Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Reduce stamping costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

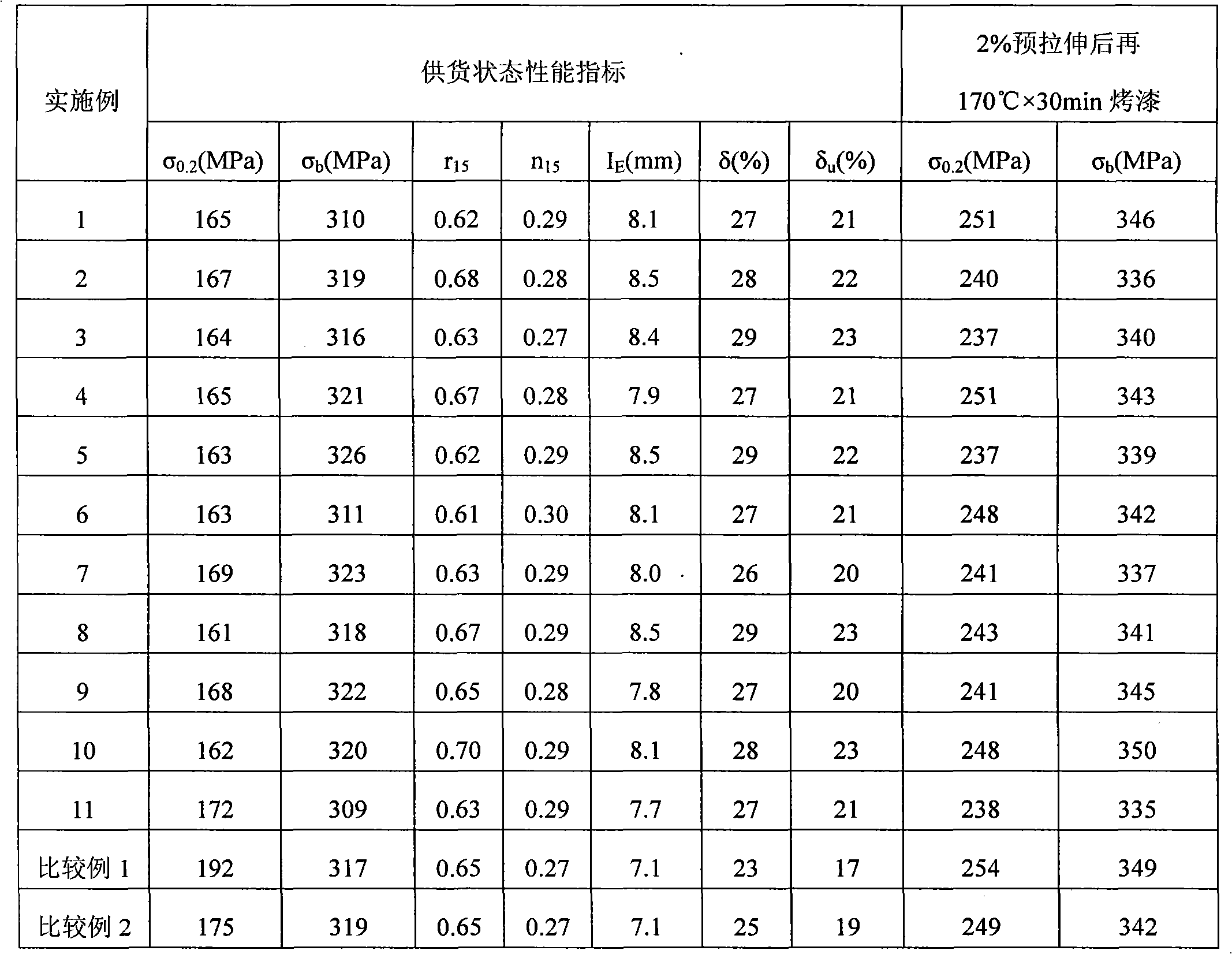

Aluminum alloy for automobile body of automobile and plate manufacturing method thereof

The invention relates to an aluminum alloy for an automobile body of an automobile and a plate manufacturing method thereof and belongs to the technical field of aluminum alloy. The alloy comprises the following components in percentage by weight: 0.6 to 1.33 percent of Mg, 0.6 to 1.33 percent of Si, 0.3 to 0.7 percent of Cu, less than or equal to 0.3 percent of Zn, less than or equal to 0.15 percent of Fe, 0.2 to 0.8 percent of Mn, 0.01 to 0.3 percent of Cr, 0.01 to 0.3 percent of Ti and the balance of Al, wherein the mass fraction ratio of Mg to Si is 1; the total content of the mass fractions of Mn, Cr and Ti alloy elements is more than or equal to 0.3 percent; and Cu content is more than or equal to 0.3 percent. The method for manufacturing the aluminum alloy for the automobile body of the automobile comprises the following steps of: (1) smelting the alloy; (2) shaping the alloy by casting; (3) performing pre-nucleation treatment; (4) performing homogenization treatment; (5) performing hot rolling; (6) performing intermediate annealing; (7) performing cold rolling; (8) performing solid solution water quenching treatment; (9) standing a product at room temperature; and (10) performing pre-ageing and standing the product at the room temperature for more than two weeks. The aluminum alloy and the method are characterized in that: an alloy casting process and a plate production process of the invention are simple and convenient to control; an alloy plate of the invention has high intensity and excellent stamping forming property; and the stamping yield of a covering part for the aluminum alloy automobile body can be effectively enhanced and stamping cost is lowered.

Owner:NORTHEASTERN UNIV

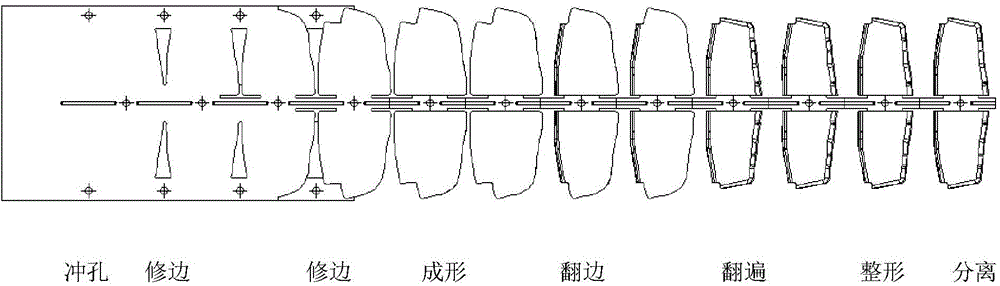

Forming process of punching die beam piece

InactiveCN101829727AReduce lossReduce stamping costsLoad-supporting pillarsInstabilityForming processes

The invention relates to the field of punching dies, in particular to a forming process of a punching die beam piece. The method comprises the following steps of: 1. expanding the material of a workpiece to obtain rough material initial dimensions, wherein the dimensions are controlled to be less than 1-5mm; carrying out debugging with the initial material of the shape to obtain a blanking line of the workpiece; and arranging blanking stock layouts according to the shape to manufacture a blanking die; 2. forming: debugging the creases, the cracks, the overlaps, the instability and the surface quality of the workpiece; 3. side reshaping: reshaping the whole profile, and correcting the springback of the last process; and 4. trimming and punching holes: punching the hole of the workpiece and trimming.

Owner:YESUN SHANGHAI MOLD +2

A Progressive Die for Double Hole Shielding Cover

The invention relates to the technical field of dies, in particular to a double-hole shielding cover progressive die. The double-hole shielding cover progressive die comprises an upper die holder, an upper die, a stripper plate, a lower die, a lower die holder, and a punching pilot hole station, a half sectioning station, a stretching station and a shielding cover punching-off station which are assembled correspondingly, wherein the upper die, the stripper plate and the lower die are correspondingly assembled with the punching pilot hole station, the half sectioning station, the stretching station, a double-side punching station, a bilateral hole turnup station, a first turnup flattening station, a second turnup flattening station, a punching side notch station and the shielding cover punching-off station which are formed sequentially. During actual production, production can be performed only by placing a material belt on the lower die, all the procedures are finished in the die, andfull automation of the whole flow is realized, so labor cost is reduced, the defective rate of the shielding covers is low, production efficiency is high, and the double-hole shielding cover progressive die is suitable for production of the shielding cover with side holes on the two sides.

Owner:DONGGUAN DAZHONG ELECTRONICS

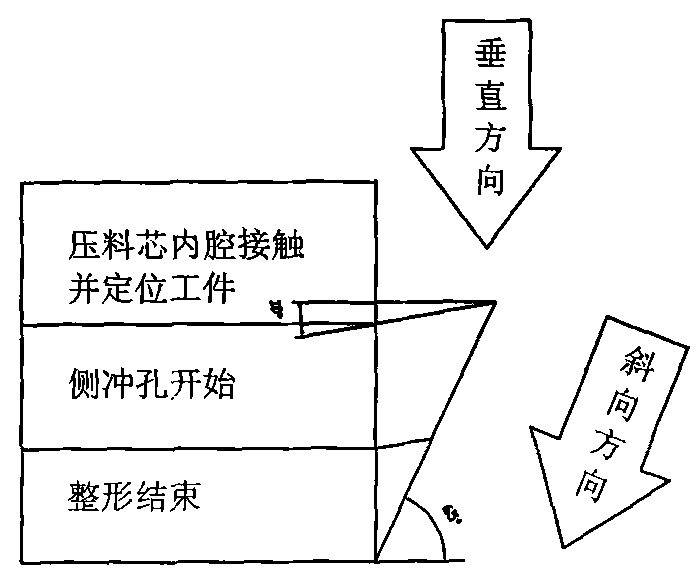

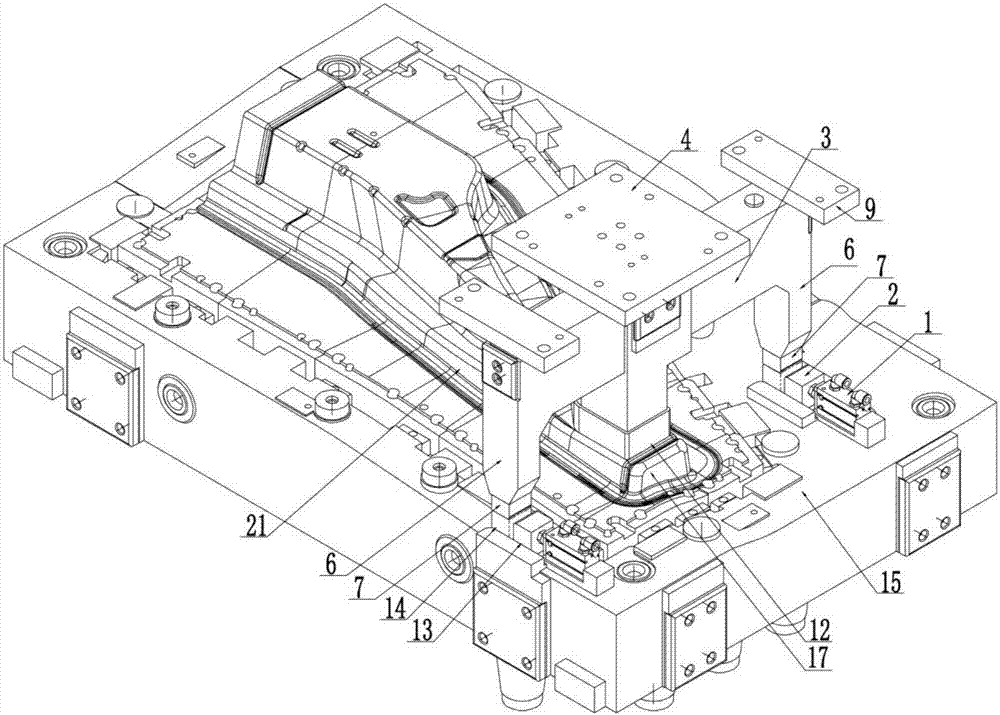

Trimming mould for automobile oil sump

The invention discloses a trimming mould for an automobile oil sump, and relates to a combined mould for shaping a plate. The mould comprises upper and lower die components capable of shaping an edge slot of the oil sump; the upper and lower die components are correspondingly provided with upper and lower trimming dies; the mould also comprises an inclined hole punching device which comprises a pressing core, a punch head, a punch head driving wedge and a bump; the bump is arranged on the lower die component and matched with the inner profile of the oil sump; the bump is provided with a lower die hole corresponding to the punch head; a waste material discharge passage which is communicated with the lower die hole is arranged in the bump; the pressing core is movably connected in the upper die component through an elastic guide mechanism; a cavity which is matched with the outer profile of the oil sump is arranged in the pressing core; the punch head is slantwise movably connected in the pressing core through an elastic resetting mechanism; the punch head driving wedge is fixedly connected with the upper die component; and the top surface of the punch head is movably connected with the punch head driving wedge through a dovetail groove or T-shaped groove. The mould has reliable action, saves the space and realizes integration of the punching mould on the trimming side of the oil sump.

