Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Reduce subjective factors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive voltage control partitioning method based on AP clustering

ActiveCN105138849AReduce subjective factorsSolving Random Search ProblemsSpecial data processing applicationsElectrical distanceRandom search

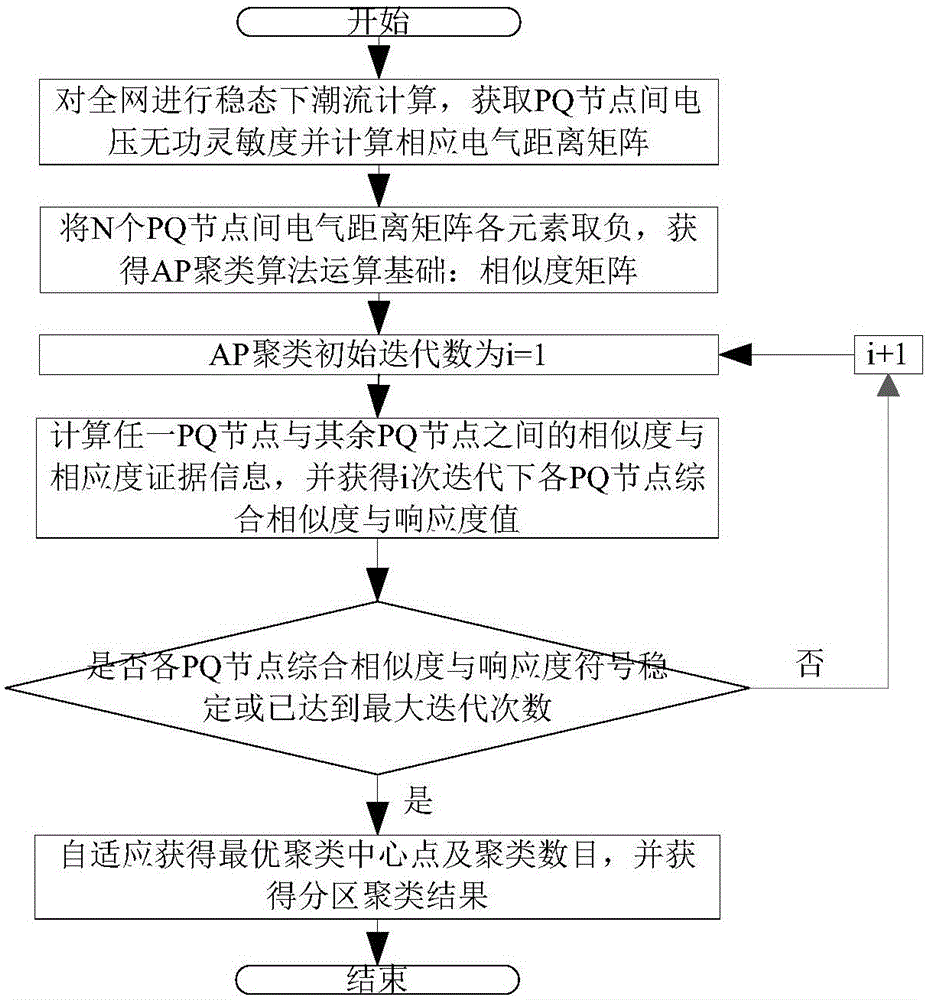

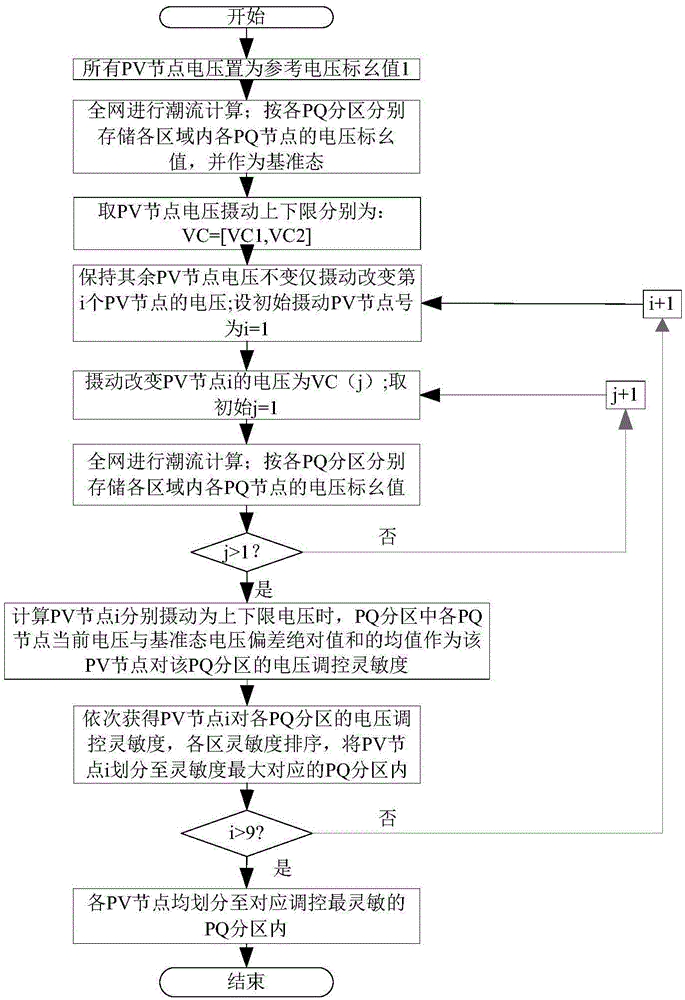

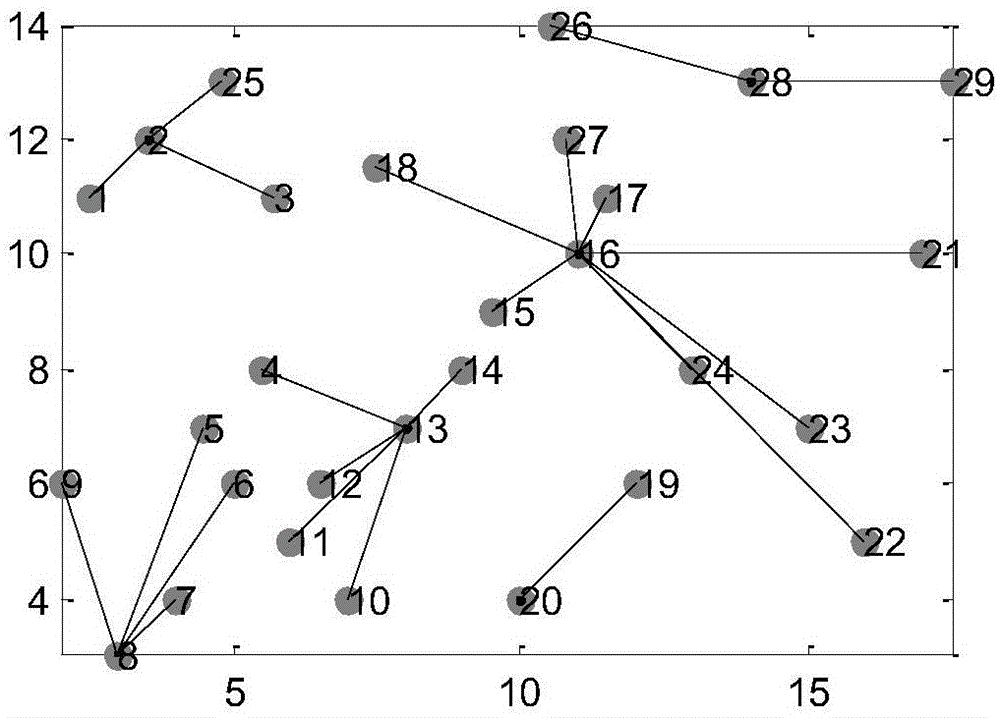

The invention discloses a reactive voltage control partitioning method based on AP clustering. The reactive voltage control partitioning method comprises the following steps that voltage reactive sensitivity is obtained based on a Jacobian matrix obtained through power flow calculation, and a PQ node electrical distance matrix is structured based on voltage sensitivity among PQ nodes; the minus of all elements of the PQ node electrical distance matrix is taken, and a similarity matrix is structured; the optimal clustering center, the optimal clustering number and a partitioning clustering result are obtained, and clustering of the PQ nodes is completed; the voltage regulating and control sensitivity of all PV nodes to all PQ partitions is calculated based on a perturbation method, and the PV nodes are partitioned into the PQ partition most sensitive in voltage regulating and control. The AP clustering algorithm is applied to voltage reactive partitions, the clustering number can be automatically obtained, unsupervised learning is carried out based on definitive evidence spreading, subjective factors in the clustering process are effectively reduced, the problem of random searching is effectively solved, and random factors are not included in the algorithm process.

Owner:SHANDONG UNIV

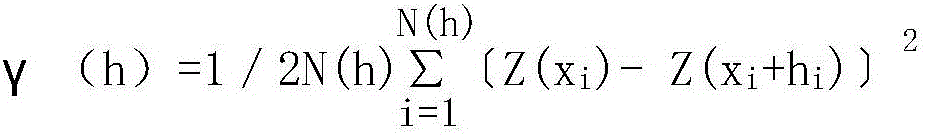

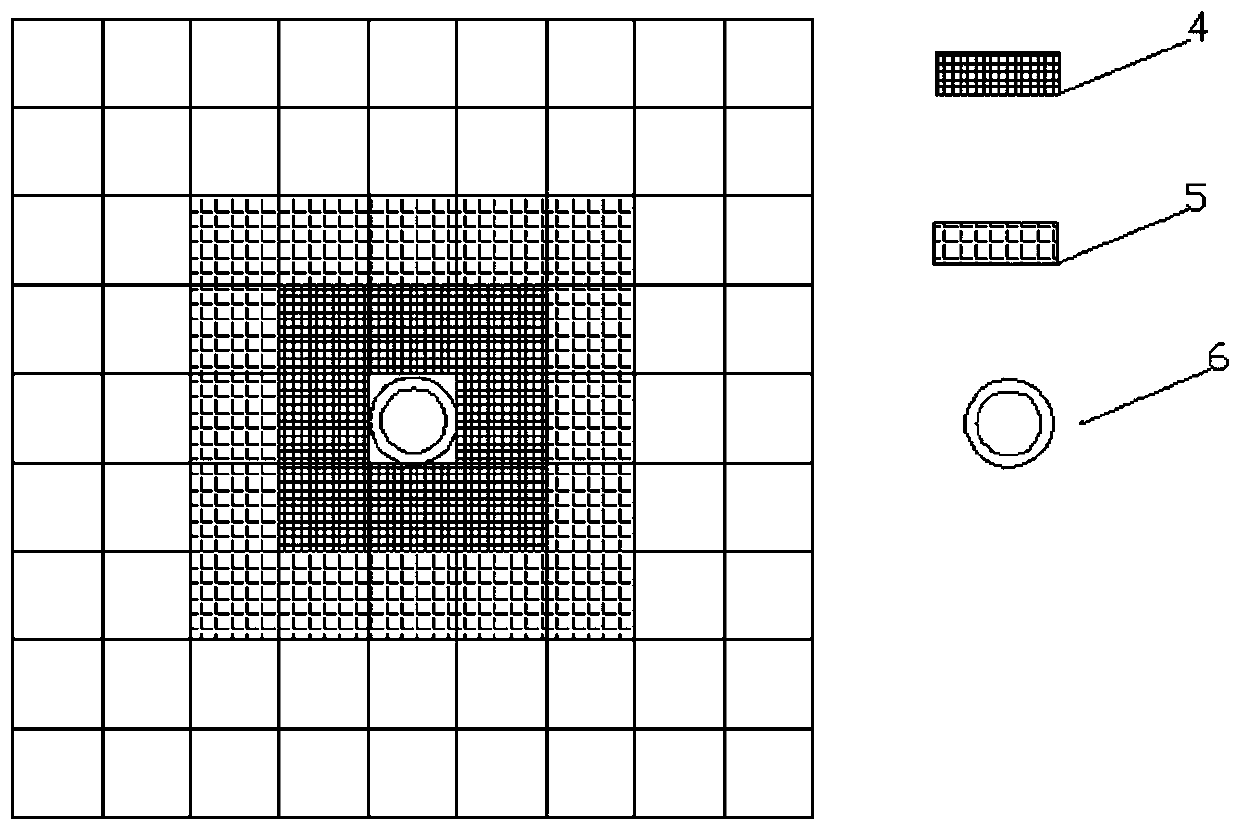

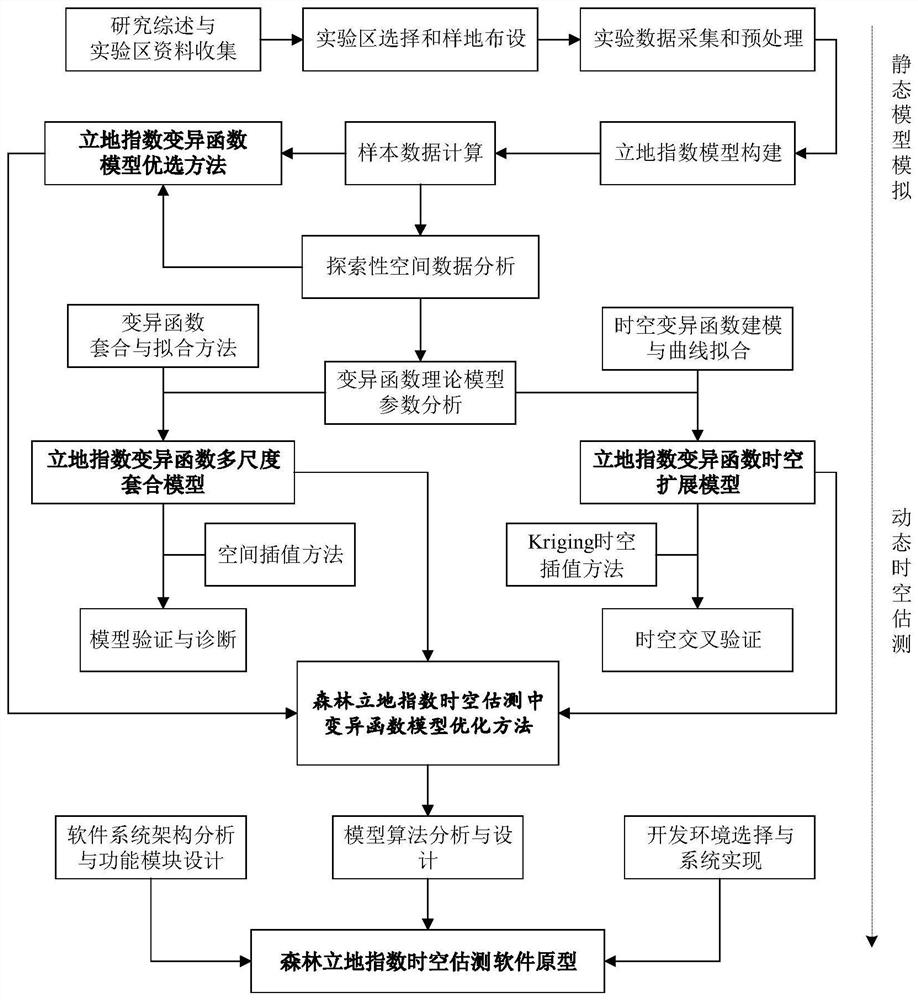

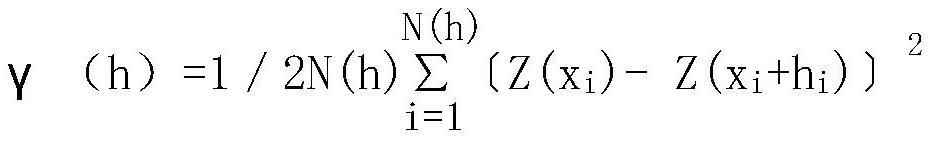

Variation function model optimization method in forest site index spatial-temporal estimation

ActiveCN106372277AEffectively characterize anisotropyEffectively characterize dependenciesDesign optimisation/simulationSpecial data processing applicationsDependabilitySpacetime

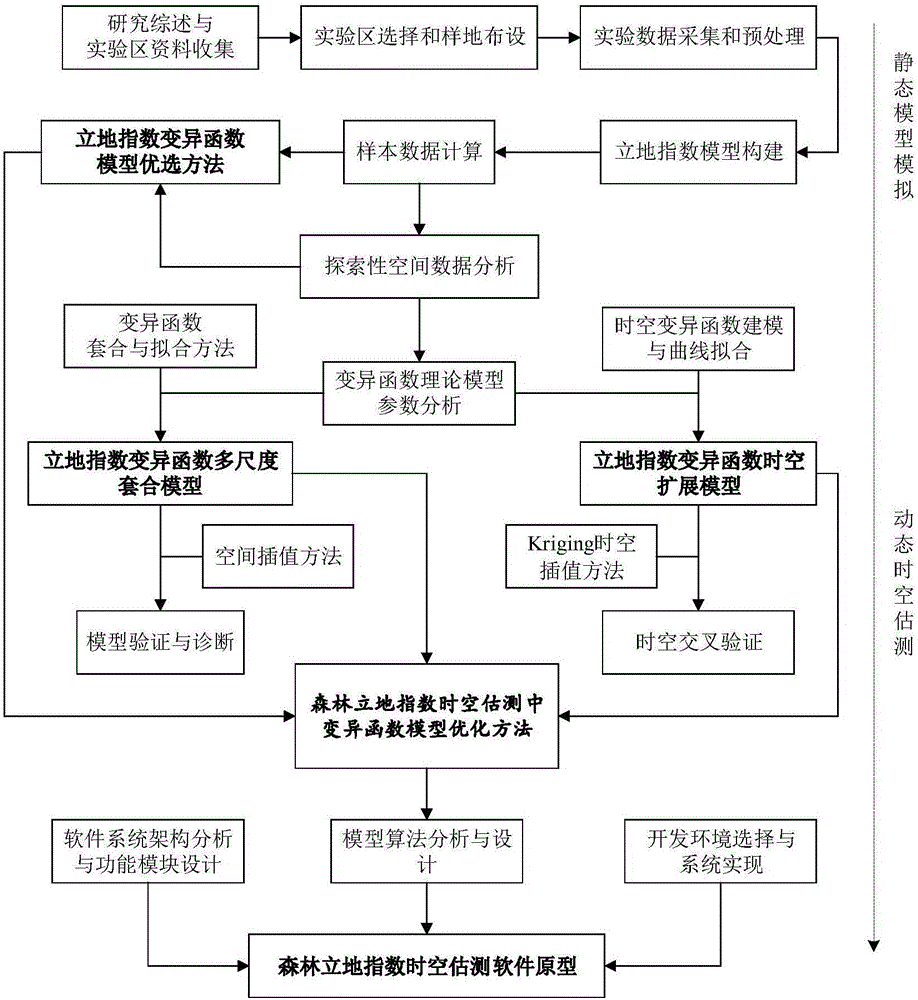

The invention discloses a variation function model optimization method in forest site index spatial-temporal estimation. The method comprises the following steps of (1) establishing a reliable site index variation function model optimization method by utilizing a computer, thereby ensuring effective combination of fixation and quantification of variation function selection; (2) establishing a unified site index variation function multi-scale nested model expression form and a computer automatic parameter optimal fitting method by utilizing the computer, and realizing an expansion algorithm of a multi-scale nested model function in mainstream statistic software, thereby ensuring effective prediction of a spatial interpolation algorithm; and (3) establishing a site index spatial-temporal variation function model expression form by utilizing the computer, and realizing a Kriging spatial-temporal interpolation algorithm, thereby improving the precision and reliability of the spatial-temporal estimation. The artificial subjective factors can be effectively reduced; the site index anisotropy and multi-scale dependence can be effectively described; the effective prediction of the spatial interpolation algorithm can be ensured; and the precision and reliability of the spatial-temporal estimation are improved.

