Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Stamping process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

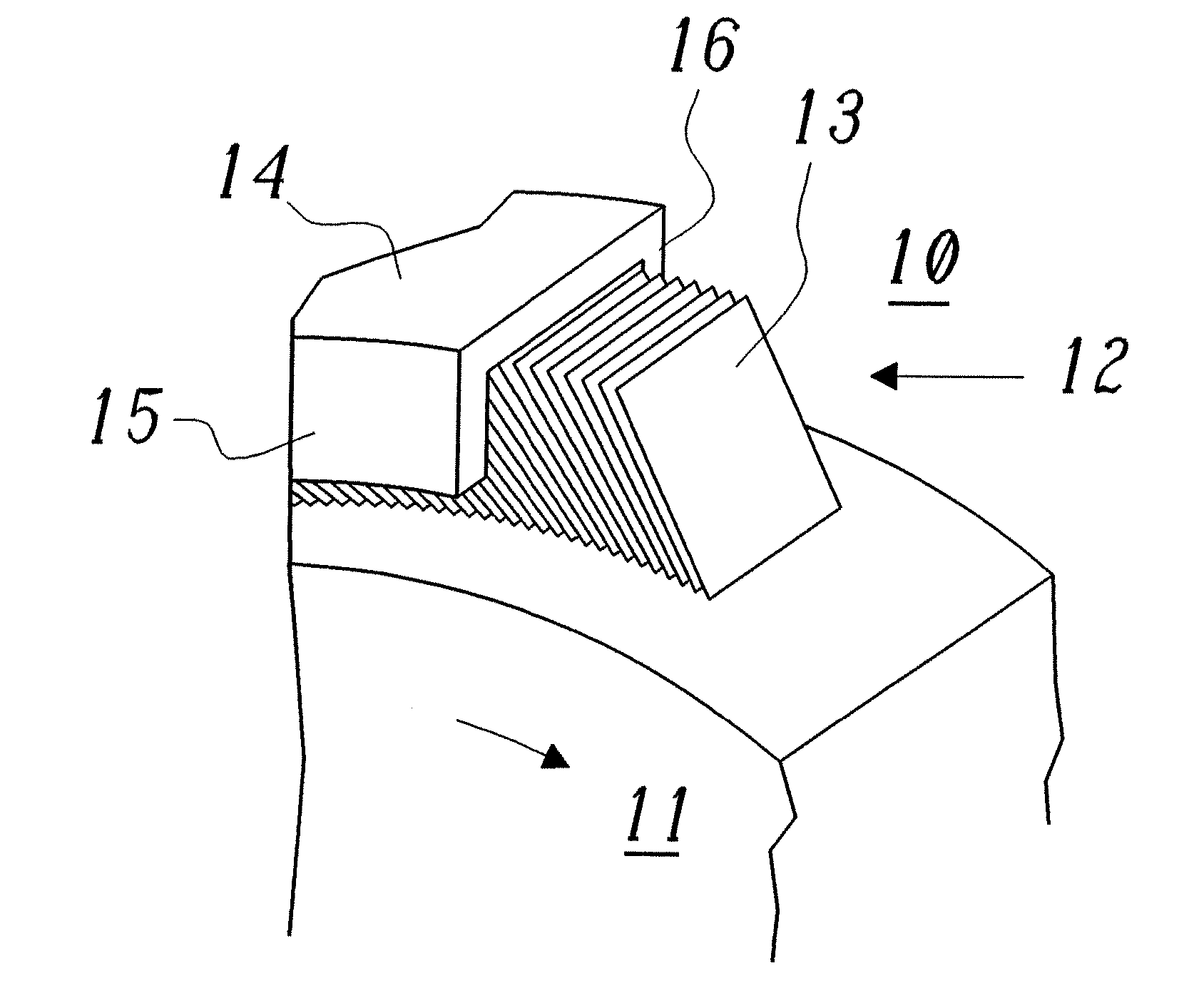

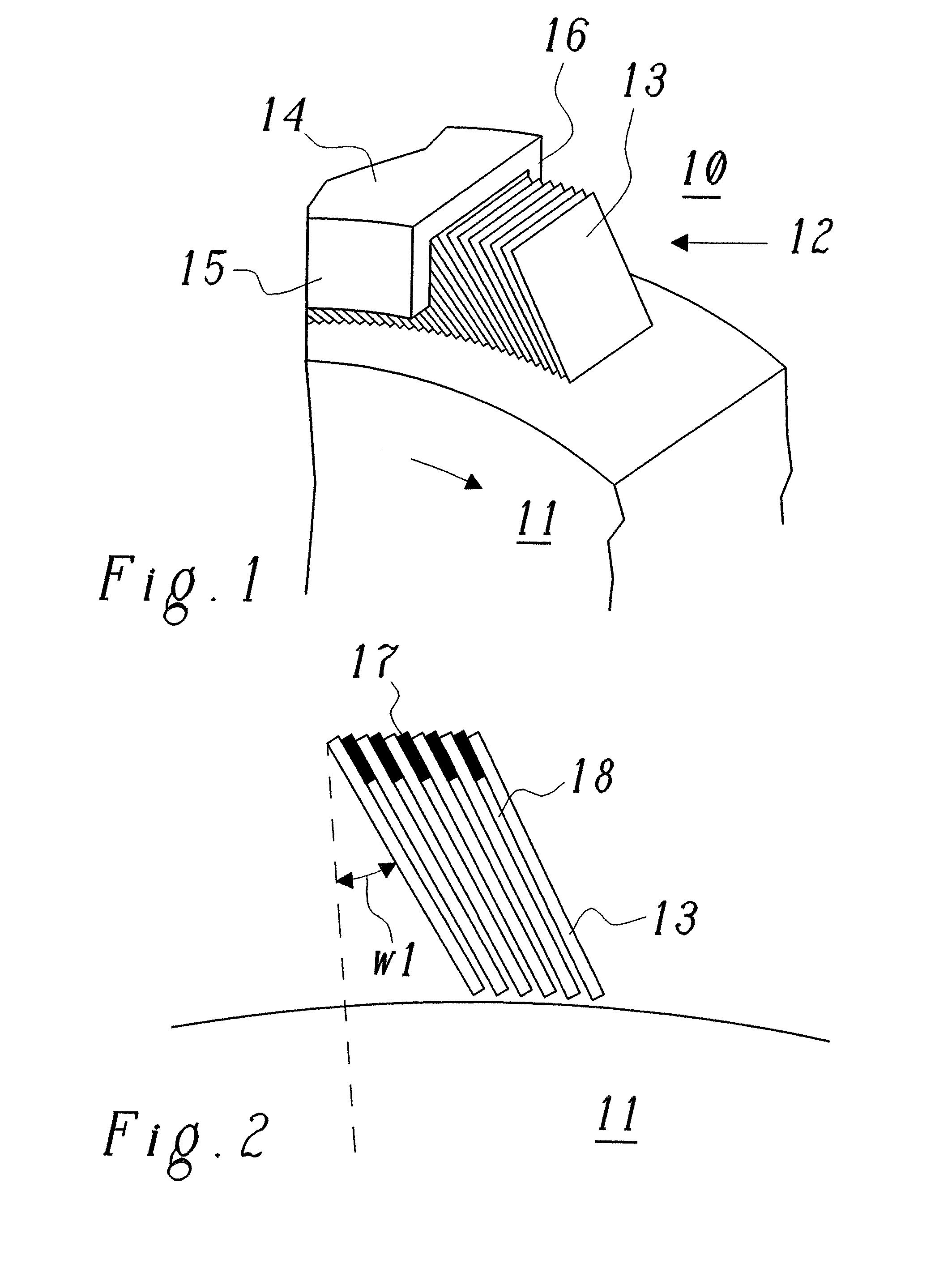

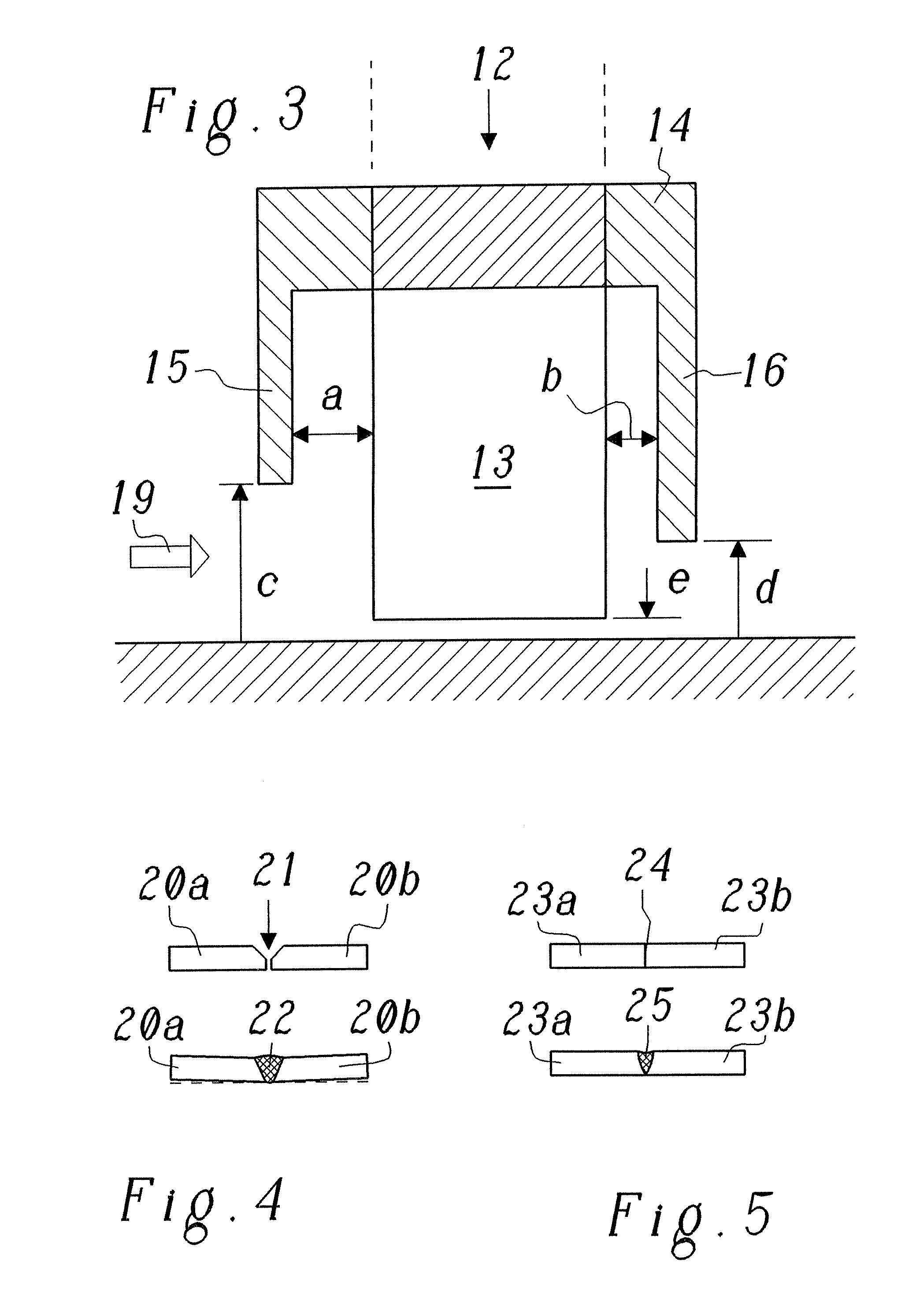

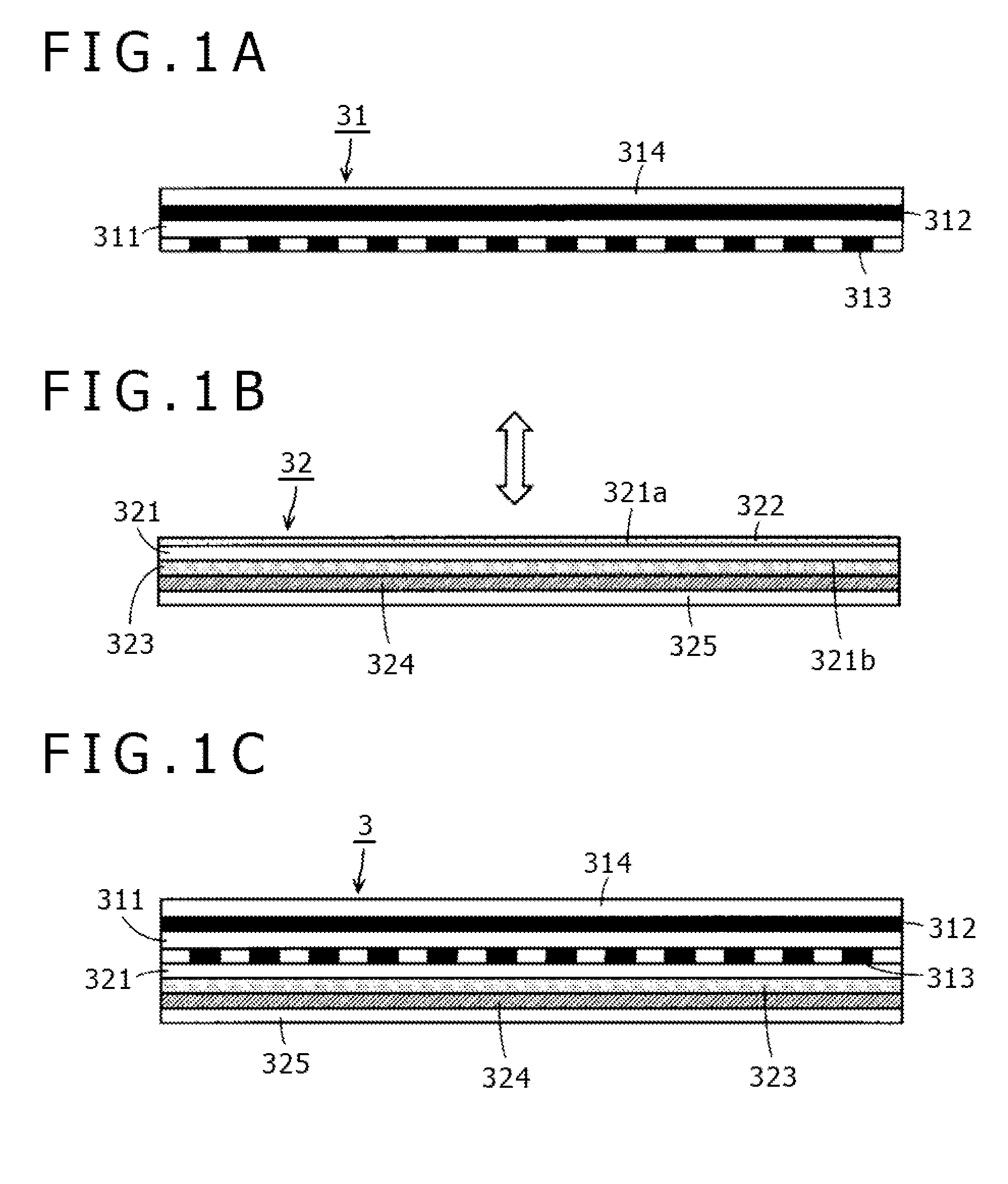

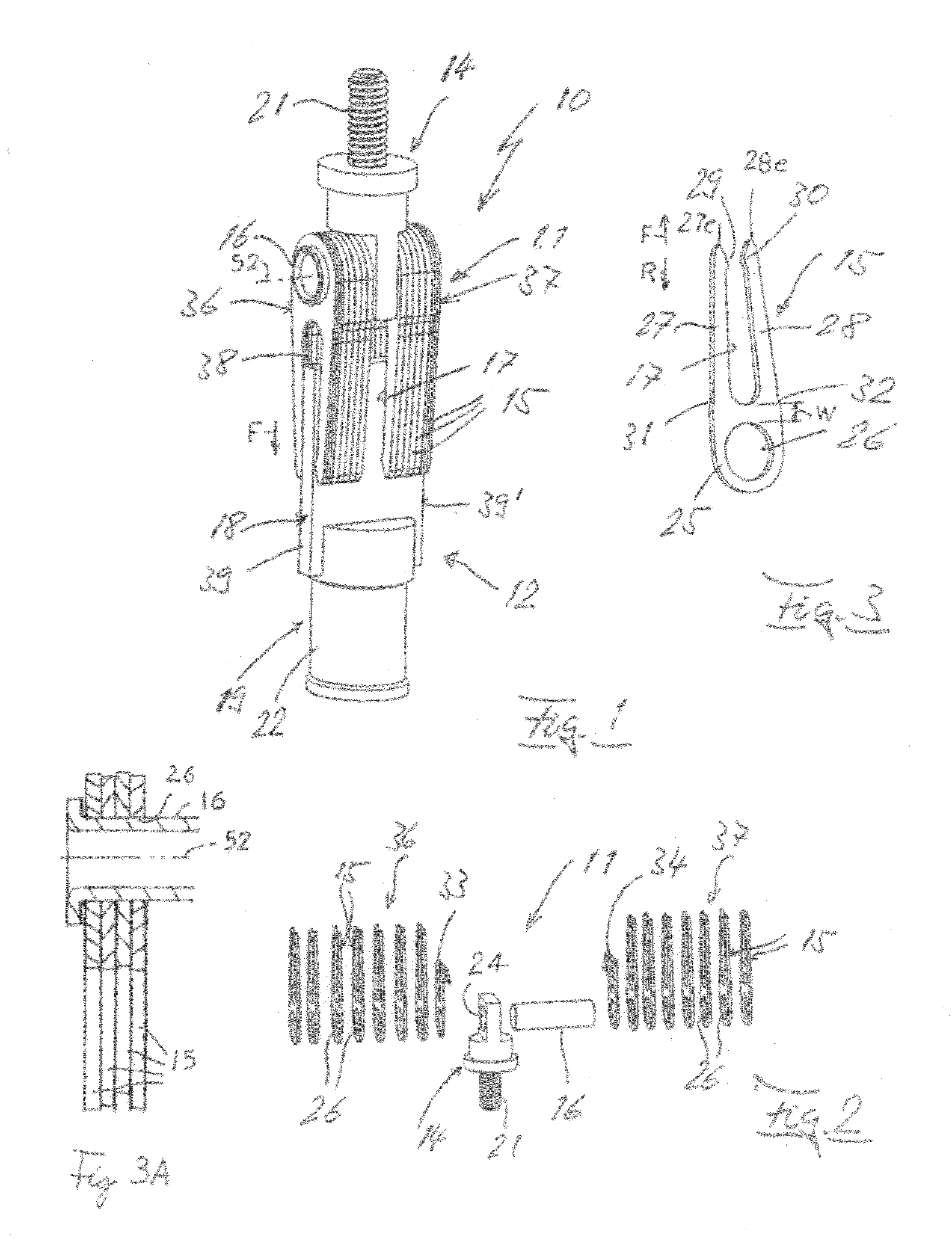

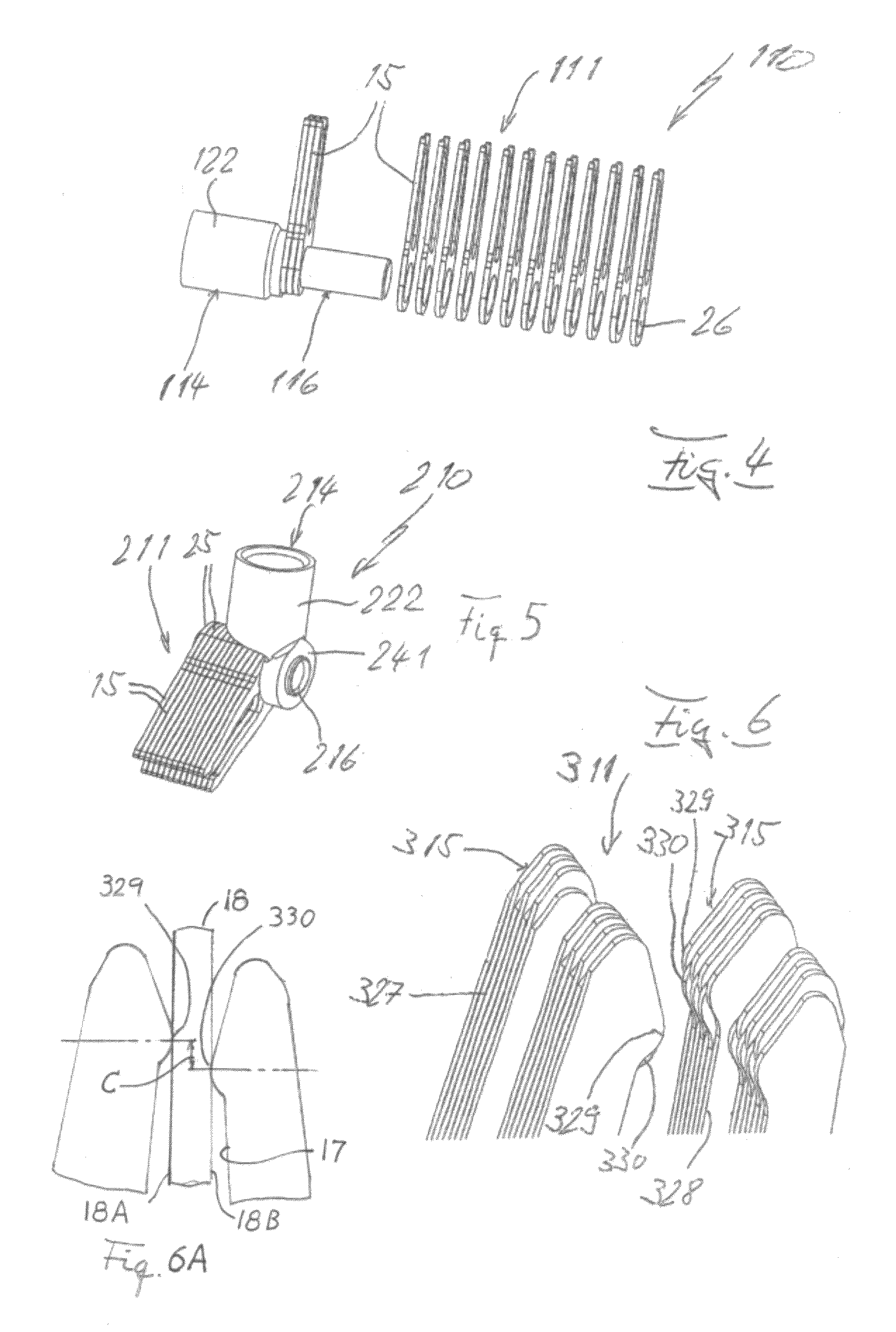

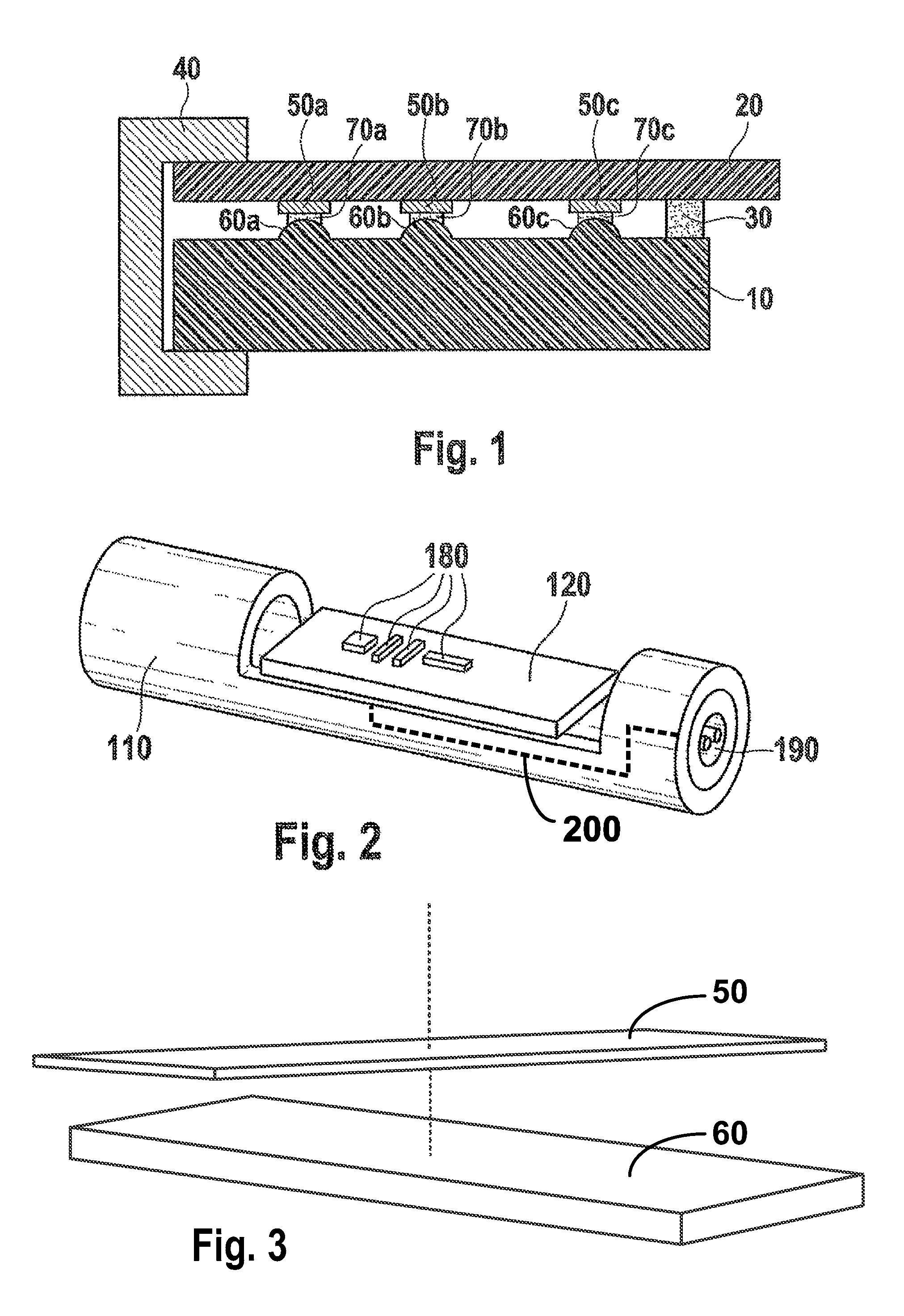

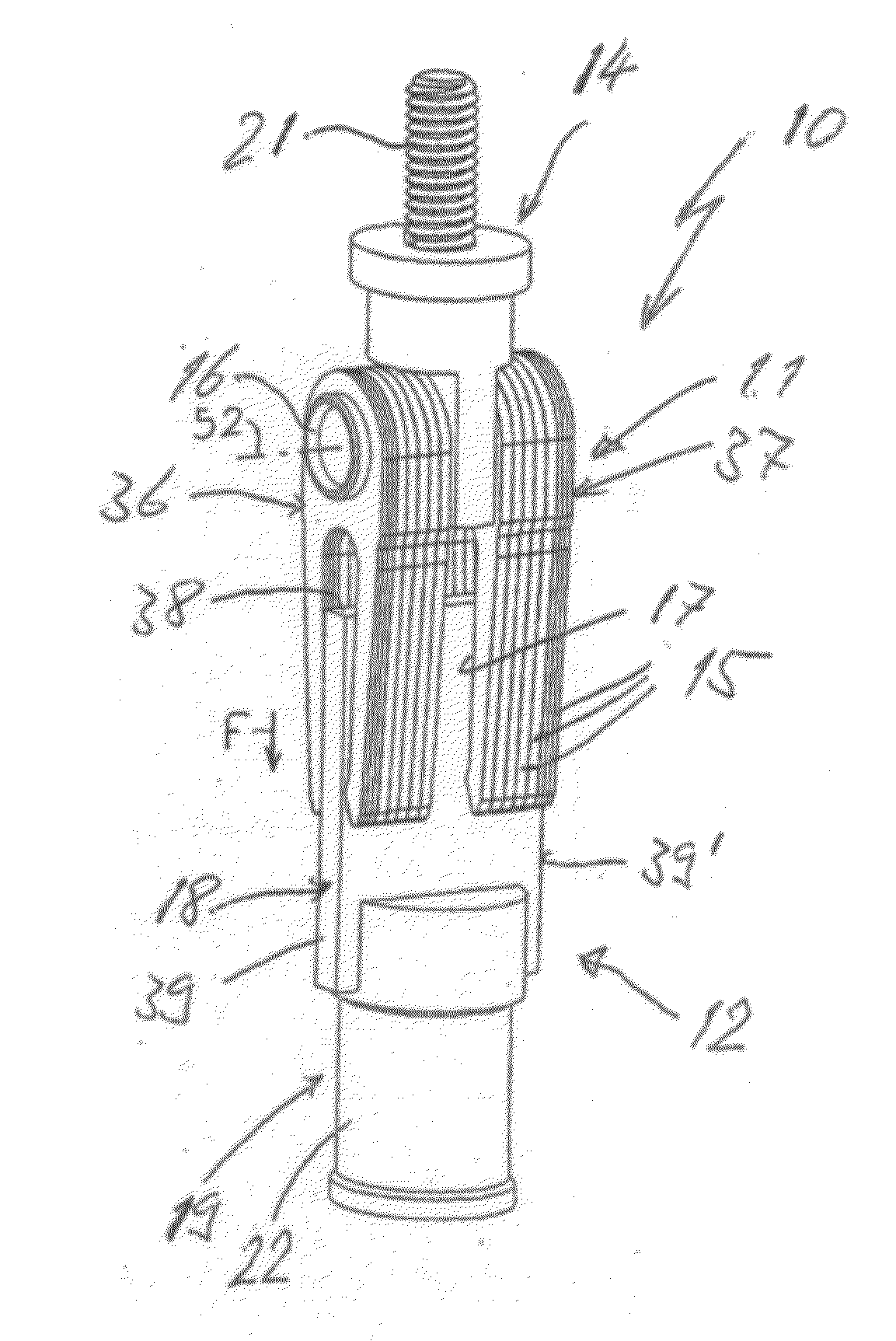

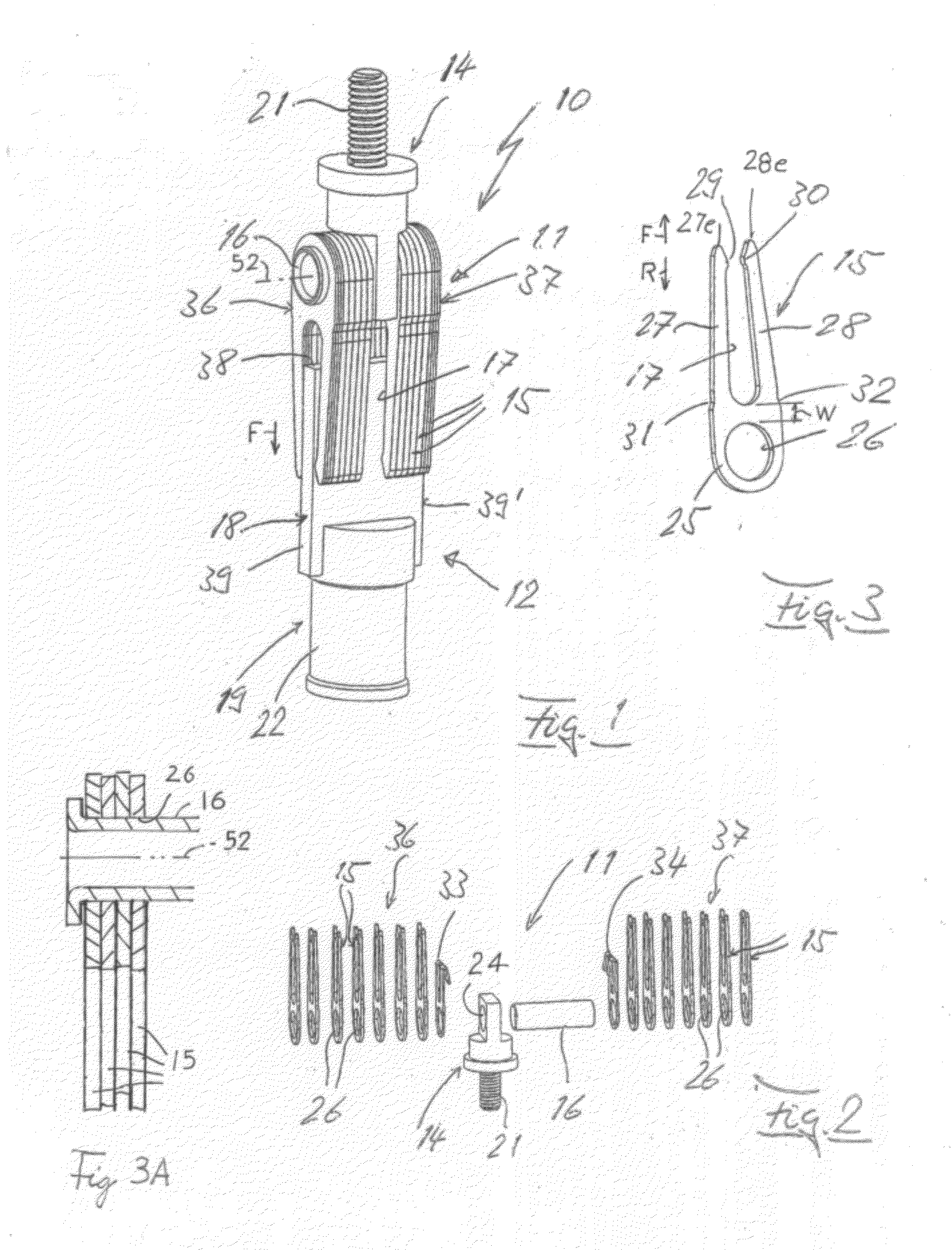

Leaf seal and method of producing a leaf seal

InactiveUS20070085277A1Reduce distractionsAvoid disadvantagesEngine sealsLeakage preventionContact lineGas turbines

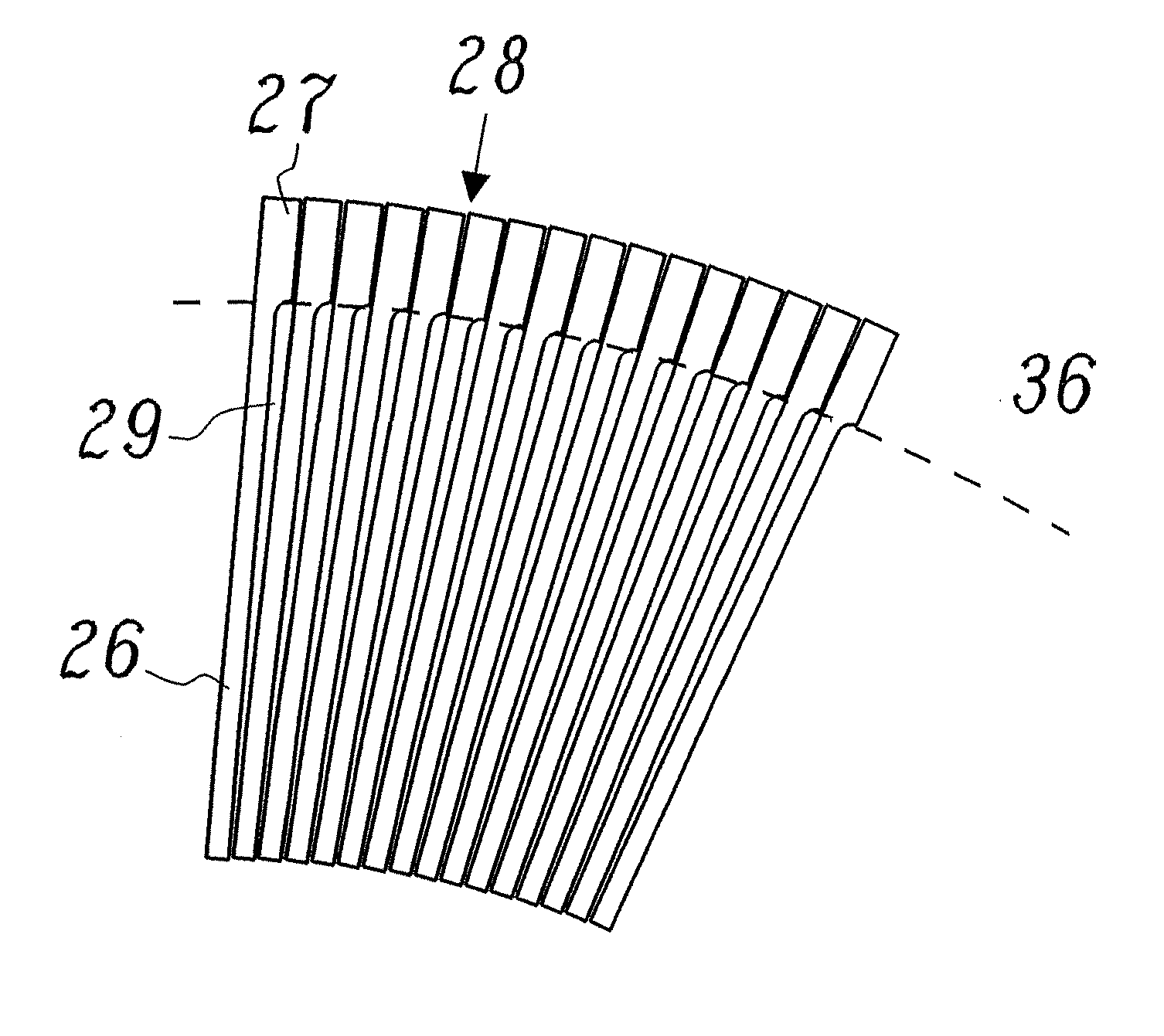

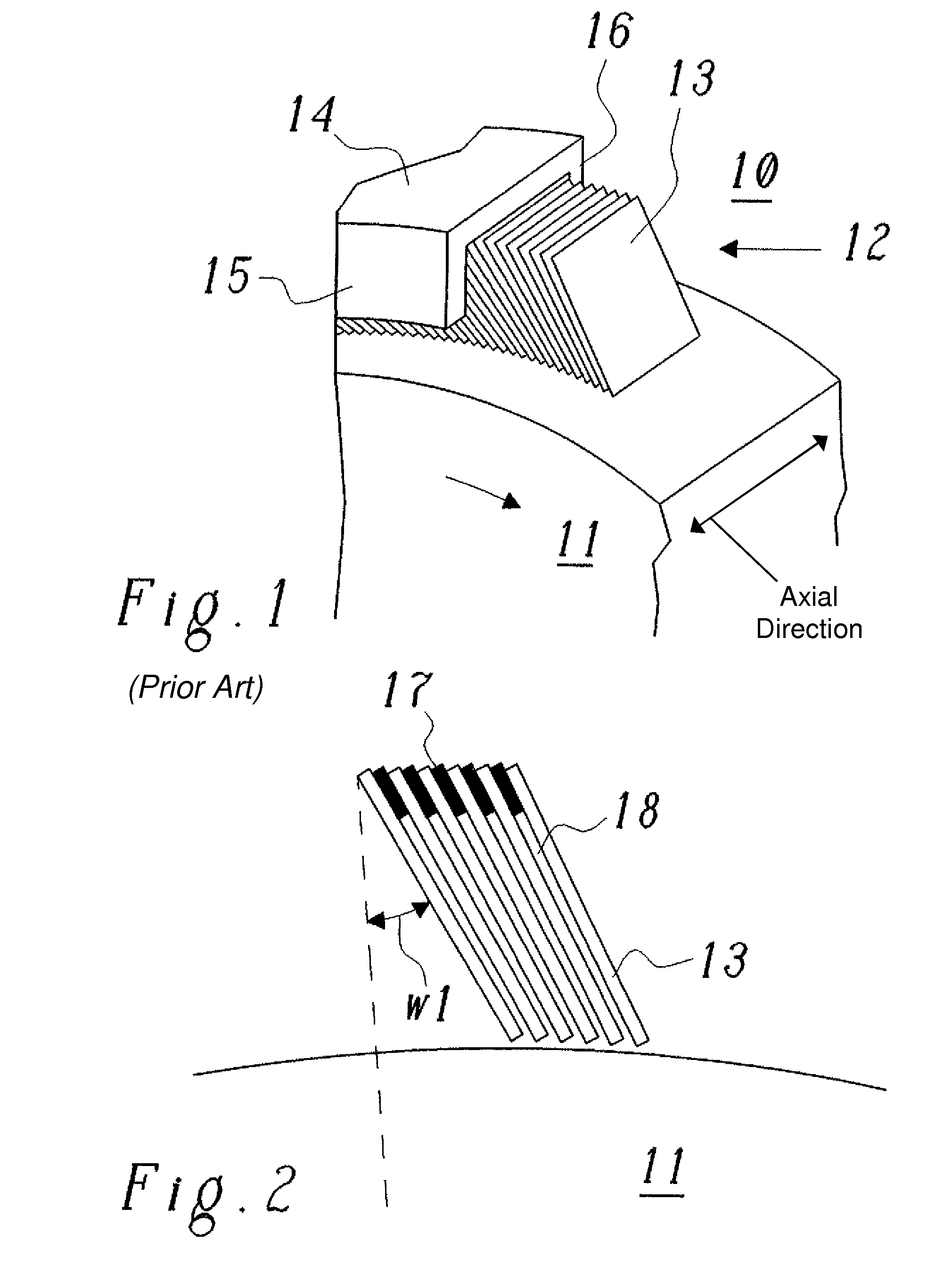

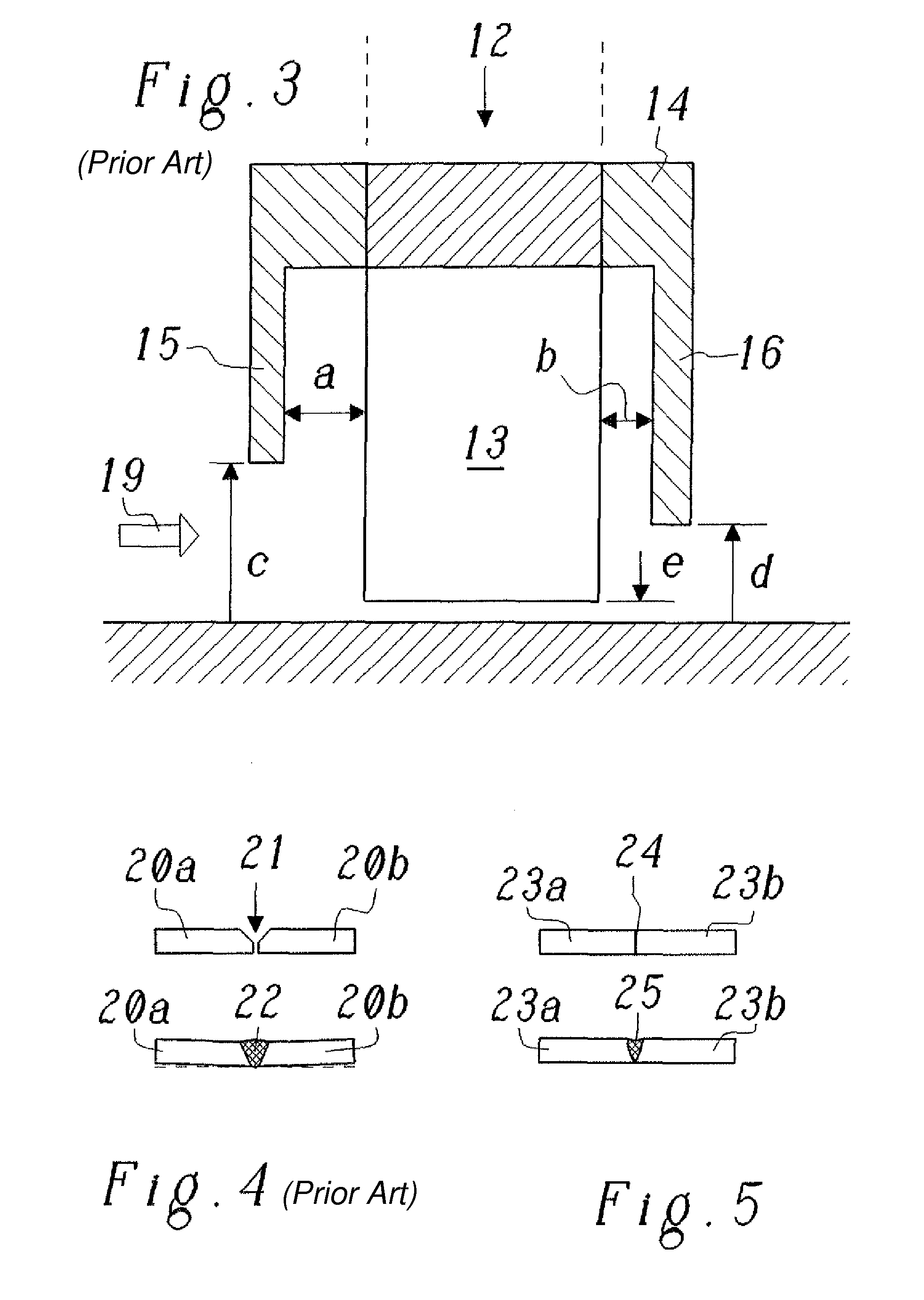

A leaf seal for sealing a shaft rotating about an axis, in particular in a gas turbine, includes a multiplicity of spaced-apart leaves (26) which are arranged in a concentric circle around the axis and are fixed in their position by welded connections produced by electron beam welding, the leaves (26), with their surfaces, being oriented essentially parallel to the axis. The welded connections of the leaves are improved by the leaves (26) being designed in such a way and being arranged in the leaf seal in such a way that they abut against one another at the side edges directly or via intermediate spacers (27) along at least one contact line (36) extending over a plurality of leaves (26), and by the welded connections being designed as welds directed along the at least one contact line (36) and oriented in axial direction.