Owner:JIANGSU KAMING MOLD

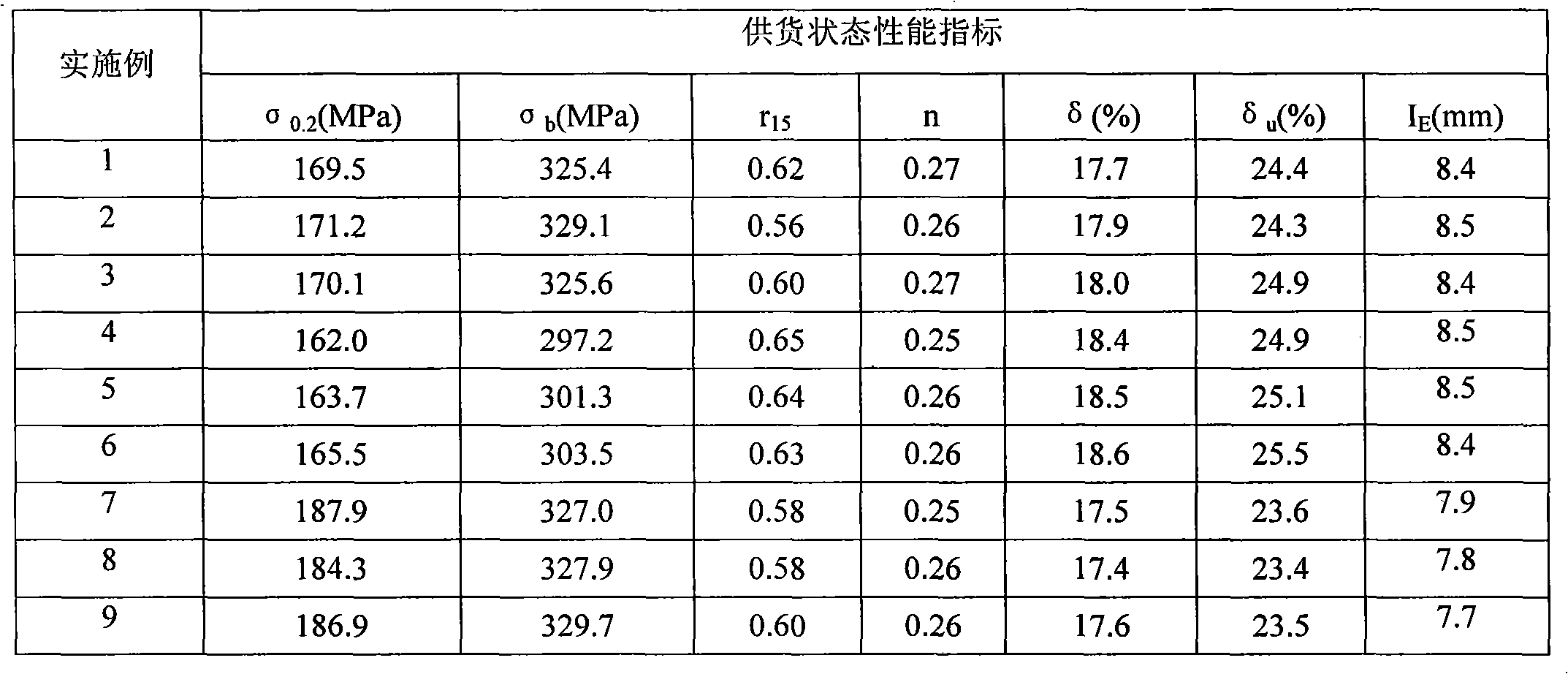

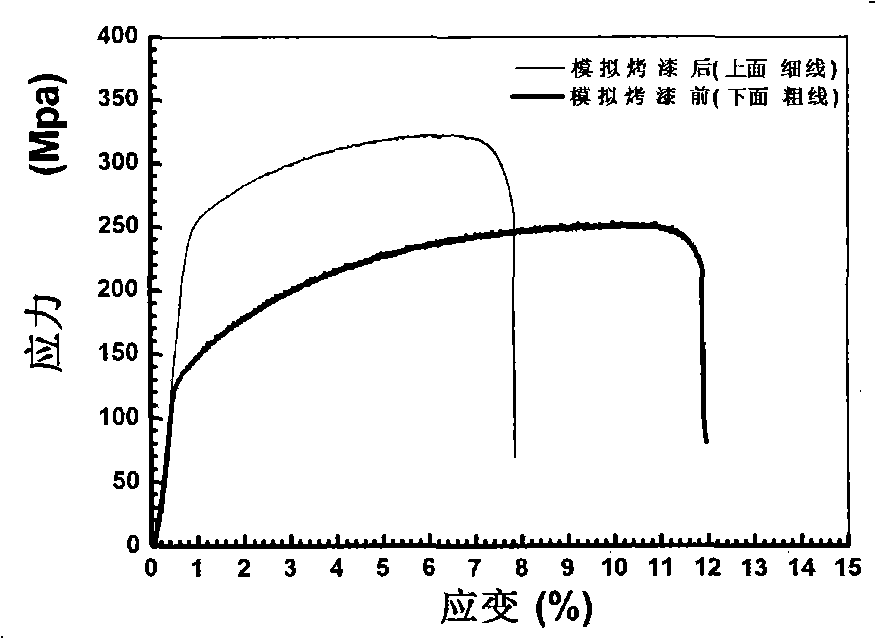

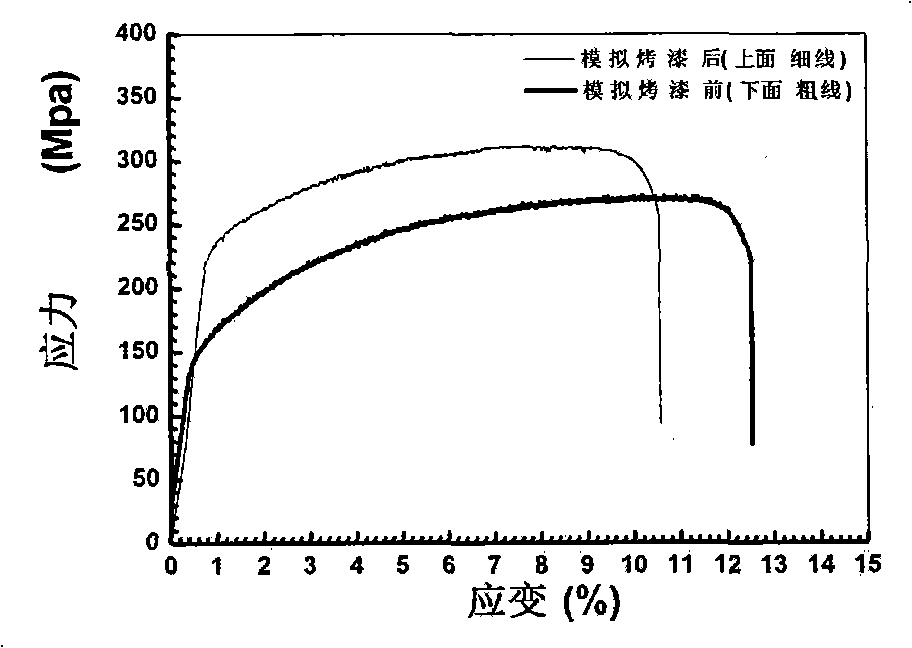

Processing method for increasing stamping formability of 6111 aluminium alloy automobile sheet

InactiveCN101885000ASolve bottlenecksImprove stamping yieldRoll mill control devicesMetal rolling arrangementsRoom temperatureIngot

The invention relates to a processing method for increasing the stamping formability of the 6111 aluminium alloy automobile sheet. The method comprises the following steps: 1. performing heat treatment to 6111 alloy ingot, which is prepared through semicontinuous casting, at 220-480 DEG C for 1-15h, heating to 550 DEG C with the furnace, keeping temperature for 24h to perform the conventional homogenizing treatment; 2. cropping the ingot and milling the face of the ingot, heating to 440-450 DEG C for hot rolling, wherein hot rolling adopts the mode of longitudinal and lateral alternation, thetotal rolling deformation is more than 85%, the finishing temperature is more than 300 DEG C and the final thickness of the hot rolled sheet is 6mm; 3. keeping the temperature of the hot-rolled sheetto 420-430 DEG C for 1h-2h, performing intermediate annealing, performing cold rolling to ensure the thickness of the sheet is 0.8 mm-1.0 mm, wherein the cold deformation is more than 75%; 4. keepingthe temperature of the cold-rolled sheet to 550 DEG C for 7min, performing solution treating and water quenching, standing at the room temperature for 1min-48h; 5. performing pre-aging treatment in adrying box at 150-220 DEG C for 4min-15min; and 6. standing at the room temperature for more than two weeks to obtain T4P temper. After the sheet is processed by the method of the invention, the stamping formability and after-painting strength are obviously improved, thus facilitating to increase the rate of stamping products and reduce the stamping cost.

Owner:NORTHEASTERN UNIV LIAONING

Pretreatment process for automobile deformed aluminum alloy plate

The invention relates to a technique of processing low-copper vehicle wrought aluminium alloy boards such as 6022, 6016 and the like, especially relates to a preprocessing technique for assuring baking hardenability and formability of vehicle wrought aluminium alloy boards.The preprocessing technique of vehicle wrought aluminium alloy boards is characterized by placing aluminum alloy boards into a furnace for solid solution treatment, 30 minutes after the solid solution heating and heat preserving under a temperature of 520 DEG C-550 DEG C, placing them into a polyether water-soluble medium of 5-10% for quenching, putting them in a room temperature for 2-3 days after being cooled, putting them into an aging treatment furnace for being treated for 10-15 minutes under a temperature of 140-170 DEG C. The invention which is a simple technique improves the yield strength, tensile strength and specific elongation of aluminum alloy boards, therefore, improving the formability, aging -resisting stability and baking hardenability of aluminum alloy boards, can achieve an satisfactory baking and overhardening effect on the existing oil paint line, improves rate of final products formed by pressing, reduces the pressing cost and promotes the application of aluminum boards in the lighteningof vehicles.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

