Microphone printed circuit board (pcb) high in utilization rate and lower punching die structure thereof

A technology of pcb board and utilization rate, which is applied in the field of micro-head pcb board and its stamping die structure, can solve the problems of low utilization rate of base material and increase of raw material cost, and achieve low stamping cost, high utilization rate and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

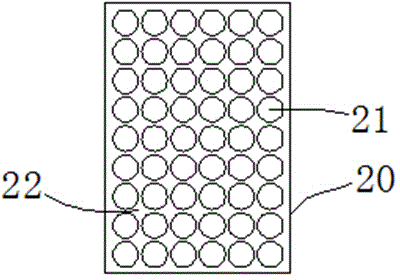

[0019] refer to figure 1 and figure 2 As shown, a microphone pcb board with high utilization rate and its stamping lower die 10 structure, it comprises a microphone pcb substrate 20 and a stamping lower die 10, and the microphone pcb substrate 20 is provided with a microphone unit 21 and a side Corner surplus material 22, described stamping lower die 10 is provided with upper left reference limit angle block 11, right upper reference limit angle block 12 and lower limit block 13, described left upper reference limit angle block 11, right upper reference limit angle block The block 12 and the lower limit block 13 wrap and position the peripheral edge of the microphone pcb substrate 20 .

[0020] like figure 2 As shown, the microphone units 21 are neatly and evenly arranged in a dot matrix, and the distance between the outermost m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com