Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce the amount of solvent used" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

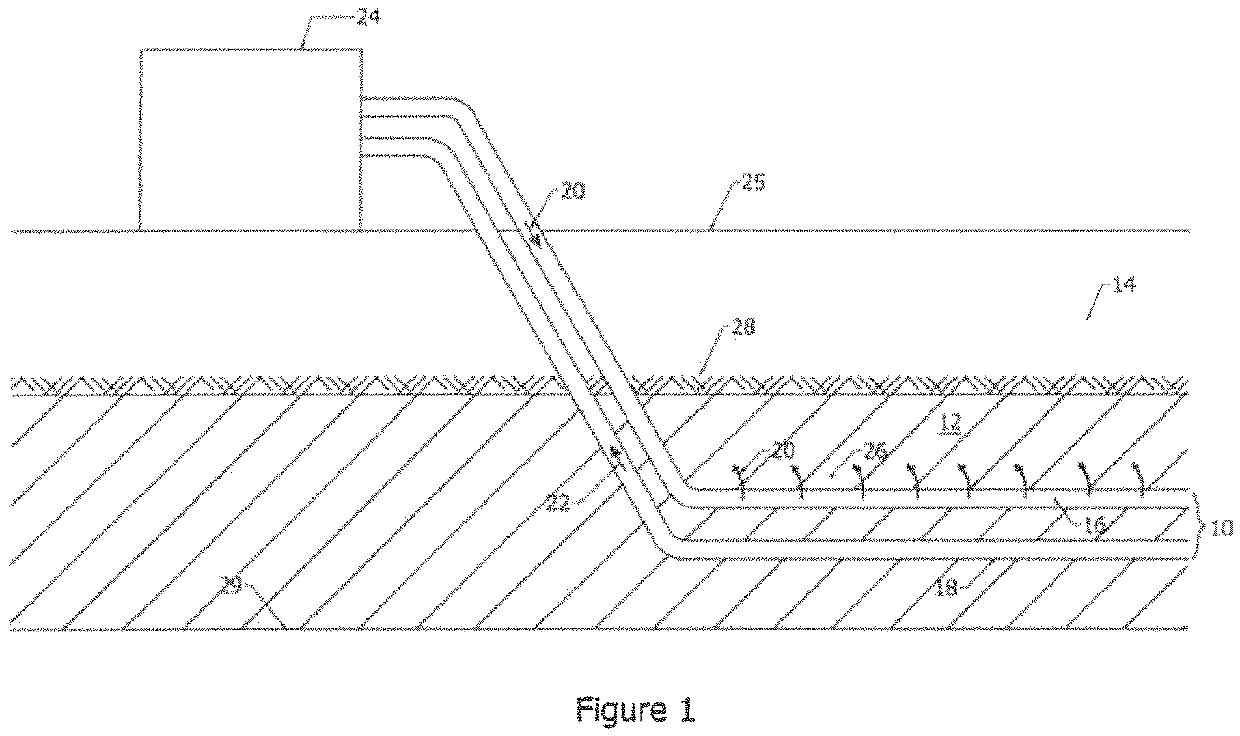

Use of a solvent and emulsion for in situ oil recovery

ActiveUS8684079B2Reduce the amount of solvent usedMinimize solvent usedFluid removalFlushingSolventPolymer chemistry

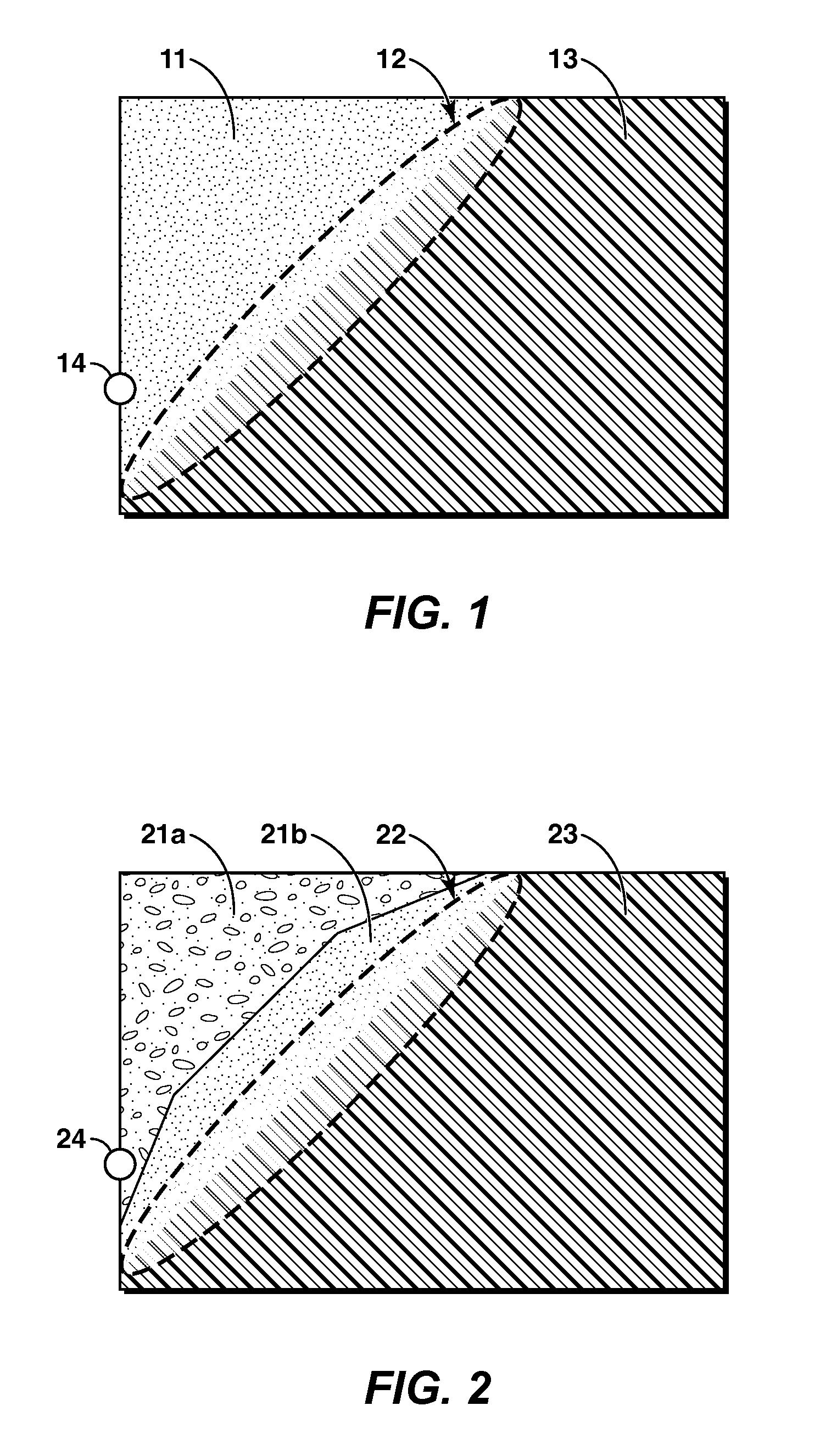

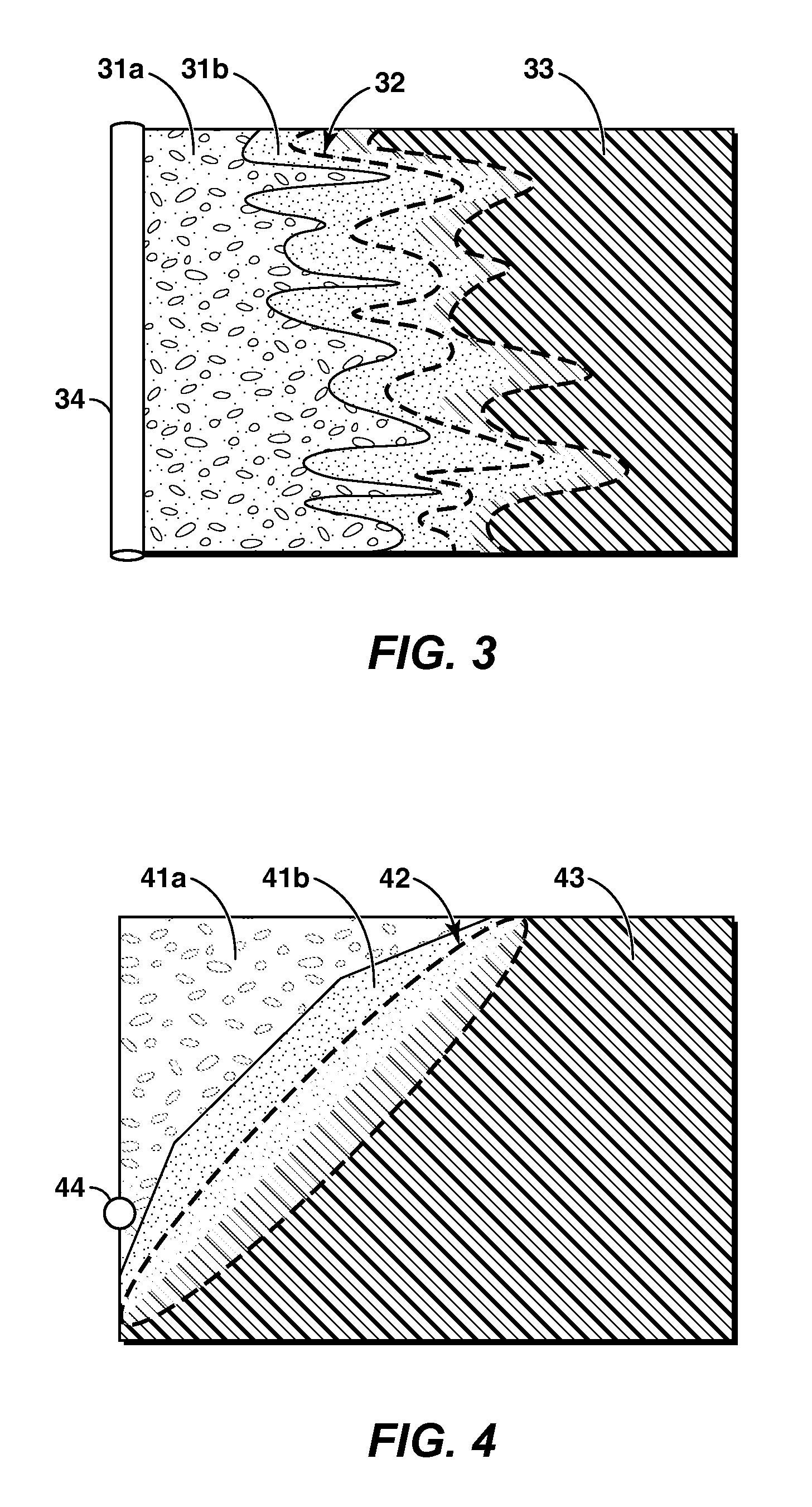

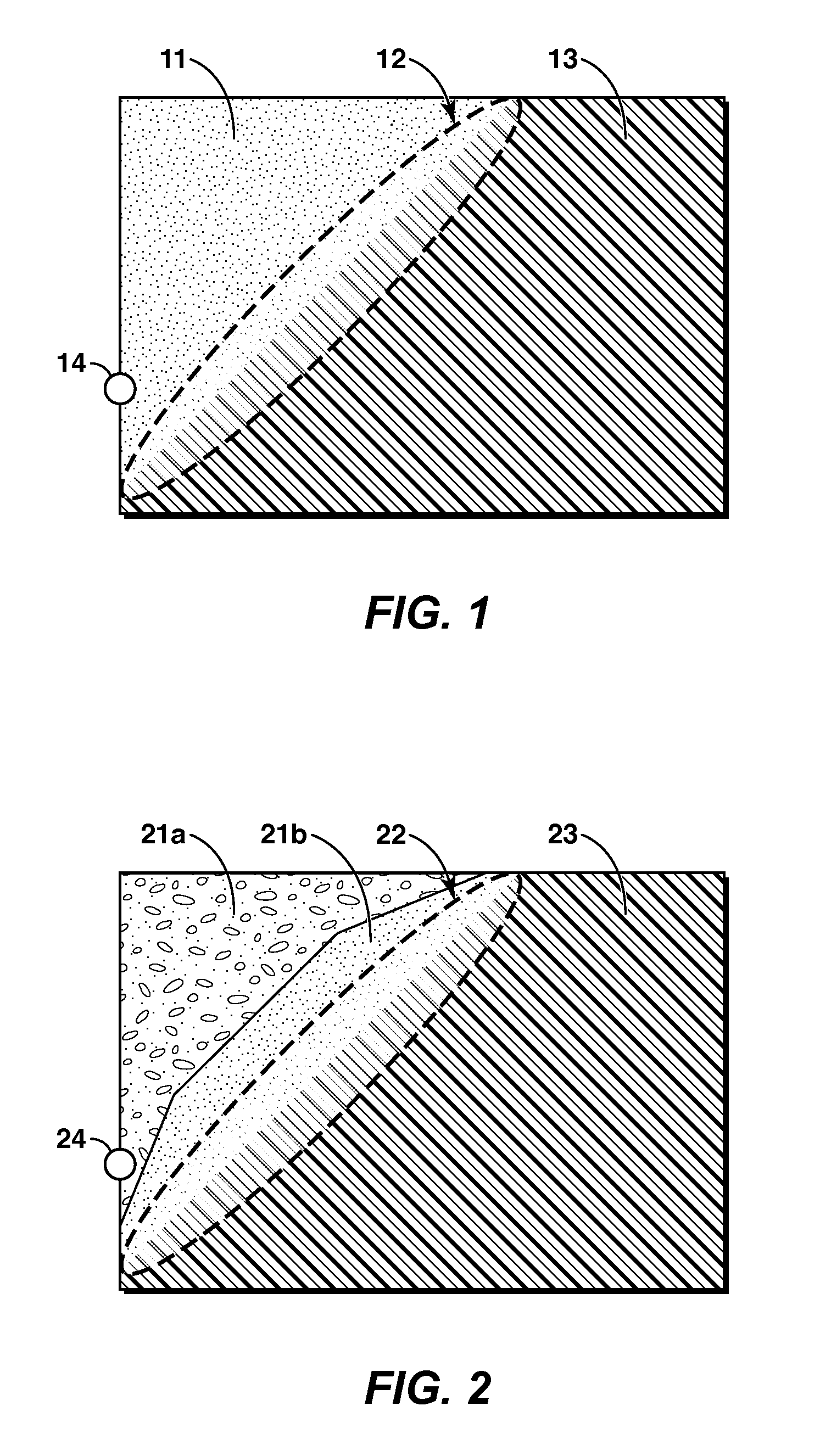

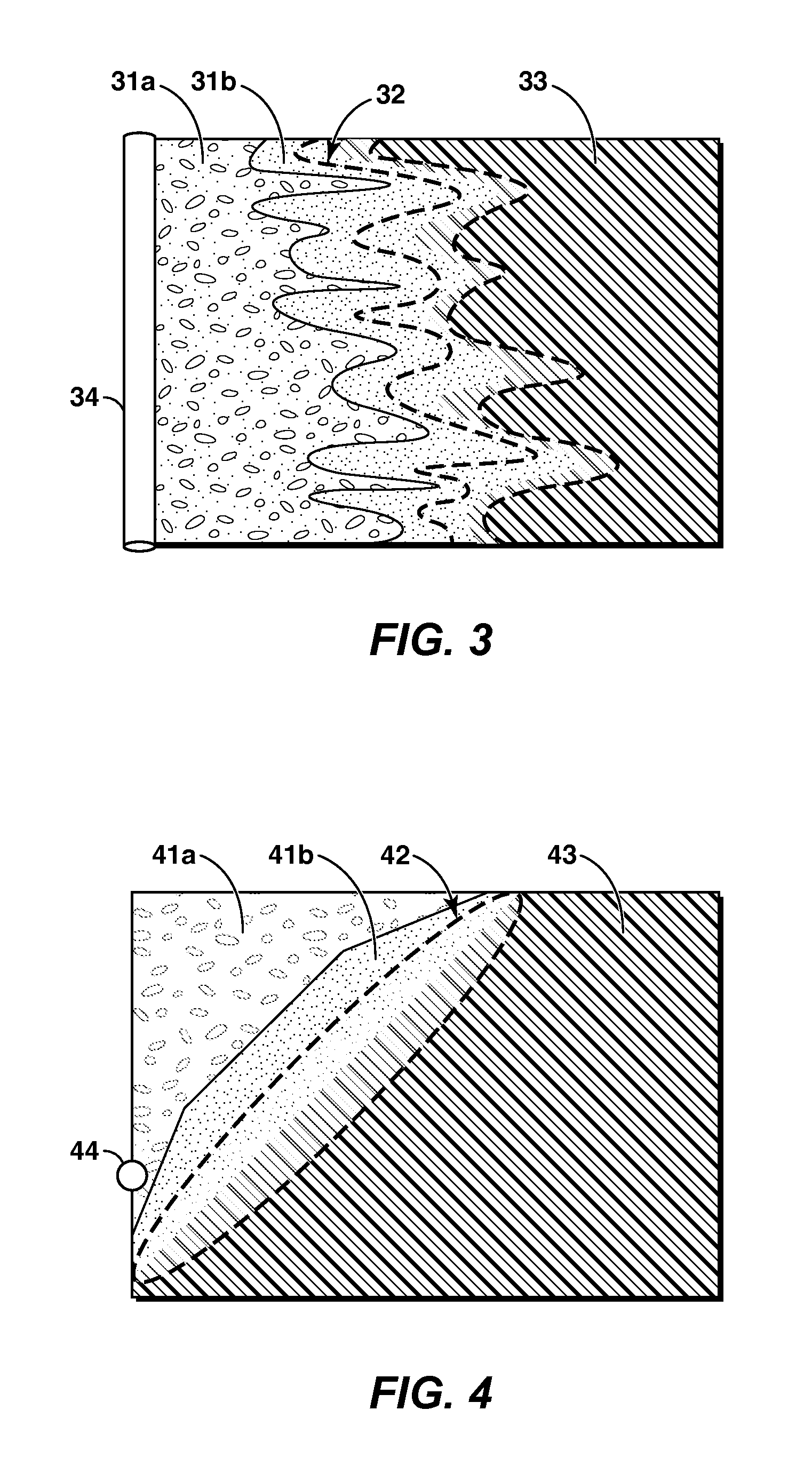

Described is a way to reduce solvent usage in solvent-dominated oil recovery processes through the use of an emulsion. Injection of an emulsion into an oil reservoir is performed as an alternative or supplement to solvent injection to minimize solvent usage per unit amount of oil recovered. The emulsion may contain solvent and the solvent may form an external-phase of the emulsion. A solvent-external emulsion may be injected and formed using an aqueous liquid or a gas as the internal phase. The emulsion may be an aqueous-external, vapor-internal emulsion with solvent being injected separately or simultaneously. Polymer may be added to viscosify the emulsions and use them for flow diversion in a solvent-dominated process.

Owner:EXXONMOBIL UPSTREAM RES CO

Preparation method of polyimide nanometer filtering membrane

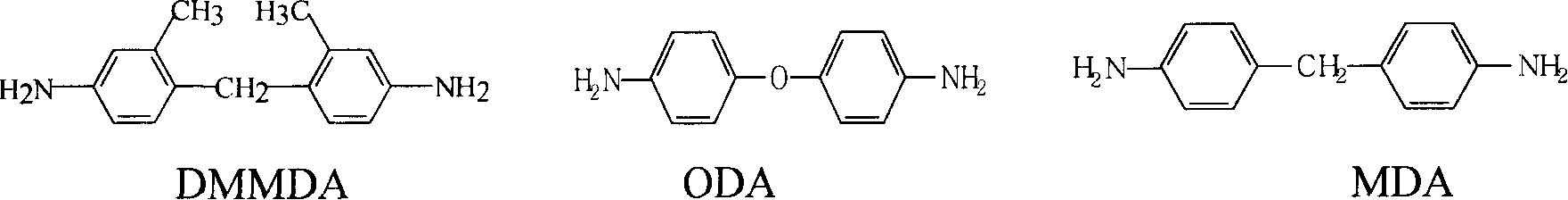

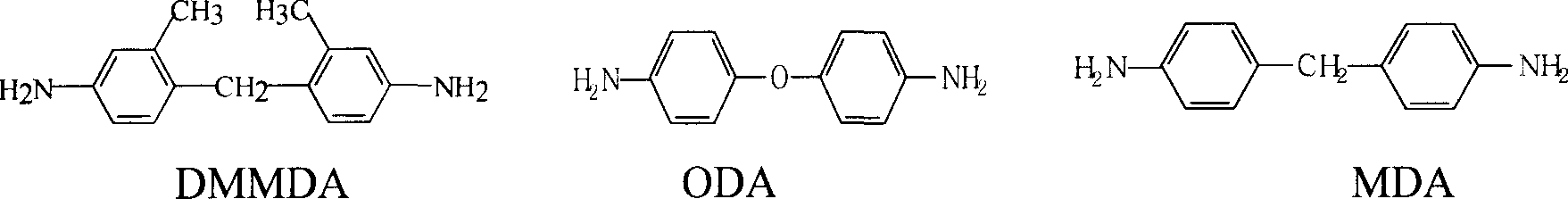

ActiveCN1911494AIncrease varietyReduce the amount of solvent usedSemi-permeable membranesPolyimide membraneBenzene

The present invention relates to a preparation process of nanofiltering polyimide membrane for recovering lubricant oil acetone-benzene dewaxing solvent. The preparation process includes the following steps: preparing polyamic acid solution, adding additive for phase transfer to prepare nanofiltering polyamic acid membrane, imidating the membrane chemically, solvent exchanging and heat treatment. Or, the preparation process may include the following steps: the first preparing partially imidated polyimide capable of being dissolved in some solvents, preparing film casting solution, filming in a phase transfer process, solvent exchanging and heat treatment. The present invention has low preparation cost, and the prepared nanofiltering polyimide membrane has lubricant oil intercepting rate greater than 90 % and mixed acetone-benzene solvent flux greater than 12 L / sq m .hr at the conditions of -18 deg.c and 3 MPa.

Owner:PETROCHINA CO LTD +1

Use of a solvent and emulsion for in situ oil recovery

ActiveUS20110226471A1Reduce the amount of solvent usedMinimize solvent usedFluid removalFlushingSolventPolymer chemistry

Described is a way to reduce solvent usage in solvent-dominated oil recovery processes through the use of an emulsion. Injection of an emulsion into an oil reservoir is performed as an alternative or supplement to solvent injection to minimize solvent usage per unit amount of oil recovered. The emulsion may contain solvent and the solvent may form an external-phase of the emulsion. A solvent-external emulsion may be injected and formed using an aqueous liquid or a gas as the internal phase. The emulsion may be an aqueous-external, vapor-internal emulsion with solvent being injected separately or simultaneously. Polymer may be added to viscosify the emulsions and use them for flow diversion in a solvent-dominated process.