Owner:XINJIANG AGRI UNIV

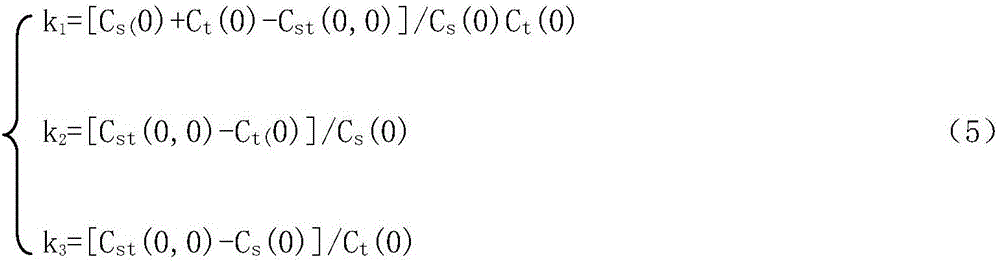

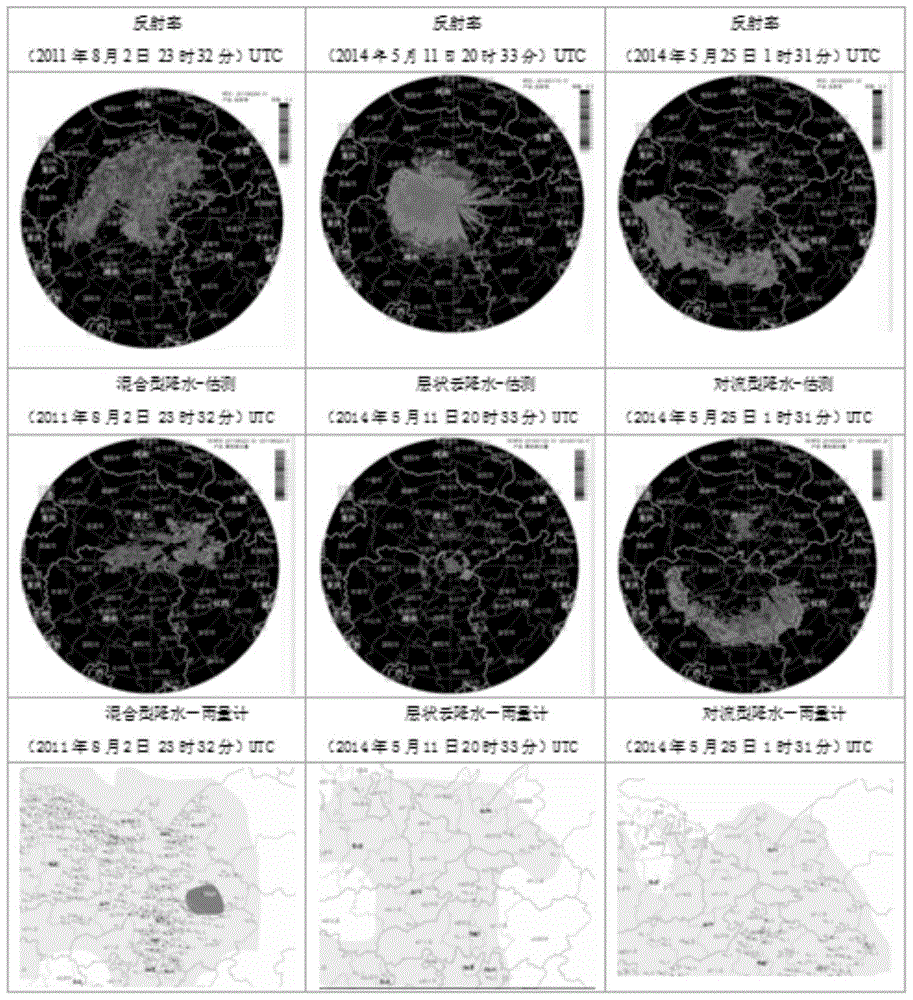

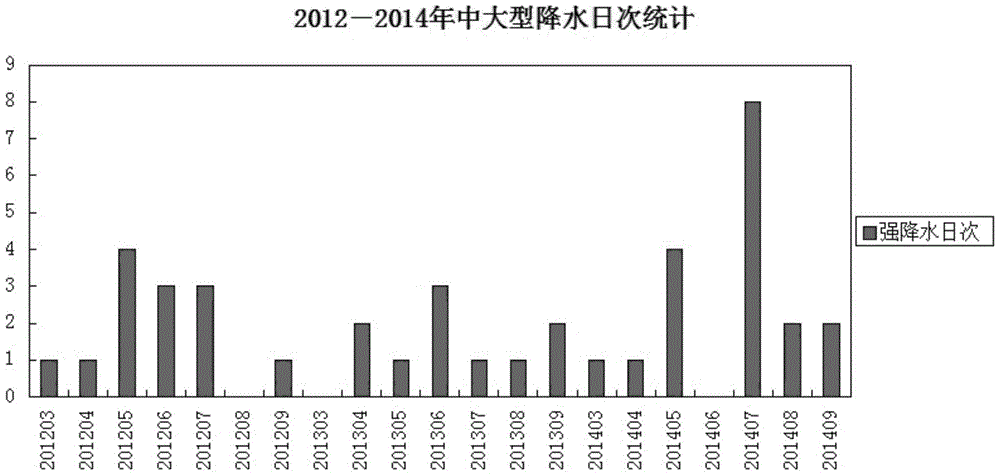

Self-analysis radar rainfall estimating method based on big data

ActiveCN105717556AReduce subjective factorsImprove accuracyWeather condition predictionRadar rainfallAlgorithm

The invention discloses a self-analysis radar rainfall estimating method based on big data. The method comprises the steps of: radar base data preprocessing; rainfall estimation by an optimal method; abnormal point detecting and filtering; characteristic value extracting; and dynamic estimated rainfall correction. An algorithm estimating radar rainfall data is provided by a research method of the big data. In the algorithm, firstly, abnormal point detection is adopted to filter out abnormal values or values of unconspicuous characteristics; then a DBSCAN algorithm is adopted to perform clustering analysis, and a deviation value of a representative station is calculated. The algorithm is used for dynamically correcting the data of the radar estimated rainfall, so that the rainfall estimation can be more accurate.

Owner:长江水利委员会水文局

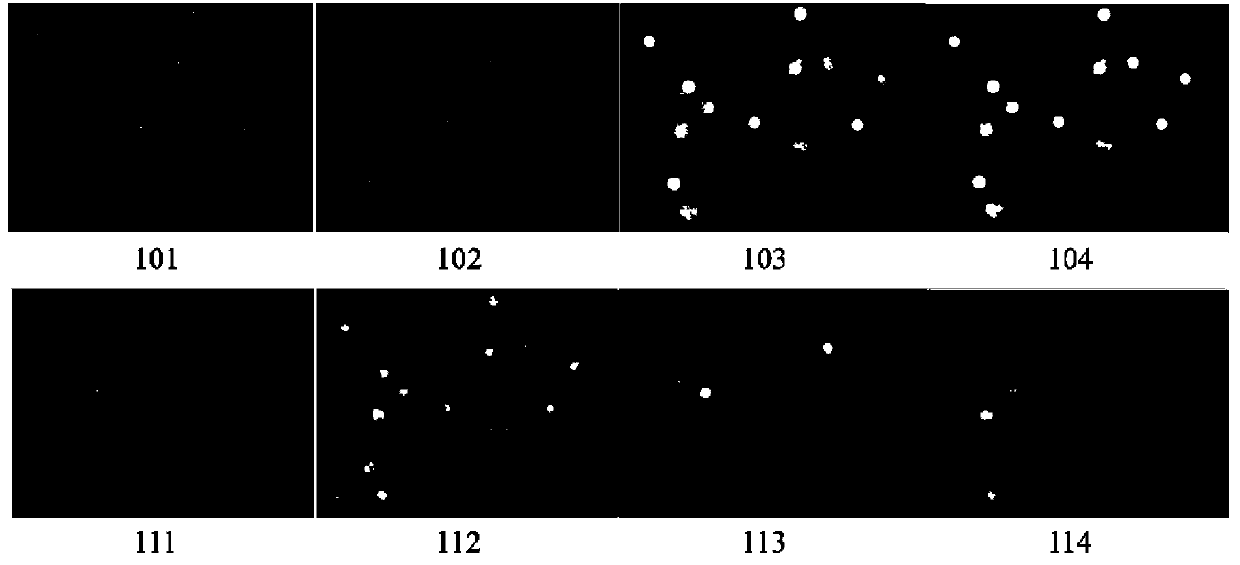

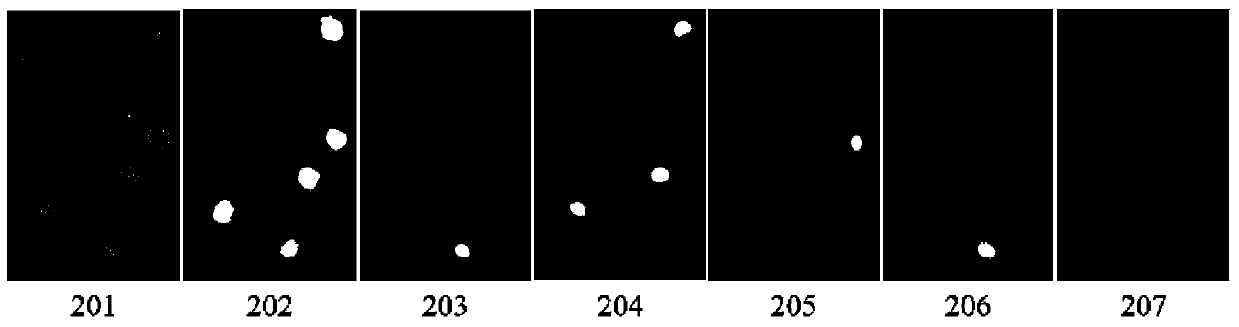

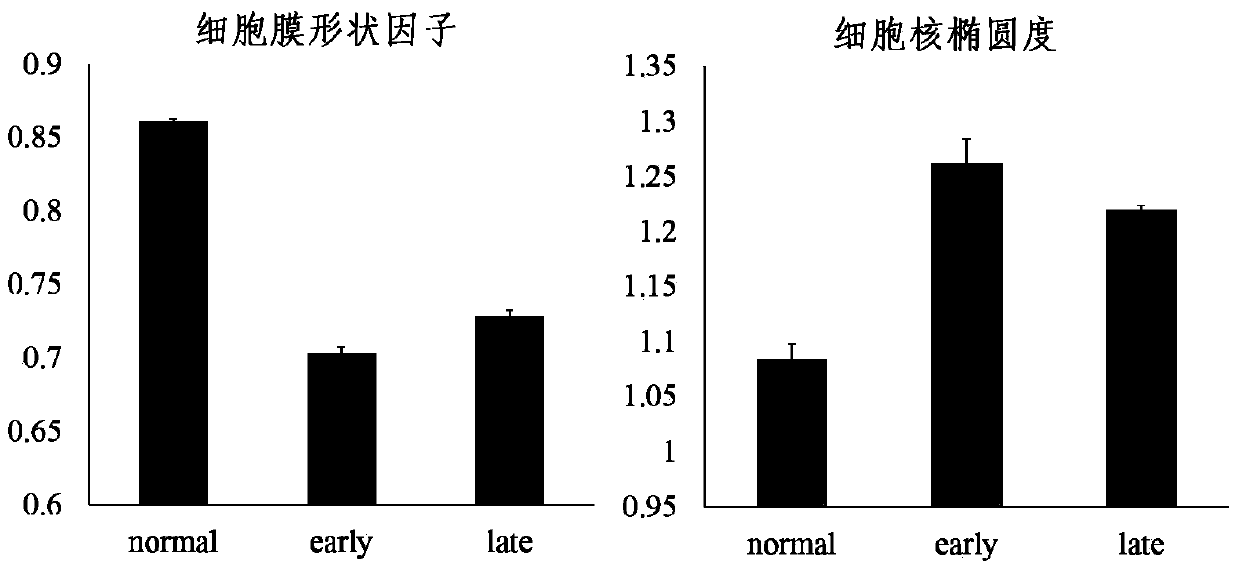

Quantitative analysis method aiming at apoptotic cell morphology of fluorescence microscopic image

InactiveCN103994964AFast splitReduce subjective factorsIndividual particle analysisMicroscopic imagePattern recognition

The invention relates to a quantitative analysis of an apoptotic cell morphology, which can effectively divide cell individuals from an image, automatically calculate cell two-dimensional morphology parameters and greatly shorten image analyzing time. The technical scheme adopted by the invention is a quantitative analysis method aiming at the apoptotic cell morphology of a fluorescence microscopic image. The quantitative analysis method comprises the following steps: (1) collecting a plurality of pairs of fluorescence microscopic cell images to be treated; (2) applying median filtering to a light microscope image in one pair of the images; carrying out gray stretching and carrying out image pre-treatment by using morphology opening operation; (3) automatically finding a threshold value by using an Otsu algorithm; (4) obtaining a divided binary image; (5) filling holes by using a morphology expansion and corrosion method, and removing small regions and incomplete targets on the boundary; (6) judging the state of a cell by the divided binary image according to a dyeing result; (7) outputting a parameter calculation result of each cell. The invention is mainly applied to the quantitative analysis method for the apoptotic cell morphology.

Owner:TIANJIN UNIV

Tongue coating and tongue proper color extracting and classifying method based on pixel

InactiveCN1931085AReduce subjective factorsQuantitativeData processing applicationsSurgeryColour centreClassification methods

The present invention provides one kind of tongue coating and tongue proper color extracting and classifying method based on pixel, and the method has high accuracy and wide application value. The method includes the first selecting typical tongue picture samples from tongue picture database, performing color clustering on each of the tongue picture samples in FCM algorithm, calibrating the color centers of the results and superposing the calibrated clustering color values of all the color sorts; the subsequent purifying treatment of each color sample set and screening samples to obtain color sample set; and final classifying and analyzing the tongue coating color and tongue proper color on each of the tongue picture with the improved KNN classifier. The present invention realizes the quantitative, objective and standardized analysis on tongue coating and tongue proper color and automatic computerized classification of 14 kinds of tongue coating and tongue proper colors.

