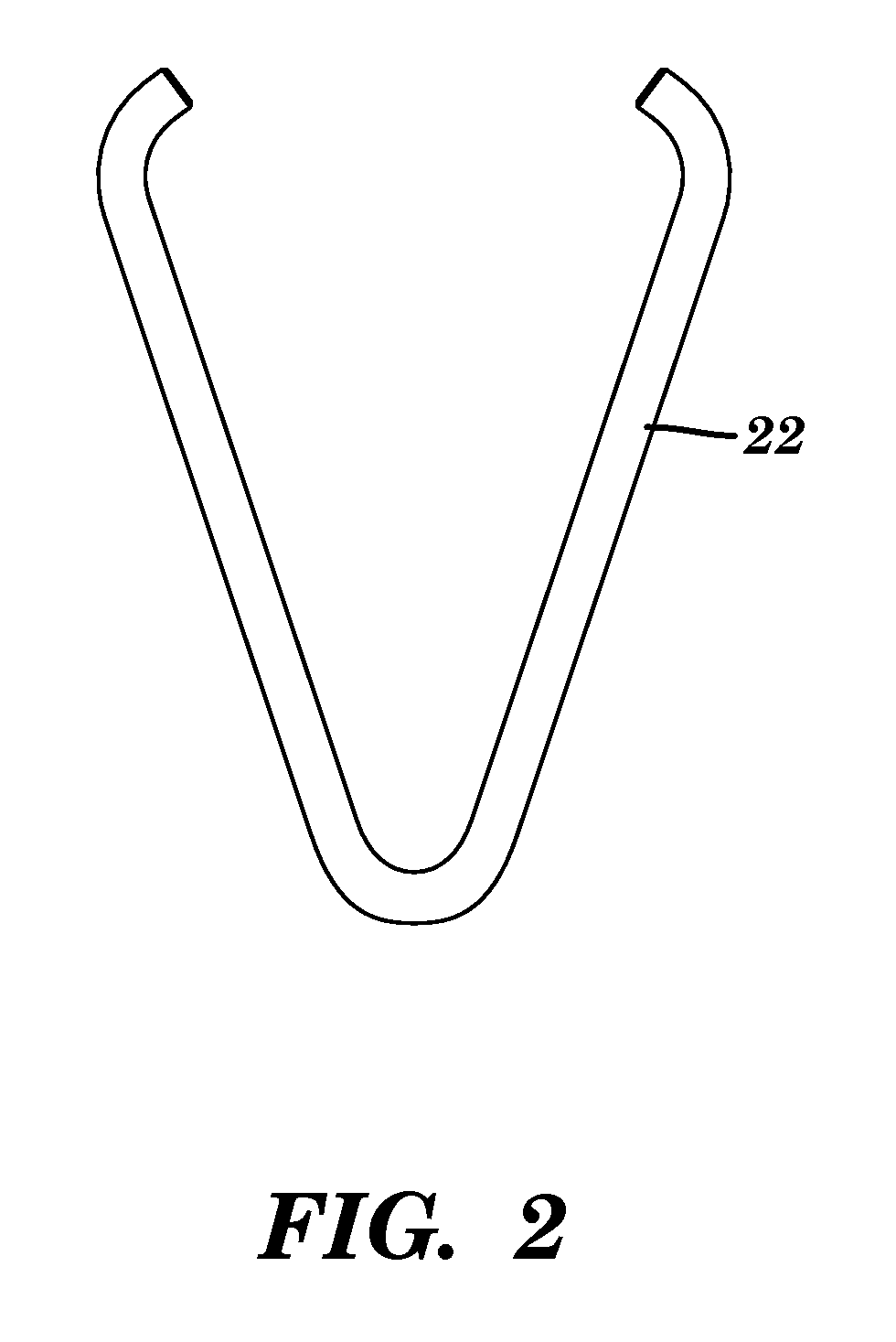

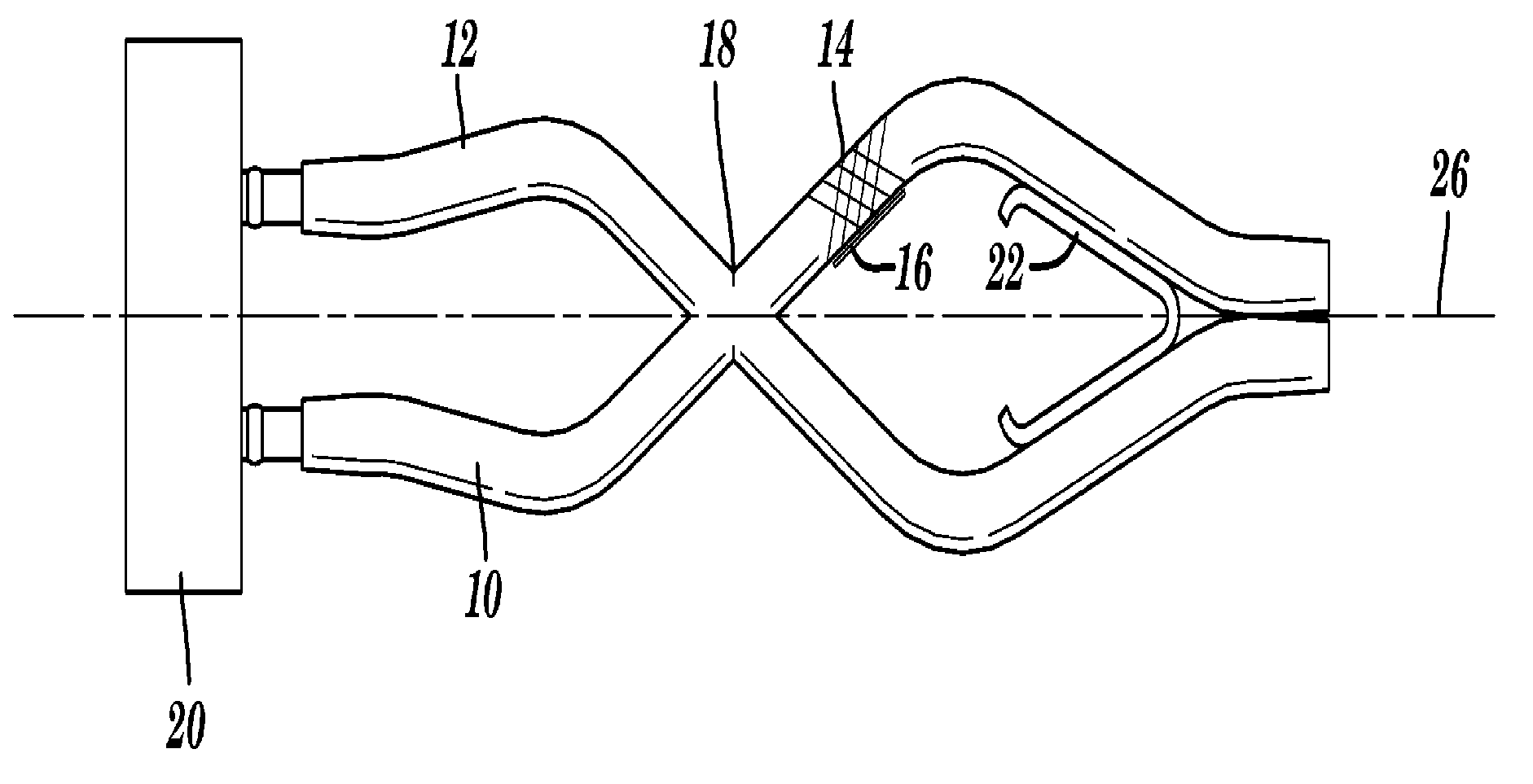

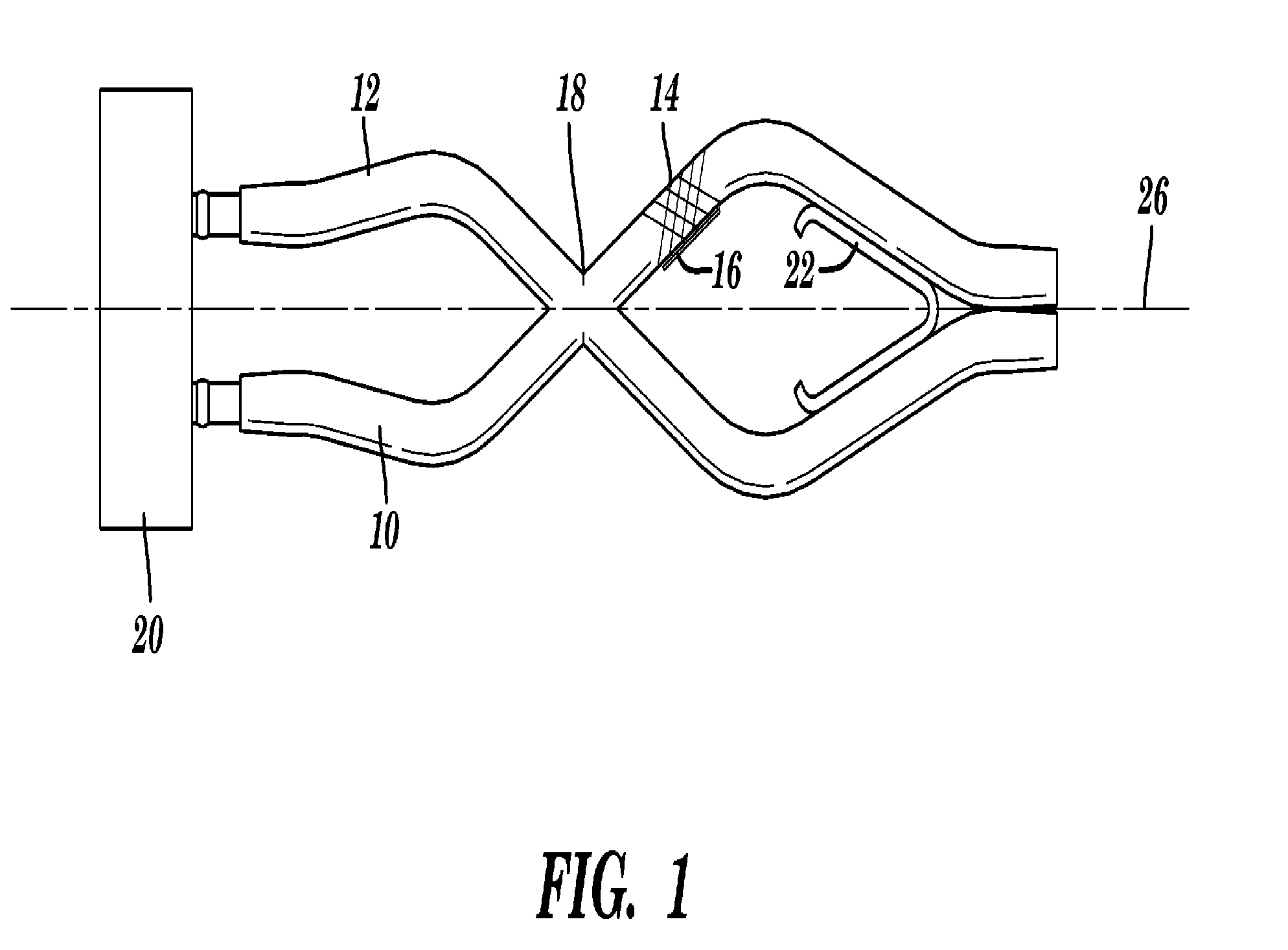

Helix heated hose

InactiveUS8455800B2Increase flexibilityReduce the moment of inertiaPipe supportsHeater elementsSpiral woundMoment of inertia

The helix heated hoses 10 and 12 use two features to increase the flexibility. The first feature is a braided-copper heating element 14, which has increased flexibility over the prior art solid copper heating element. The element is spiral wound around the hose and held in place with a moisture barrier 16. The second feature is the helix twist 18 located just before the point where the hoses 10 and 12 attach to the manifold 20. The helix feature is created with the helix support 22, which initiates