Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Increase punching force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

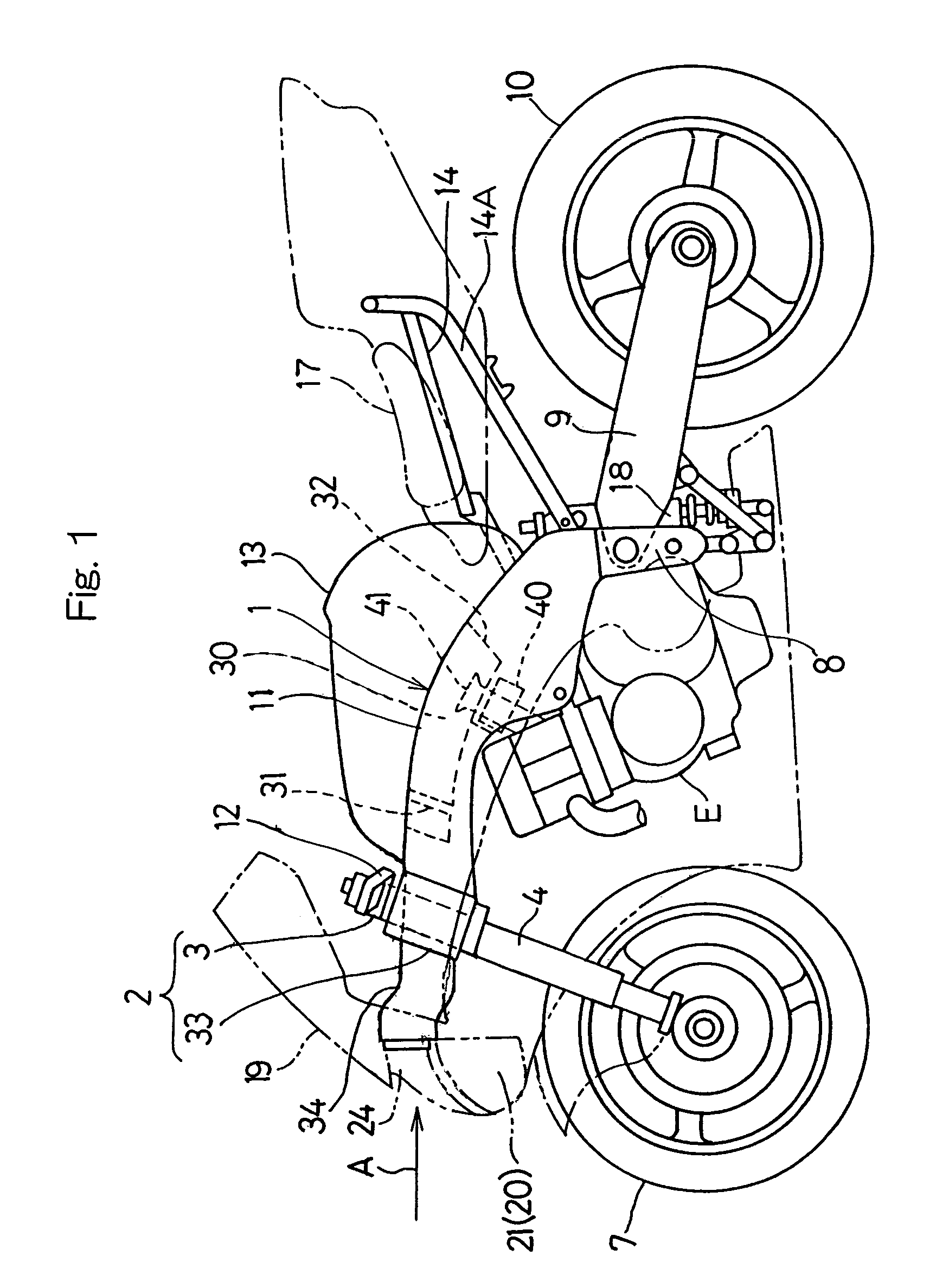

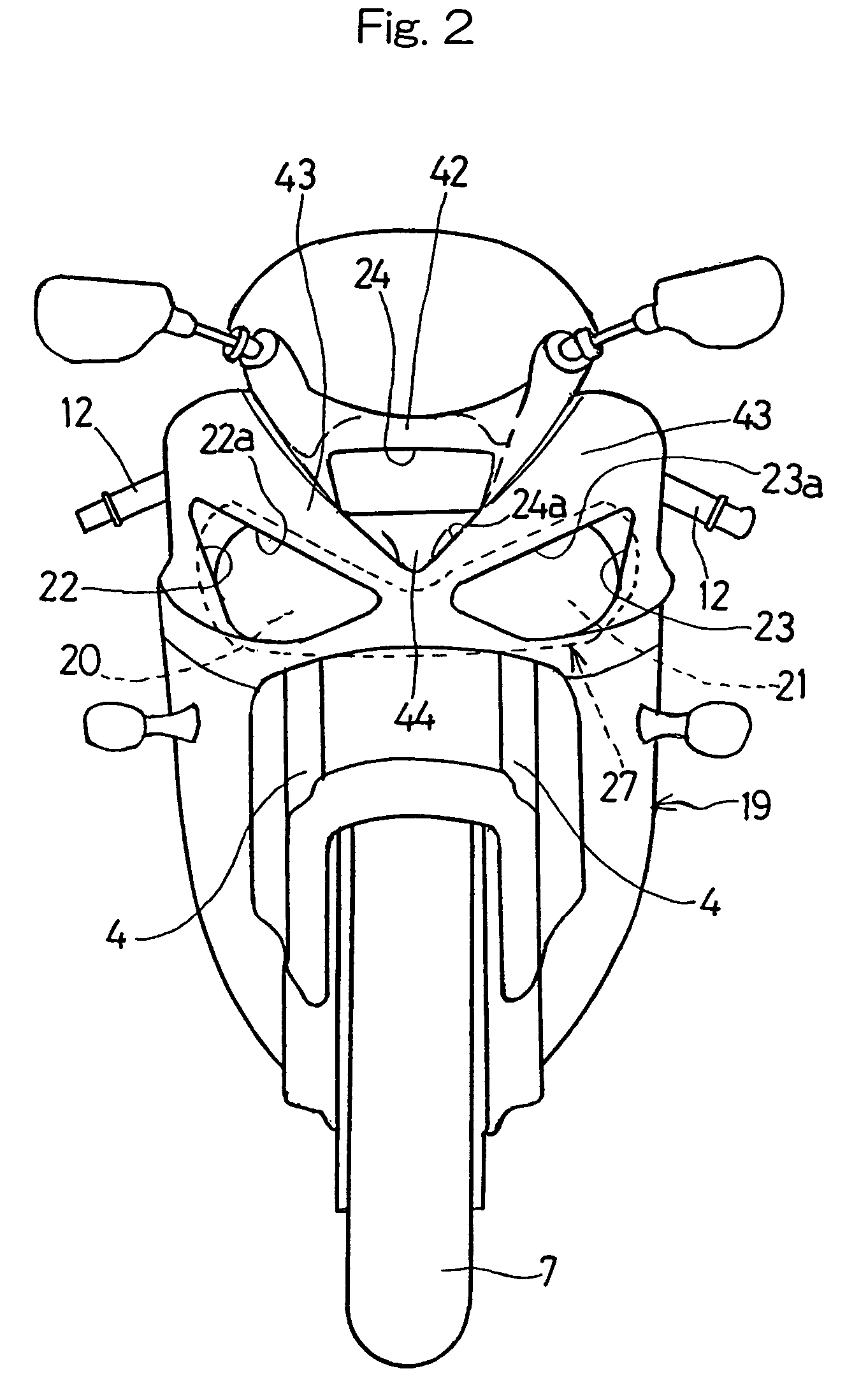

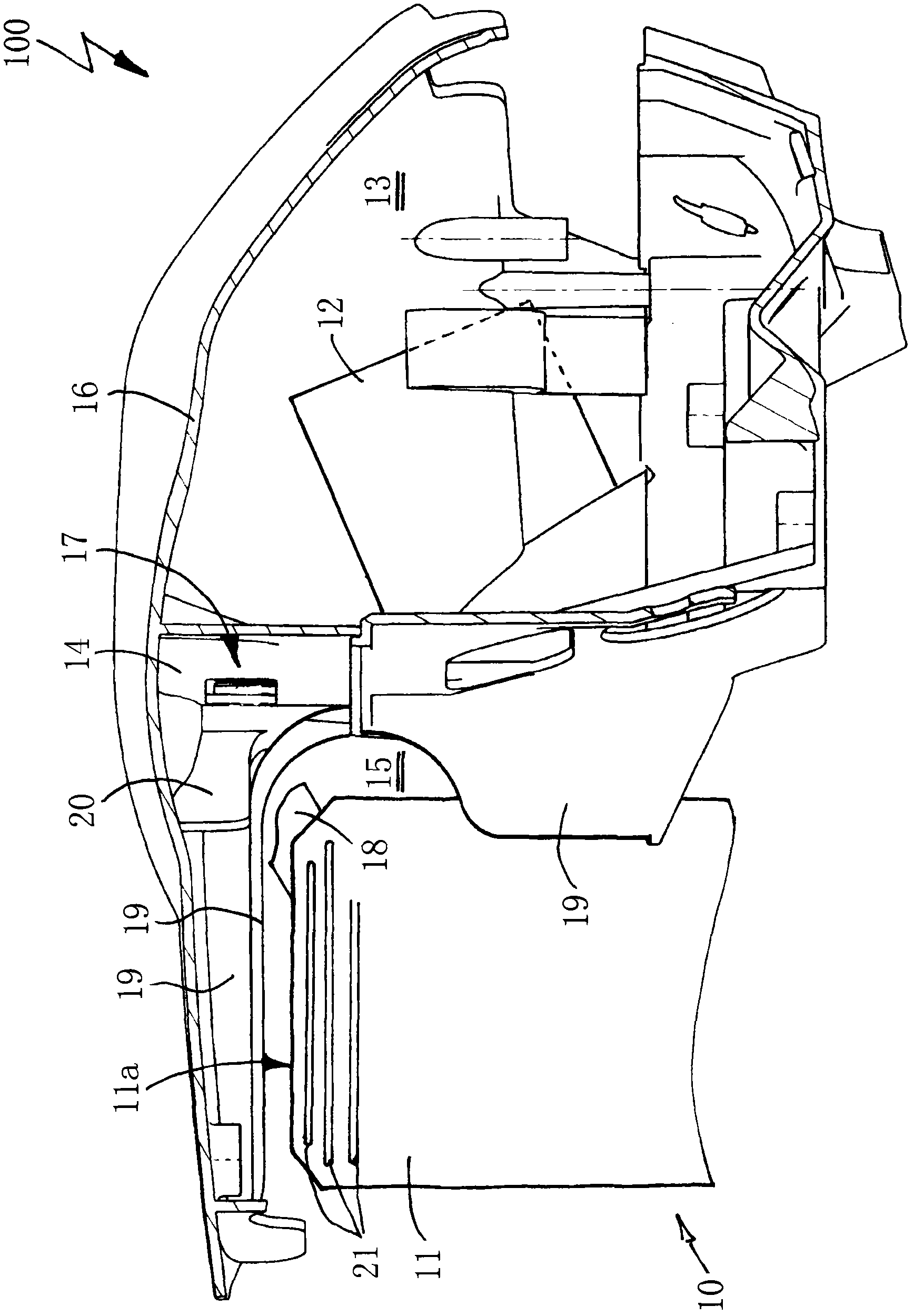

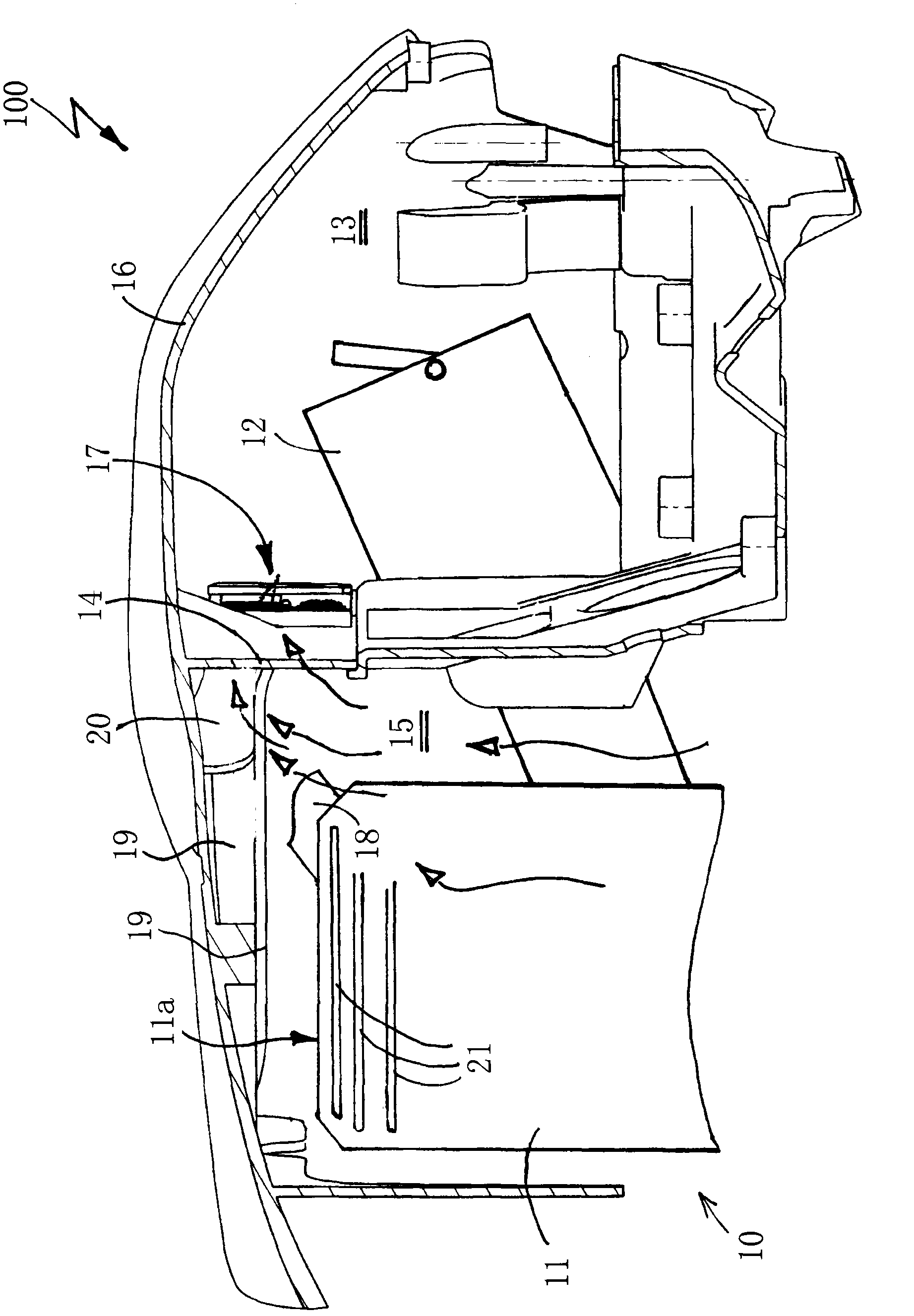

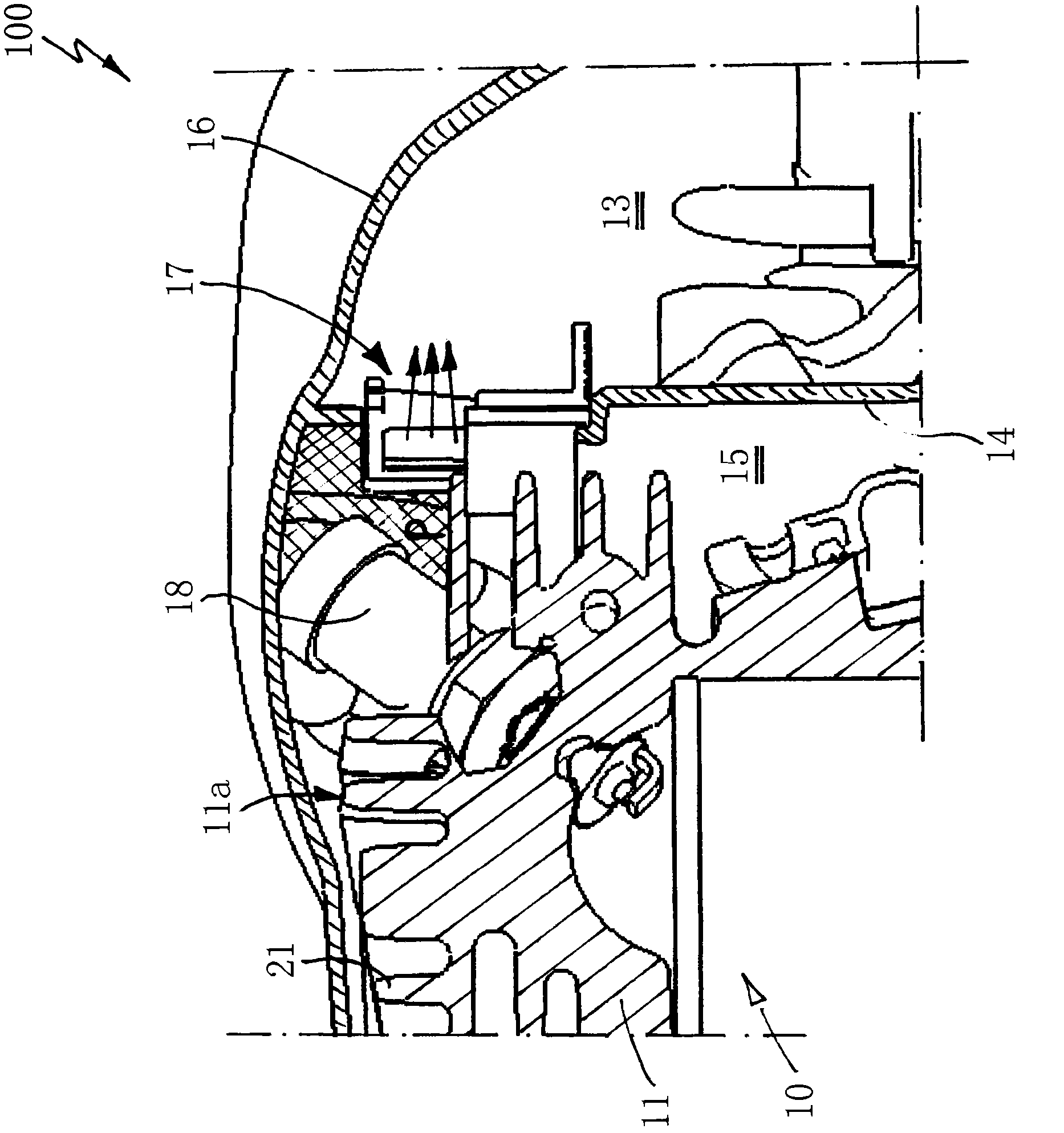

Air intake system for vehicle combustion engine

ActiveUS7270207B2Simple structureReduce manufacturing costInternal combustion piston enginesWeather guardsCombustionEngineering

To provide an air intake system for a vehicle, so simple in structure as to reduce the cost and effective to increase the ram pressure, a front cowling (19) is mounted on a front portion of a vehicle body structure (1). This front cowling (19) has left and right headlight windows (20 and 21) aligned with left and right headlights (22 and 23), respectively, and also has an air intake opening (24) defined therein at a location above the headlight windows (20 and 21) for introducing an external combustion air (A) towards the vehicle engine (E). An intake air passage (35) is provided for introducing the combustion air (A), then entering the air intake opening (24), towards an air cleaner (30) by way of opposite lateral portions of a head tube (3).