Owner:HARBIN INST OF TECH

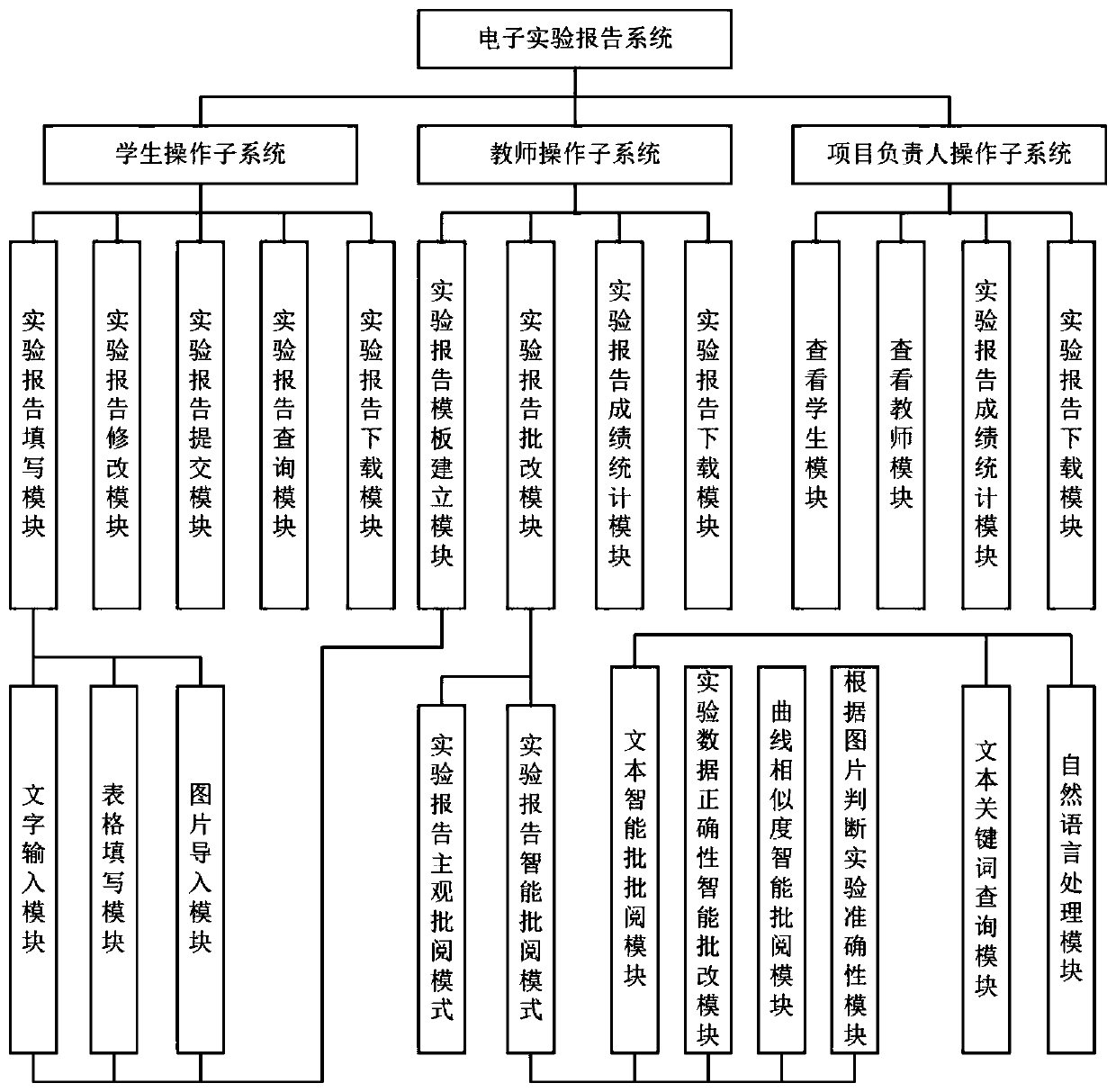

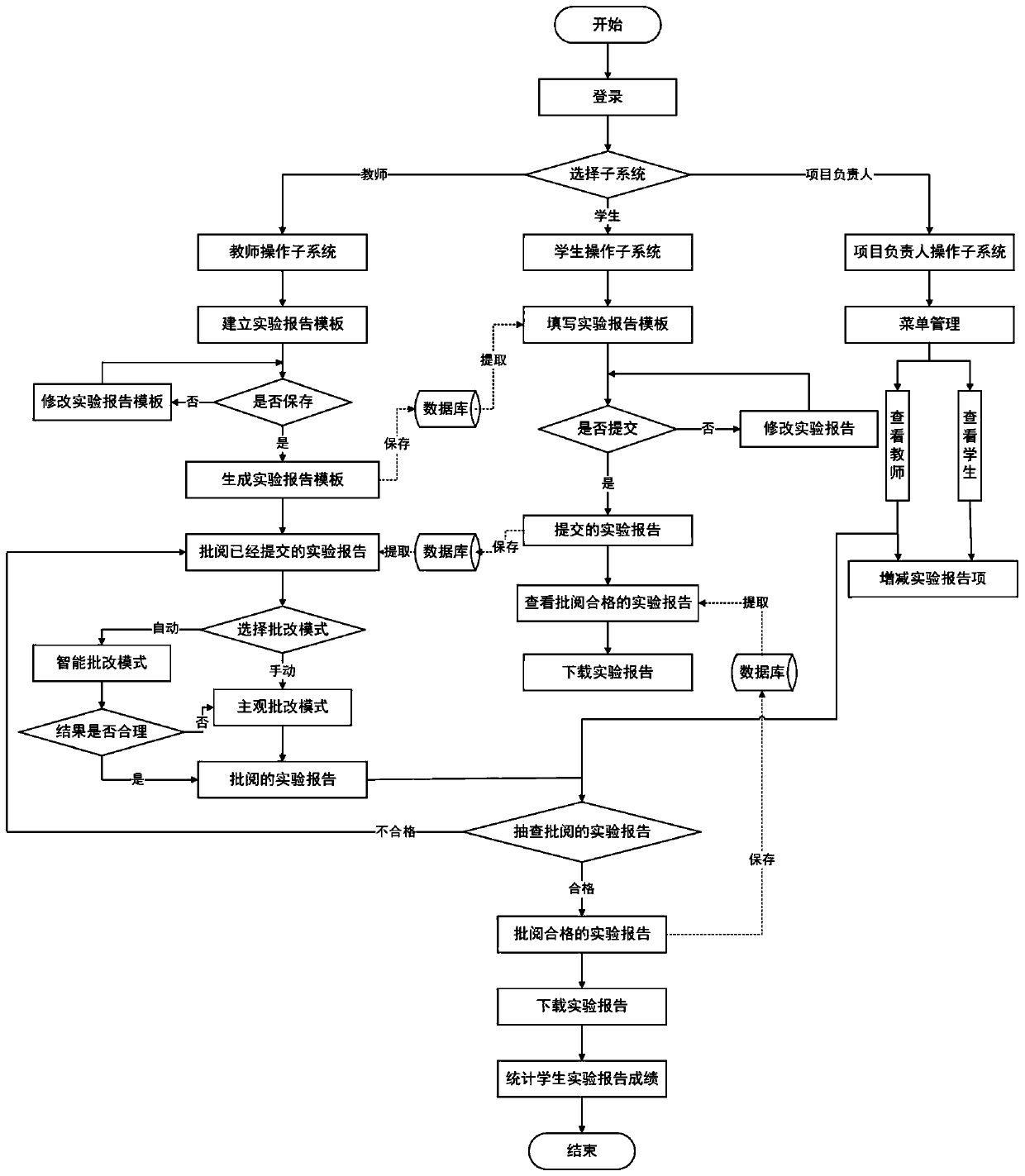

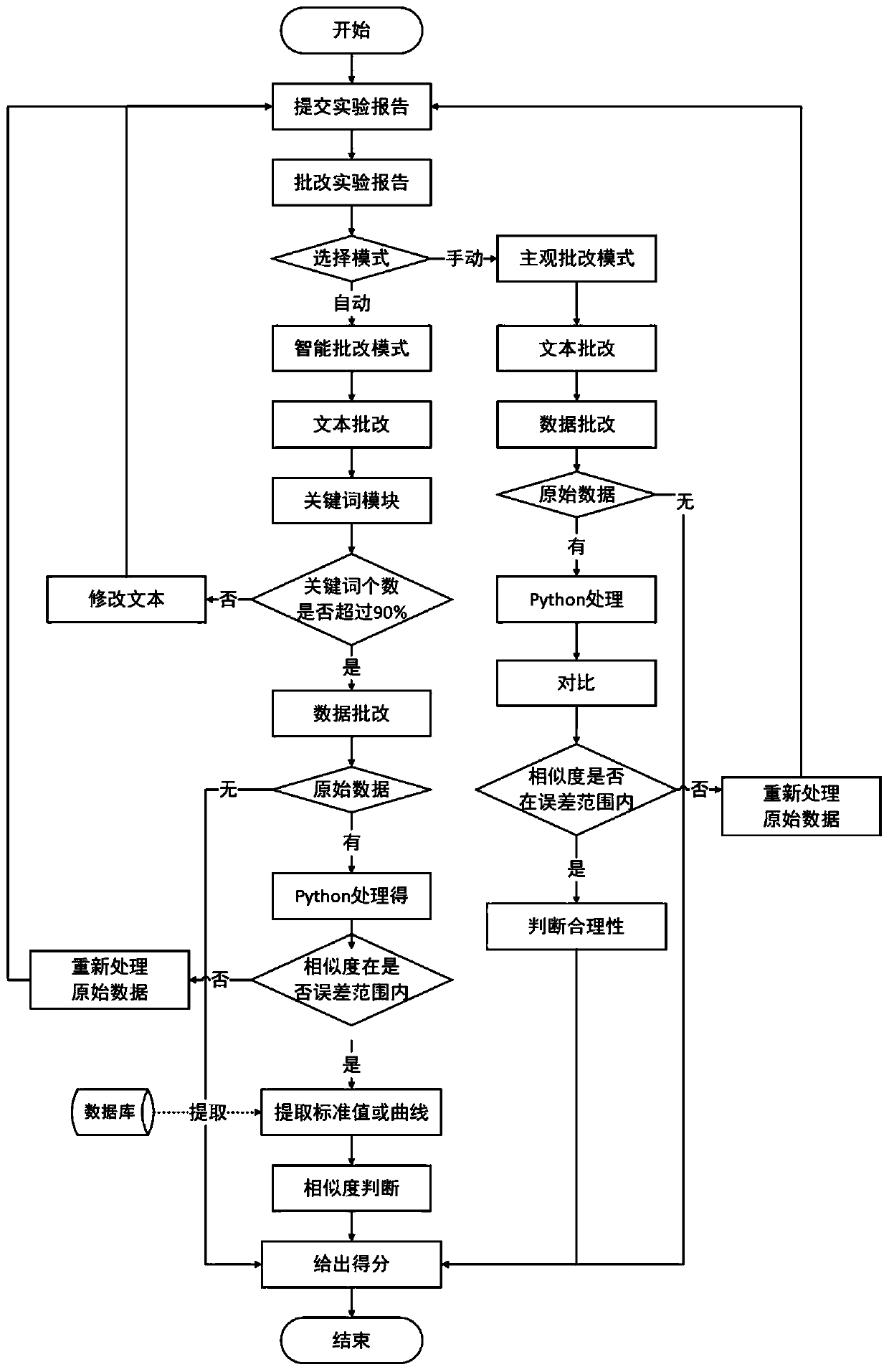

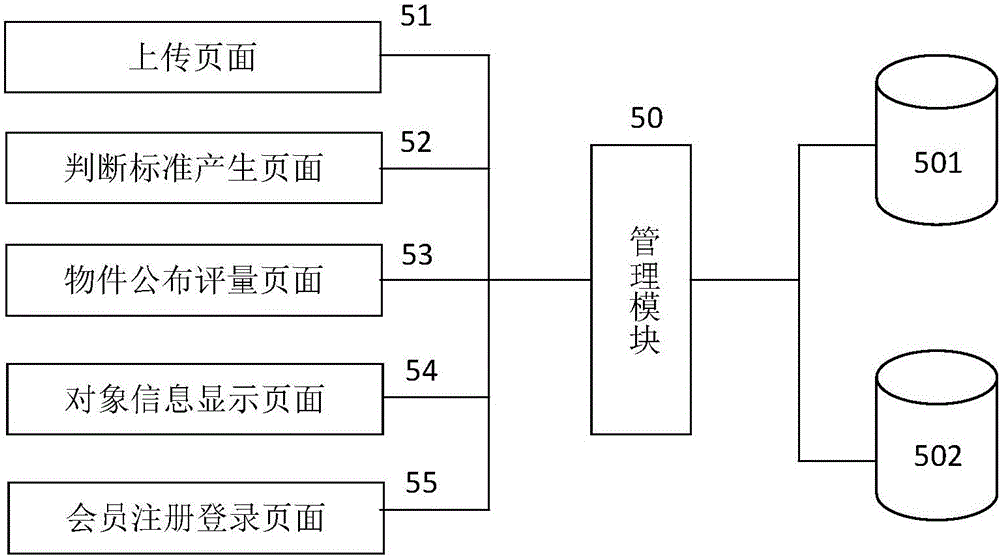

Electronic experiment report generating, intelligent marking, storing and downloading system

InactiveCN110969412ASubmit efficientlyEfficient managementOffice automationMobile endProject manager

An electronic experiment report automatic generating, intelligent correcting, storing and downloading system comprises a student operation subsystem, a teacher operation subsystem and a project principal operation subsystem; each subsystem comprises a plurality of modules, different systems and different modules interact with one another, and the functions of automatic generating, intelligent correcting, storing and downloading of the electronic experiment reports are achieved. The electronic experiment report can be edited at a PC terminal and can also be edited at a mobile terminal. Studentscan fill in the experiment report at any time at the mobile terminal and check the correction condition of the experiment report, thereby saving time. And the correction of the experiment report canbe completed at the mobile terminal without time limitation, thereby saving the time of teachers and improving the working efficiency. The problem of information communication hysteresis between teachers and students is solved, role setting is free and flexible, the teachers can serve as both experiment teachers and project managers, and the teachers or the project managers can check the experiment report filling submission condition and the experiment report reviewing condition at any time. Meanwhile, paperless and green experiment reports are achieved, and the requirement for sustainable development of the modern society is met.

Owner:DALIAN UNIV OF TECH

Adaptive data driving fault diagnosis method and device in complex refining process

ActiveCN104483958AReduce subjective factorsFind quicklyElectric testing/monitoringRelation graphAlgorithm

The invention relates to an adaptive data driving fault diagnosis method and a device in a complex refining process. The method comprises steps that, a relation graph among relevant process parameters causing a fault is established, and the process parameters causing the fault are determined; time sequence of all the process parameters and time sequence of the fault are acquired through the process parameters; whether the time sequence of the process parameters is covariance stationary is determined; if not, first order difference processing on the time sequence of the process parameters is carried out; a regression equation is constructed by utilizing the time sequence of the process parameters and the time sequence of the fault after covariance stationary, and a first residual error quadratic sum and a second residual error quadratic sum are acquired according to the regression equation; F examination is carried out; a largest path of a cause and effect relation magnitude is searched according to the relation graph; the time sequence of the process parameter which corresponds to a start point of the path is the root reason of the fault, and the terminal point of the path corresponds to the time sequence of the fault; and the largest path of the cause and effect relation magnitude is the propagation path of the fault in a system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

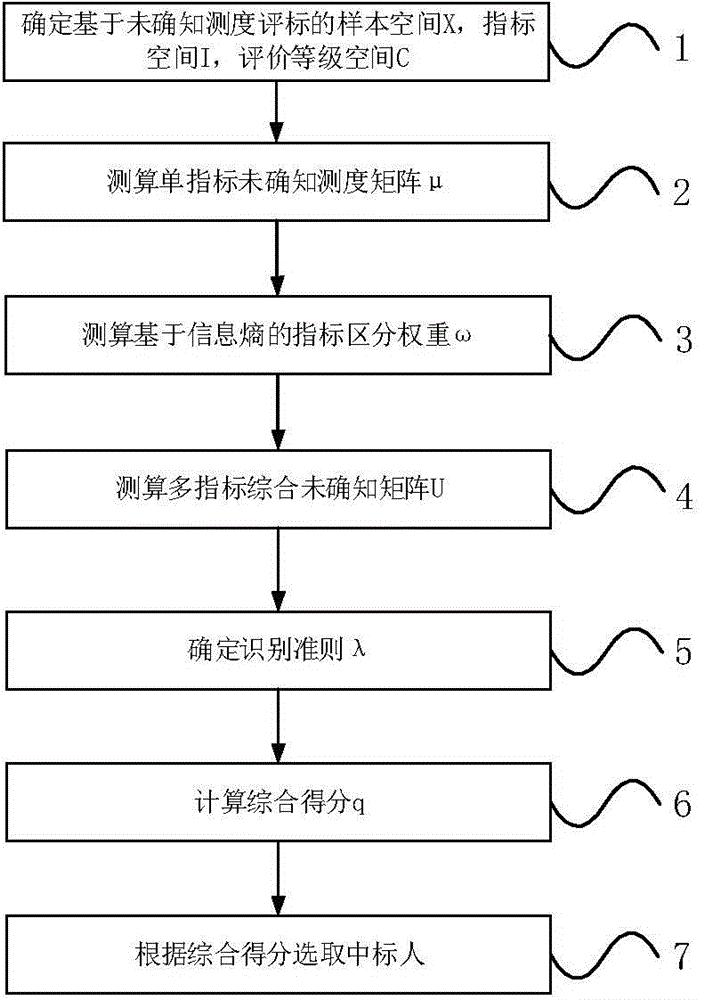

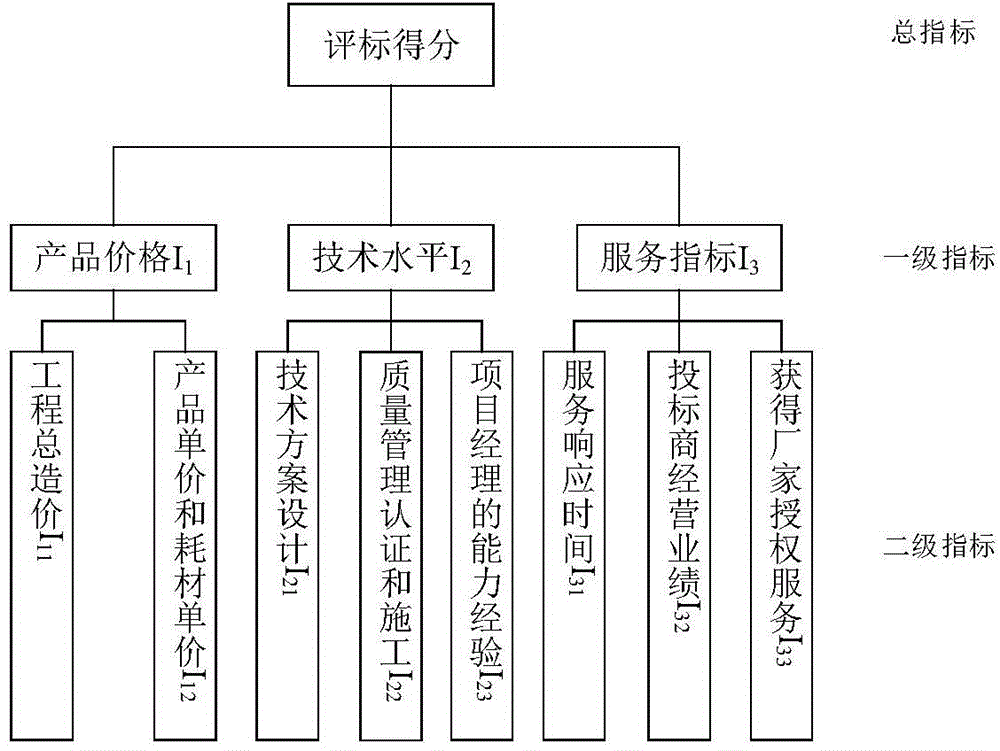

Bid evaluation method based on unascertained measurement comprehensive evaluation

The invention discloses a bid evaluation method based on unascertained measurement comprehensive evaluation. The method specifically comprises the following steps: (1) sample space X, index space I and evaluation grade space C on the basis of unascertained measurement bid evaluation are determined; (2) a single-index unascertained measurement matrix mu is measured; (3) information entropy-based index classification weight omega is measured; (4) a multi-index comprehensive unascertained matrix U is measured; (5) a recognition criterion lambda is determined; (6) a comprehensive score q is calculated; and (7) a winning bidder is selected according to the comprehensive score. According to the method of the invention, subjective factors in the bid evaluation process can be reduced, evaluation becomes objective, scientificalness of the bid evaluation method and fairness of bid evaluation are enhanced, data statistics and calculation can be carried out via a computer system, and difficulties of popularization and application can be reduced greatly.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Live broadcast bright spot video editing method, device and equipment, and storage medium

ActiveCN111698575AImplement quality assessmentAccurate and effective determinationSelective content distributionEngineeringVideo editing

The invention discloses a live broadcast bright spot video editing method, device and equipment and a storage medium. The method comprises the steps of: obtaining video data and user activity data ofeach anchor user, wherein the user activity data and the video data are synchronous in time, and the user activity data comprises a plurality of user activity dimensions which represent participationbehavior activity degrees of related audience users in the live broadcast process of the anchor users; dividing the video data of each anchor user into a plurality of video clips by taking a preset fixed duration as a unit, and quantitatively determining a comprehensive score of each video clip according to the user activity data to which each user activity dimension belongs; sorting the video clips according to the comprehensive scores, and determining one or more video clips as target clips according to the comprehensive scores; and determining the video data of which the duration span covers the target segment as the bright spot video. According to the embodiment of the invention, related bright spot videos can be identified from historical video data generated by network live broadcastmore accurately and efficiently.

Owner:广州方硅信息技术有限公司

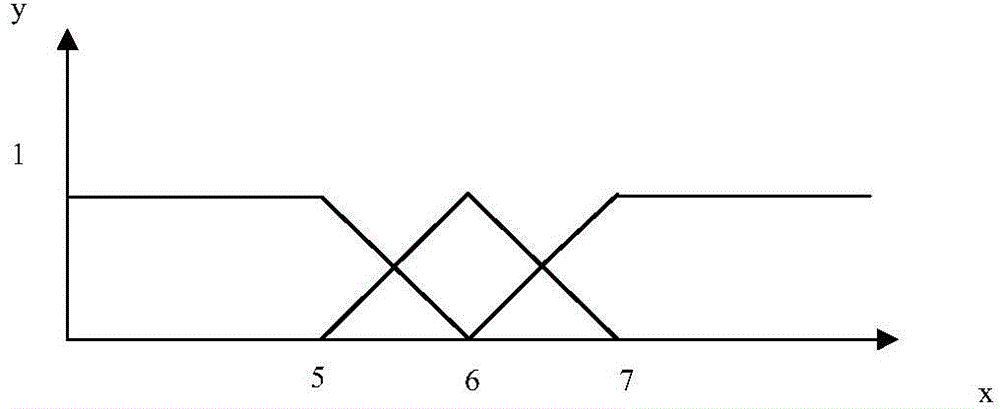

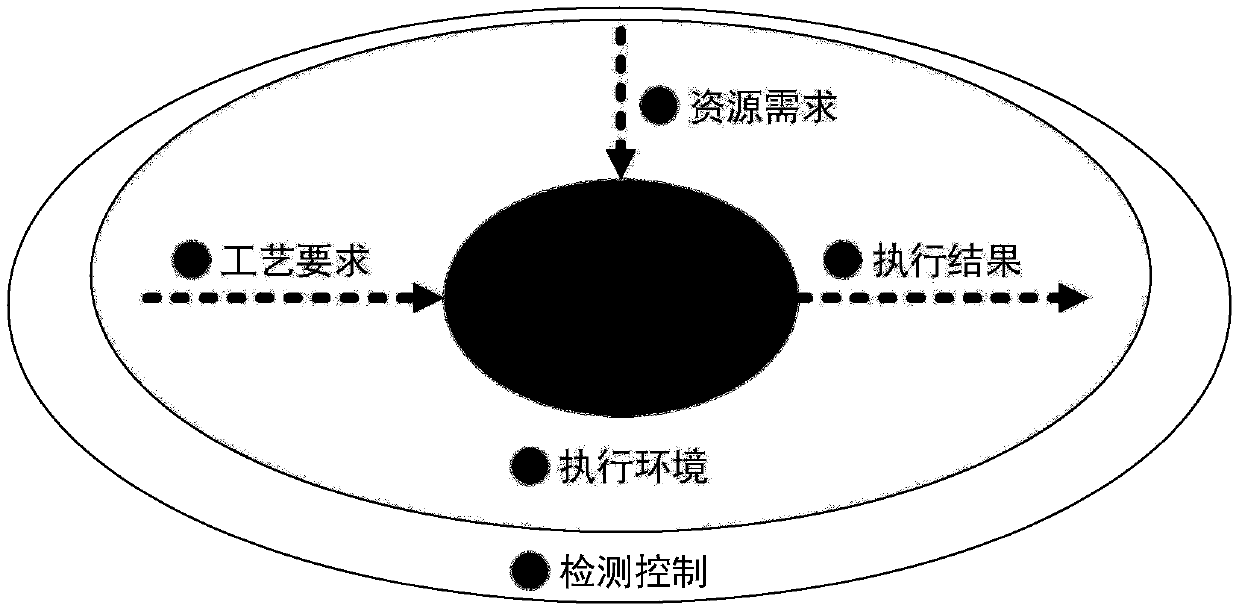

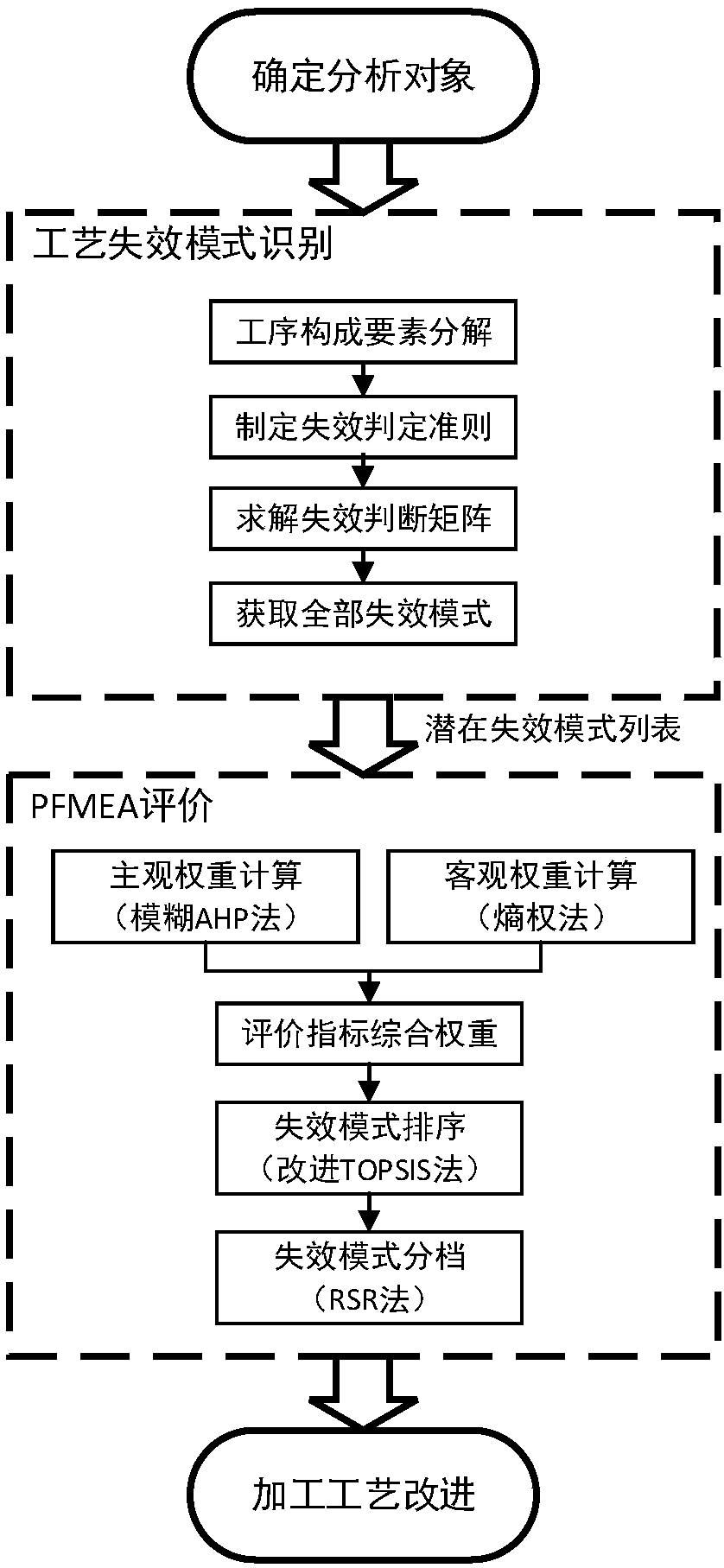

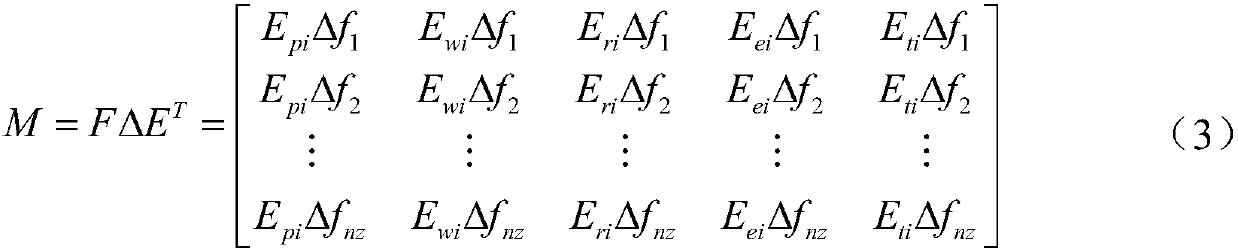

Fuzzy theory-based process failure mode identification and evaluation method

InactiveCN108510209AReduce subjective factorsSubjective evaluation resultResourcesManufacturing computing systemsEntropy weight methodDecomposition