the twist around 24 inches back from the point of termination. The helix feature works to reduce the moment of inertia about the neutral axis 26 of the two supply hoses 10 and 12.

Owner:GRACO INC

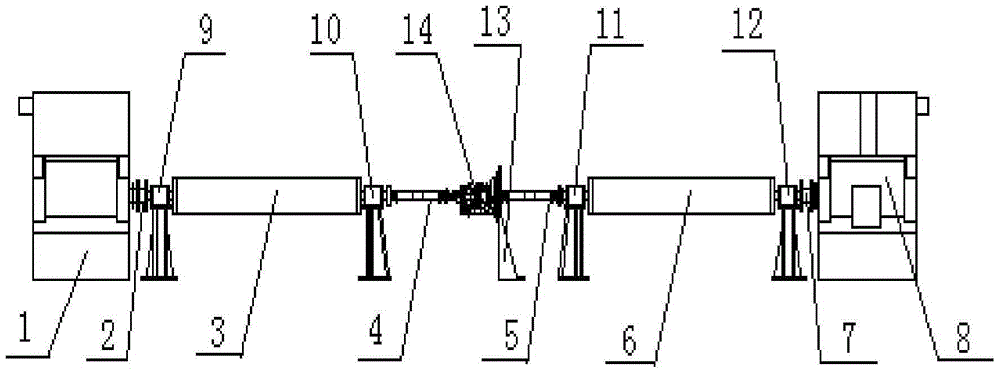

Testing system

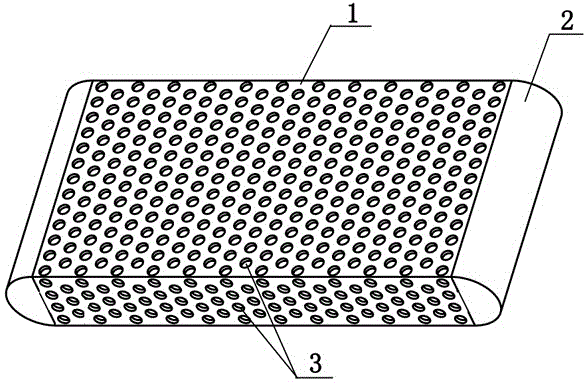

InactiveCN105223018ALight in massReduce the moment of inertiaMachine gearing/transmission testingFiberCarbon fibers

Owner:BEIQI FOTON MOTOR CO LTD

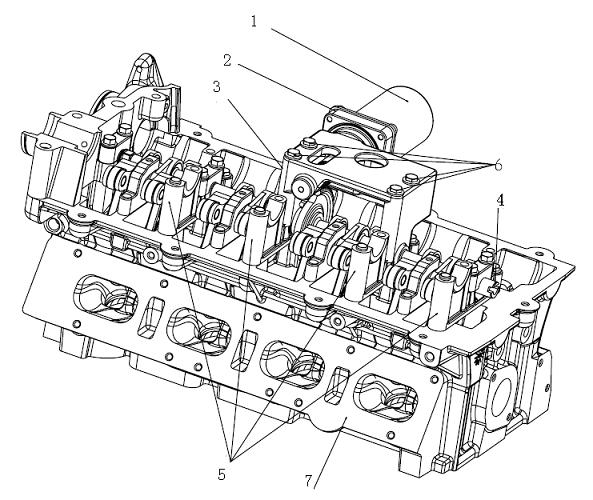

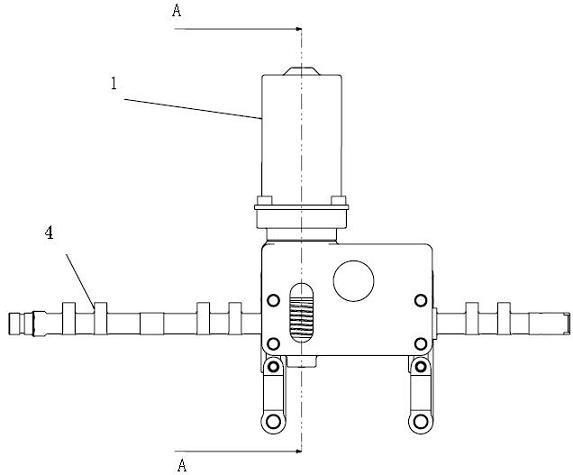

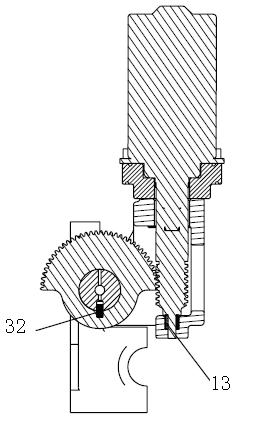

Eccentric shaft control system of complete-variable air valve lift mechanism

ActiveCN102140944AImprove reliabilityPrecise regulationValve drivesMachines/enginesElectric machineControl system

