Metal sheet warm forming device based on induced high-frequency electromagnetic field

A high-frequency electromagnetic field, metal sheet technology, applied in metal processing equipment, forming tools, manufacturing tools and other directions, can solve the problems of difficulty, difficult forming, good strength, etc., to simplify the stamping process, improve stamping efficiency, and reduce stamping costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

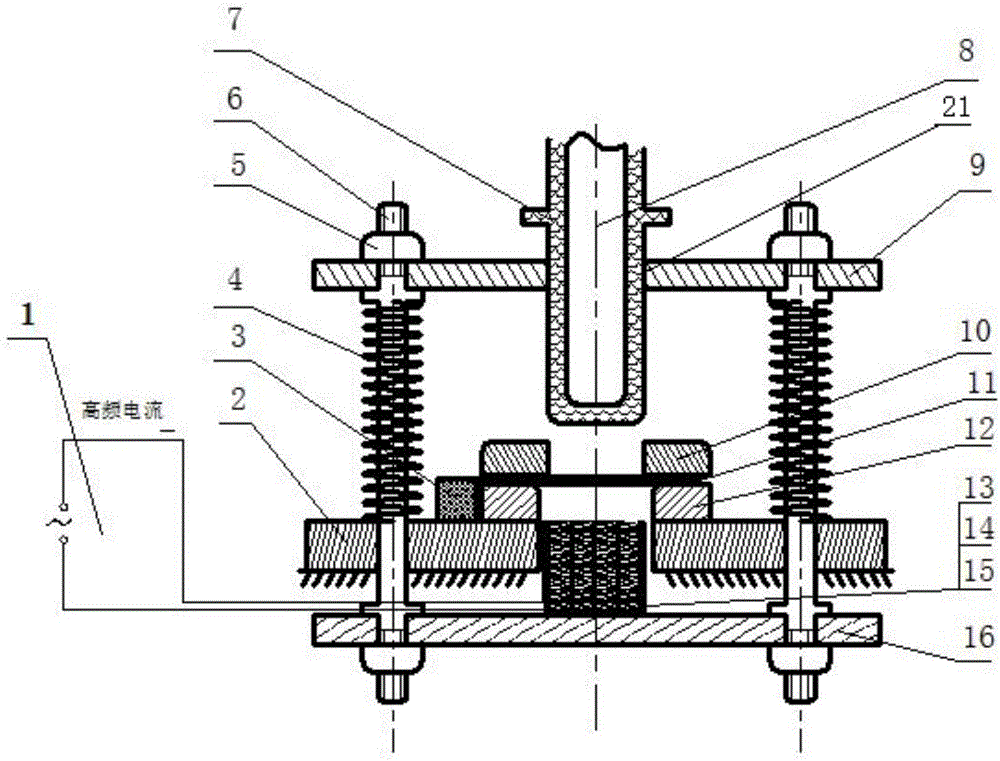

[0027] like Figure 1 to Figure 5 As shown, this embodiment provides a metal sheet warm forming device based on an induced high-frequency electromagnetic field. The worktable 2 is provided with a punching hole 21 that penetrates through the upper and lower sides, and the support frame includes an upper support plate 9, The lower support plate 16 located on the lower side of the worktable 2 and the connecting rod 6 slidably connected to the worktable 2, there are two connecting rods 6, and the two connecting rods 6 are located on both sides of the punching port 21 respectively, and the connecting rods 6 are sleeved. There is a spring 4, one end of the spring 4 is clamped between the workbench 2 and the upper support plate 9, and the spring 4 plays the role of supporting the whole support frame. The two ends of the connecting rod 6 are assembled and connected to the upper support plate 9 and the lower support plate 16 through the nut 5 respectively. The punch forming assembly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com