The invention discloses a fuzzy theory-based process failure mode identification and evaluation method, which belongs to the field of machining and can be popularized to the field of improvement of machining quality of other products. The method comprises the following steps of solving a failure judgment matrix in combination with a process failure judgment criterion based on process element decomposition, thereby realizing identification of process failure modes; obtaining a fuzzy evaluation matrix by virtue of an expert system and a fuzzy evaluation level; based on an analytic hierarchy process of a fuzzy theory, calculating subjective weights of evaluation indexes, calculating objective weights of the evaluation indexes by an entropy weight method, and calculating weights of the evaluation indexes in combination with the subjective weights and the objective weights; obtaining a sequence of the process failure modes by a TOPSIS (technique for order preference by grey similarity to ideal solution) method; in combination with the failure mode sequence, grading the process failure modes by a rank sum ratio method; and performing product machining process improvement on processes ofthe process failure modes with the relatively high grade, thereby improving the product machining quality and reliability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

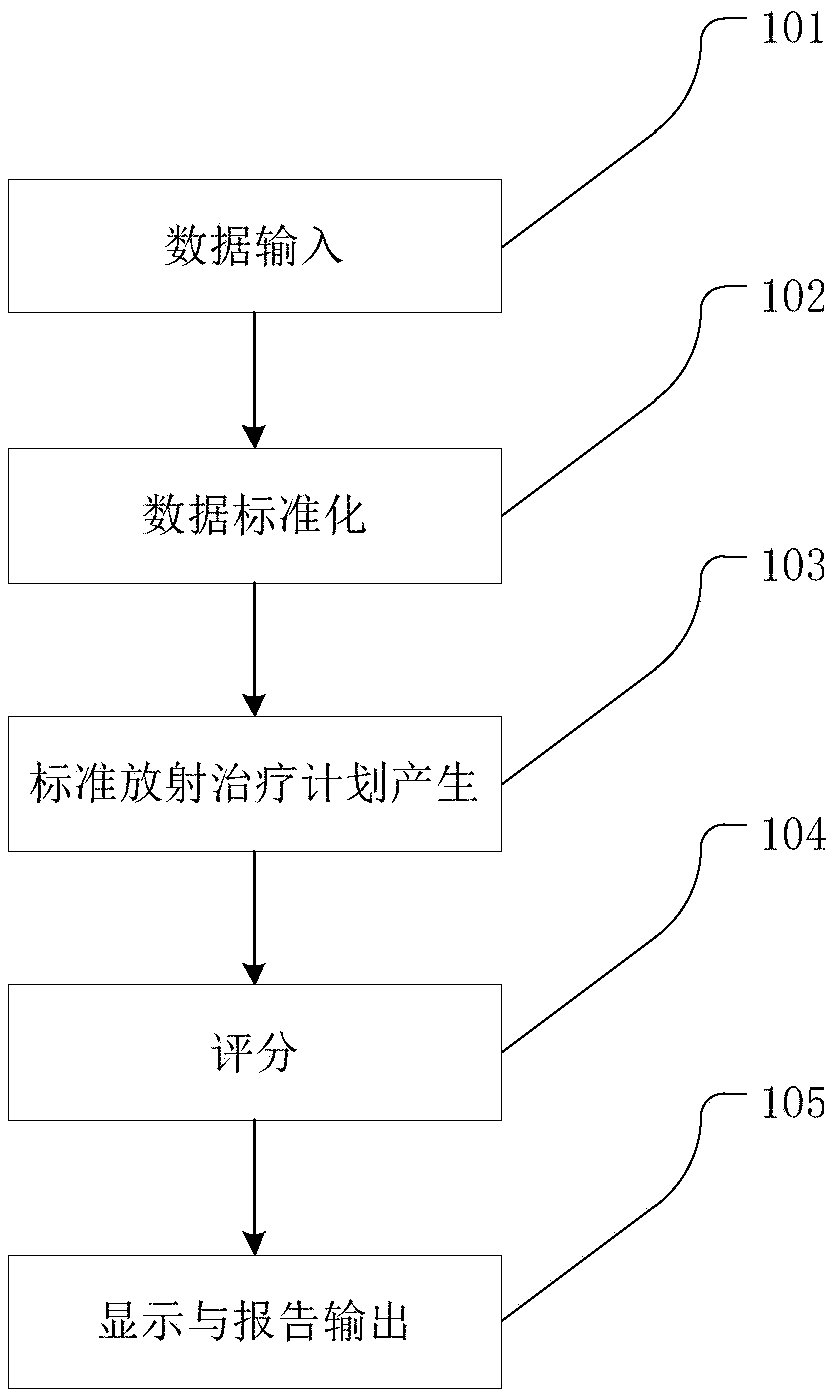

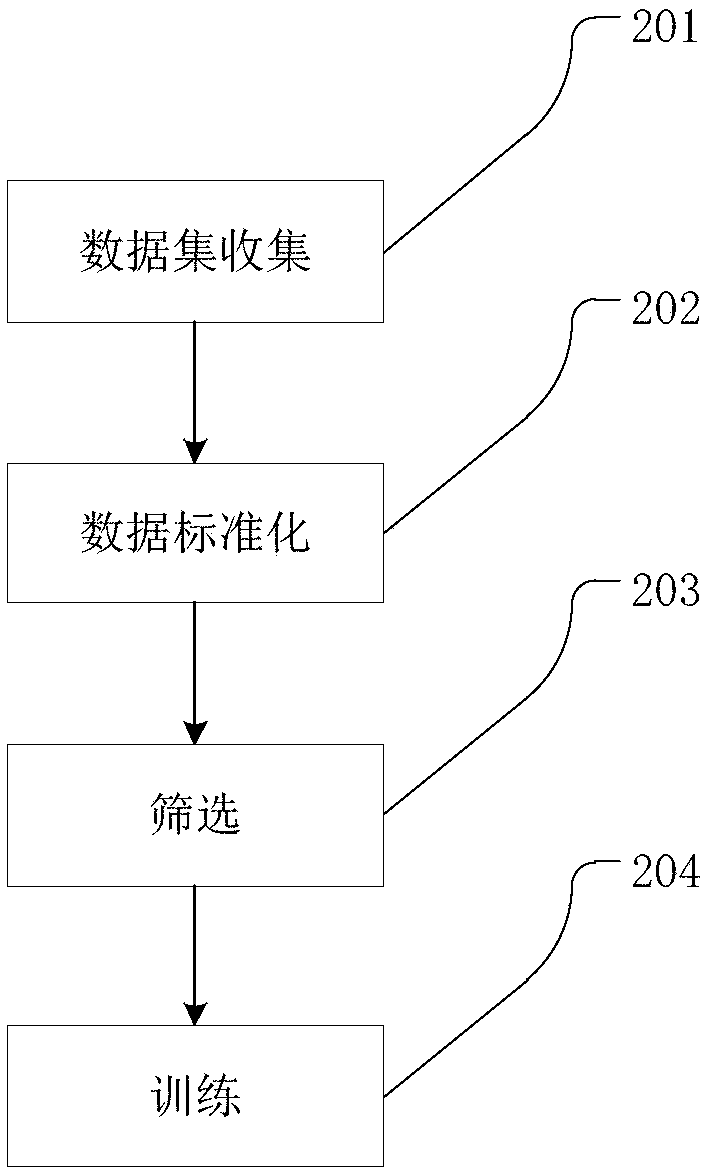

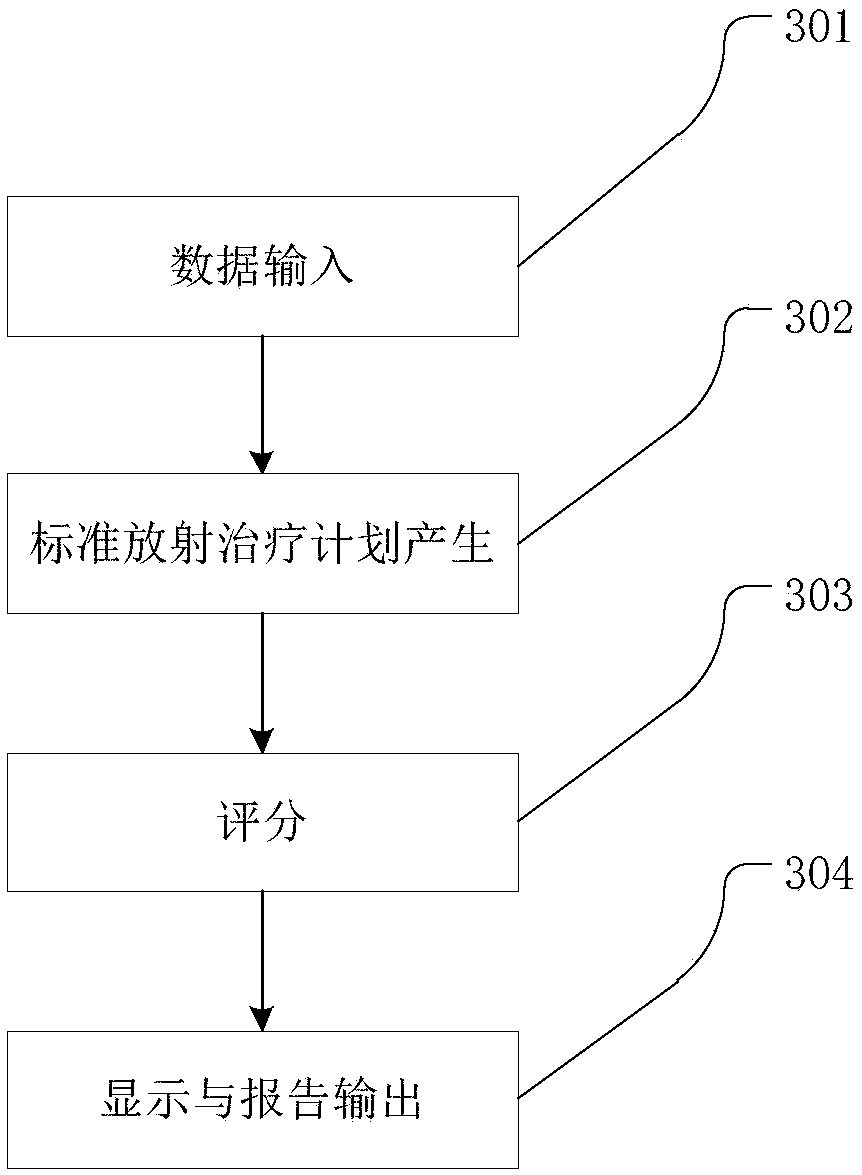

Cloud radiation therapy plan evaluation method, equipment and storage medium

ActiveCN109771843AEasy to collectReduce subjective factorsX-ray/gamma-ray/particle-irradiation therapyPatient databasePlan evaluation

The invention belongs to the technical fields of medical treatment and cloud service, and relates to a cloud radiation therapy plan evaluation method, equipment and a storage medium. The method comprises the steps of: inputting a radiotherapy plan data to-be-evaluated into a patient database according to a standard format; using a machine learning method to generate a standard radiotherapy plan corresponding to the radiotherapy plan to-be-evaluated; automatically comparing the radiotherapy plan to-be-evaluated with the standard radiotherapy plan for scoring; and displaying the scoring resultsobtained by the machine learning method and outputting a result report. The evaluation method provided by the invention is beneficial to collecting expert knowledge and forming an expert knowledge base, which reduces artificial subjective factors, improves objectivity and reduces errors.

Owner:BEIJING LINKING MEDICAL TECH CO LTD

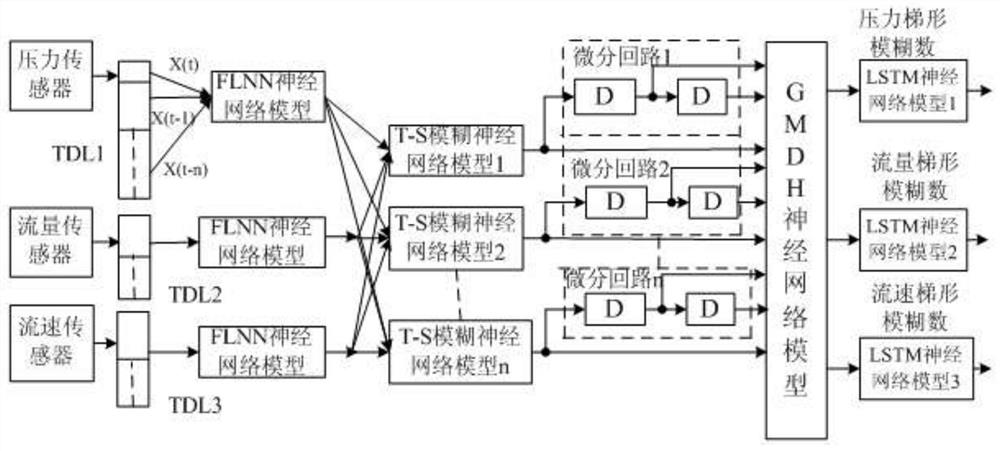

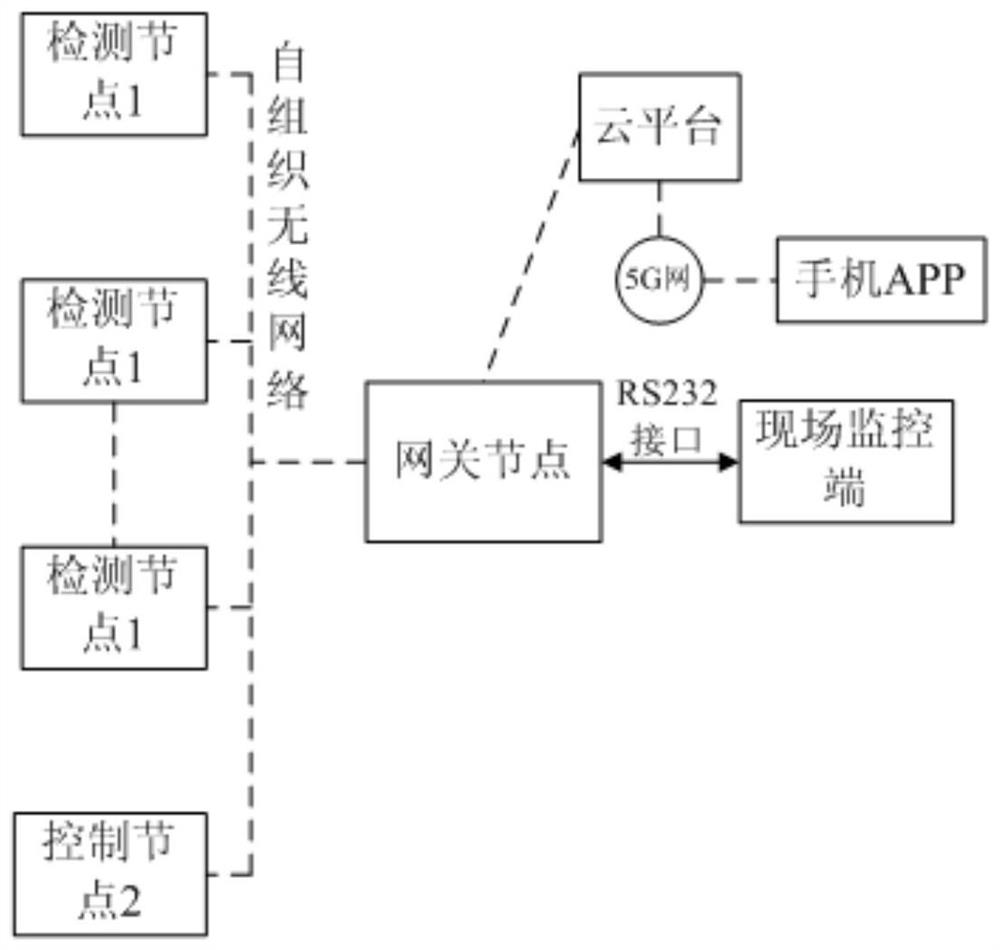

Pipe network big data detection system

ActiveCN112904756AReduce the amount of network calculationsFast trainingProgramme controlComputer controlIntelligent managementDistributed computing

The invention discloses a pipe network big data detection system which is composed of a pipe network parameter acquisition platform and a pipe network safety big data processing subsystem, the pipe network parameter acquisition platform detects pipe network parameters, the pipe network safety big data processing subsystem classifies pipe network safety, and pipe network operation benefits and reliability are improved; the method effectively solves the problems that an existing pipe network has no influence on pipe network safety according to nonlinearity and large lag of pipe network parameter changes, large pipe network area, complex parameter changes and the like, pipe network parameters are not predicted, and pipe network safety is not pre-warned, so that reliable operation and intelligent management of the pipe network are greatly influenced.

Owner:平行数字科技(江苏)有限公司

Method for determining thickness of wall of container for simulating explosion test in deepwater environment

ActiveCN103837117AReduce wall thicknessReduce processing costsMeasurement devicesEngineeringProcessing cost

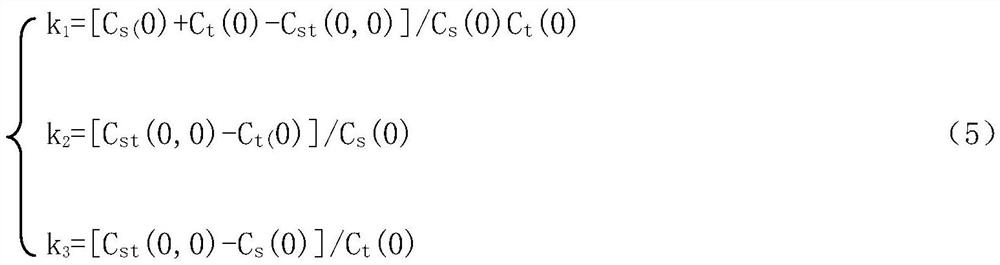

The invention relates to a method for determining the thickness of the wall of a container for simulating an explosion test in a deepwater environment. According to the technical scheme, under the conditions that the constraint condition of the container (the container is called for short) for simulating the explosion test in the deepwater environment, the simulated water depth, the allowable powder charging amount, the container structure, the container size and the container materials are known, a model (please see the formula in the specification) for determining the thickness of the wall of the container for simulating the explosion test in the deepwater environment is built, and then the thickness delta e of the wall of the container is obtained according to the model for determining the thickness of the wall of the container. The method has the advantages of being capable of meeting actual bearing requirements and lowering processing cost, and being safe, reliable and convenient to use.