The invention relates to an eccentric shaft control system of a complete-variable air valve lift mechanism. An engine cylinder cover (7) is provided with a bearing seat (5); the bearing seat (5) is provided with an eccentric shaft (4); the eccentric shaft (4) is provided with an eccentric wheel (43); a worm (12) is installed on a rotor of a motor (1); a worm wheel (14) is fixedly connected to an eccentric shaft neck (44); and during the meshing process of the worm (12) and the worm wheel (14) driven by the motor (1), through the effect of an angle limiting device, the adjustment of an adjustment air valve from zero to the maximum value can be realized through the rotation changes of the eccentric shaft (4) from zero to 180 degrees. According to the invention, because the rotation changes of the eccentric shaft from zero to 180 degrees are controlled by the angle limiting device, the adjustment of the adjustment air valve from zero to the maximum value can be realized, and the accurate regulation and control, and prevention of system failure are ensured, so that the reliability of the engine is strengthened.

Owner:CHERY AUTOMOBILE CO LTD

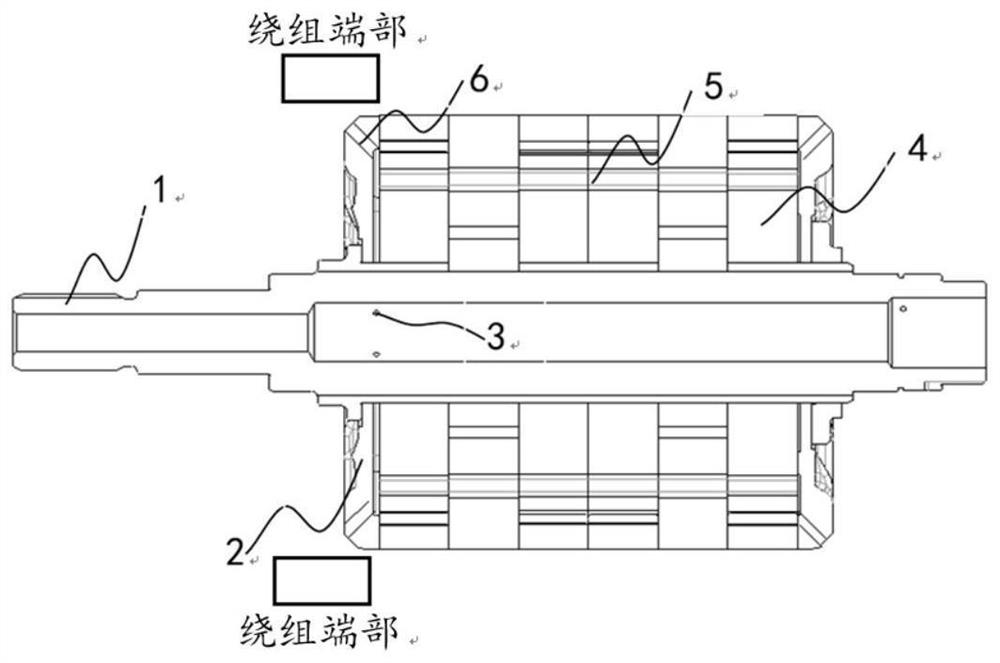

Direct cooling system applied to rotor and winding of high-speed permanent magnet motor

PendingCN113364184AReduce direct coolingReduce output efficiencyMagnetic circuit rotating partsElectric machinesElectric machinePermanent magnet motor

The invention relates to a direct cooling system applied to a rotor and a winding of a high-speed permanent magnet motor. Cooling liquid enters from a hollow cavity of a rotating shaft, passes through a rotating shaft guide hole under the rotating centrifugal effect of the rotor and flows into an area formed by the end face of the end plate and a rotor core; the area formed by the end face and the rotor core is communicated with a rotor de-weight hole and an end plate guide hole; one part of the cooling liquid is thrown out from the end plate guide hole and is in contact with the inner end face of the winding for heat exchange, and winding cooling is completed; and the other part of the cooling liquid passes through the rotor de-weight hole communicated with the rotor core, so that the cross flow in the axial direction is completed, and the rotor iron core is cooled. According to the invention, the hollow shaft, the end plates, the rotor core, the permanent magnet magnetic isolation bridges and other structures are fully utilized to set the cooling flow channels, so that the influence of the cooling flow channels on electromagnetic performance is reduced; through a rotor encapsulation process, the change of a cooling flow channel structure is realized, and the flow demand and the temperature rise demand are balanced. and the rotation inertia is reduced, the oil stirring loss is reduced, and the motor performance output and the system efficiency are improved.