Owner:KAWASAKI MOTORS LTD

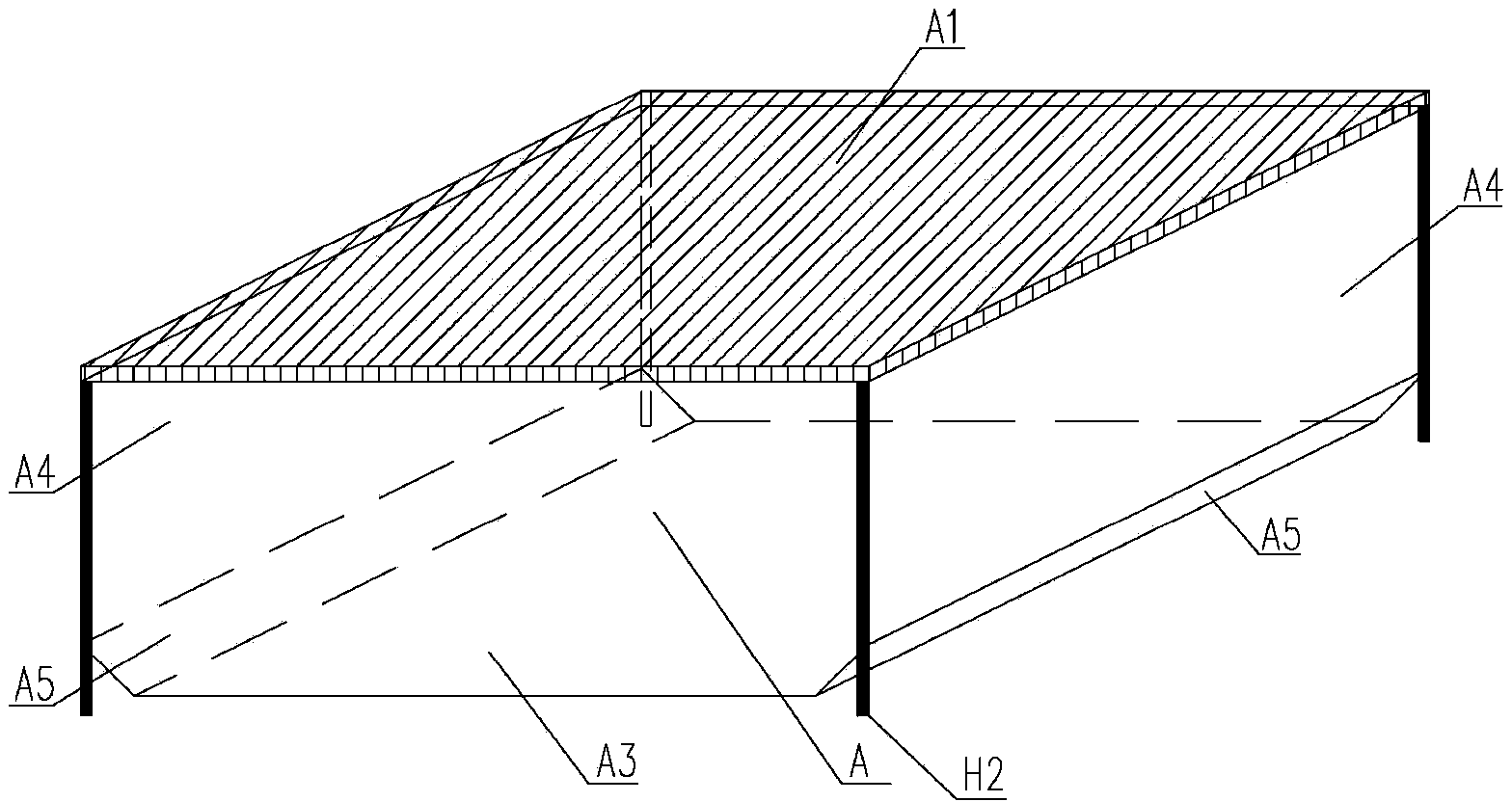

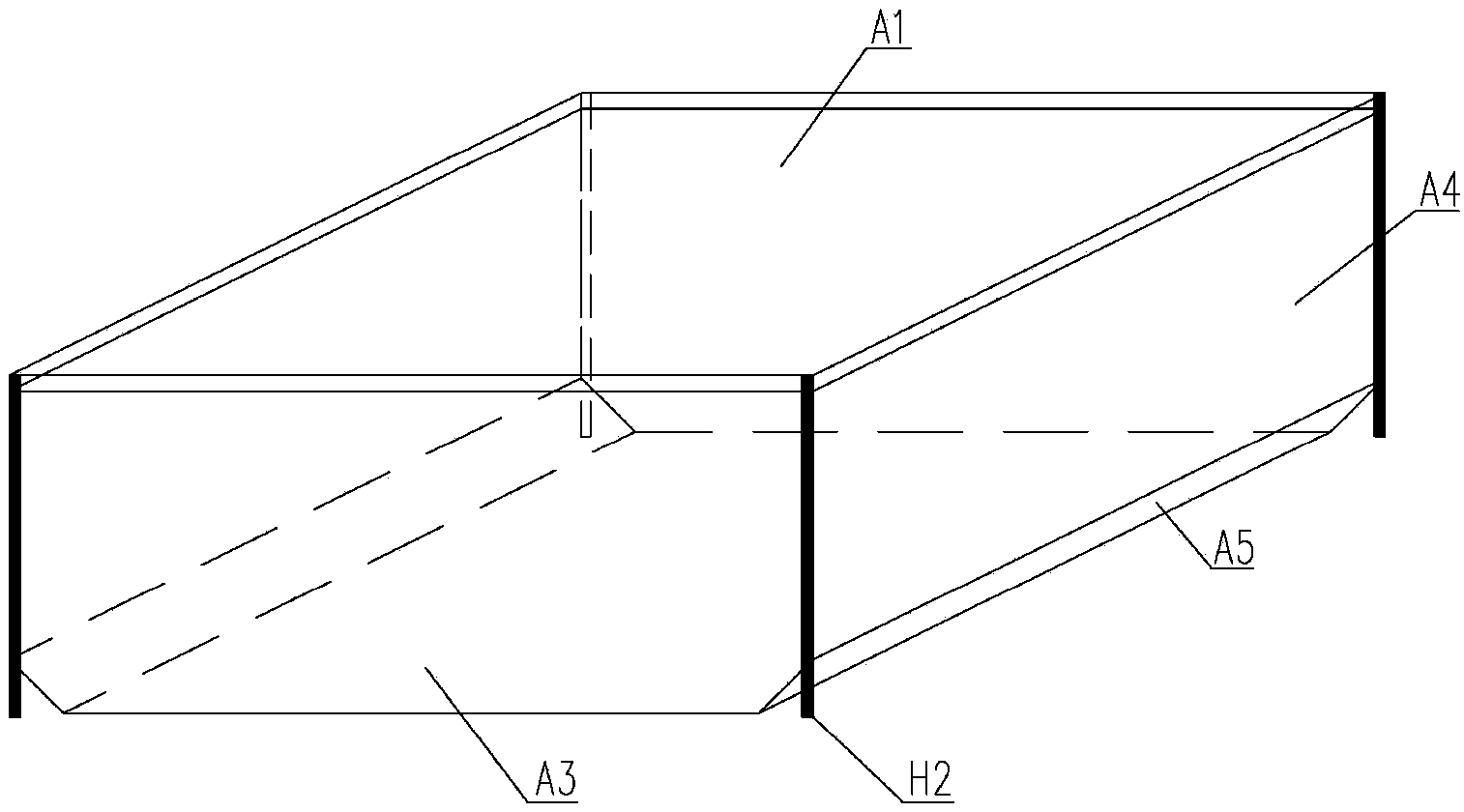

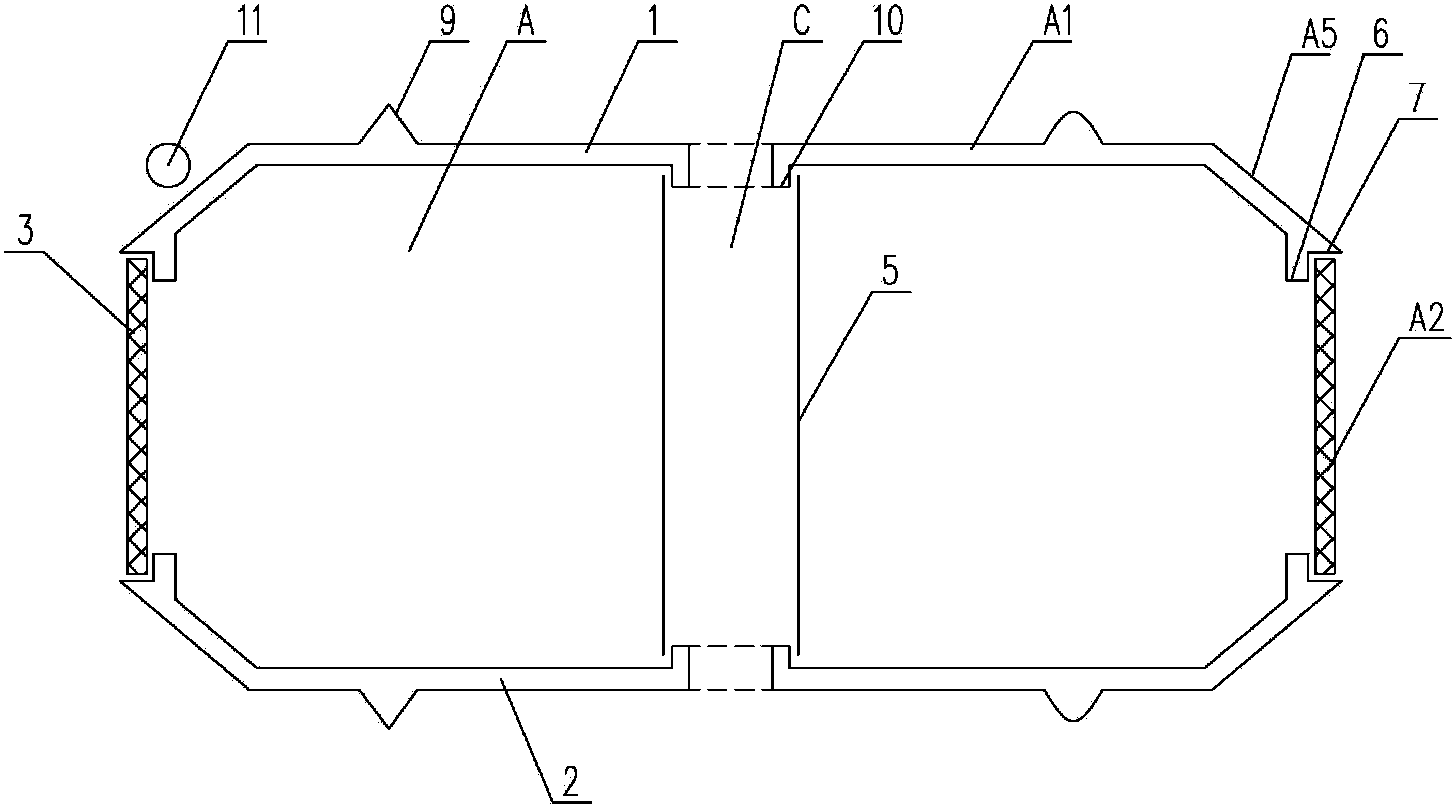

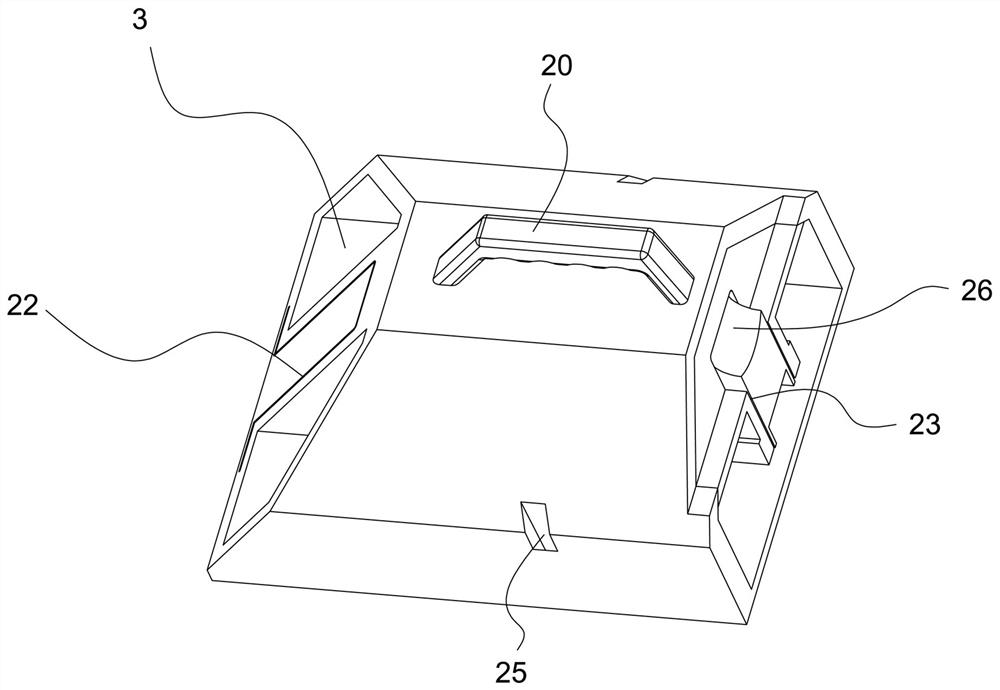

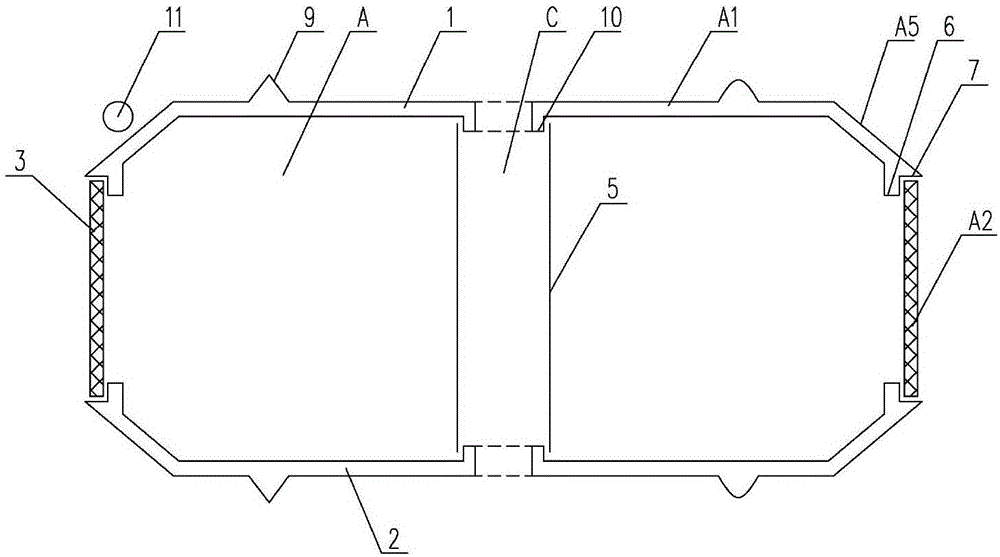

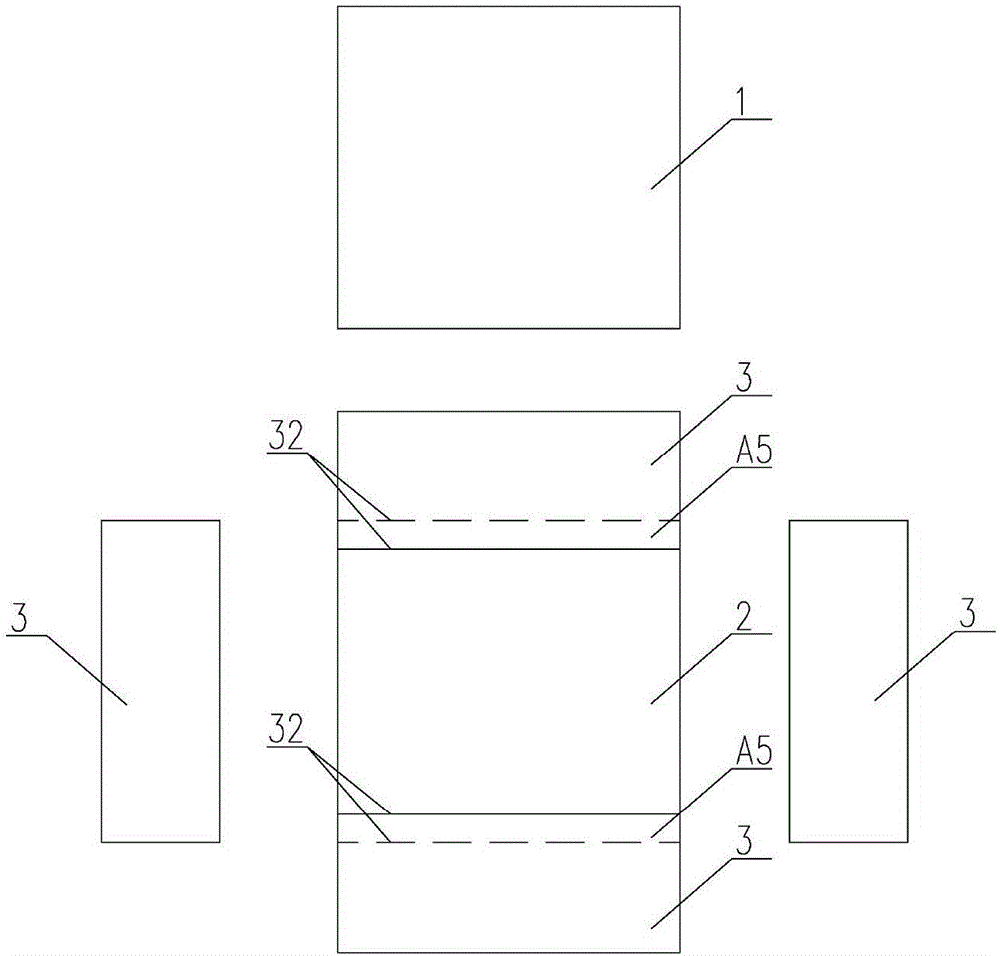

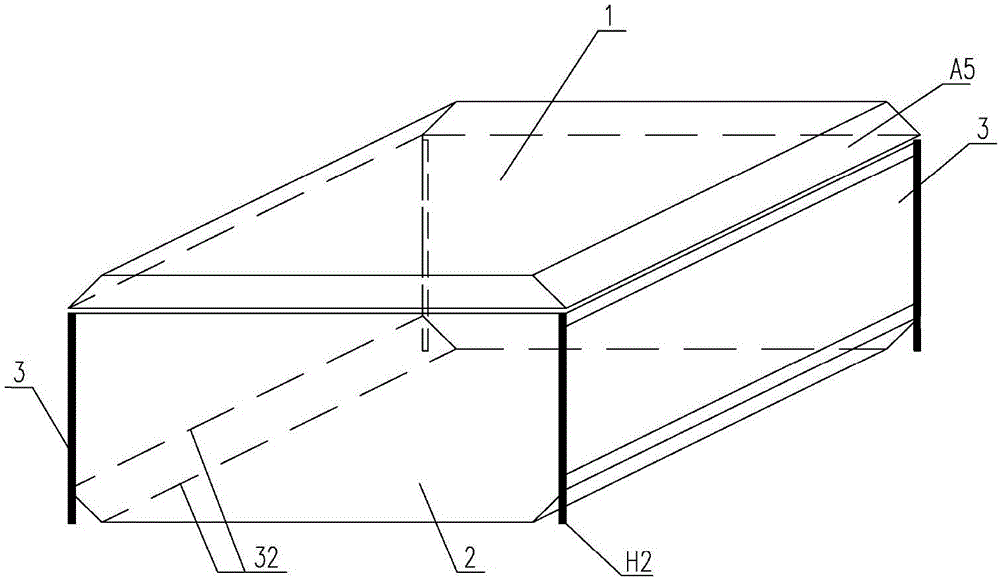

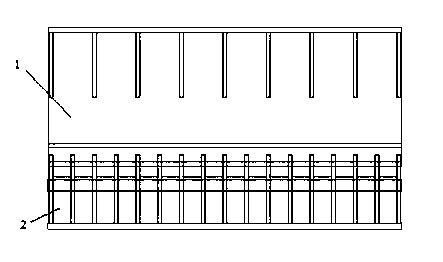

Cast-in-situ hollow floor with pores formed by reticular box-shaped component

The invention provides a cast-in-situ hollow floor with pores formed by a reticular box-shaped component. The cast-in-situ hollow floor comprises a reinforced concrete girder or a profile steel girder, a reinforced concrete ribbed beam, an upper flange plate, a lower flange plate and the reticular box-shaped component, wherein the reticular box-shaped component comprises a box roof, a box body and a box bottom; the box roof is compounded with cement mortar, polyfoam or a panel; the box body and the box bottom are made of reticular bodies; each reticular body comprises a reticular plate, a reinforcing rib and a connecting net, which constitute an integral structure with mutual effect; each of the reinforcing ribs is V-shaped; the reticular box-shaped component comprises at least two reticular bodies; at least two structural slopes are arranged at the corner parts between the box bottom and the box body of the reticular box-shaped component; the reticular bodies of the reticular box-shaped component are made of a steel material or a molding material. The cast-in-situ hollow floor with the pores formed by the reticular box-shaped component adopts the unsealed reticular box-shaped component to substitute the existing fully-sealed hollow fillers and solid fillers as the cast-in-situ hollow floor pore-forming technology. The cast-in-situ hollow floor with the pores formed by the reticular box-shaped component is favorable to realization of building and energy conservation integration and the multifunctional floor.