Owner:EXXONMOBIL UPSTREAM RES CO

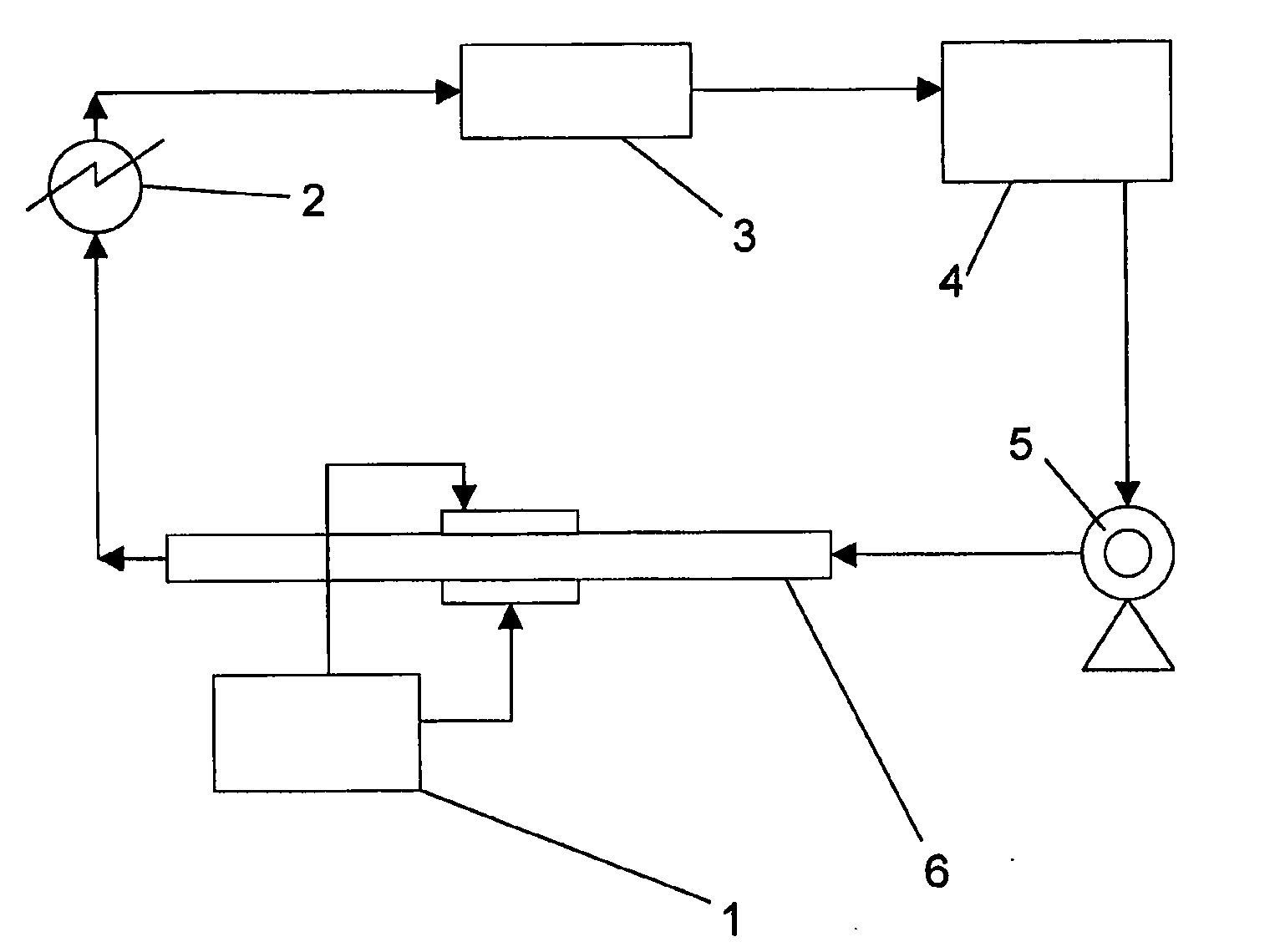

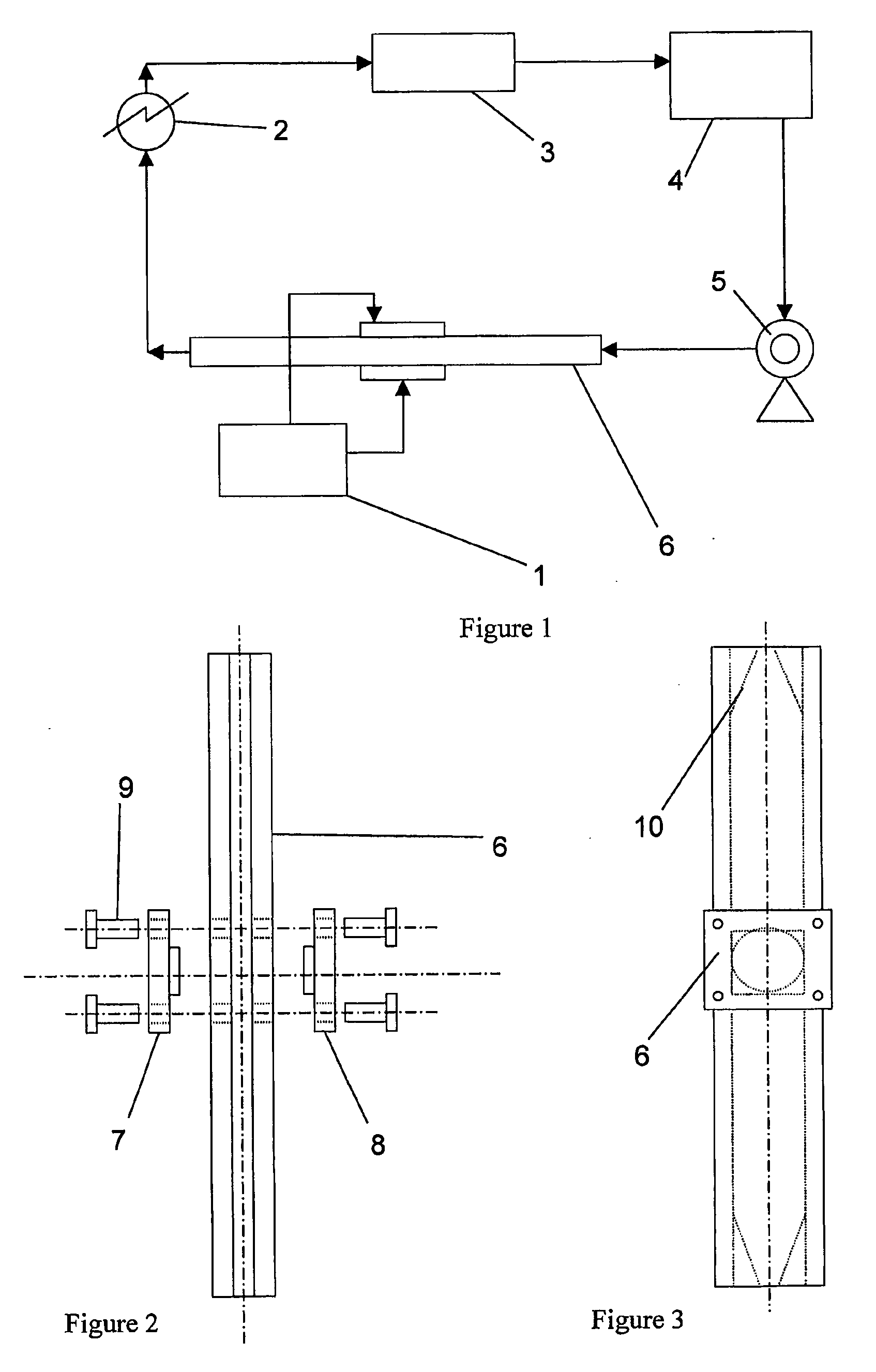

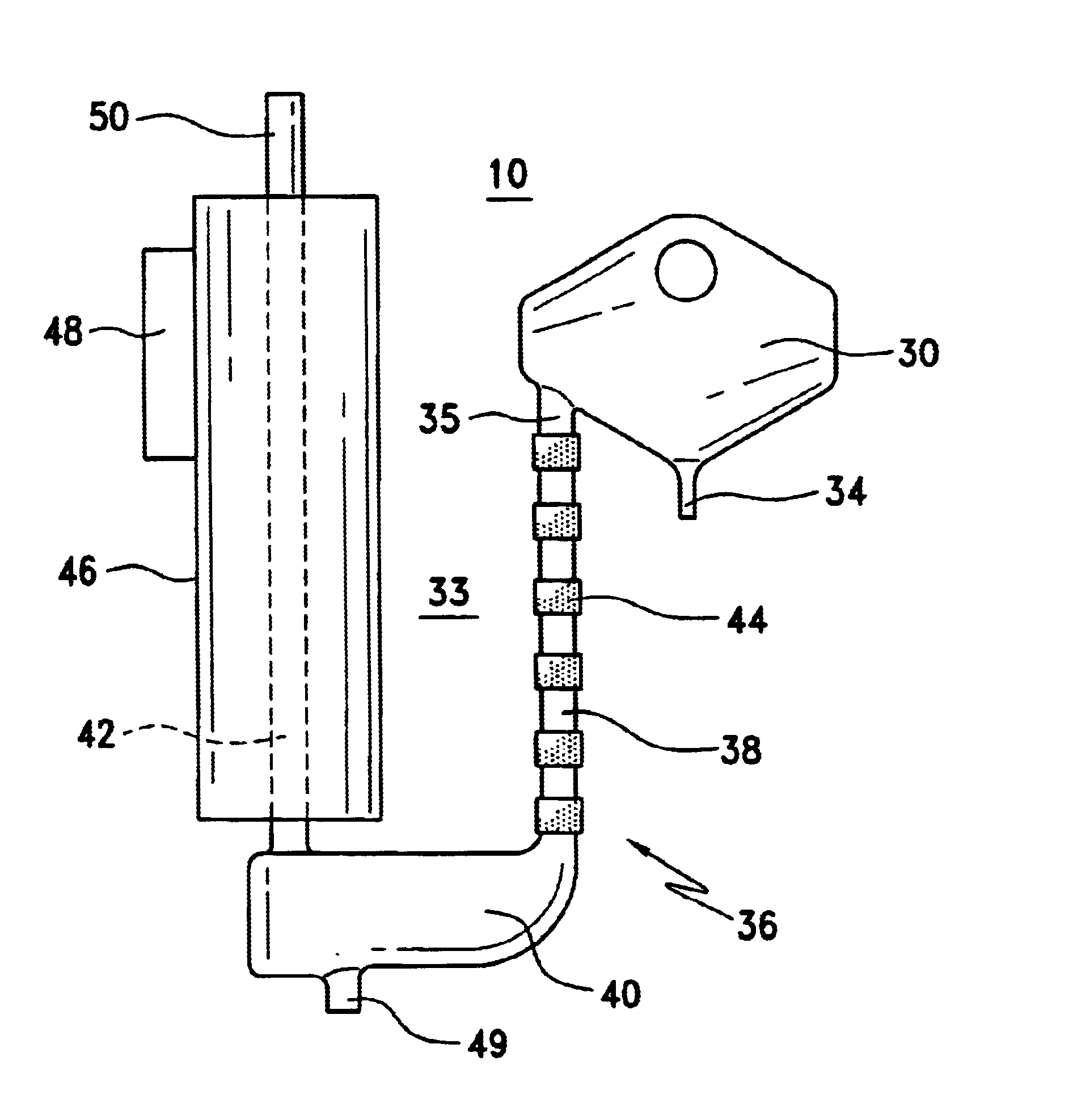

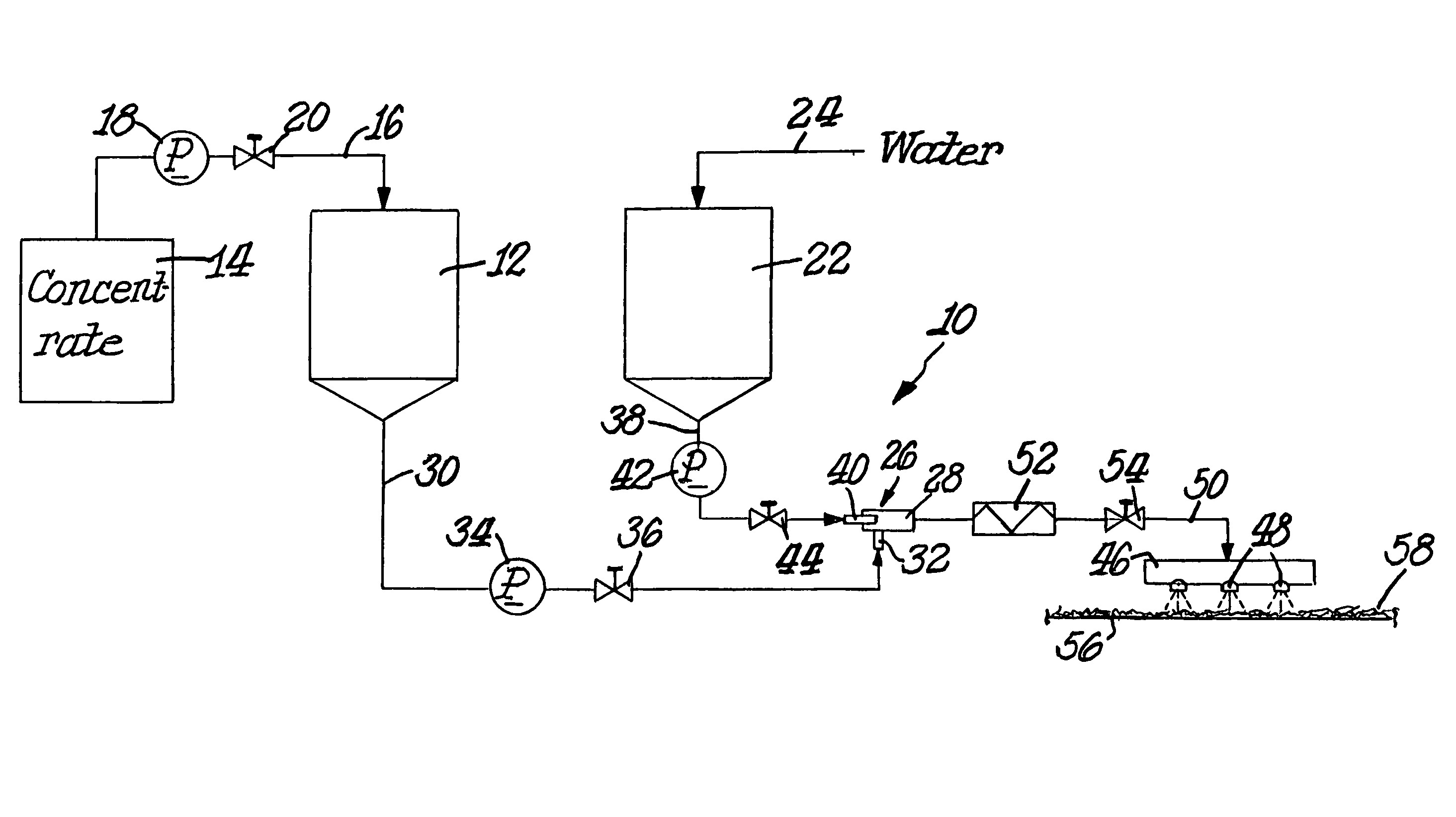

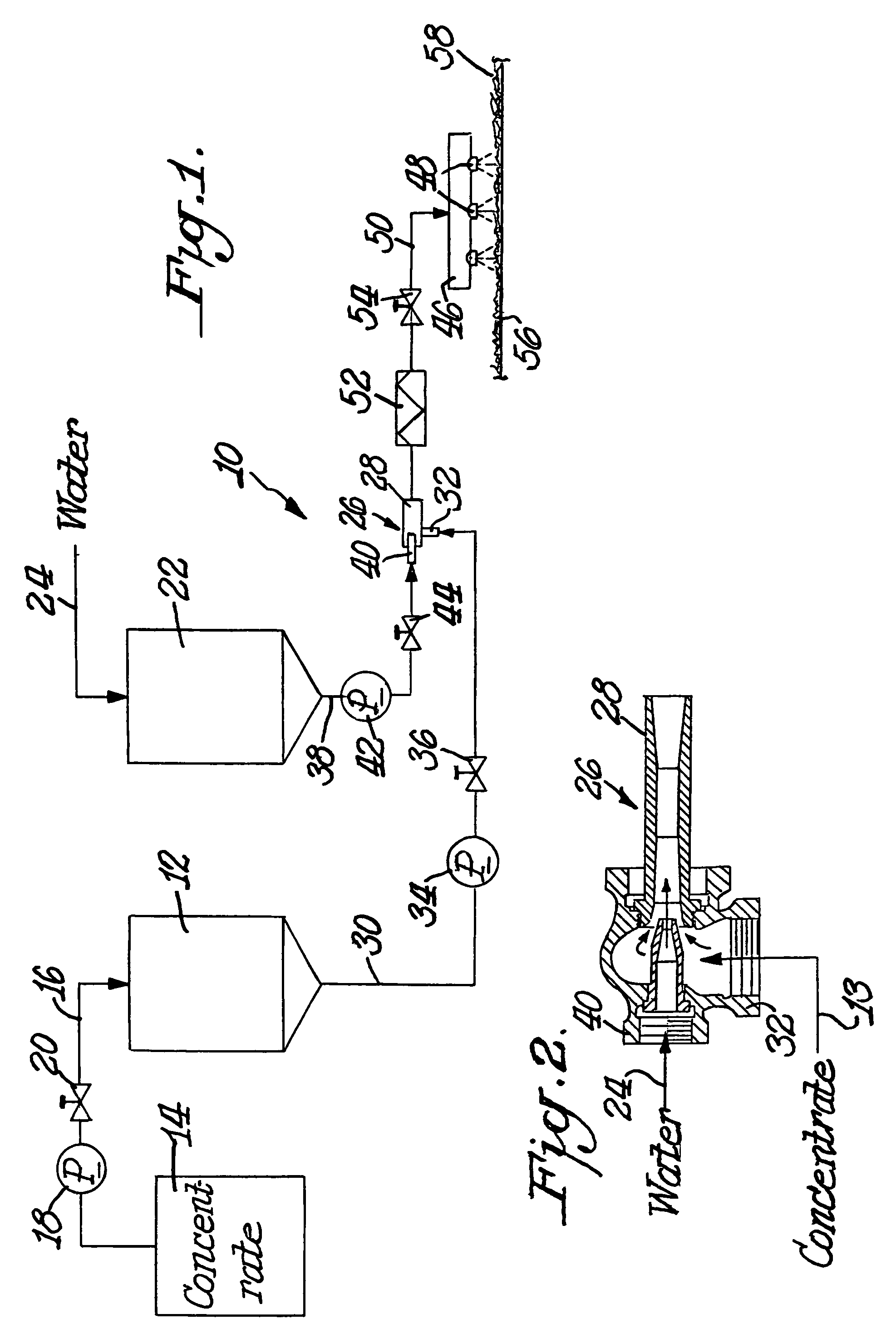

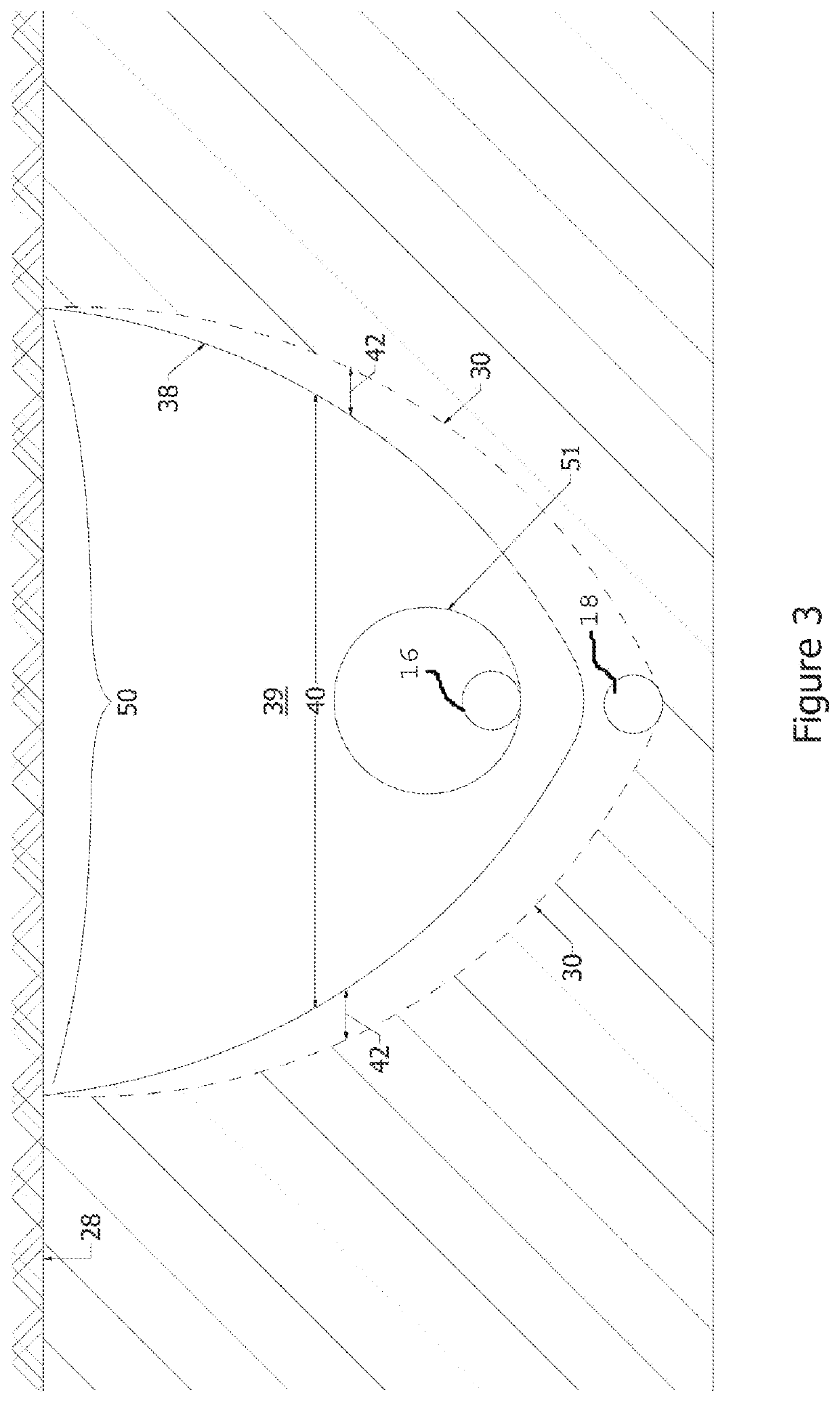

Tobacco flavor applicator

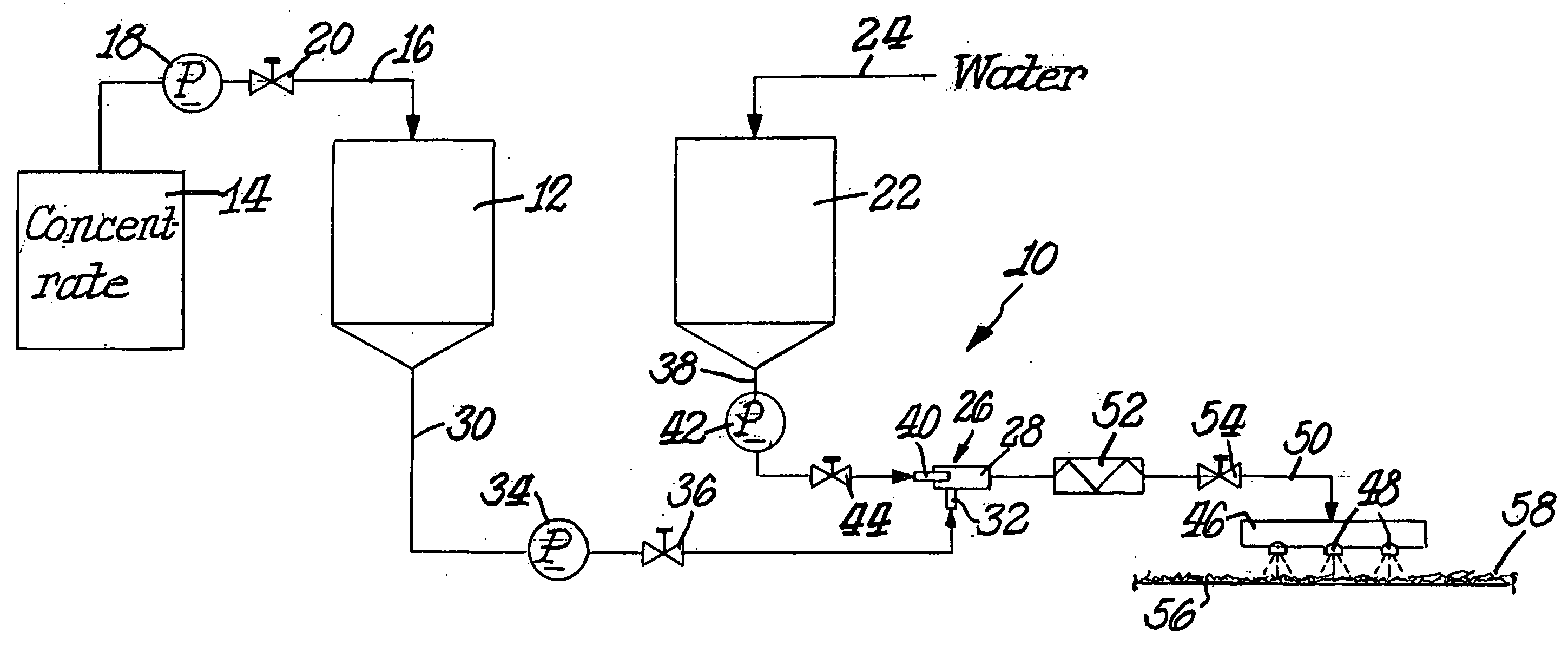

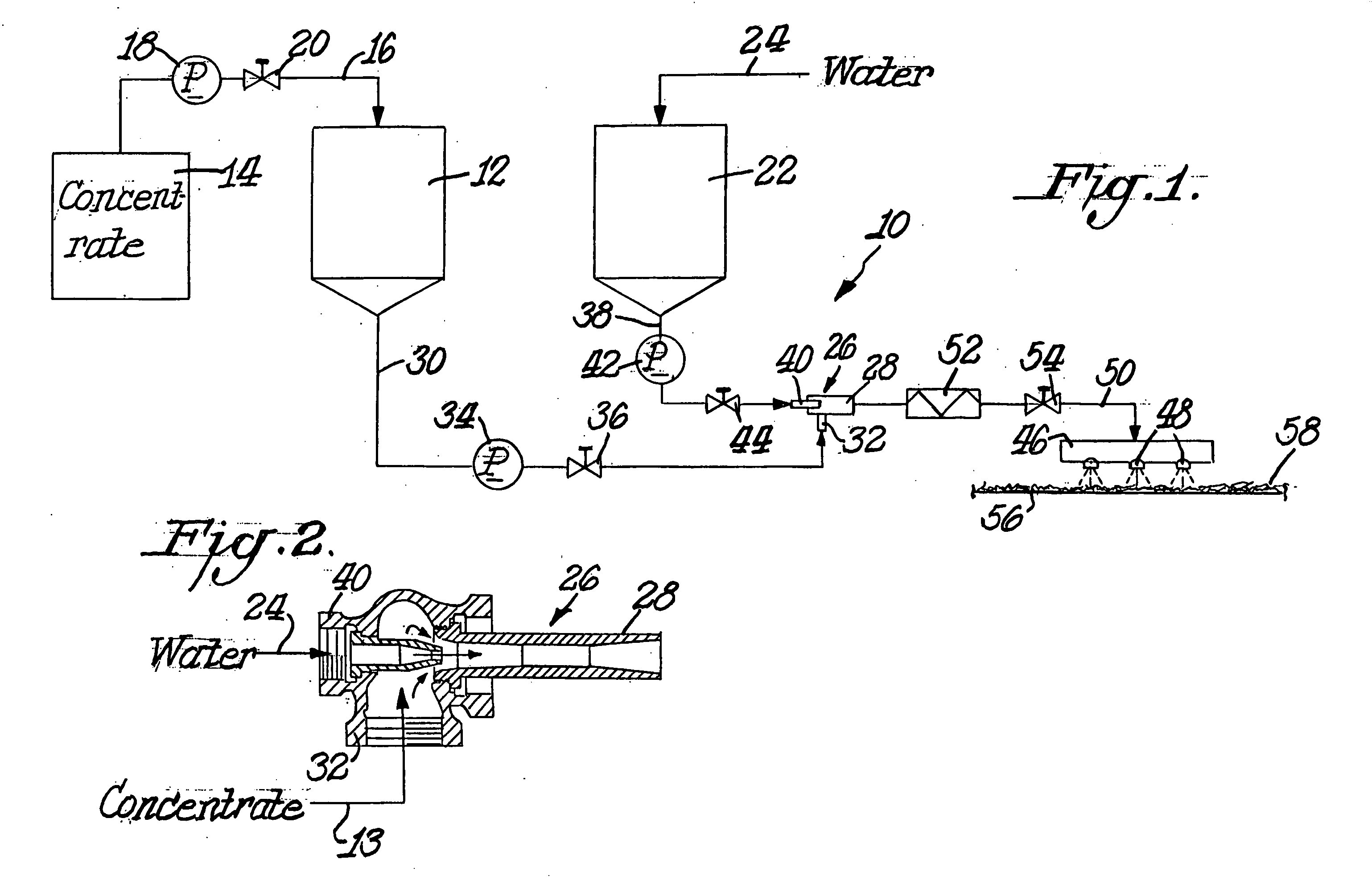

ActiveUS20060124143A1Improve production efficiencyReduce the amount of solvent usedTobacco preparationTobacco treatmentFood flavorWaste management