Owner:ANSALDO ENERGIA IP UK LTD

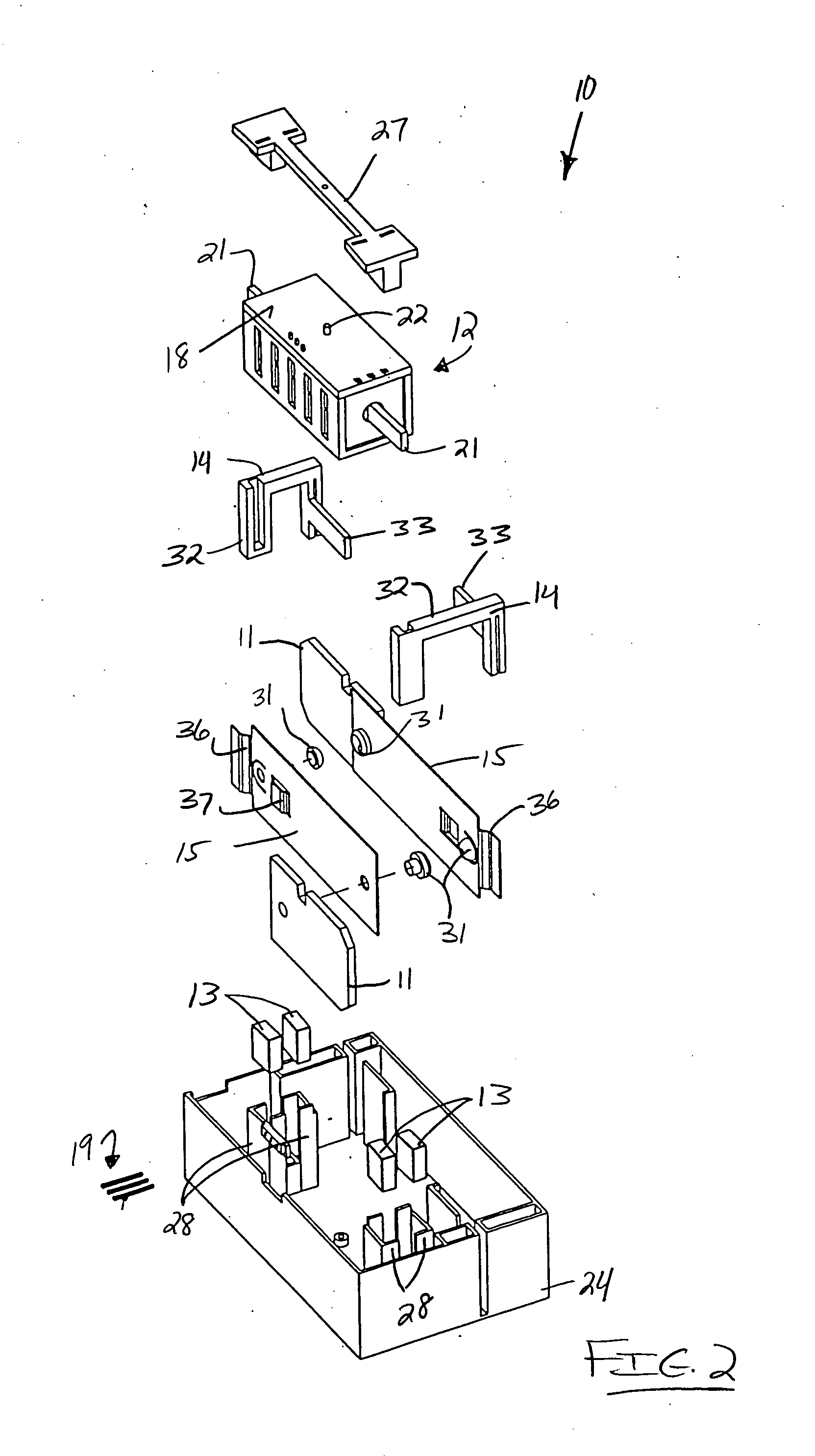

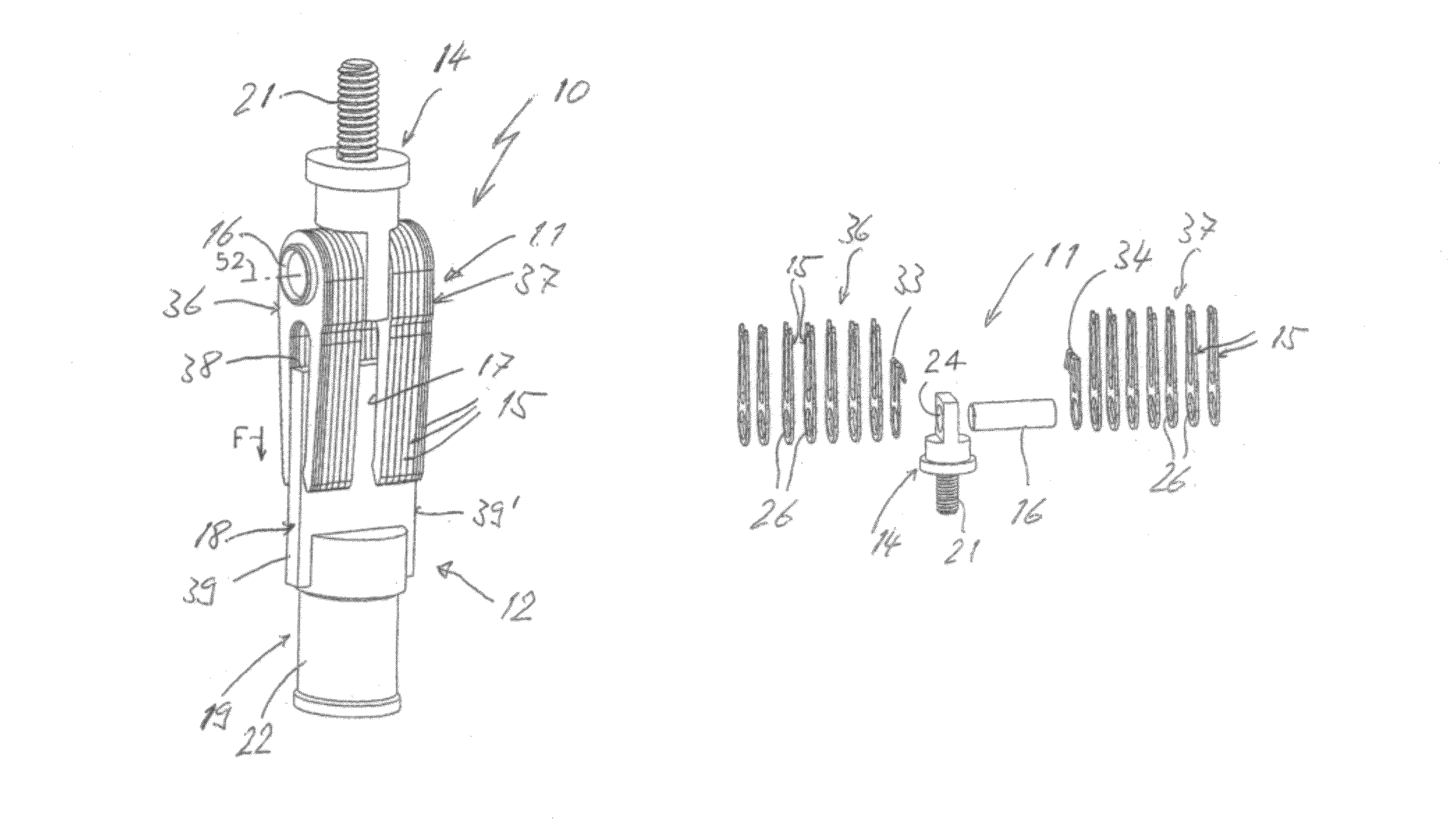

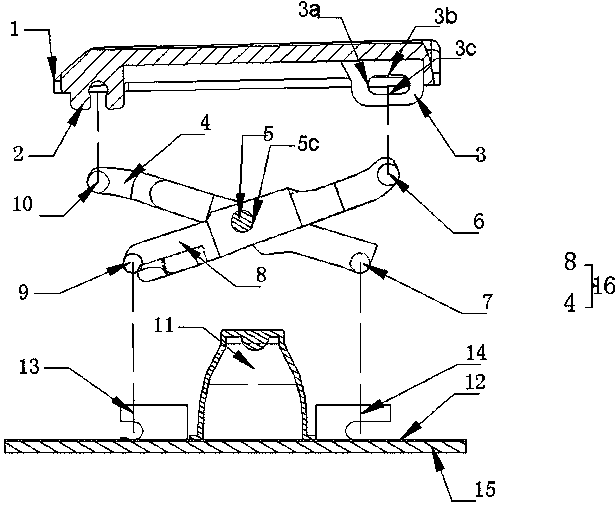

Bi-stable electromagnetic relay with x-drive motor

ActiveUS20120206222A1Maximize damping effectStamping process is simpleRelay detailsElectromagnetic relay detailsDrive motorEngineering

An electromagnetic relay assembly comprises a rotatable electromagnetic coil assembly, first and second pairs of opposed permanent magnets, and a switch assembly. The coil assembly comprises a coil, a core, and a rotatable coil housing. The coil is wound around the core. The core comprises opposed core termini, and the coil housing has an axis of rotation orthogonal to the coil axis. The magnet pairs fixedly positioned adjacent the core termini such that the core termini are respectively displacable intermediate the magnet pairs. The coil operates to create a magnetic field directable through the core for imparting coil housing rotation about the axis of rotation via attraction to the positioned / anchored magnets. The core termini displace linkage arms, and the linkage arms actuate contact-spring assemblies of the switch assembly intermediate open and closed positions.

Owner:HONGFA HLDG U S

Leaf seal and method of producing a leaf seal

InactiveUS8585058B2Reduce distractionsAvoid disadvantagesEngine sealsLeakage preventionContact lineGas turbines

A leaf seal for sealing a shaft rotating about an axis, in particular in a gas turbine, includes a multiplicity of spaced-apart leaves (26) which are arranged in a concentric circle around the axis and are fixed in their position by welded connections produced by electron beam welding, the leaves (26), with their surfaces, being oriented essentially parallel to the axis. The welded connections of the leaves are improved by the leaves (26) being designed in such a way and being arranged in the leaf seal in such a way that they abut against one another at the side edges directly or via intermediate spacers (27) along at least one contact line (36) extending over a plurality of leaves (26), and by the welded connections being designed as welds directed along the at least one contact line (36) and oriented in axial direction.

Owner:ANSALDO ENERGIA IP UK LTD

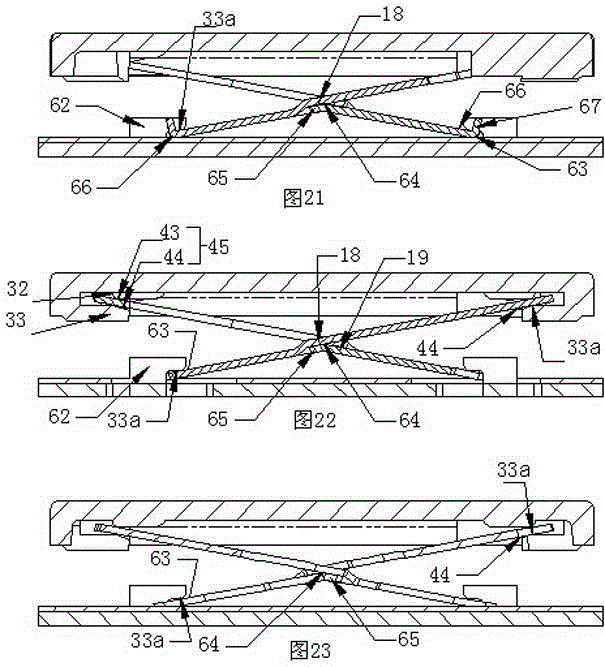

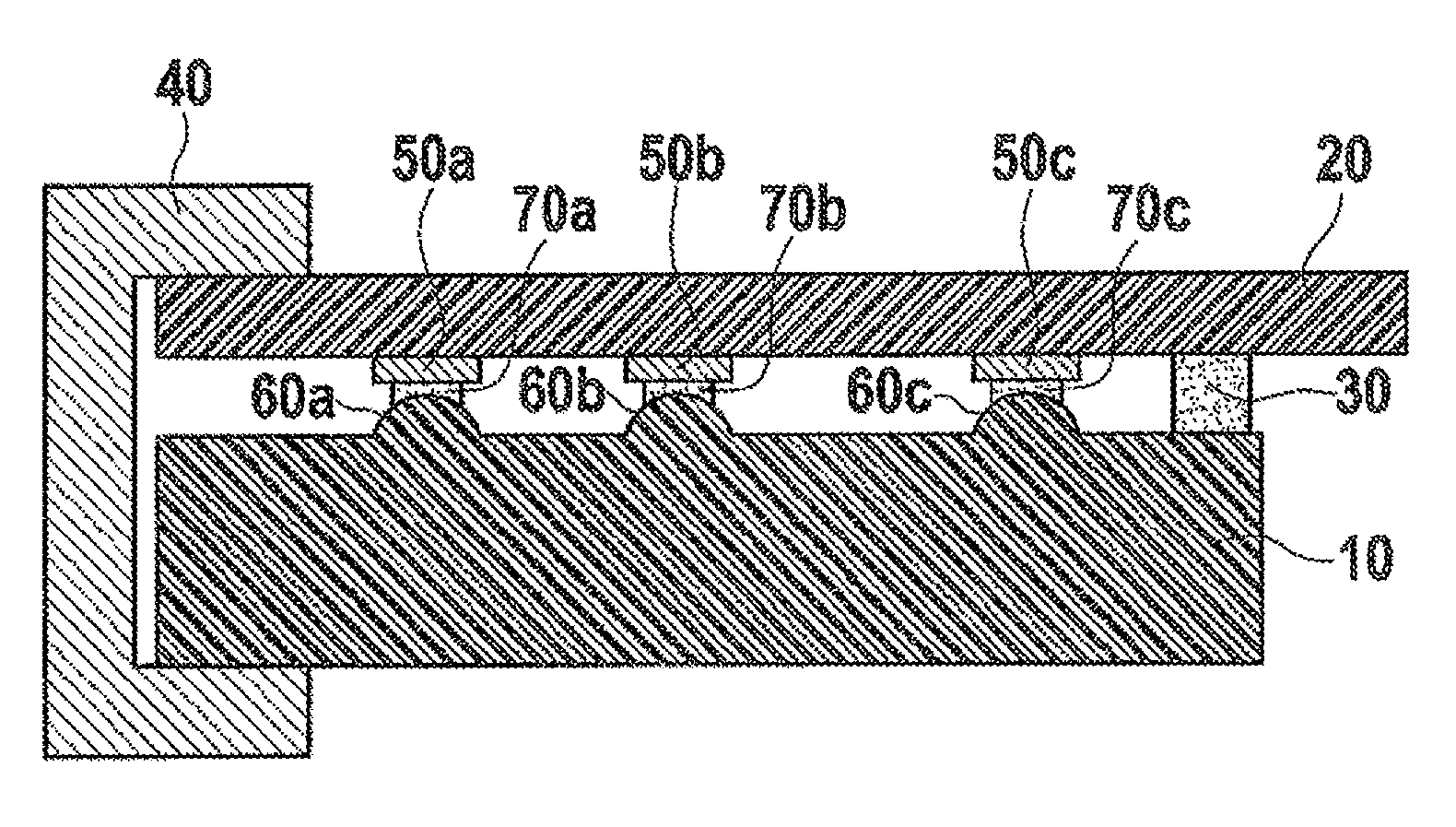

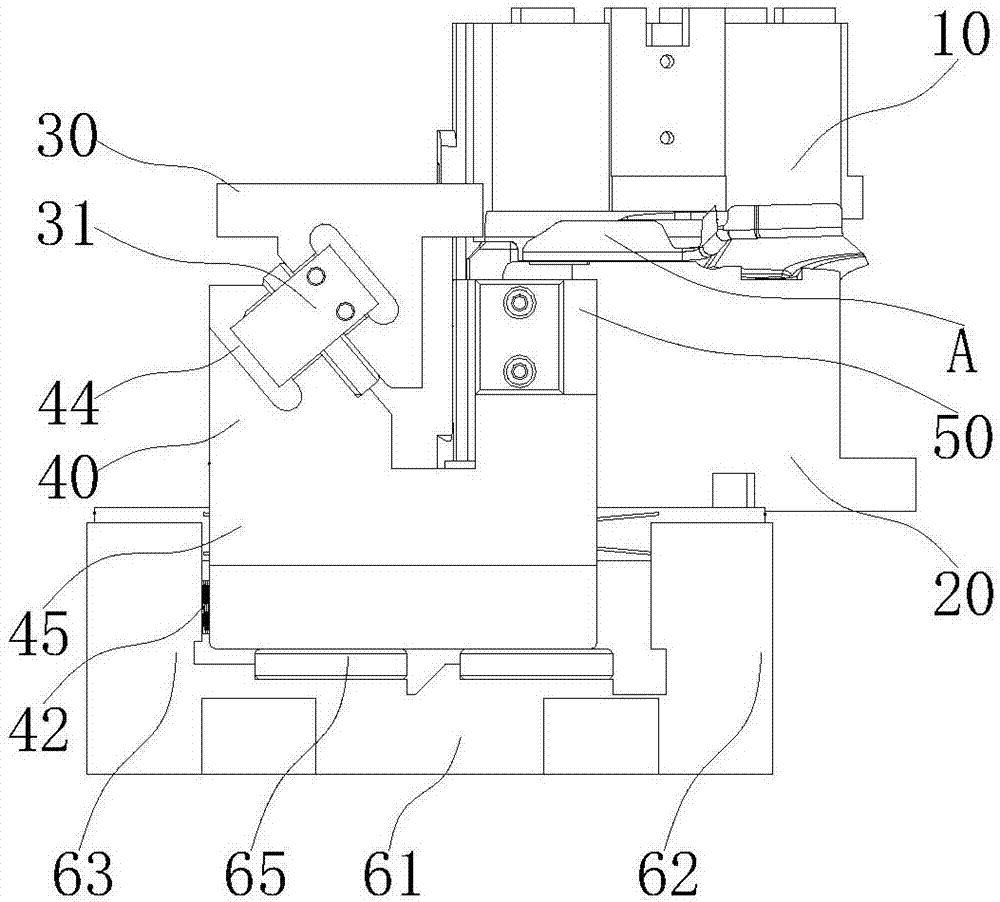

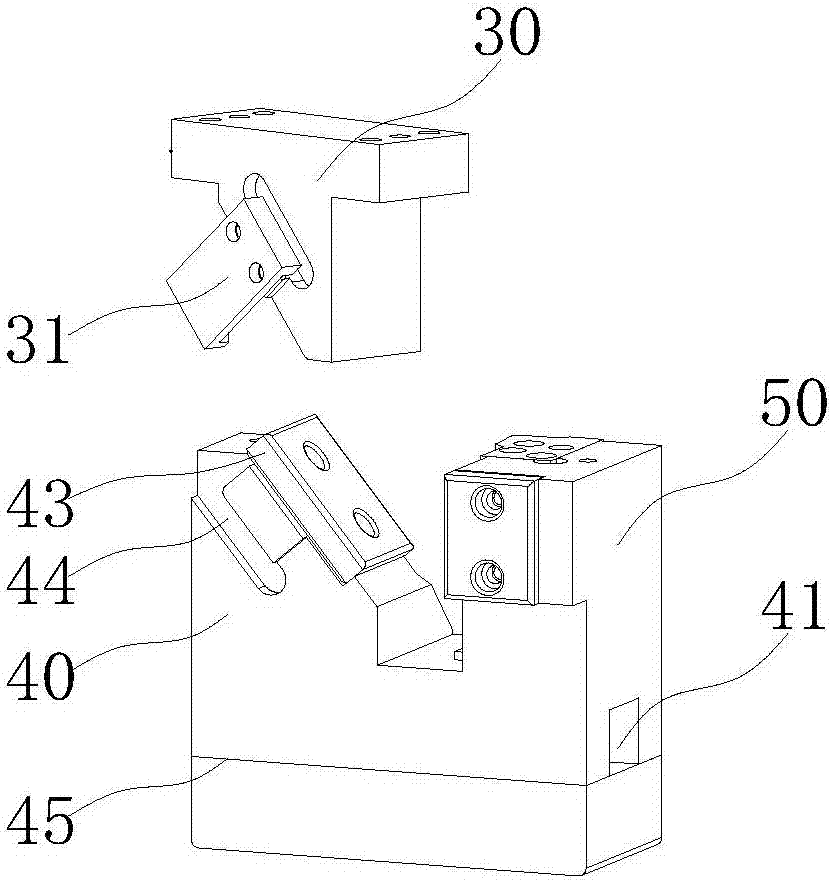

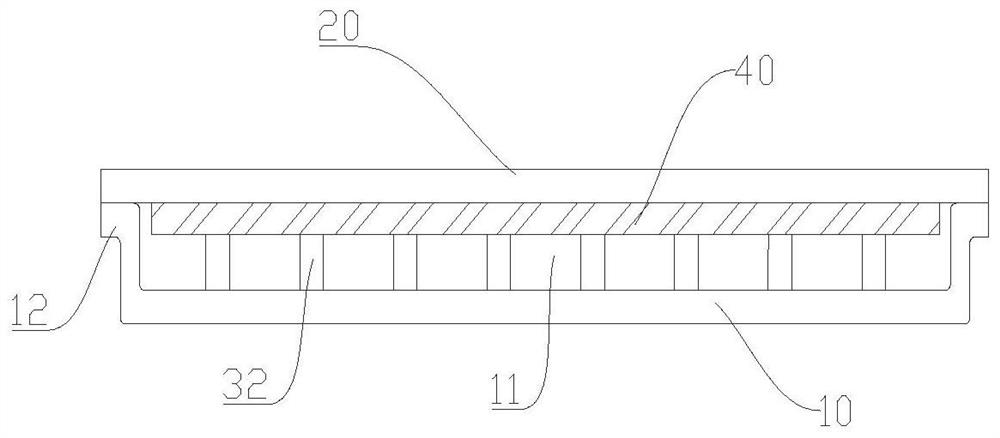

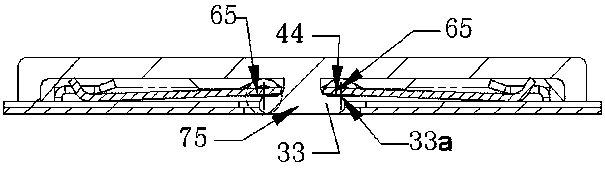

Surface fitting and scissors foot supported key switch device

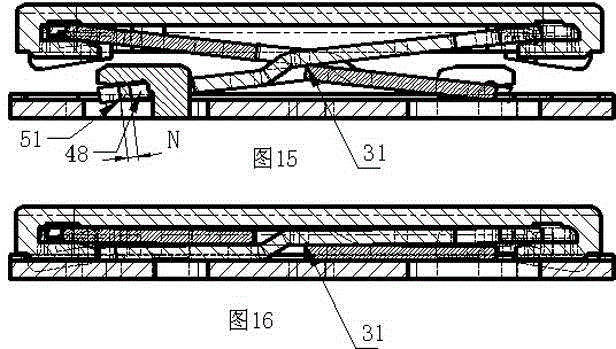

The present invention discloses a surface fitting and scissors foot supported key switch device. The surface fitting and scissors foot supported key switch device comprises a keycap, an elastomer, a switch loop having a switch contact, a supporting plate having a matching part, and a scissors foot support having the upper and lower matching parts. The scissors foot support is in rotatable or slip connection with the keycap and the matching part of the support plate respectively via the upper and lower matching parts and forms a synchronous linkage supporting structure by the mutual force transmission, thereby guaranteeing that the keycap does the elevating motion parallel with the supporting plate. The surface fitting and scissors foot supported key switch device is characterized in that a concave bottom surface in the keycap is equipped with the key matching protruding shoulder 32, the key matching protruding shoulder 32 and a key inverted buckling boss 33 of the keycap form a matching part of the keycap, and the upper matching part of the scissors foot support is composed of a scissors upper end upper plate surface 43 and a scissors upper end plate lower surface 44. If the problems that the wear resistance of the scissors foot support, the keycap and the supporting plate can be improved and a thinner metal plate can be used to produce the scissors foot support to simultaneously reduce the material cost and the height of a keyboard further, can be solved, a conventional sheet metal scissors foot support can substitute for a conventional widely used plastic scissors foot support.