Owner:HUNAN BDF ENERGY SAVING TECH

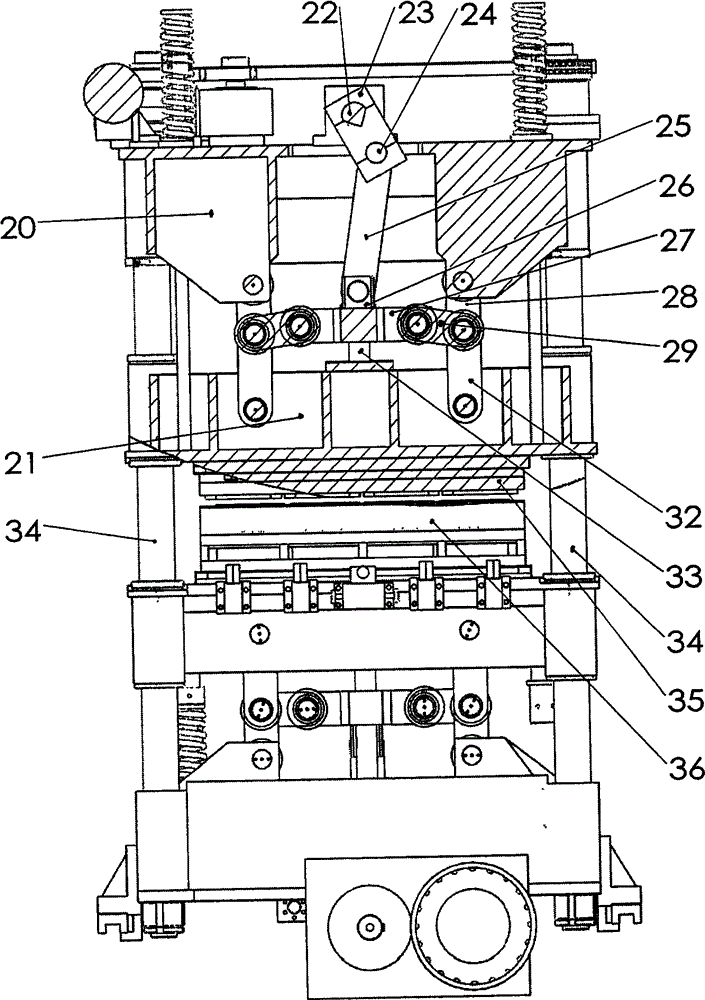

A Progressive Die for Double Hole Shielding Cover

The invention relates to the technical field of dies, in particular to a double-hole shielding cover progressive die. The double-hole shielding cover progressive die comprises an upper die holder, an upper die, a stripper plate, a lower die, a lower die holder, and a punching pilot hole station, a half sectioning station, a stretching station and a shielding cover punching-off station which are assembled correspondingly, wherein the upper die, the stripper plate and the lower die are correspondingly assembled with the punching pilot hole station, the half sectioning station, the stretching station, a double-side punching station, a bilateral hole turnup station, a first turnup flattening station, a second turnup flattening station, a punching side notch station and the shielding cover punching-off station which are formed sequentially. During actual production, production can be performed only by placing a material belt on the lower die, all the procedures are finished in the die, andfull automation of the whole flow is realized, so labor cost is reduced, the defective rate of the shielding covers is low, production efficiency is high, and the double-hole shielding cover progressive die is suitable for production of the shielding cover with side holes on the two sides.