Owner:CHINA FIRST AUTOMOBILE

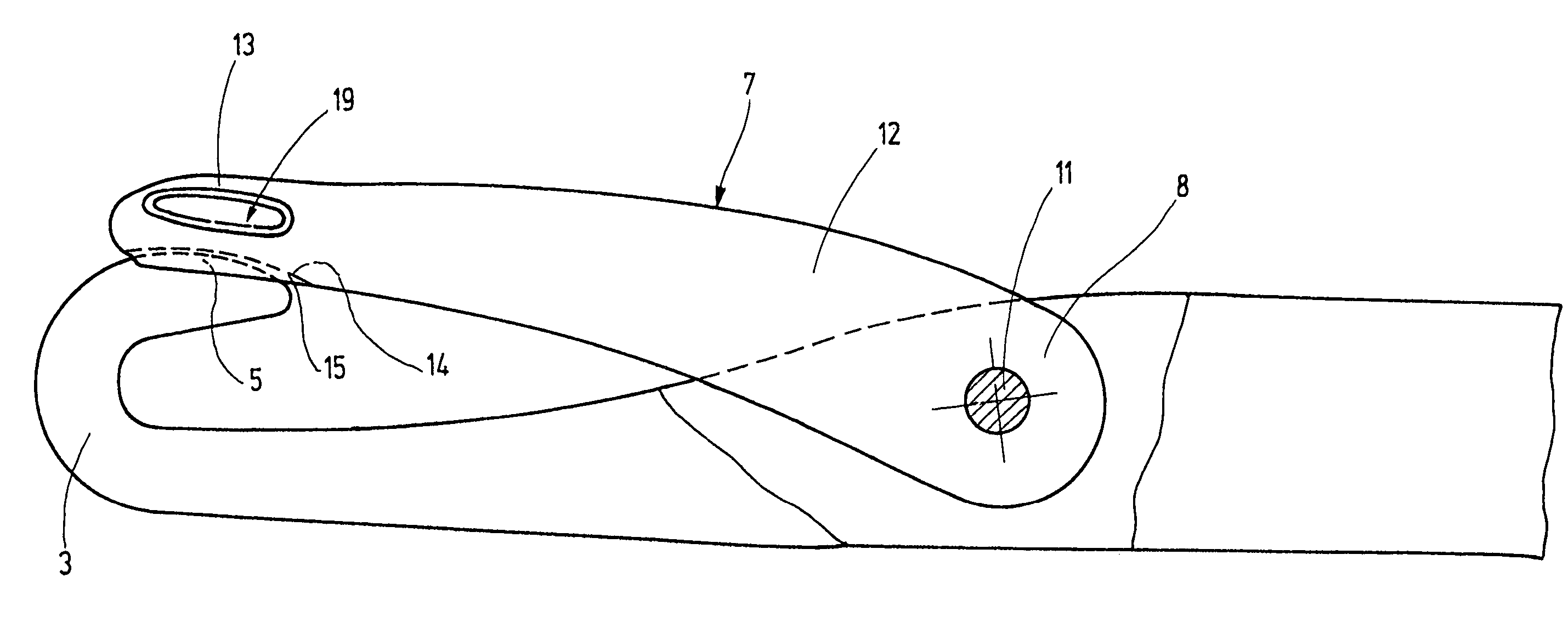

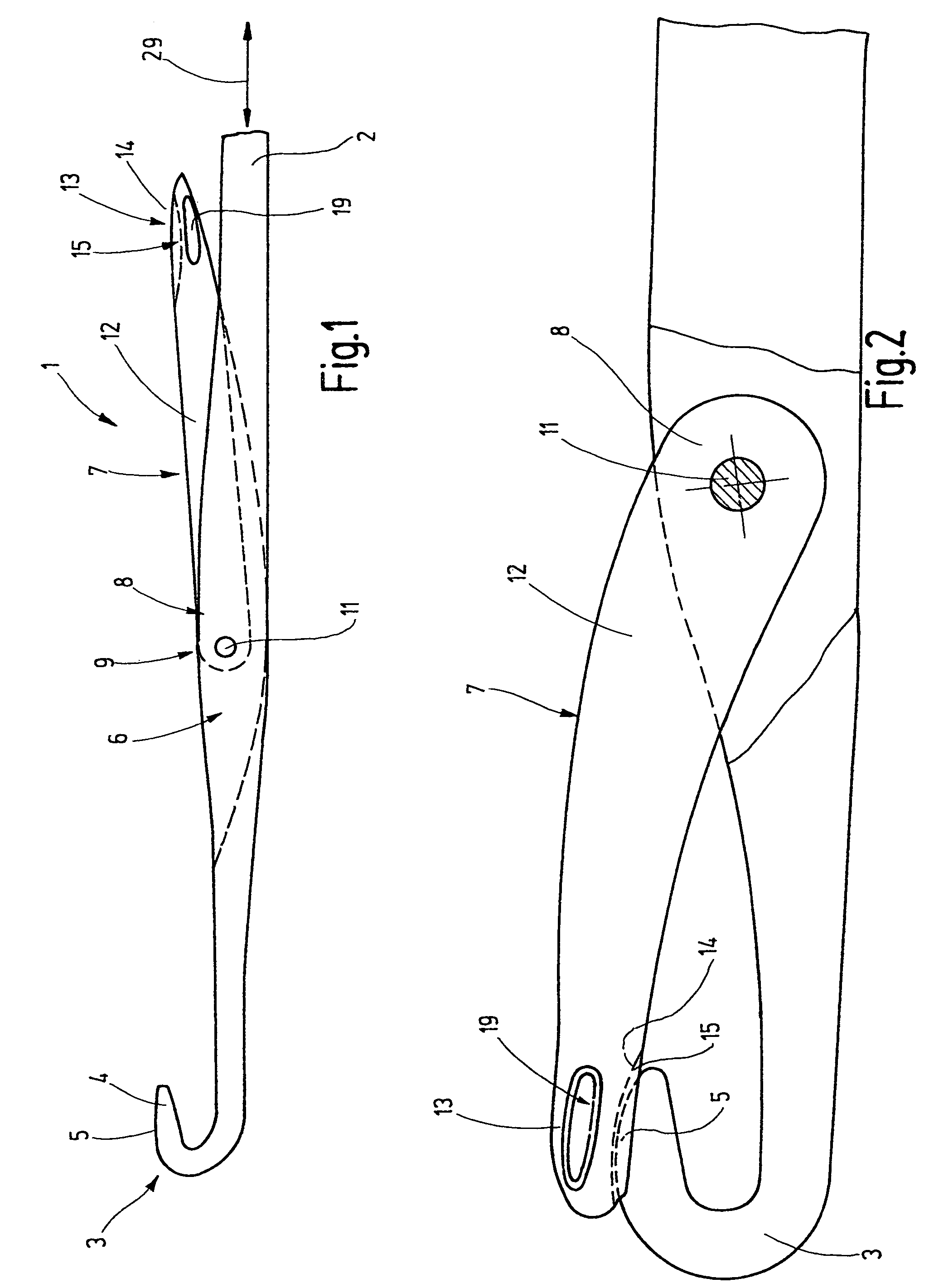

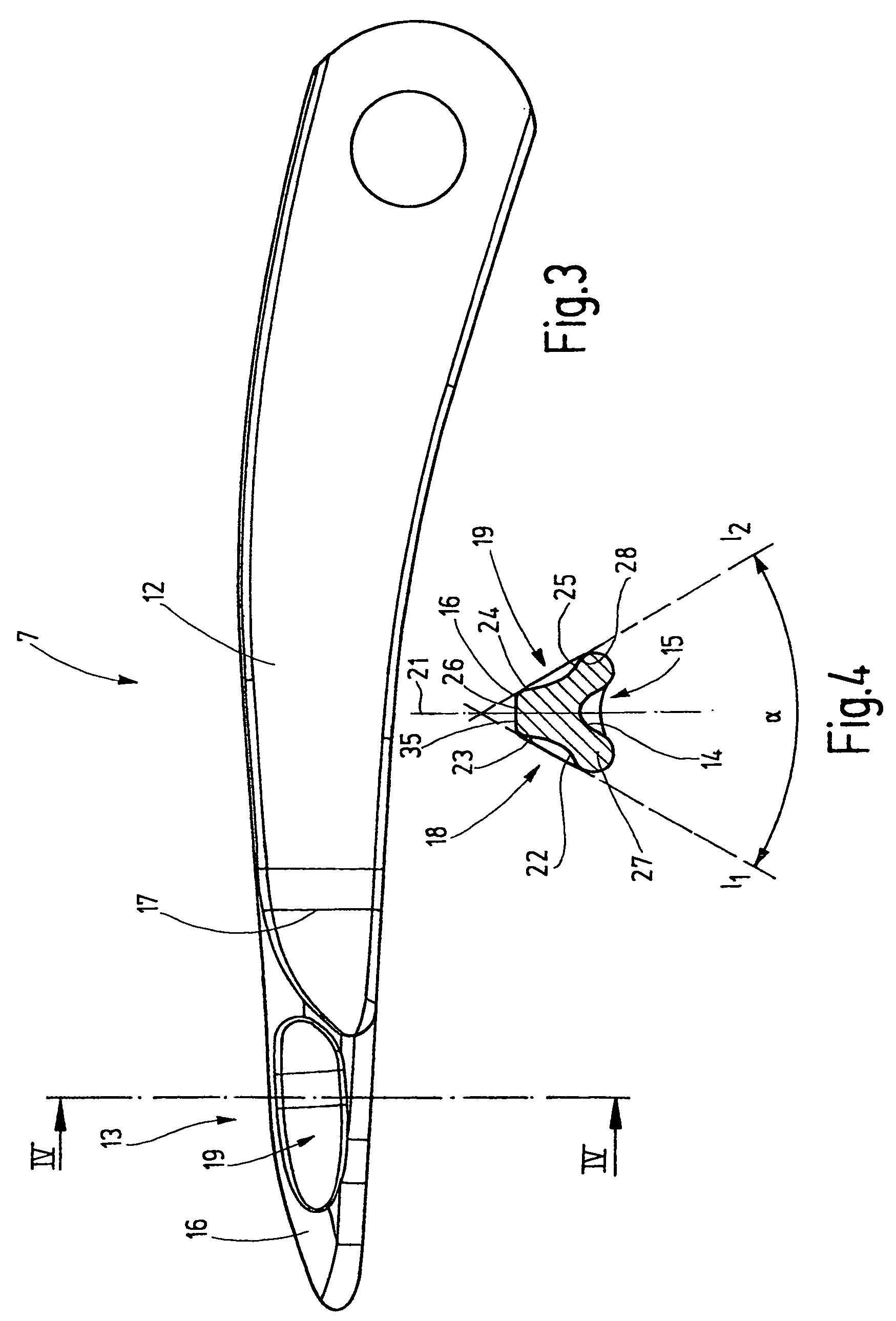

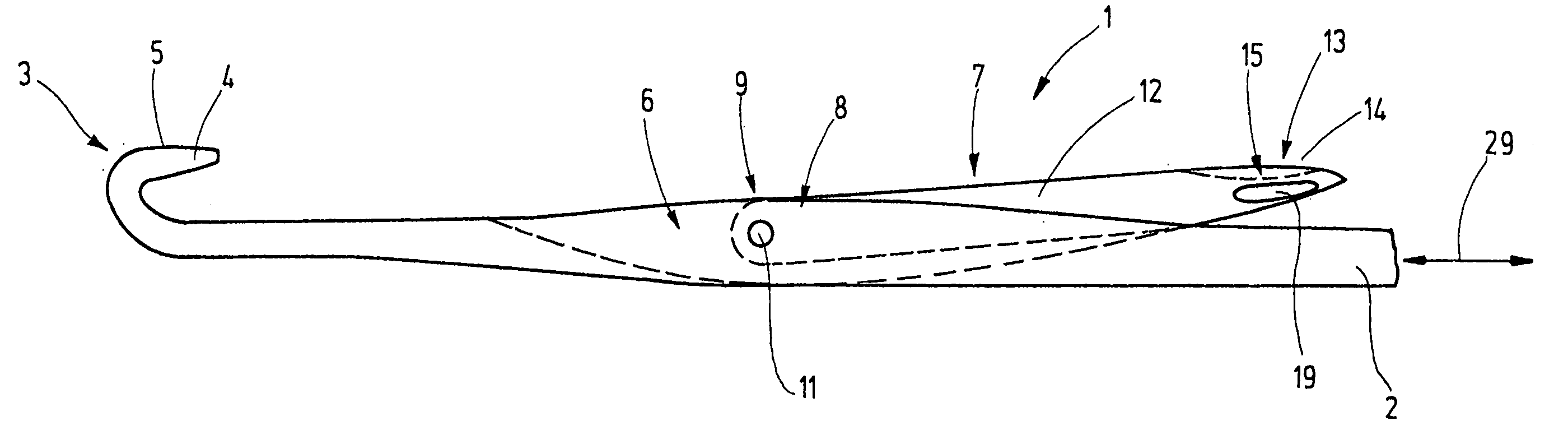

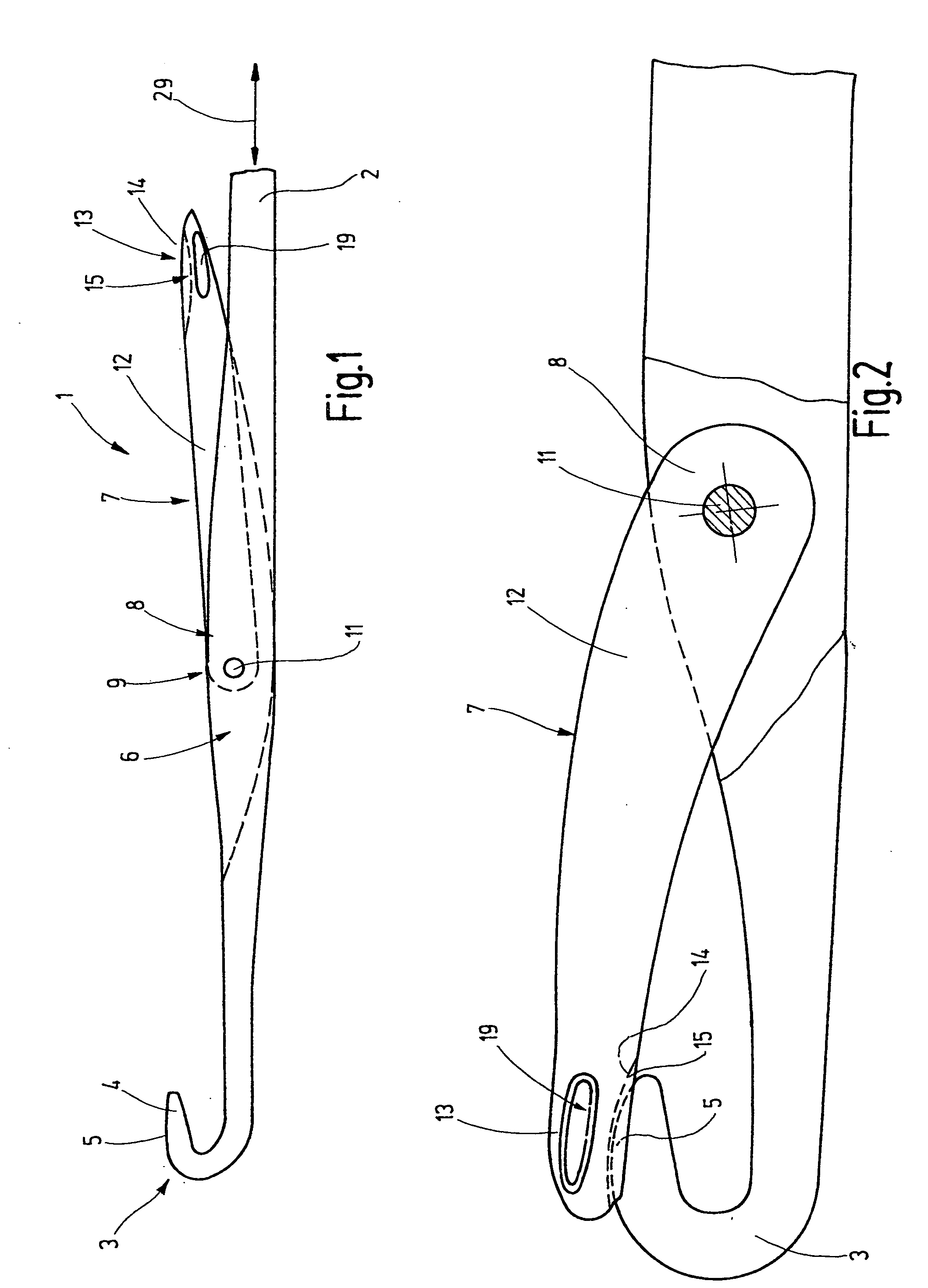

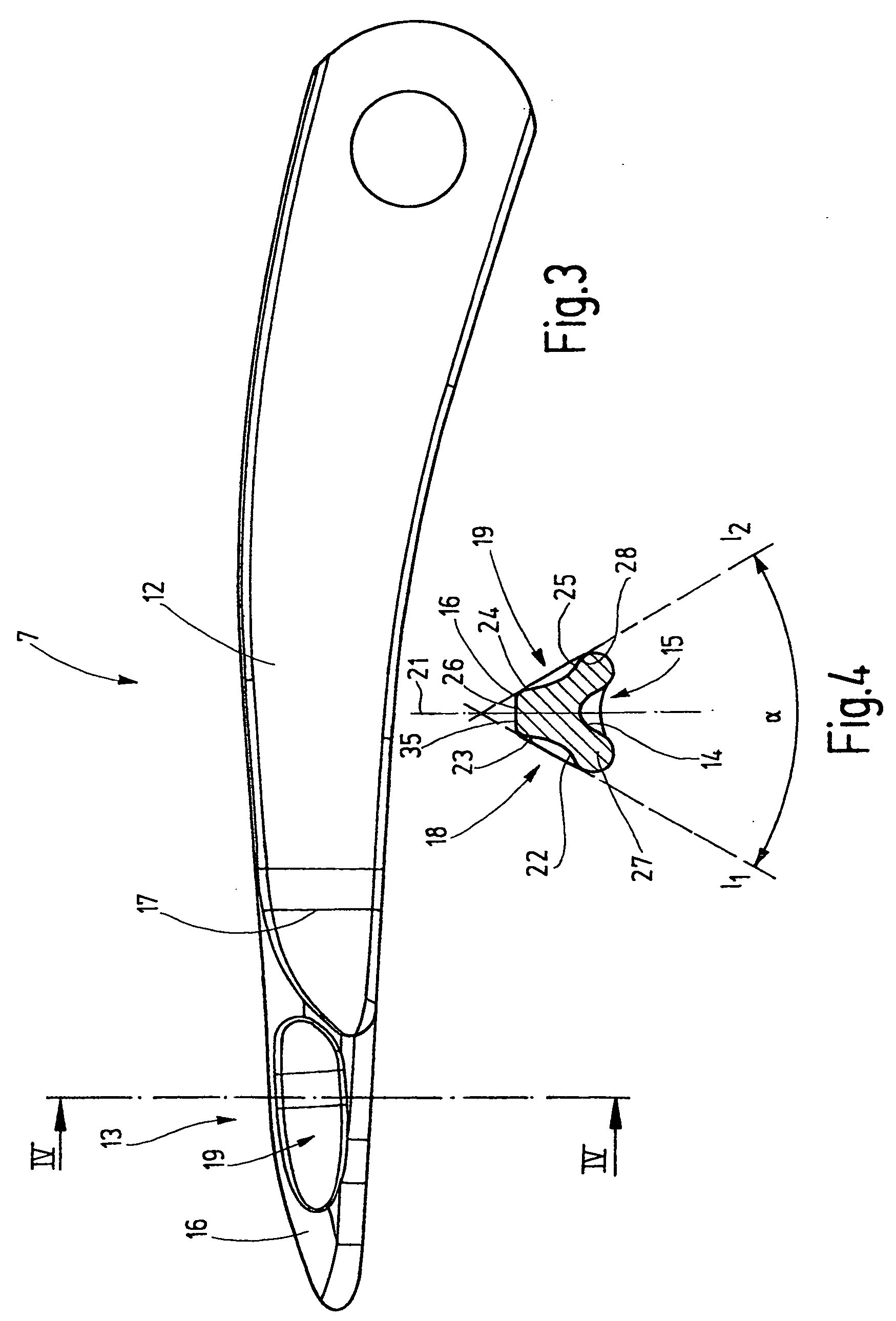

Latch needle for a loop-forming textile machine

ActiveUS7007516B2Reduce weightExtended service lifeSeed arrangmentsKnittingEngineeringMoment of inertia

The latch needle (1) of the invention has a latch (7), which is provided on its free end, on its side facing away from the hook (3), with one or more recesses (18, 19). The function of these recesses is to reduce the moment of inertia of the latch (7), which leads to an increased service life of the latch. Between the recesses (18, 19), a rib remains, whose top side functions like a skid for loops to be transferred. The indentations (18, 19) are preferably elongated depressions. However, corresponding openings may be provided as a substitute instead.