A system of applying liquid flavor to cut tobacco material includes a first tank of concentrated liquid flavor and a second tank of water. A venturi device is constructed and arranged to receive and meter concentrated liquid flavor and water from the first and second tanks and to discharge mixed flavor and water from an outlet end. A first line is connected between the first tank and a suction port on the venturi device, and a second line is connected between the second tank and an intake port on the venturi device. A spray assembly is in fluid communication with the discharge outlet of the venturi device for applying mixed flavor and water to cut tobacco.

Owner:PHILIP MORRIS USA INC

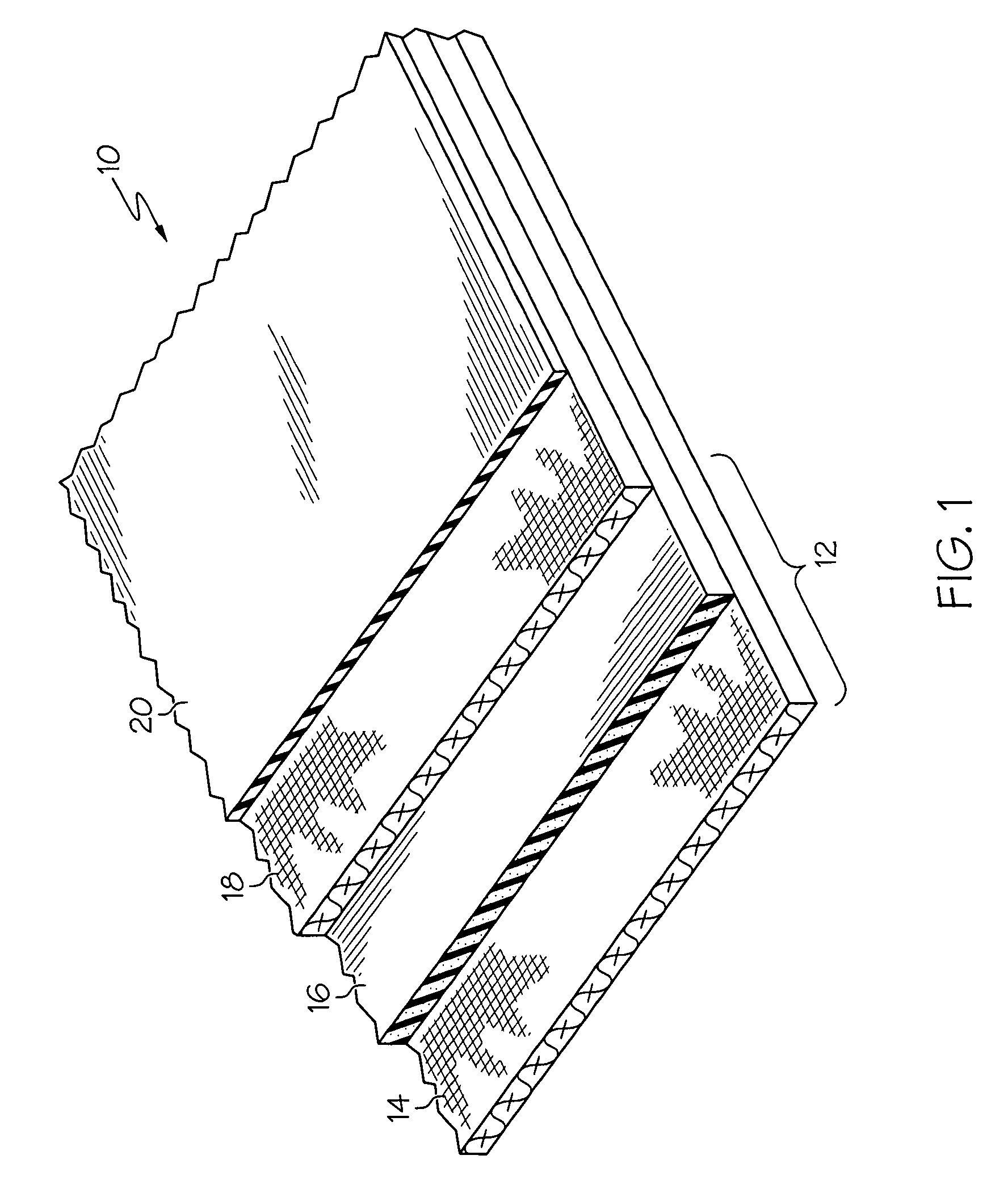

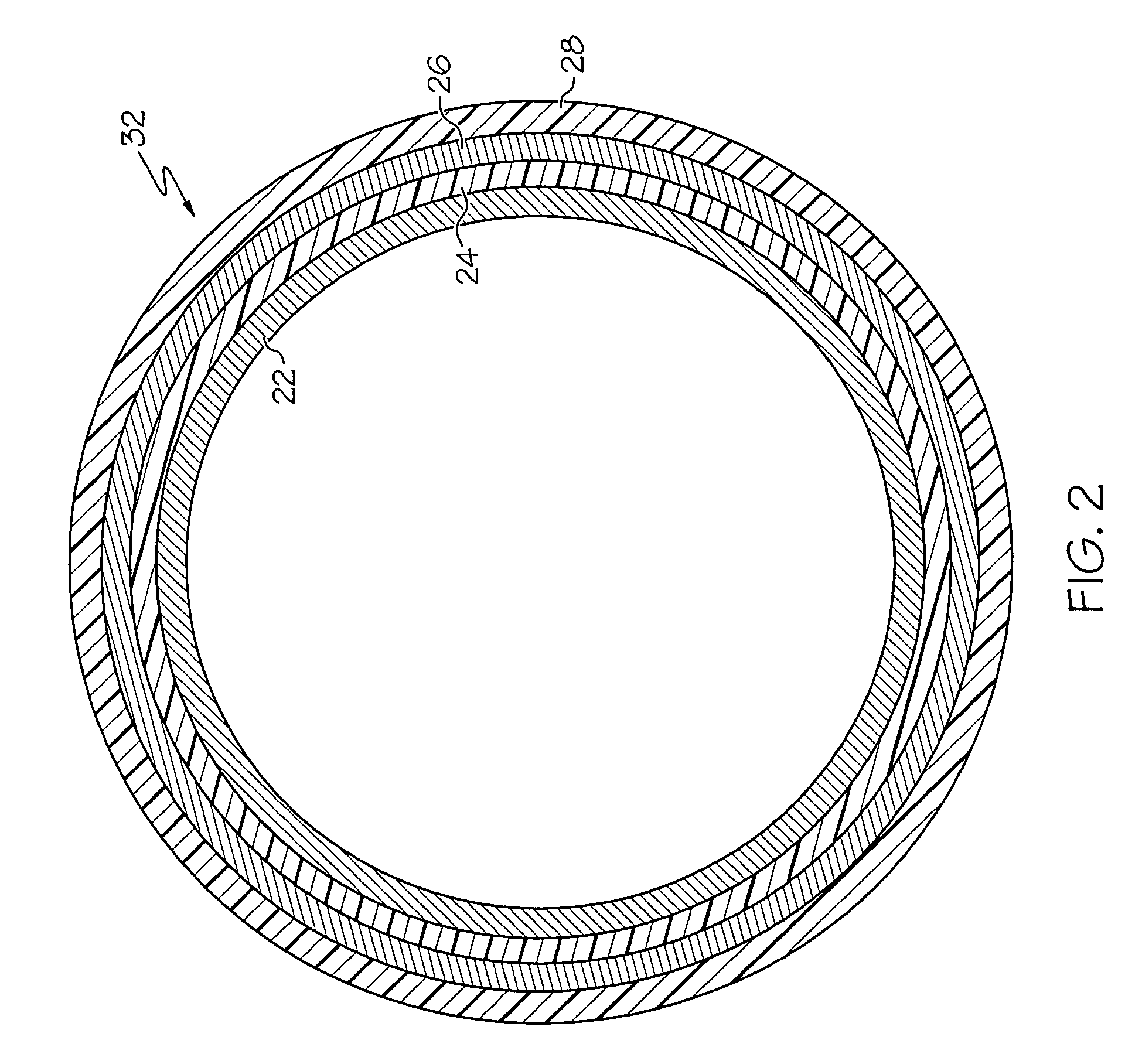

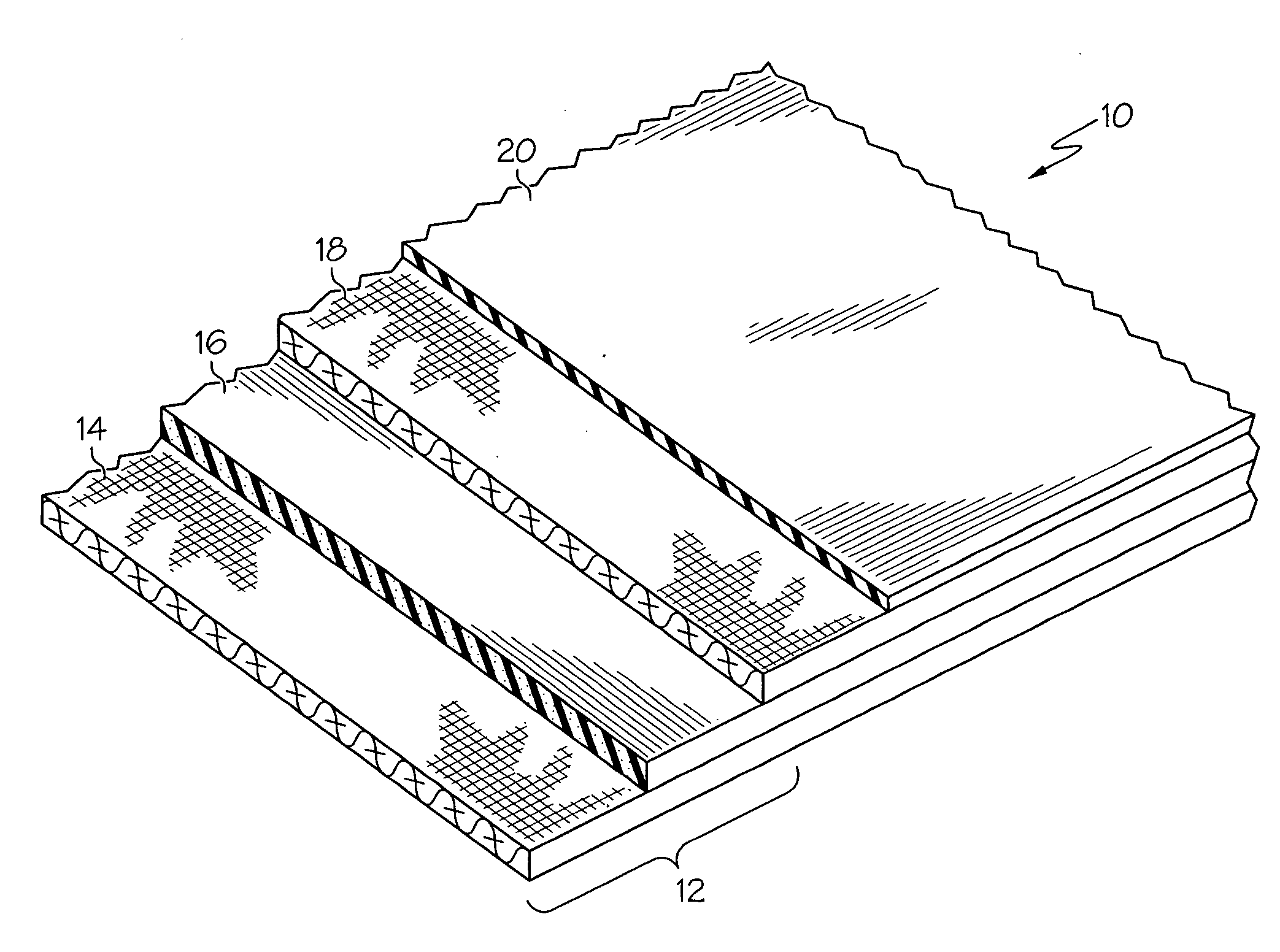

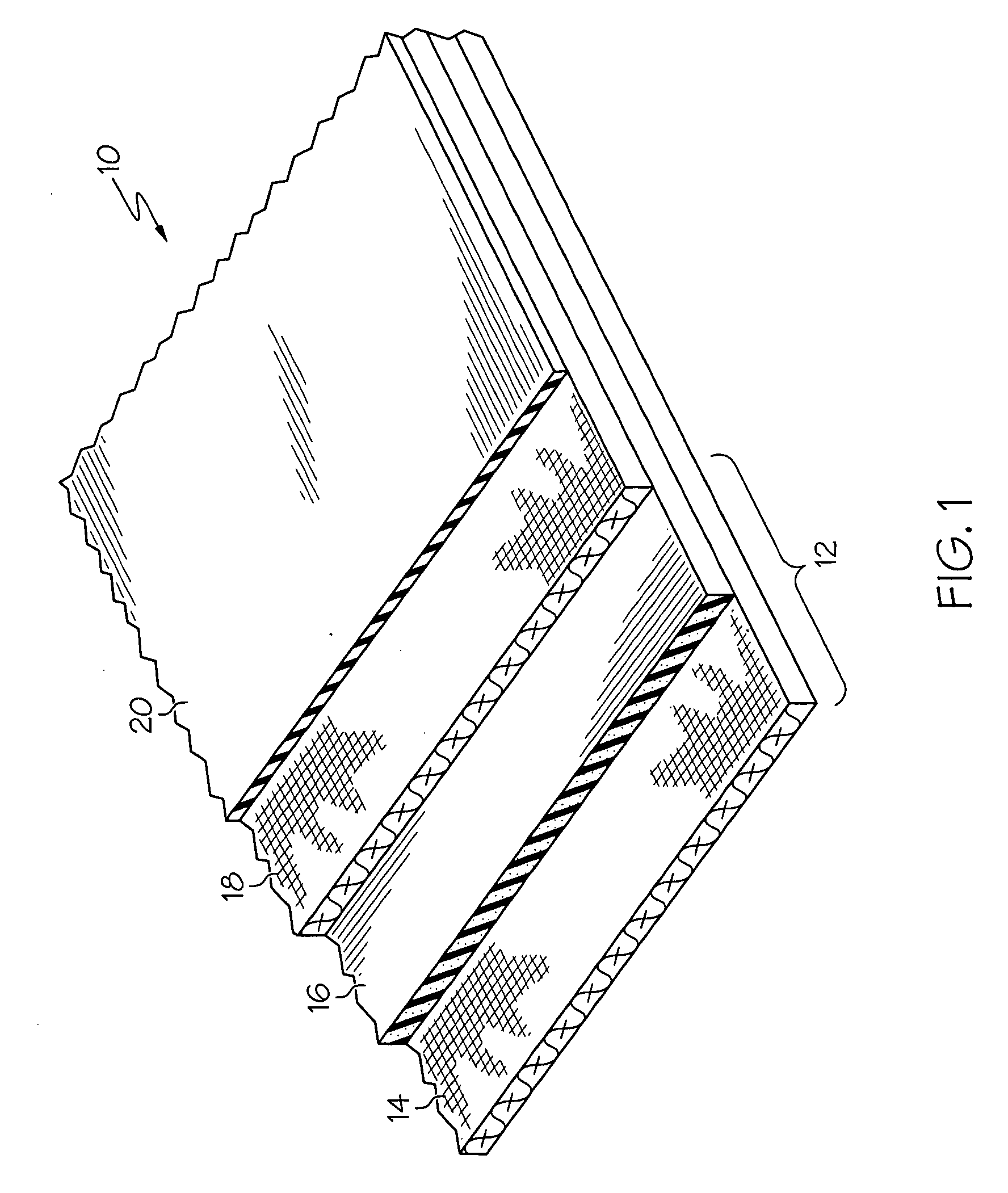

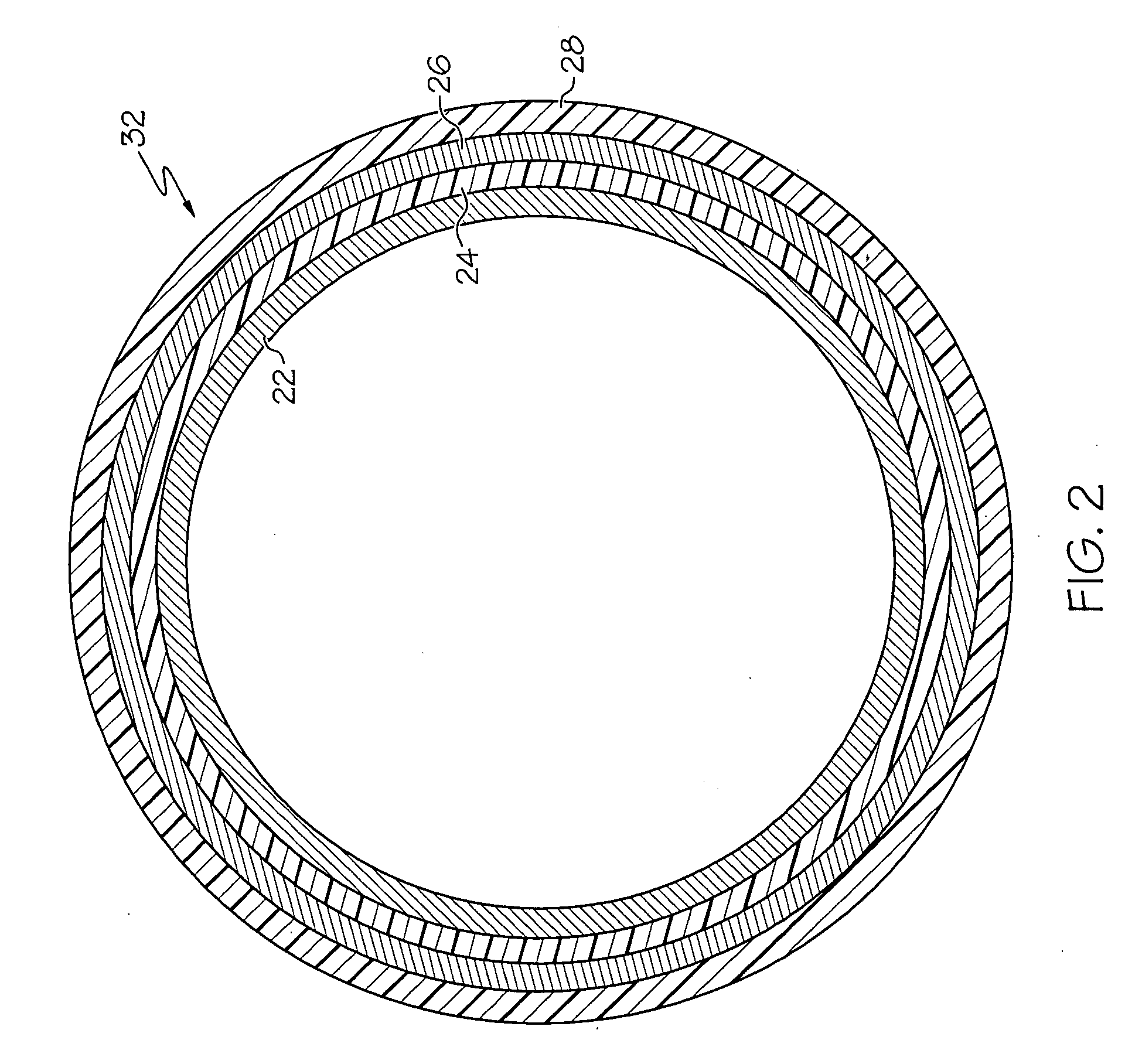

Image transfer product including a thin printing surface layer

ActiveUS8409698B2Efficient preparationReduce the amount of solvent usedRecord information storageLight beam reproducingSurface layerImage transfer

An image transfer product such as an offset printing blanket or sleeve is provided which comprises a very thin printing surface layer in combination with a smooth image reinforcement layer comprising a polymeric film, a fabric, or a polymer-coated fabric. The thin printing surface layer has a thickness between about 0.001 to about 0.012 inches (about 0.025 to about 0.3 mm). The image transfer product is more efficiently manufactured due to reduced solvent usage and reduced number of coating passes, and in use, exhibits uniform feed, web control, and registration characteristics.