Owner:WUHAN UNIV OF SCI & TECH

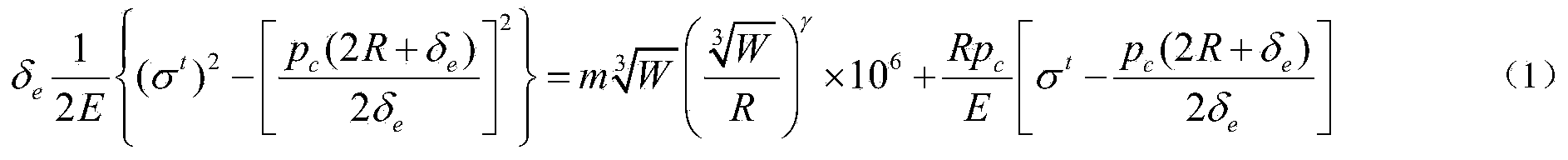

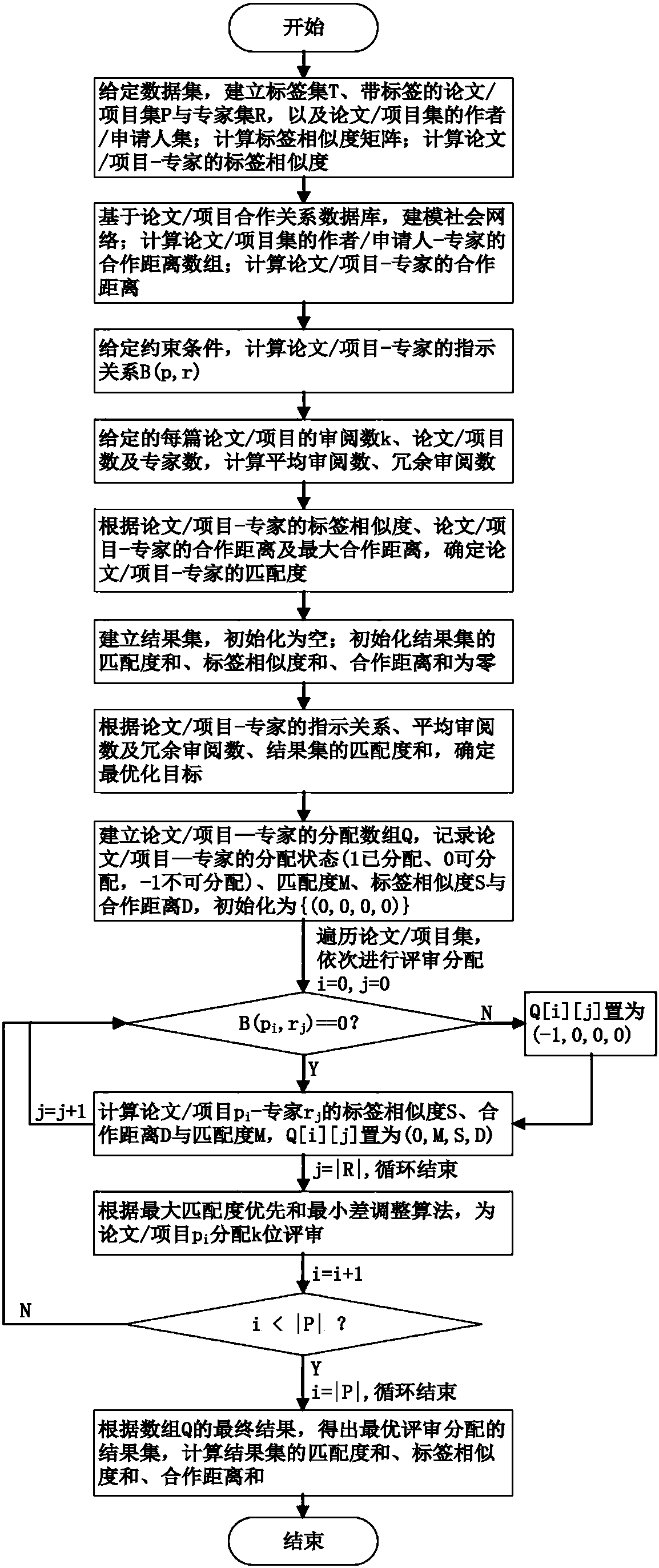

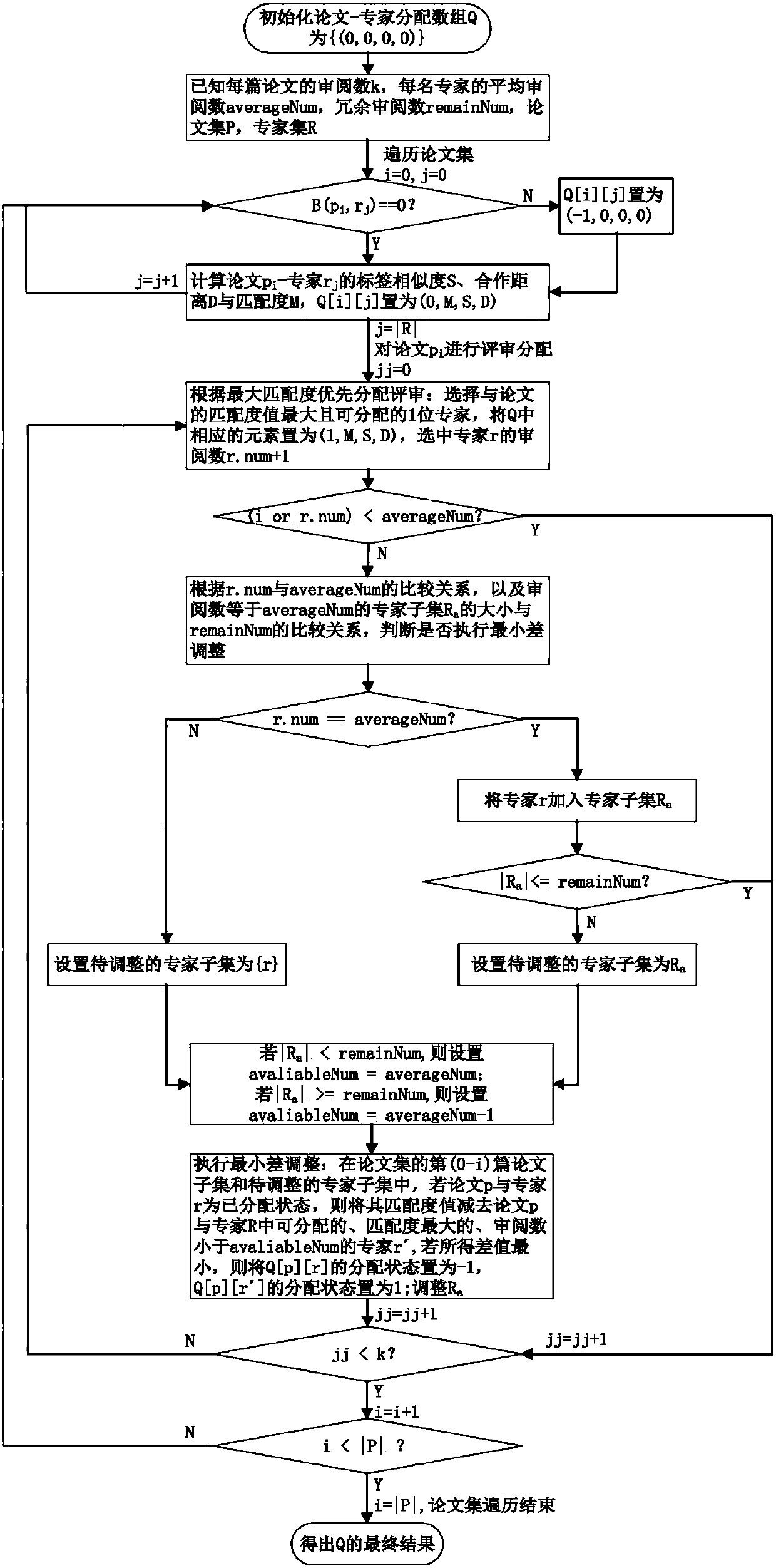

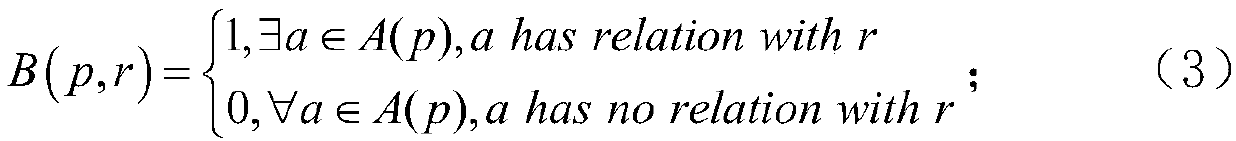

Review allocation method of fusing academic expertise and social network

ActiveCN107194672ABalanced distribution of reviewsReduce subjective factorsOffice automationArray data structureAlgorithm

The invention discloses a review allocation method of fusing academic expertise and a social network, and belongs to the field of computer application technology. According to the method, a label set, a paper / project set and an expert set are established, and label similarity degrees of papers / projects and experts are calculated according to a label similarity degree matrix; the social network is modeled based on a paper / project cooperation database, and cooperation distances of the papers / projects and the experts are calculated; an allocation array of the papers / projects and the experts is established, the paper set is traversed, and review allocation is carried out in sequence according to an algorithm of maximum matching degree priority and minimum difference adjustment; and an optimal allocation result and the sum of matching degrees, the sum of the label similarity degrees and the sum of the cooperation distances thereof are output. Meeting constraint conditions that authors / applicants of the papers / projects and the experts do not in cooperation, do not in teacher-student relations and do not belong to the same institutions, the method can realize balanced review allocation, maximize the sum of the label similarity degrees and the sum of the cooperation distances of review allocation, and ensure the objectivity, the fairness and the impartiality of the review result.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

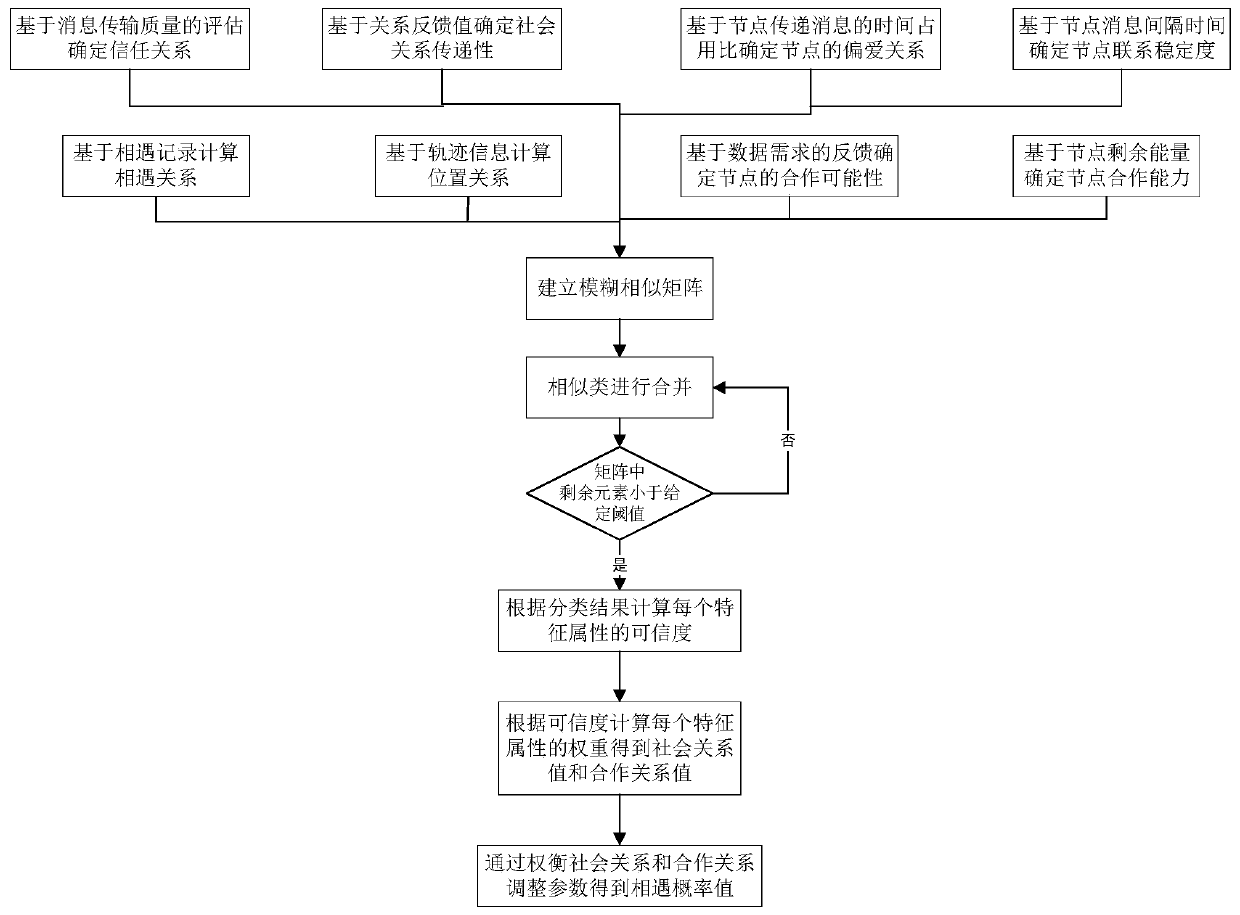

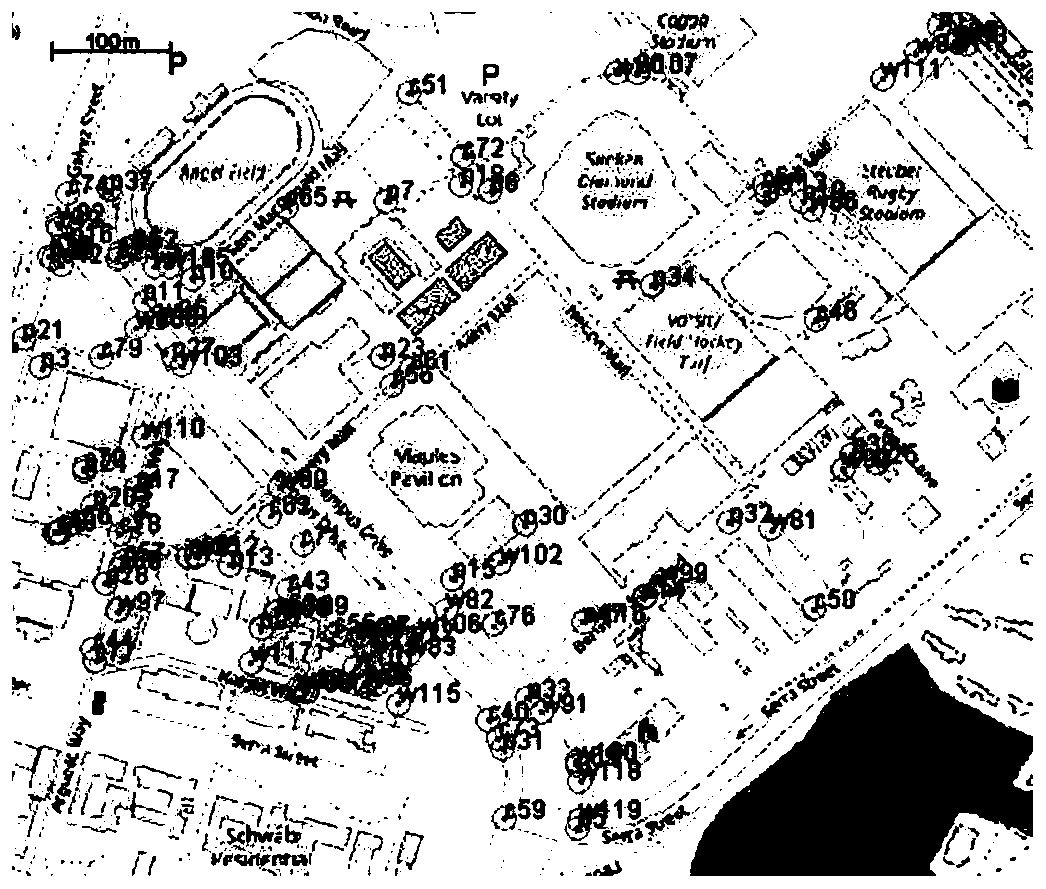

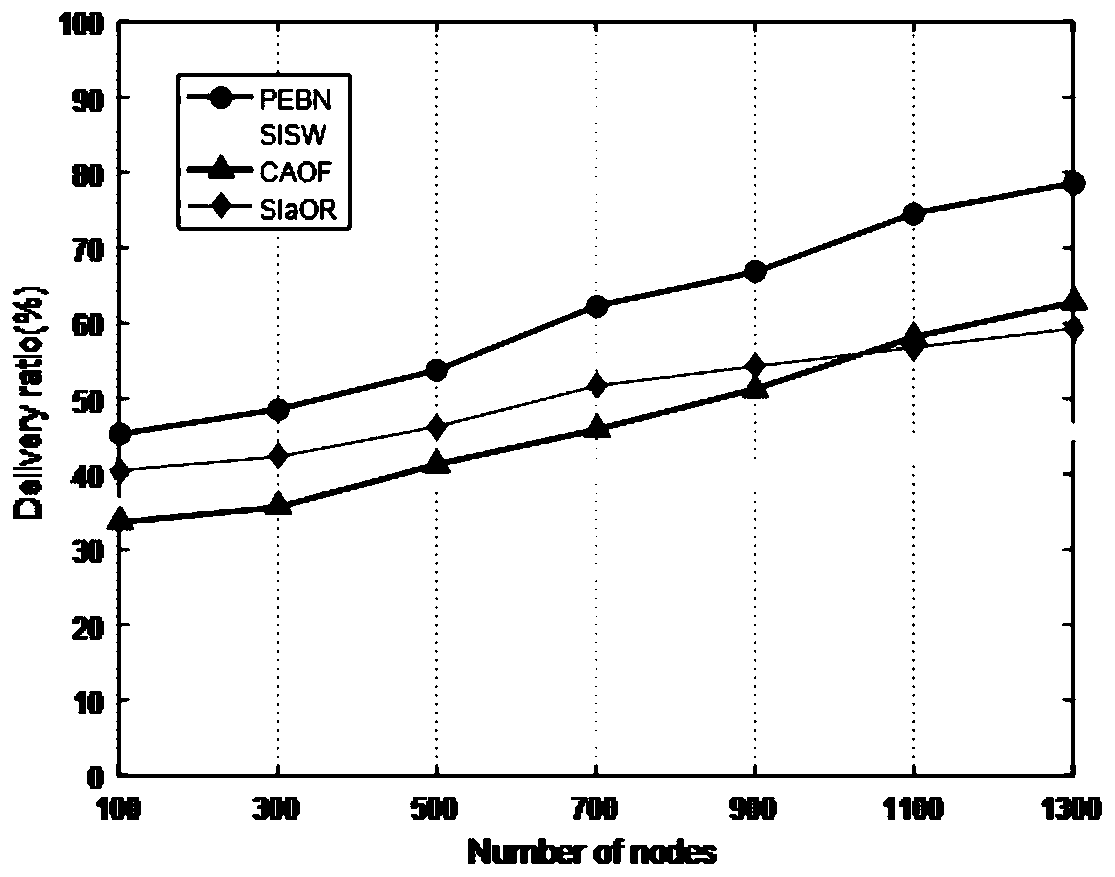

Method for predicting message passing node based on meeting probability of target node

ActiveCN110417572AReduce negative impactImprove performanceData switching networksMessage passingData transmission

The invention provides a method for predicting a message passing node based on the meeting probability of a target node. A fuzzy similarity matrix is established based on various relationship characteristics of nodes, different attributes of mobile nodes are deeply researched by forming the fuzzy similarity matrix, the social attribute change rule of the mobile nodes is mined, and the weights of the different attributes are dynamically and adaptively distributed. The social relationship and cooperation relationship of the nodes are further quantified. Finally, experiments verify that a good effect is achieved when the encountering model provided by the invention is used for screening the trusted node as the next hop node of data transmission, so that the data is always transmitted along the trusted cooperative node in the network, and meanwhile, the influence of malicious node non-cooperation on the performance of the network is reduced.