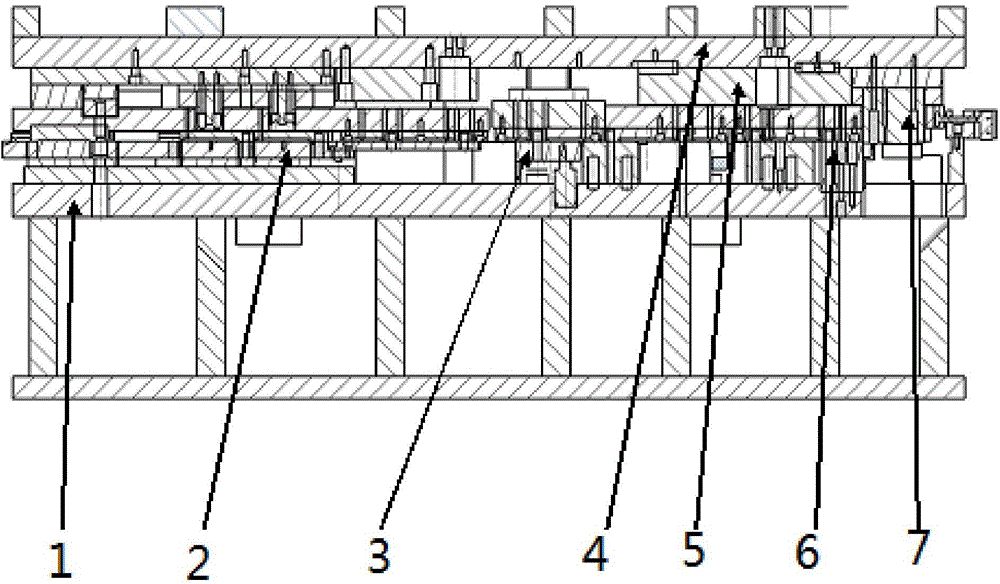

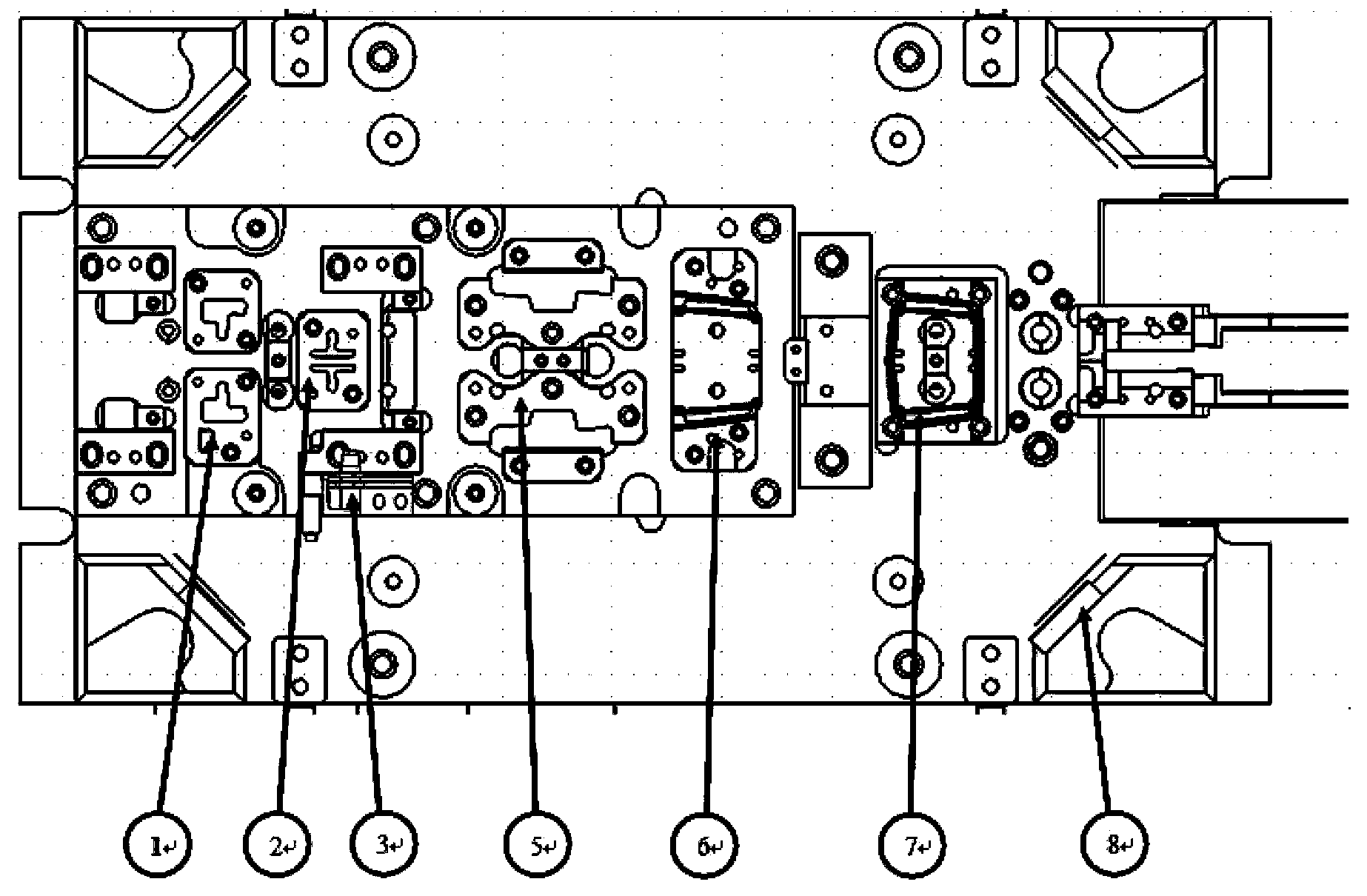

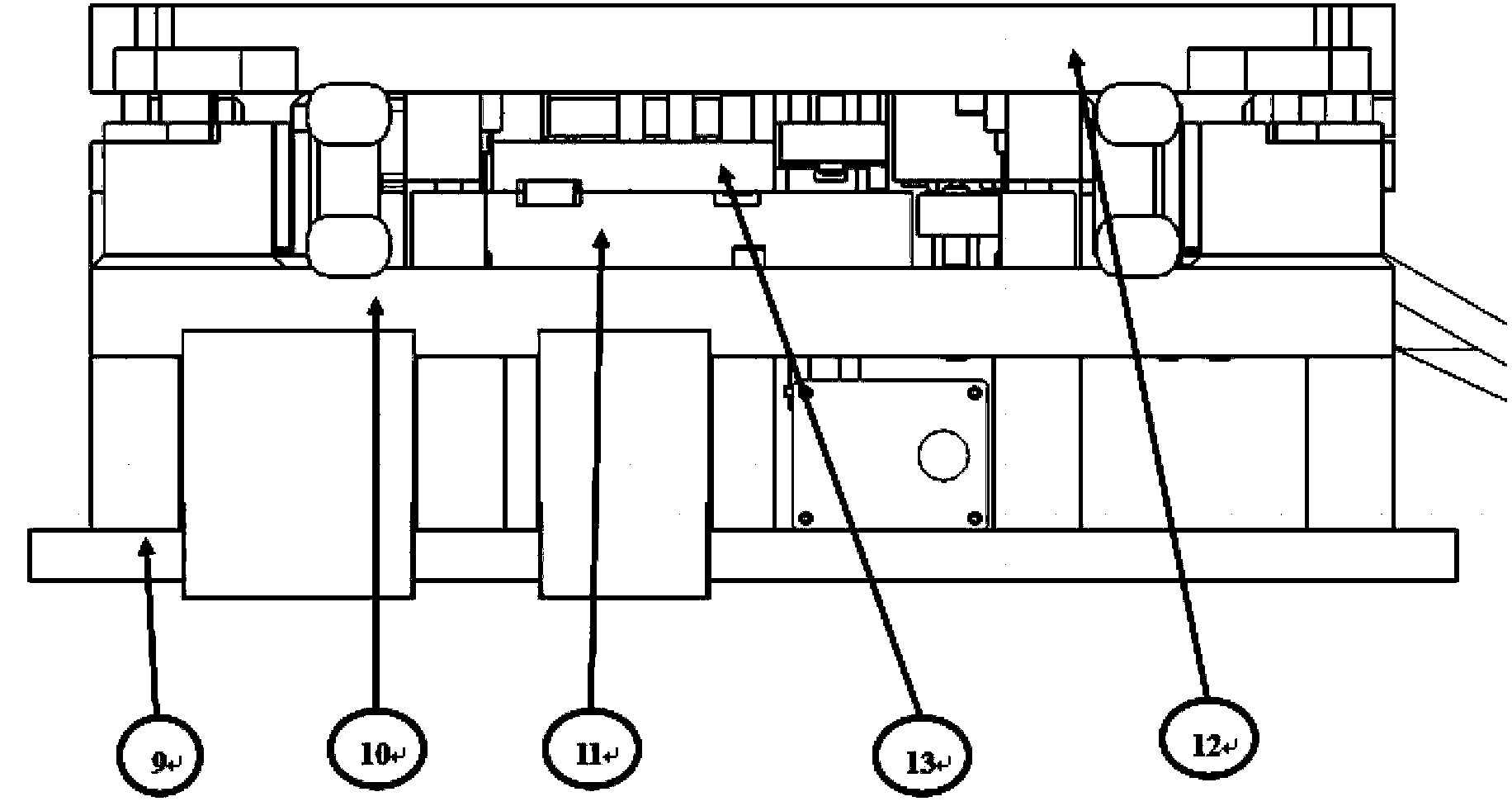

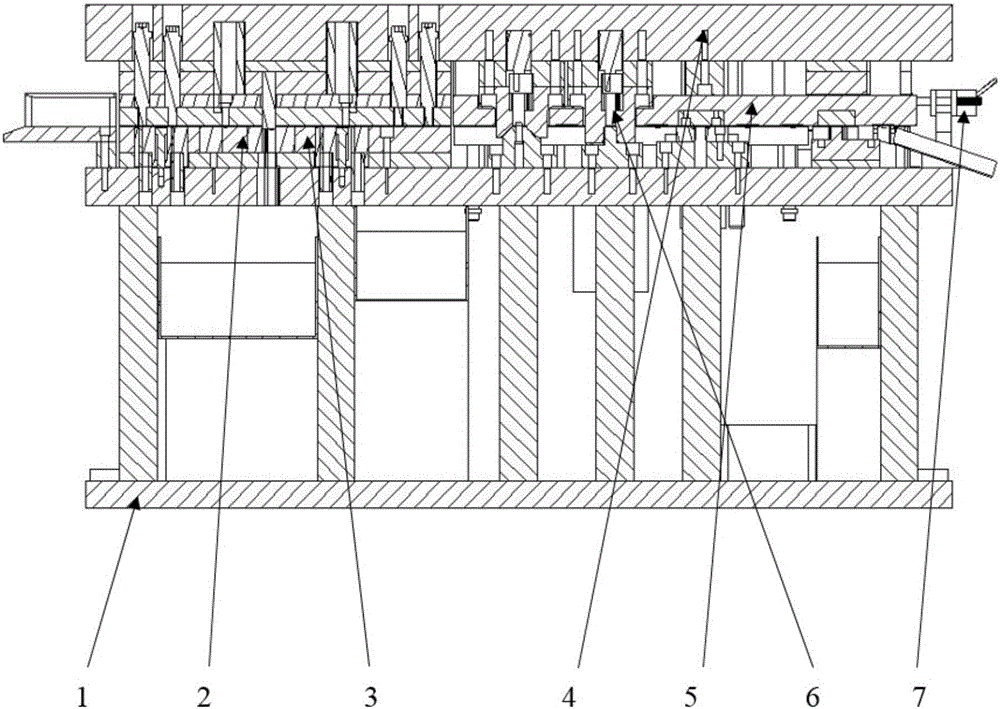

Continuous production die for rear portion blanking plate parts of automobile carling

InactiveCN104525741AExtended service lifeAvoid damageShaping toolsVehicle componentsEngineeringMechanical engineering

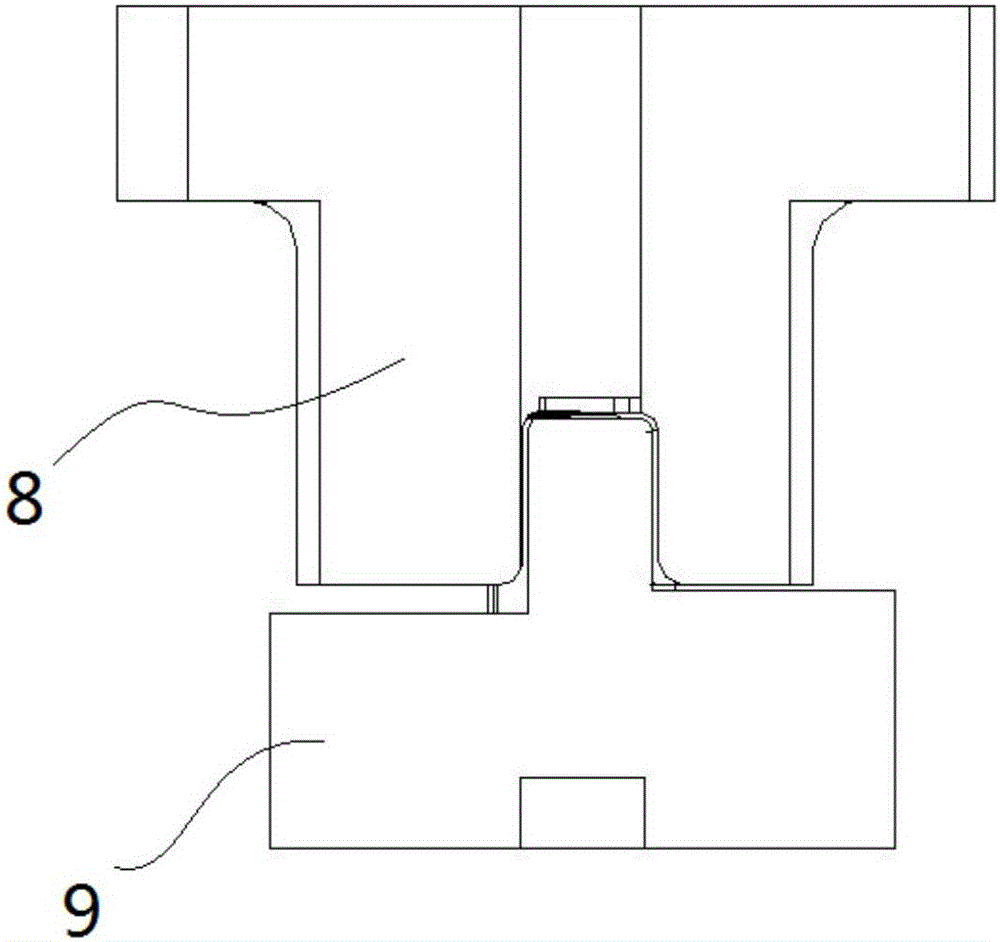

The invention relates to a continuous production die for rear portion blanking plate parts of an automobile carling. The continuous production die for the rear portion blanking plate parts of the automobile carling comprises a lower die portion and an upper die portion, the lower die portion comprises a lower die seat (1), a stamping female die cutter (2), a lower die trimming cutter block (3), a lower flanging male die (8), a shaping block, and a discharge opening,wherein the stamping female die cutter(2),the lower die trimming cutter block(3),the lower flanging male die(8),the shaping block and the discharge opening are arranged on the lower die seat(1) in sequence.The upper die portion comprises an upper die seat (4), a stamping male die cutter, an upper die trimming cutter block, a flanging cutter (9), a pressure plate (5) and a shaping punch (6), wherein the stamping male die cutter,the upper die trimming cutter block,the flanging cutter (9) ,the pressure plate (5) and the shaping punch (6) are arranged at the lower surface of the upper die seat (4) in sequence; the pressure plate (5) is arranged at the lower middle portion of the upper die trimming cutter block and is connected with the upper die trimming cutter block. Compared with the prior art, the continuous production die for the rear portion blanking plate parts of the automobile carling has the advantages of being high in quality, convenient to maintain low in cost and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

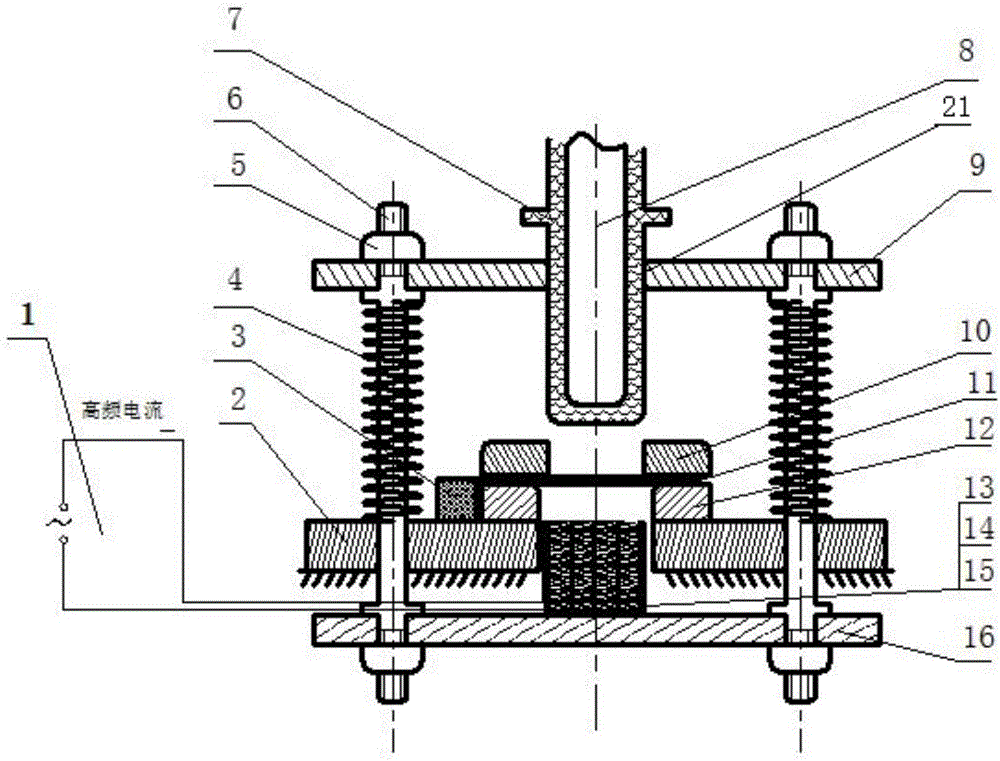

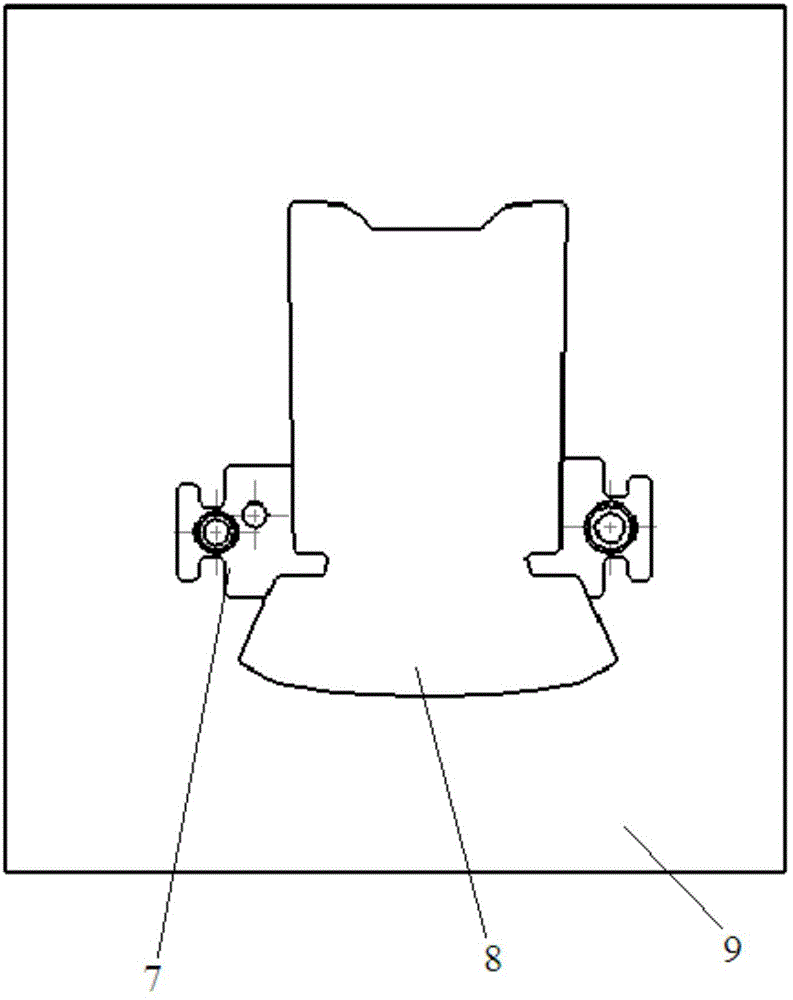

Stamping part reshaping die

ActiveCN103551460AShorten production timeAvoid stickingShaping toolsEngineeringMechanical engineering

The invention discloses a stamping part reshaping die and relates to the technical field of a die structure, aiming at realizing the upward large-angle adjustment of a stamping part and the decrease of stamping cost. The stamping part reshaping die comprises an upper die holder and a lower die holder, wherein the upper die holder is provided with an upper die punch; the upper die punch is provided with an upper adjustment face which is the same as the after-reshaping upper surface of a reshaping part in the stamping part; the lower die holder is provided with a lower die punch; the lower die punch is connected with a first nitrogen spring driving the lower die punch to move; the lower die punch is provided with a lower adjustment face which is the same as the after-reshaping lower surface of the reshaping part in the stamping part; the first nitrogen spring is used for driving the lower die punch to slide and approach the upper die punch, and in the case of die assembly, enabling the lower adjustment face and the upper adjustment face to be mutually close to the reshaping part of the stamping part in a matching way. The stamping part reshaping die is mainly used for reshaping the stamping part.