Owner:DAY INT

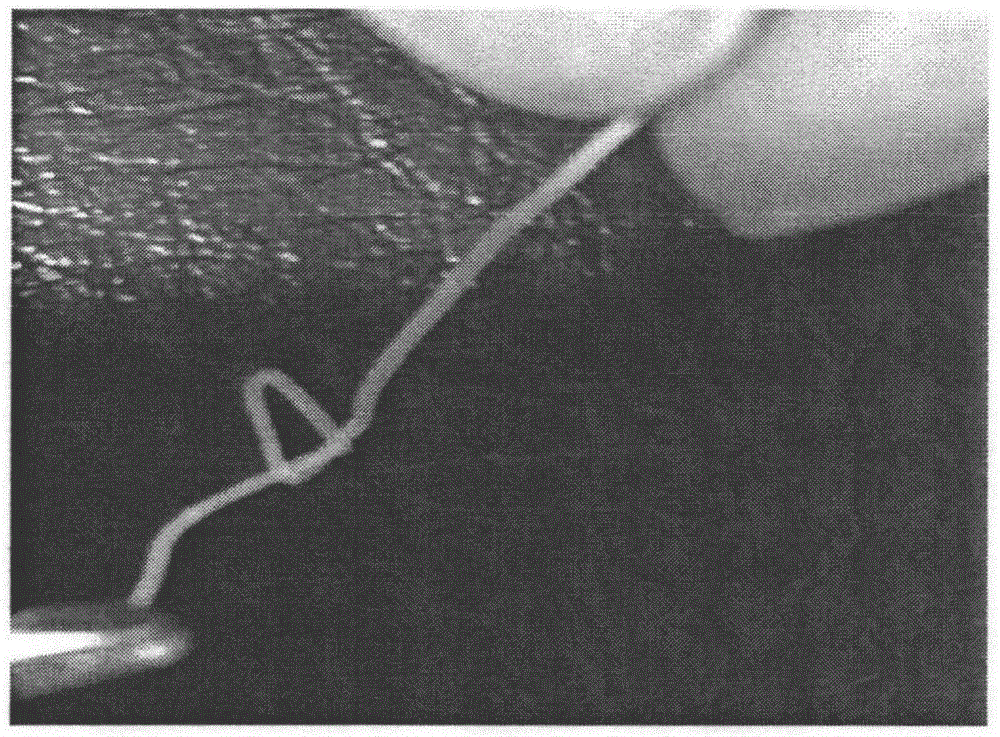

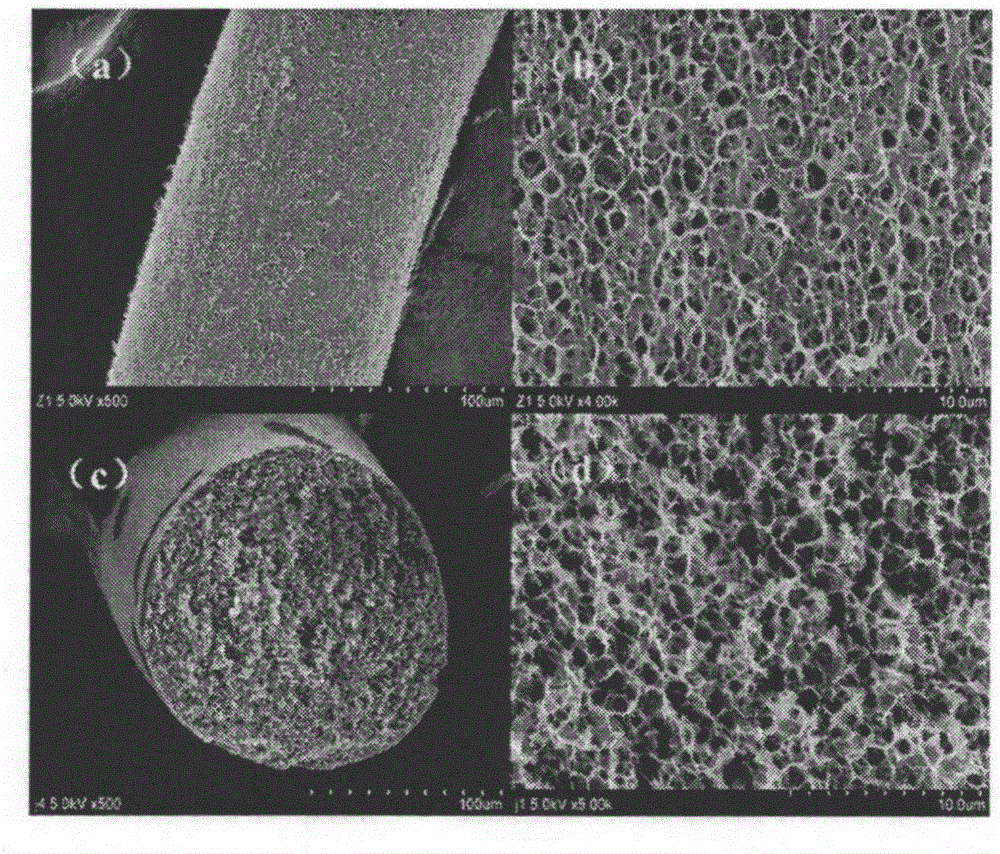

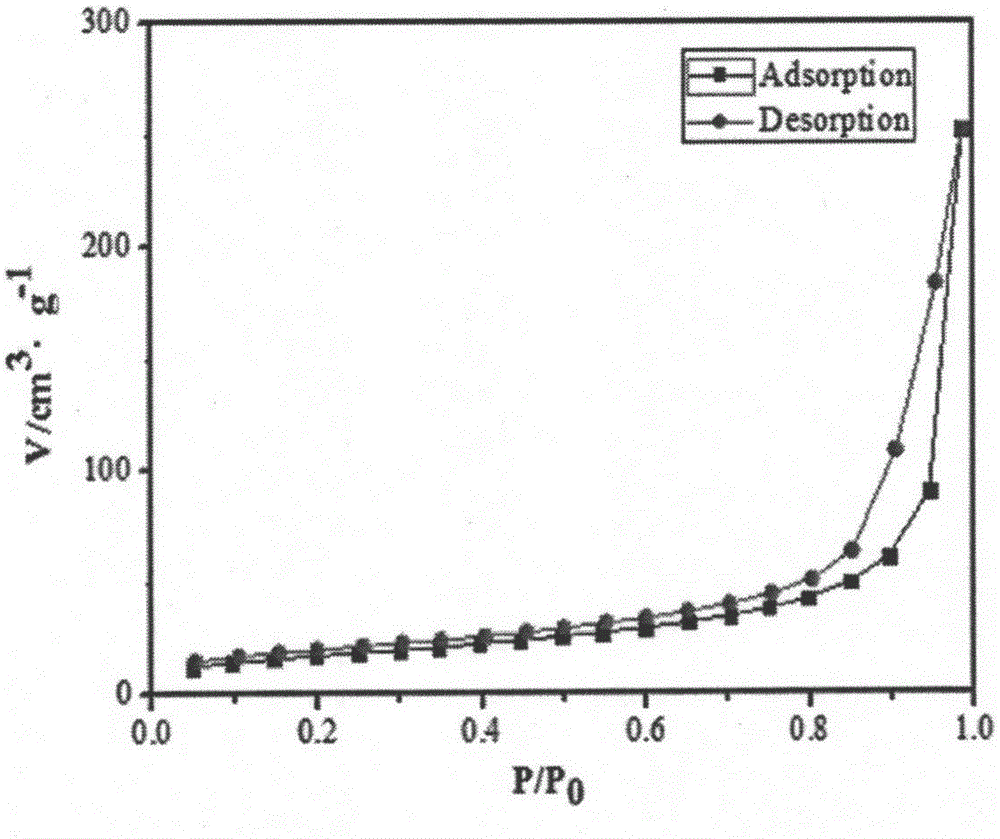

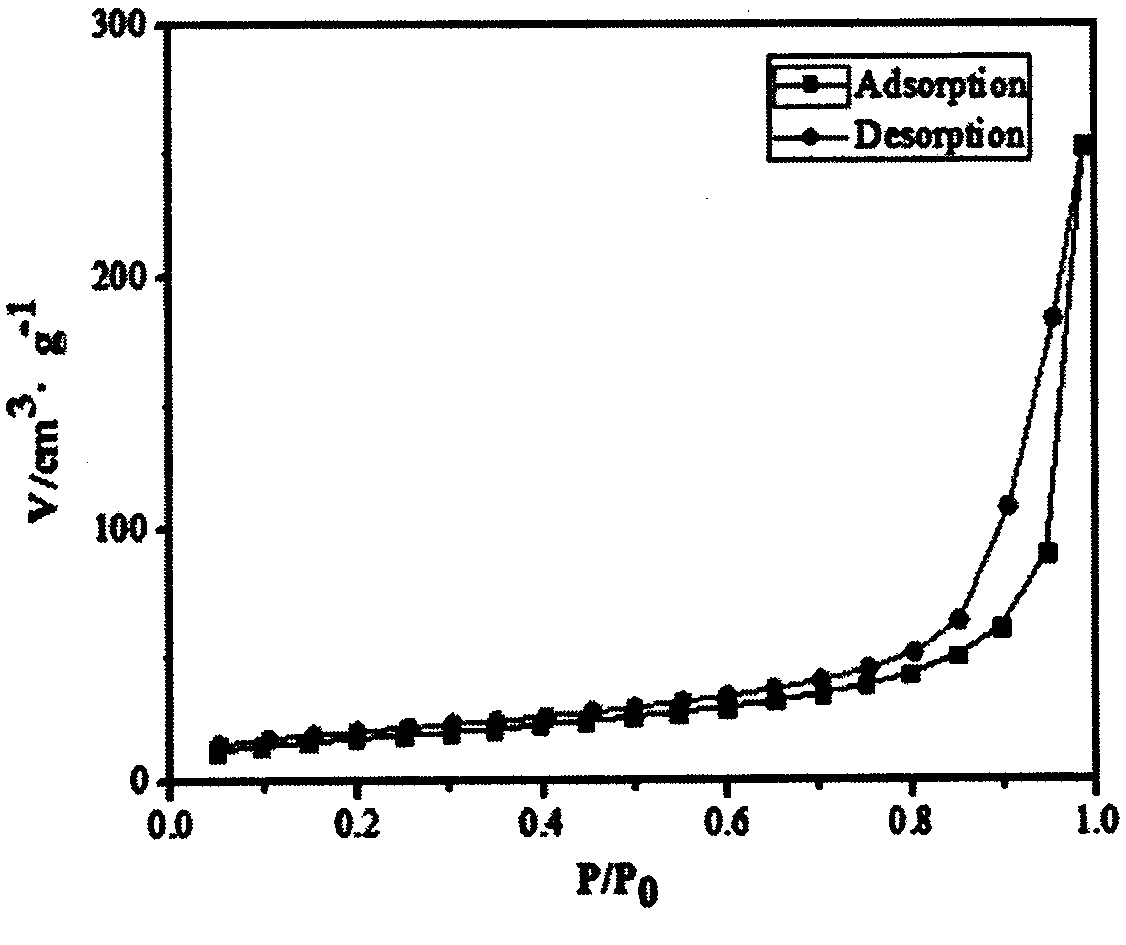

Continuous cellulose aerogel fiber and preparation method thereof

ActiveCN105970325AAdjustable specific surface areaShorten the timeArtificial filaments from cellulose solutionsWet spinning methodsFiberPorosity

The invention provides a continuous cellulose aerogel fiber and a preparation method thereof. The preparation method comprises the following steps: dispersing cellulose into a dispersing agent so as to obtain a spinning stock solution; extruding the spinning stock solution into a coagulating bath for wet-method spinning so as to obtain cellulose aerogel fiber; winding the cellulose aerogel fiber in the coagulating bath, and soaking into an aging liquid for aging; washing the aged cellulose aerogel fiber till the pH is neutral, and drying, so as to obtain the continuous cellulose aerogel fiber. The preparation method provided by the invention has the characteristics that raw materials are cheap and easy to obtain, the preparation process is simple, green and pollution-free, the continuous cellulose aerogel fiber is good is spinnability, and the problem that cellulose aerogel is hard to spin into fiber is solved. The diameter of the cellulose aerogel fiber provided by the invention is smaller than 120 [mu]m, the cellulose aerogel fiber has the characteristics of high specific surface area (greater than or equal to 88m<2> / g), high porosity (greater than or equal to 85%), and low density (less than or equal to 0.2 / cm<3>), meanwhile the fiber specific surface area can be adjusted, and the cellulose aerogel fiber can be used in fields such as functional clothes, sensing, catalyst loading and adsorption filtration, cosmetics and biological treatment.

Owner:DONGHUA UNIV

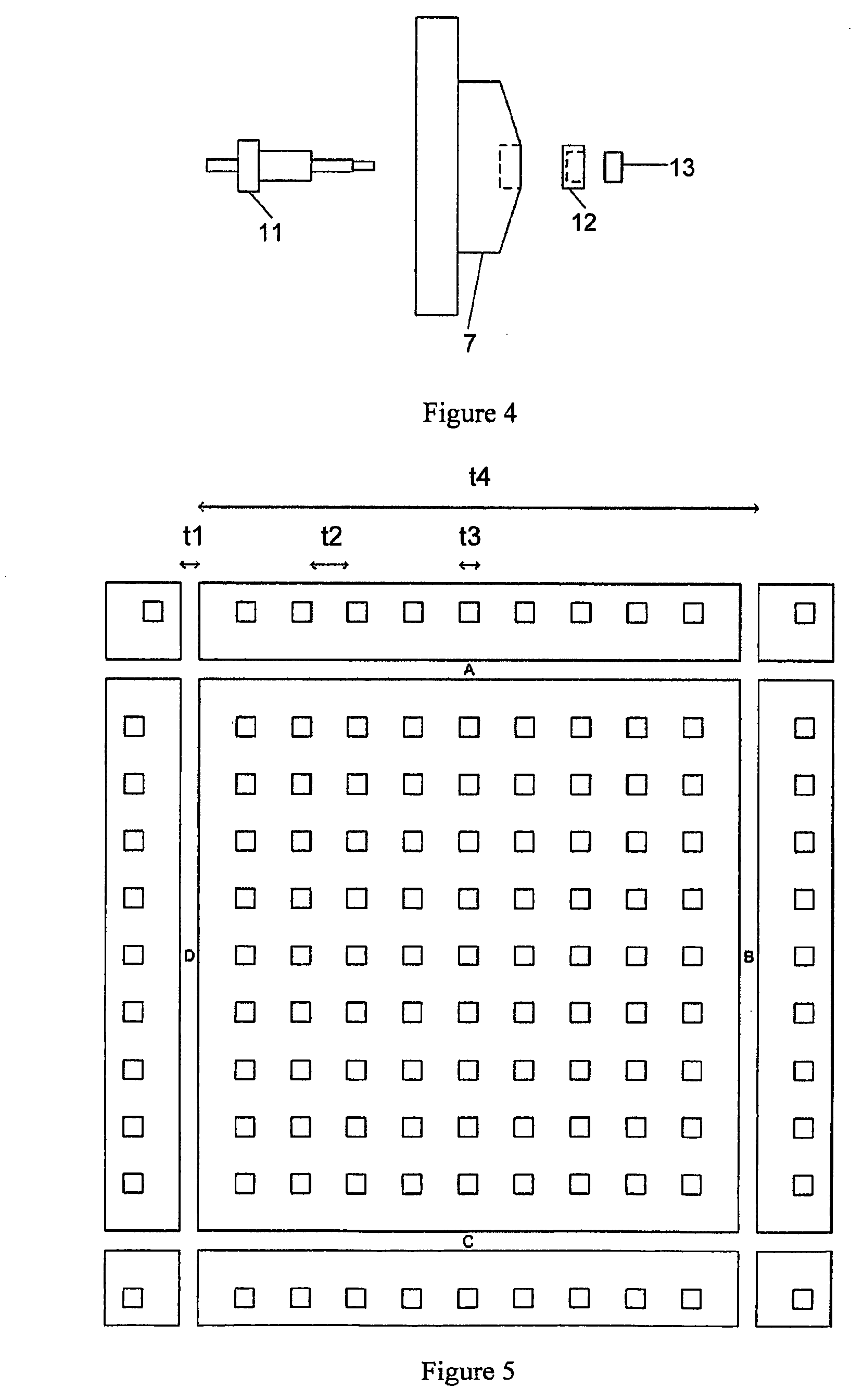

Process for Manufacturing Micro-and Nano-Devices

InactiveUS20080283501A1Eliminate needReduce the amount of solvent usedDecorative surface effectsElectrodesElectrochemical responsePower flow

A method of depositing or etching a micro- or nano-scale pattern on a work piece is disclosed, including the steps of: (a) placing the work piece in an electrochemical reactor in close proximity to a patterned tool; (b) connecting the work piece such that it is the anode if is to be etched or the cathode if it is to be deposited, and the patterned tool such that it is the counter electrode; (c) pumping electrolytic fluid necessary for the electrolytic operation of the cell formed between the two electrodes; and (d) applying a current across the electrodes to etch or deposit the work piece.