Owner:CENT SOUTH UNIV

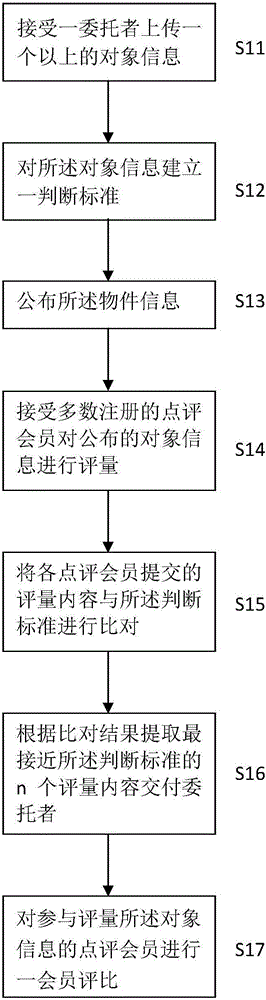

Internet-based object assessment method and system

InactiveCN106204132AIncrease specificationExpand the number of reviewsMarketingObjective assessmentInternet based

The invention relates to an internet-based object assessment method and system. The following steps are implemented mainly by a platform: accepting operation of uploading one or more pieces of object information by a consignor; establishing a judgment standard for the object information; publishing the object information; accepting operation of performing assessment on the published object information by registered commenting members; comparing assessment contents submitted by each commenting member with the judgment standard; and providing n pieces of the assessment contents closest to the judgment standard for the consignor. In addition, scoring, grading and / or rewarding is carried out according to the response time of the commenting members participating in the assessment and the approach degree between the assessment contents of the commenting members and the judgment standard; and an objective assessment result can be provided for the consignor by utilizing the technology, and the commenting members participating in the assessment can be rewarded due to the approach degree between the positivity of the commenting members participating in the assessment and the judgment standard, thereby providing an objective and high-credibility assessment interactive platform.

Owner:孙东耀

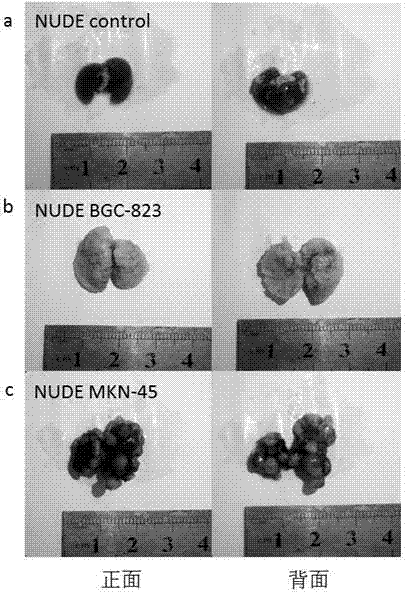

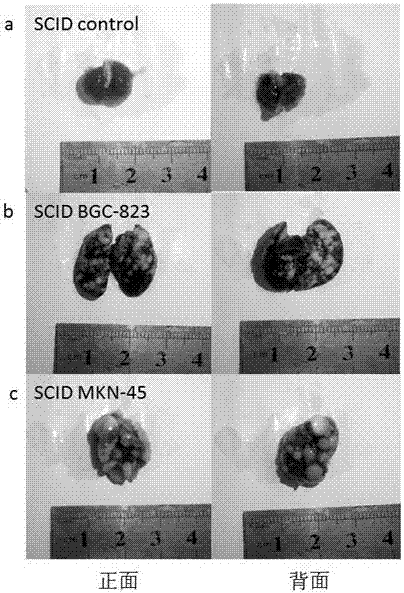

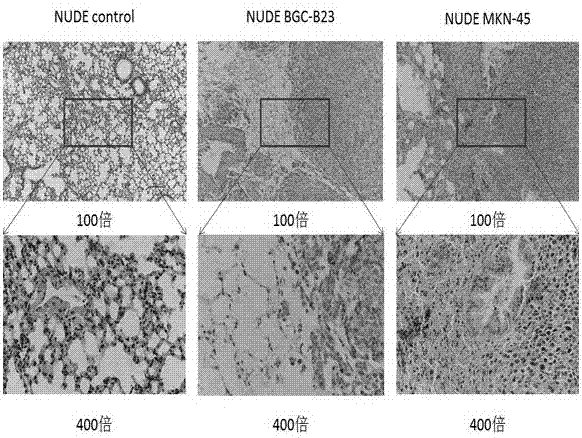

Mouse model with lung metastasis of gastric cancer and establishment method thereof

InactiveCN107006429AImprove transfer efficiencyAssessing the science of transfer methodsMammal material medical ingredientsMaterial analysisAbnormal tissue growthLymphatic Spread

The invention relates to a mouse model with lung metastasis of gastric cancer and an establishment method thereof, and belongs to the technical field of experimental animals. According to the mouse model and the establishment method thereof, BGC-823 and MKN-45 gastric cancer cells are cultured in vitro, and resuspended to a proper concentration with sterile PBS when the cell viability is strong. After the cells are cultured inside the body of immunodeficient NUDE and SCID mice inoculated in immunodeficience through the caudal vein, the mouse model with lung metastasis of gastric cancer is successfully obtained by the identifications including the statistics of surface lung nodules, HE staining and IHC staining. According to the mouse model establishment, needed experimental conditions and operation are simple and convenient, lung metastasis lesions after the experiment are obvious, metastasis efficiency is high, and mice with metastatic lesions have moderate survival cycles. In the evaluation and statistics of the metastasis results, the macroscopic counting of the lung nodules is improved into the microscopic counting of the IHC staining positive cells, thereby obtaining more objective and accurate results. The animal model of tumor metastasis may be widely used in scientific research and teaching.

Owner:JIANGSU UNIV

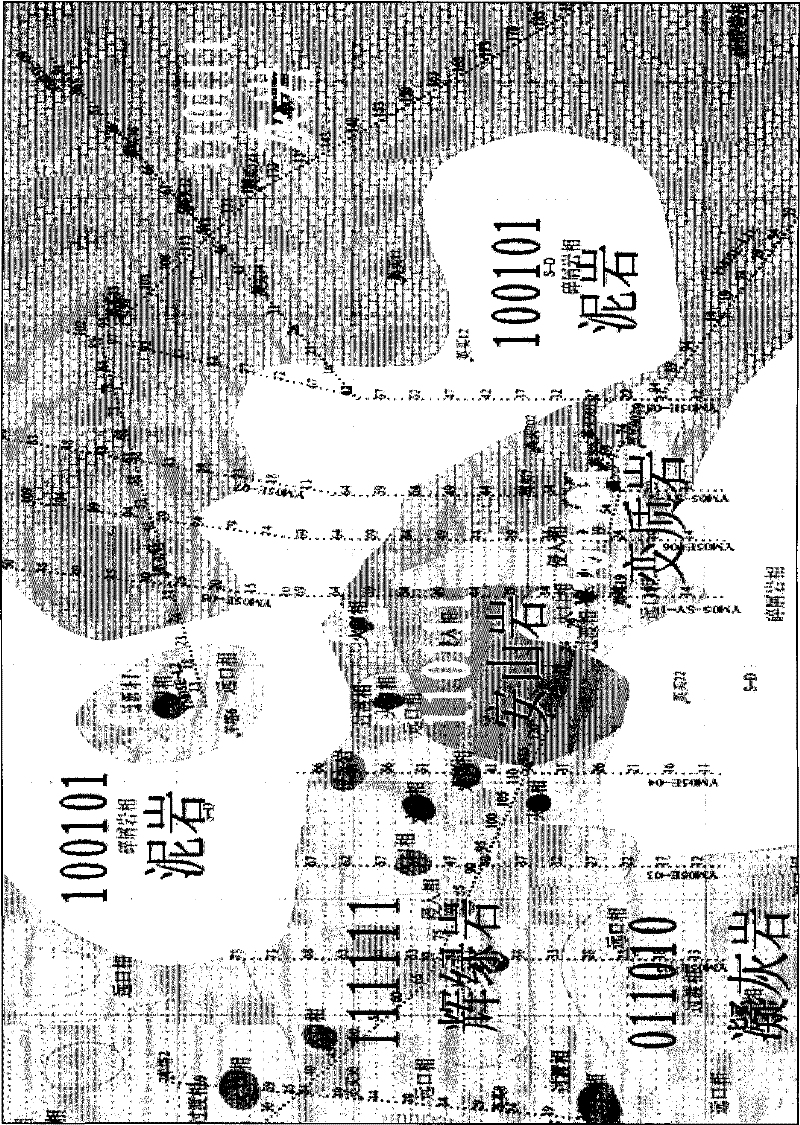

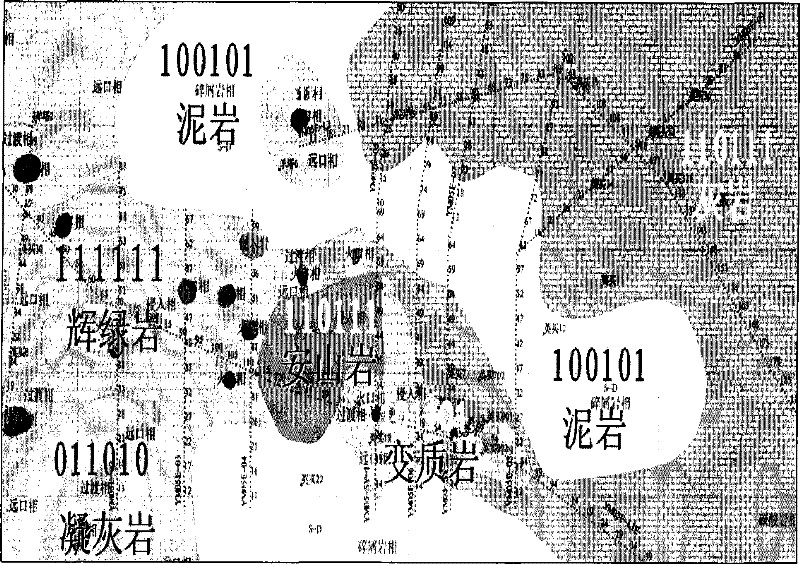

Method for recognizing the lithology of petrosilex by using the combined characteristics of gravity-magnetic-electronic anomaly

ActiveCN101520518BEasy to identifyReduce subjective factorsEarth material testingGeological measurementsLithologyMagnetic susceptibility

The invention provides a geophysical prospecting technical method for recognizing the lithology of petrosilex by using the combined characteristics of gravity-magnetic-electronic anomaly, which compriThe invention provides a geophysical prospecting technical method for recognizing the lithology of petrosilex by using the combined characteristics of gravity-magnetic-electronic anomaly, which compriulation to quantitative statistics, the invention reduces human subjective factors from experience, avoids the situation that different geological interpreters obtain different results and improveseculation to quantitative statistics, the invention reduces human subjective factors from experience, avoids the situation that different geological interpreters obtain different results and improvesthe recognition effect of petrosilex.the recognition effect of petrosilex.ses the following steps of collecting and recording the physical characteristics of drill core; carrying out cluster analysis on the density, magnetic susceptibility and resistivity of rock by using kses the following steps of collecting and recording the physical characteristics of drill core; carrying out cluster analysis on the density, magnetic susceptibility and resistivity of rock by using k-means clustering and obtaining the clustering code of the drill core; carrying out gravity and magnetic anomaly stripping to the gravity and magnetic prospecting result for obtaining the anomaly and-means clustering and obtaining the clustering code of the drill core; carrying out gravity and magnetic anomaly stripping to the gravity and magnetic prospecting result for obtaining the anomaly andadopting the same clustering to conduct three-dimensional anomaly coding; and combining the clustering code of the physical characteristics of rock with gravity-magnetic-electronic anomaly code for readopting the same clustering to conduct three-dimensional anomaly coding; and combining the clustering code of the physical characteristics of rock with gravity-magnetic-electronic anomaly code for reflecting the lithology of each petrosilex in an exploratory area. By developing the method for recognizing the lithology of petrosilex by using integral gravity-magnetic-electronic from qualitative spflecting the lithology of each petrosilex in an exploratory area. By developing the method for recognizing the lithology of petrosilex by using integral gravity-magnetic-electronic from qualitative spec

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

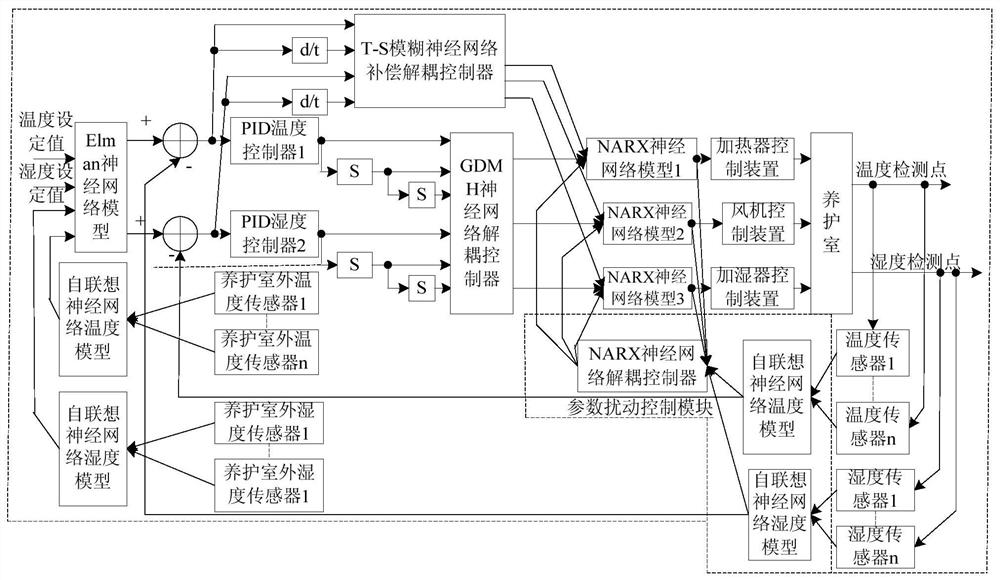

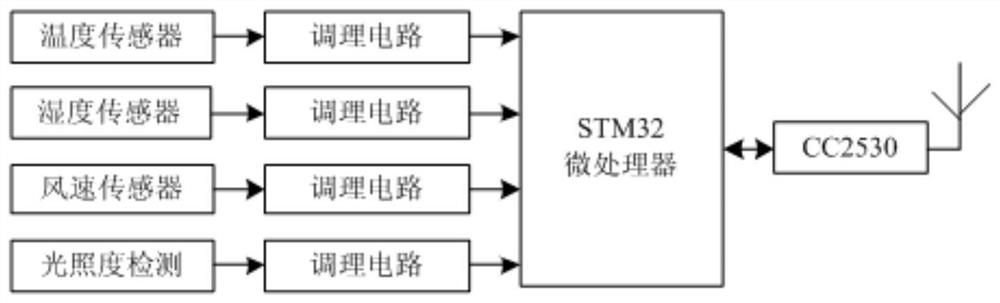

Building material curing room environment intelligent system

PendingCN113065749AImprove accuracyImprove calculation accuracyNeural architecturesResourcesBuilding materialEnvironmental geology

The invention discloses a building material curing room environment intelligent system, which consists of a curing room environment parameter acquisition and control platform and a curing room parameter intelligent decoupling control subsystem, and is used for detecting and managing internal and external environment parameters of a curing room and accurately adjusting the environment parameters of the curing room. According to the invention, the problems that the environment of the existing curing room is not influenced by nonlinearity and large lag of the change of the environment parameters inside and outside the curing room, large and complex area of the environment inside and outside the curing room and the like, the environment parameters inside and outside the curing room are not predicted and accurately detected and decoupled, and then environmental parameter adjustment and production management of the curing room are greatly influenced are effectively solved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

