Fuzzy theory-based process failure mode identification and evaluation method

A technology of process failure and fuzzy theory, applied in the field of mechanical processing, can solve problems such as inaccurate semantic quantification of experts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] The rotor system of an aerospace engine is an important engine subsystem, and its assembly quality has a significant impact on the vibration performance and performance of the whole machine. A good rotor system assembly process is the basis for ensuring the quality characteristics of the rotor system such as coaxiality and initial unbalance. Therefore, the present invention takes the assembly process of the aerospace engine rotor system as an example to verify the above-mentioned PFMEA method.

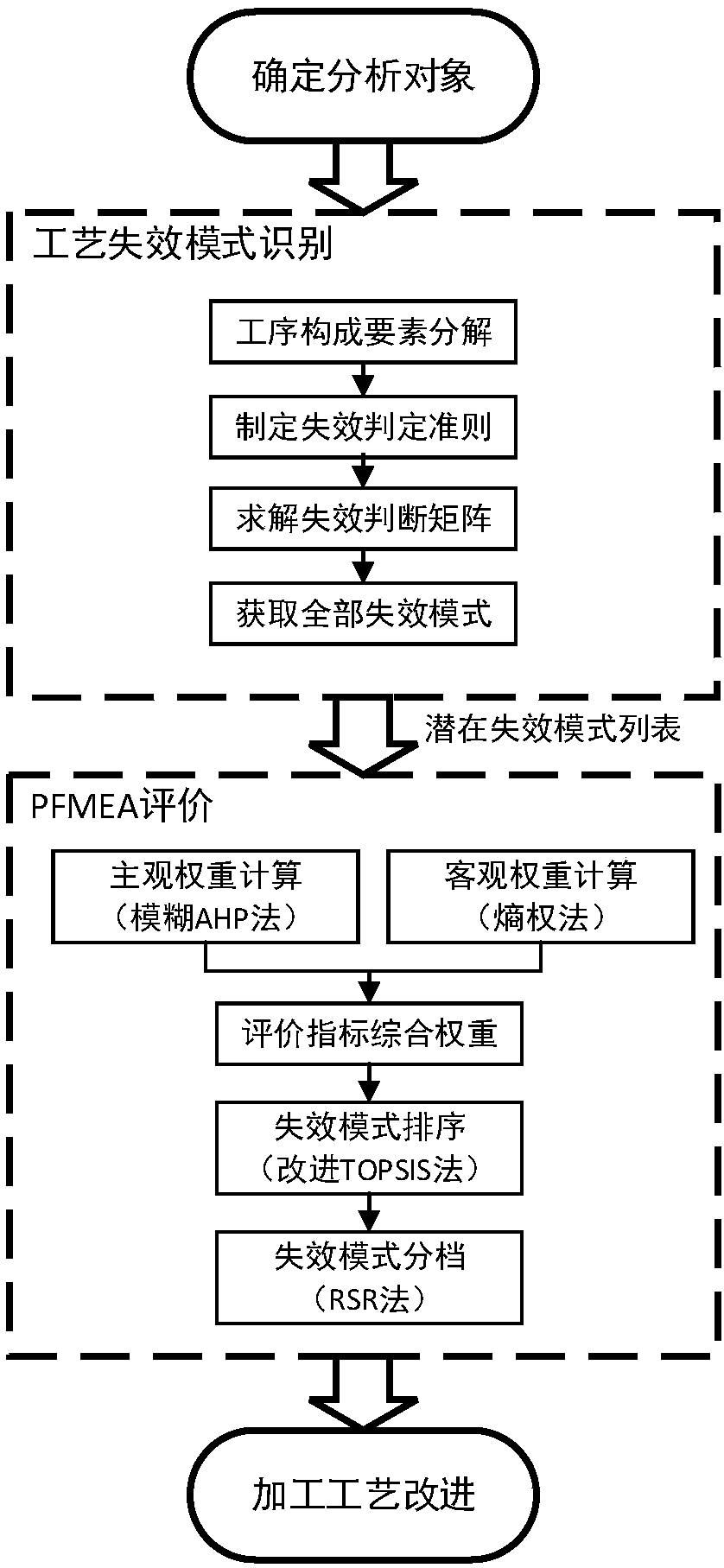

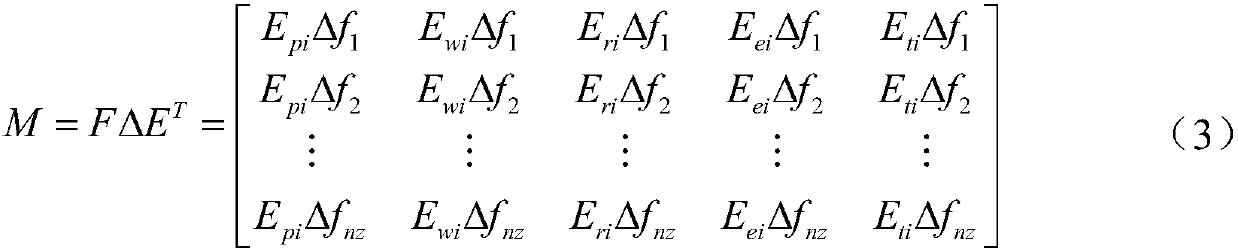

[0121] Step 1: Based on the decomposition of process components and combined with process failure judgment criteria, solve the failure judgment matrix to realize the identification of process failure modes.

[0122] Step 1-1: Decomposition of process components.

[0123] First, according to the assembly process of the rotor system, the decomposition of the process elements is completed, as shown in Table 5:

[0124] Table 5 Rotor assembly process and decomposition of process e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com