Owner:NEWCASTLE UPON TYNE UNIV OF

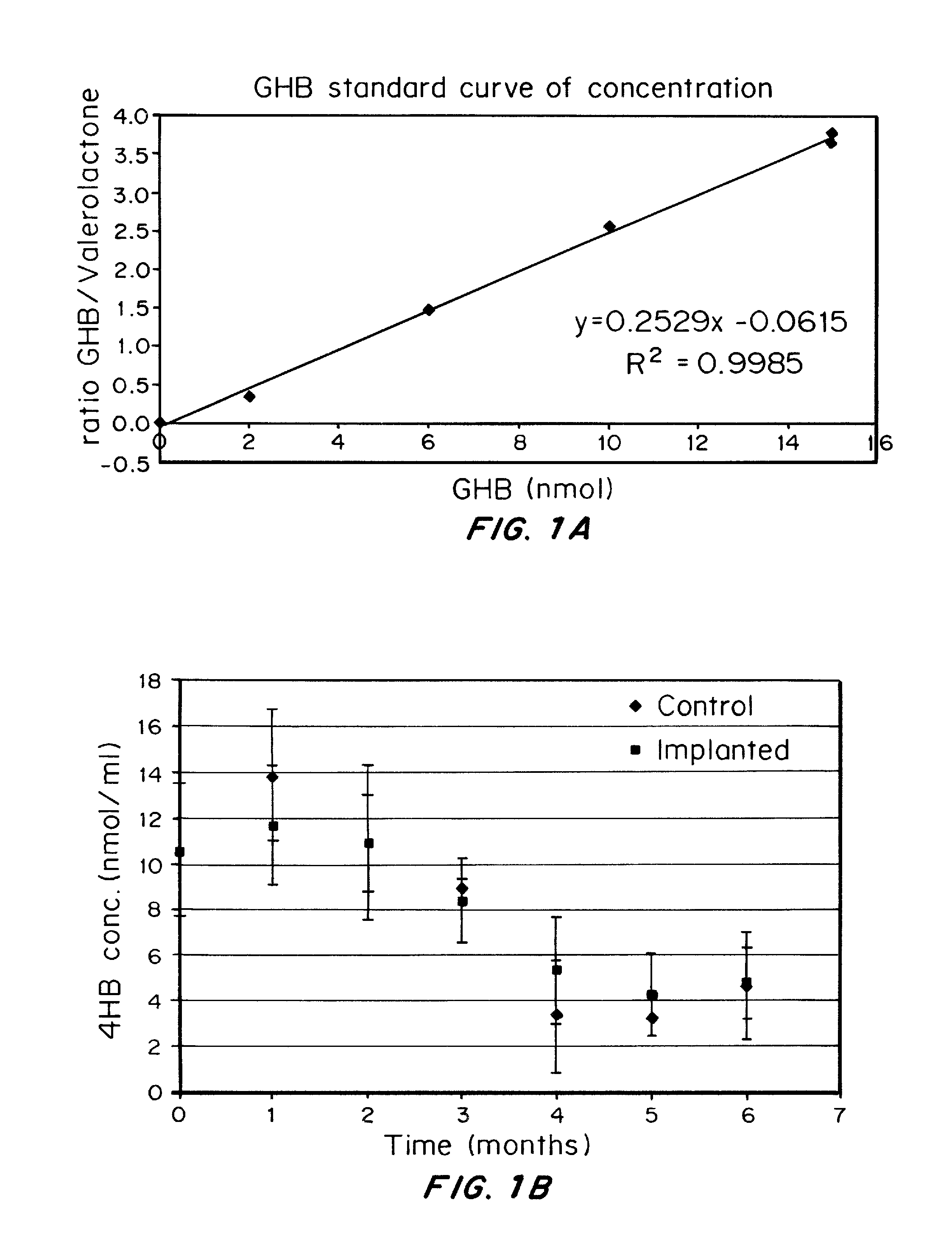

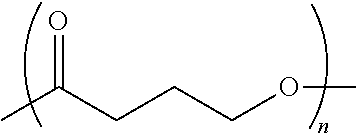

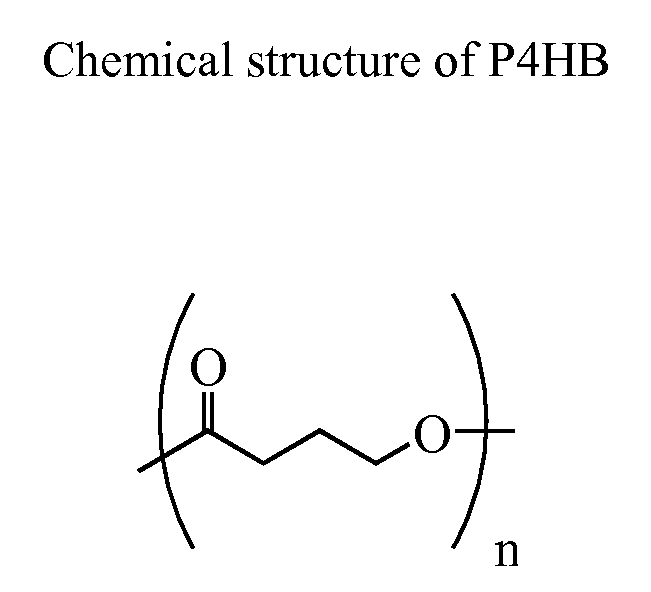

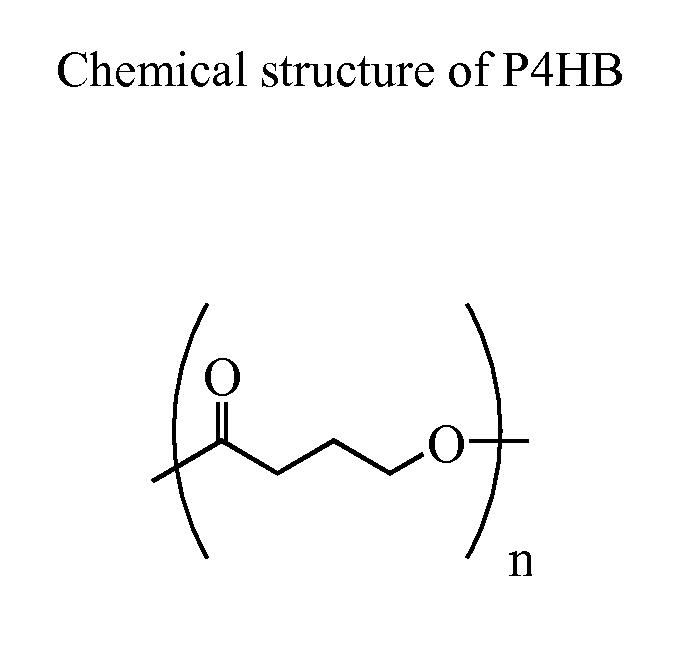

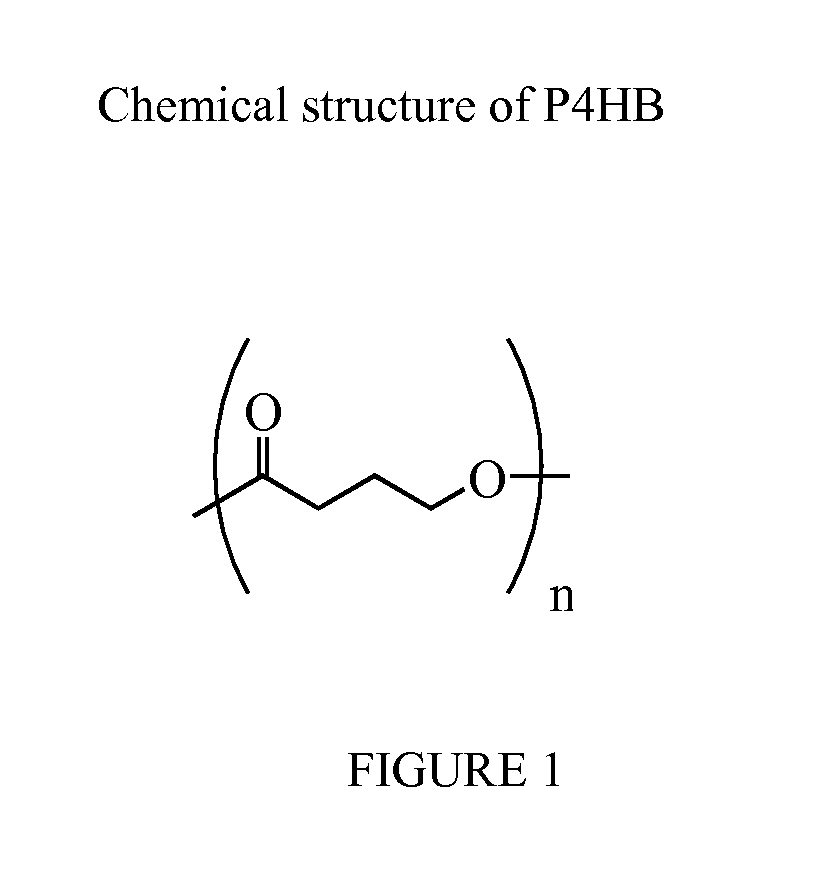

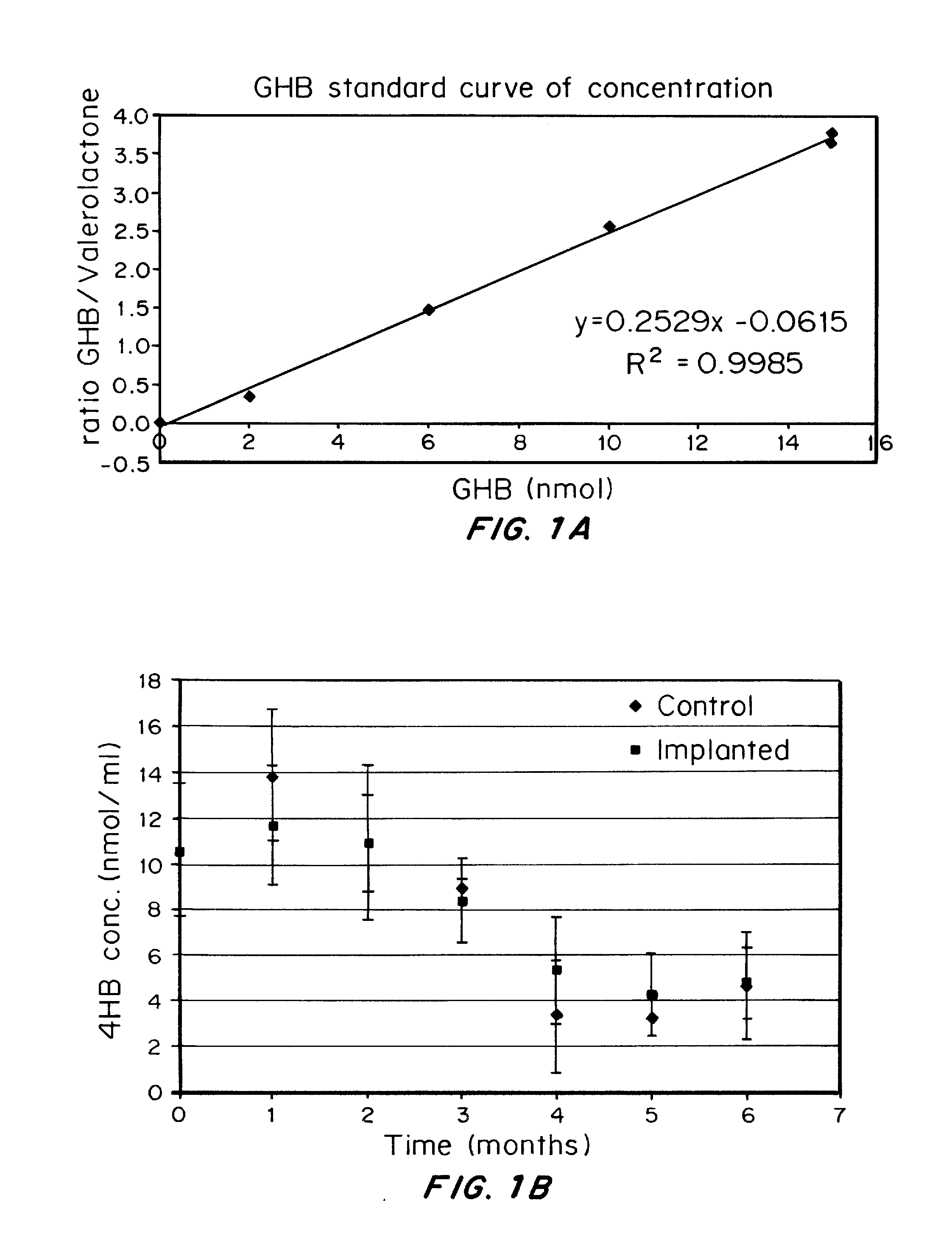

Compositions and devices of poly-4-hydroxybutyrate

Compositions of P4HB with high purity have been developed. The compositions are prepared by washing P4HB biomass prior to solvent extraction, and precipitating P4HB from solution. The same solvent is preferably used to wash the P4HB biomass, and as a non-solvent to precipitate the polymer from a P4HB solvent solution. The highly pure P4HB compositions are suitable for preparing implants. The implants may be used for the repair of soft and hard tissues.

Owner:TEPHA INC

Compositions and devices of poly-4-hydroxybutyrate

Compositions of P4HB with high purity have been developed. The compositions are prepared by washing P4HB biomass prior to solvent extraction, and precipitating P4HB from solution. The same solvent is preferably used to wash the P4HB biomass, and as a non-solvent to precipitate the polymer from a P4HB solvent solution. The highly pure P4HB compositions are suitable for preparing implants. The implants may be used for the repair of soft and hard tissues.

Owner:TEPHA INC

Poly (arylene ether) and process for making the same

A process for removal of a catalyst from a polymerization reaction mixture, comprises adding at least one polar solution to the reaction mixture to form a first at least two phase mixture, wherein one phase of the first at least two phase mixture is a first polymer phase; liquid / liquid centrifuging the first at least two phase mixture to separate the phases; removing the first polymer phase from the first at least two phase mixture; adding water to the first polymer phase to form a second at least two phase mixture, where one phase of the second at least two phase mixture is a second polymer phase; and separating the second polymer phase from the second at least two phase mixture.

Owner:SABIC GLOBAL TECH BV

General method for increasing stereoselectivity in stereoselective reactions

InactiveUS7858831B2Easy to handleLow costGroup 4/14 element organic compoundsOrganic compound preparationEnantiomerSolvent

This invention is directed to a method of performing a stereoselective reaction without use of a solvent comprising contacting a reactant with a chiral reagent under sonication conditions to form an excess of an enantiomer.

Owner:RGT UNIV OF CALIFORNIA

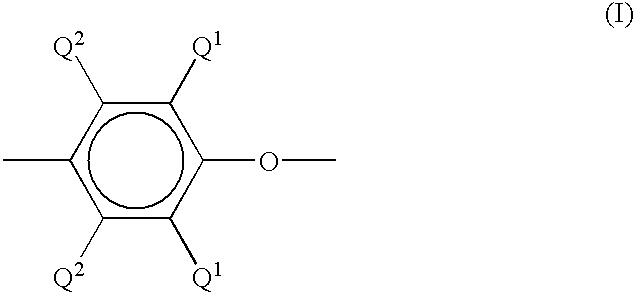

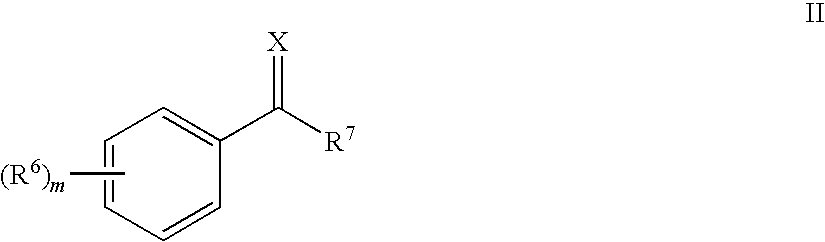

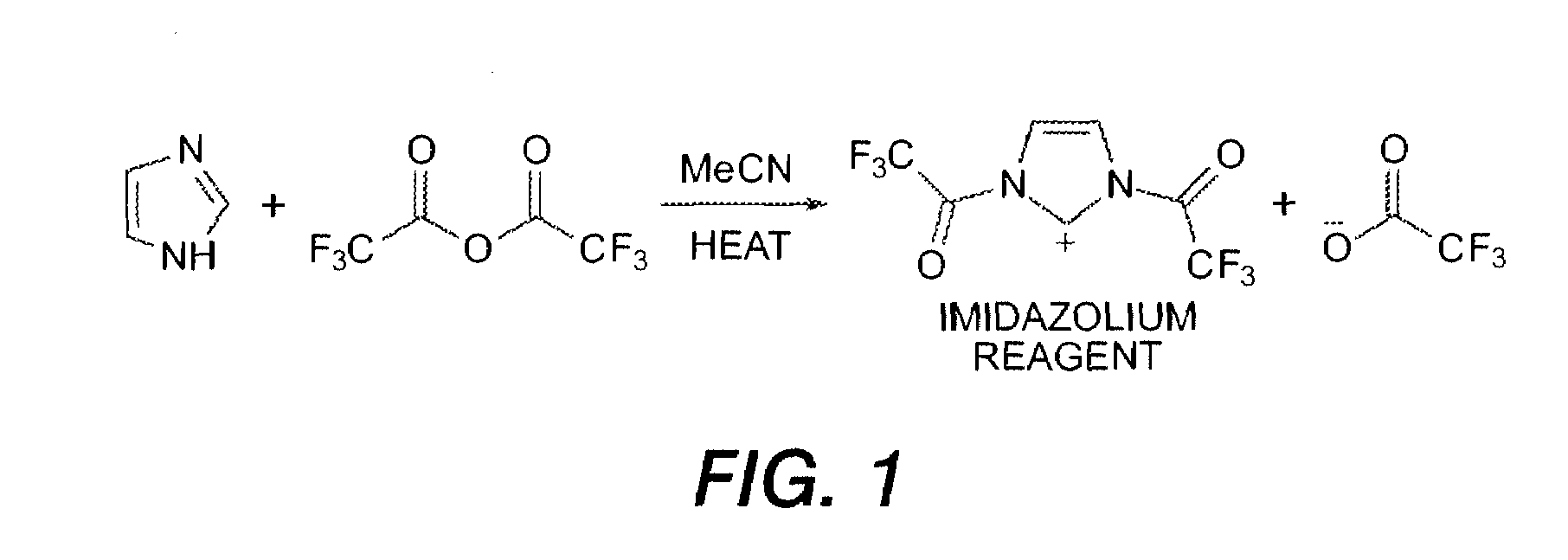

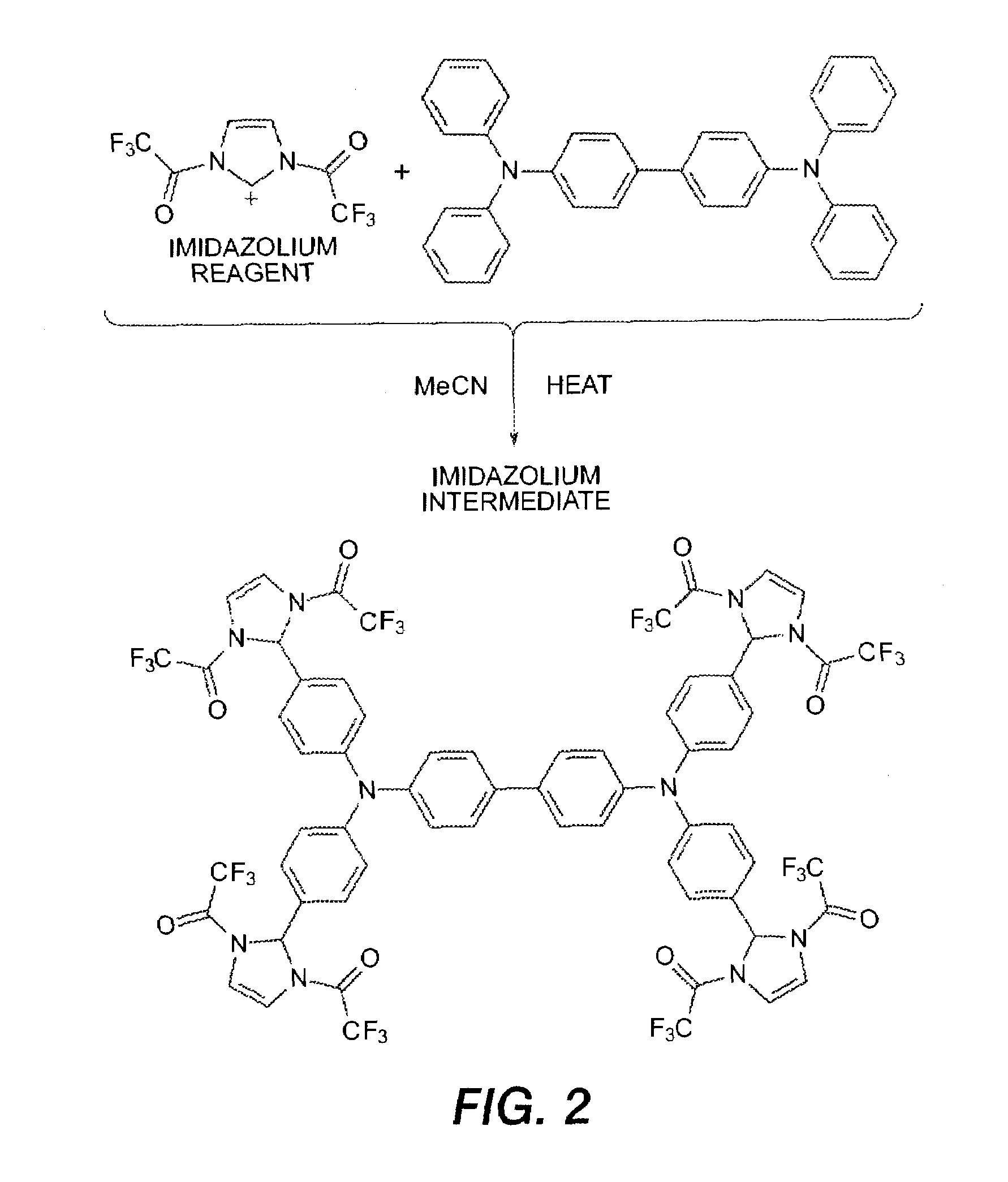

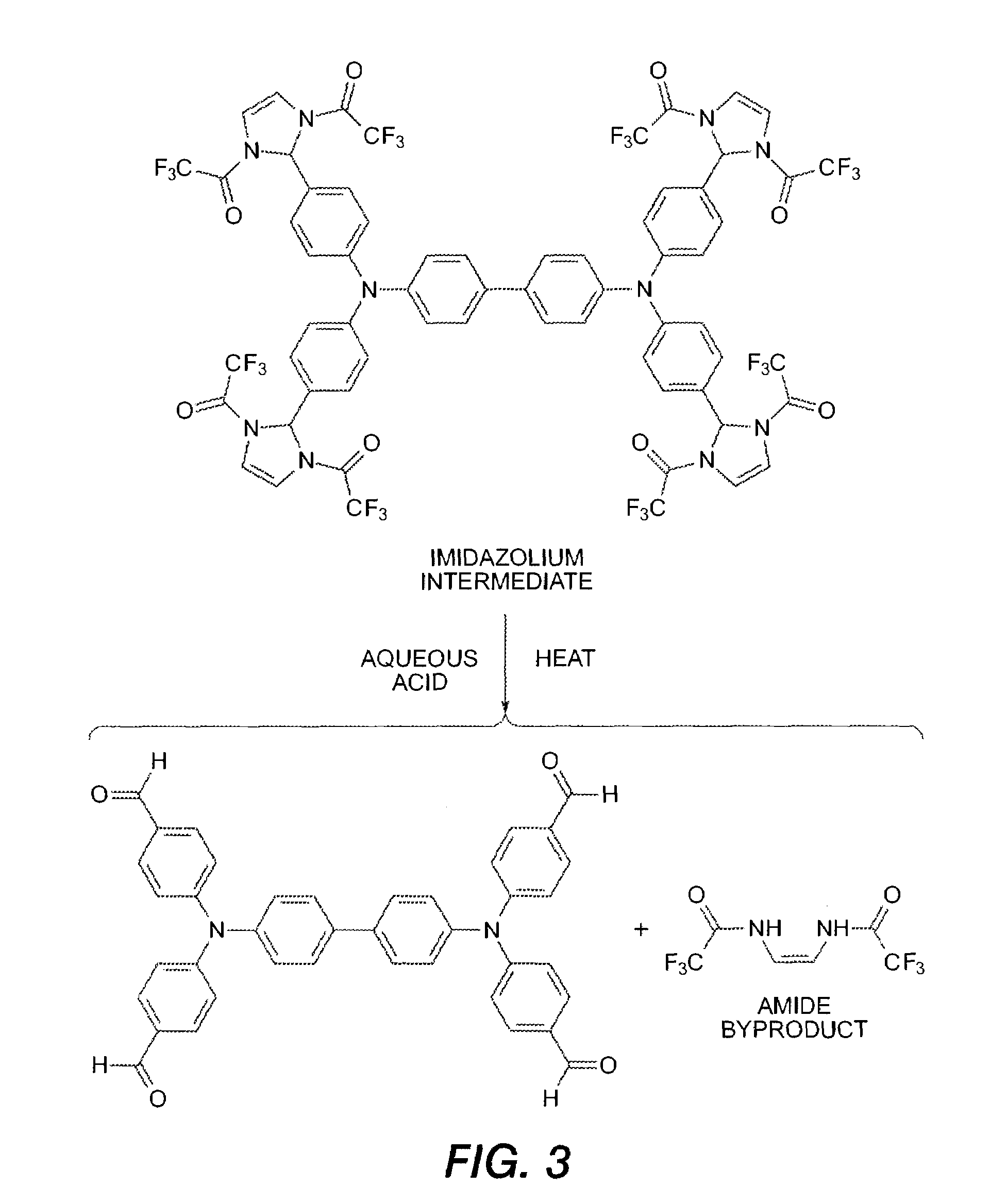

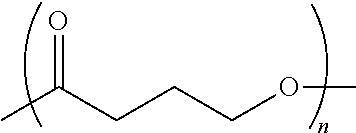

Electrophilic aromatic substitution with diacyl imidazolium

Polyimidazoline molecules and methods of making them are provided. A representative polyimidazoline has a structure:wherein:X is trifluoroacetyl or trifluoromethanesulfonyl; R1, R2, and R3 are each independently selected from a hydrogen, C1-C4 alkyl, C3-C7 cyclic alkyl, C1-C4 alkoxy, alcohol, and halogen; and n is 1 to 3.

Owner:XEROX CORP

Compositions and Devices of Poly-4-Hydroxybutyrate

Compositions of P4HB with high purity have been developed. The compositions are prepared by washing P4HB biomass prior to solvent extraction, and precipitating P4HB from solution. The same solvent is preferably used to wash the P4HB biomass, and as a non-solvent to precipitate the polymer from a P4HB solvent solution. The highly pure P4HB compositions are suitable for preparing implants. The implants may be used for the repair of soft and hard tissues.

Owner:TEPHA INC

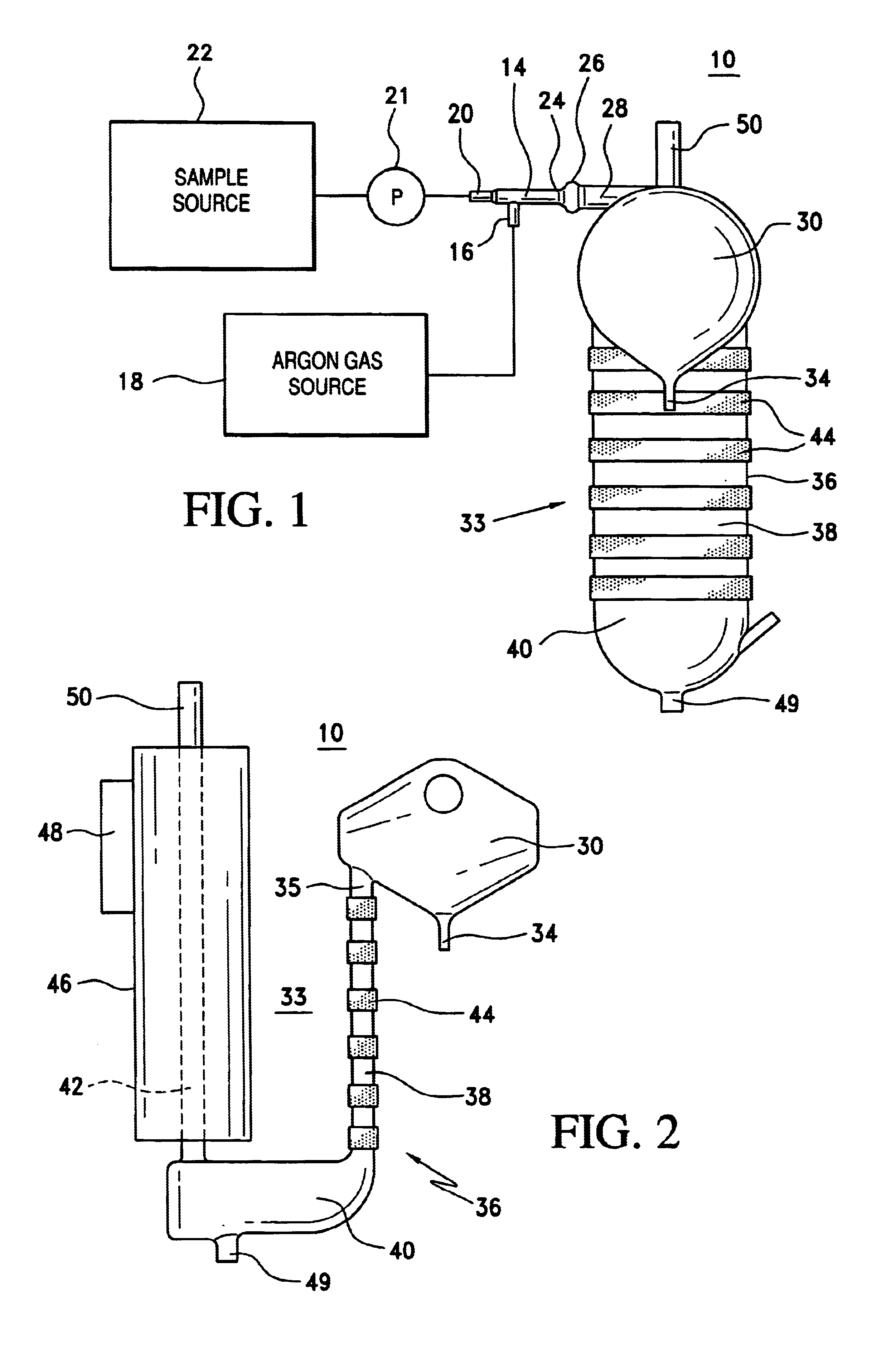

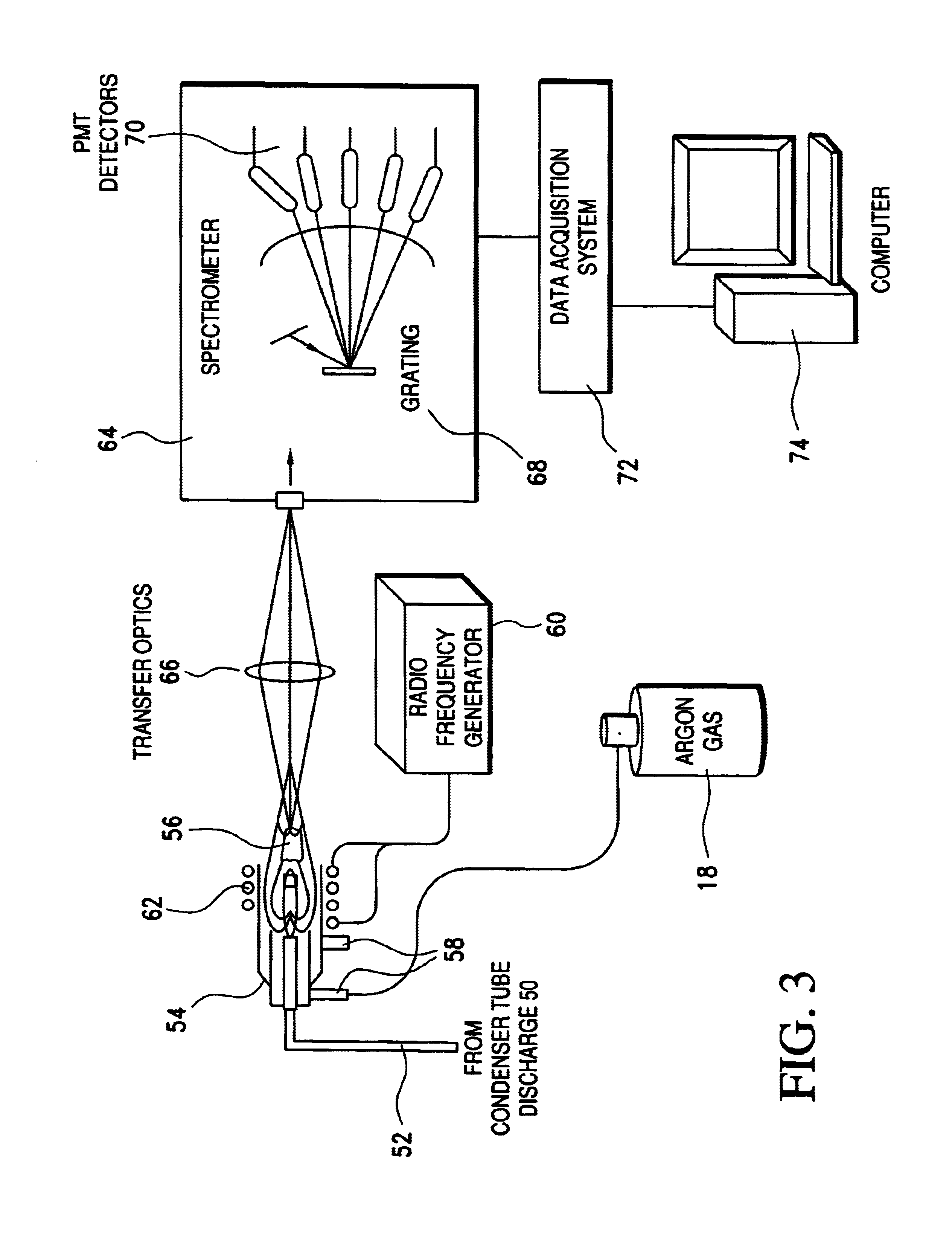

Spectrometer sample generating and injecting system using a microliter nebulizer

InactiveUS6859272B2Reduce the amount of solvent usedEnhances sample signal strengthBurnersEmission spectroscopyNebulizerSpray nozzle

A system atomizes liquids into a gaseous medium for formation and injection of a sample into an analytical apparatus, such as a plasma spectrometer. The system employs a high efficiency nebulizer that generates a fine aerosol through use of a nozzle having improved surface wetness characteristics, preferably in combination with a deflecting surface. A desolvator is employed to remove excess solvent from the atomized sample prior to injection into the spectrometer to avoid temperature reduction or extinguishment of the plasma by the sample.