Owner:陈峰

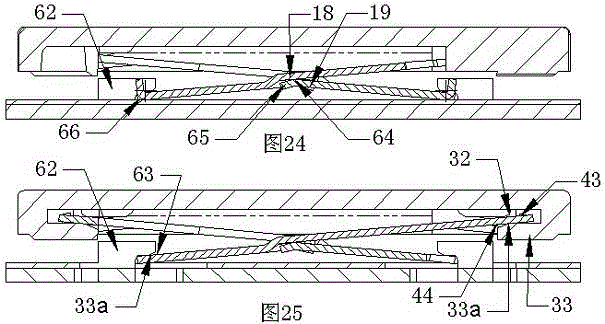

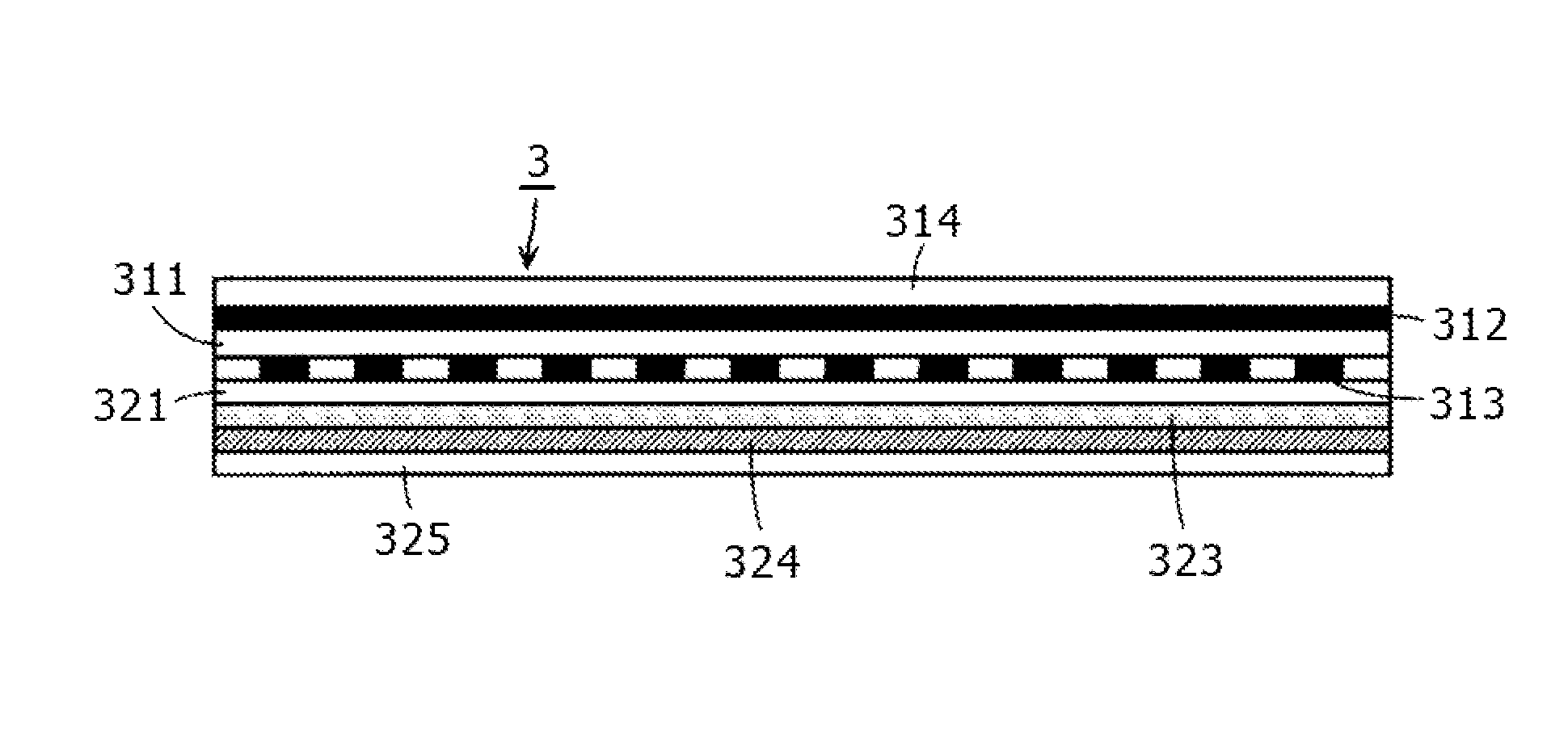

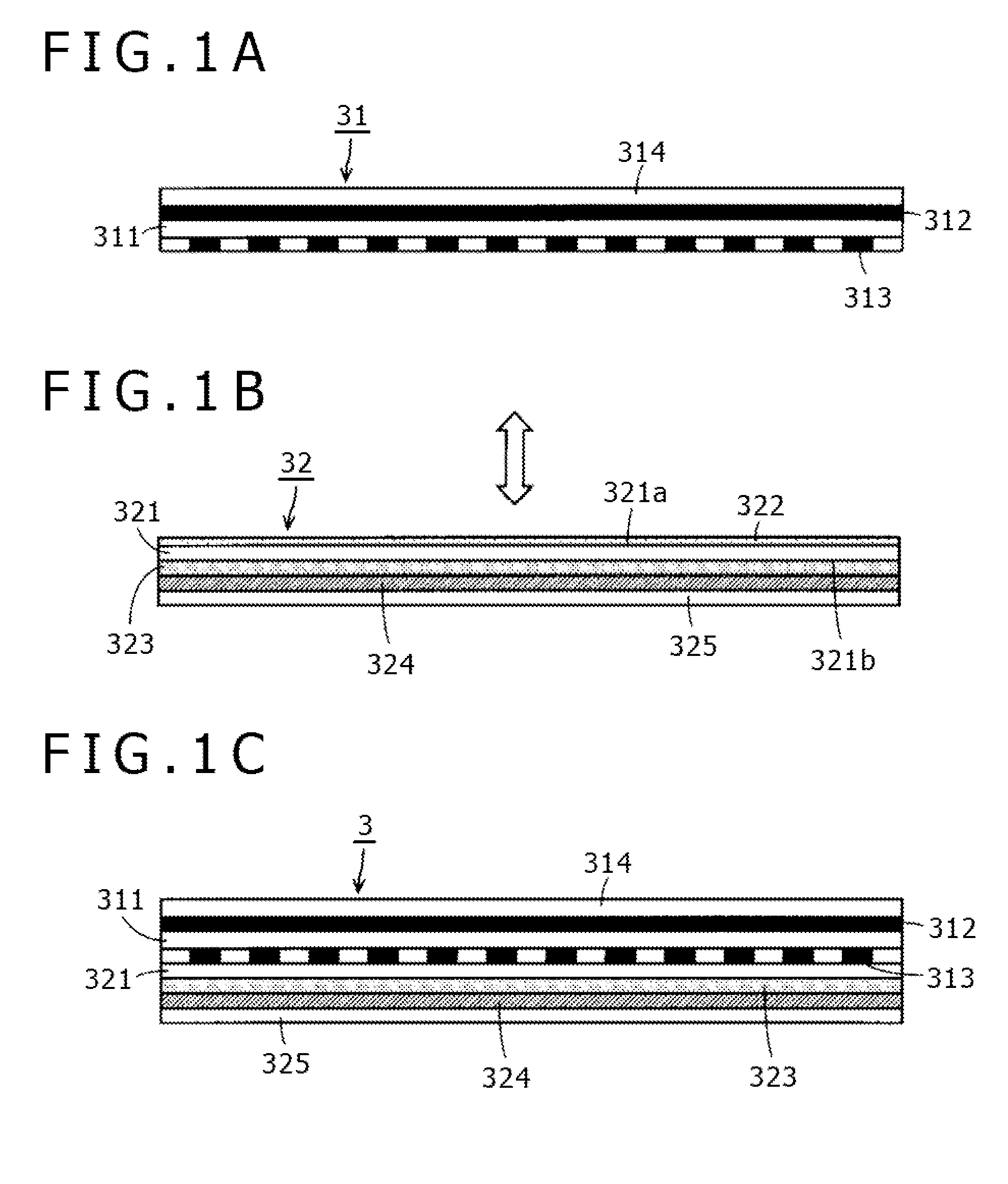

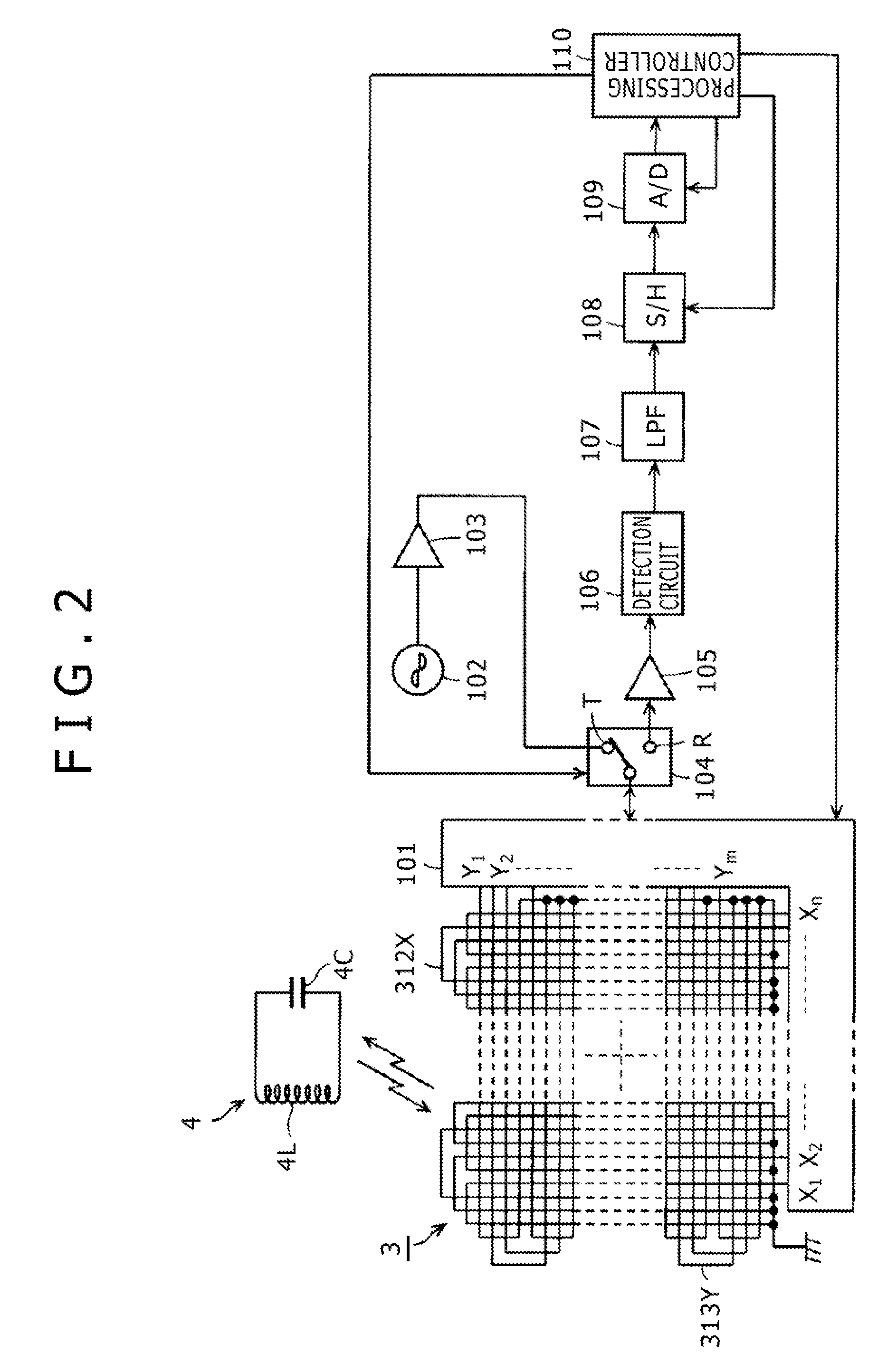

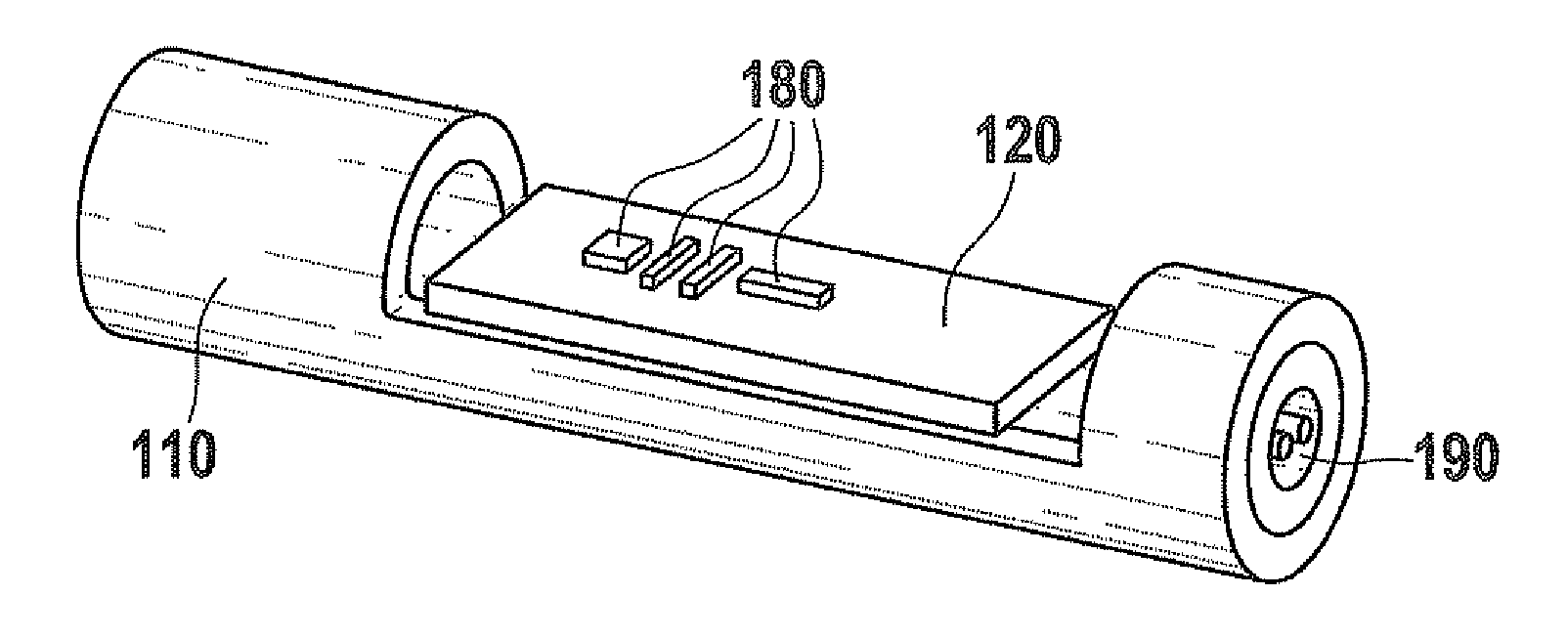

Electromagnetic induction sensor, overlay member for electromagnetic induction sensor, and manufacturing method of electromagnetic induction sensor

ActiveUS20150027232A1Reduce hardnessEasy to cutConductive pattern formationSingle device manufacturingElectromagnetic couplingElectrical conductor

Disclosed herein is an electromagnetic induction sensor that is used with a position indicator and includes coils for electromagnetic coupling with the position indicator. The electromagnetic induction sensor includes: a sensor board main body that includes an insulating substrate and a surface sheet attached to a side of a first surface of the insulating substrate, on which side a position is indicated by the position indicator; at least part of conductors forming the coils being formed on a second surface of the insulating substrate opposite from the first surface; and an overlay member that includes a magnetic powder material layer and is adhered to the side of the second surface of the sensor board main body.

Owner:WACOM CO LTD

Contact arrangement

ActiveUS8366451B2Easy to adjustSimple modelOne pole connectionsRotary current collectorElectrical resistance and conductanceKnife blades

Owner:ITT MFG ENTERPRISES LLC

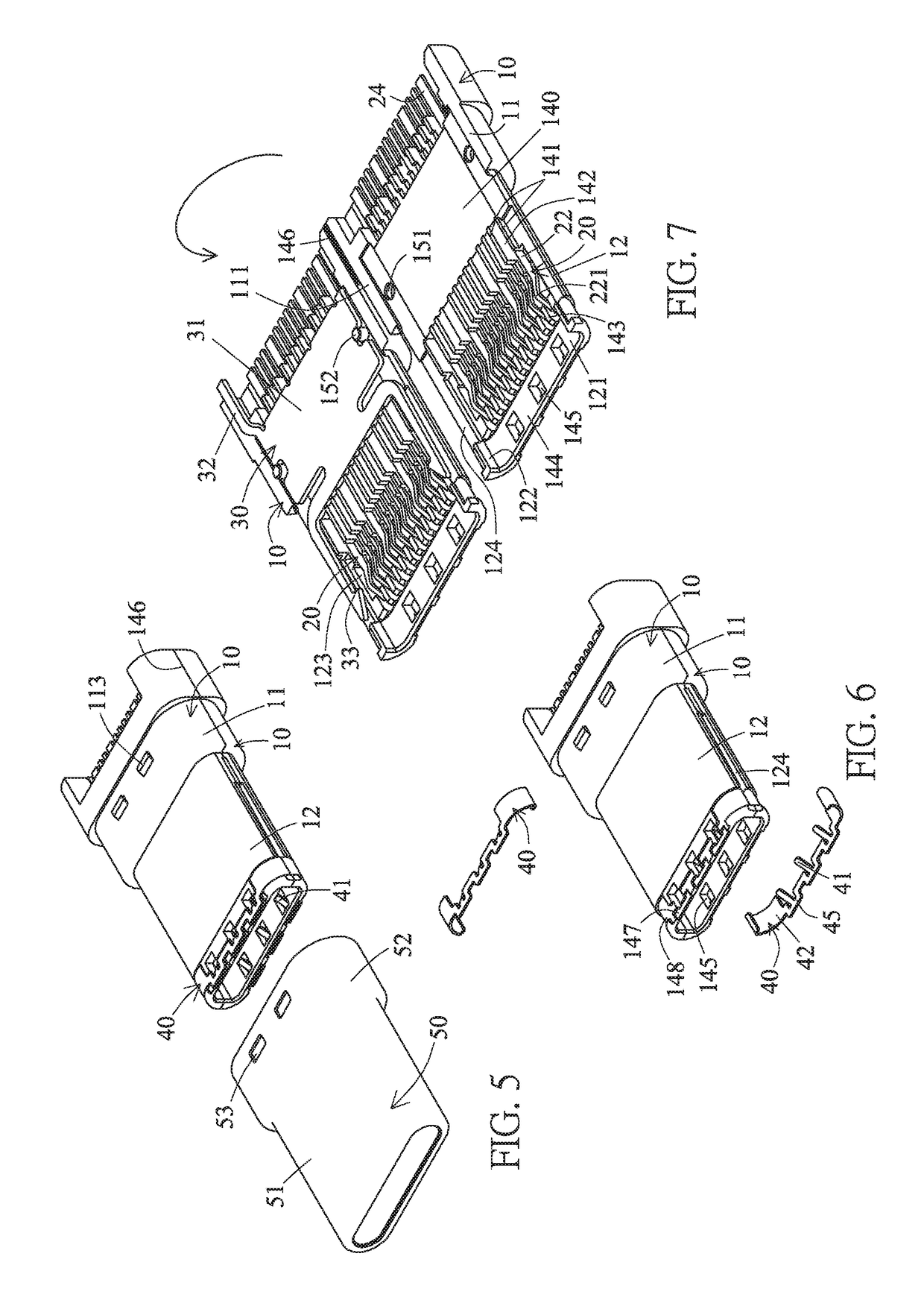

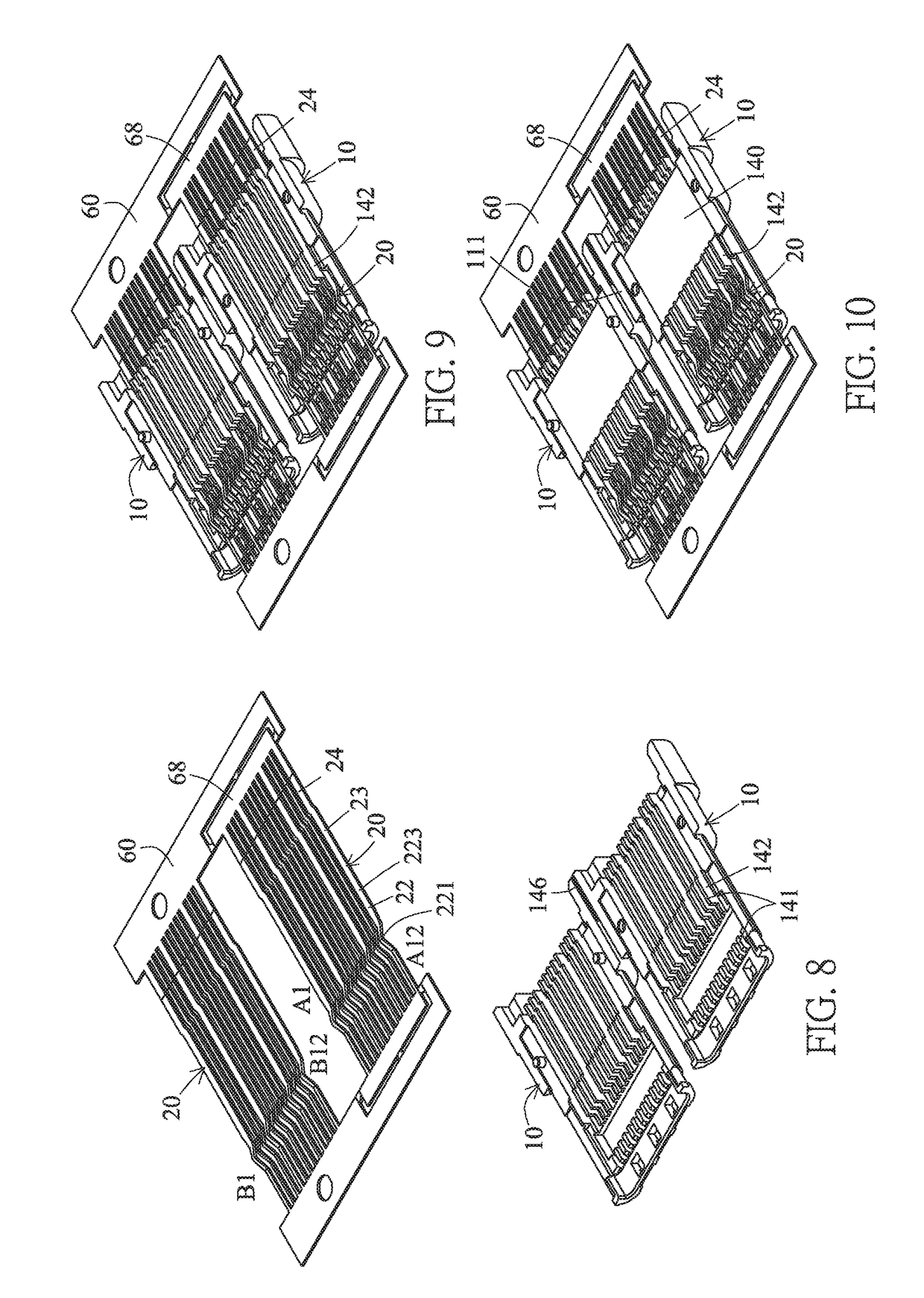

Bidirectional duplex electrical connector

ActiveUS20190027868A1Easy to assembleIncrease forceContact member manufacturingContact member assembly/disassemblyEngineeringHigh surface

A bidirectional duplex electrical connector includes: two insulation seats each integrally provided with a base portion and a docking portion, wherein inner surfaces of the two insulation seats are provided with one row of separation columns performing separation to form one row of front-to-rear extending terminal slots, the terminal slot extends to the docking portion from the base portion; two rows of terminals assembled into the two rows of terminal slots of the two insulation seats in a vertical direction, wherein the terminal is integrally provided with, from front to rear, an elastically movable portion, a fixing portion and a pin, a front section of the elastically movable portion corresponds to the docking portion and is curved and provided with a contact projecting beyond the high surface in a vertical direction, the elastically movable portion is vertically elastically movable, a rear section of the elastically movable portion and the fixing portion are on the same level and rest against a bottom surface of the terminal slot, a depth of the terminal slot is greater than a material thickness of the terminal, so that the rear section of the elastically movable portion and the fixing portion fall into the terminal slot, and the insulation seat is provided with a fixing structure fixing the fixing portions of the one row of terminals; and a metal housing covering the two insulation seats.