Owner:GREAT WALL MOTOR CO LTD

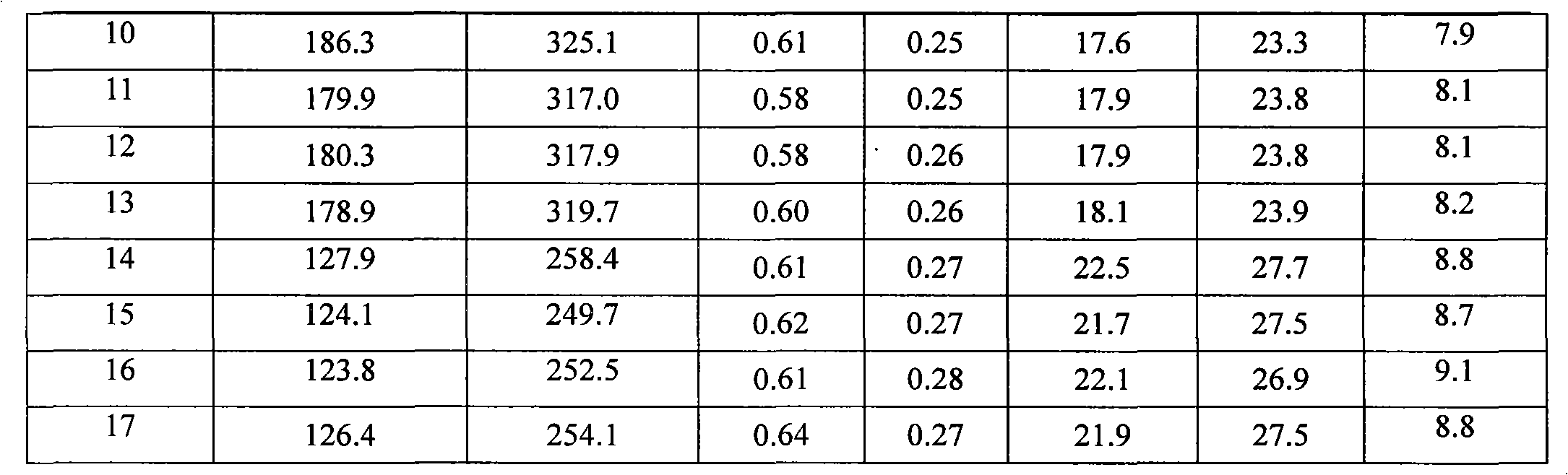

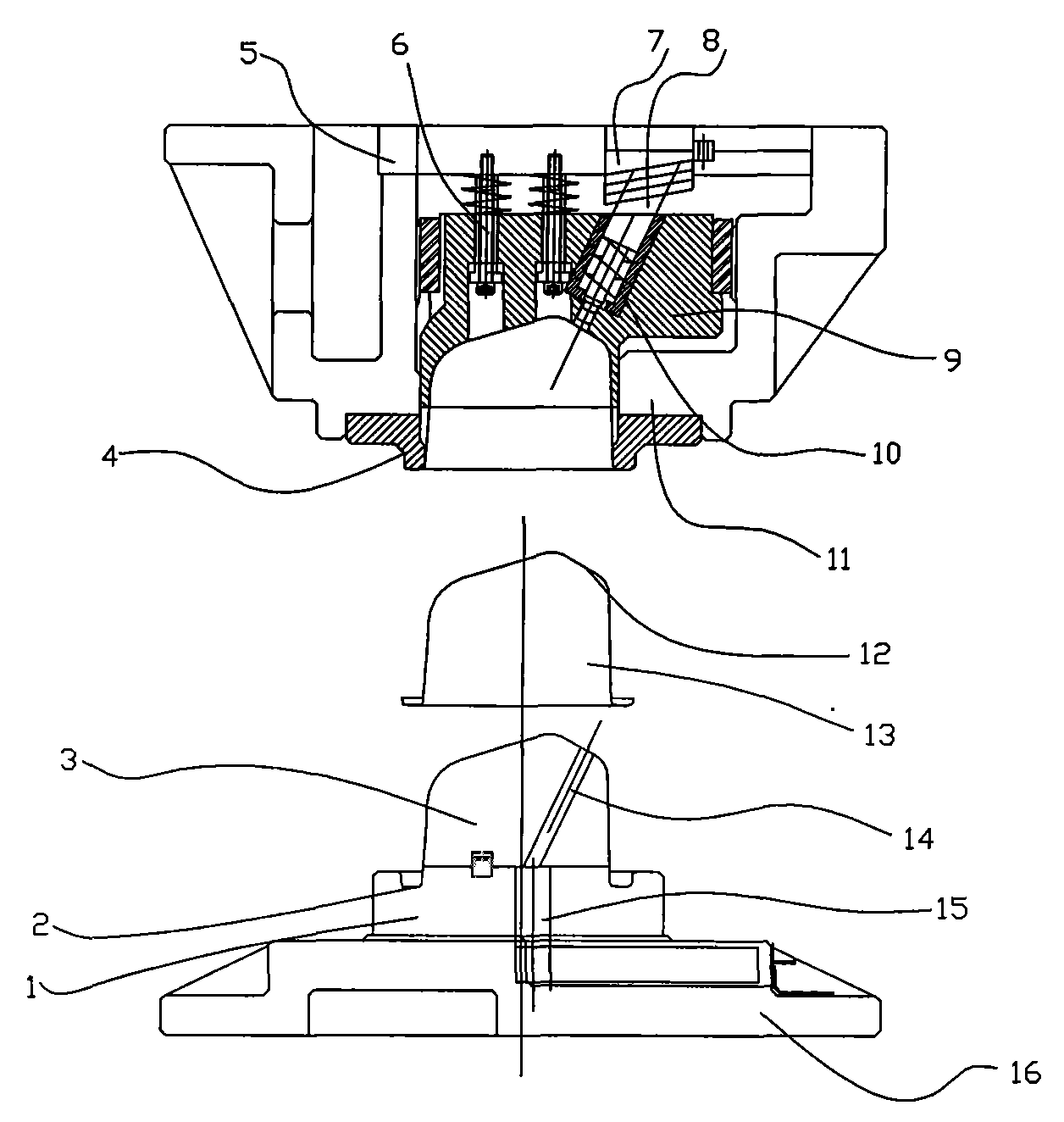

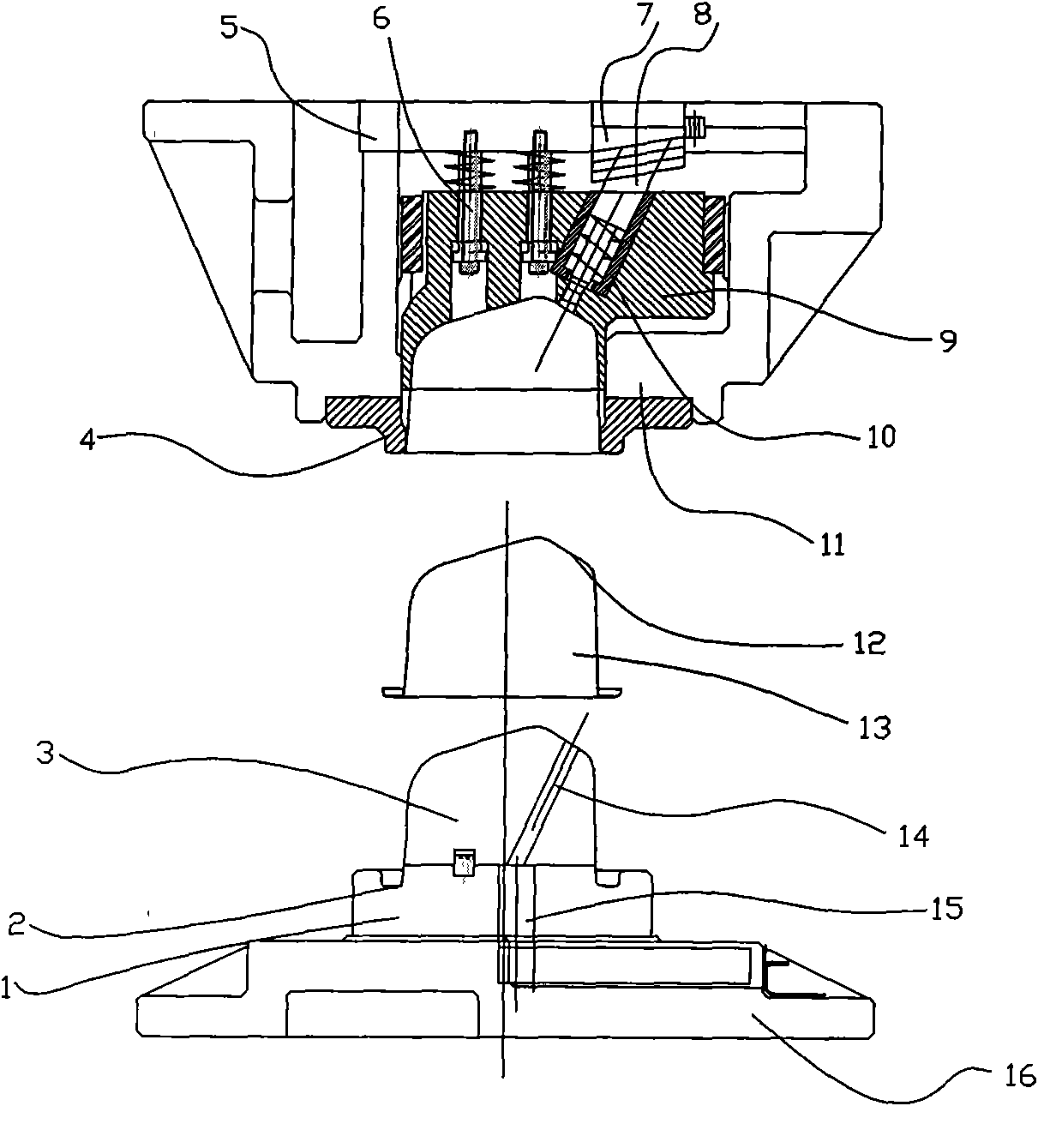

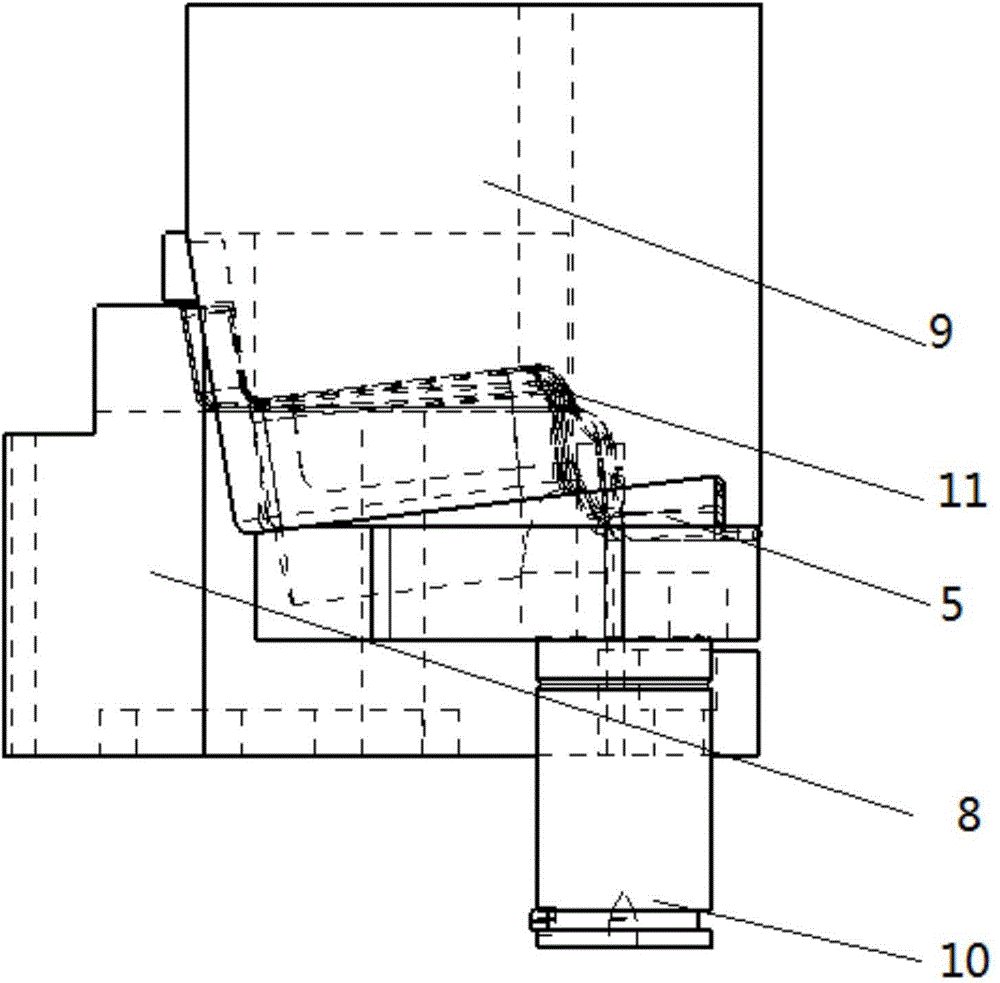

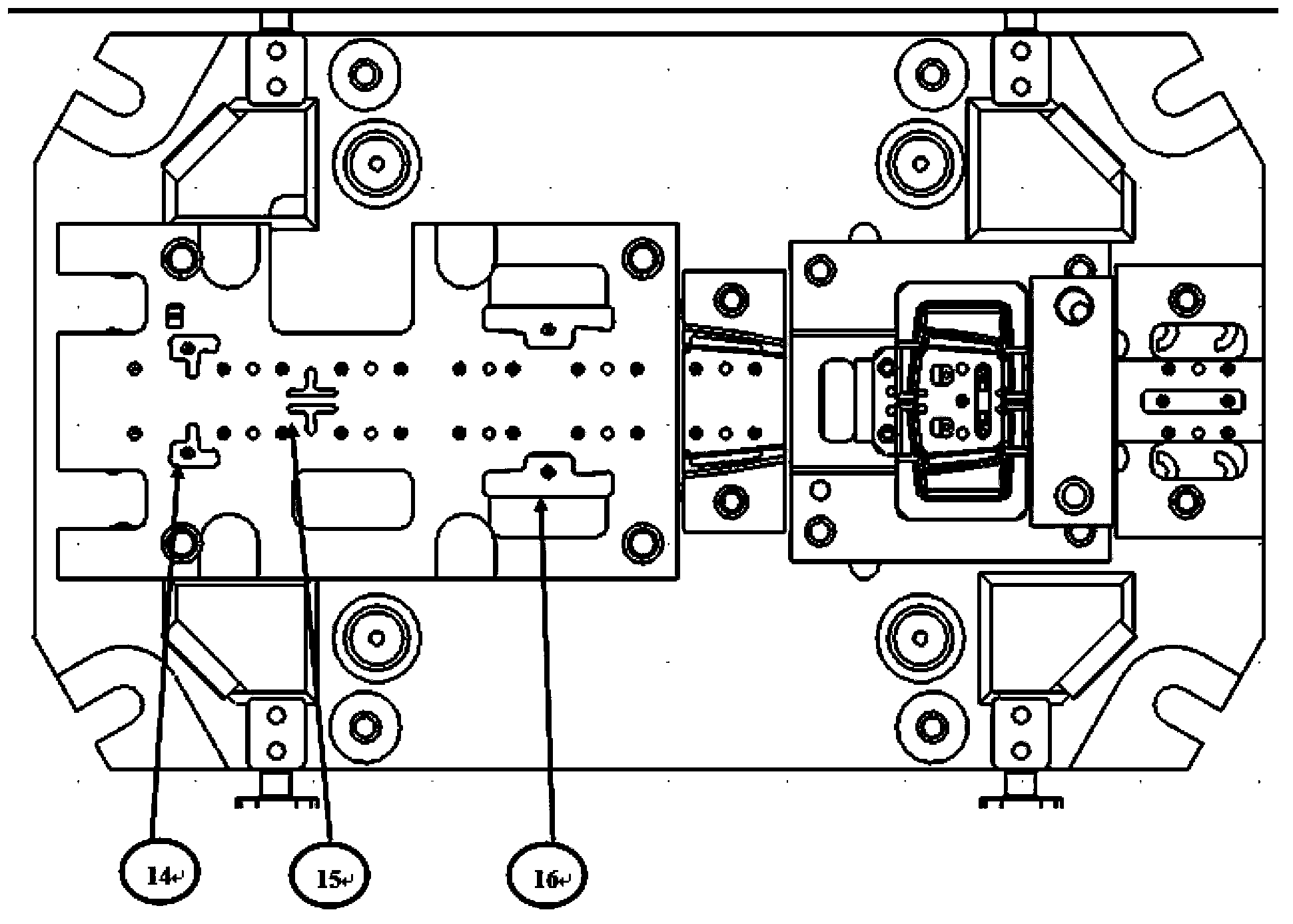

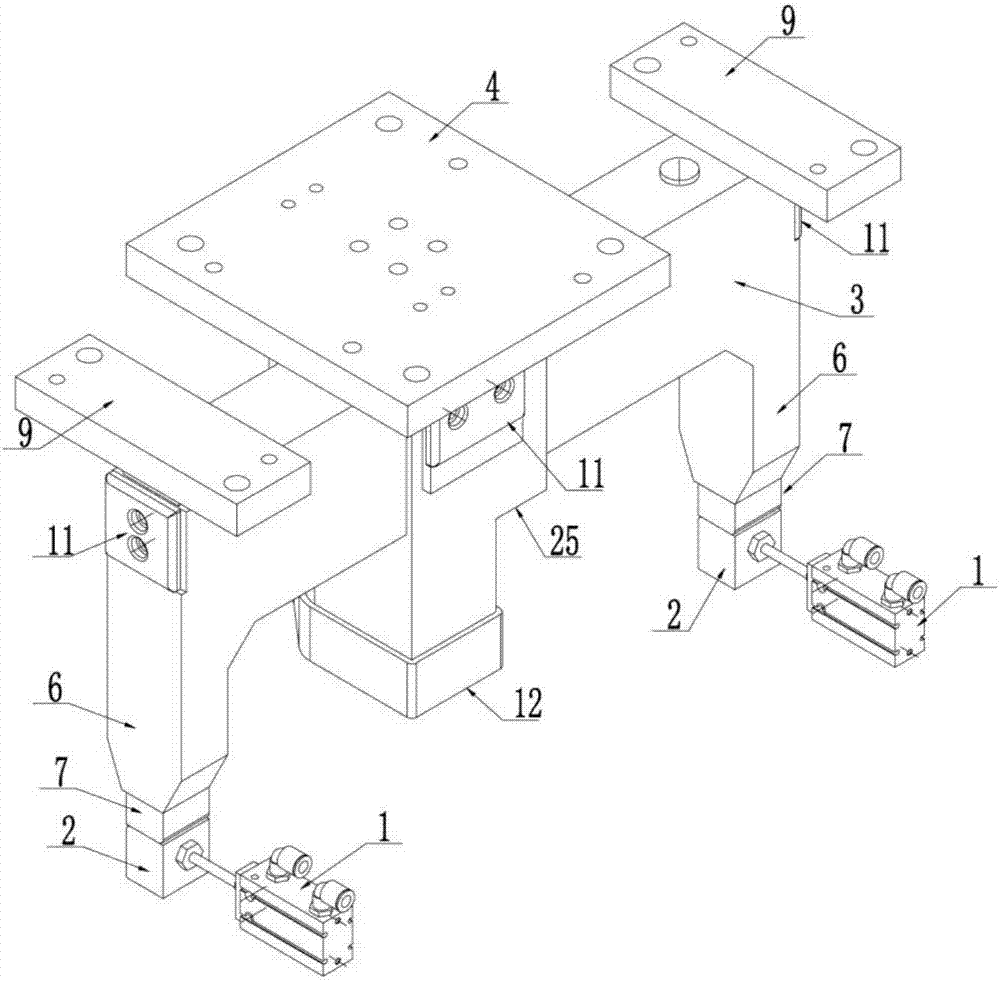

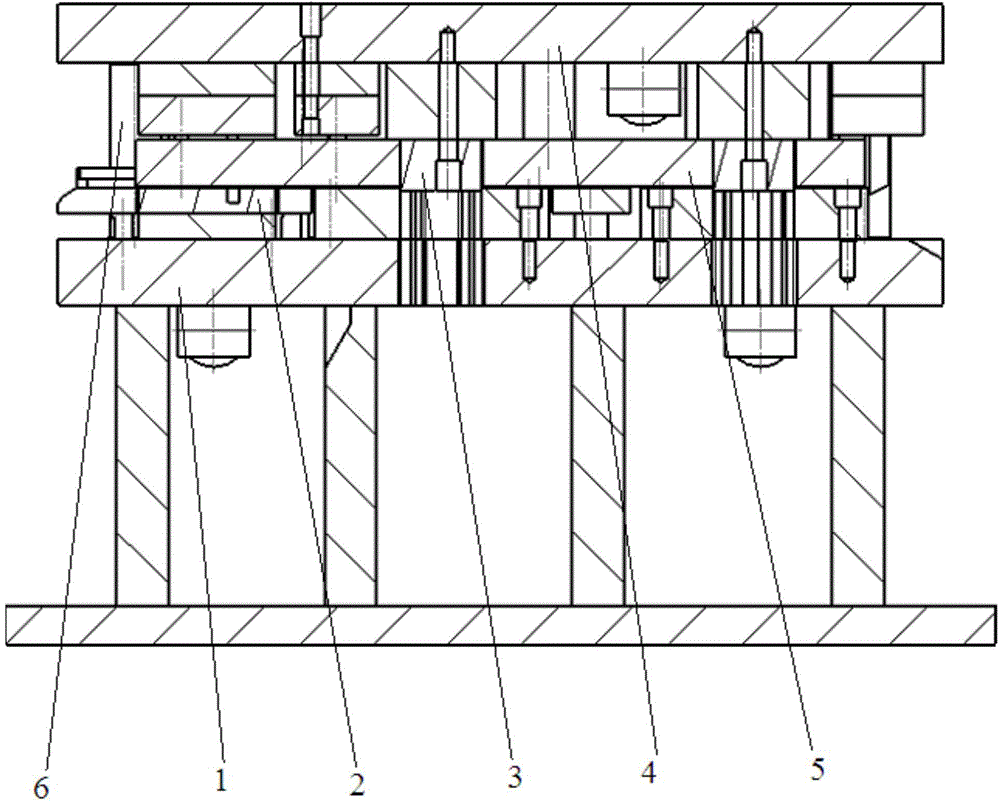

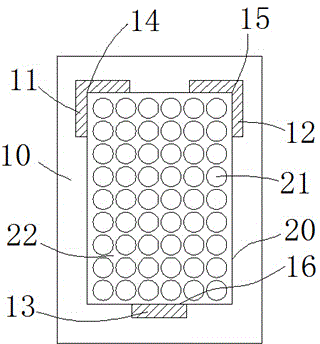

Gas spring reinforcing plate grading mold

The invention relates to a gas spring reinforcing plate grading mold which consists of a lower mold part and an upper mold part, wherein the lower mold part comprises a mold foot (9), a lower mold base (10), a lower mold punching female mold (1), a lower mold trimming cutter block (2), a feeding sensor (3), a lower mold forming cutter, a lower mold guide plate (8) and a jacking plate (11), wherein the mold foot (9) and a mold foot pad plate are arranged at the lowermost part of the mold; the lower mold base (10) is arranged on the upper plane of the mold foot (9); the lower mold punching female mold (1), lower mold trimming cutter block (2), the feeding sensor (3), the lower mold forming cutter and the jacking plate (11) are fixed on the upper surface of the lower mold base (10); the upper mold part comprises an upper mold pressing plate (13), an upper mold punching head (14), an upper mold punching trimming cutter (15), an upper mold forming cutter block (16) and an upper mold base (12). Compared with the prior art, the gas spring reinforcing plate grading mold has the advantages of simple structure, convenience in use, convenience in repairing, stable production and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

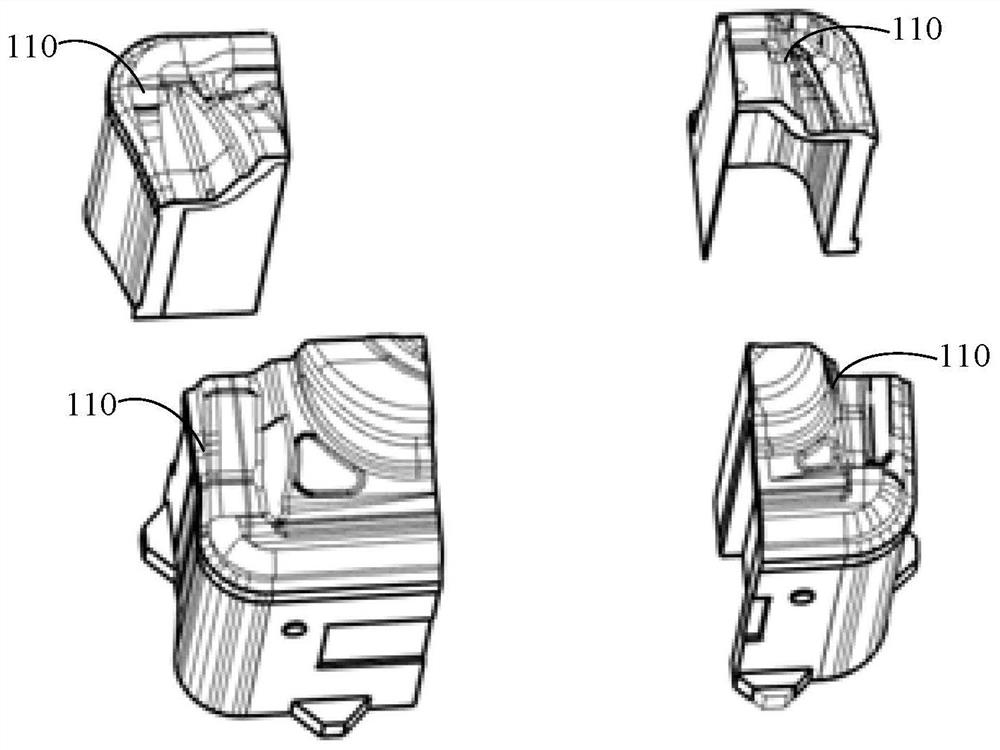

Pipe fitting notching die

The invention discloses a pipe fitting notching die. The pipe fitting notching die comprises an upper die plate and a lower die plate; the lower die plate is provided with a sliding block seat; a sliding block is arranged in the sliding block seat; a spring is arranged between each end surface formed along the length direction of the sliding block and the inner lateral side of the sliding block seat; a cylindrical groove with two open ends is hollowed out along the width direction of the sliding block; a core rod is arranged in the cylindrical groove in an interference fit mode; one side of the sliding block seat is provided with a pipe fitting through hole and the other side of the sliding block seat is provided with a sliding groove; a guide mechanism is