Owner:CORNELL RES FOUNDATION INC

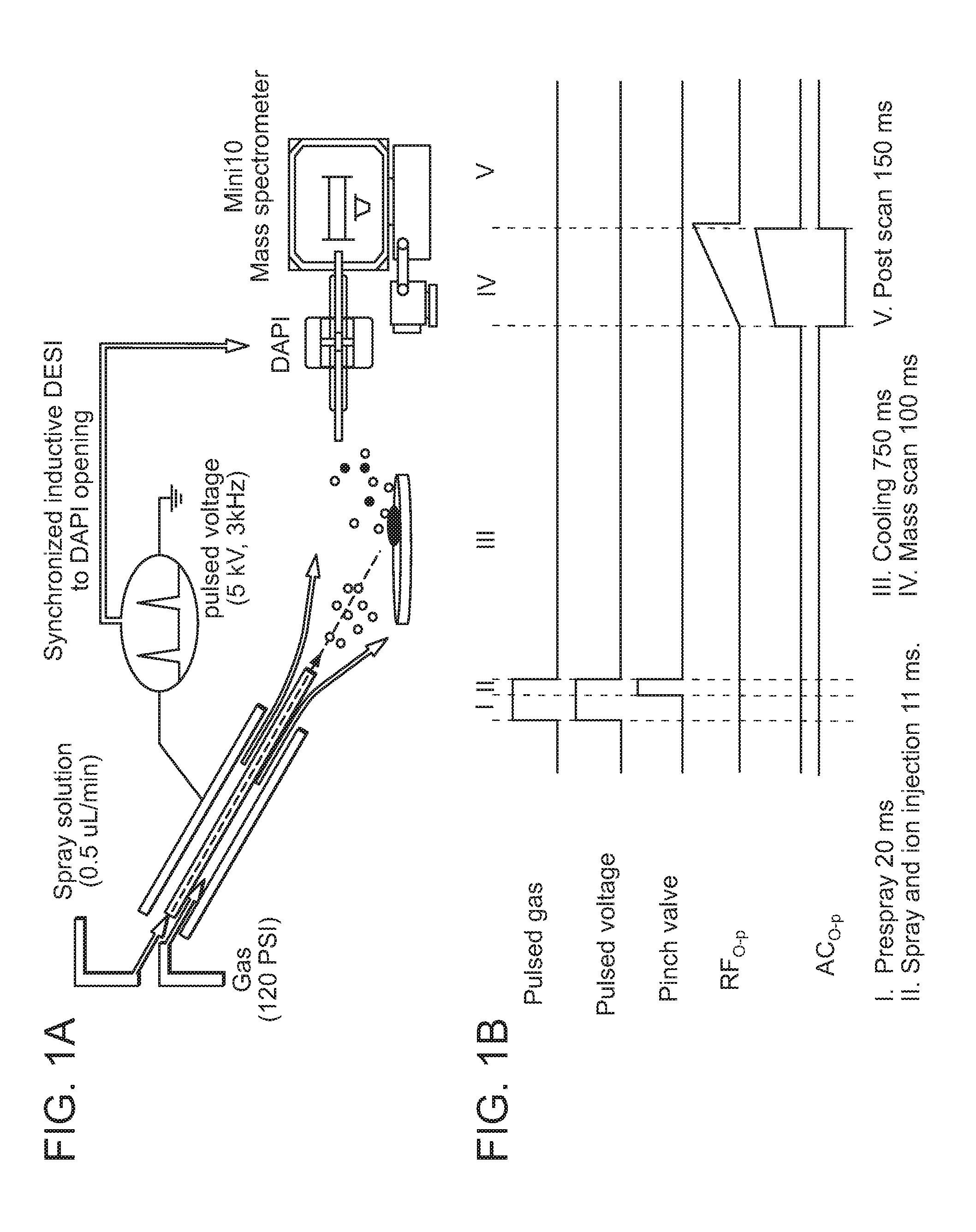

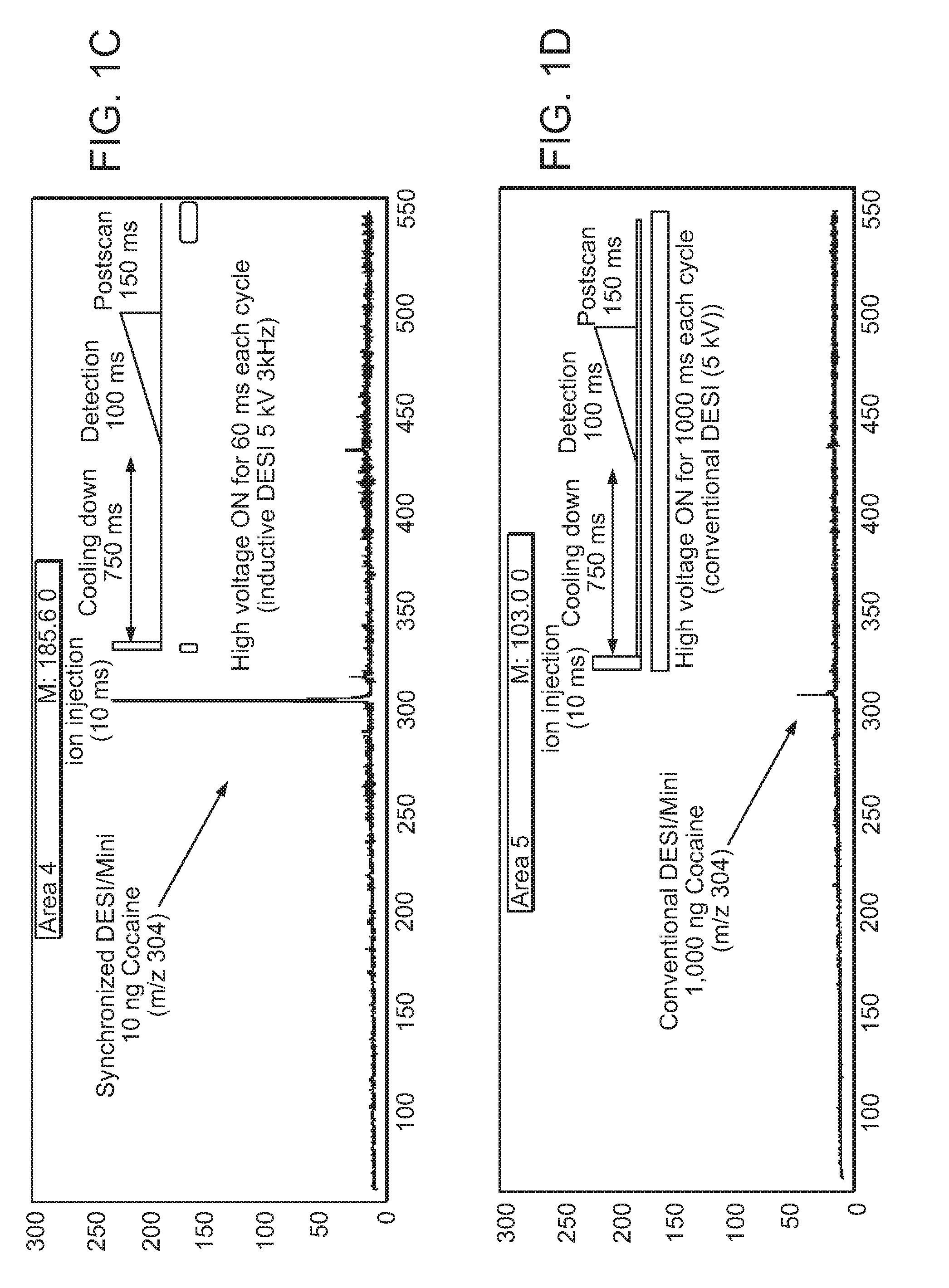

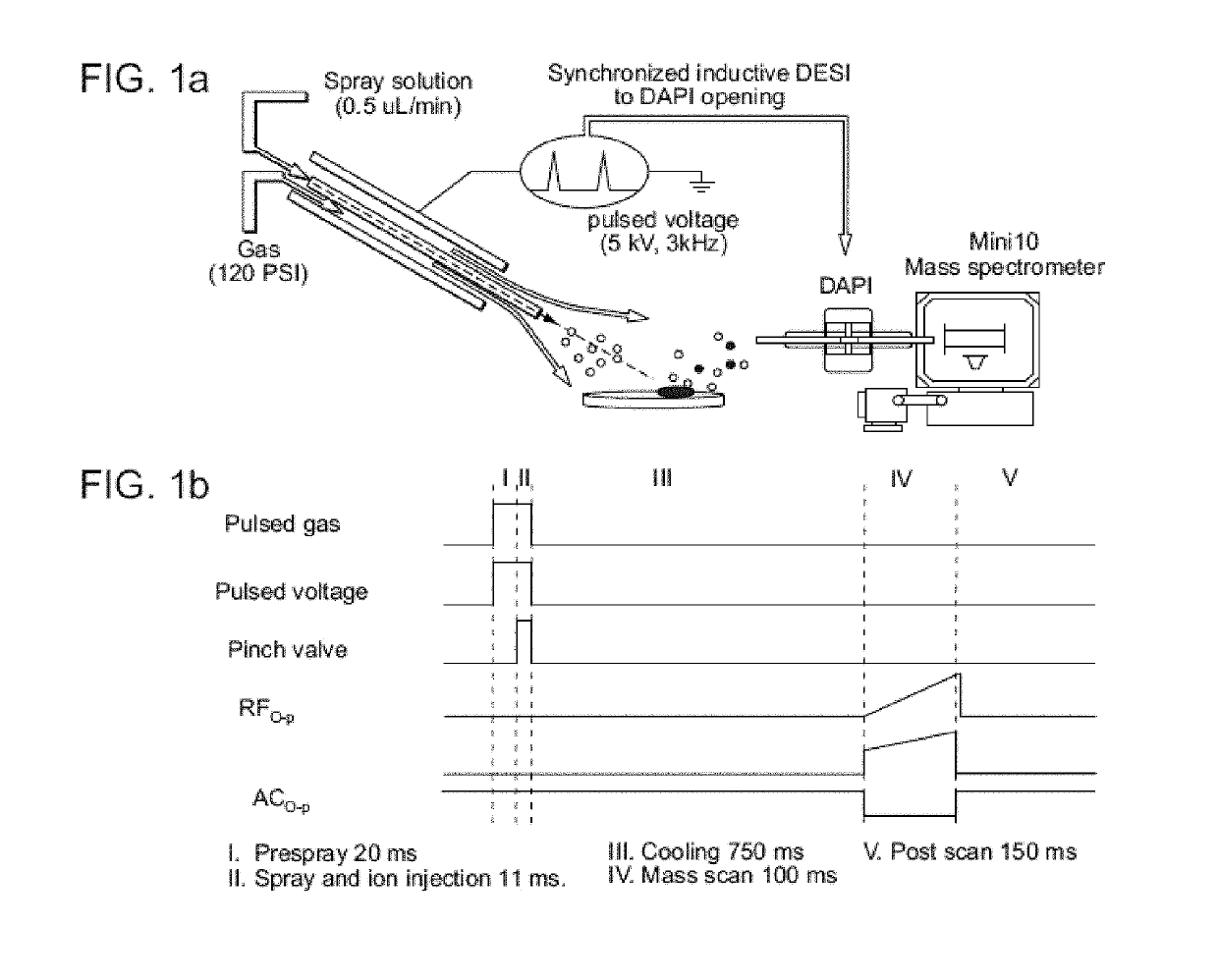

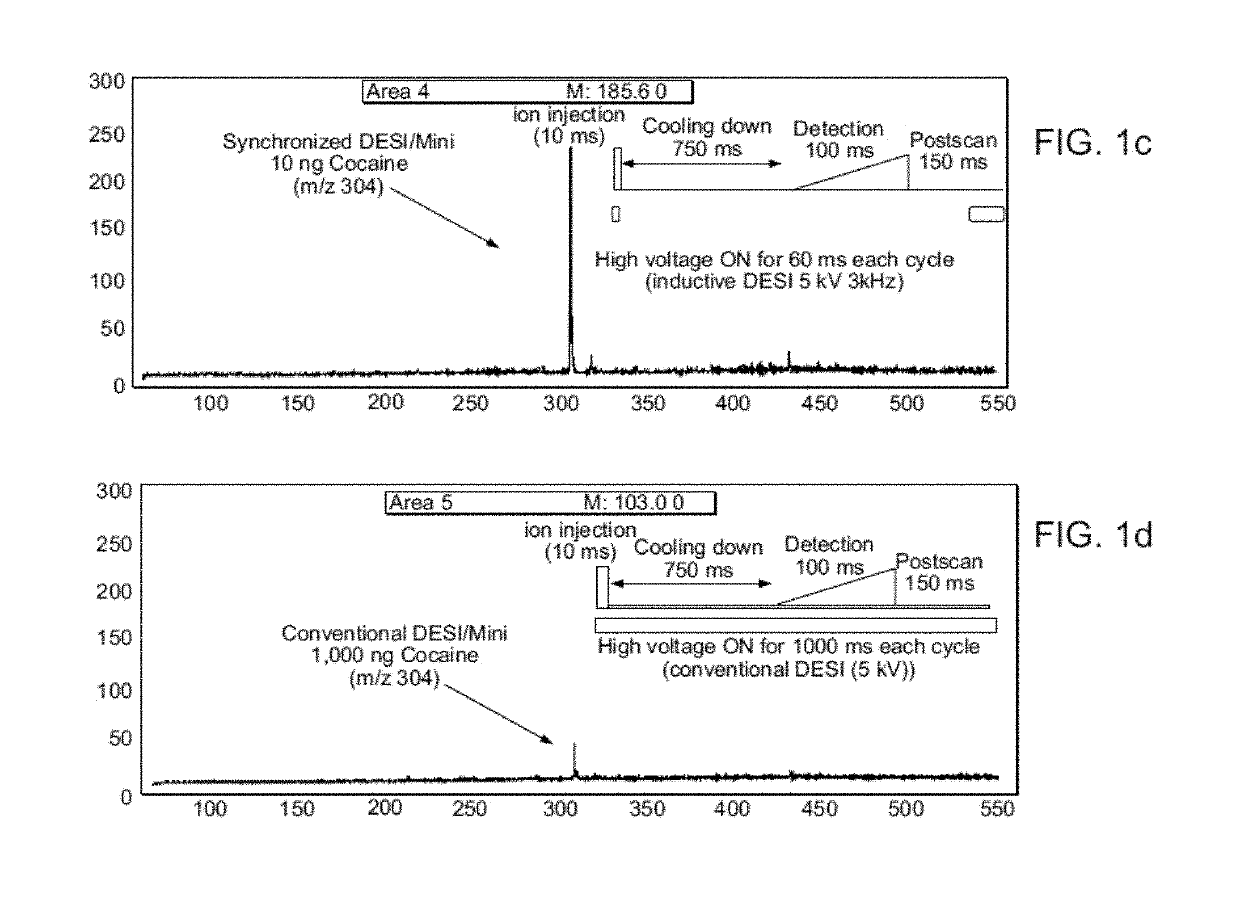

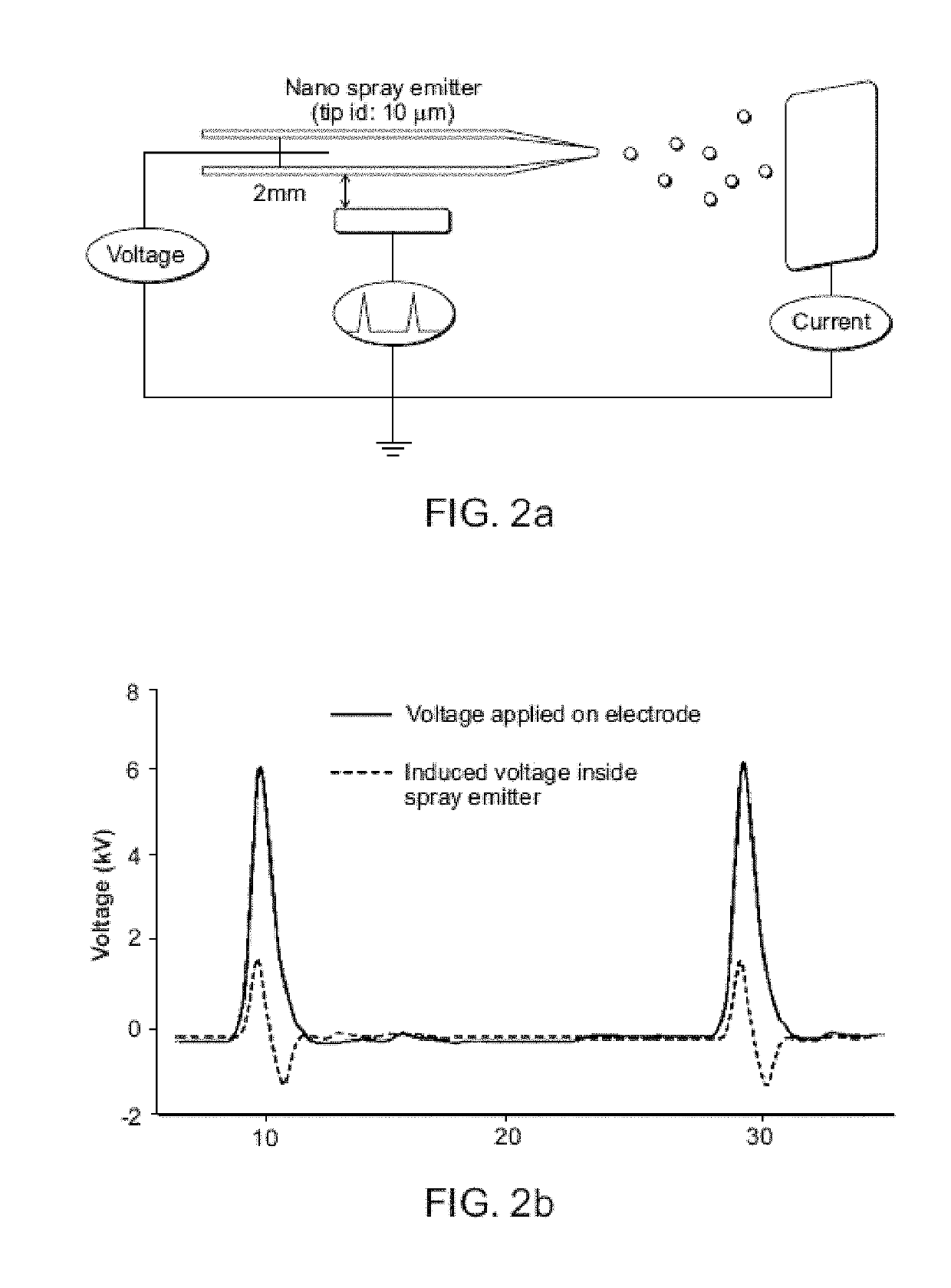

Synchronization of ion generation with cycling of a discontinuous atmospheric interface

ActiveUS20160118236A1High sensitivityReduce the amount of solvent usedStability-of-path spectrometersSamples introduction/extractionMass Spectrometry-Mass SpectrometryMass analyzer

The invention generally relates to methods and devices for synchronization of ion generation with cycling of a discontinuous atmospheric interface. In certain embodiments, the invention provides a system for analyzing a sample that includes a mass spectrometry probe that generates sample ions, a discontinuous atmospheric interface, and a mass analyzer, in which the system is configured such that ion formation is synchronized with cycling of the discontinuous atmospheric interface.

Owner:PURDUE RES FOUND INC

Image transfer product including a thin printing surface layer

ActiveUS20090142587A1Efficient preparationReduce the amount of solvent usedRecord information storageLight beam reproducingSurface layerImage transfer

An image transfer product such as an offset printing blanket or sleeve is provided which comprises a very thin printing surface layer in combination with a smooth image reinforcement layer comprising a polymeric film, a fabric, or a polymer-coated fabric. The thin printing surface layer has a thickness between about 0.001 to about 0.012 inches (about 0.025 to about 0. 3 mm). The image transfer product is more efficiently manufactured due to reduced solvent usage and reduced number of coating passes, and in use, exhibits uniform feed, web control, and registration characteristics.