Owner:TOP YANG TECH ENTERPRISE CO LTD

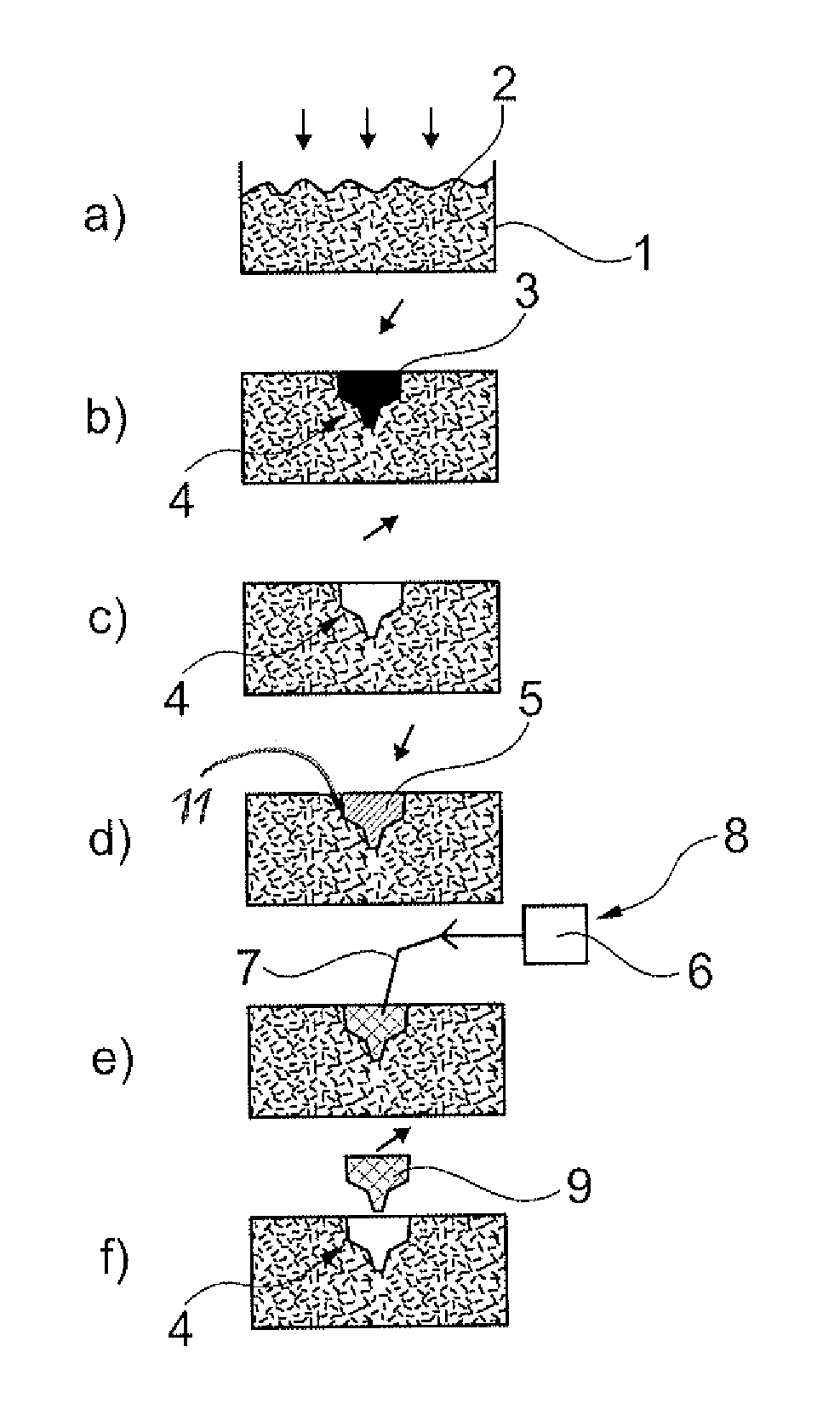

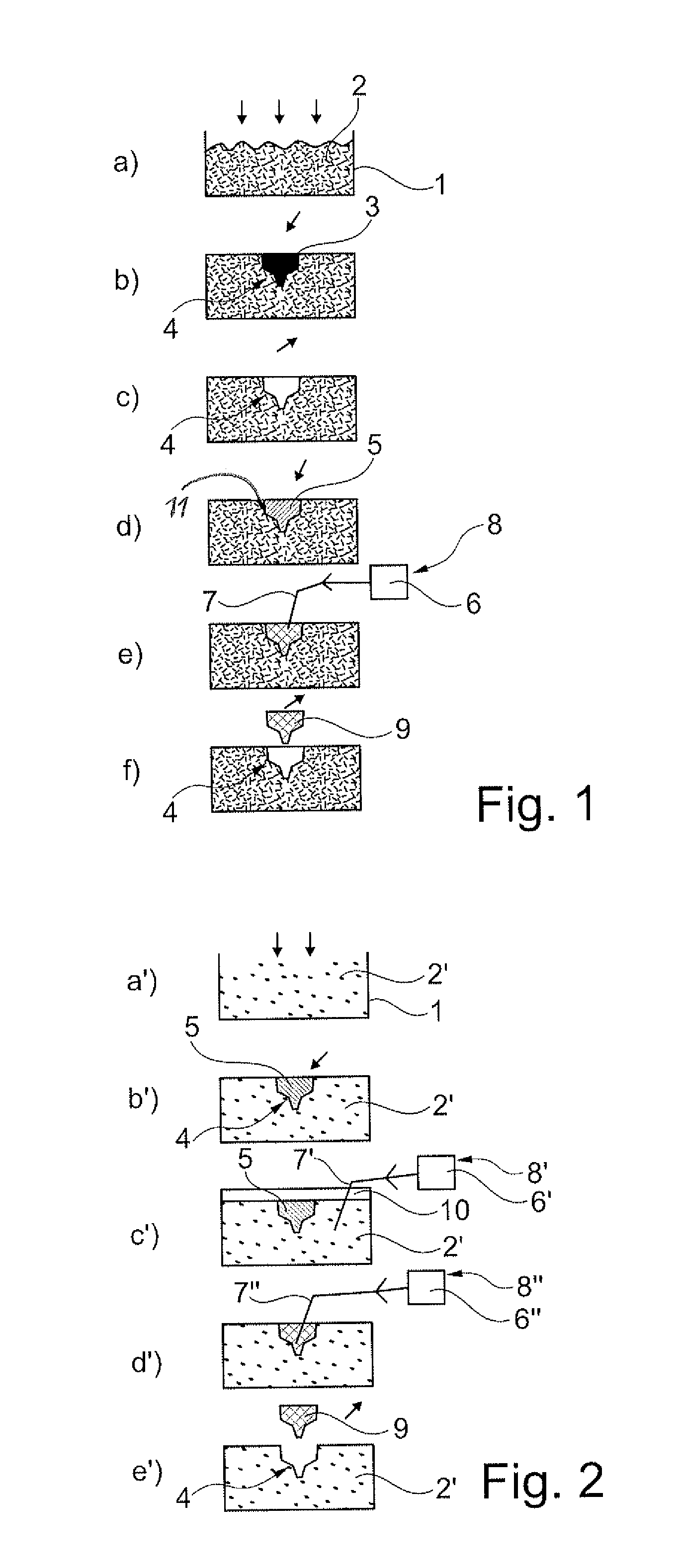

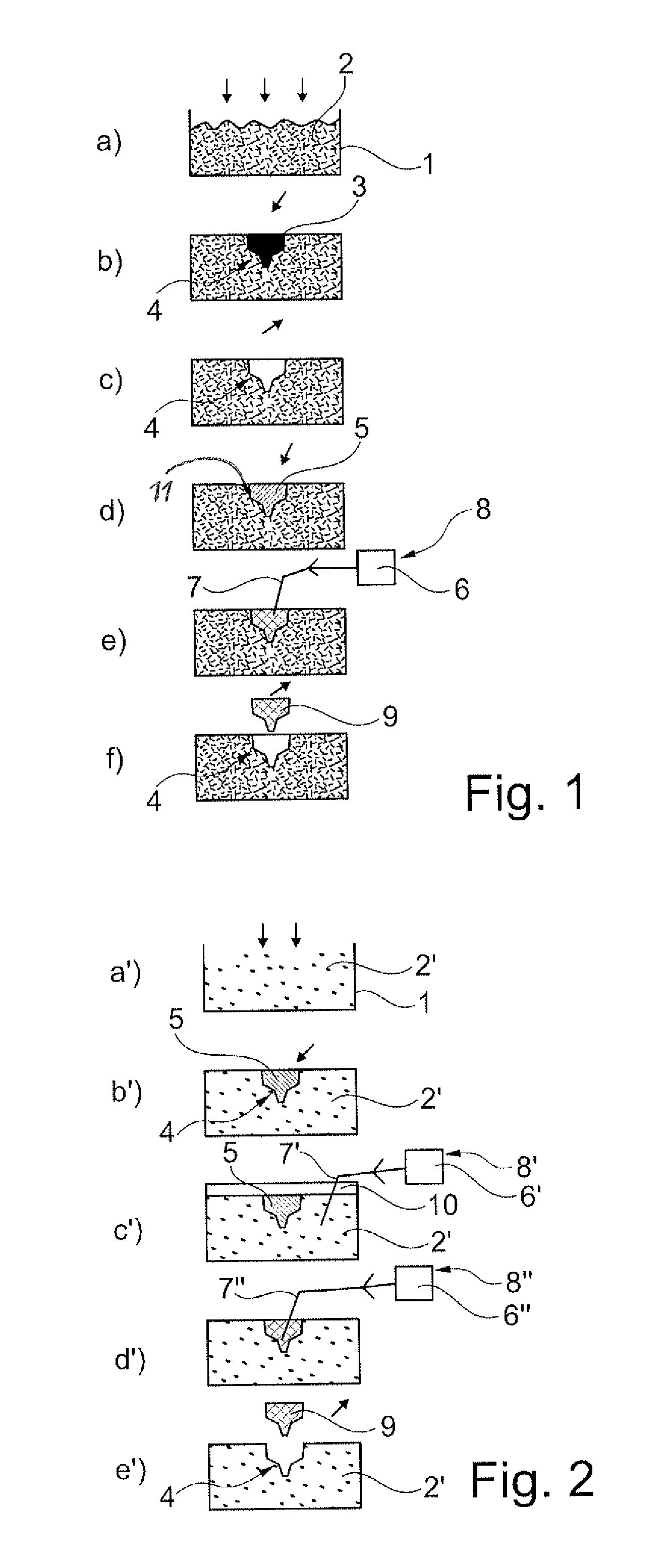

Method And Apparatus For Producing A Fiber-Reinforced Plastics Casting

ActiveUS20140306372A1High geometric varianceComplex shapeCeramic shaping apparatusSynthetic resinMaterials science

An apparatus and method for producing a fiber-reinforced plastics casting (FRP), includes a moulding box filled with free flowing moulding material, in what a prototype of casting or a textile preform is inserted, forming a mould cavity for infiltration the inserted preform of textile with synthetic resin material in order to form a fiber-reinforced plastics casting (FRP).

Owner:AIRBUS OPERATIONS GMBH

Electromagnetic induction sensor, overlay member for electromagnetic induction sensor, and manufacturing method of electromagnetic induction sensor

ActiveUS9441992B2Improve detection accuracyReduce hardnessUsing electrical meansSingle device manufacturingElectromagnetic couplingElectrical conductor

Disclosed herein is an electromagnetic induction sensor that is used with a position indicator and includes coils for electromagnetic coupling with the position indicator. The electromagnetic induction sensor includes: a sensor board main body that includes an insulating substrate and a surface sheet attached to a side of a first surface of the insulating substrate, on which side a position is indicated by the position indicator; at least part of conductors forming the coils being formed on a second surface of the insulating substrate opposite from the first surface; and an overlay member that includes a magnetic powder material layer and is adhered to the side of the second surface of the sensor board main body.

Owner:WACOM CO LTD

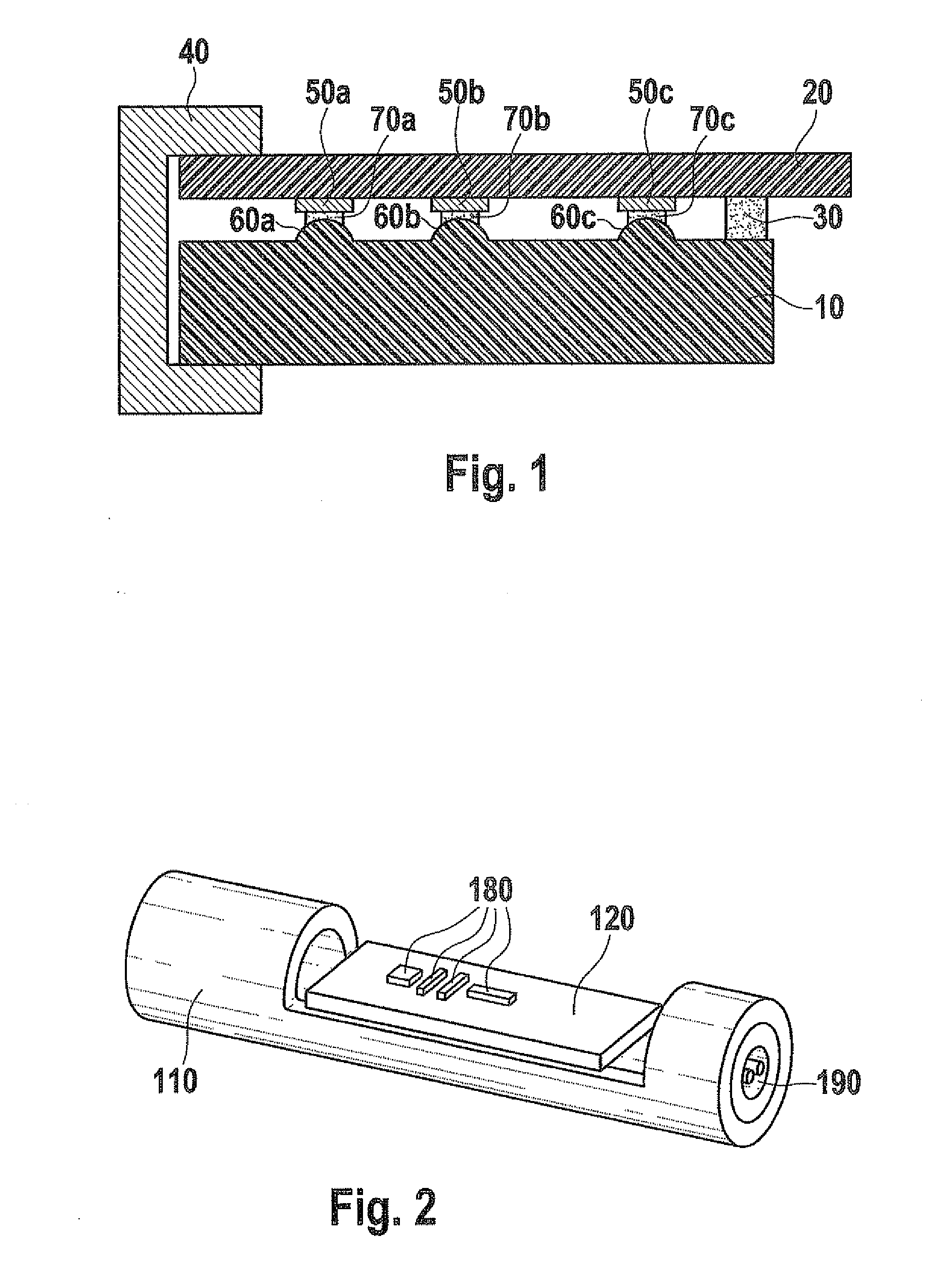

Electric circuit configuration having an MID circuit carrier and a connecting interface connected to it

InactiveUS9560772B2High densityIncrease component densityPrinted circuit assembling3D rigid printed circuitsElectricityEngineering

An electric circuit configuration having an MID circuit carrier and a connecting interface, the connecting interface being situated on a surface of the MID circuit carrier. The electric circuit configuration further includes at least one electrical contact pair having at least one connecting interface contact element and at least one MID contact element that is provided on the surface and is situated on the connecting interface contact element. The exemplary embodiments and / or exemplary methods of the present invention further relates to a contact element group having at least one electrical contact element for the electrical contacting of an MID circuit carrier, which is developed on a surface of an MID circuit carrier, is electrically connected to it, and extends away from the surface. The at least one contact element is connected to a line element of the MID circuit carrier.

Owner:ROBERT BOSCH GMBH

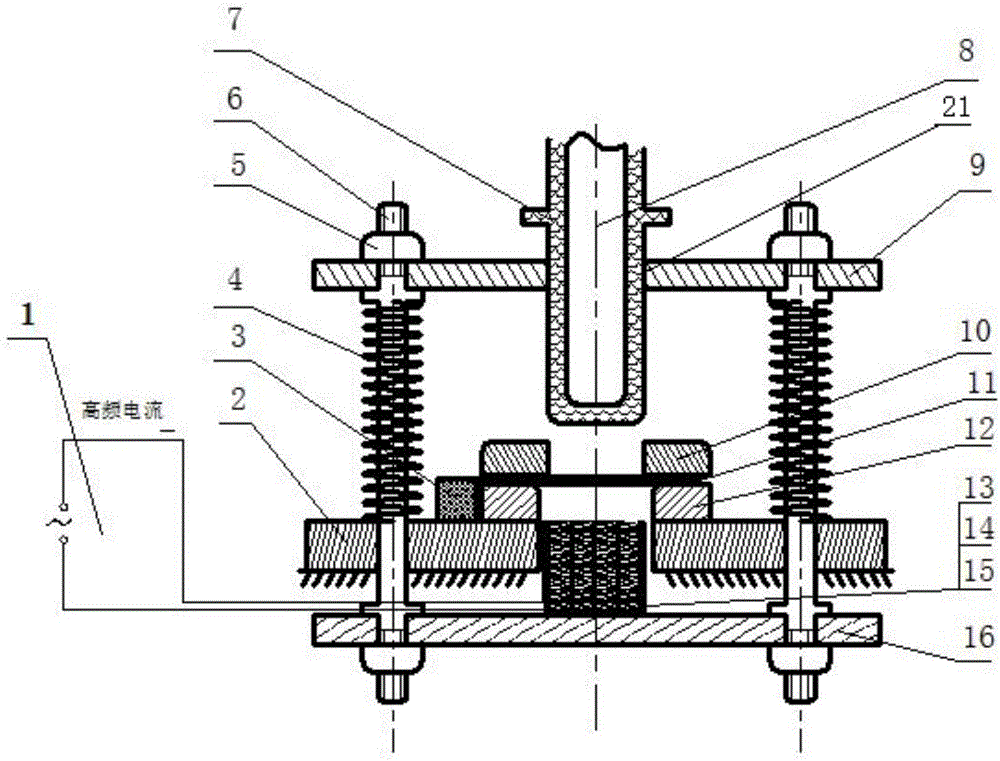

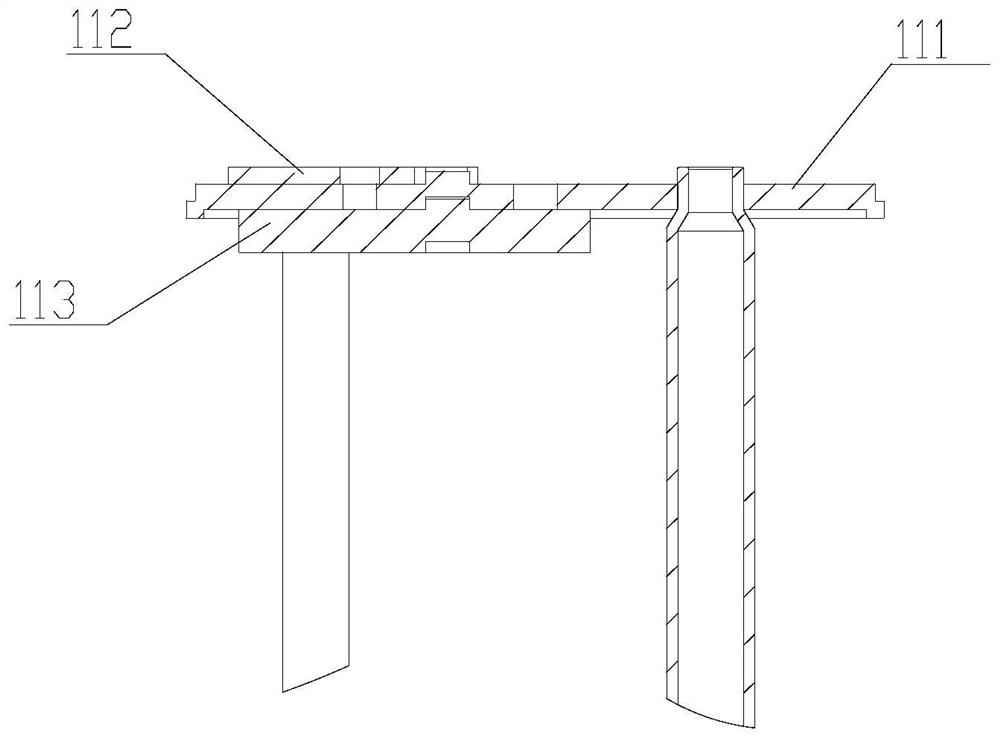

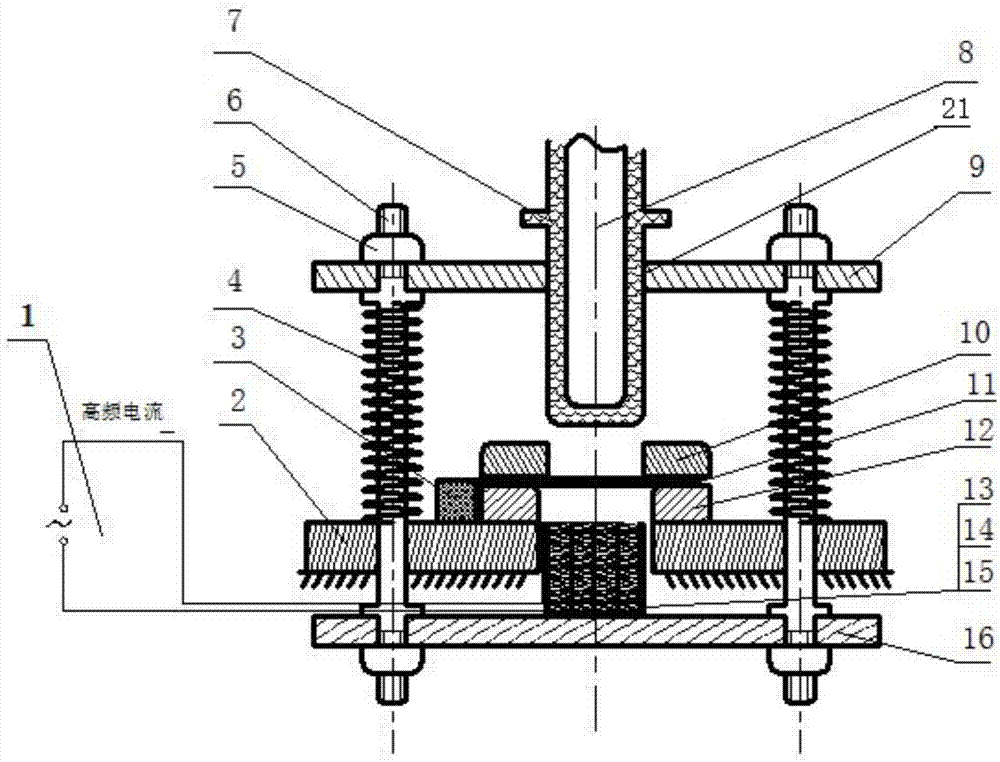

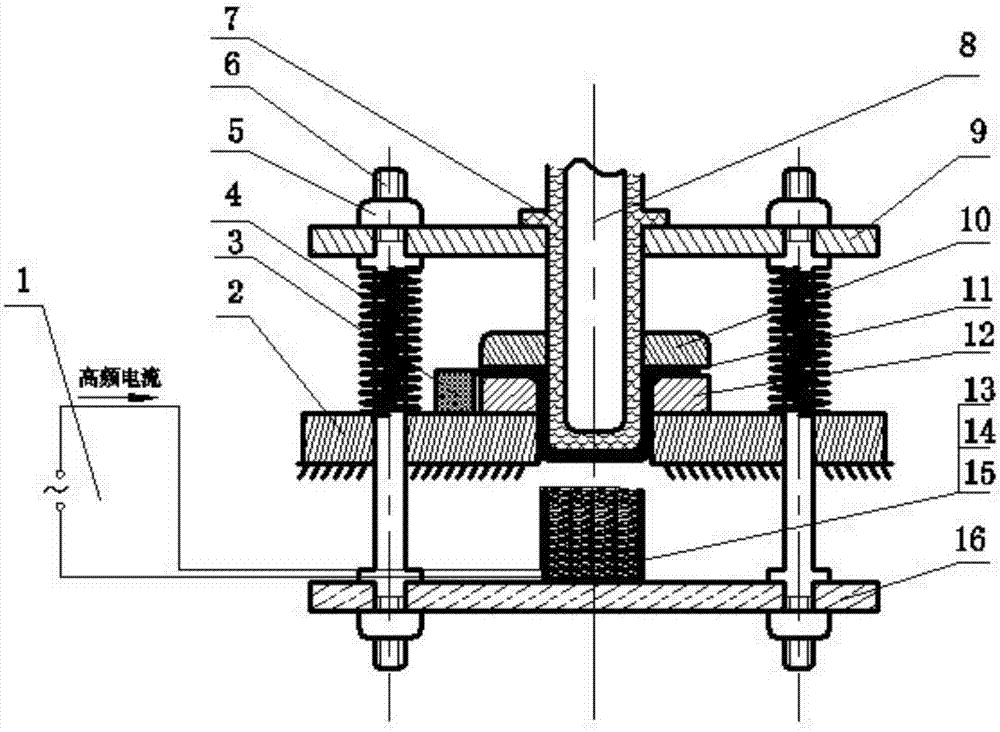

Metal sheet warm forming device based on induced high-frequency electromagnetic field

ActiveCN105921582AStamping process is simpleProduction batch limitShaping toolsEngineeringMetal sheet

The invention provides a metal sheet warm-hot forming device based on an induced high-frequency electromagnetic field. A vertical-through stamping opening is formed in a workbench; a support frame comprises an upper supporting plate above the workbench, a lower supporting plate under the workbench, and connecting rods connected with the workbench in a sliding manner; two ends of each connecting rod are respectively connected with the upper supporting plate and the lower supporting plate in an assembling manner; a male mold forming assembly comprises a male mold, a mold guiding plate and a blank holder; the male mold is arranged right above the stamping opening and movably connected with the upper supporting plate; the mold guiding plate is arranged on the edge of the stamping opening and movably connected with the workbench; the blank holder is arranged above and movably connected with the mold guiding plate; and a high-frequency electromagnetic field generator is arranged just under the stamping opening and connected with the lower supporting plate in an assembling manner. The metal sheet warm forming device has the beneficial effects that a metal sheet stamping process can be simplified; limitation of stamping part production lot can be avoided; metal sheet stamping cost can be reduced; metal sheet stamping efficiency can be improved; the metal sheet warm forming device is also suitable for stamping forming of plates which are high in strength and difficult to form, and stamping parts obtained after stamping forming are excellent in quality.

