A key switch device supported by scissor feet that fit face to face

A scissor foot and surface matching technology, applied in the direction of electric switches, electrical components, contact operating parts, etc., can solve the problems of loss of accuracy of keycaps, support plates, inability to process sheets, affecting the keyboard, etc., and achieve low key heights. , Reduce material cost and improve the effect of matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

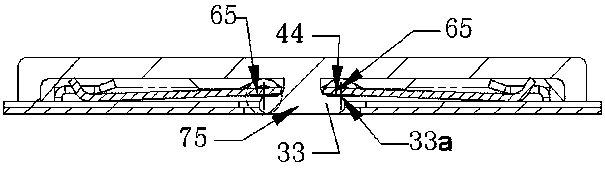

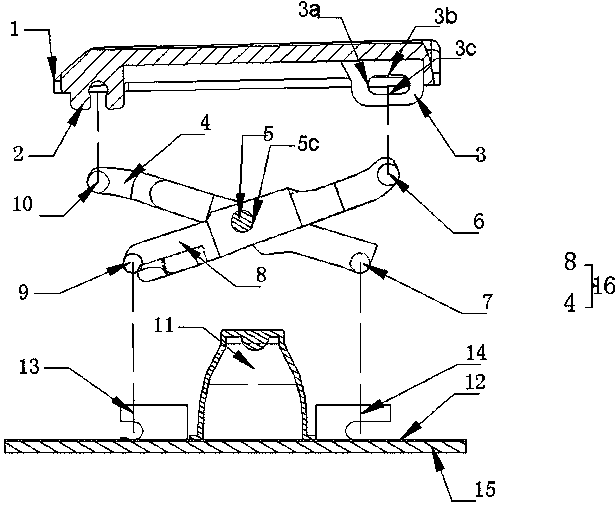

[0121] see Figure 8 -- Figure 14 , a kind of scissor foot support of the present invention is supported and the key switch device of keycap face-to-face cooperation, comprises keycap,, elastic body, membrane switch piece, the supporting plate that has matching part, the scissor foot support that has upper and lower matching part, scissor foot The support is connected to the keycap and the supporting plate by rotating or slidingly through the upper and lower matching parts. The scissor foot support forms a synchronous linkage support structure through the transmission of force between each other to ensure that the keycap moves up and down parallel to the support plate. The concave bottom surface 30 has a key matching convex shoulder 32, and the key matching convex shoulder 32 and the key undercut boss 33 of the key cap constitute the matching part of the key cap; , 44 forms below the upper end plate of the scissors.

[0122] The scissors foot support 16 is connected in rota...

Embodiment 2

[0175] see Figure 17 , Figure 18 1. On the bottom surface of the concave bottom surface of the keycap between the two matching parts in the width direction of the keycap 1, a left and right rigid key limiting boss 55 and a left and right two key fitting part bosses 57 are respectively arranged, Wherein the key-limiting boss 55 is located at the middle position between the two sections of key fitting bosses 57, and the fitting parts of the key limiting boss 55, the key fitting boss 57, and the keycap 1 are all arranged along the width direction.

[0176] The keycap anti-off structure is made of key spacing boss 55, and key spacing boss 55 inner side limiting boss guides the surface 56, and key spacing boss 55 outside is provided with key spacing boss end 58.

[0177] The key fitting portion boss 57 protrudes upwards from the bottom surface of the concave bottom surface of the keycap to form a square boss, and the corners on the outside of the boss 57 of the key fitting porti...

Embodiment 3

[0196] see Figure 32 1. The scissors support 16 is an inverted eight shape, and the lower matching part of the scissors support 16 is composed of the scissors lower support part, the scissors lower end upper plate surface 63 of the scissors support 16, and the scissors anti-off structure; the scissors The lower support part of the scissors of the foot support 16 and the anti-off structure of the scissors are all located on the lower plate surface 66 of the lower end of the scissors; The undercut fit arc 33a of the snap fit portion fits.

[0197] On the support plate 15 there is a stamping boss that limits the horizontal movement of the lower support portion of the scissors, and the concave surface 72 of the support plate is formed on the support plate 15 by stamping the stamping boss. The scissors lower end lower plate surface 66 of the scissors foot support 16 is bent and formed (that is, the lower end of the scissors support arc) and the support plate lower concave surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com