Owner:DONGGUAN DAZHONG ELECTRONICS

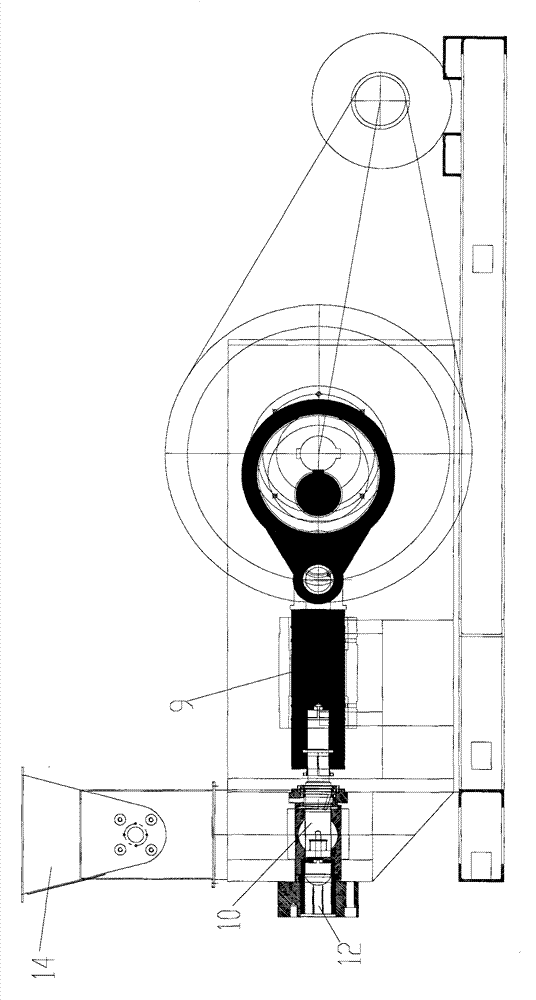

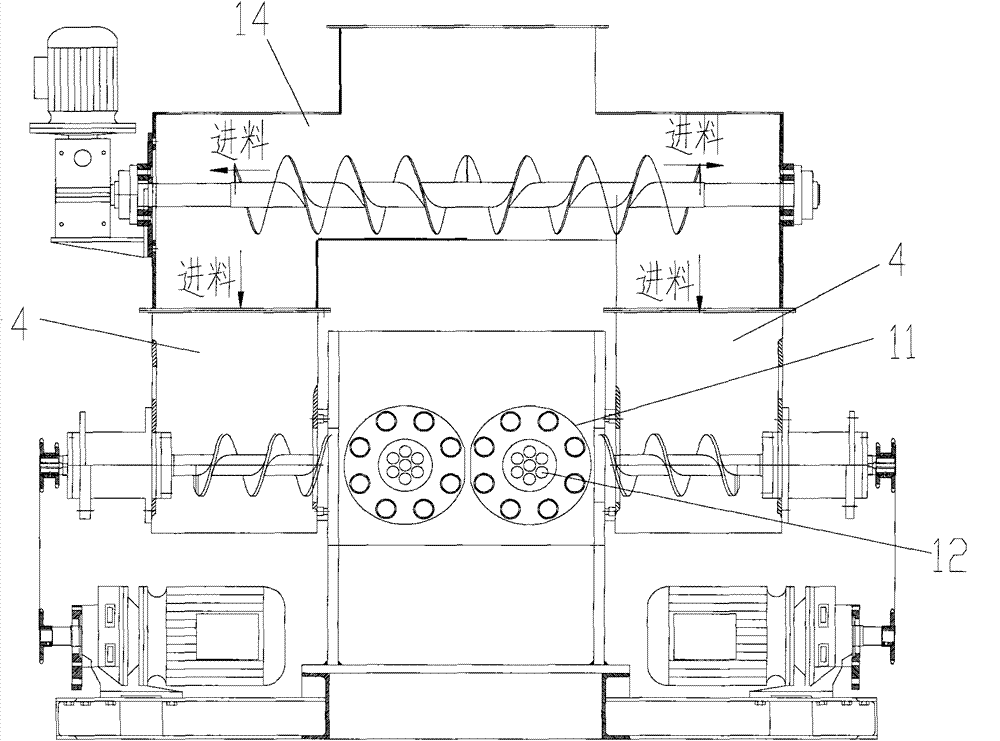

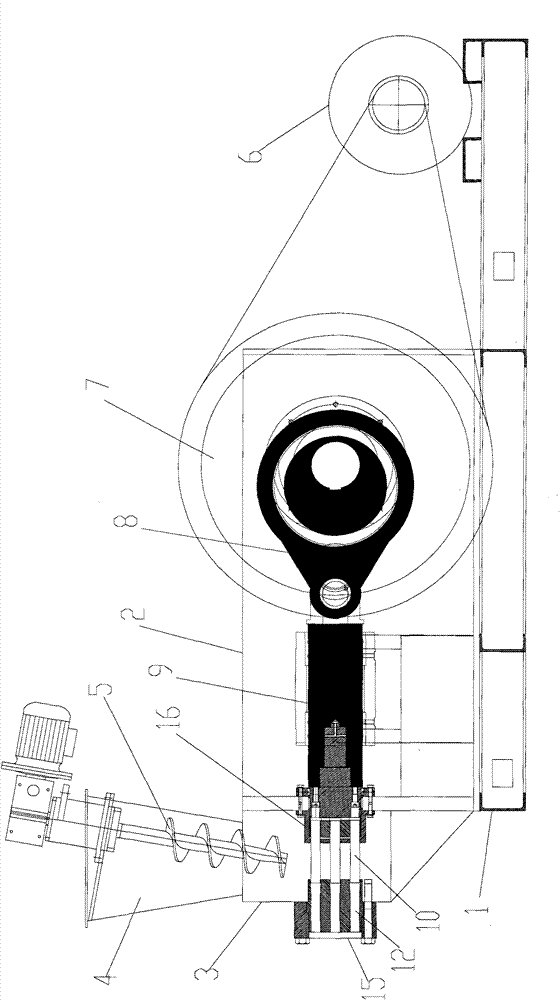

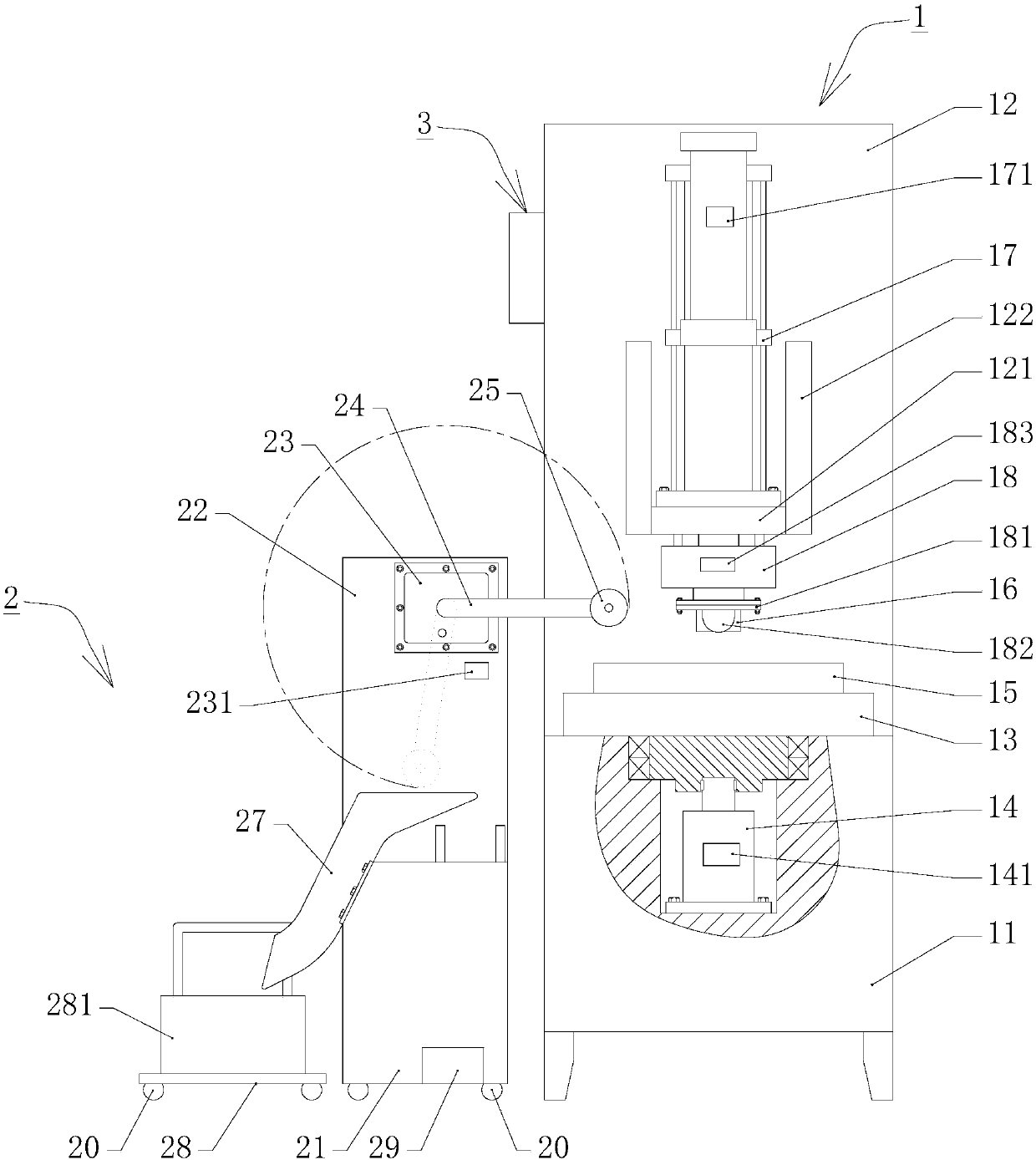

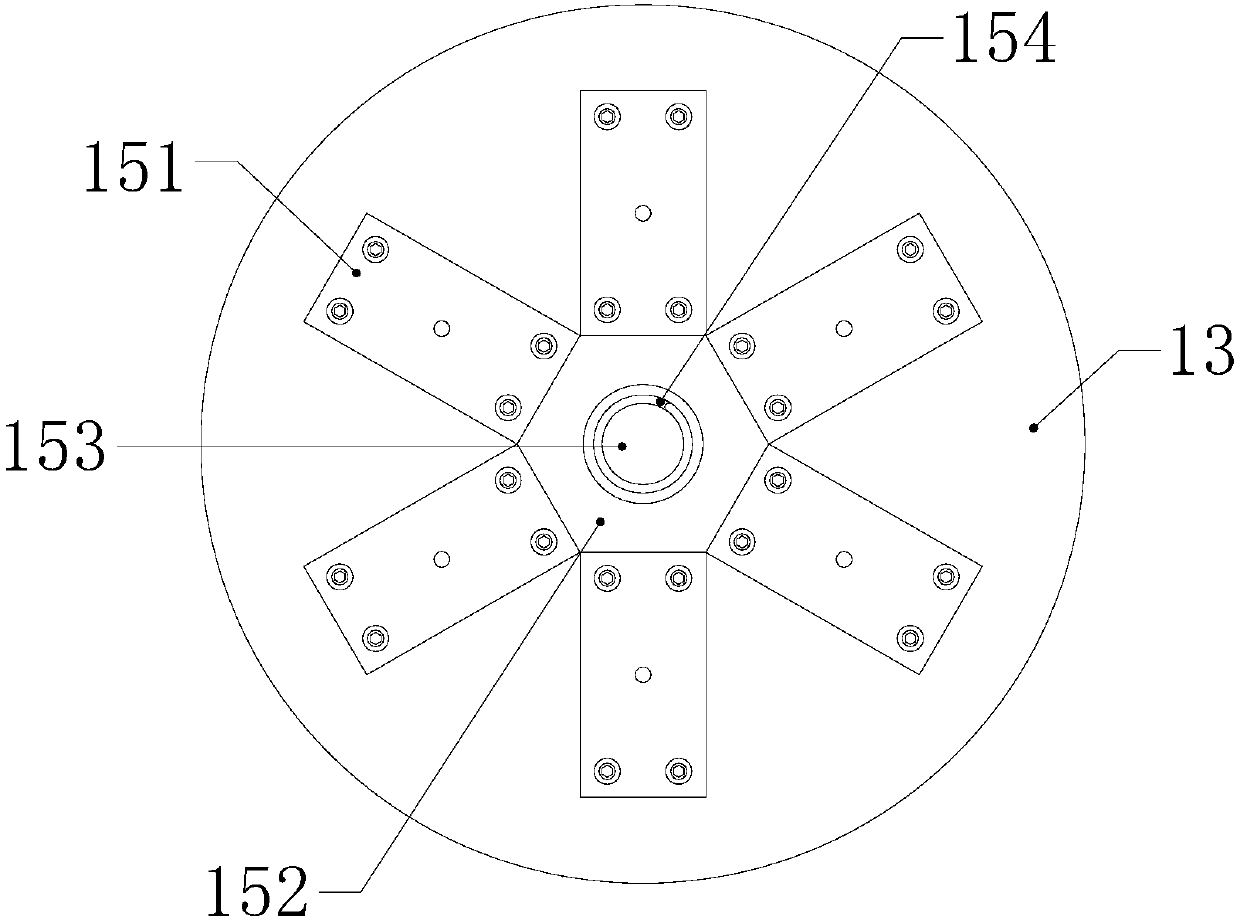