Owner:SHANDONG UNIV OF SCI & TECH

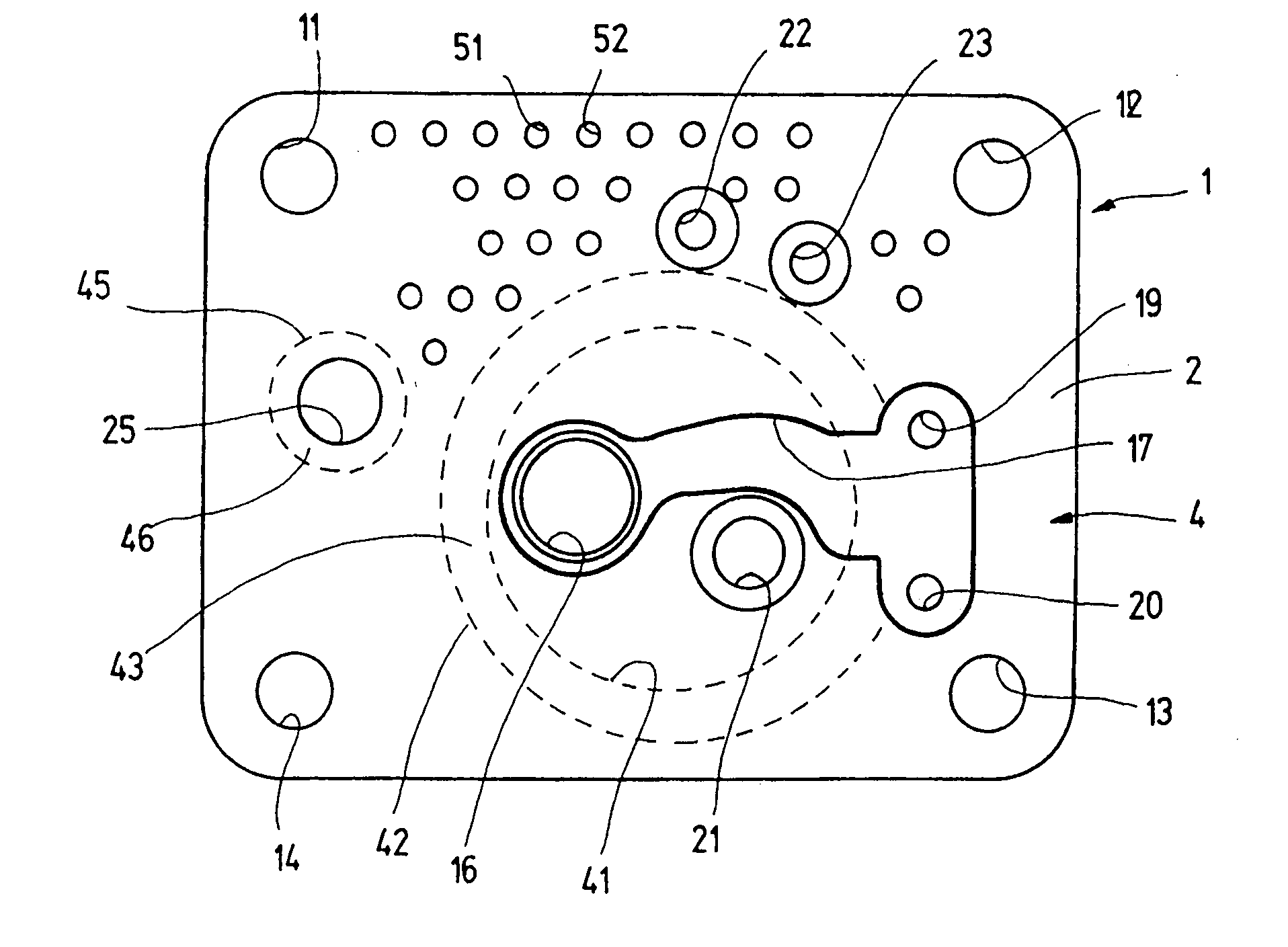

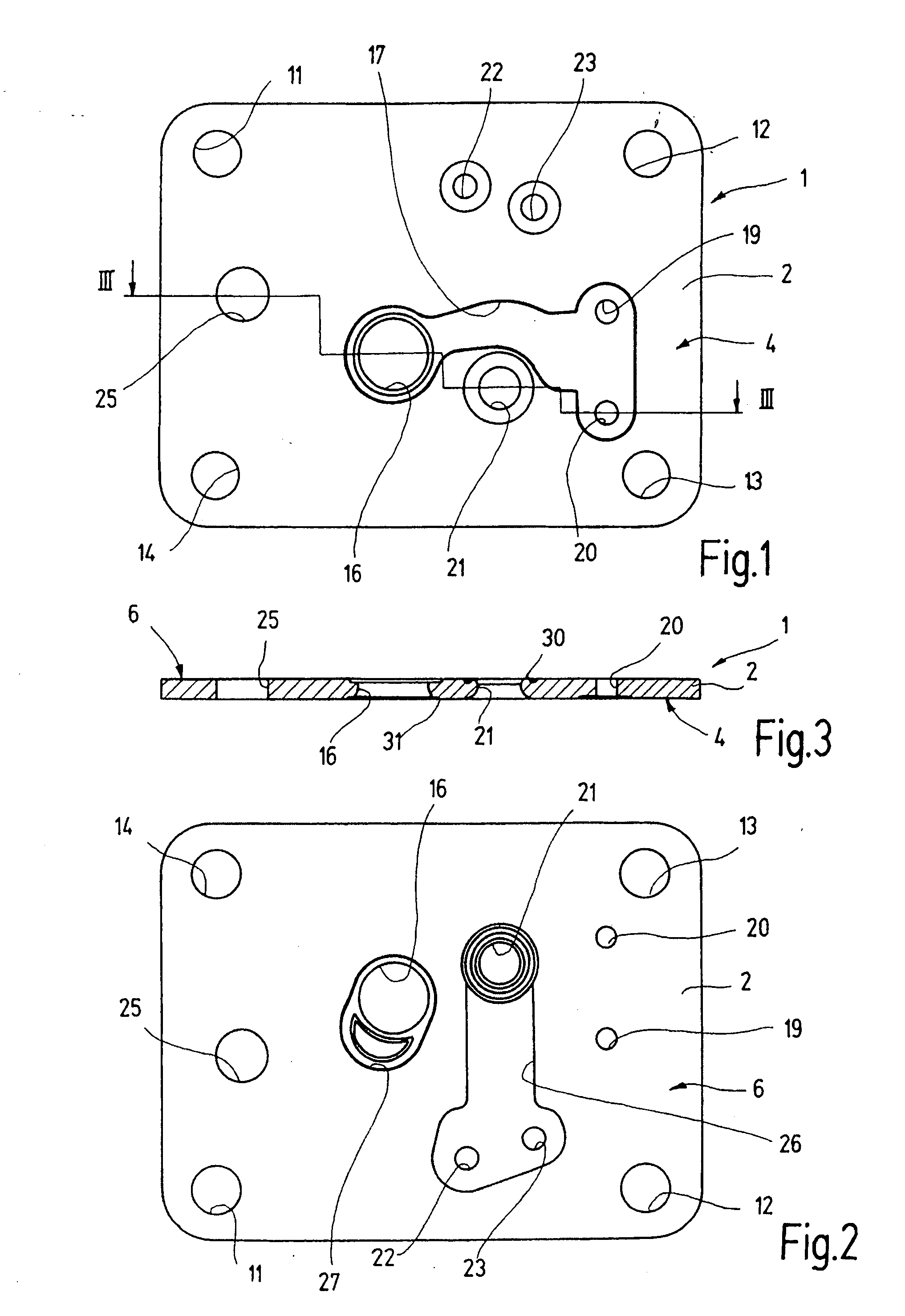

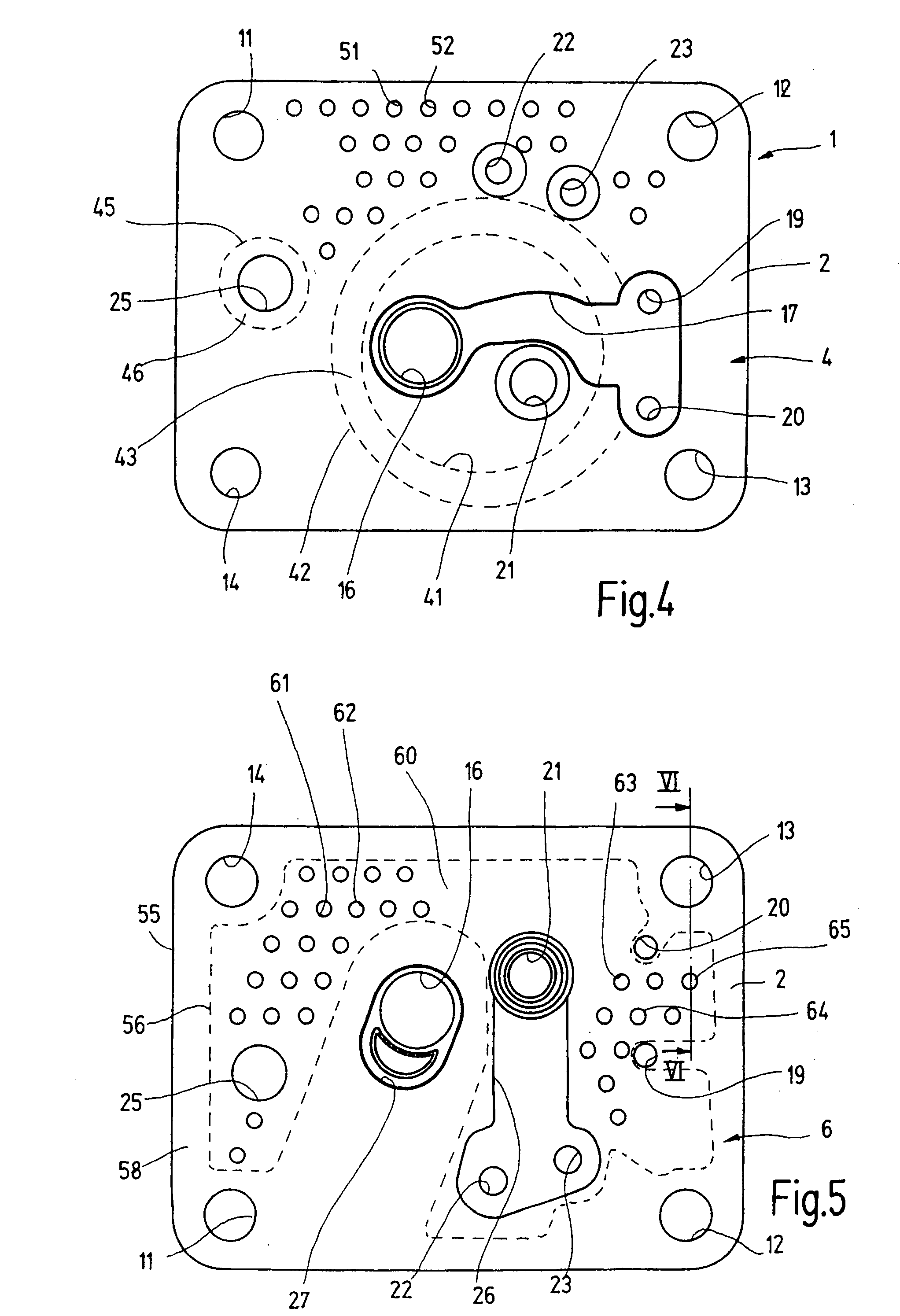

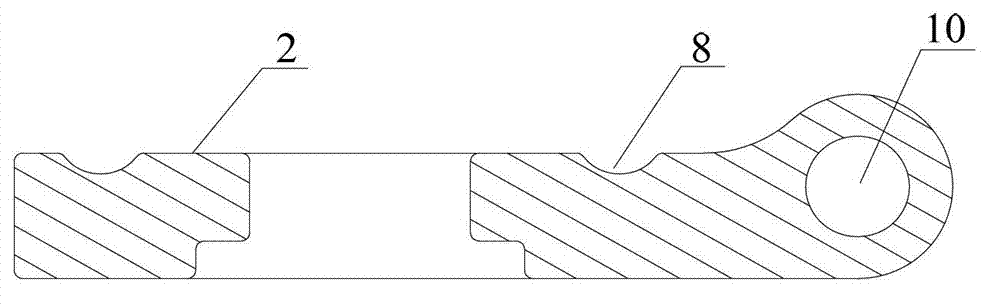

Valve plate for a reciprocating compressor

InactiveUS20070221274A1Easy to manufactureSimple and cheap to manufacturePositive displacement pump componentsCheck valvesEngineeringValve seat

The invention concerns a valve plate for a reciprocating compressor, the valve plate being made as a sintered part, having on at least one valve plate surface at least one valve seat surface (30, 31) being worked after sintering. In order to simplify the manufacturing of the valve plate, the valve plate surface has at least one defined area portion with a relatively uneven surface and at least one defined area portion with a relatively even surface.

Owner:SECOP GMBH +1

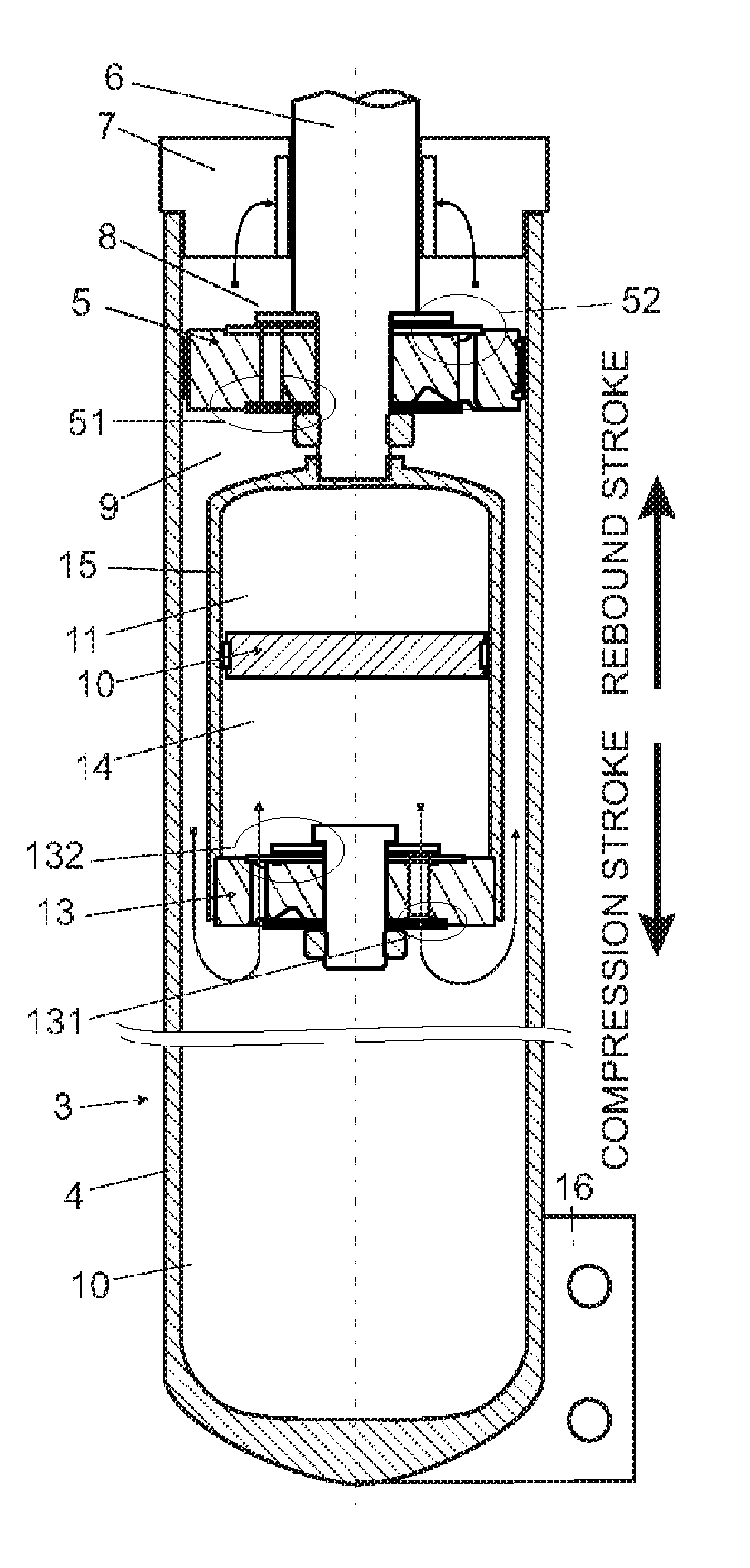

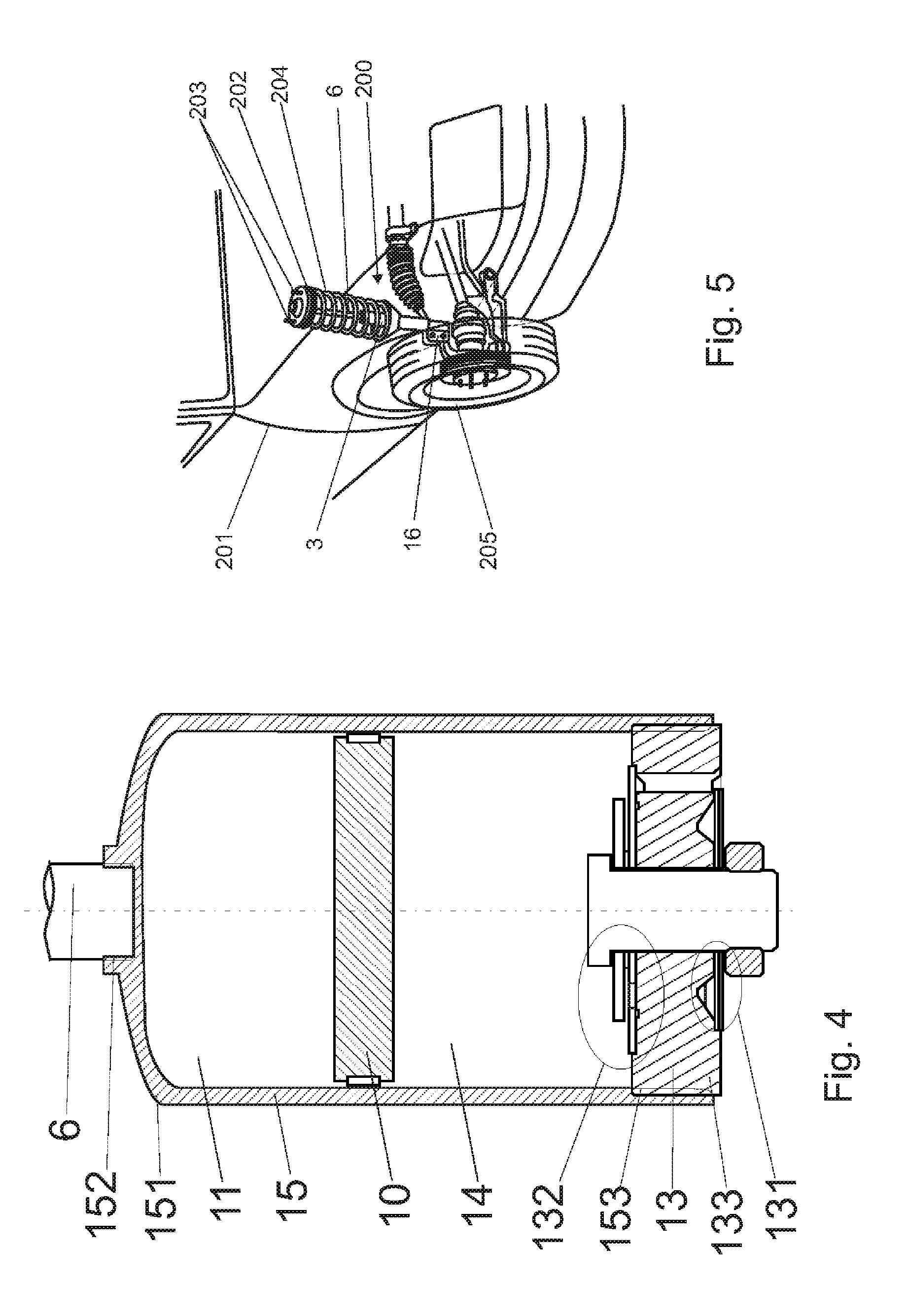

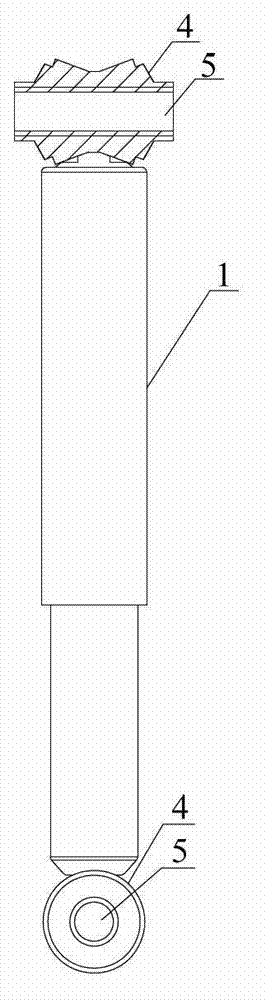

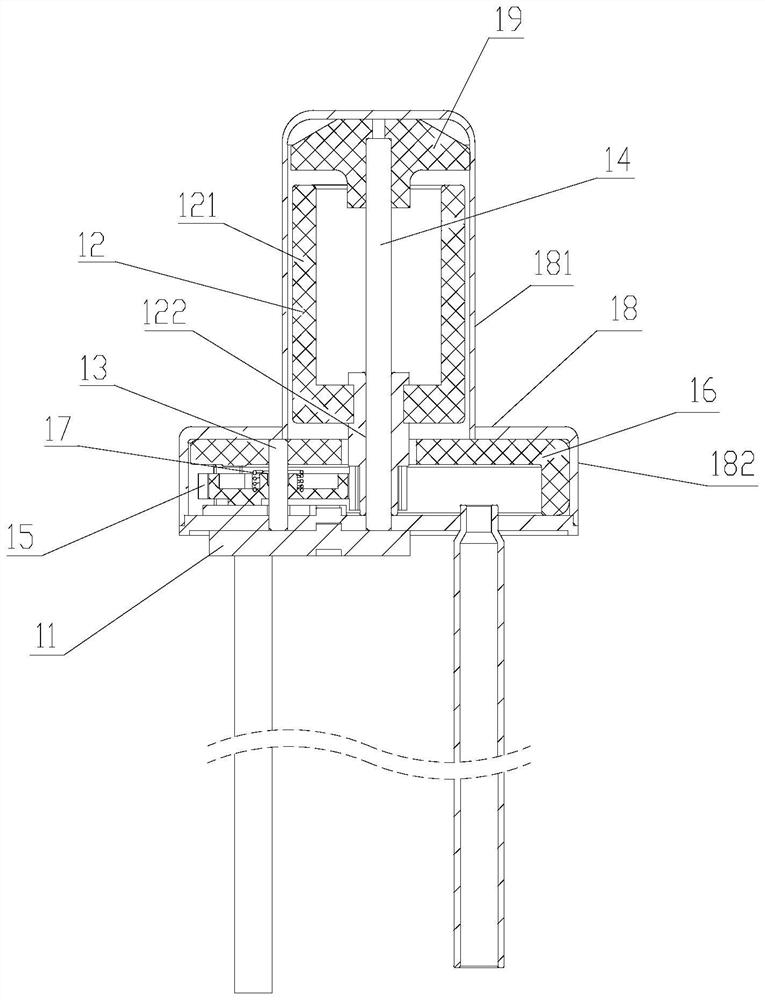

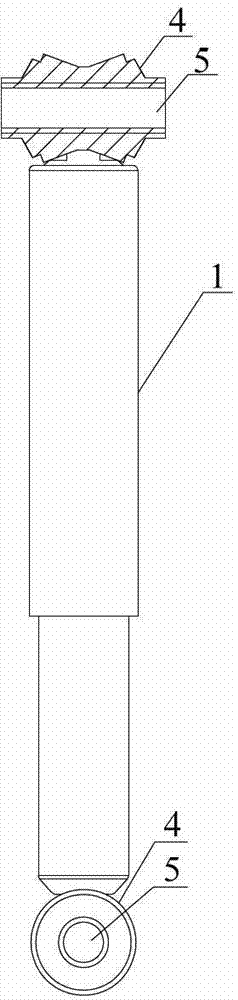

Hydraulic suspension damper

ActiveUS20160167474A1Easy constructionStamping process is simpleSpringsSprings/dampers design characteristicsGas chamberPiston rod

A hydraulic damper (3) includes a tube (4), a piston assembly (5) disposed slidably inside the tube (4), and an additional valve assembly (13). A compression chamber (9) is defined between the piston assembly (5) and the additional valve assembly (13). An additional compensation chamber (14) is defined between the additional valve assembly (13) and one side of a slideable partition (10). A gas chamber (11) is defined at the other side of the slidable partition (10). The damper includes an additional chamber assembly (15) to retain all the advantages of a twin-tube damper while providing the single construction offered by a mono-tube damper. One end of the additional chamber assembly (15) is attached to the slidable piston chamber (5) or to said piston rod (6) at the compression side thereof and the other end of said additional chamber assembly (15) is terminated with the additional valve assembly (13).