Owner:GROZ BECKERT KG

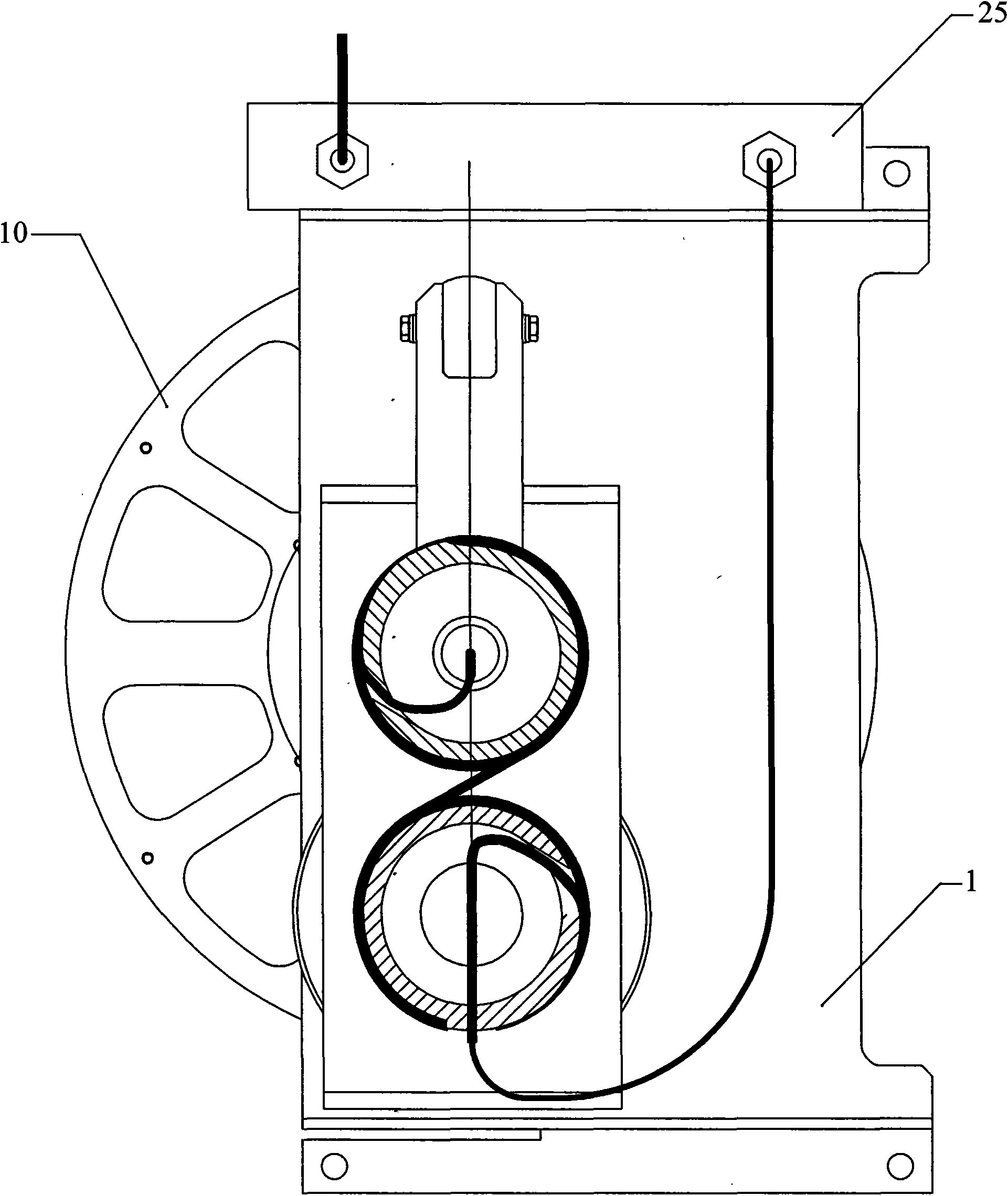

Movement speed and displacement integrated testing device and method of cable arranging device of marine winch

ActiveCN106865437ALarge measuring displacement rangeGuaranteed to be tightMeasurement devicesWinding mechanismsGear wheelCoil spring

The invention discloses a movement speed and displacement integrated testing device and method of a cable arranging device. The testing device comprises a supporting seat, a coil spring, a rope storing drum, a supporting shaft, a testing gear and a two-way hall switch, wherein the supporting shaft is mounted on a bracket, and the rope storing drum is mounted on the supporting shaft through a bearing; one end of the coil spring is fixedly connected with the bracket, and the other end of the coil spring is fixed to the rope storing drum; the testing gear which is coaxially fixedly mounted on the rope storing drum; the two-way hall switch corresponding to the testing gear is mounted on the bracket, and an axis of the two-way hall switch passes through the center of the gear; a steel wire rope end head locking device corresponding to the rope storing drum is arranged on the bracket. According to the testing device, the movement speed and displacement are measured in a way of pulling a coiling drum to test the contact mode of a steel wire rope, so that the measurement moving range is wide; a vortex type coil spring is arranged and can provide a certain tensioning force and returning force so as to ensure that the testing steel wire rope is tensioned as well as avoid disordering of the rope, and as a result, the tracking measuring accuracy is high.