arranged in the sliding groove; the guide mechanism is fixedly connected with the sliding block; the inner side of the upper die plate is provided with a backing plate; an inclined wedge is fixedly arranged on the backing plate; the inclined wedge is formed by a first inclined wedge and a second inclined wedge; the inner side inclined surfaces of the first inclined wedge and the second inclined wedge are matched with the two end surfaces formed in the length direction of the sliding block respectively. According to the pipe fitting notching die, the structure is simple, the operation is convenient, two notches can be stamped and cut out at one time, and accordingly the stamping times are reduced under the condition that the concentricity of the two notches is ensured, the stamping cost is low, the product quality is high, and the production efficiency is high.

Owner:NANJING HUIDE MACHINERY

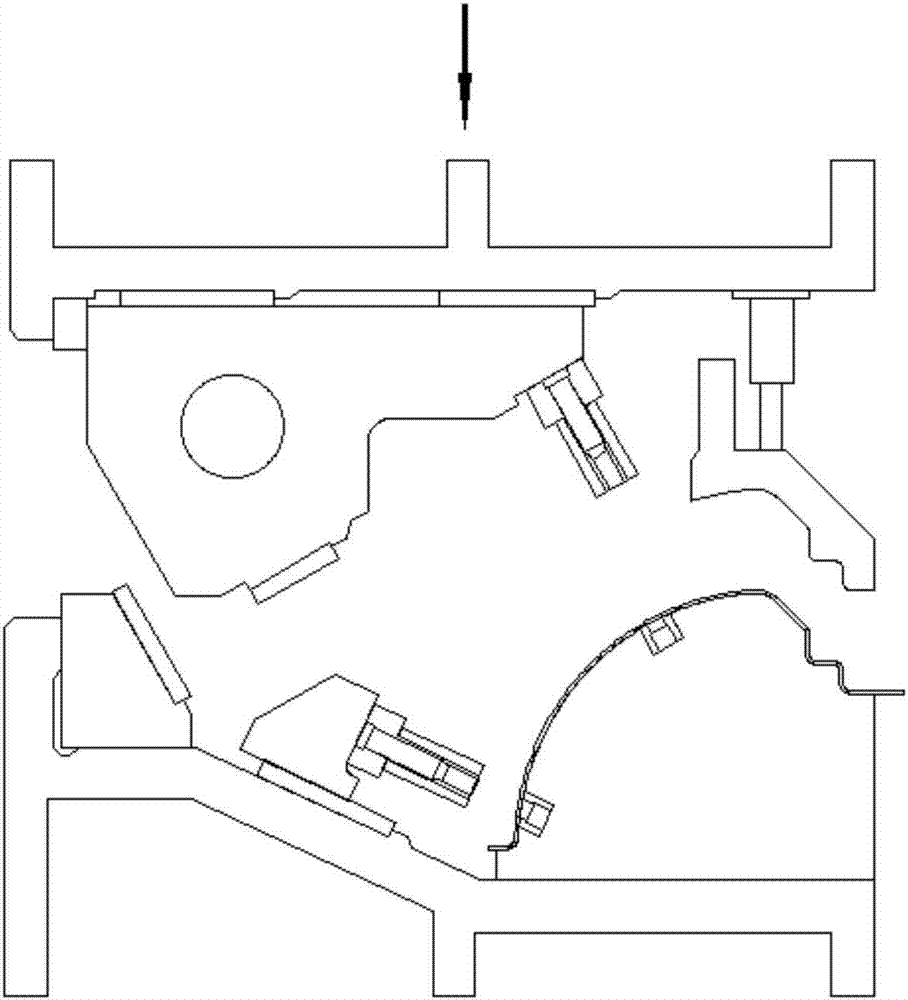

Die for multi-angle side-punching machining

InactiveCN107999607ARealize side punchingReduce the number of settingsPerforating toolsPunchingEngineering

The invention provides a die for multi-angle side-punching machining. The die for multi-angle side-punching machining comprises an upper die base, a material pressing device arranged on the upper diebase, a lower die base and a lower male die arranged on the lower die base. A first tapered wedge sliding block is hoisted on the upper die base and provided with a first plunger chip and can transversely slide relative to the upper die base. The lower die base is provided with a second tapered wedge sliding block and a tapered wedge drive base which is used for driving the first tapered wedge sliding block to transversely move. The tapered wedge drive base and the side face of the first tapered wedge sliding block are provided with oblique fitting surfaces. The second tapered wedge sliding block is provided with a plunger chip. The second tapered wedge sliding block is arranged on the lower die base in a sliding manner, and the lower end of the first tapered wedge sliding block is provided with an oblique fitting surface. The lower male die is provided with a female die corresponding to the punching position of a part. According to the die for multi-angle side-punching machining, punching at different angles is completed through a set of tapered wedges in a procedure, the number of die sets is reduced, the punching cost is reduced, and the production period is shortened.