Owner:BEIJINGWEST INDUSTRIES

Electric circuit configuration having an mid circuit carrier and a connecting interface connected to it

InactiveUS20110083894A1High densityIncrease component density3D rigid printed circuitsPrinted circuit aspectsElectricityEngineering

An electric circuit configuration having an MID circuit carrier and a connecting interface, the connecting interface being situated on a surface of the MID circuit carrier. The electric circuit configuration further includes at least one electrical contact pair having at least one connecting interface contact element and at least one MID contact element that is provided on the surface and is situated on the connecting interface contact element. The exemplary embodiments and / or exemplary methods of the present invention further relates to a contact element group having at least one electrical contact element for the electrical contacting of an MID circuit carrier, which is developed on a surface of an MID circuit carrier, is electrically connected to it, and extends away from the surface. The at least one contact element is connected to a line element of the MID circuit carrier.

Owner:ROBERT BOSCH GMBH

Side-flanging die structure

InactiveCN107096839AImprove work efficiencyStamping process is simpleShaping toolsFlangingEngineering

The invention discloses a side-flanging die mechanism. A material pressing core and a fixed lower die are compounded to form a product and keep a clamping state. A to-be-flanged area of the product protrudes to the exterior of a forming area of the material pressing core and the fixed lower die. A driving block and a sliding slanting wedge are matched correspondingly and arranged relative to the to-be-flanged area of the product. The sliding slanting wedge is connected with a flanging cutter. The junction line between the to-be-flanged area and the forming surface of the product is located on the side face, close to the fixed lower die, of the flanging cutter and is always on an advancing route of the side face. The driving block is pressed down to abut against the sliding slanting wedge to make relative slipping, and produced slanting cutting force pushes the sliding slanting wedge to move in the horizontal direction far from the fixed lower die. The sliding slanting wedge drives the flanging cutter to complete the side flanging action of the to-be-flanged area. The sliding slanting wedge drives the flanging cutter to move in the horizontal direction far from the fixed lower die, namely, the to-be-flanged area is subjected to horizontal side flanging from inside to outside, the stamping process is simplified, and working efficiency is improved.

Owner:CHERY AUTOMOBILE CO LTD

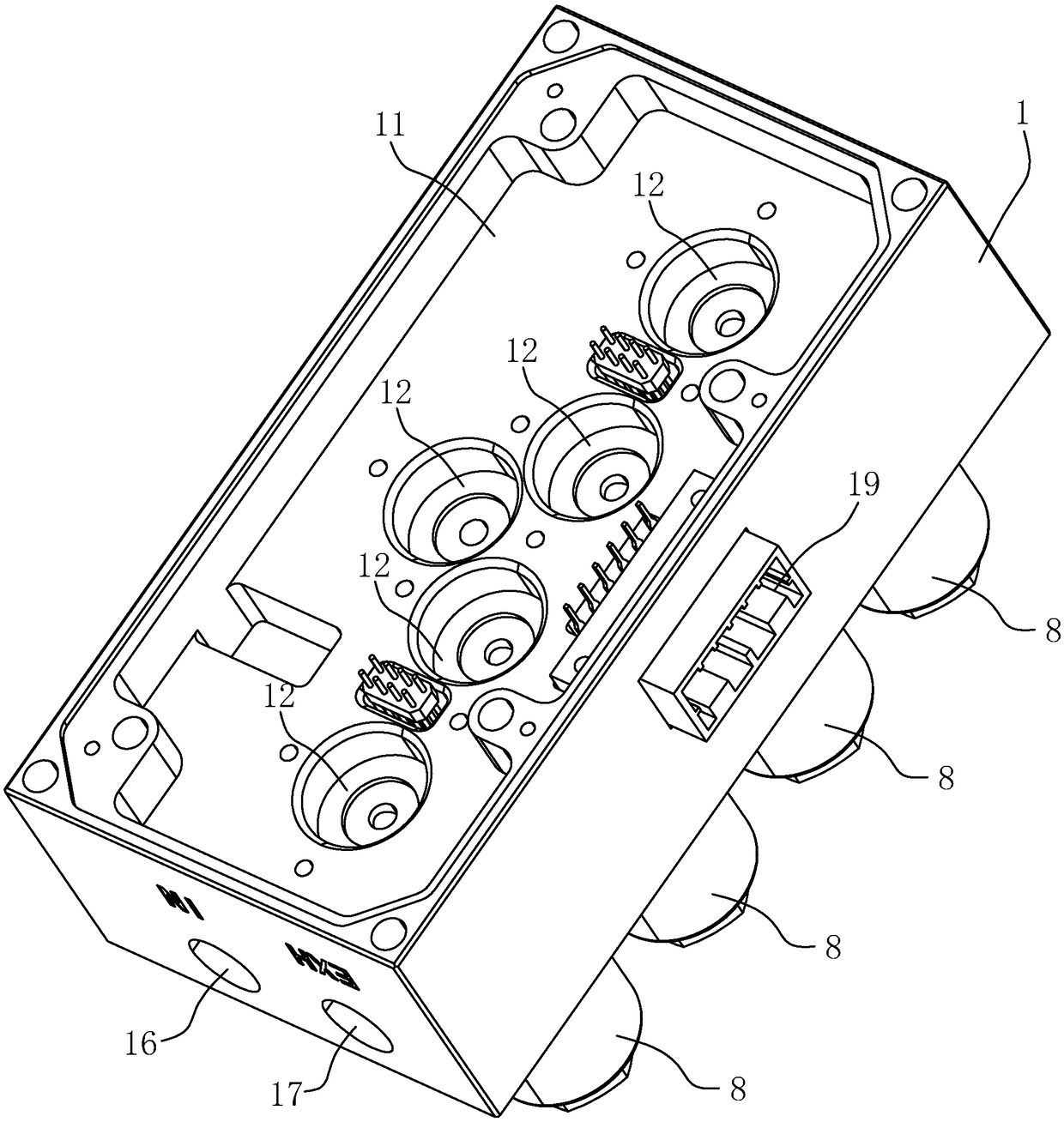

Multi-linkage valve

PendingCN109083882AStable structureSimple injection molding processServomotor componentsElectricityEngineering

The invention relates to a multi-linkage valve. The multi-linkage valve comprises a valve body, an installing plate, a control circuit board, pressure sensors and a cover plate, a cavity is formed inthe surface of the valve body, and multiple counter bored holes are formed in the bottom wall of the cavity; the installing plate is located inside the cavity and provided with through holes and installing bases, the installing bases and the through holes correspond to the counter bored holes in position and number, and the installing bases are inserted into the counter bored holes; the control circuit board is located in the cavity and gets away one side of the bottom wall of the cavity relative to the installing plate; the pressure sensors are installed inside the installing bases and electrically connected to the control circuit board through pins; the cover plate is used for sealing the cavity. The multi-linkage valve solves the problem that pressure sensors of a common linkage valve are arranged to protrude, and as a result the size is too large; the pressure sensors are arranged inside the valve body to be directly connected with the control circuit board electrically, and therefore the multi-linkage valve has the advantages of being low in production cost and small in size.

Owner:深圳市德平国瀚汽车电子科技有限公司

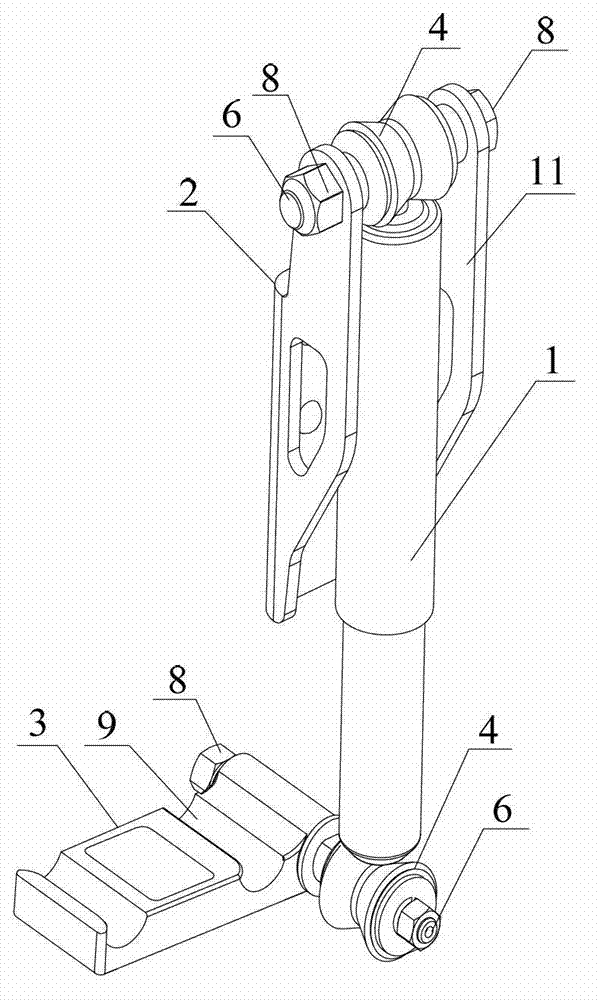

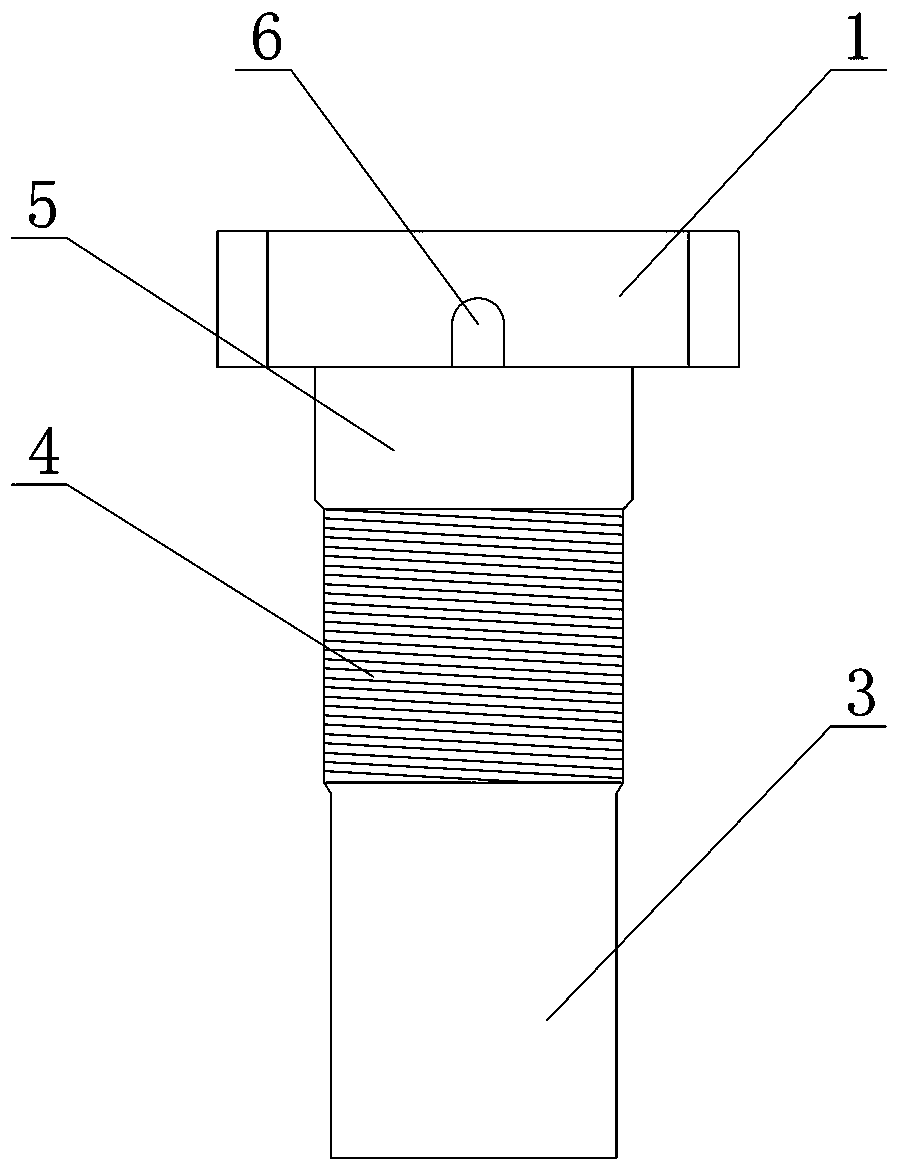

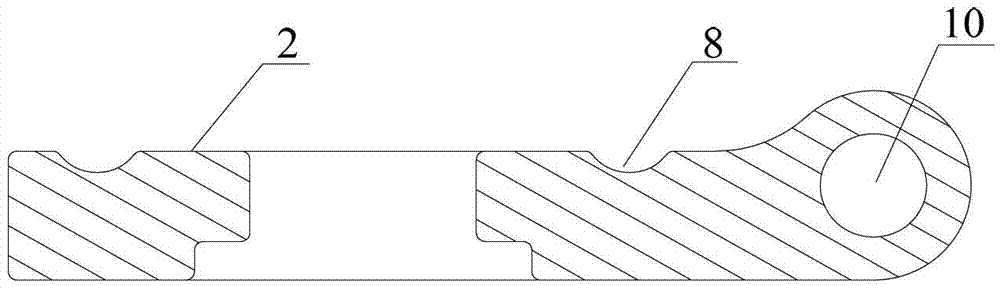

Shock absorber device of medium-sized and heavy type trucks

The invention discloses a shock absorber device, and relates to a shock absorber device of medium-sized and heavy type trucks. The shock absorber device of the medium-sized and heavy type trucks comprises a shock absorber assembly (1) and is characterized in that an upper support (2) is arranged at the upper end of the shock absorber assembly (1), and a cover plate (3) is arranged at the lower end of the shock absorber assembly. The shock absorber device of the medium-sized and heavy type trucks is simple in structure, low in cost and capable of avoiding a steering track rod, a brake chamber and other parts, and therefore interference among the shock absorber assembly, the steering track rod, the brake chamber and other parts is prevented form occurring. Therefore, the shock absorber device of the medium-sized and heavy type trucks is suitable for being popularized and used.

Owner:CNHTC CHENGDU WANGPAI COMML VEHICLE

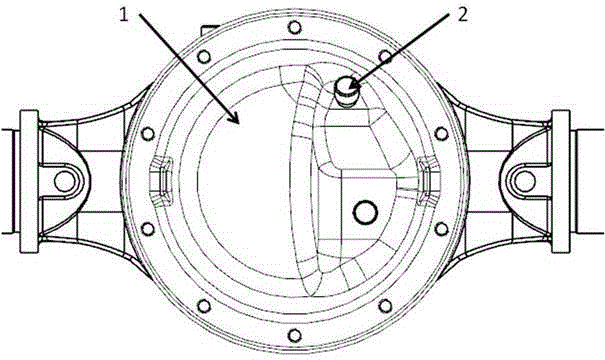

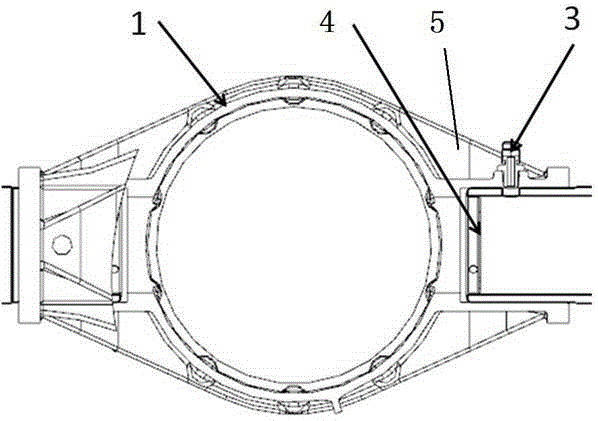

Rear axle housing assembly of automobile

ActiveCN103612543AGuaranteed to workOvercoming the Defects of Oil LeakageAxle unitsStress concentrationStamping process

The invention relates to automobile chassis, in particular to a rear axle housing assemble of an automobile in automobile chassis. The rear axle housing assembly of the automobile comprises a ventilation plug, an axle bag, a shell body rear cover and a separating plate, the shell body rear cover is connected with the axle bag, the separating plate is connected with the axle bag in an attached mode, a vent hole is formed in the axle bag, the vent hole is formed in the attachment position of the separating plate and the axle bag, and the ventilation plug is arranged in the vent hole. The rear axle housing assembly has the advantages that the mounting position of the ventilation plug is transferred to the axle bag from the shell body rear cover, the structure of the shell body rear cover is simplified, the stamping process of the shell body rear cover is simplified, manufacturing cost is lowered, the stress concentration of an axle tube is lowered, the separating plate has the function of an oil baffle, the normal work of the ventilation plug can be guaranteed, and the oil leakage defect of the ventilation plug is overcome.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Contact arrangement

ActiveUS20120052752A1Easy to adjustSimple modelOne pole connectionsRotary current collectorElectrical resistance and conductanceKnife blades

Owner:ITT MFG ENTERPRISES LLC

Valve device

PendingCN114382917ASimplify the manufacturing processIncrease productivityOperating means/releasing devices for valvesMultiple way valvesEngineeringVALVE PORT

The valve device comprises a valve body, a valve seat, a rotor component and an adjusting component, wherein the rotor component and the adjusting component are arranged in the valve body; the outer portion of the valve seat is connected with an inlet pipe and an outlet pipe, a sealing face matched with the adjusting component is arranged in the valve seat, and the sealing face is provided with a valve port. The rotor part is in transmission connection with the adjusting part so as to drive the adjusting part to rotate; the adjusting component controls the communicating state of the valve port and the inlet pipe by rotating to different working positions on the sealing face, the valve seat comprises at least two layers of flat plates which are stacked and connected in a welded mode, and each layer of flat plate is a stamping part. The valve device is simple in manufacturing process and high in production efficiency.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

A vapor chamber and its internal structure manufacturing method

ActiveCN110986640BImprove consistencyImprove yield rateIndirect heat exchangersModifications by conduction heat transferInjection portStamping process

The invention discloses a manufacturing method of a soaking plate and its internal structure, comprising the following steps: processing grooves and welding edges on the first cover plate and reserving a material injection port by using a stamping process, and processing the second cover plate into a flat plate ; weld a plurality of support columns in the groove of the first cover; attach a liquid-absorbing core on the inner wall of the first cover or the inner wall of the second cover; attach the first cover and the second cover to each other Combined to form a cavity, the support column and the liquid-absorbing core are located in the cavity; the edge of the first cover and the second cover are welded; the cavity communicates with the outside through the injection port; the cavity is filled with workers through the injection port After massaging, the air inside the cavity is extracted through the injection port, and then the injection port is blocked and sealed to form a vapor chamber. The method of the invention adopts a stamping process to process the soaking plate and its internal support structure, the method is simple and easy to operate, and the production efficiency is improved; in addition, the use of a large amount of chemical reagents is avoided, and the method is safe and pollution-free.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

Method and apparatus for producing a fiber-reinforced plastics casting

An apparatus and method for producing a fiber-reinforced plastics casting (FRP), includes a molding box filled with free flowing molding material, in what a prototype of casting or a textile preform is inserted, forming a mold cavity for infiltration the inserted preform of textile with synthetic resin material in order to form a fiber-reinforced plastics casting (FRP).

Owner:AIRBUS OPERATIONS GMBH

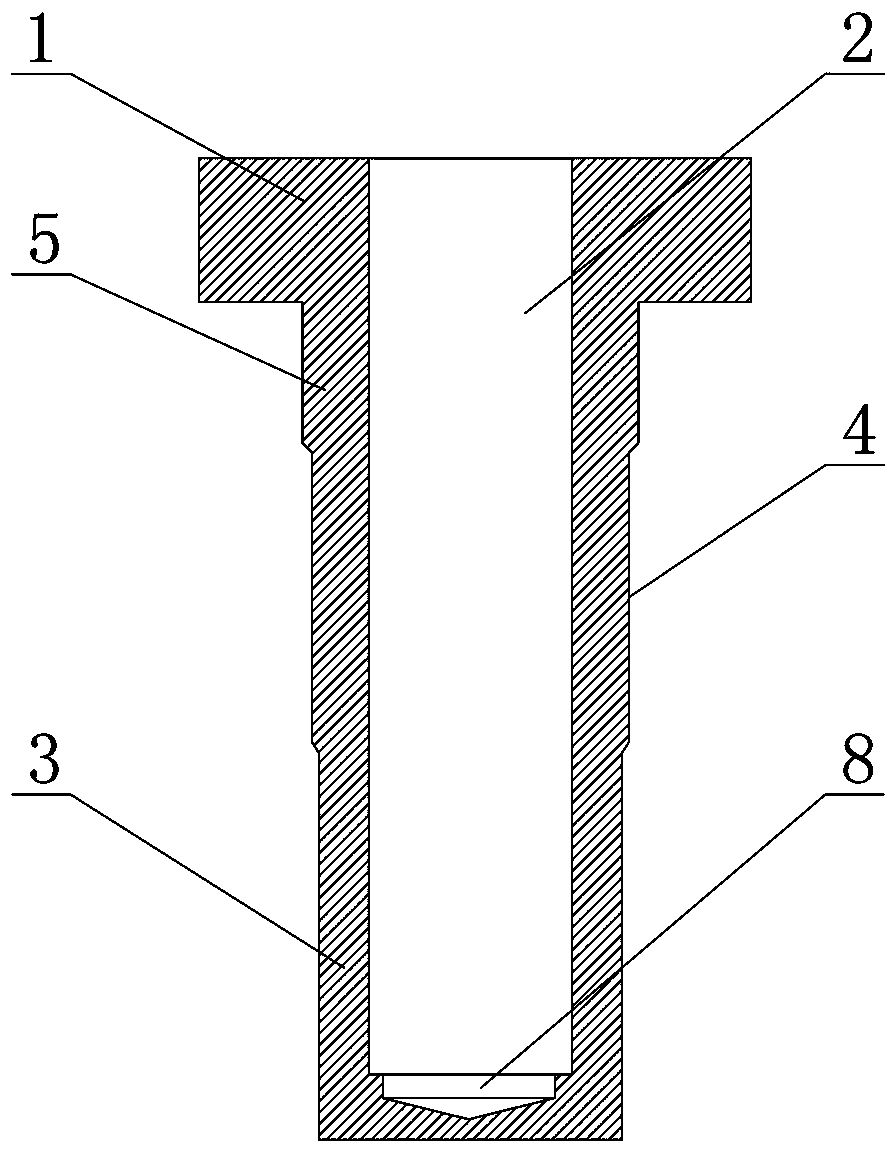

Steel ingot foot and manufacturing method thereof

The invention provides an ingot foot. The ingot foot comprises a body formed through integrally cold upsetting and punching. The body comprises a flange formed through cold upsetting, an ingot foot formed by extending from the bottom end of the flange and a blind hole formed in the ingot foot through repeated punching, wherein an opening of the blind hole is formed in the top end of the flange, and a boss is formed at the bottom end of the blind hole through punching. As cold upsetting integral forming is adopted, the strength and the consistency of the ingot foot are guaranteed, material wastage is reduced due to the cold upsetting process, the structural strength and the performance of the ingot foot are better than the structural strength and the performance of an assembly ingot foot, and the production cost is low. The invention further provides a method for manufacturing the ingot foot. The method comprises the steps of cold upsetting forming of billet and finish machining and forming of a final product. Basic sizes of the blind hole, the flange and the ingot foot are formed through billet forming, and the requirement for accuracy of all parts is met through finish machining. The ingot foot has the advantages of being clear in labor division, simple in forming step, good in product strength and consistency and capable of greatly reducing the manufacturing cost.

