Die for multi-angle side-punching machining

A side punching and multi-angle technology, applied in the field of stamping dies, can solve problems such as complex procedures, large number of dies, increased manufacturing costs and production cycles, and achieve the effects of reducing stamping costs, reducing the number of die sets, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

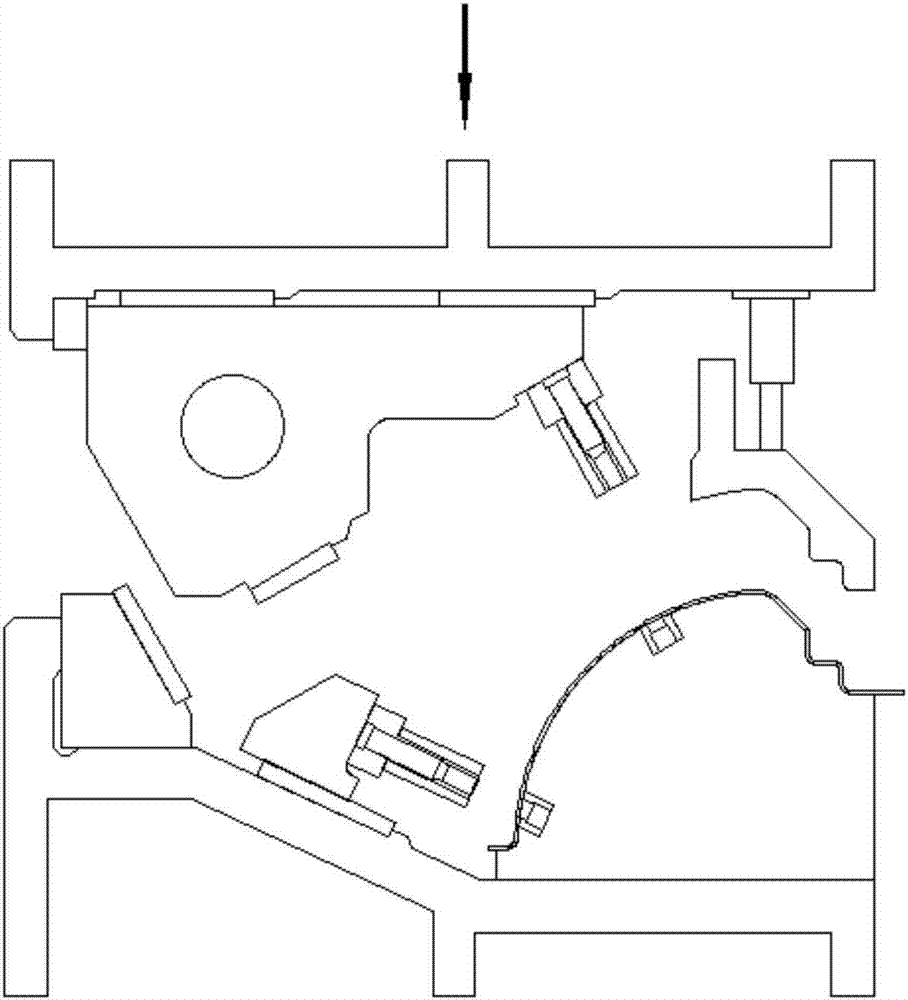

[0023] Such as figure 1 As shown, the part needs to be punched at two different positions, and the punching angles are different, that is, the first punching hole A and the second punching hole B; in the prior art, the first punching hole is punched out in the first set of molds Hole, punch out the second hole in the next set of molds, the processing cycle is longer, and the mold cost is higher.

[0024] Such as figure 2 As shown, the present invention provides a mold for multi-angle side punching, which is used to punch holes in different positions of the part 7, including an upper mold base 2, a lower mold base 1, a presser 6 and a lower punch 8. Among them, the presser 6 is set on the upper die base 2, and a nitrogen spring 4 is arranged between the upper die base 2, the lower punch 8 is set on the lower die base 1, and the lower punch 8 is provided with two Die 5 corresponding to each punching position.

[0025] The key is: the first wedge slider 14 is hoisted on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com