Owner:CHONGQING PINGWEI AUTOMOBILE TECH CO LTD

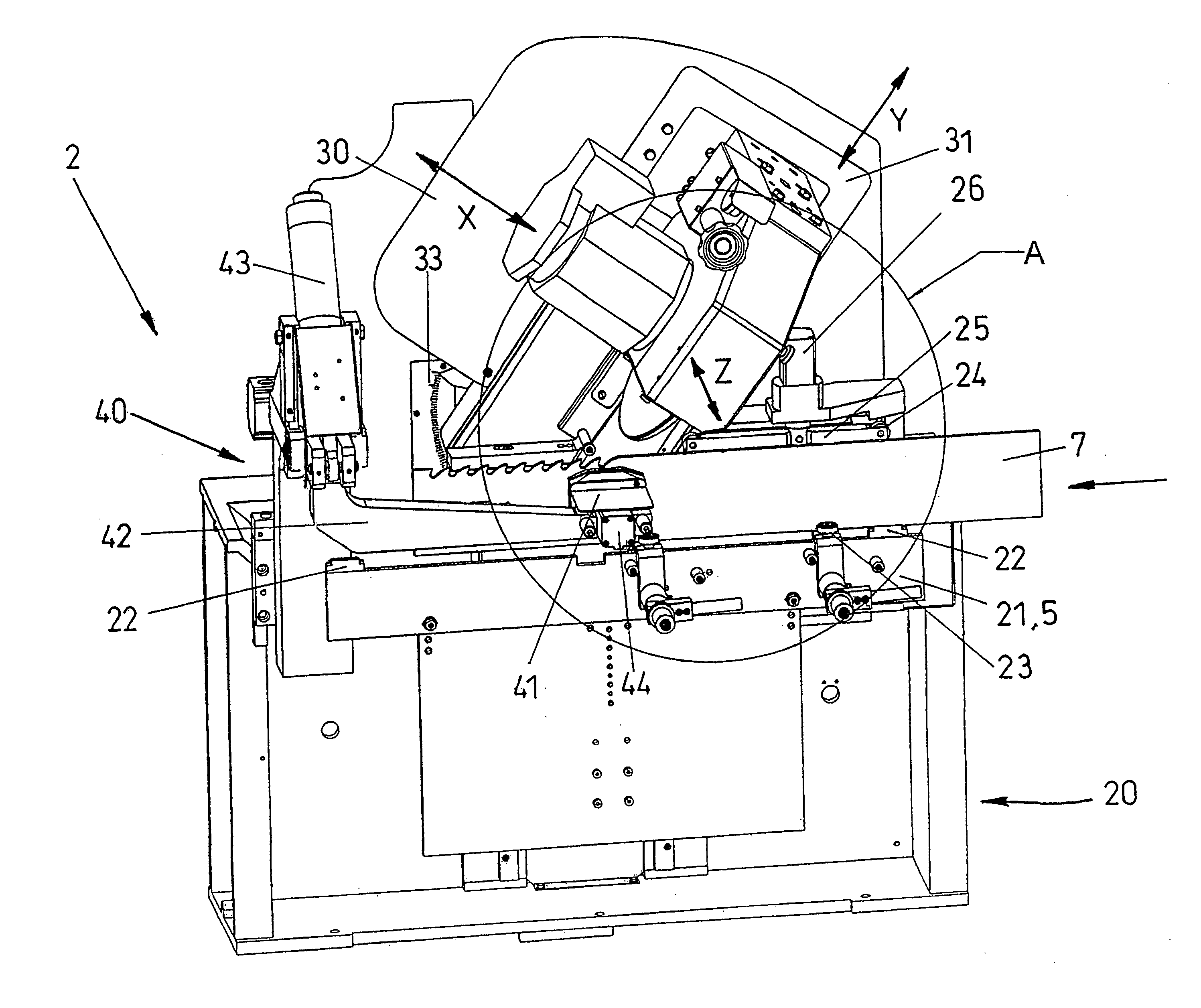

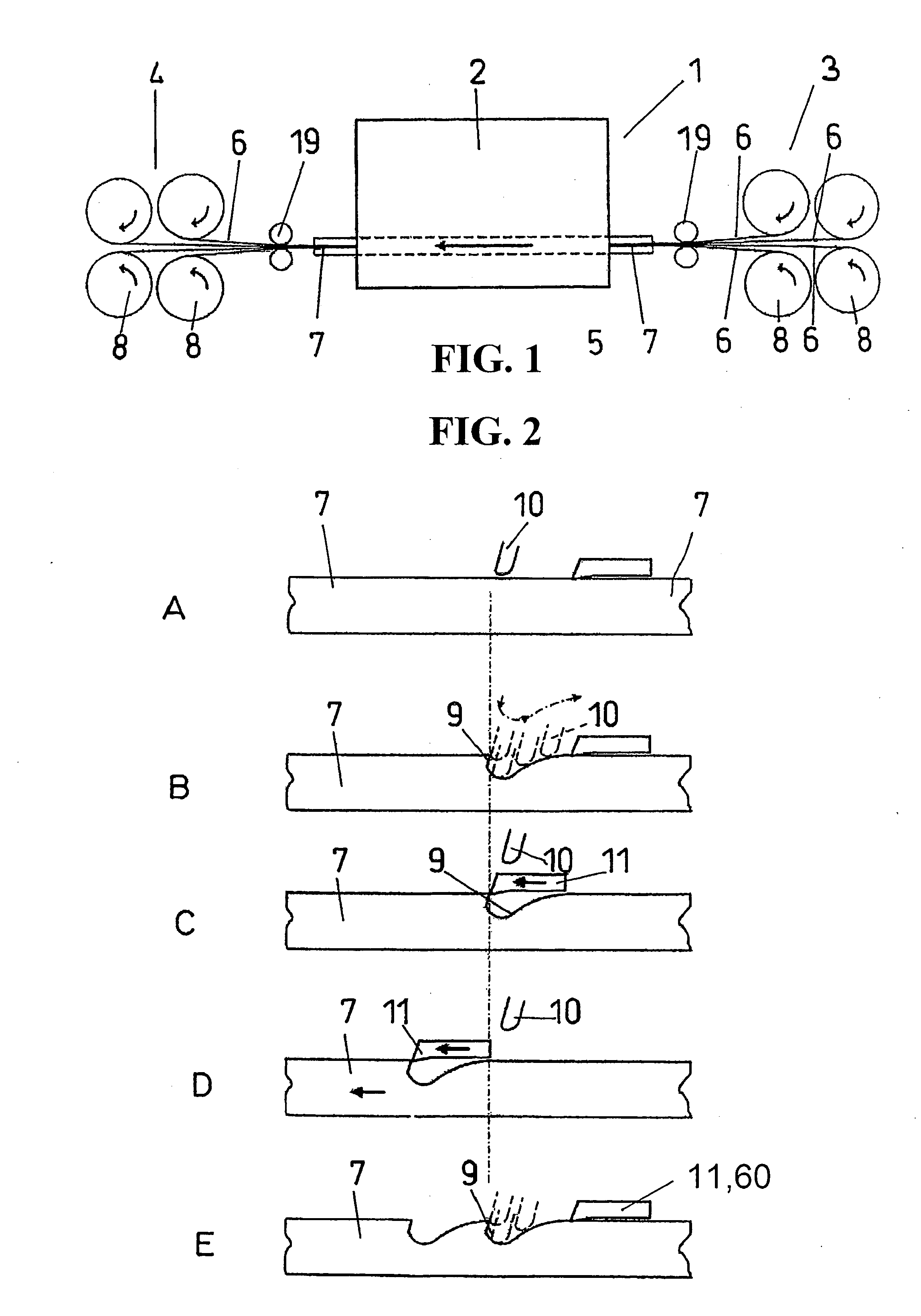

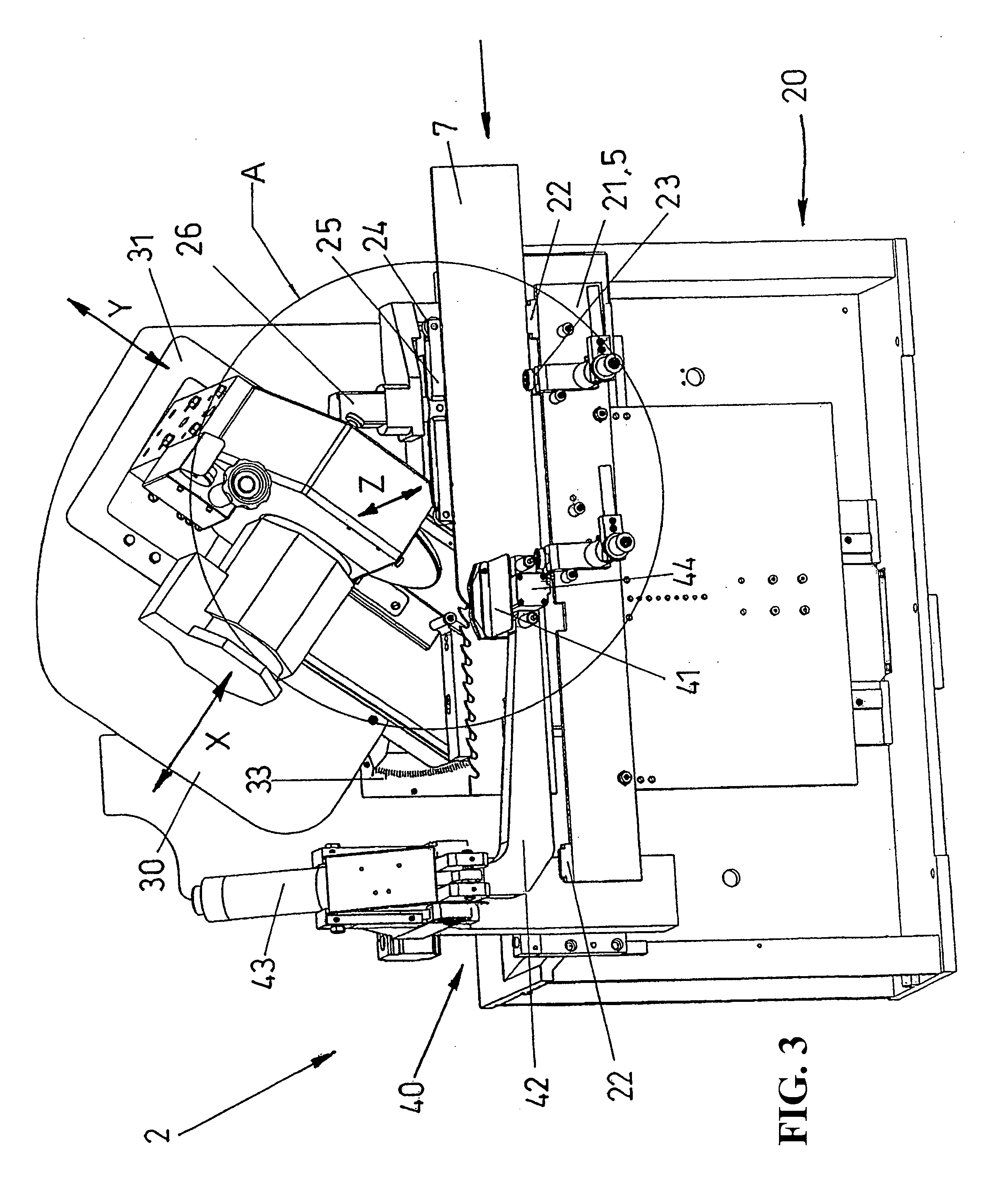

Method of and device for producing band saw blades

ActiveUS20110030510A1Rapid and cost-effective production processReduce stamping costsMetal sawing tool makingMetal sawing toolsMetallurgy

A method and device for producing band saw blades, particularly for the timber-processing industry. A blank band saw blade is produced from a metal band, such as a metal band that can be stored on a roll. Several metal bands are combined into a flush metal band packet which can be introduced into a saw band grinding machine. The metal bands are pressed onto a planar guide. The metal band packet is clamped and a grinding machine operates to produce a desired saw tooth profile. A pawl is introduced into a tooth profile which is ground into the metal band packet. The clamped metal band packet is then loosened and advanced with a predetermined tooth spacing.

Owner:ISELI & MASCHFAB

Heat treatment method for improving shaping property and bake-hardening property of 6XXX series aluminum alloy sheet

InactiveCN101831599AExtended retention of bake-hardening propertiesImprove machining accuracySheet steelEconomic benefits

The invention provides a heat treatment method for improving shaping property and bake-hardening property of a 6XXX series aluminum alloy sheet and greatly prolonging bake-hardening property keeping time. The 6XXX series aluminum alloy sheet undergoes heat treatment for some time after solution quenching treatment and before stamping forming. The technical scheme of the invention makes automated operation convenient and can be easily realized and save energy and equipment investments. After the 6XXX series aluminum alloy sheet undergoing the solution quenching treatment is treated by the method provided by the invention, the shaping property and the baking varnish strengthening property of the 6XXX series aluminum alloy sheet are obviously improved, and more importantly, by the preheat treatment of the method, the bake-hardening property keeping time of the aluminum alloy sheet is greatly prolonged to 3 to 4 months, even 6 months; due to the advantages, the aluminum alloy sheet is enabled to replace the steel plate so as to reduce the weight of an automobile body; and thus, the aim of saving energy and reducing emission while creating good economic benefits is also achieved.

Owner:HUNAN UNIV

Pneumatic device

The invention discloses a pneumatic device used for selectively punching. The pneumatic device comprises an upper die (6), a lower die, a punch head (7) arranged on the upper die (6) and a punching channel arranged between the upper die (6) and the lower die; a controller, a cylinder (1), a punching control part, a punching mechanism and a resetting device connected in turn are arranged in the upper die (6); and the punching mechanism extends along the vertical direction, and the lower surface of the punching mechanism is connected with the punch head (7). The pneumatic device has the advantages of simple process and low price.