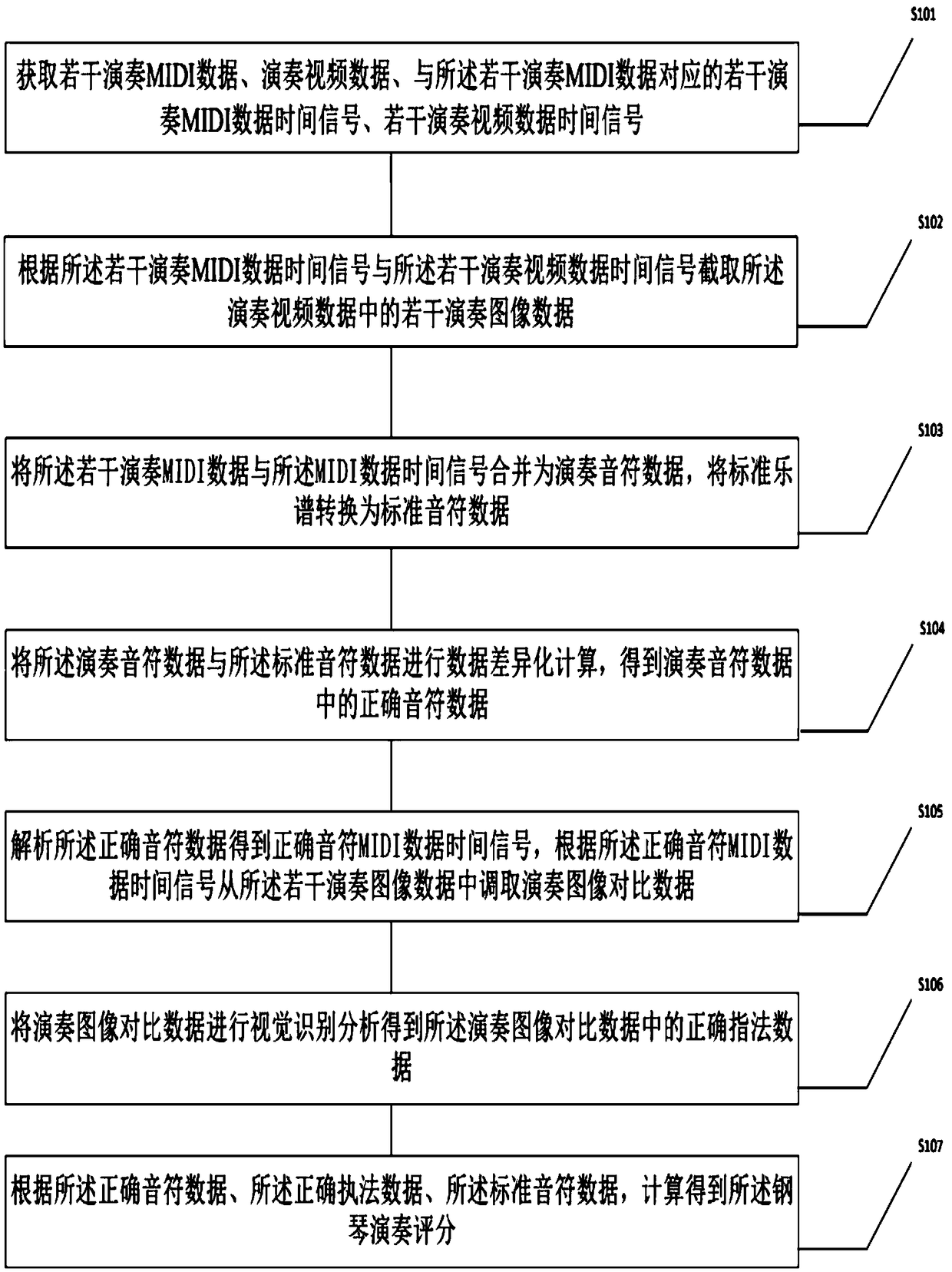

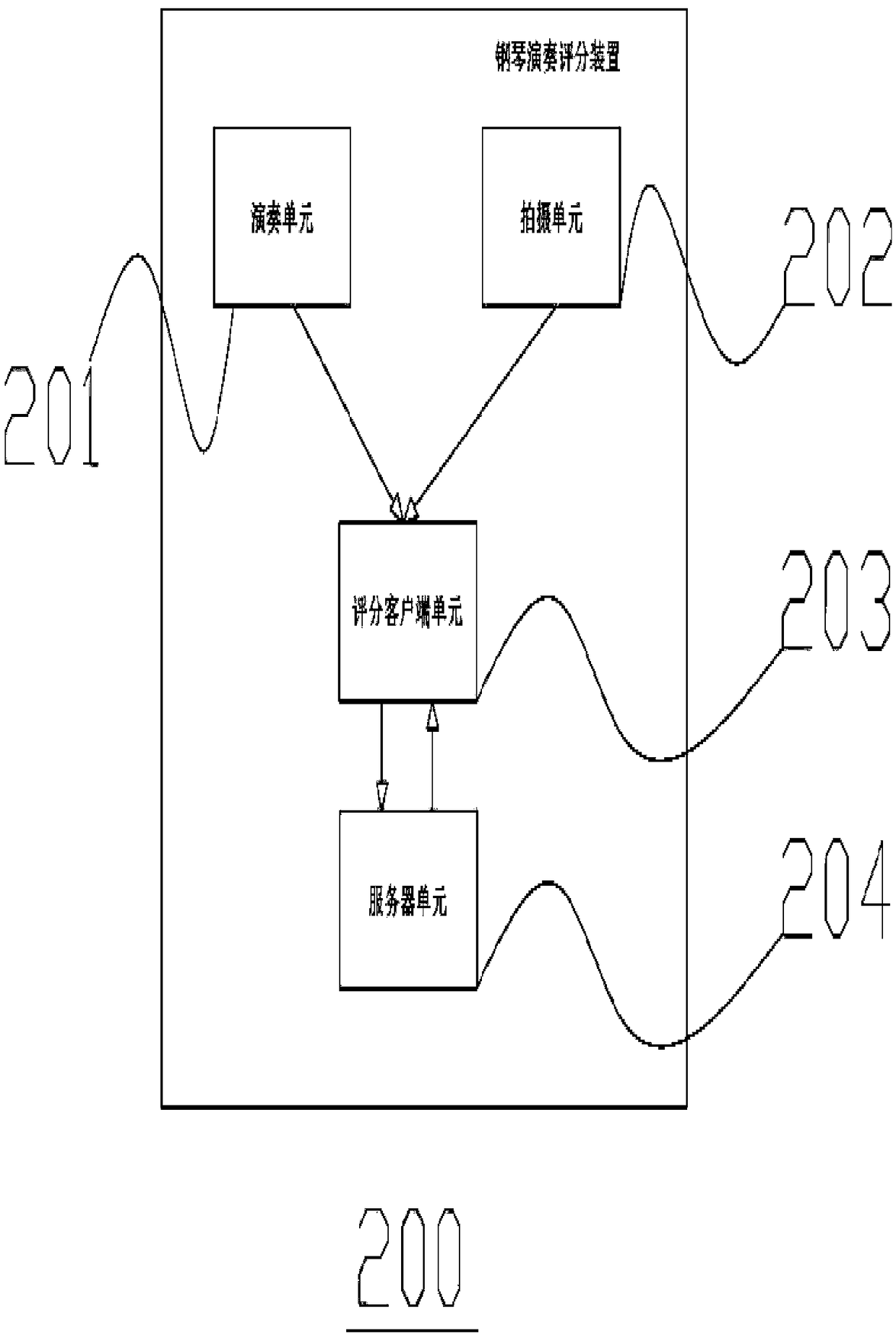

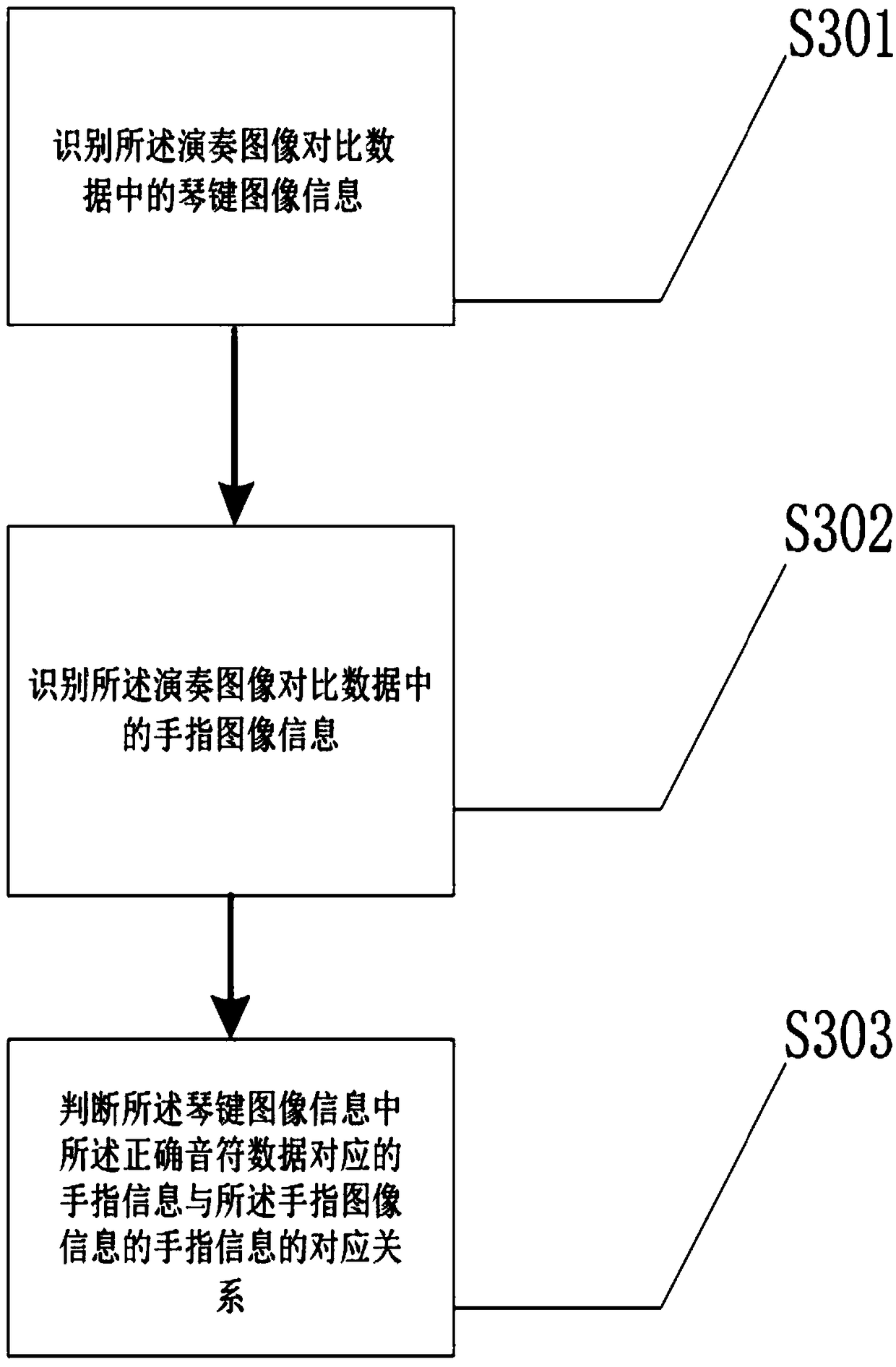

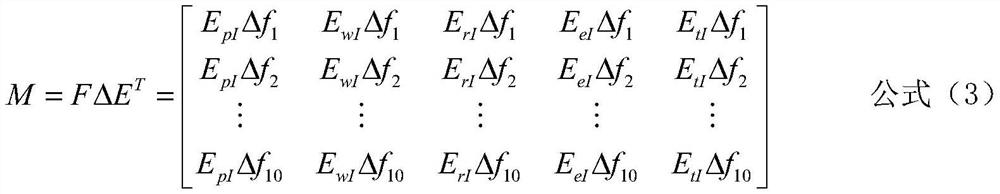

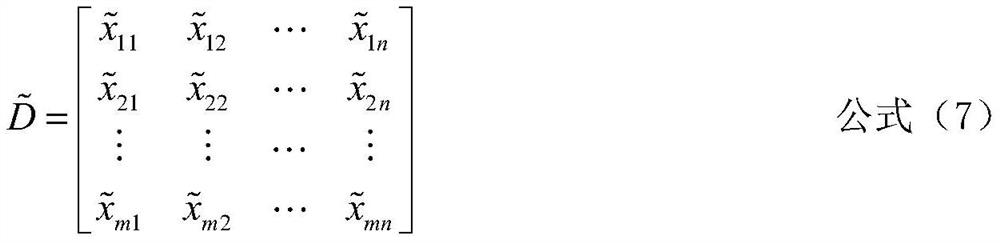

Piano performance scoring method, device and computer storage medium

ActiveCN109344794AReduce dependenceEasy to trace backElectrophonic musical instrumentsCharacter and pattern recognitionPianoData profiling

the invention discloses a piano performance scoring method, device and computer storage medium. The method comprises following steps: obtaining playing MIDI data, playing video data, playing the MIDIdata time signal, Play Video Data Time Signal, processing The four kinds of data and comparing the data with the standard note data converted from the standard score, and analyzing the data. Finally,judging the correctness of the notes and fingering of the examinee. Combining with the difficulty of the examinee, the piano performance of the examinee is scored. Apparatus for applying the method comprises: A playing unit for generating playing MIDI data, a shooting unit for shooting playing video data, a scoring client unit for receiving, storing, and transmitting playing MIDI data and playingvideo data, and a server unit for judging the correctness of a candidate's note and fingering and feeding back the scoring result.

Owner:SHENZHEN MICROBLUE INTELLIGENCE TECH CO LTD

Multi-procedure process reliability quantitative modeling method

PendingCN112800585AReduce subjective factorsThe evaluation result is accurateDesign optimisation/simulationInference methodsProcess qualityProcess failure

The invention discloses a multi-procedure process reliability quantitative modeling method. The method comprises the following specific steps: step 1, identifying a process failure mode; step 2, evaluating a process failure mode, and finding out quality characteristics of a key process; step 3, constructing a mapping relation between the process factors and key process quality characteristics; and step 4, carrying out modeling on the process reliability. The method can be applied to multi-process manufacturing quality analysis and evaluation of products such as turbine engines with complex structures, and the problem of manufacturing quality analysis of complex and multi-process products can be solved.

Owner:BEIJING POWER MACHINERY INST

Identification method of indoor fire site or fire point

InactiveCN104458782AReduce controversyReduce subjective factorsMaterial analysis by measuring secondary emissionFire pointComputer science

The invention discloses anidentification method of an indoor fire site or fire point. The method comprises the following steps: firstly initially identifying a suspected fire site or fire point; by taking the initially identified suspected fire site or fire point as a center, selecting points and collecting checked materialsat an equal interval according to the outward symmetrical diverging direction, and confirming samples; performing the comparative analysis of components of ashes at the suspected fire sites and the collected samples in the diverging direction through an electron microscopy-energy spectrum analyzer, thereby confirming the fire spreading direction; and finally, selecting more than or equal to three fire spreading directions, if an intersection of extension lines of directions opposite to the fire spreading directions is overlapped with the initially identified suspected fire site or fire point, identifying that the initially identified suspected fire site or fire point is the fire site or fire point.

Owner:JIANGSU POLICE INST

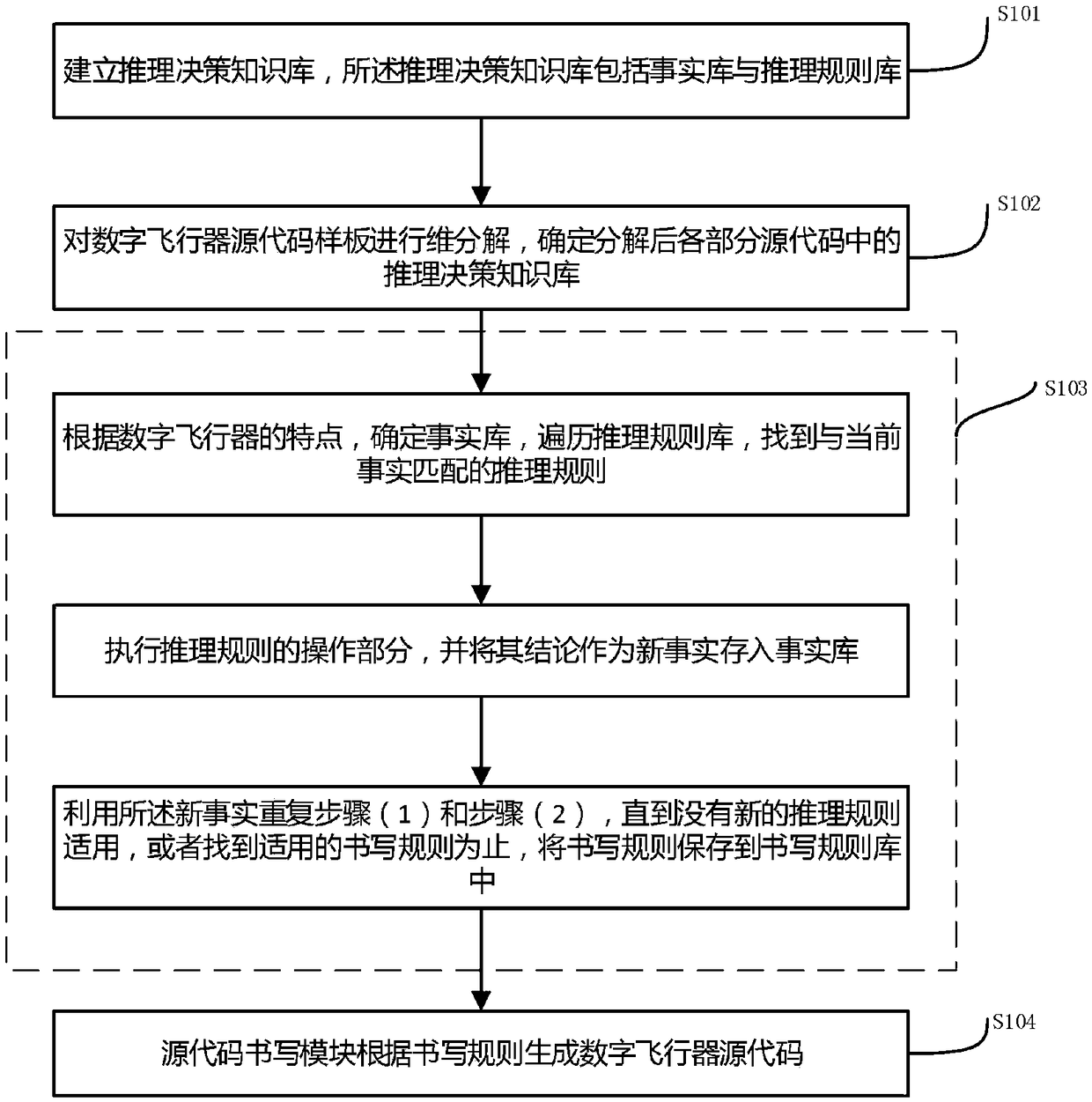

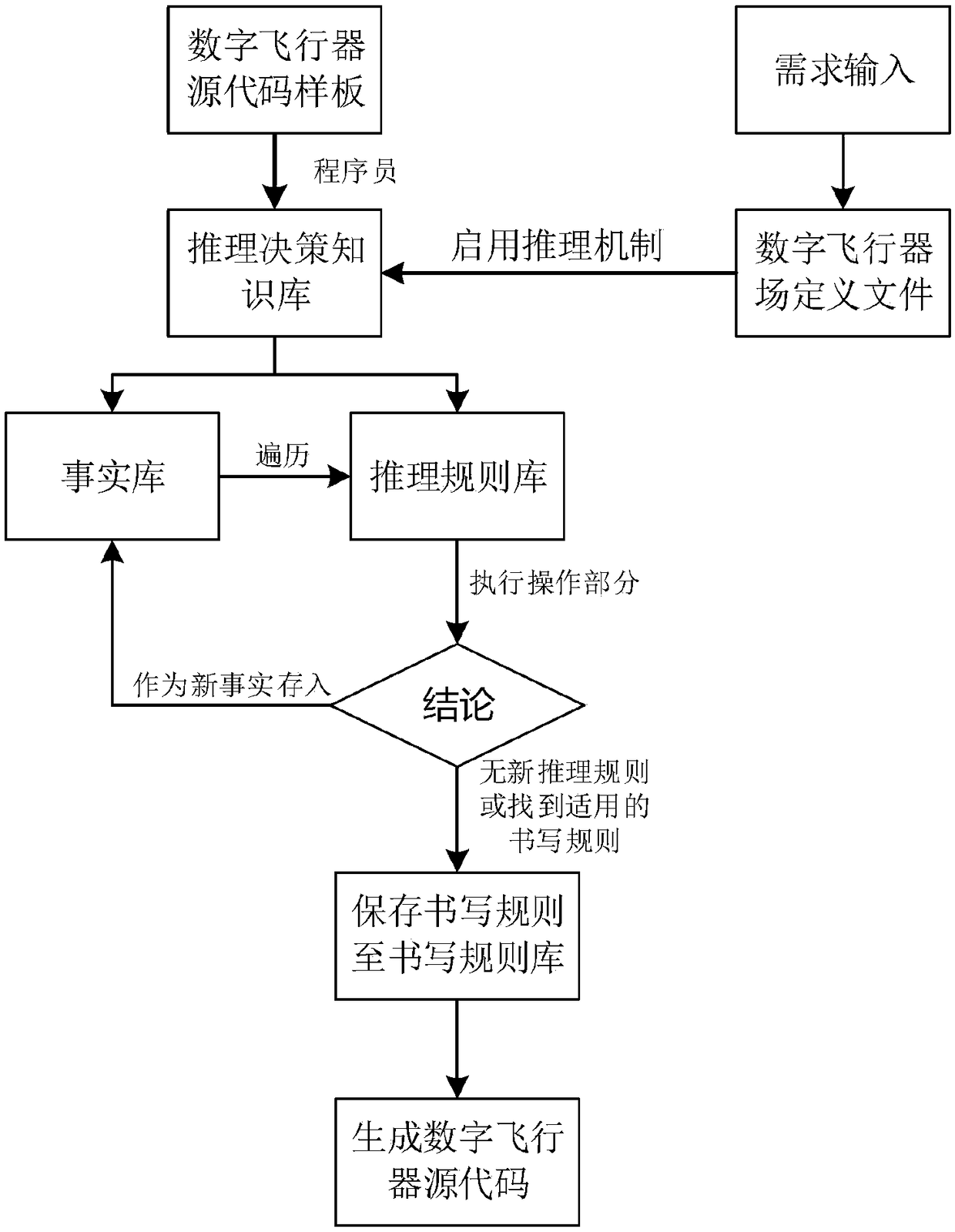

Reasoning decision method for digital aircraft source code written by artificial intelligence programmer

ActiveCN108304624AReduce subjective factorsWork lessGeometric CADCharacter and pattern recognitionAlgorithmDecomposition

The invention discloses a reasoning decision method for a digital aircraft source code written by an artificial intelligence programmer. The method comprises the following steps that: establishing a reasoning decision knowledge base, wherein the reasoning decision knowledge base comprises a factbase and a reasoning rule library; carrying out dimension decomposition on the sample plate of the digital aircraft source code, and determining the reasoning decision knowledge base in each part of decomposed source code; according to the input of the digital aircraft, starting a reasoning mechanism; and according to a writing rule, generating the digital aircraft source code by a source code writing module. By use of the method, the decision process of a human written program is decomposed, the important decision process of digital aircraft source code development is intelligentized according to the character of each part, the subjective factor of people in the digital aircraft source code isreduced, the repeated development work of people is avoided, and program development efficiency is improved.

Owner:BEIHANG UNIV

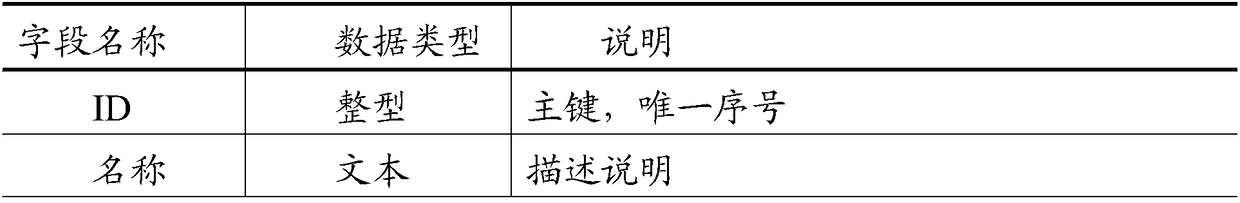

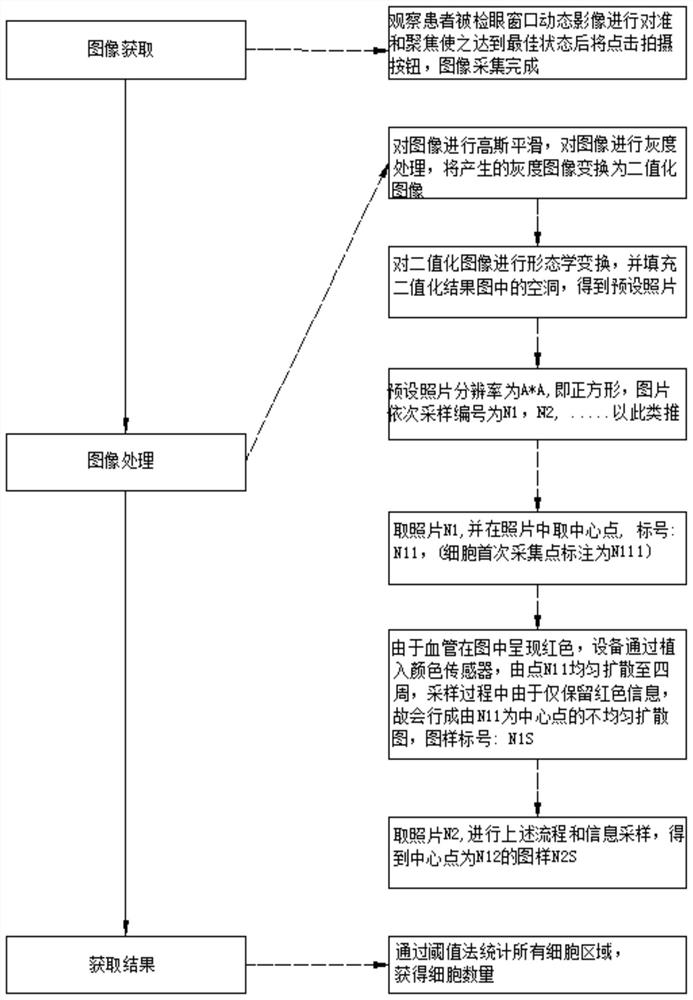

Corneal endothelial cell counter positioning and photographing method based on iris characteristics

PendingCN112200873AReduce subjective factorsConvenient labelingImage enhancementImage analysisCorneal endothelial cellBinary image

The invention relates to the technical field of cell counting and acquisition, in particular to a corneal endothelial cell counter positioning and photographing method based on iris characteristics, which comprises the following steps: S1, acquiring an image: observing a dynamic image of a detected eye window of a patient, aligning and focusing to reach an optimal state, and clicking a photographing button to finish image acquisition; and S2, image processing: S201, performing Gaussian smoothing on the image, performing gray processing on the image, and converting the generated gray image intoa binary image. According to the invention, gray scale change, de-noising, binarization change and morphological change are carried out on the cell image, subjective factors in cell morphological observation are reduced, point locations are conveniently marked in the pattern, a color sensor is added to conveniently carry out vertical comparison on the sampled image, a first marked point locationis conveniently found in N different front and back photos, and therefore, cell sampling can be carried out on the overlapped position.