Owner:HUNAN UNIV OF SCI & TECH

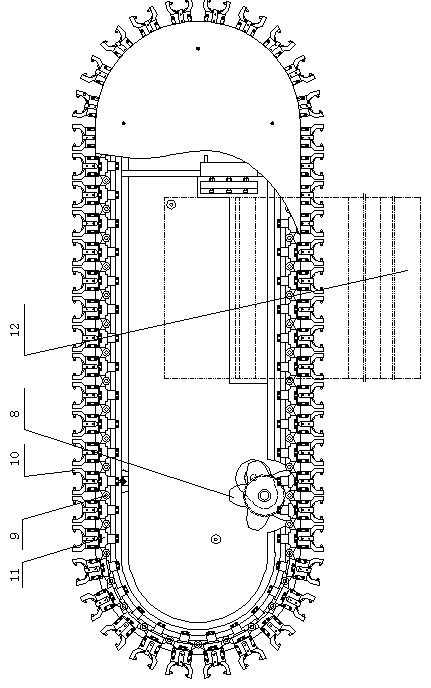

Automatic tool changing device

InactiveCN103447869AWith beautifulCooperate generouslyPositioning apparatusMetal-working holdersEngineeringChange control

The invention relates to the technical field of automatic machine tools, in particular to an automatic tool changing device. An upper guide rail body and a lower guide rail body are fixedly arranged on an upright and are of an upper-lower connection structure, chain knots, toolholder bodies and chain links are sequentially connected and placed in the upper guide rail body and the lower guide rail body, the chain links are fixed on the upper guide rail body and the lower guide rail body, the chain knots and the toolholder bodies are mounted and fixed on the chain links, a chain wheel mounting shaft is arranged on the upper guide rail body and the lower guide rail body, a chain wheel is connected on the chain wheel mounting shaft, a servo motor and a speed reducing mechanism are fixedly connected on the upper guide rail body and the lower guide rail body, the speed reducing mechanism is connected with the chain wheel to drive the same, and a tool-changing detection device is arranged at the edge of the upper guide rail body. Reliability of a tool magazine is greatly improved, production cycle is greatly prolonged greatly, and tool changing of the automatic tool changing device is completed through matching of the tool magazine and a spindle. The tool magazine is fixed and the spindle moves for tool changing, so that moving inertia of the tool magazine is reduced, the structure of the tool magazine is simplified, and tool changing control is simple and reliable.

Owner:JIANGSU SHINRI HEAVY IND SCI & TECH

Welding head moving device and wire welding machine

PendingCN112743264AImprove wire bonding accuracyReduce weightLine/current collector detailsWelding/cutting auxillary devicesCentre of rotationEngineering

The invention discloses a welding head moving device and a wire welding machine. The welding head moving device comprises a bonding head structure, wherein the bonding head structure comprises a bonding head frame hinged to a welding head base body, and a wire welding machine wire clamp and an invar transducer which are respectively fixed onto the bonding head frame; the wire welding machine wire clamp adopts a piezoelectric ceramic element as a driving source; and the gravity center of the bonding head structure coincides with or approximately coincides with the rotation center. As the bonding head structure uses the invar transducer with lighter weight and the wire welding machine wire clamp with lighter weight, the overall weight of the bonding head structure can be reduced, and the rotation inertia of the Z axis is reduced; and the gravity center of the bonding head structure can be set to coincide with or approximately coincide with the rotation center as much as possible, so that the stability of the bonding head structure during rotation is improved, the acceleration of the bonding head structure can be improved finally, and the wire welding precision of the wire welding machine is improved.

Owner:GKG PRECISION MACHINE

Driving device and light amount controller

InactiveUS7679231B2Reduce moment of inertiaIncrease torqueTelevision system detailsColor television detailsMagnetic polesMoment of inertia

A driving device which makes it possible to reduce the moment of inertia of a rotor and increase torque. A magnet is formed to have a hollow cylindrical shape and has magnetized sections which are magnetized to have alternately different poles in a circumferential direction thereof. A coil is wound coaxially with the magnet and is disposed in axially side-by-side relation to the magnet. A stator yoke is formed of a soft magnetic material and fixes the magnet and the coil. A rotor yoke is formed of a soft magnetic material, and has magnetic pole portions formed in opposed relation to the magnetized sections, for being magnetized by the coil. The rotor yoke is supported in a manner rotatable with respect to the stator yoke. An rotation restricting part limits a range of rotation of the rotor yoke within a predetermined angle.

Owner:CANON KK

Helix heated hose

InactiveUS20100237061A1Increase flexibilityReduce the moment of inertiaPipe supportsHeater elementsSpiral woundEngineering

The helix heated hoses 10 and 12 use two features to increase the flexibility. The first feature is a braided-copper heating element 14, which has increased flexibility over the prior art solid copper heating element. The element is spiral wound around the hose and held in place with a moisture barrier 16. The second feature is the helix twist 18 located just before the point where the hoses 10 and 12 attach to the manifold 20. The helix feature is created with the helix support 22, which initiates the twist around 24 inches back from the point of termination. The helix feature works to reduce the moment of inertia about the neutral axis 26 of the two supply hoses 10 and 12.

Owner:GRACO INC

Automated assembly apparatus and automated assembly method

ActiveUS10252384B2Accurate operationIncrease speedProgramme-controlled manipulatorAssembly machinesMechanical engineeringRobot

An automated assembly apparatus comprises an assembly robot that includes a Y-axis movement unit, a first X-axis movement unit movable in a Y-axis direction along the Y-axis movement unit, and a grip unit movable in an X-axis direction along the X-axis movement unit, and a workbench unit including a Z-axis movement unit arranged below the assembly robot with respect to an Z-axis and a workbench movable in the Z-axis direction along the Z-axis movement unit, wherein an assembly operation for a first assembly component gripped by the grip unit and a second assembly component mounted on the workbench unit is performed through movement in the Z-axis direction by the workbench unit.