Owner:DAY INT

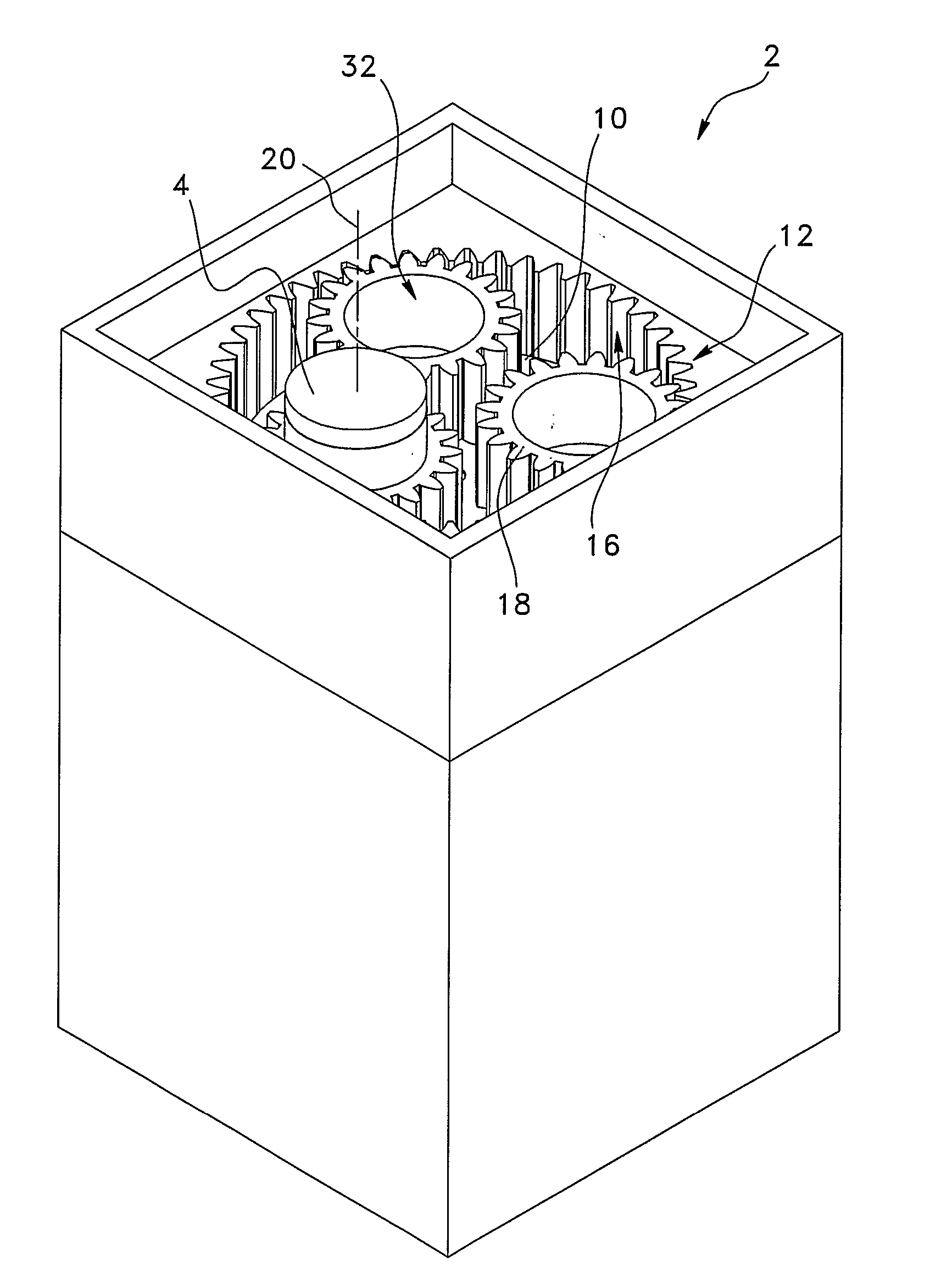

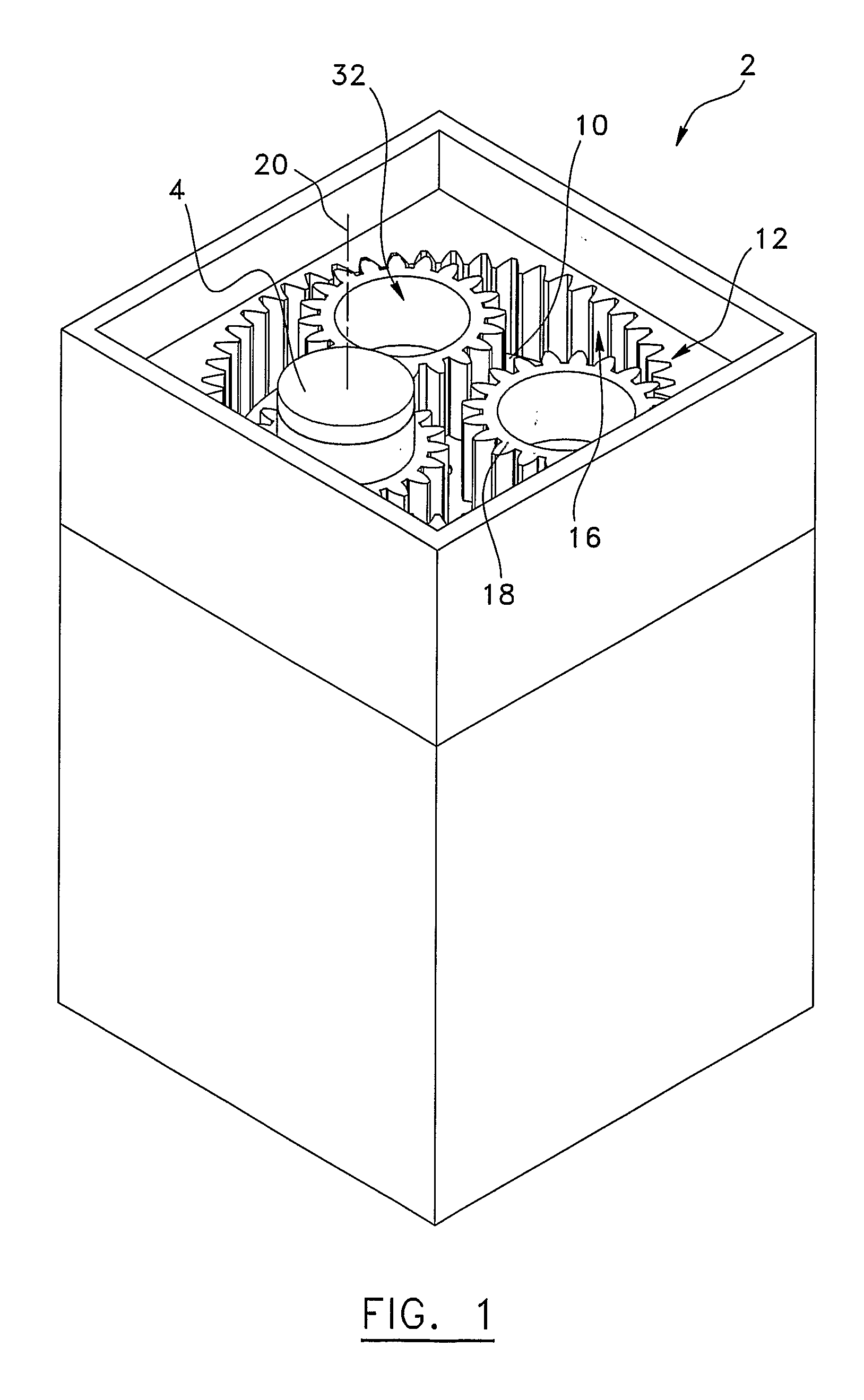

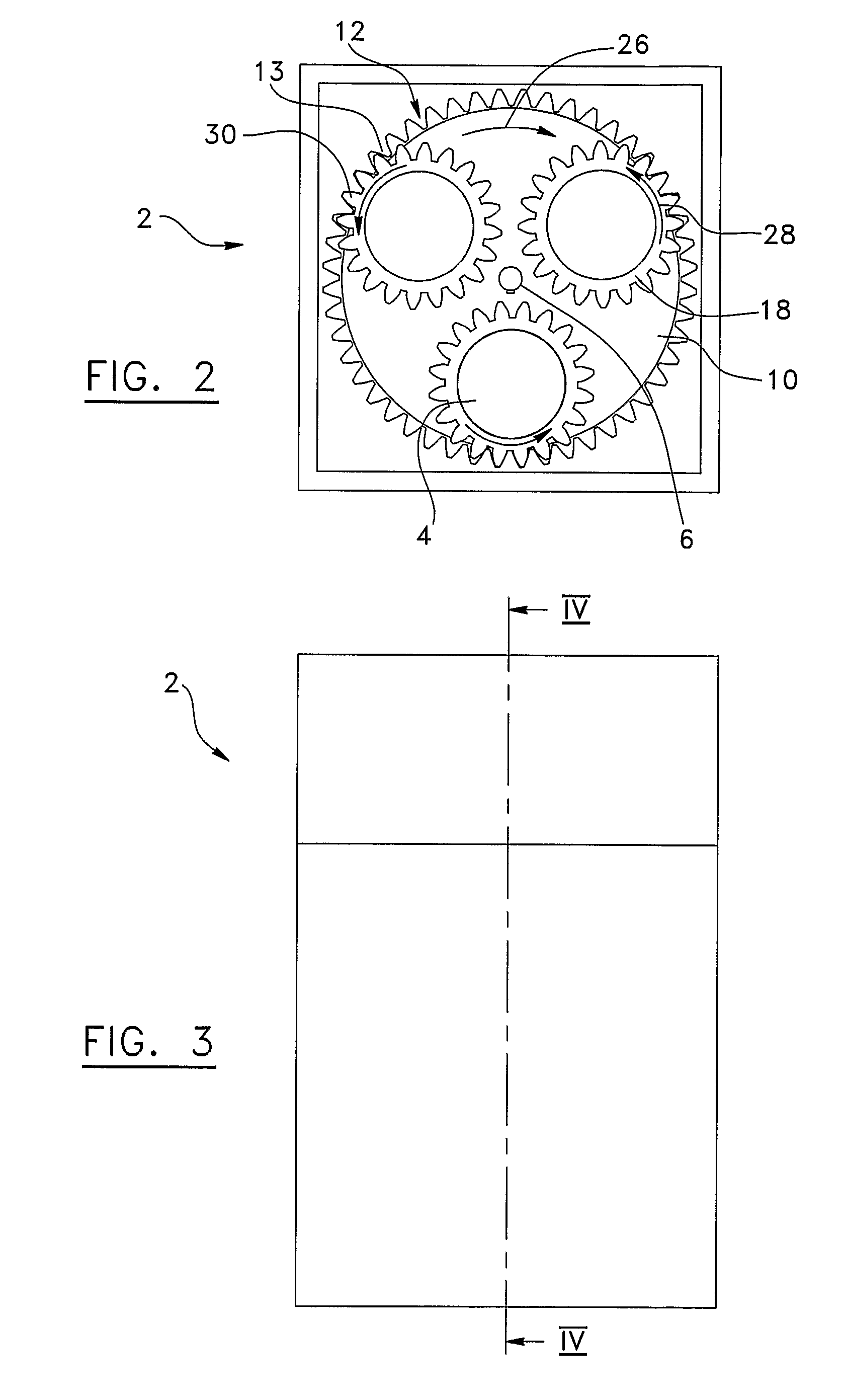

Bladeless mixer

ActiveUS20070183252A1Reduce the amount of solvent usedWell mixedRotating receptacle mixersShaking/oscillating/vibrating mixersHybrid compoundDrive shaft

A bladeless mixer / mill for agitating and mixing a compound / product. The mixer / mill comprises a driving shaft rotatable about a first vertical axis of rotation, and a motor unit operatively coupled to the driving shaft for rotating the same. A support plate is mounted onto the driving shaft and is rotatable about the first vertical axis. The mixer / mill also has a stationary ring gear coaxial to the support plate. The stationary ring gear has a portion with an inner surface extending above the support plate. At least one pinion gear is rotatably mounted onto the support plate about a second vertical axis of rotation parallel to the first vertical axis of rotation. The pinion gear has an outer surface complementary to the inner surface of the stationary ring gear. The outer surface of the pinion gear meshes with the inner surface of the stationary ring gear. The pinion gear has a cavity wherein the compound / product to be agitated and mixed / milled is inserted.

Owner:G EXPLORE

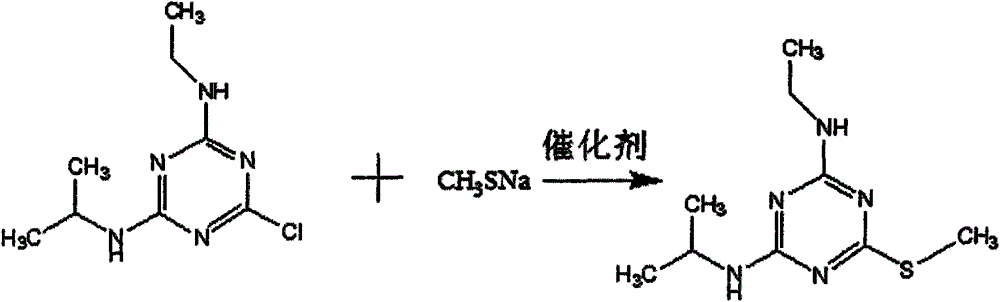

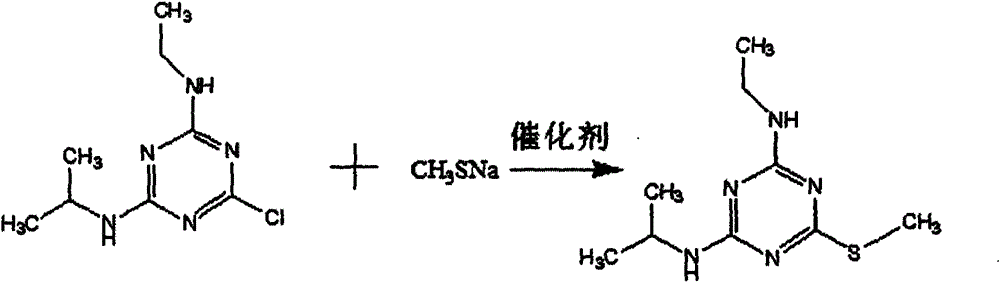

Method for producing ametryn

InactiveCN104447594AReduce the amount of solvent usedReduce manufacturing costOrganic chemistryPhase-transfer catalystTime range

The invention discloses a method for producing ametryn. The method is characterized in that the ametryn is prepared from raw materials atrazine and sodium methyl mercaptide by virtue of a reaction with water as a solvent and quaternary ammonium salt as a phase transfer catalyst, wherein the molar ratio of the atrazine to the sodium methyl mercaptide is 1: 1.05 to 1: 1.15; the ratio of the atrazine to the water is 1: 2 to 1: 4; the ratio of the quaternary ammonium salt to the atrazine is 1: 20 to 1: 200; the reaction temperature ranges from 90 to 100 DEG C; and the reaction time ranges from 2 to 5 hours. According to the method for producing the ametryn, the water is taken as the solvent, and compared with a traditional method for synthesizing the ametryn, the dosage of the solvent is reduced, the production cost is reduced, the safety of the reaction process is improved, and meanwhile, the generation of three wastes is reduced, and therefore, the method for producing the ametryn has a higher industrial value.

Owner:SHANDONG QIAOCHANG CHEM

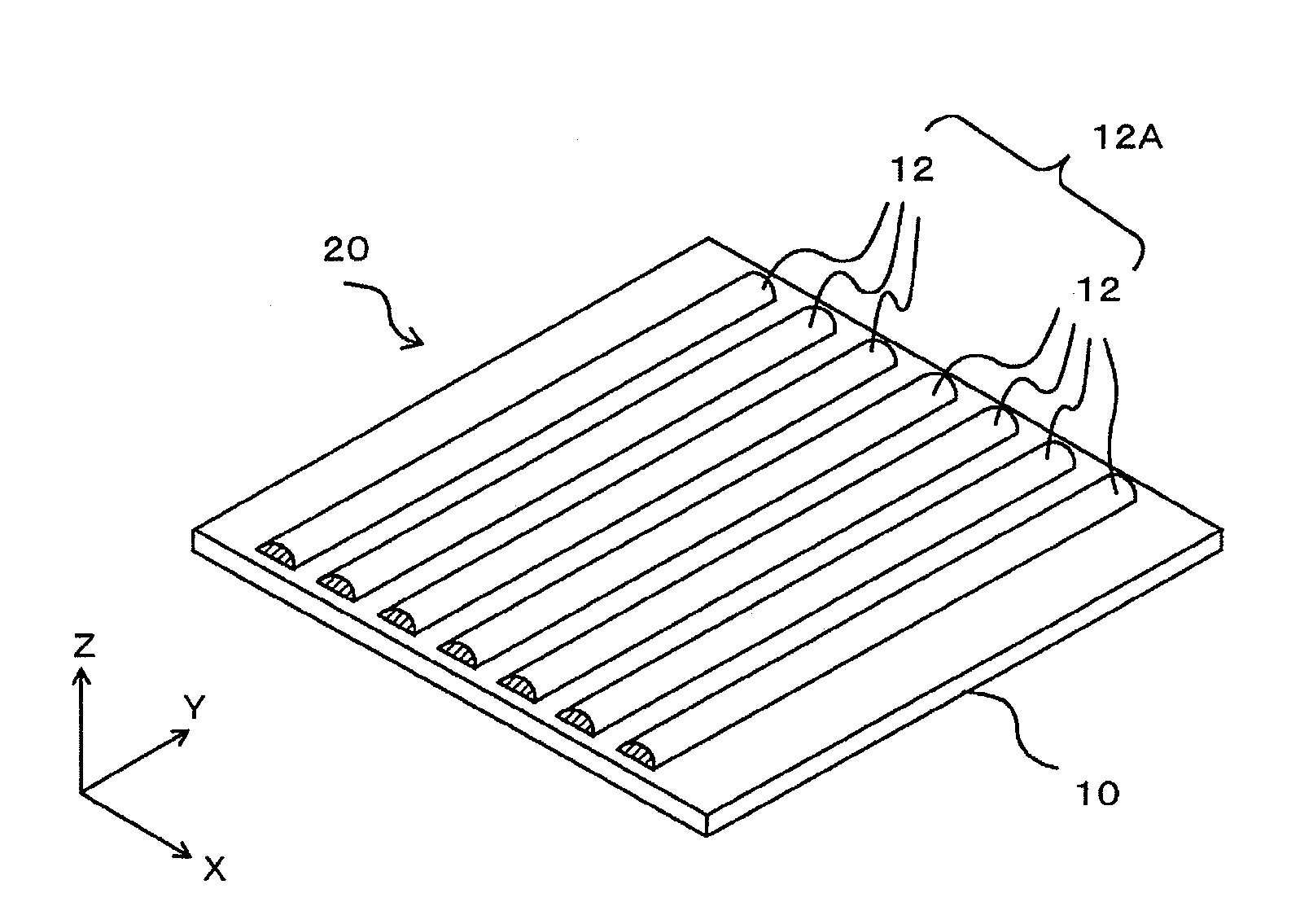

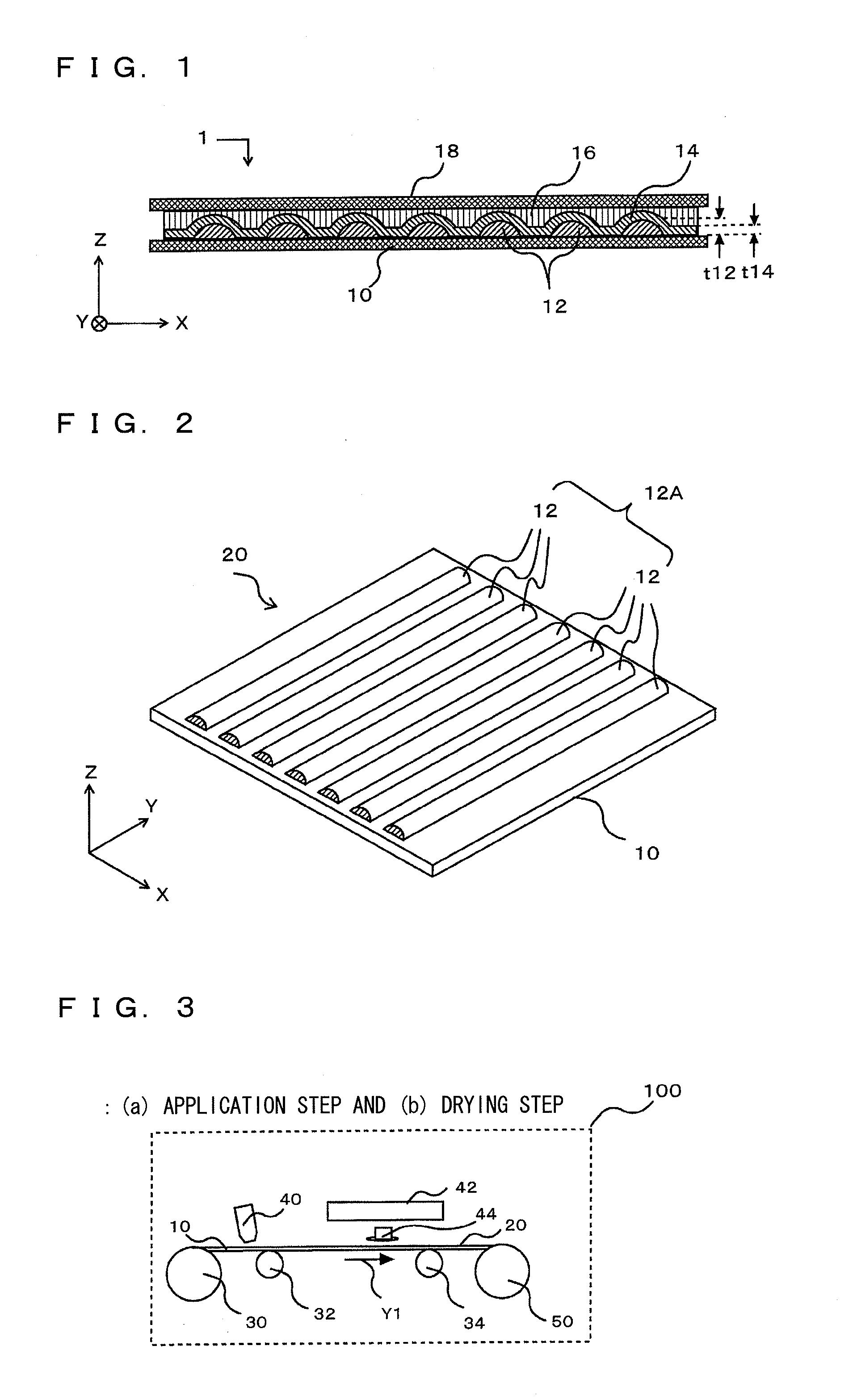

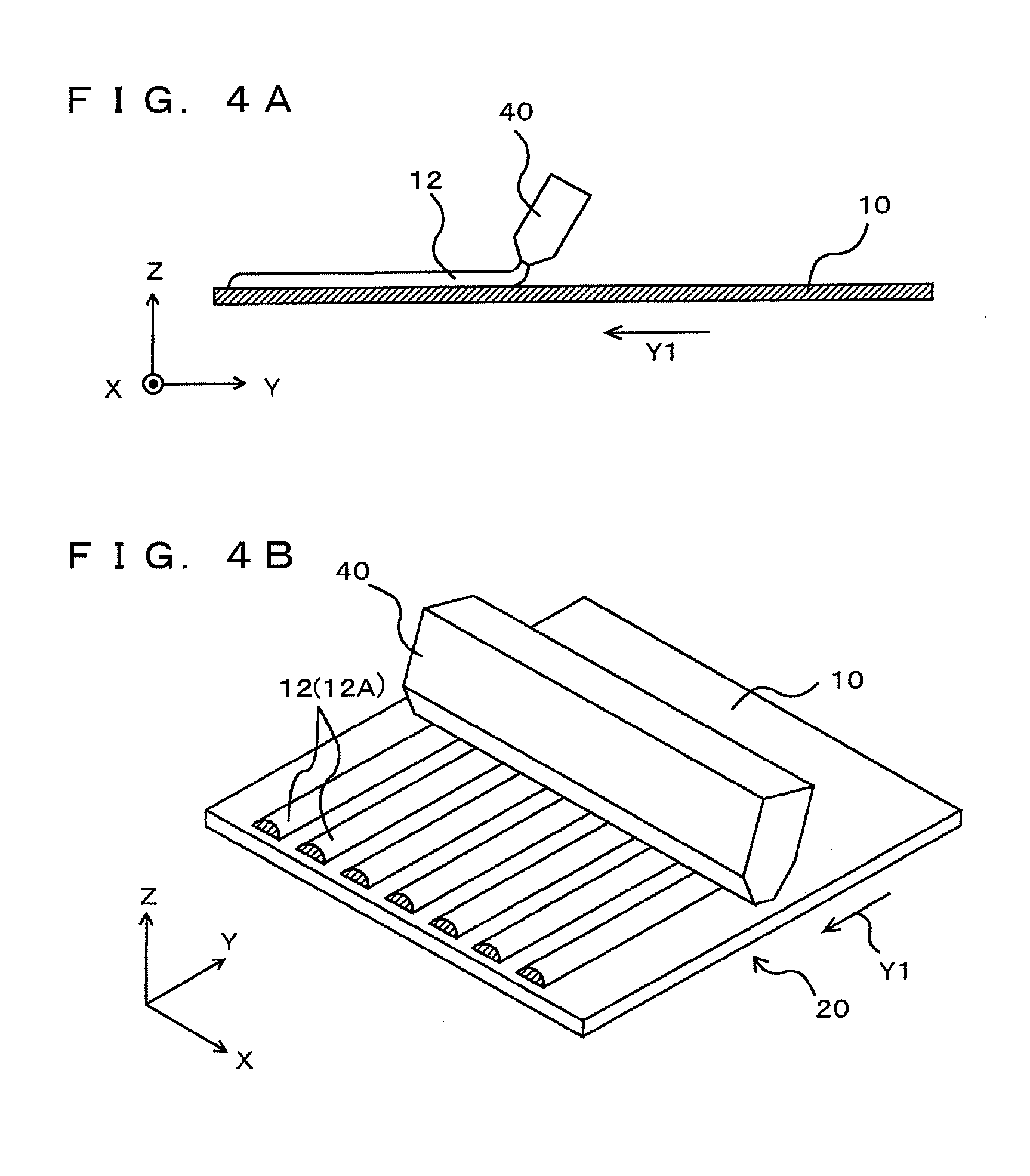

Method for manufacturing electrode for battery

InactiveUS20140072697A1Small porosityHigh densityElectrode collector coatingCoatingsDry mixingSlurry

A method for manufacturing an electrode for a battery includes: a mixing step of dry-mixing an active material and a conductive aid; a pressing step of applying a pressure for pressing to the mixture obtained in the mixing step; a step of mixing a solvent into the mixture after the pressing step to prepare a slurry (in paste form) active material; and an application step of applying the slurry active material onto a current collector to form an active material layer.

