Four-rotor driving type geared motor

A motor and driving technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of short driving stroke, increase of driving device components and weight, and complex structure, so as to reduce the difficulty of processing and assembly and improve the magnetic pole. Utilization rate, the effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

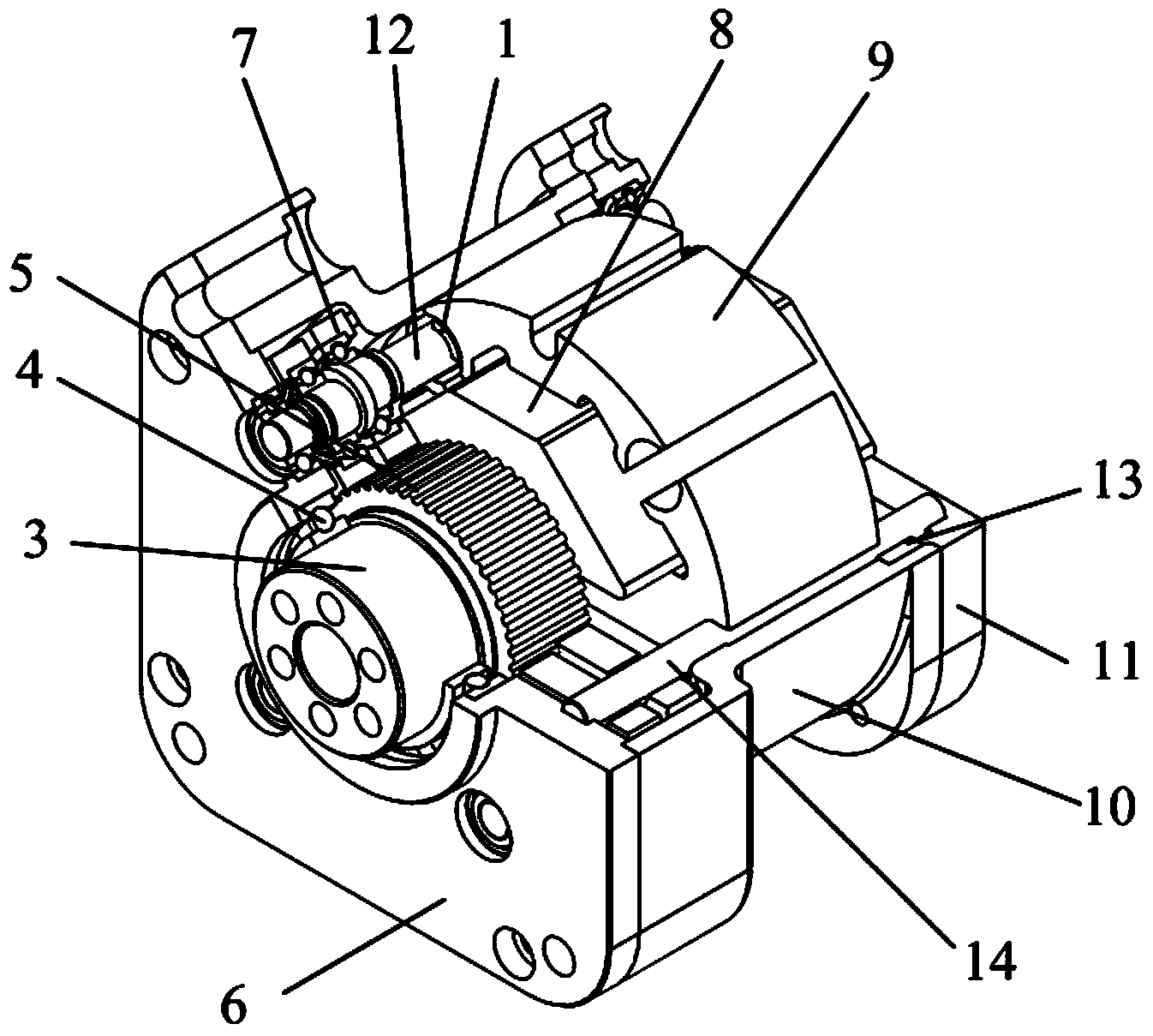

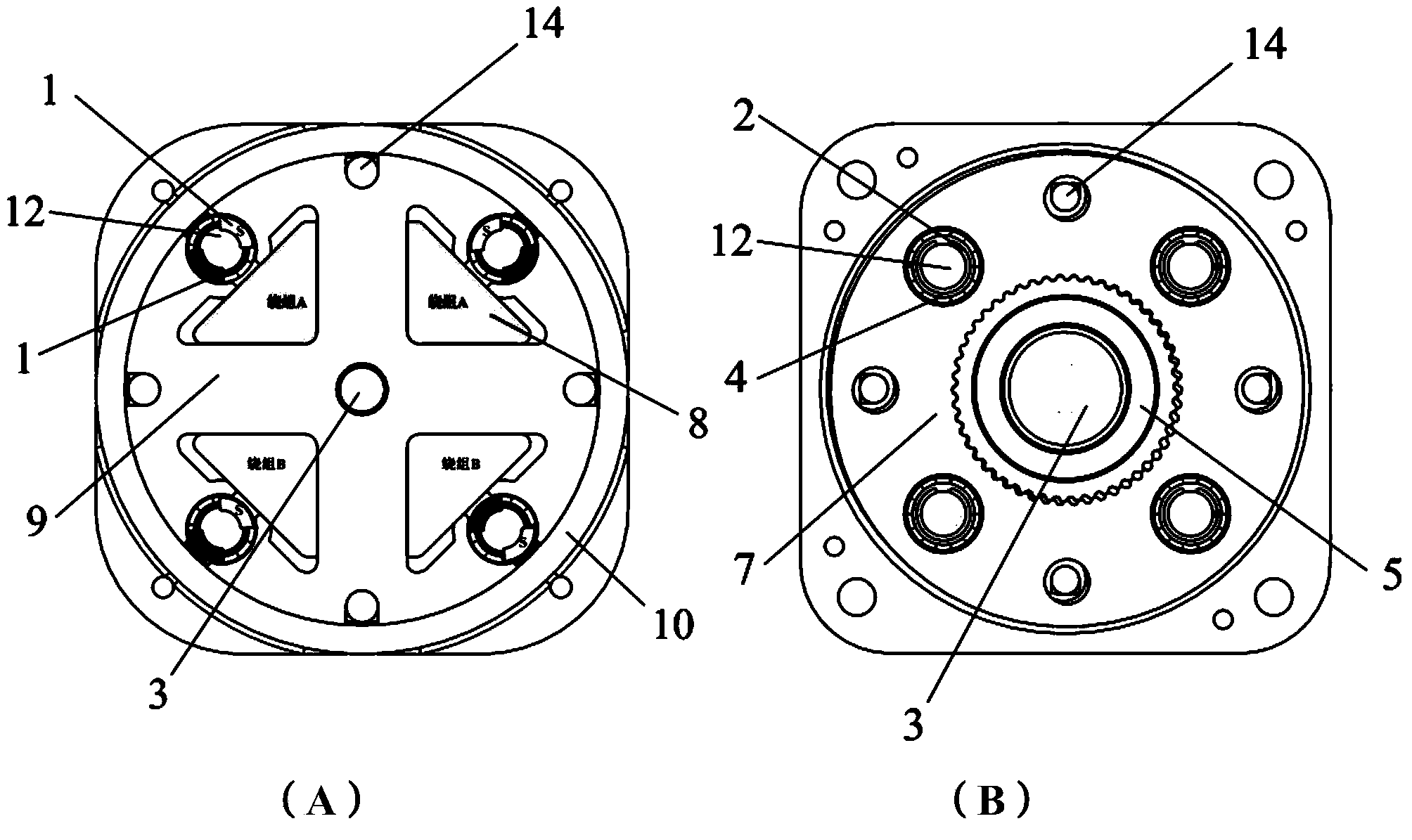

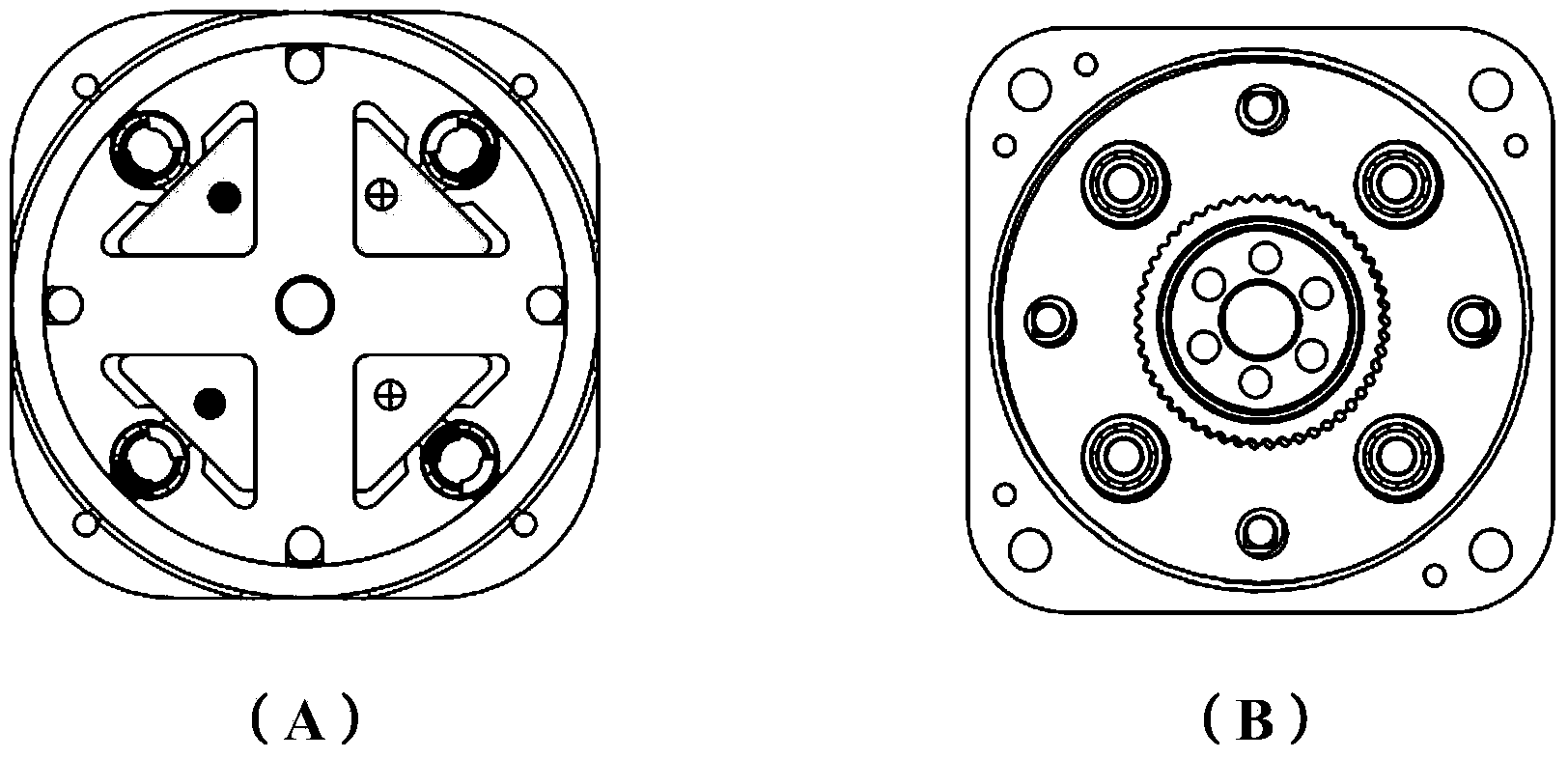

[0034] See Figure 1~Figure 18 , Introduce the structure and composition of the four-rotor drive meshing motor of the present invention: it is a motor that integrates the motor and the reducer, has a certain self-locking, braking, and can directly output low speed and high torque. The motor is equipped with: motor stator 9, winding 8, rotor permanent magnet 1, internal gear ring 7, external gear 5 and main shaft 3 of the gear reducer, eccentric shaft 12, and the supporting part is the housing 10, the front cover 6 and the rear Cover 11. The central semicircular hole on the external gear 5 is sleeved in the middle section of the main shaft 3. By the revolving meshing movement of the inner ring gear 7 with the external gear 5, the external gear 5 drives the main shaft 3 to output a low-speed and high-torque rotation movement; Both ends of the four positioning pins 14 of the semicircular holes on the ring gear 7 and the stator 8 are fixedly mounted in the holes on the motor end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com