Owner:SUZHOU UIGREEN PRECISION TECH

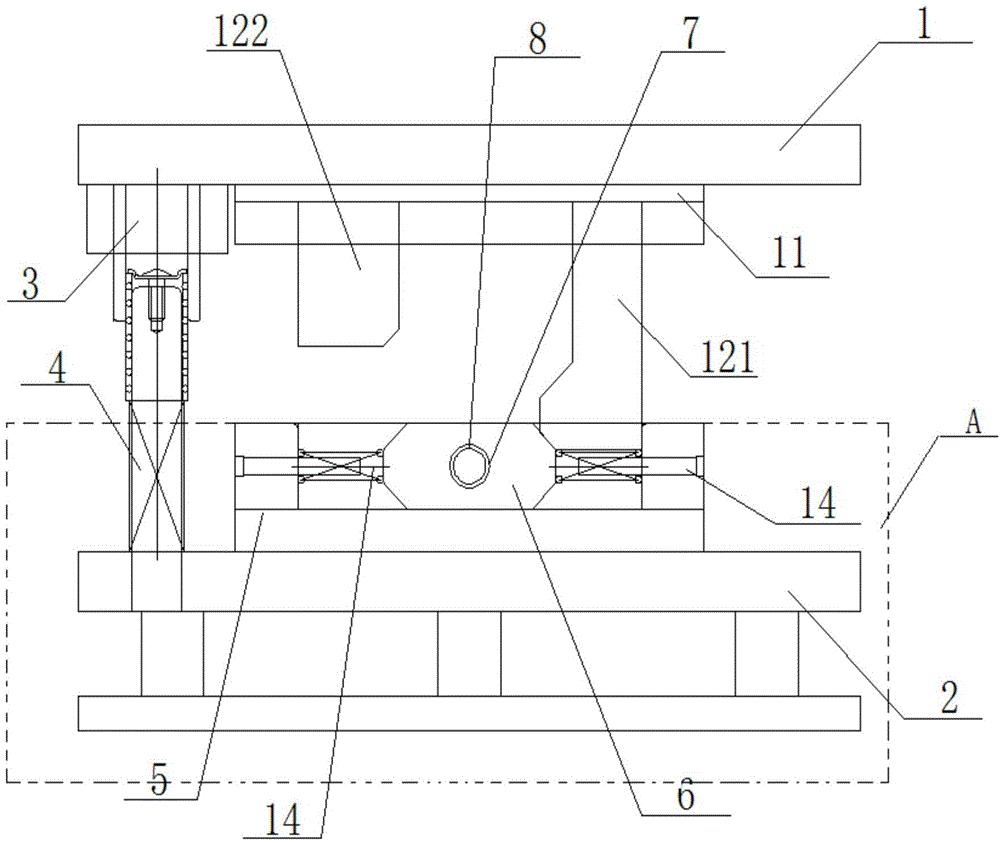

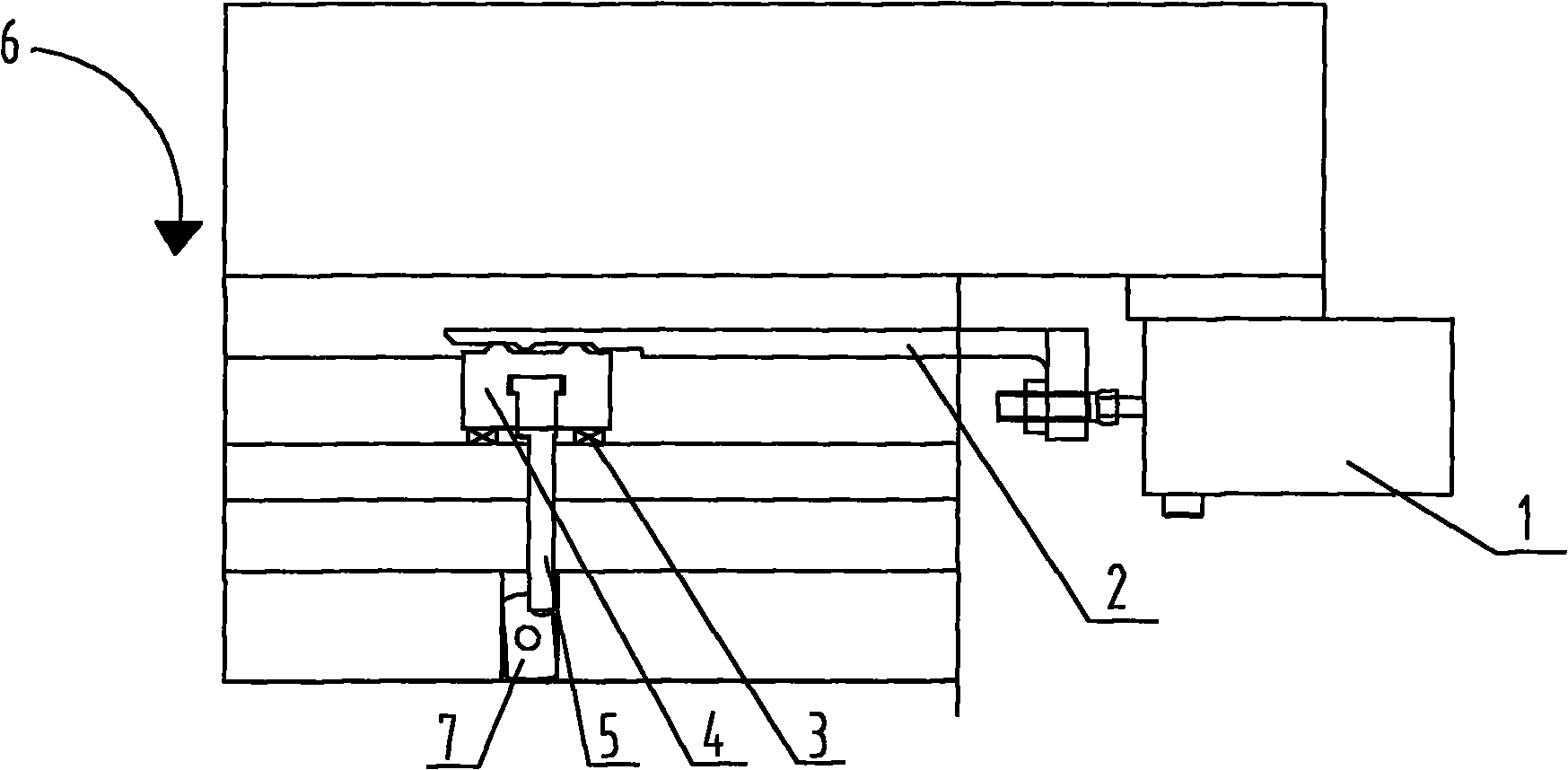

Lagging mechanism for drawing die and application method

The invention discloses a hysteresis mechanism for a drawing die and an application method thereof. The hysteresis mechanism includes a hysteresis cylinder and a hysteresis cushion block, the hysteresis cushion block is connected with the piston rod of the hysteresis cylinder, the hysteresis cylinder is mounted on a blank holder, and the blank holder is installed On the lower die, the drawing die also includes an upper die, the upper die is provided with a binder body, a limit cover plate is arranged above the binder body, a nitrogen cylinder is arranged on the limit cover plate, and the ejector rod of the nitrogen cylinder and the binder body The height of the contact and hysteresis pads is the same as the movement stroke of the binder body; the application method of the hysteresis mechanism: 1. Place the sheet; 2. Clamp the mold and stamp the sheet into a finished product; 3. Start the hysteresis mechanism; 4. Delay the mold opening press body Exit; 5. Take out the stamping part. In the process of mold opening, the binder body starts to withdraw after the end of the binder ring stroke, so that the binder ring and the binder body move first and then later, avoiding the two moving at the same time and damaging the stamping part, and it can be used without air cushion The delay function is used on the press to save resources and reduce stamping costs.

Owner:烟台泰利汽车模具股份有限公司

Automobile metal plate stamping die

PendingCN113477816AAvoid wastingEven by forceShaping toolsMetal-working feeding devicesStructural engineeringManufacturing engineering

The invention relates to the technical field of automobile metal plate part processing, in particular to an automobile metal plate stamping die. The die comprises a die body, supporting rods are fixedly connected to the four corners of the top end of the die body, a supporting plate is jointly and fixedly connected to the upper ends of the four supporting rods, and a hydraulic cylinder is fixedly installed in the center of the top end of the supporting plate; and the lower end of the hydraulic cylinder penetrates through the supporting plate, a die pressing plate is fixedly connected to the lower end of the hydraulic cylinder, the die pressing plate is slidably connected with the supporting rods, and a lifting mechanism is fixedly connected to the upper end of the die pressing plate. According to the device, in combination with the lifting mechanism, a stamping-formed metal plate part is conveniently taken down from the device, the metal plate part does not need to be manually removed from the die from the front end and the rear end, ad thus waste of manpower resources is avoided; the metal part plate is removed from the die from the four corners, stress on the metal plate part is more uniform during die removing, deformation of the metal plate part due to uneven stress during die removing is avoided, and the effect of the metal plate part can be effectively guaranteed.

Owner:李玉祥

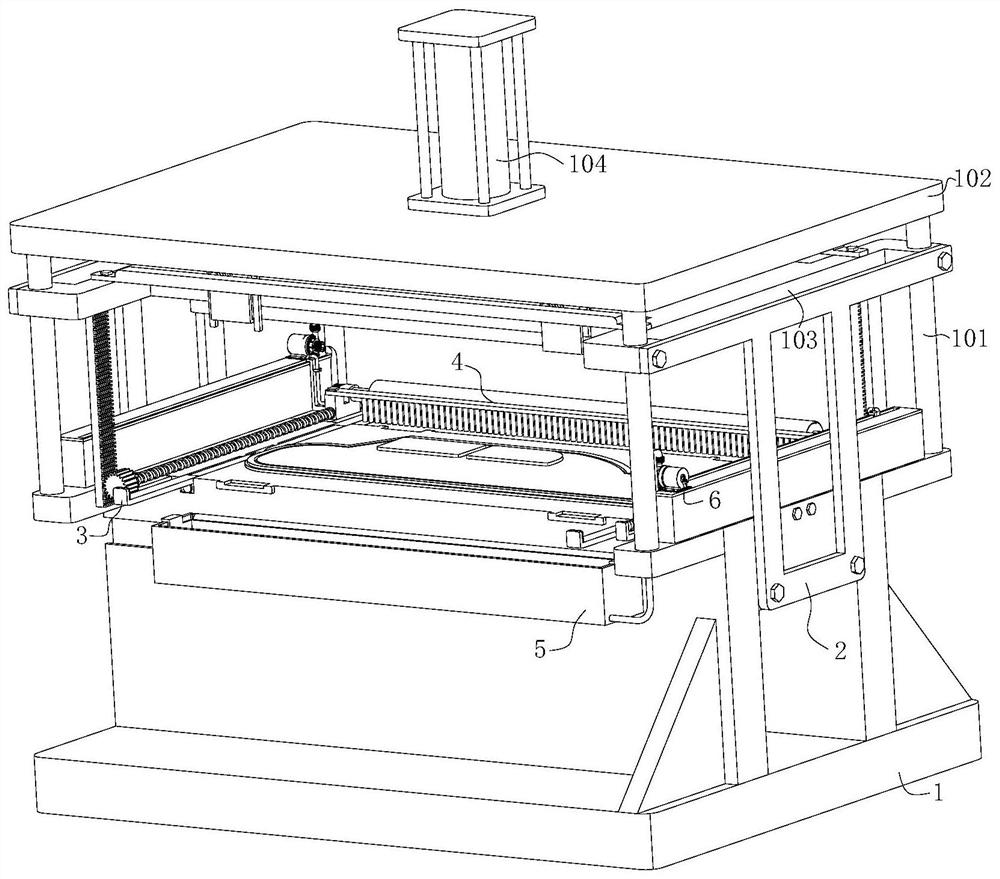

Metal sheet warm forming device based on induced high-frequency electromagnetic field

ActiveCN105921582AStamping process is simpleProduction batch limitShaping toolsEngineeringMetal sheet

The invention provides a metal sheet warm-hot forming device based on an induced high-frequency electromagnetic field. A vertical-through stamping opening is formed in a workbench; a support frame comprises an upper supporting plate above the workbench, a lower supporting plate under the workbench, and connecting rods connected with the workbench in a sliding manner; two ends of each connecting rod are respectively connected with the upper supporting plate and the lower supporting plate in an assembling manner; a male mold forming assembly comprises a male mold, a mold guiding plate and a blank holder; the male mold is arranged right above the stamping opening and movably connected with the upper supporting plate; the mold guiding plate is arranged on the edge of the stamping opening and movably connected with the workbench; the blank holder is arranged above and movably connected with the mold guiding plate; and a high-frequency electromagnetic field generator is arranged just under the stamping opening and connected with the lower supporting plate in an assembling manner. The metal sheet warm forming device has the beneficial effects that a metal sheet stamping process can be simplified; limitation of stamping part production lot can be avoided; metal sheet stamping cost can be reduced; metal sheet stamping efficiency can be improved; the metal sheet warm forming device is also suitable for stamping forming of plates which are high in strength and difficult to form, and stamping parts obtained after stamping forming are excellent in quality.

Owner:SHANDONG UNIV OF SCI & TECH

Stamping die and vulnerable part informatization management system

InactiveCN104407570AGuarantee normal productionThe implementation effect is goodProgramme controlComputer controlInformatizationManagement system

The invention discloses a stamping die and vulnerable part informatization management system comprising an industrial control host, a router, a database, a die management module and a die and vulnerable part maintenance module. The industrial control host, the die management module and the die and vulnerable part maintenance module are connected with the router. The die and vulnerable part maintenance module is also connected with the database. Abnormal rate in the stamping production process is reduced and production efficiency is enhanced.

Owner:哈特盈致(中山)智能科技有限公司

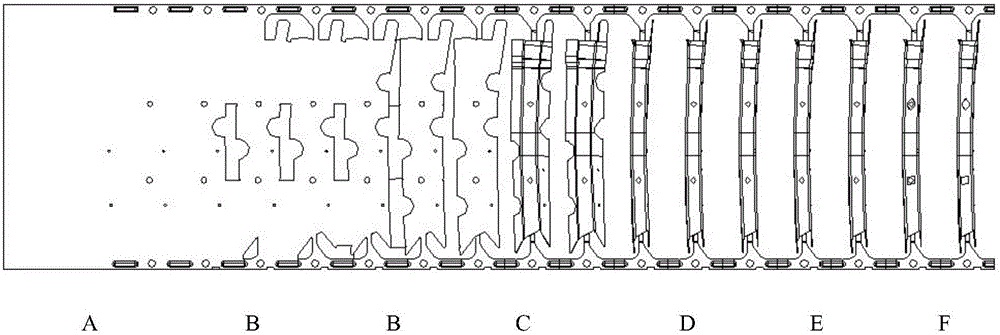

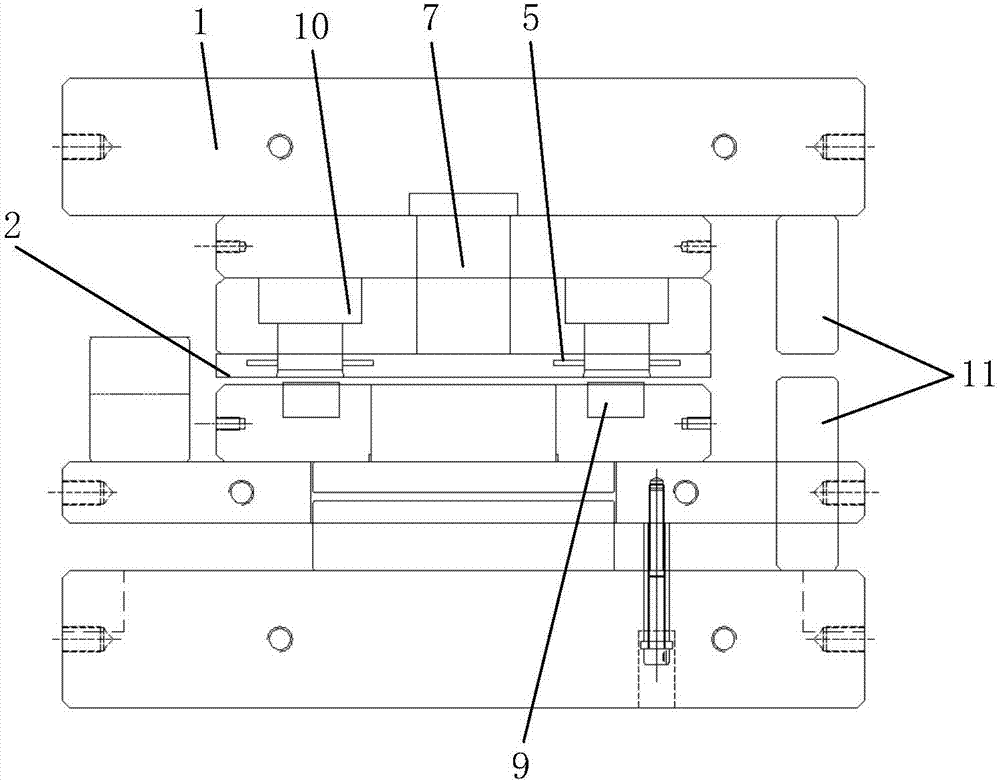

Continuous production die for automobile activated carbon canister support parts

The invention relates to a continuous production die for automobile activated carbon canister support parts. The continuous production die comprises an upper die part, a lower die part and guide pillars, wherein the lower die part comprises a lower die base, a stamping concave die knife and a lower die trimming knife block, and the stamping concave die knife and the lower die trimming knife block are fixed to the upper surface of the lower die base; the upper die part comprises an upper die base, a pressure plate, a punch and an upper die trimming knife block, the pressure plate, the punch and the upper die trimming knife block are fixed to the lower surface of the upper die base, the pressure plate is arranged on the upper die trimming knife block and connected with the upper die trimming knife block, and the punch is arranged on the pressure plate; the upper die base is connected with the lower die base through the guide pillars. Compared with the prior art, the continuous production die has the advantages of being long in service life, convenient to maintain, high in stamping efficiency, low in stamping cost and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

