Vacuum pump blade with oil grooves and vacuum pump

A technology of vacuum pump and vane, applied in the field of vacuum pump and vane, can solve the problems of increased friction loss, poor sealing, easy wear, etc., and achieve the effect of small friction loss and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

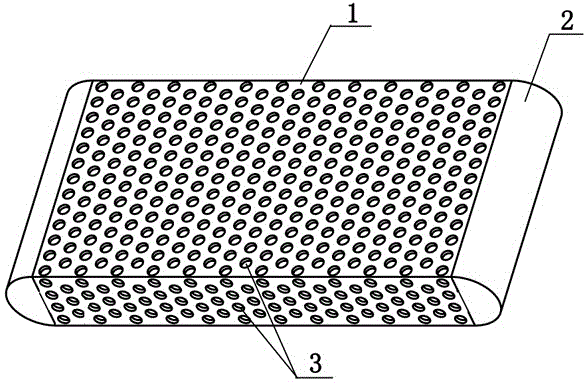

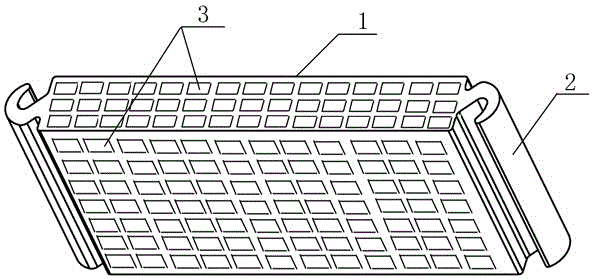

[0018] Such as figure 1 The shown vacuum pump blade with oil grooves includes a blade body 1 and an end portion 2. Several neatly arranged circular grooves 3 are arranged on the upper, lower, front and rear sides of the blade body 1. In the grooves 3 Inject an appropriate amount of lubricating oil. The blade is installed in the rotor 4, the blade body 1 passes through the groove of the rotor 4, and the gap between the blade body 1 and the inside of the groove of the rotor 4 is sealed by oil. The blade end 2 is tightly fitted with the inner lining ring of the vacuum pump 5, and the gap between the blade and the side wall of the inner chamber of the vacuum pump 5 is sealed by oil. When working, the rotor 4 drives the blades to rotate in the vacuum pump 5, and the end 2 further clings to the inner wall of the vacuum pump, and the blade body 1 reciprocates stably along the length direction of the blade body 1 in the rotor to further make the end 2 press the inner lining of the va...

Embodiment 2

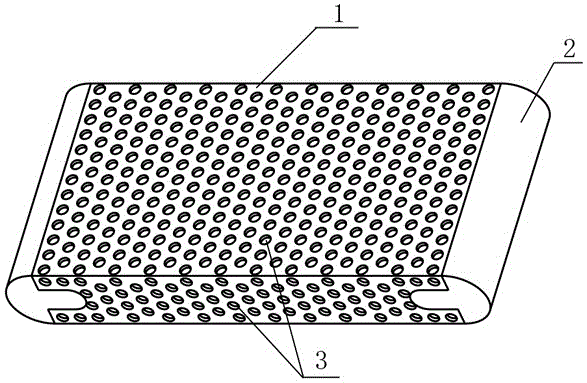

[0020] Such as figure 2 In the shown vacuum pump vane with oil grooves, the body 1 and the end 2 are detachable and connected to each other through shape fitting. Such as Figure 4 As shown, the blades are installed in the rotor 4, and the rest are the same as in the first embodiment.

Embodiment 3

[0022] Such as figure 1 The vacuum pump blade with oil groove shown is different in that the vacuum pump blade includes a shell 11 and an insert 12, the shell 11 is made of polyphenylene sulfide-glass fiber, and the insert 12 is injection molded from a glass fiber composite board Formed or molded, the parts are joined together using injection molding. Such as Figure 4 As shown, several neatly arranged circular grooves 3 are arranged on the upper, lower, front, and rear surfaces of the shell 11 of the blade, and an appropriate amount of lubricating oil is injected into the grooves 3 . The blade is installed in the rotor 4, the blade body 1 passes through the groove of the rotor 4, and the gap between the blade body 1 and the inside of the groove of the rotor 4 is sealed by oil. The blade end 2 is tightly fitted with the inner lining ring of the vacuum pump 5, and the gap between the blade and the side wall of the inner chamber of the vacuum pump 5 is sealed by oil. When wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com