Owner:郑州诚优成电子科技有限公司 +1

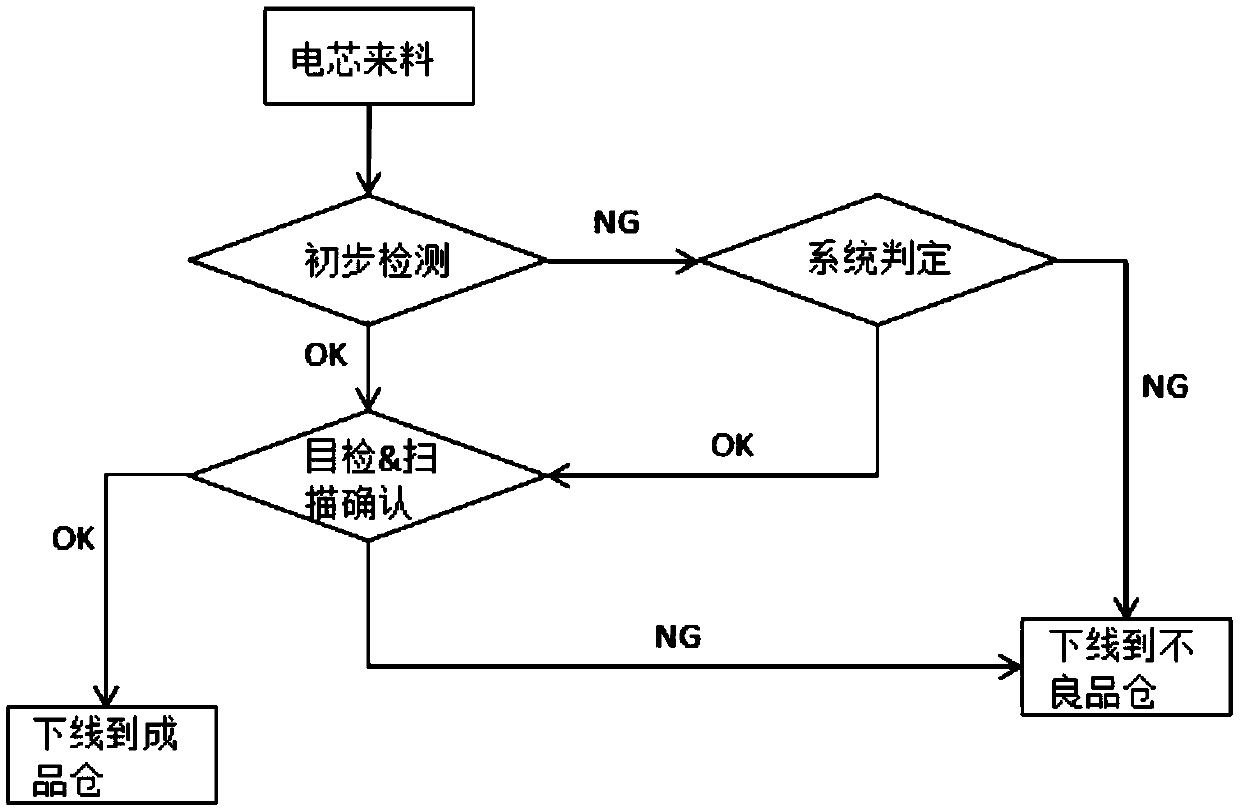

X-Ray- based battery cell detecting method

InactiveCN109655472AAvoid mixingImprove qualityOptically investigating flaws/contaminationMaterial analysis by transmitting radiationManufacturing technologyVirtual screen

The invention belongs to the technical field of battery cell manufacturing, and particularly relates to an X-Ray-based battery cell detecting method. The X-Ray- based battery cell detecting method comprises the following steps: S1, preliminary detection: carrying out automatic preliminary X-detection on battery cells by an X-Ray machine, and transferring the qualified battery cells to a visual detection area, and the unqualified battery cell entering the next step of detection; S2, system judgment: calling the picture information of the unqualified products in the S1, generating a virtual screen ruler, detecting the battery cells by using the screen ruler, and transferring the battery cell which is detected to be qualified to a visual inspection area; S3, visual inspection: carrying out visual inspection on the battery cells transferred in the S1 and the S2, and discharging the battery cells passing the visual inspection to a finished product warehouse; S4, reinspection: carrying out X-ray inspection again before delivery of the battery cells. Through the above steps, unqualified battery cells are effectively prevented, the quality of the battery cells is improved. The judgment ofa system is objective, and subjective factors of manual inspection are reduced. In addition, the production efficiency is improved, and the production cost is saved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

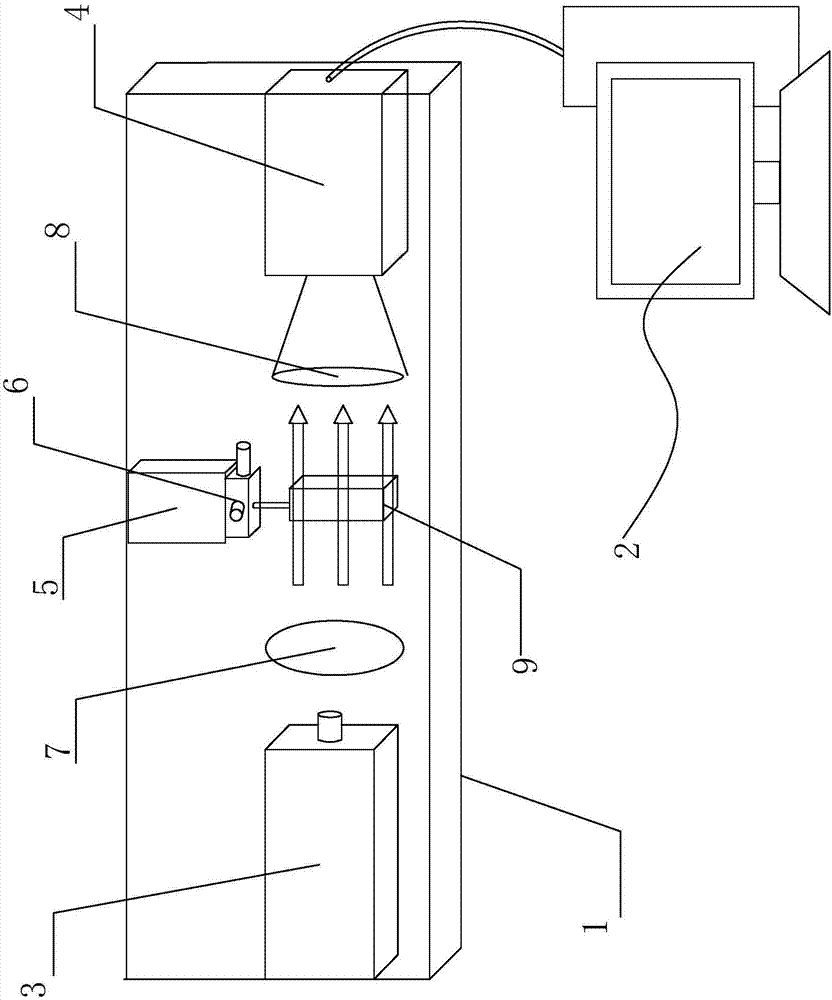

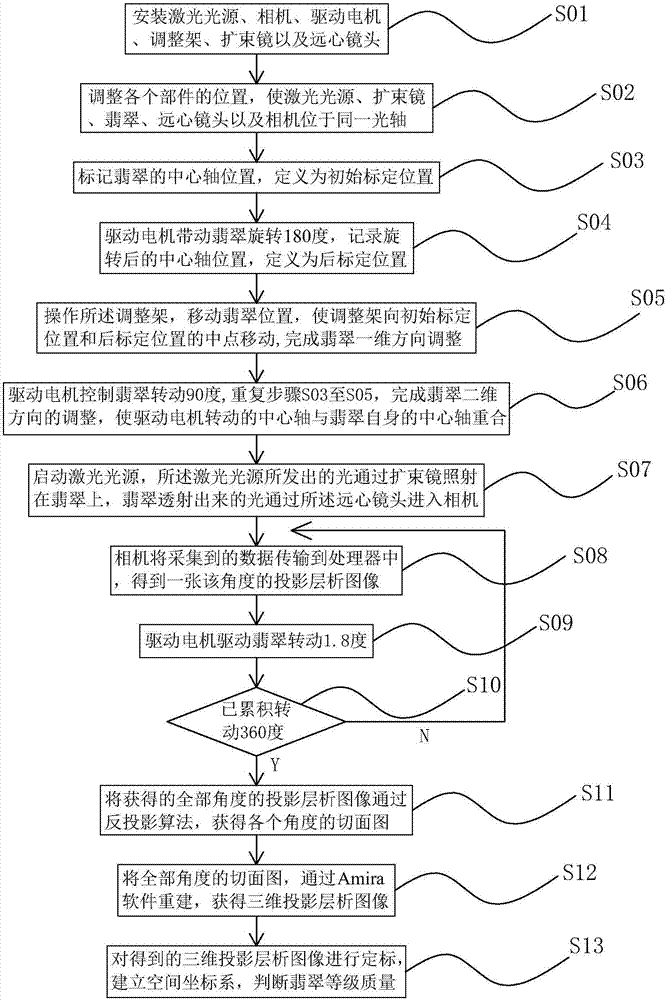

Jade 3D imaging detection device and detection method thereof

InactiveCN107219228AImprove accuracyReduce human subjective factorsInvestigating jewelsLaser lightDrive motor

The invention discloses a jade 3D imaging detection device including a device casing, a processor, a laser light source, a camera and a driving motor, the output end of the processor is connected with the driving motor, the input end of the processor is connected with the camera, the laser light source and the camera are respectively arranged in two opposite inner sides of the device casing, the driving motor drives the rotation of jade, and the jade, the laser light source and the camera are in the same optical axis. The laser light source produces a light beam, the light beam transmits the camera by the jade, captured image data is transferred by the camera to the processor for image processing to achieve internal 3D image reconstruction of the jade, and by a 3D image, the grade quality of the jade can be easily determined, accuracy is high, artificial subjective factors are few, and at the same time, the jade 3D imaging detection device has the advantages of low cost and high cost performance.

Owner:FOSHAN UNIVERSITY

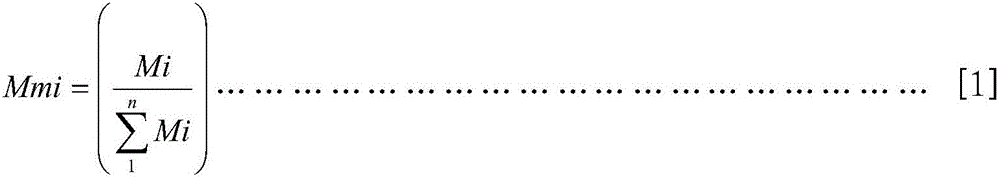

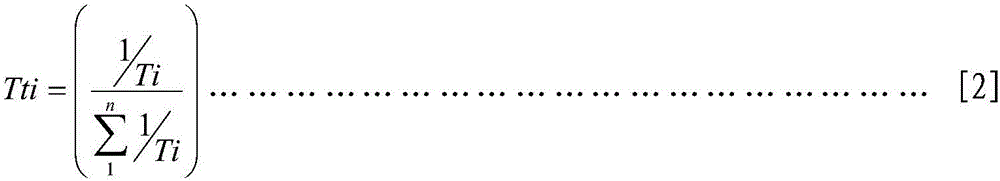

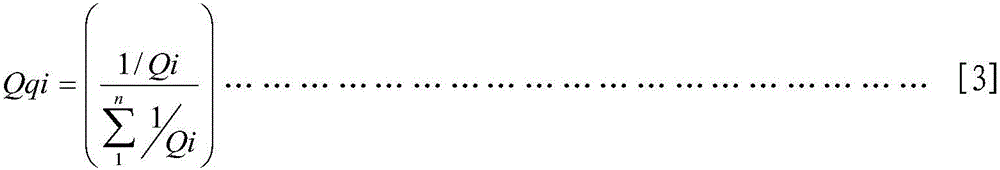

Method for determining transport task index weights of helicopters

The invention belongs to a helicopter assessment technology and relates to a method for determining transport task index weights of helicopters. The method for calculating the transport task index weights of the helicopters is characterized by comprising the following steps of performing transport performance capacity sorting of helicopters same in type; performing transport task simulation experiments of the helicopters; determining a group of transport performance index weight values; determining effective index weight values; and determining a transport performance index weight range. According to the method for determining the transport task index weights of the helicopters, provided by the invention, subjective factors are reduced and the accuracy of an assessment result is improved; and not only relative comparison but also difference degree of helicopter performance can be given.

Owner:CHINA HELICOPTER RES & DEV INST

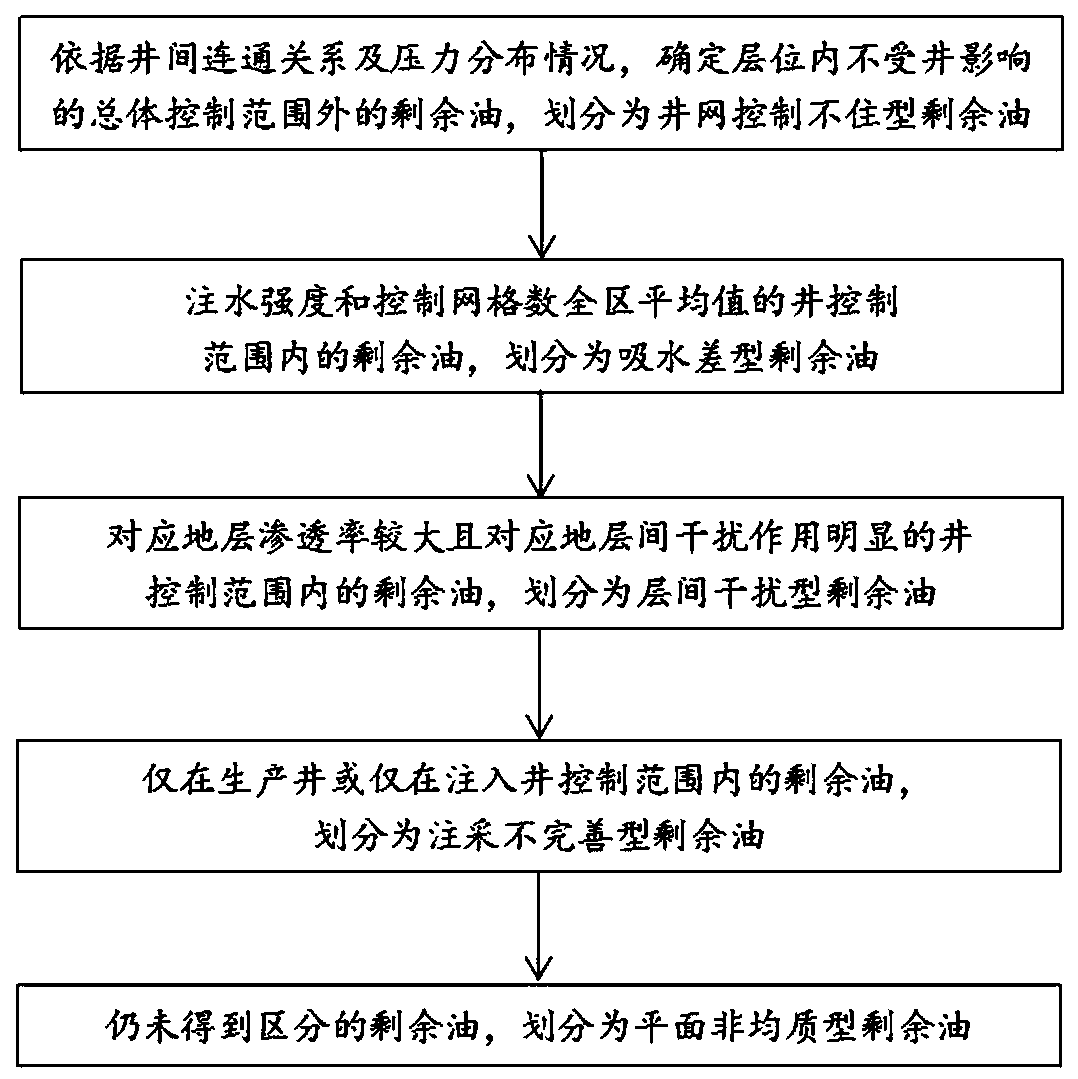

A method for quantitatively dividing remaining oil of an oil field in a high water cut period

ActiveCN109726946AMeet the actual needs of the siteEnhanced overall recoveryResourcesHorizonNetwork control

The invention belongs to the technical field of oil exploitation, and particularly relates to a method for quantitatively dividing remaining oil of an oil field in a high water cut period, which comprises the following steps of: 1, determining remaining oil outside an overall control range which is not influenced by a well in a horizon according to a well-to-well communication relationship and a pressure distribution condition, and dividing the remaining oil into well network control incapable remaining oil; 2, dividing the water injection intensity into water absorption difference type residual oil when the water injection intensity is smaller than the whole average water injection intensity and the single well control area is smaller than the average single well control area; 3, screening out one third of the production well and the injection well with higher corresponding stratum permeability, analyzing the liquid production amount and the water injection amount of the production well and the injection well, and dividing the liquid production amount of the corresponding stratum into interlayer interference type remaining oil if the liquid production amount of the corresponding stratum can reach half of the water absorption amount; 4, finding out residual oil only in the control range of the production well or the injection well, and dividing the residual oil into injection-production imperfect residual oil; 5, If after step 1-4, the remaining oil that has not been distinguished, classifying the remaining oil as a planar heterogeneous residual oil..

Owner:NORTHEAST GASOLINEEUM UNIV

Optimization method of variogram model in spatio-temporal estimation of forest site index

ActiveCN106372277BAchieve integrationReduce human subjective factorsDesign optimisation/simulationSpecial data processing applicationsBox modelEngineering

Owner:XINJIANG AGRI UNIV

Multifunctional pupil pen

PendingCN113598702AReduce subjective factorsImprove accuracySensorsEye diagnosticsInfraredEmergency treatment

The invention provides a multifunctional pupil pen. The multifunctional pupil pen comprises a pupil pen assembly, an infrared temperature measuring assembly and a pulse and blood oxygen assembly. The pupil pen assembly can display the size of a pupil on a pupil display surface and also can observe numbers on an aperture matched with the pupil; the infrared temperature measuring assembly can display the body temperature on a body temperature display surface; and the pulse and blood oxygen assembly can display pulse and blood oxygen on a pulse display surface and a blood oxygen display surface respectively, so that a medical staff can perform observation conveniently. When a certain vital sign is not in a normal range, a warning lamp representing the vital sign flickers to prompt that close monitoring is needed, and emergency treatment measures are given. An infrared temperature sensor measures the body temperature in a non-contact mode, so that cross infection can be prevented; and the influence of dust, liquid and the like on the sensitivity of the sensor can be prevented by tightly buckling a first dustproof cover. After the pulse and blood oxygen of a patient are measured and a second dustproof cover is buckled, a disinfection core can fully disinfect a first clamping piece and a second clamping piece, so that cross infection is prevented, and the safety of the patient is ensured.

Owner:苗建磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com