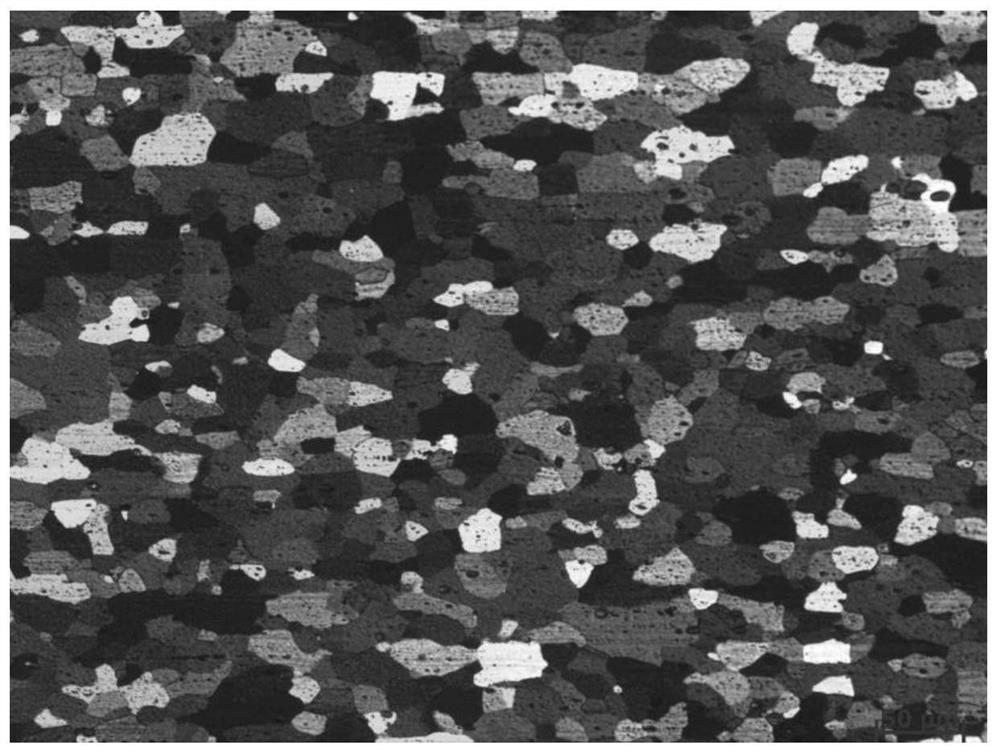

Preparation process of 5754 aluminum alloy plate with high formability

InactiveCN112553485AFully brokenGood formabilityFurnace typesMetal rolling arrangementsThermal insulationIngot

The invention belongs to the field of aluminum alloy machining and manufacturing, and relates to a preparation process of 5754 aluminum alloy plate with high formability. The aluminum alloy raw material is composed of, in percentage by weight, less than or equal to 0.15% of Si, 0.20-0.35% of Fe, less than or equal to 0.10% of Cu, 0.20-0.30% of Mn, 2.80-3.10% of Mg, 0.08-0.12% of Cr, less than or equal to 0.08% of Zn, 0.01-0.03% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurity, and the balance Al. The preparation process comprises the following steps that the aluminum alloy raw material is prepared to make an aluminum alloy ingot, the aluminum alloy ingot is subjected to homogenizing treatment at proper homogenization temperature, intracrystalline segregation and dendrite segregation are eliminated after thermal insulation is carried out on the ingot, rough non-equilibrium phases and eutectic phases are reduced, cast ingot structures and components are uniform, the hot rolling speed is controlled, precipitated phases are promoted to be fully crushed, the rolling reduction is controlled and intermediate annealing is added in a coldrolling stage, and the final finished product has good forming performance and comprehensive mechanical performance.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Automobile part continuous production die provided with pre-flanging mechanism

InactiveCN105964785AExtended service lifeAvoid damageShaping toolsVehicle componentsPunchingEngineering

The invention relates to an automobile part continuous production die provided with a pre-flanging mechanism. The automobile part continuous production die provided with the pre-flanging mechanism comprises an upper die part, a lower die part and guide posts. The upper die part comprises an upper die seat, a press plate, a puncher pin, an upper die trimming knife, an upper die pre-flanging mechanism body, an upper die complete flanging mechanism body and a material ejection groove, wherein the press plate, the puncher pin, the upper die trimming knife, the upper die pre-flanging mechanism body and the upper die complete flanging mechanism body are fixed to the lower surface of the upper die seat; and the material ejection groove is formed in the lower surface of the upper die seat. The lower die part comprises a lower die seat, a punching female die body, a lower die trimming knife, a lower die pre-flanging mechanism body, a lower die complete flanging mechanism body and a material ejection rod, wherein the punching female die body, the lower die trimming knife, the lower die pre-flanging mechanism body, the lower die complete flanging mechanism body and the material ejection rod are fixed to the upper surface of the lower die seat. In the working process, the puncher pin and the punching female die body are matched for conducting punching action; the lower die trimming knife and the upper die trimming knife are matched for conducting trimming action; the upper die pre-flanging mechanism body and the lower die pre-flanging mechanism body are matched for conducting pre-flanging action; and the upper die complete flanging mechanism body and the lower die complete flanging mechanism body are matched for conducting complete flanging action. Compared with the prior art, the automobile part continuous production die provided with the pre-flanging mechanism has the advantages of being long in service life, convenient to maintain, high in punching efficiency and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Secondary roller mill for waste iron sheet

InactiveCN103331300AImprove the utilization rate of residual valueReduce stamping costsMetal rolling arrangementsPunchingElectric machinery

The invention provides a secondary roller mill for a waste iron sheet, which includes a waste conveyor belt (1), a main body (6) and a motor fixing bracket (5), wherein the waste conveyor belt (1) is powered by power motor groups I (2) arranged at the front and rear end of the main body (6); power motor groups II (3) are fixed through the motor fixing bracket (5); the power motor groups II (3) provide power for relative rotation of paired rollers (4); a loading baffle (8) and a discharging baffle (7) are both fixed on the main body (6). The secondary roller mill performs secondary rolling on waste leftover materials in the past; after the fact that the mechanical properties of the materials conform to the national or industrial standards is verified, the materials are put into production and use; therefore, the scrap value use ratio of the materials is promoted, and the punching cost is saved.

Owner:NANJING HUIDE MACHINERY

A heat treatment method that improves the formability and bake hardenability of 6XXX series aluminum alloy sheets

ActiveCN101545083BExtended retention of bake-hardening propertiesImprove machining accuracyEconomic benefitsEnergy conservation

Owner:HUNAN UNIV

Double-hole shielding cover progressive die

The invention relates to the technical field of dies, in particular to a double-hole shielding cover progressive die. The double-hole shielding cover progressive die comprises an upper die holder, an upper die, a stripper plate, a lower die, a lower die holder, and a punching pilot hole station, a half sectioning station, a stretching station and a shielding cover punching-off station which are assembled correspondingly, wherein the upper die, the stripper plate and the lower die are correspondingly assembled with the punching pilot hole station, the half sectioning station, the stretching station, a double-side punching station, a bilateral hole turnup station, a first turnup flattening station, a second turnup flattening station, a punching side notch station and the shielding cover punching-off station which are formed sequentially. During actual production, production can be performed only by placing a material belt on the lower die, all the procedures are finished in the die, andfull automation of the whole flow is realized, so labor cost is reduced, the defective rate of the shielding covers is low, production efficiency is high, and the double-hole shielding cover progressive die is suitable for production of the shielding cover with side holes on the two sides.

Owner:DONGGUAN DAZHONG ELECTRONICS

Processing method for increasing stamping formability of 6111 aluminium alloy automobile sheet

InactiveCN101885000BSolve bottlenecksImprove stamping yieldRoll mill control devicesMetal rolling arrangementsRoom temperatureIngot

The invention relates to a processing method for increasing the stamping formability of the 6111 aluminium alloy automobile sheet. The method comprises the following steps: 1. performing heat treatment to 6111 alloy ingot, which is prepared through semicontinuous casting, at 220-480 DEG C for 1-15h, heating to 550 DEG C with the furnace, keeping temperature for 24h to perform the conventional homogenizing treatment; 2. cropping the ingot and milling the face of the ingot, heating to 440-450 DEG C for hot rolling, wherein hot rolling adopts the mode of longitudinal and lateral alternation, thetotal rolling deformation is more than 85%, the finishing temperature is more than 300 DEG C and the final thickness of the hot rolled sheet is 6mm; 3. keeping the temperature of the hot-rolled sheetto 420-430 DEG C for 1h-2h, performing intermediate annealing, performing cold rolling to ensure the thickness of the sheet is 0.8 mm-1.0 mm, wherein the cold deformation is more than 75%; 4. keepingthe temperature of the cold-rolled sheet to 550 DEG C for 7min, performing solution treating and water quenching, standing at the room temperature for 1min-48h; 5. performing pre-aging treatment in adrying box at 150-220 DEG C for 4min-15min; and 6. standing at the room temperature for more than two weeks to obtain T4P temper. After the sheet is processed by the method of the invention, the stamping formability and after-painting strength are obviously improved, thus facilitating to increase the rate of stamping products and reduce the stamping cost.

Owner:NORTHEASTERN UNIV LIAONING

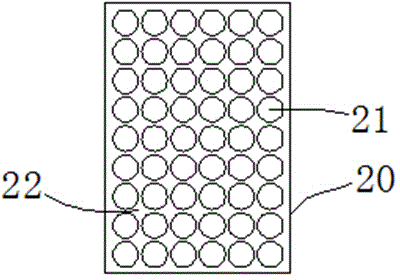

Microphone printed circuit board (pcb) high in utilization rate and lower punching die structure thereof

InactiveCN105478586AIncrease profitReduce stamping processShaping toolsMetal-working feeding devicesLower limitPunching

The invention discloses a microphone printed circuit board (pcb) high in utilization rate and a lower punching die structure thereof. The microphone pcb comprises a microphone pcb base material and a lower punching die. The microphone pcb base material is provided with a microphone unit and leftovers. The lower punching die is provided with an upper left basic limiting angle block, an upper right basic limiting angle block and a lower limiting check block. The upper left basic limiting angle block, the upper right basic limiting angle block and the lower limiting check block are used for wrapping and positioning the periphery of the microphone pcb base material. The microphone pcb is free of technological plate edges required by a conventional circuit board base material, the punching process for positioning basic holes is eliminated, and the finished microphone pcb is directly formed; the number of punching procedures is small, the punching cost is low, the utilization rate of pcb materials is increased, and economic benefits are remarkable.

Owner:苏州市三生电子有限公司

Lower punching die for microphone printed circuit board (pcb)

InactiveCN105478585AIncrease profitReduce stamping processShaping toolsMetal-working feeding devicesLower limitPunching

The invention discloses a lower punching die for a microphone printed circuit board (pcb). The lower punching die is characterized in that the lower punching die is provided with an upper left basic limiting angle block, an upper right basic limiting angle block and a lower limiting check block; the upper left basic limiting angle block, the upper right basic limiting angle block and the lower limiting check block are located on the upper left portion, the upper right portion and the lower portion of the lower punching die respectively. The lower punching die can process circuit board base materials without technological plate edges, the punching process for positioning basic holes is eliminated, and the finished microphone pcb is directly formed; the number of punching procedures is small, the punching cost is low, the utilization rate of pcb materials is increased, and economic benefits are remarkable.

Owner:苏州市三生电子有限公司

Stamping device of automobile stamping part

The invention discloses a stamping device of an automobile stamping part. The stamping device of the automobile stamping part comprises stamping dies and a base. The number of the stamping dies is multiple. The multiple stamping dies are distributed in the circumferential direction with the center of a pressure disc as the circle center. Each stamping die comprises a working position die and a male used for stamping a workpiece to the corresponding working position die. The working position dies are fixed relative to the base. When workpiece stamping is needed, according to supplies and demands, the corresponding stamping die is needed to be arranged, multi-operation sequential stamping is conducted on the workpiece through the multiple stamping dies on the stamping device of the automobile stamping part, and finally, the workpiece after being stamped is taken out. According to the stamping device of the automobile stamping part, through the arrangement of the multiple stamping dies, when the workpiece needs the multiple stamping operations, stamping can be completed directly on the stamping device of one automobile stamping part, multi-workpiece stamping can be conducted simultaneously, and the stamping cost of the workpiece is reduced effectively.

Owner:聊城市博源节能科技有限公司

Light alloy plate stamping forming process and stamping device

ActiveCN112058984AImprove diffusion abilityImprove plasticityShaping toolsFurnace typesAlloyForming processes

The invention discloses a light alloy plate stamping forming process and stamping device. The light alloy plate stamping forming process comprises the following steps that 1, a light alloy material isheated to the solid solution temperature of the light alloy material or above; 2, the heated light alloy material is placed between a female die and a male die; 3. the detection temperature of each area of the light alloy material is obtained; and 4, when the female die and the male die are closed for stamping, electric pulse treatment is carried out on the areas according to the detected temperature. According to the technical scheme, the production quality, the production energy efficiency and the production efficiency can be favorably improved.

Owner:深圳新顿科技有限公司

Preheat treatment for improving automobile plate of 6111 aluminium alloy formation and baking paint hardening performance

The invention is about the pretreatment of the formability of the 6111 A-alloy autocar board and the sclerosing of the stoving varnish. The process is to treat the 6111 board by the solution hardening, stable it for 2h-5d in the room temperature, then to preheating treatment for 7min-15min in 180 DEG C-200 DEG C. The formability of the 6111 A-alloy autocar board and the sclerosing of the stoving varnish are all improved qpparently, it is used to improve the presswork ratio. So the car factory can use the A-alloy board to produce the car body instead of the steel plate.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com