Owner:信阳市津乾机械设备制造有限公司

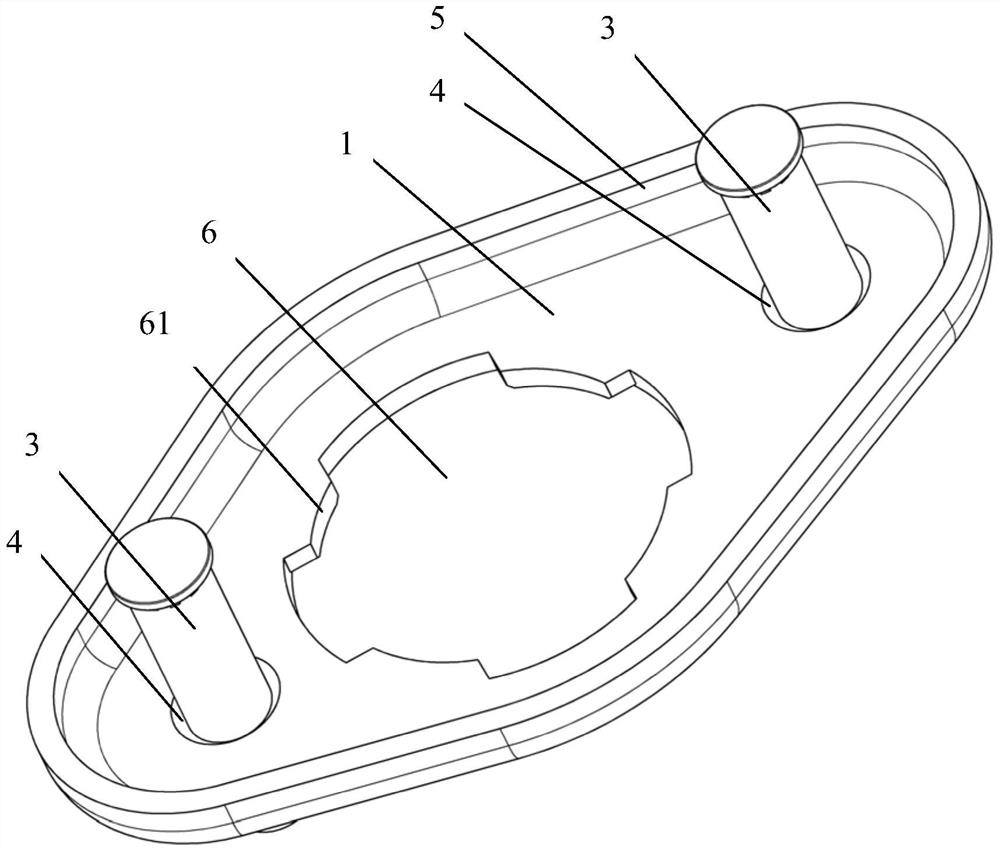

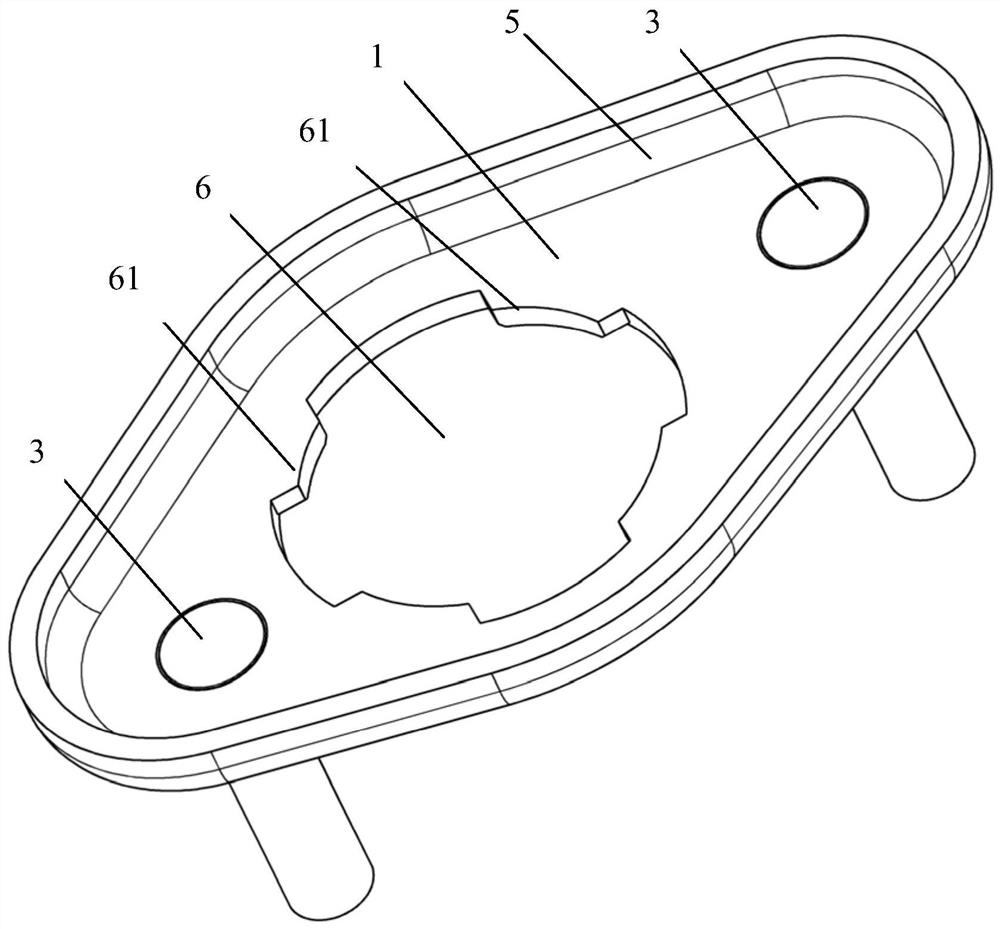

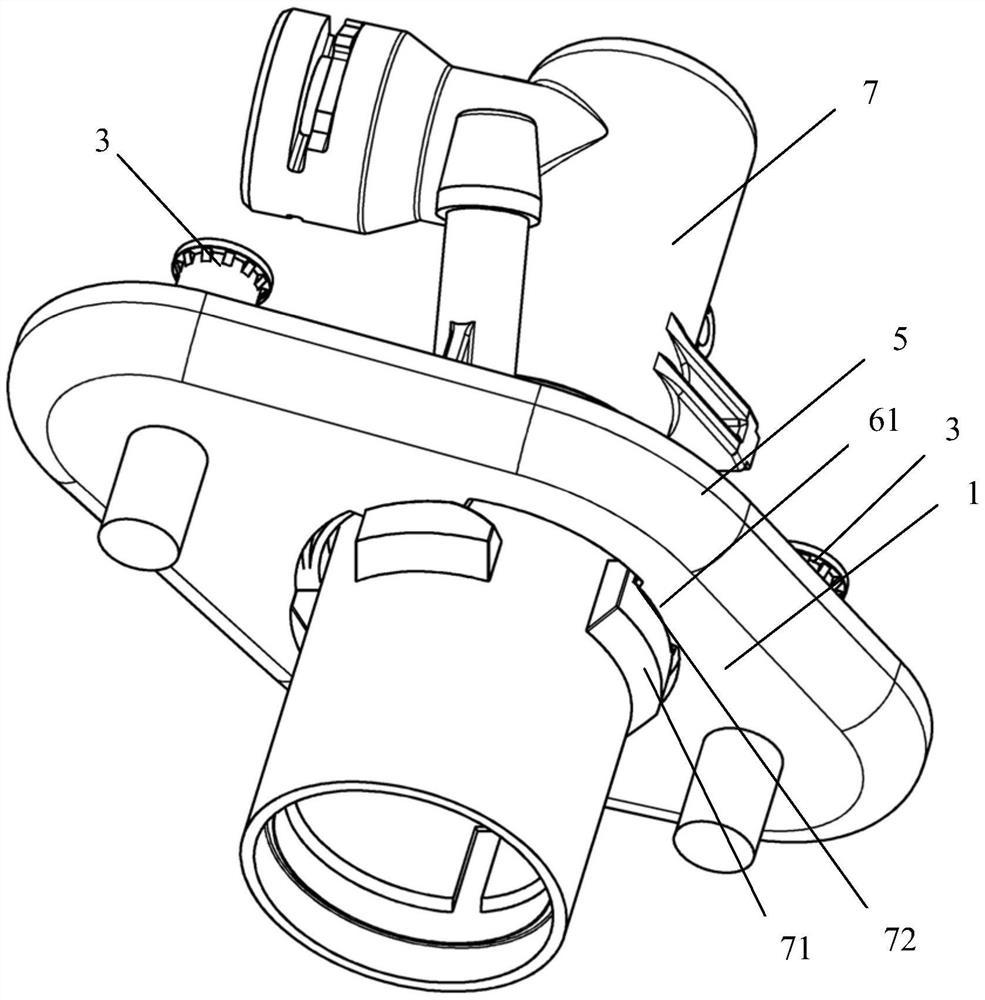

Flange and its assembly with clutch hydraulic master cylinder

ActiveCN105333027BLow installation space requirementAchieve installationFluid actuated clutchesCouplingsMaster cylinderClassical mechanics

The invention relates to a flange plate and its assembly assembly with a clutch hydraulic master cylinder, wherein the plate body of the flange plate is a metal part, and the peripheral edge of the plate body is stamped to form a circle of continuous flanging, and the mounting holes at both ends of the plate body All are fixedly pressed into the head of the threaded part, and the threaded body of the threaded part protrudes from the outside of the disc body. The metal flange with flanging is stronger than the simple metal flange, which can meet the requirement of bearing the maximum loading force, and is thinner than the plastic flange, which can significantly reduce the requirement for installation space.

Owner:SCHAEFFLER TECH AG & CO KG

A rear axle housing assembly of an automobile

ActiveCN103612543BGuaranteed to workOvercoming the Defects of Oil LeakageAxle unitsStress concentrationEngineering

The invention relates to automobile chassis, in particular to a rear axle housing assemble of an automobile in automobile chassis. The rear axle housing assembly of the automobile comprises a ventilation plug, an axle bag, a shell body rear cover and a separating plate, the shell body rear cover is connected with the axle bag, the separating plate is connected with the axle bag in an attached mode, a vent hole is formed in the axle bag, the vent hole is formed in the attachment position of the separating plate and the axle bag, and the ventilation plug is arranged in the vent hole. The rear axle housing assembly has the advantages that the mounting position of the ventilation plug is transferred to the axle bag from the shell body rear cover, the structure of the shell body rear cover is simplified, the stamping process of the shell body rear cover is simplified, manufacturing cost is lowered, the stress concentration of an axle tube is lowered, the separating plate has the function of an oil baffle, the normal work of the ventilation plug can be guaranteed, and the oil leakage defect of the ventilation plug is overcome.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Warm and hot forming device for sheet metal based on induced high-frequency electromagnetic field

ActiveCN105921582BStamping process is simpleProduction batch limitShaping toolsHigh intensityEngineering

The invention proposes a metal plate warm forming device based on induced high-frequency electromagnetic field. The workbench is provided with punching openings that penetrate up and down. The plate and the connecting rod slidingly connected with the workbench, the two ends of the connecting rod are respectively assembled to connect the upper supporting plate and the lower supporting plate, the punch forming assembly includes a punch which is located directly above the punching port and is movably connected with the upper supporting plate, located at the punching The guide plate on the edge of the punching port is movably connected to the workbench, the blank holder is located above the guide plate and is movably connected to the guide plate, and the high-frequency electromagnetic field generator is located directly below the punching port and is assembled and connected to the lower supporting plate. The beneficial effects of the present invention are: the sheet metal stamping process can be simplified without being limited by the production batch of stamping parts; the stamping cost of the sheet metal can be reduced, and the stamping efficiency of the sheet metal can be improved; The stamping parts after forming are of good quality.

Owner:SHANDONG UNIV OF SCI & TECH

Shock absorber device of medium-sized and heavy type trucks

The invention discloses a shock absorber device, and relates to a shock absorber device of medium-sized and heavy type trucks. The shock absorber device of the medium-sized and heavy type trucks comprises a shock absorber assembly (1) and is characterized in that an upper support (2) is arranged at the upper end of the shock absorber assembly (1), and a cover plate (3) is arranged at the lower end of the shock absorber assembly. The shock absorber device of the medium-sized and heavy type trucks is simple in structure, low in cost and capable of avoiding a steering track rod, a brake chamber and other parts, and therefore interference among the shock absorber assembly, the steering track rod, the brake chamber and other parts is prevented form occurring. Therefore, the shock absorber device of the medium-sized and heavy type trucks is suitable for being popularized and used.

Owner:CNHTC CHENGDU WANGPAI COMML VEHICLE

A key switch device supported by scissor feet that fit face to face

ActiveCN105006395BReduce material costsHigh matching precisionContact operating partsElastomerThin metal

The present invention discloses a surface fitting and scissors foot supported key switch device. The surface fitting and scissors foot supported key switch device comprises a keycap, an elastomer, a switch loop having a switch contact, a supporting plate having a matching part, and a scissors foot support having the upper and lower matching parts. The scissors foot support is in rotatable or slip connection with the keycap and the matching part of the support plate respectively via the upper and lower matching parts and forms a synchronous linkage supporting structure by the mutual force transmission, thereby guaranteeing that the keycap does the elevating motion parallel with the supporting plate. The surface fitting and scissors foot supported key switch device is characterized in that a concave bottom surface in the keycap is equipped with the key matching protruding shoulder 32, the key matching protruding shoulder 32 and a key inverted buckling boss 33 of the keycap form a matching part of the keycap, and the upper matching part of the scissors foot support is composed of a scissors upper end upper plate surface 43 and a scissors upper end plate lower surface 44. If the problems that the wear resistance of the scissors foot support, the keycap and the supporting plate can be improved and a thinner metal plate can be used to produce the scissors foot support to simultaneously reduce the material cost and the height of a keyboard further, can be solved, a conventional sheet metal scissors foot support can substitute for a conventional widely used plastic scissors foot support.

Owner:陈峰

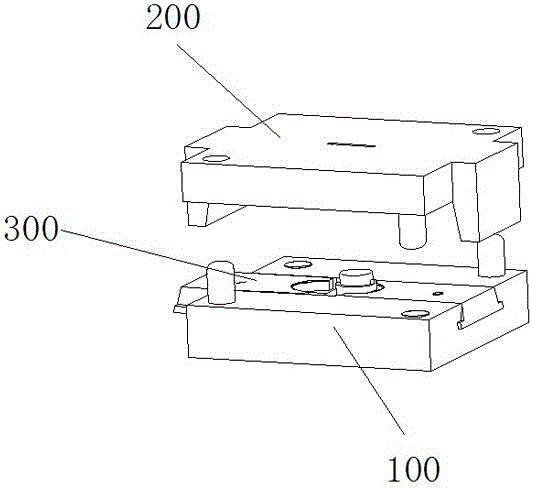

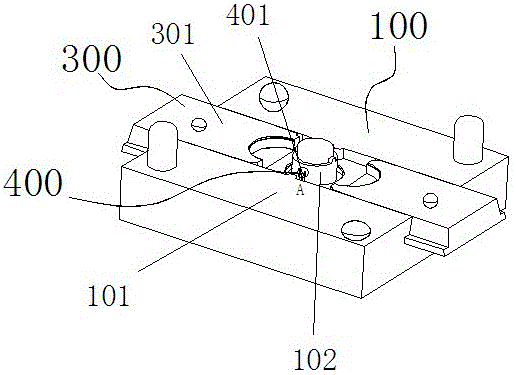

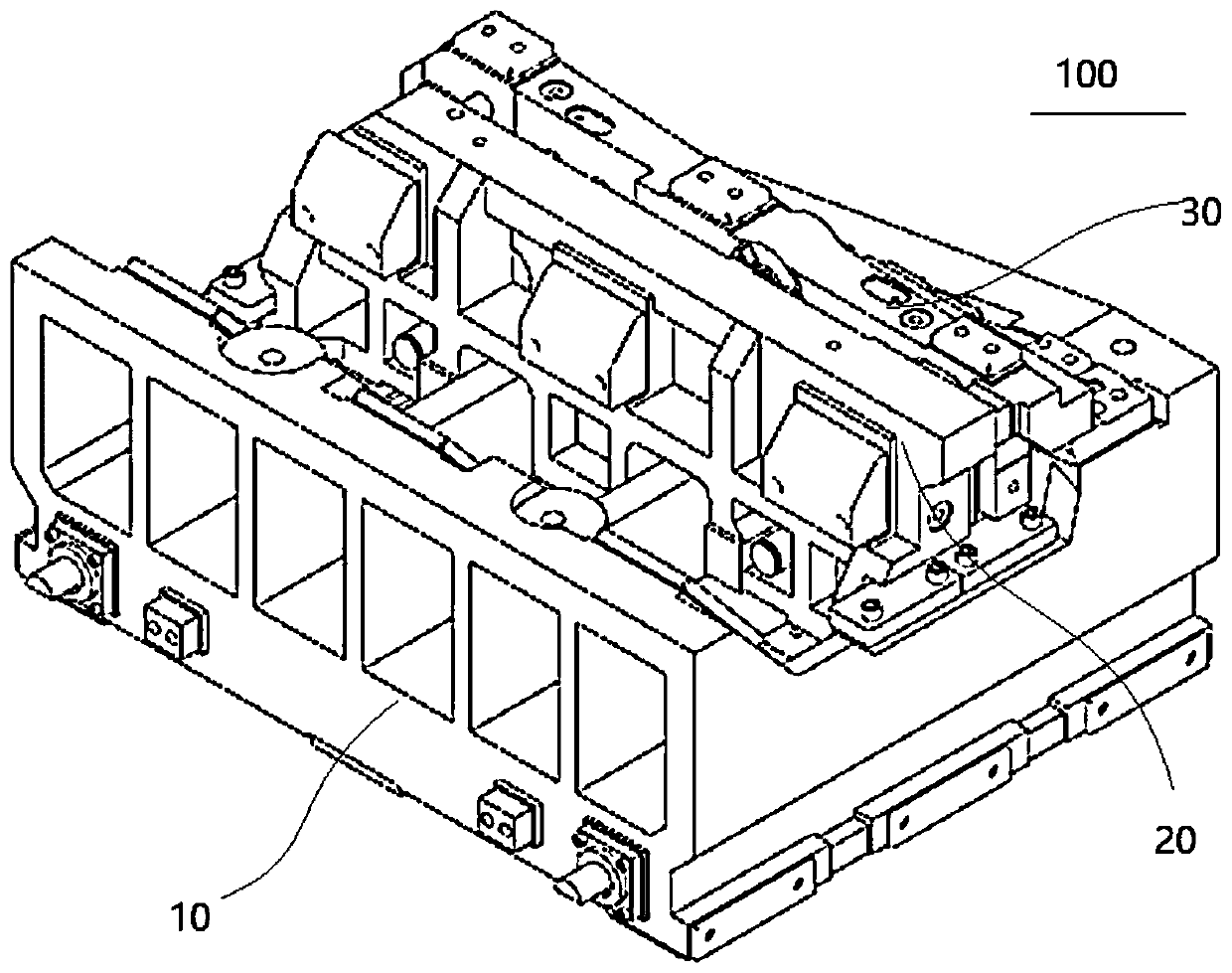

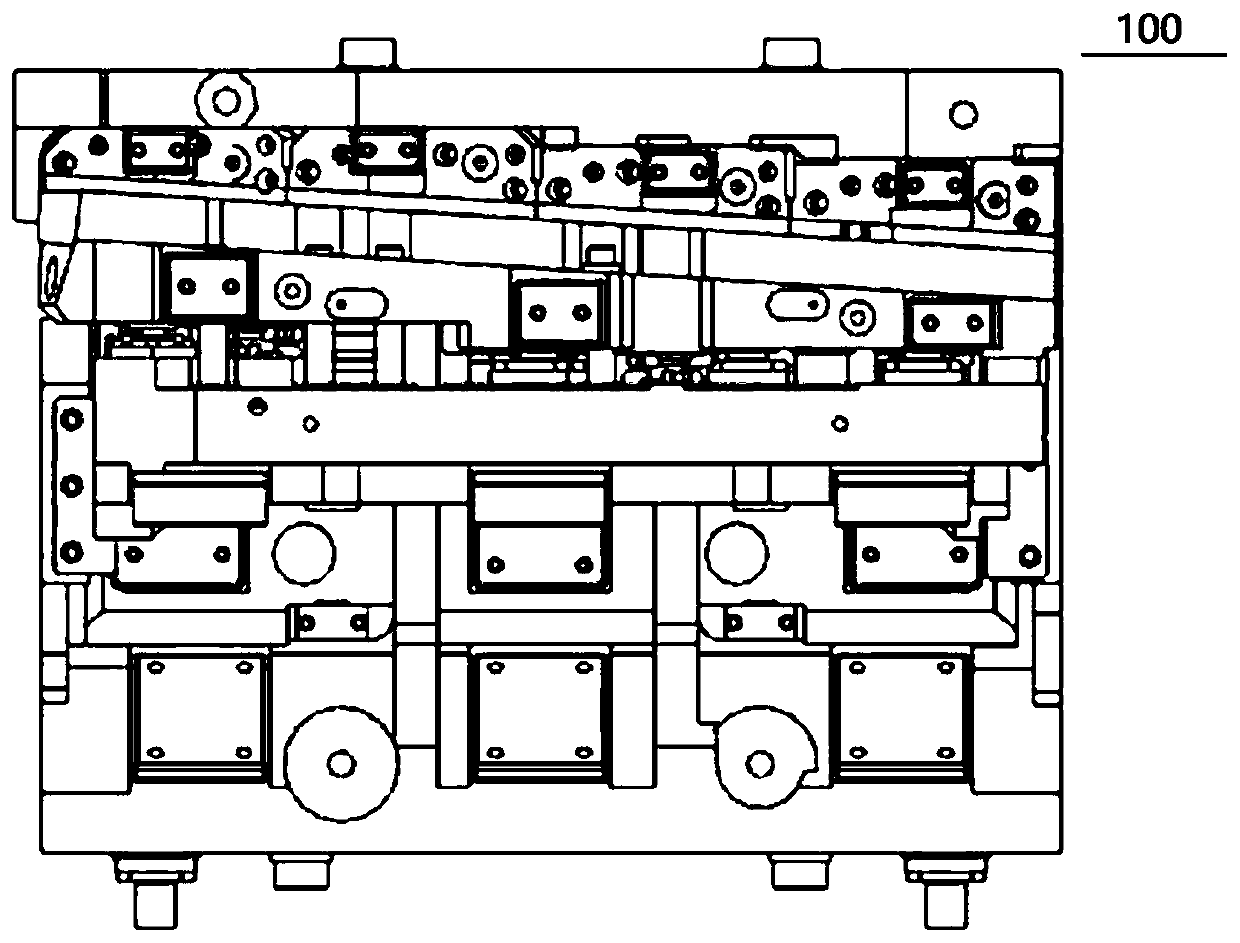

Injection mold for magnetic conduction ring assembly and manufacturing method thereof

The invention discloses an injection mold for a magnetic conduction ring assembly, comprising a lower mold assembly (100), an upper mold assembly (200) and a positioning mechanism (300) provided on the lower mold assembly (100) , the lower mold assembly (100) includes a lower mold (101), a mandrel (102) provided on the lower mold (101), and a guide device (400) arranged on the mandrel (102), the upper The mold assembly (200) includes an upper mold (201) and an injection gate (202) arranged on the upper mold (201). The invention also discloses a manufacturing method for processing the magnetic conduction ring assembly through the above-mentioned injection mold, which has no holes for positioning, accurate positioning of the upper and lower magnetic conduction rings, simple processing technology, and good performance of the manufactured product.

Owner:杭州新世宝电动转向系统有限公司

Horizontal flanging die mechanism

ActiveCN111438243AStamping process is simpleImprove work efficiencyShaping toolsMetal-working feeding devicesStamping processIndustrial engineering

The invention provides a horizontal flanging die mechanism. The mechanism comprises a pulley mechanism, a rollback mechanism and a side material pressing core assembly, wherein one end of the upper surface of the pulley mechanism is provided with a flanging insert, and a mounting part and a sliding part are defined in the pulley mechanism; the rollback mechanism is arranged in the sliding part ina sliding mode; the side material pressing core assembly is arranged in the mounting part, and a male die cutting edge is arranged below one side of the side material pressing core assembly. Accordingto the horizontal flanging die mechanism, in the whole flanging process, the pulley mechanism, the rollback mechanism and the side material pressing core assembly jointly complete feeding and returning actions, the male die cutting edge is machined below one side of the side material pressing core assembly and functions as material pressing and a male die, the pulley mechanism drives the flanginginsert to move in the horizontal direction far away from a fixed male die, and a flanging area of a workpiece is horizontally flanged from inside to outside. The horizontal flanging die mechanism simplifies the stamping process and improves the working efficiency.

Owner:BAIC GRP ORV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com