Owner:CANON KK

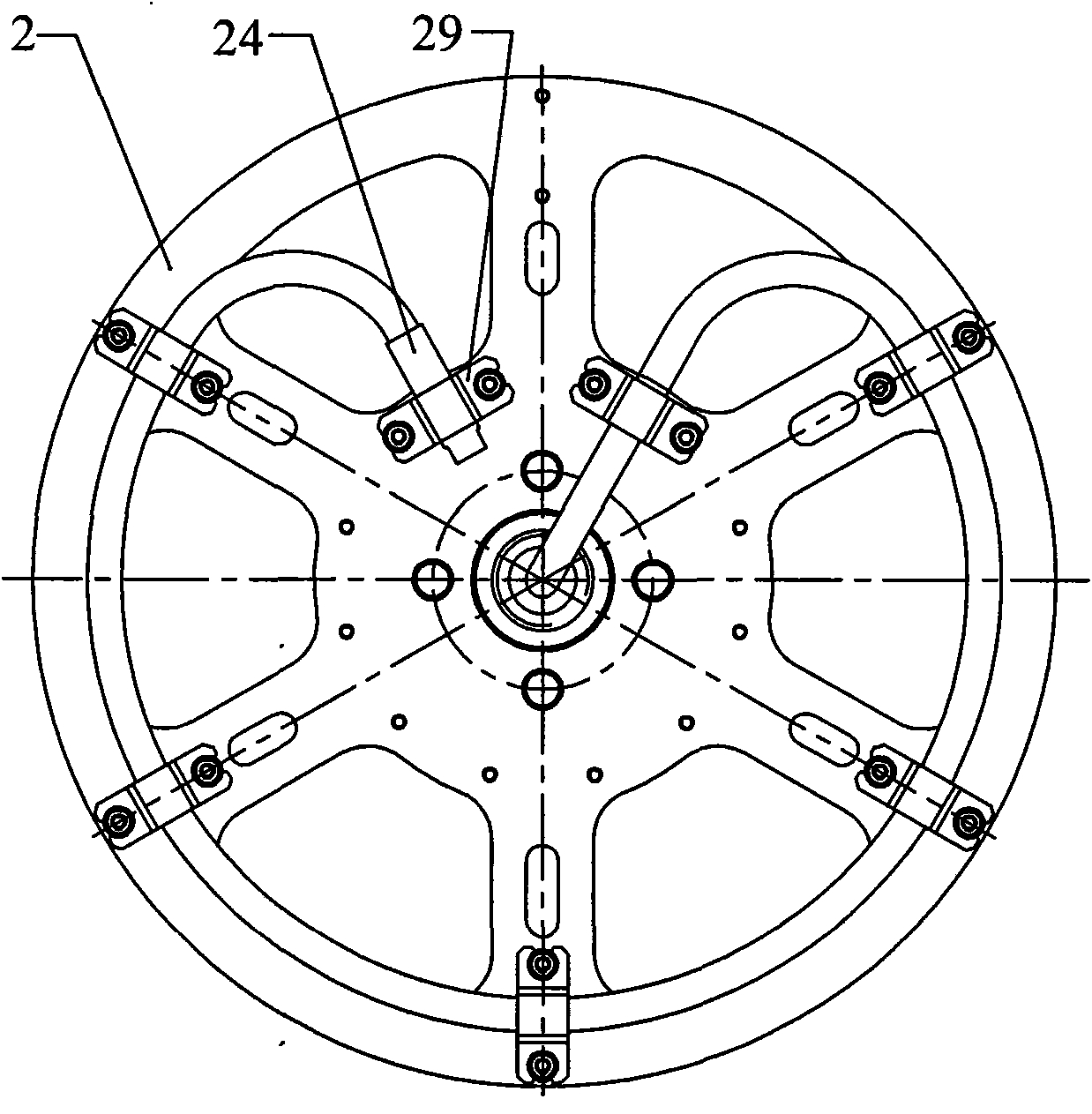

Cable storage type rotary optical cable signal transporting device

The invention discloses a cable storage type rotary optical cable signal transporting device, comprising a main spindle, a transmission gear system, a rotary cable storage mechanism formed by a levorotation cable storage roller and a dextrorotation cable storage roller and a transmission input part which is connected with the main spindle and comprises an optical fiber terminal seat, wherein a terminal disk which is fixedly connected with the main spindle is arranged in the transmission input part, the output end of a limiting torque clutch is connected with a half-coupling fixed on the terminal disk, the input end of the limiting torque clutch is connected with a transmission sleeve, a drive disk is connected with a drive poking rod which is fixed on the transmission sleeve through a connecting piece, and the drive disk, the limiting torque clutch and the main spindle share the same rotation center. The invention solves the problems that because cycles of reciprocating rotation of anexternal optical cable winding mechanism exceed a preset allowed rotation angle of a carried transfer optical cable on the cable storage rollers, the carried transfer optical cable can be stretched tobe broken, and other rotation parts are damaged to lead to signal transmission interruption.

Owner:雷步忠 +1

Four-rotor driving type geared motor

ActiveCN103532298ASimple structureHigh pole utilizationMechanical energy handlingRadial planeGear drive

The invention discloses a four-rotor driving type geared motor. Four rotor shafts are symmetrically arranged in the radial direction, and each rotor shaft comprises an eccentric shaft and two tile-type permanent magnets symmetrically mounted on the rear segment; a stator is in a structure that a circular ring is arranged on the outer side, and the middle part is crisscross, a circular gap is arranged on each of the four corners, two symmetrical pole shoes are arranged at each gap, one segment, on which the permanent magnet is mounted, of each of the four rotor shafts passes through the corresponding circular gap to form a single-phase bipolar magnetic pole; upper bearings are mounted on the two eccentric segments of the four rotor shafts and are respectively mounted in the bearing block holes of two inner gear rings, and the two ends of each rotor shaft are respectively mounted in bearing holes formed in a front cover and a rear cover; two windings are symmetrically mounted on the stator in the radial direction, the four rotor shafts can be simultaneously driven to rotate by properly controlling the conduction time and current direction of the two windings, meanwhile the inner gear ring is driven to move in a revolution manner in a radial plane and be meshed with a fixed shaft outer gear, and the outer gear drives a main shaft to output rotation. According to the four-rotor driving type geared motor, the structure is compact, and the transmission ratio is large.

Owner:河南盛世恒信科技有限公司

Latch needle for a loop-forming textile machine

ActiveUS20050217322A1Reduce weightExtended service lifeSeed arrangmentsKnittingEngineeringMoment of inertia

The latch needle (1) of the invention has a latch (7), which is provided on its free end, on its side facing away from the hook (3), with one or more recesses (18, 19). The function of these recesses is to reduce the moment of inertia of the latch (7), which leads to an increased service life of the latch. Between the recesses (18, 19), a rib remains, whose top side functions like a skid for loops to be transferred. The indentations (18, 19) are preferably elongated depressions. However, corresponding openings may be provided as a substitute instead.

Owner:GROZ BECKERT KG

Defense Related Robotic Systems

A robot quick-release assembly has a first joint member and a robot component mounted thereon, the first joint member has a first coupler and a second joint member, a robot arm mounted thereon has a second coupler, a clamp, and a locking collar. The first coupler can be coaxially aligned with the second coupler and pressed into the second joint member, and detachably connected to the second joint member. The first mechanical coupler is detachably connected to the second mechanical coupler for transferring power across the quick-release assembly. The robot component can receive an additional electrical connector, the additional electrical connector supplying power to the robot component. The quick-release assembly coupling assembly further exerts large forces with the application of a relatively small torque to the locking collar by applying a two stage wedge engagement and can further include a sequencing system.

Owner:RE2

Vacuum pump blade with oil grooves and vacuum pump

InactiveCN105090035AReduce weightSave materialRotary piston pumpsRotary piston liquid enginesPulp and paper industryVacuum pump

The invention discloses a vacuum pump blade with oil grooves. The vacuum pump blade comprises a blade body and ends and is characterized in that the surface of the blade body is provided with a plurality of grooves. The surface of the blade body of the vacuum pump is provided with the grooves for storing oil, and friction between the blade and the side wall of an inner cavity of the vacuum pump and between the blade and the inner side of a groove of a rotor can be lowered in the rotating process of the blade, so that heat generation is lowered, noise is lowered, power consumption is reduced, and the service life is prolonged.

Owner:OECHSLER PLASTIC PROD TAICANG

A non-contact induction power supply device for ultrasonic milling

ActiveCN105529836BSmall turning radiusImprove rotational stabilityCircuit arrangementsResonanceMoment of inertia

The invention discloses a non-contact inductive power supply device for ultrasonic milling, which mainly includes a primary side and a secondary side. The spatial position relationship between the primary side and the secondary side is arranged as an inner and outer concentric circle, and there is no mechanical connection between the two, wherein the structure of the primary side is only about 2 / 5 of the circumference in the circumferential direction. Complete circular columnar structure. The secondary side is optimized to realize mutual compensation at the working vibration frequency of the ultrasonic vibration system by using the leakage inductance of the secondary side coil and the equivalent capacitive reactance of the ultrasonic vibration system without additional compensation components. . The non-contact induction power supply device has a compact structure, a small moment of inertia, and can be expanded and installed, which can meet the working requirements of automatic tool change, high-speed rotation of the spindle, and high power of the ultrasonic vibration system in ultrasonic milling; install two sets of the non-contact The induction power supply device can also meet the power supply requirements of ellipse ultrasonic milling.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com