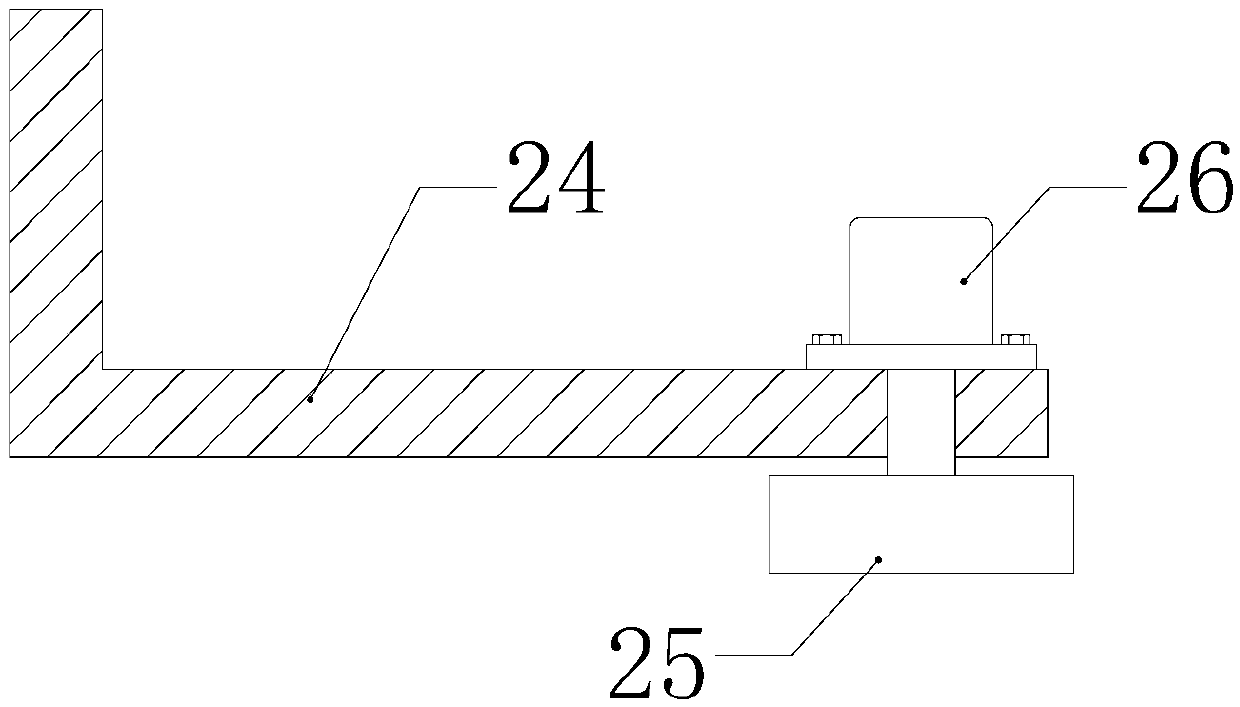

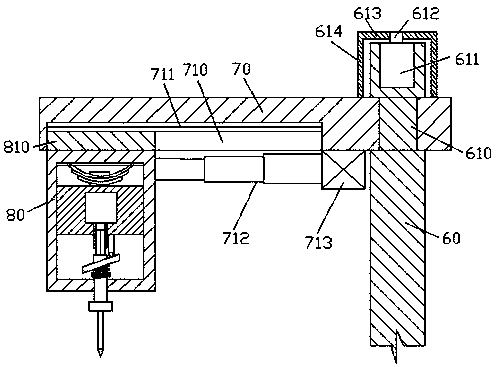

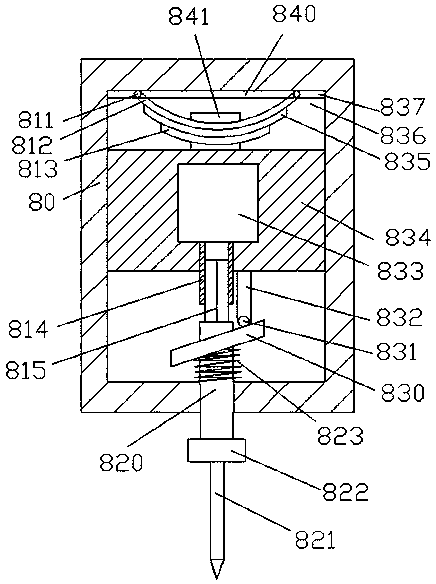

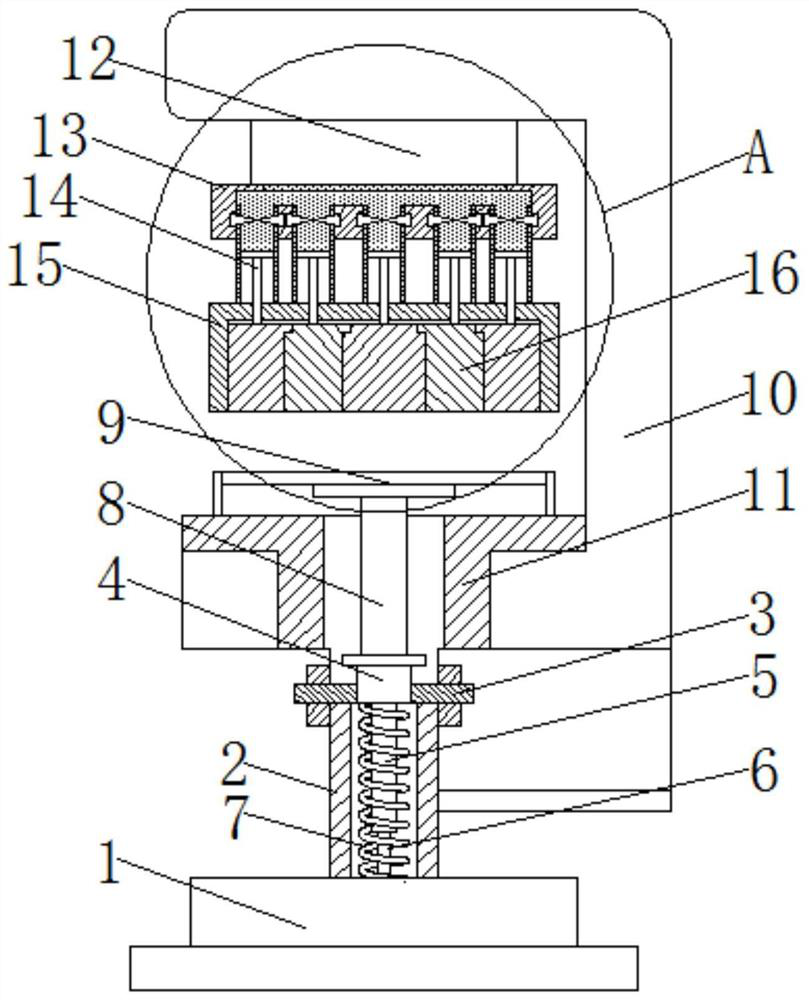

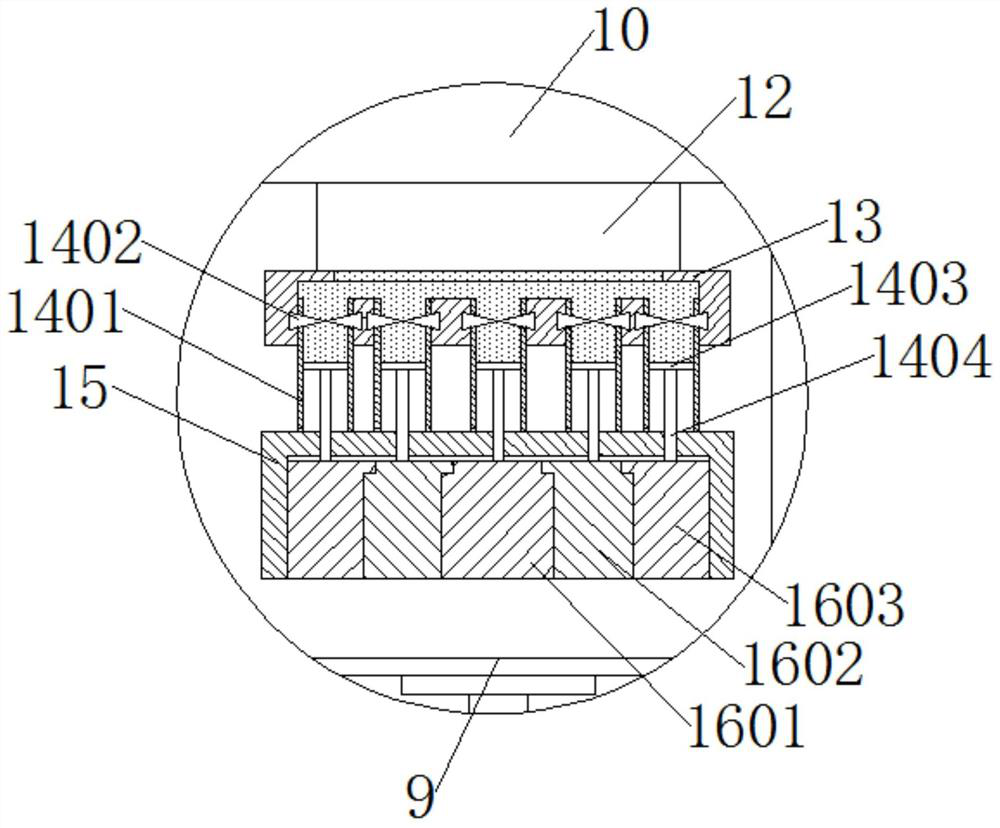

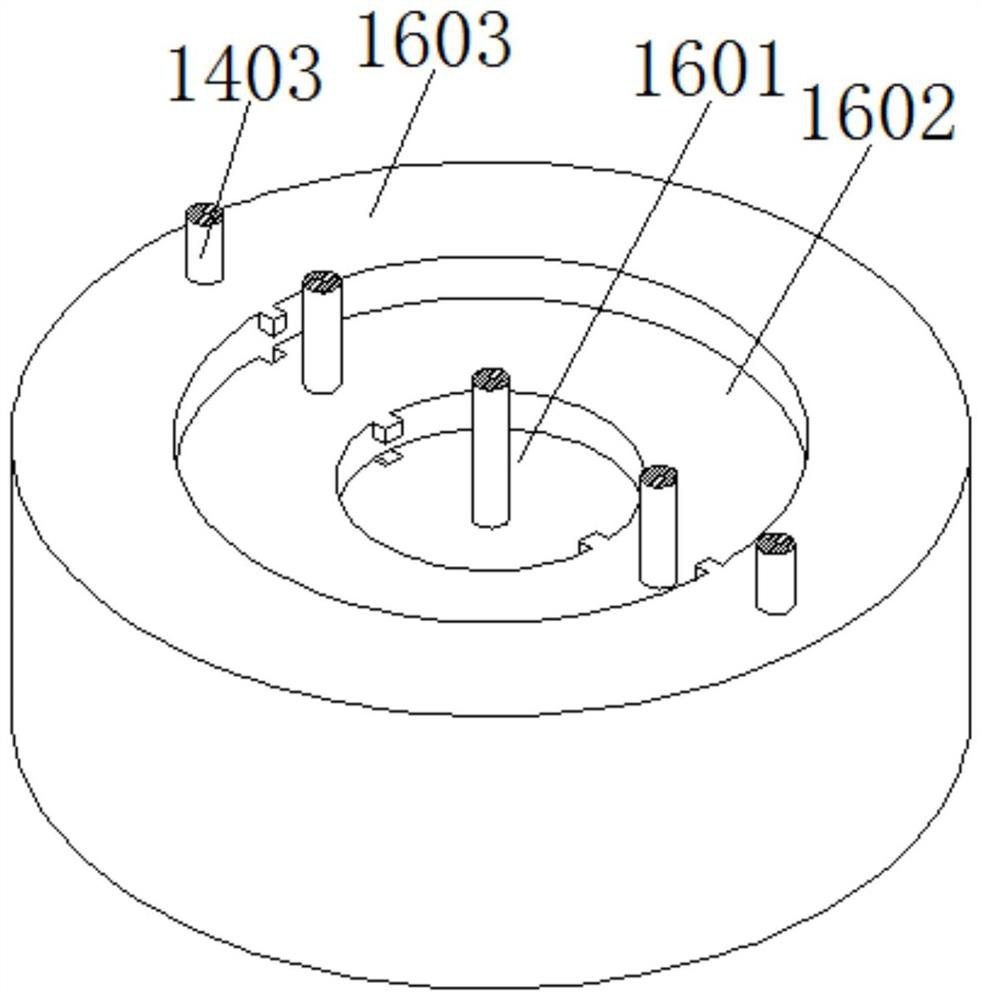

