Multi-procedure process reliability quantitative modeling method

A modeling method and reliability technology, applied in the direction of reasoning method, design optimization/simulation, special data processing application, etc., can solve problems such as complex multi-process product manufacturing quality analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] Examples are given below to describe the present invention in detail.

[0129] This embodiment provides a multi-process process reliability quantitative modeling method, and the specific steps of the method are as follows:

[0130] Step 1, identifying process failure modes;

[0131] Step 2. Evaluate process failure modes and find key process quality characteristics;

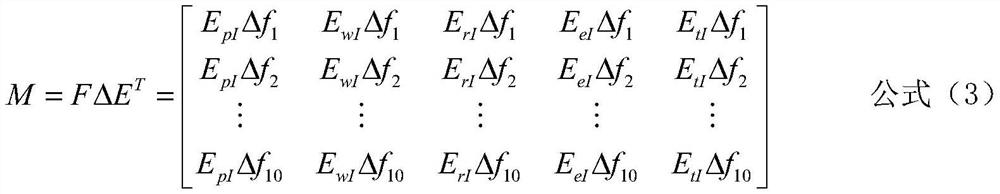

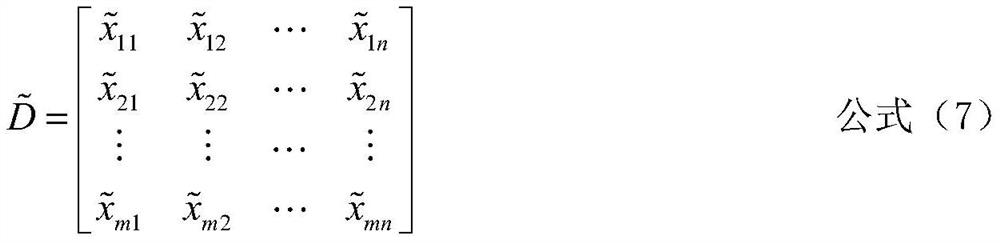

[0132] Step 3, constructing the mapping relationship between process factors (5M1E) and key process quality characteristics;

[0133] Step 4, modeling the process reliability;

[0134] Among them, in step 1, the specific steps for identifying the process failure mode are as follows:

[0135] Step 1-1, decompose the constituent elements of the process:

[0136] Decompose the process constituent elements of any process in the product manufacturing process according to process requirements, execution results, resource requirements, execution environment and detection control; let any one of the processes be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com