Flange and its assembly with clutch hydraulic master cylinder

A technology for assembling components and clutches, which is applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problem that the separation of flanges and threaded parts cannot be delivered to customers together, metal flanges cannot meet the loading force requirements, and plastic The flange takes up a lot of space and other problems, and achieves the effects of low cost, convenient installation and operation, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

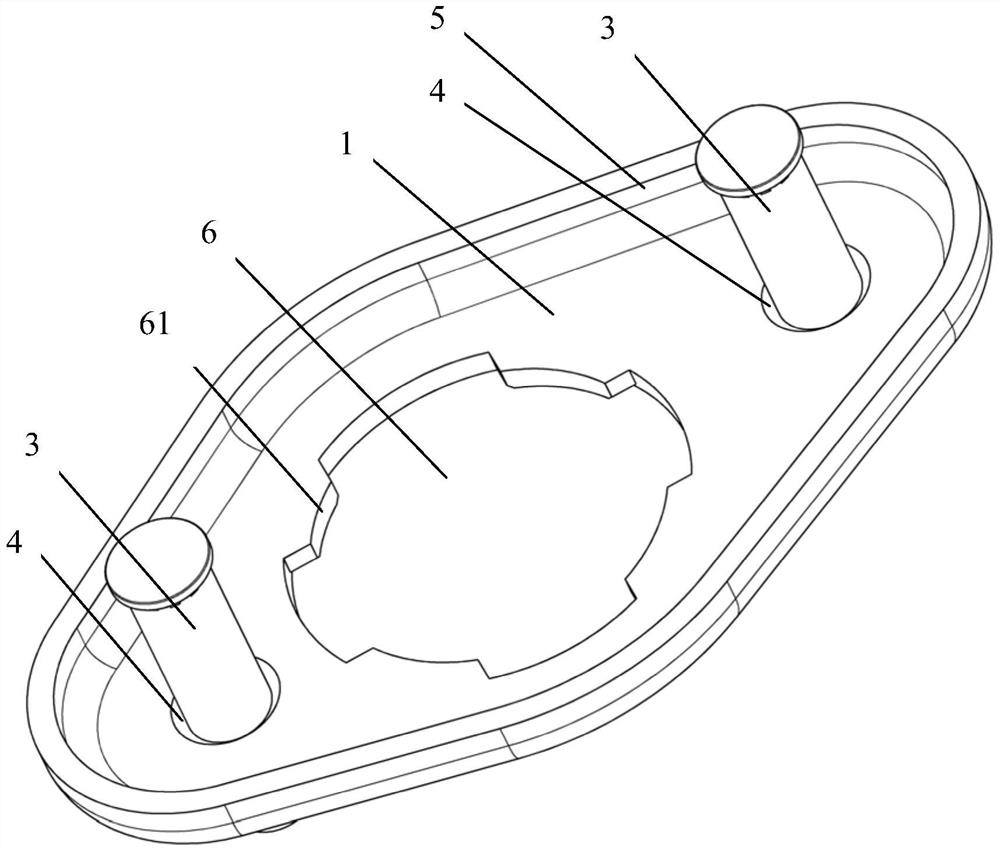

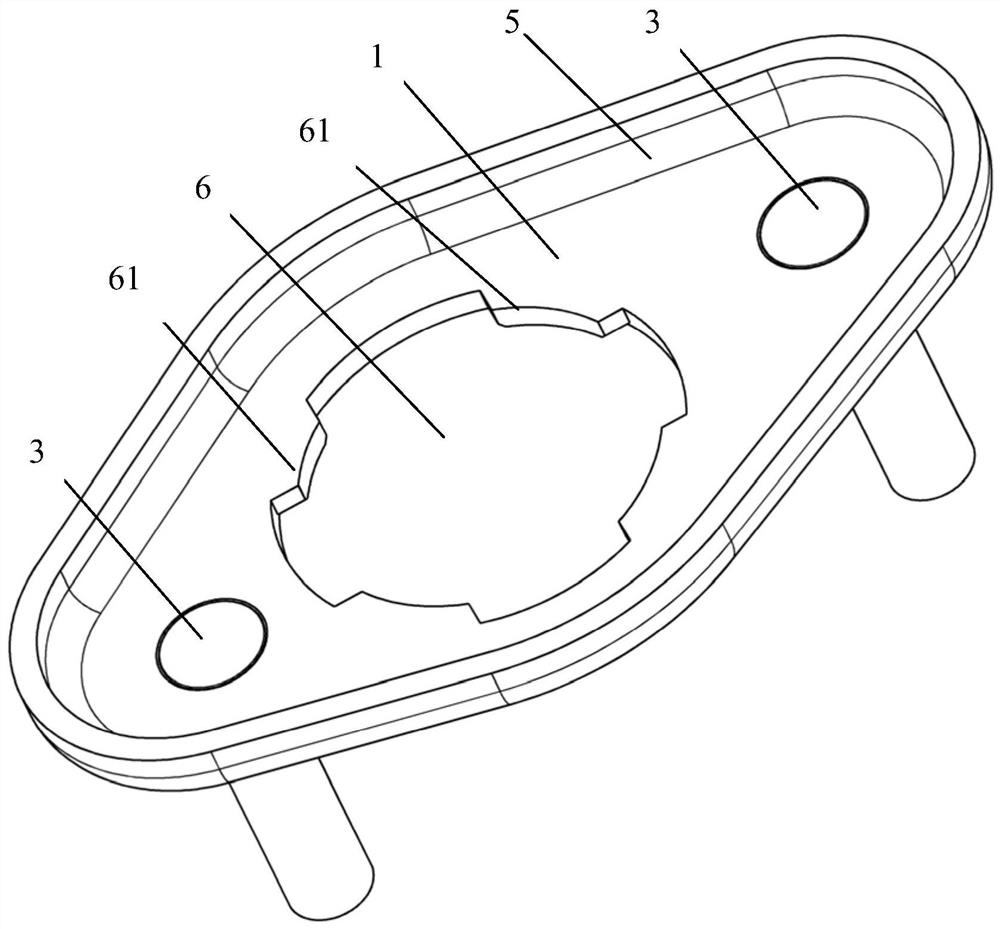

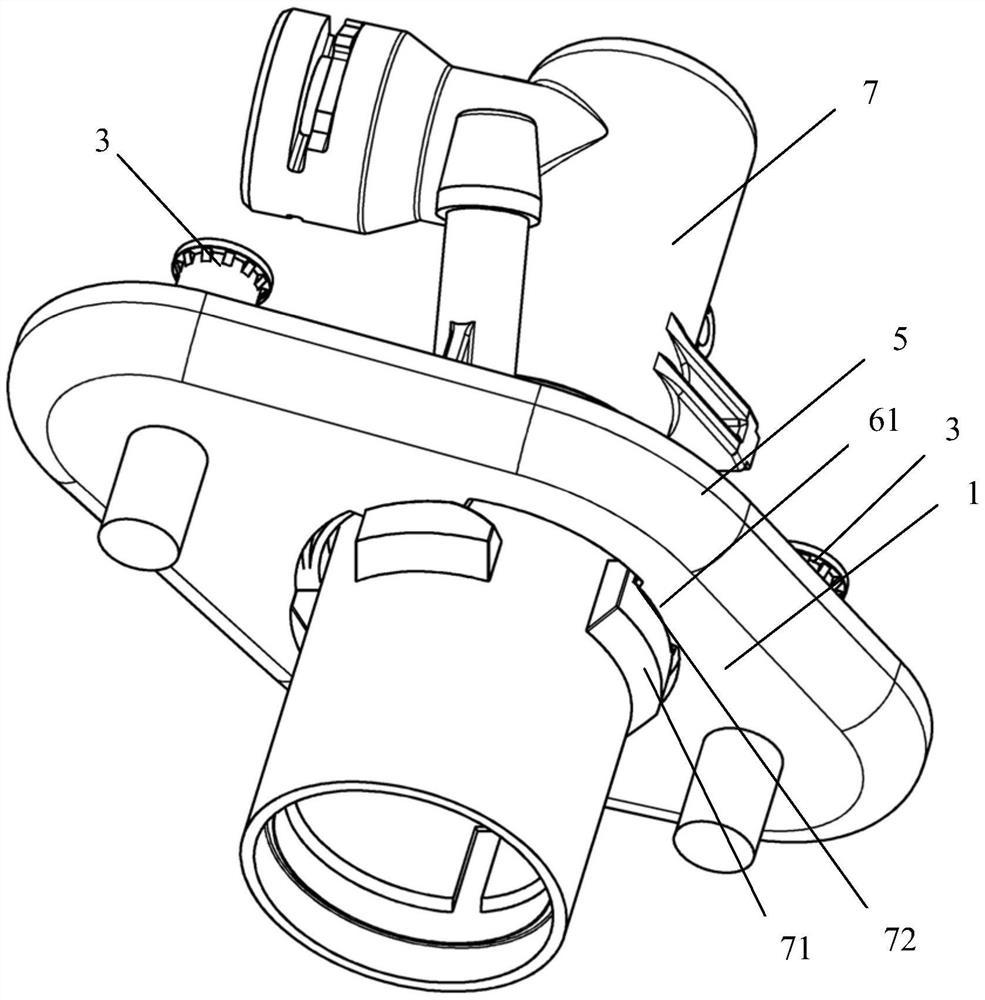

[0013] refer to figure 1 , figure 2 , a flange, including a disc body 1, the two ends of the disc body 1 have mounting holes 4, the disc body 1 is a metal part, and the peripheral edge of the disc body 1 is punched to form a circle of continuous flanges 5, with a turn The metal flange with edge is stronger than the simple metal flange, and can meet the requirement of bearing the maximum loading force of 5000N. The metal flange with flanging not only meets the requirement in strength, but also is thinner than the plastic flange. , the thickness of the existing plastic flange will exceed 10mm, while the thickness of the metal flange of the present invention will be reduced to 2-3mm, which significantly reduces the requirements for installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com