Owner:DAINIPPON SCREEN MTG CO LTD

Tobacco flavor applicator

ActiveUS8353299B2Reduce the amount of solvent usedEliminate wasteTobacco preparationTobacco treatmentFood flavorWaste management

A system of applying liquid flavor to cut tobacco material includes a first tank of concentrated liquid flavor and a second tank of water. A venturi device is constructed and arranged to receive and meter concentrated liquid flavor and water from the first and second tanks and to discharge mixed flavor and water from an outlet end. A first line is connected between the first tank and a suction port on the venturi device, and a second line is connected between the second tank and an intake port on the venturi device. A spray assembly is in fluid communication with the discharge outlet of the venturi device for applying mixed flavor and water to cut tobacco.

Owner:PHILIP MORRIS USA INC

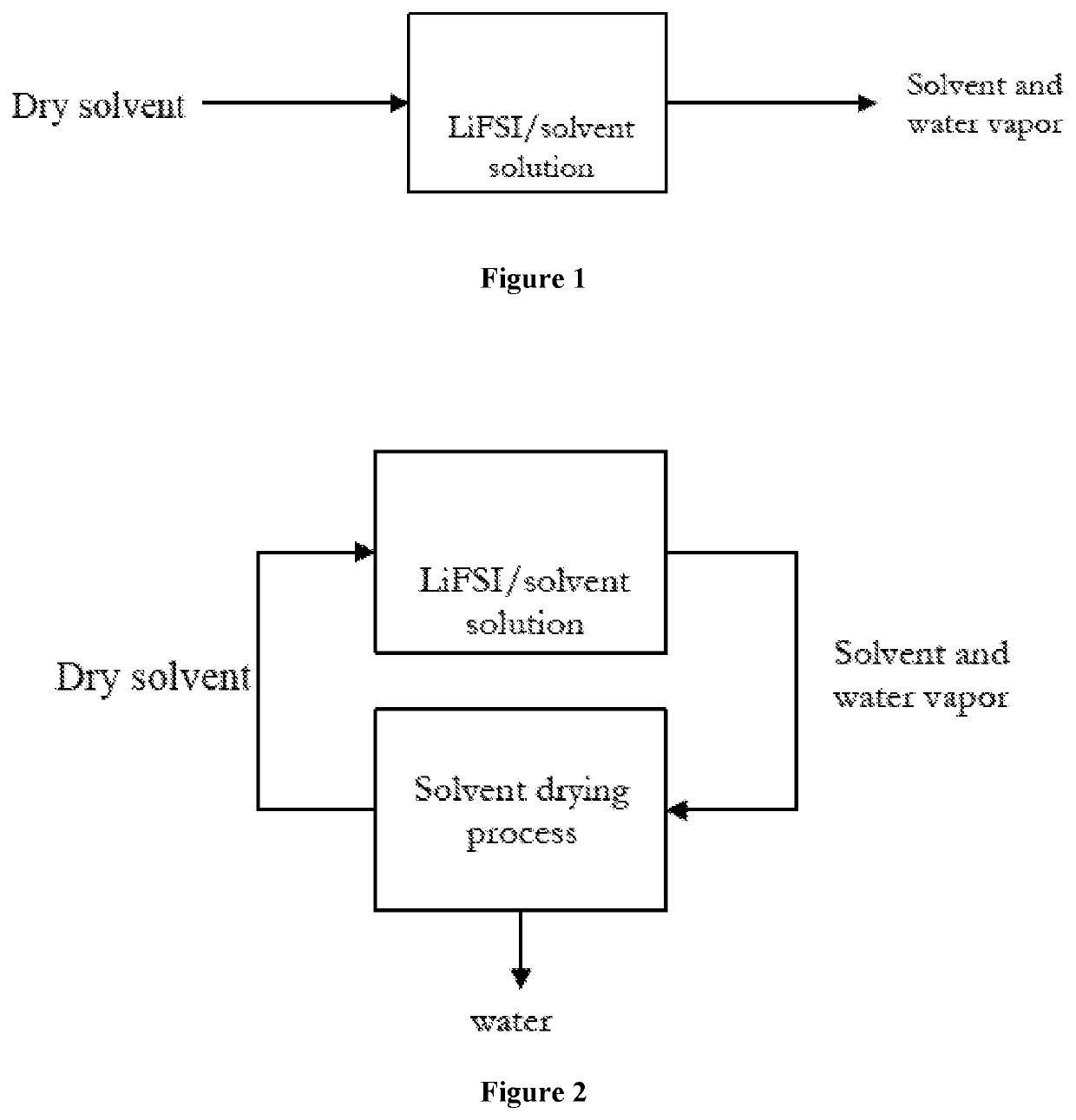

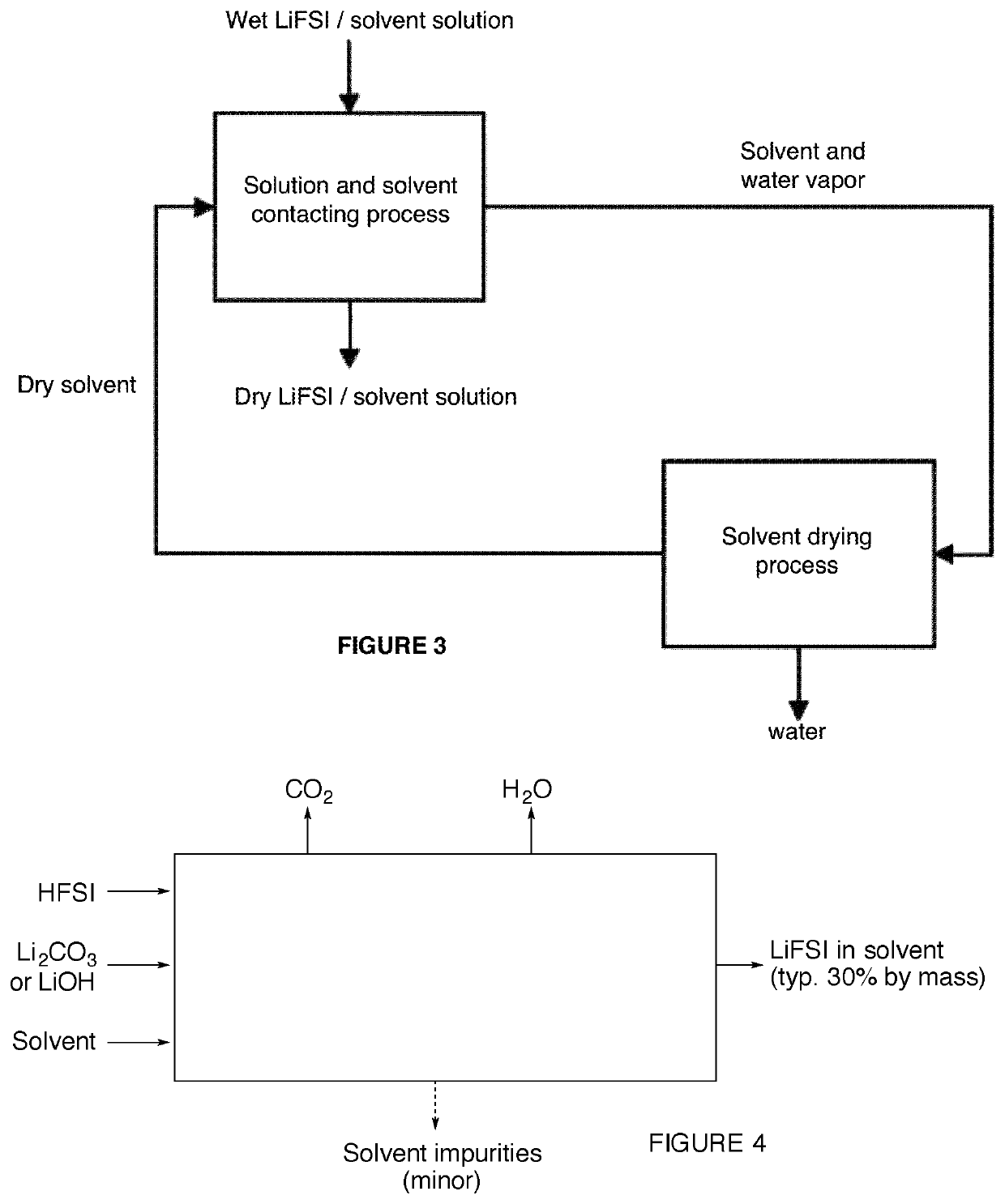

Method for drying electrolyte solution

ActiveUS10505228B2Cost-effectiveReduce the amount of solvent usedIon-exchange process apparatusIon-exchanger regenerationElectrolytic agentEnvironmental engineering

The present invention provides a method for producing low-water-content electrolyte solutions. In particular, the present invention provides a method of removing water from a liquid solution comprising a non-aqueous solvent, a hygroscopic metal salt and water. It also provides a method for producing a low-water content electrolyte solution without isolation of the metal salt. The method of the invention is useful in producing low water content electrolyte solutions for batteries such as lithium- or lithium-ion batteries.

Owner:SYNTHIO CHEM LLC

Process for production of finely fibrous cellulose composite prepreg sheet, process for production of finely fibrous cellulose composite sheet, and process for production of finely fibrous cellulose composite laminate sheet

ActiveUS8999088B2Efficient executionImprove productivityNon-fibrous pulp additionSpecial paperPorous substrateCellulose

A method of producing a finely fibrous cellulose composite prepreg sheet, sheet or laminate sheet, the method including a mixing an emulsion of a reactive compound with an aqueous suspension containing a finely fibrous cellulose to prepare a mixed liquid dewatering the mixed liquid by filtration on a porous substrate to form a water-containing sheet; and heating and drying the water-containing sheet. A method of producing a finely fibrous cellulose composite sheet, the method including subjecting the finely fibrous cellulose composite prepreg sheet produced by the method described above to a curing treatment.

Owner:OJI HLDG CORP

Compositions and devices of poly-4-hydroxybutyrate

ActiveUS20150126615A1High purityHigh yieldSuture equipmentsCosmetic preparationsNon solventSolvent extraction

Compositions of P4HB with high purity have been developed. The compositions are prepared by washing P4HB biomass prior to solvent extraction, and precipitating P4HB from solution. The same solvent is preferably used to wash the P4HB biomass, and as a non-solvent to precipitate the polymer from a P4HB solvent solution. The highly pure P4HB compositions are suitable for preparing implants. The implants may be used for the repair of soft and hard tissues.

Owner:TEPHA INC

Method for decolorization of dyed polyester fiber

ActiveUS20200270790A1Efficient removalLow process temperaturePlastic recyclingSolvent treatment with solvent recoveryPolyesterFiber

A method for decolorization of a dyed polyester fiber is provided. The method for decolorization of a dyed polyester fiber includes step of: providing an ether-alcohol solvent and a polyester fiber containing a dye; heating the ether-alcohol solvent up to a boiling point of the ether-alcohol solvent to continuingly generate a fresh gas; wherein a temperature of the fresh gas ranges from 90° C. to 200° C. which is between a glass transition temperature of the polyester fiber and a melting point of the polyester fiber; extracting the dye from the polyester fiber via the fresh gas and forming an extracting condensate containing the dye; reflowing the extracting condensate back into the ether-alcohol solvent; repeating the steps mentioned above to obtain a decolorized polyester fiber.

Owner:NANYA PLASTICS CORP

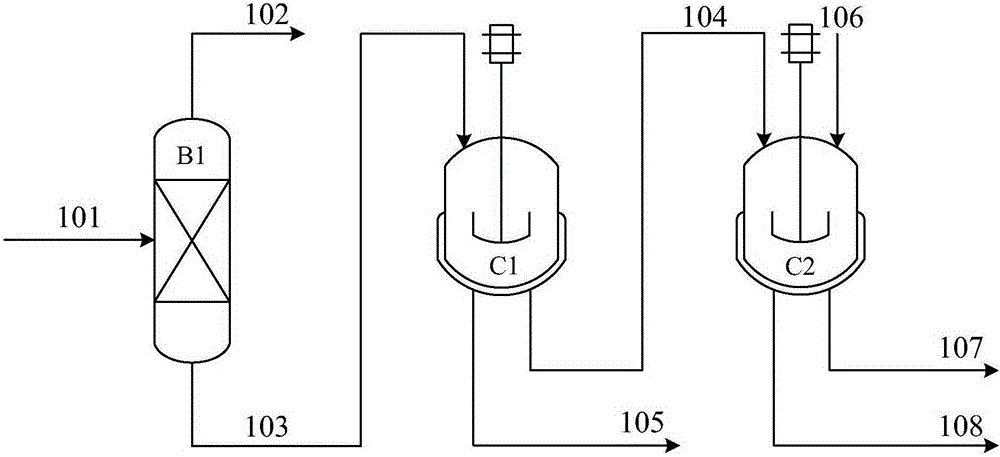

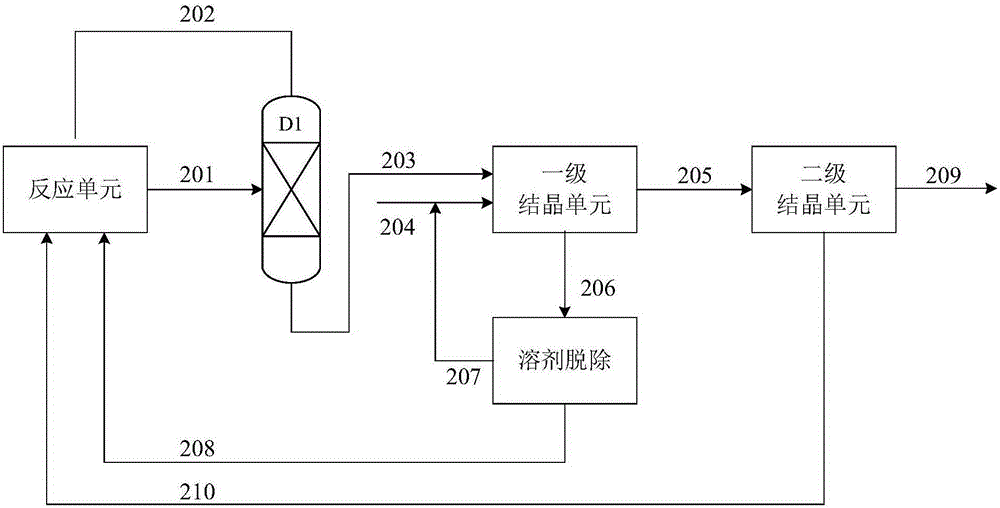

Separation and purification method for 2,6-diisopropylnaphthalene

InactiveCN106608809AGuaranteed product purityReduce the amount of solvent usedHydrocarbon purification/separationHydrocarbonsSolventChemistry

The invention relates to a separation and purification method for 2,6-diisopropylnaphthalene. The method is mainly used for solving the technical problem that the product purity is low when 2,6-diisopropylnaphthalene is separated and purified in the prior art. According to the adopted technical scheme, the method comprises the following steps that a liquid mixture containing 2,6-diisopropylnaphthalene enters a rectifying tower, naphthalene, isopropylnaphthalene and other light components are removed, the light-component-removed materials enter a first crystallizer, a material flow containing crude 2,6-diisopropylnaphthalene crystals is obtained through a suspension crystallization process, the crude crystals enter a second crystallizer, and a material flow containing the high-purity 2,6-diisopropylnaphthalene product is obtained through a solvent crystallization, washing and drying process. Accordingly, the technical problem is well solved, and the method can be used in industrial production for separating and purifying 2,6-diisopropylnaphthalene.

Owner:CHINA PETROLEUM & CHEM CORP +1

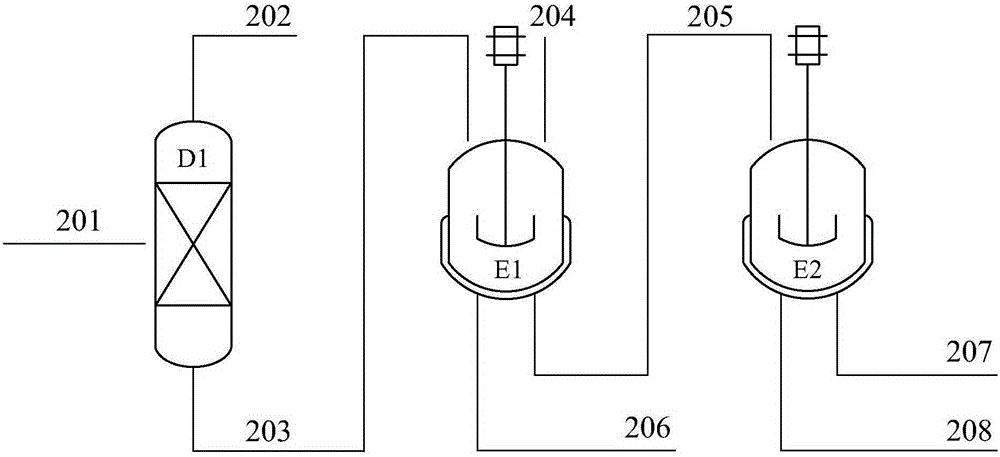

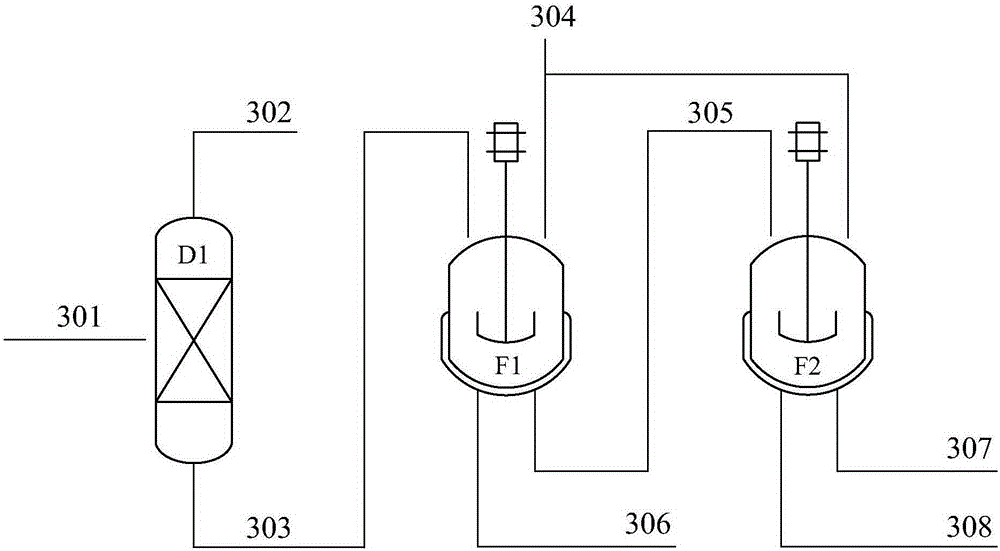

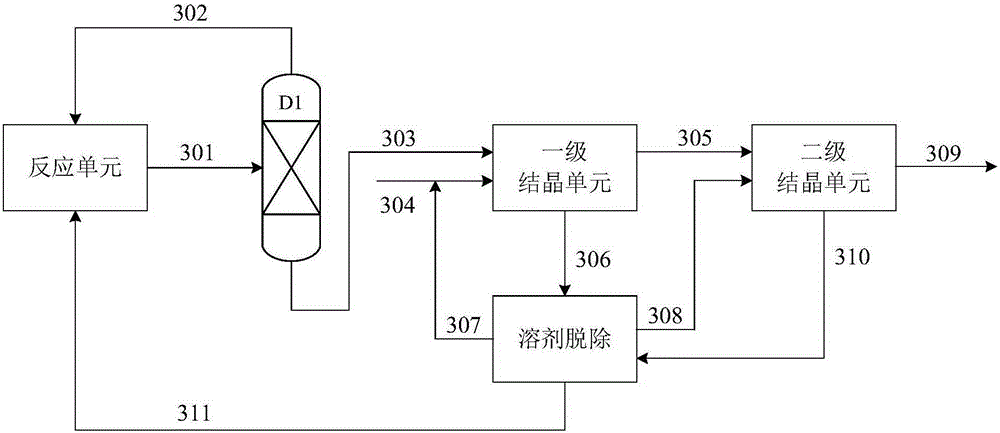

Method for refining 2,6-diisopropylnaphthalene

InactiveCN106608810AGuaranteed product purityReduce the amount of solvent usedDistillation purification/separationHydrocarbonsSolventChemistry

The invention relates to a method for refining 2,6-diisopropylnaphthalene, and is used for mainly solving the technical problems of low purity and low yield of products during separation and purification of 2,6-diisopropylnaphthalene in the prior art. The technical problems are relatively well solved by adopting the technical scheme comprising that the method comprises the following steps: allowing an isopropylnaphthalene mixed material liquid from a reaction unit to enter a rectifying tower, removing naphthalene, monoisopropylnaphthalene and other light components, then allowing the product to enter a primary crystallization unit, and carrying out suspension crystallization to obtain a crude 2,6-diisopropylnaphthalene crystal; allowing the crude crystal to enter a secondary crystallization unit, carrying out solvent crystallization, washing and drying to obtain the high-purity 2,6-diisopropylnaphthalene product; circulating the light components of the refining process, a primary crystallization mother liquor and a secondary crystallization mother liquor having a solvent removed back to the reaction unit, continuing to carry out the reaction to generate 2,6-diisopropylnaphthalene. The method can be used for industrial production of separation and purification of 2,6-diisopropylnaphthalene.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of continuous cellulose airgel fiber and its preparation method

ActiveCN105970325BAdjustable specific surface areaShorten the timeArtificial filaments from cellulose solutionsWet spinning methodsCelluloseFiber

The invention provides a continuous cellulose aerogel fiber and a preparation method thereof. The preparation method comprises the following steps: dispersing cellulose into a dispersing agent so as to obtain a spinning stock solution; extruding the spinning stock solution into a coagulating bath for wet-method spinning so as to obtain cellulose aerogel fiber; winding the cellulose aerogel fiber in the coagulating bath, and soaking into an aging liquid for aging; washing the aged cellulose aerogel fiber till the pH is neutral, and drying, so as to obtain the continuous cellulose aerogel fiber. The preparation method provided by the invention has the characteristics that raw materials are cheap and easy to obtain, the preparation process is simple, green and pollution-free, the continuous cellulose aerogel fiber is good is spinnability, and the problem that cellulose aerogel is hard to spin into fiber is solved. The diameter of the cellulose aerogel fiber provided by the invention is smaller than 120 [mu]m, the cellulose aerogel fiber has the characteristics of high specific surface area (greater than or equal to 88m<2> / g), high porosity (greater than or equal to 85%), and low density (less than or equal to 0.2 / cm<3>), meanwhile the fiber specific surface area can be adjusted, and the cellulose aerogel fiber can be used in fields such as functional clothes, sensing, catalyst loading and adsorption filtration, cosmetics and biological treatment.

Owner:DONGHUA UNIV

Methods of managing solvent inventory in a gravity drainage extraction chamber

ActiveUS11021942B2Reduce amount of liquid solventMitigate increased solvent demandConstructionsFluid removalCondensation temperatureSolvent

A method of managing a liquid solvent inventory in a condensing solvent gravity drainage extraction chamber includes growing the extraction chamber by injecting a solvent vapour under conditions which cause at least a portion of the solvent vapour to condense on a hydrocarbon extraction interface at a condensation temperature, then accumulating within the extraction chamber condensed liquid solvent which is draining through the chamber under the influence of gravity, which liquid solvent includes a hydrocarbon rich fluid production layer which is proximal to said extraction interface, and then heating a portion of the extraction chamber from a location near, in and / or above the injector to create a heated zone having a temperature above the condensation temperature without heating the hydrocarbon rich production layer to permit the hydrocarbon rich production layer to continue to drain to a production well.

Owner:HATCH LTD

Synchronization of ion generation with cycling of a discontinuous atmospheric interface

ActiveUS20190189415A1High sensitivityReduce the amount of solvent usedSamples introduction/extractionMaterial analysis by electric/magnetic meansMass Spectrometry-Mass SpectrometryMass analyzer

Owner:PURDUE RES FOUND INC

Method for preparation of high enzymatic resistance hydroxyalkylcellulose derivatives

ActiveUS8093376B2Promote degradationIncrease resistanceSugar derivativesSugar derivatives preparationEthylene oxideTurbidity

The present invention relates to a process of preparing hydroxyalkyl cellulose derivatives having improved enzymatic resistance. In particular, the present invention relates to a process of preparing hydroxyalkyl cellulose derivatives by reacting cellulose and ethylene oxide in the presence of alkali metal hydroxide, wherein the reaction between cellulose and ethylene oxide is performed in the presence of isopropyl alcohol azeotropic solvent in a horizontally agitated reactor, wherein the ethylene oxide is supplied via two steps, thus resulting in a two-step reaction, and the amount of alkali metal hydroxide remaining after the first reaction is controlled, thereby enabling to provide hydroxyalkyl cellulose derivatives having improved enzymatic resistance and turbidity and to remarkably decrease the solvent usage to have economical and environmental advantages.

Owner:LOTTE FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com