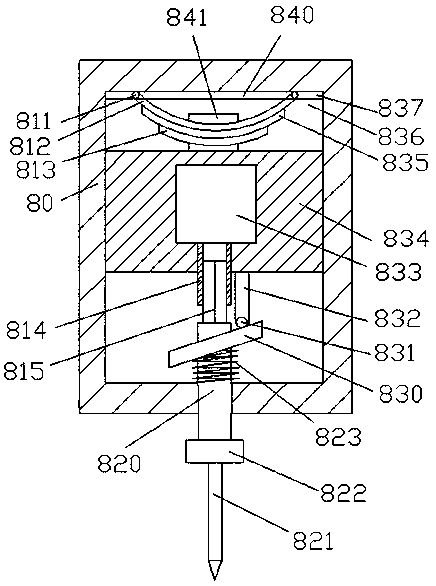

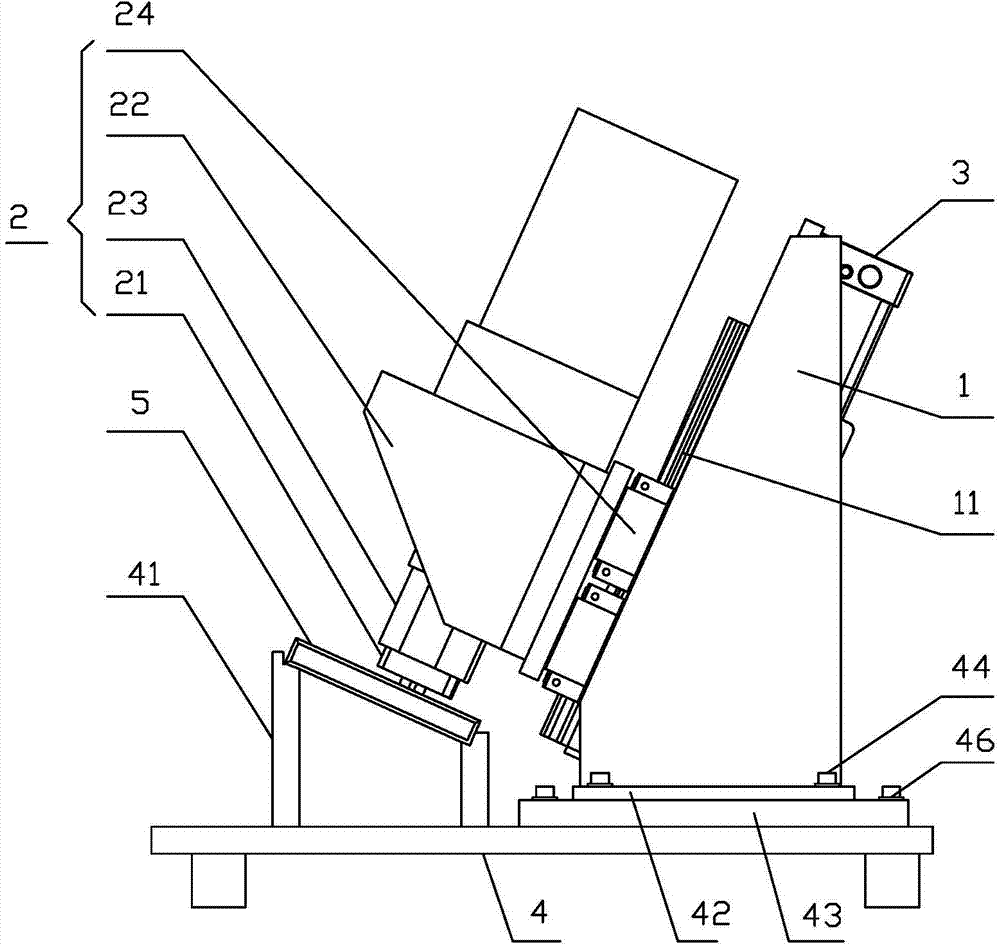

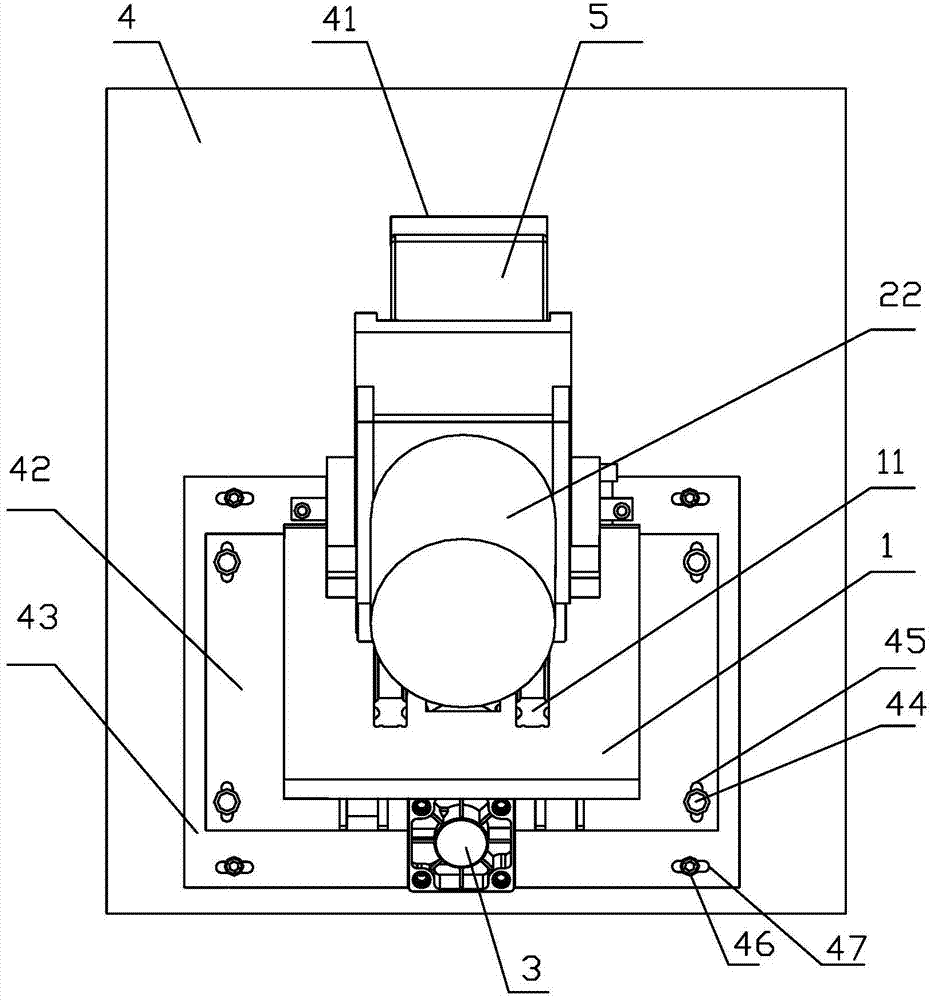

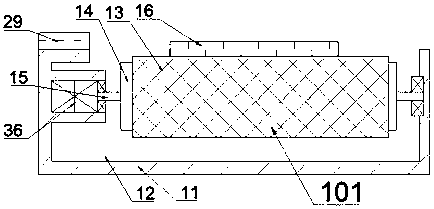

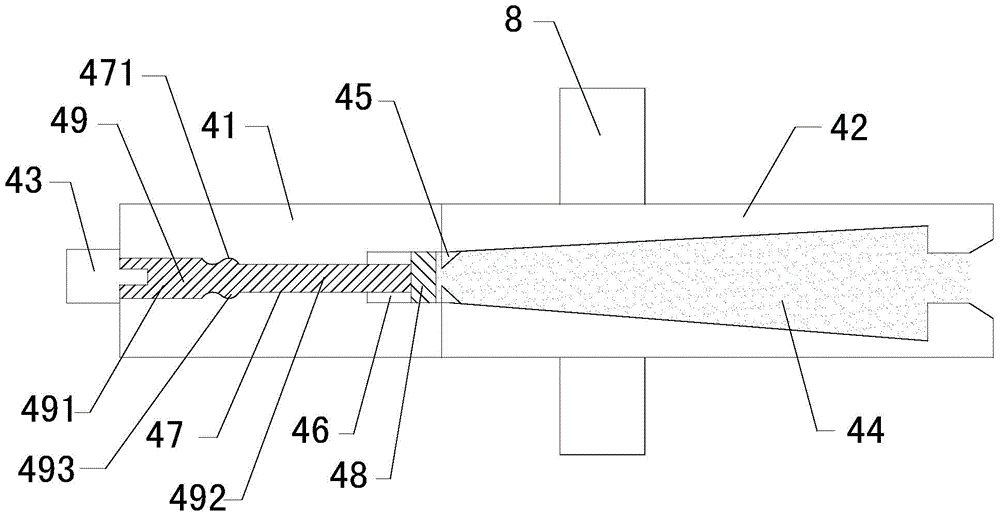

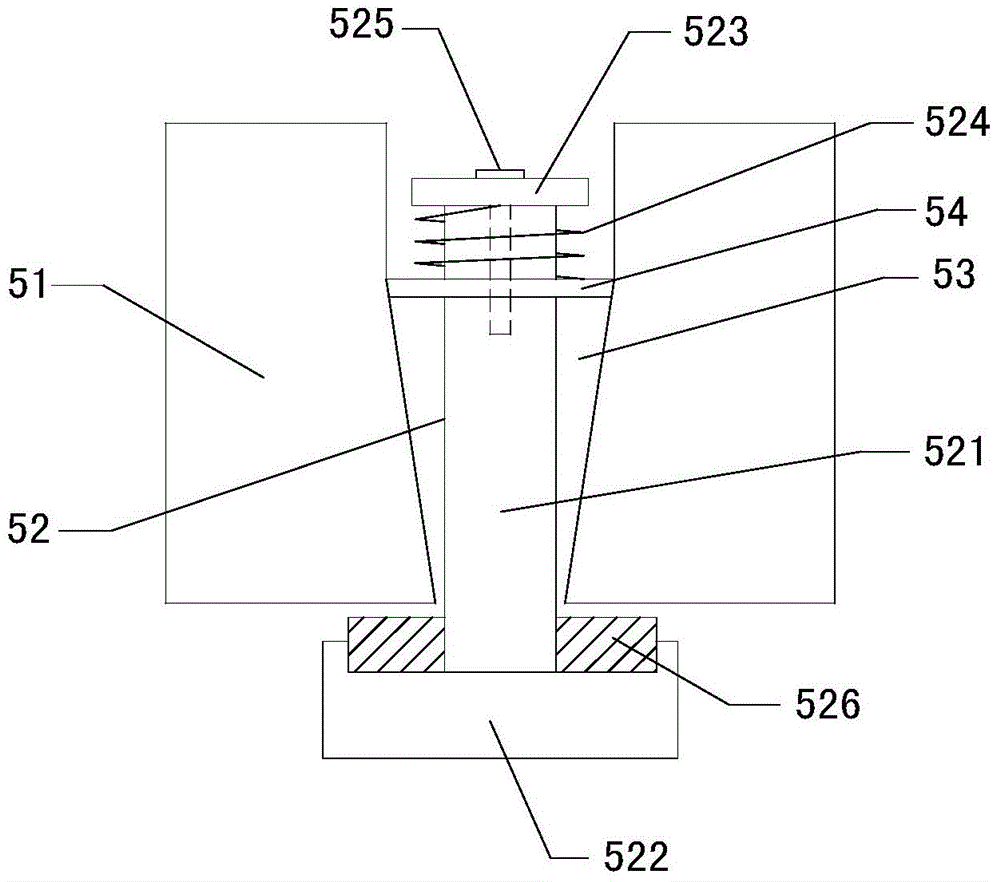

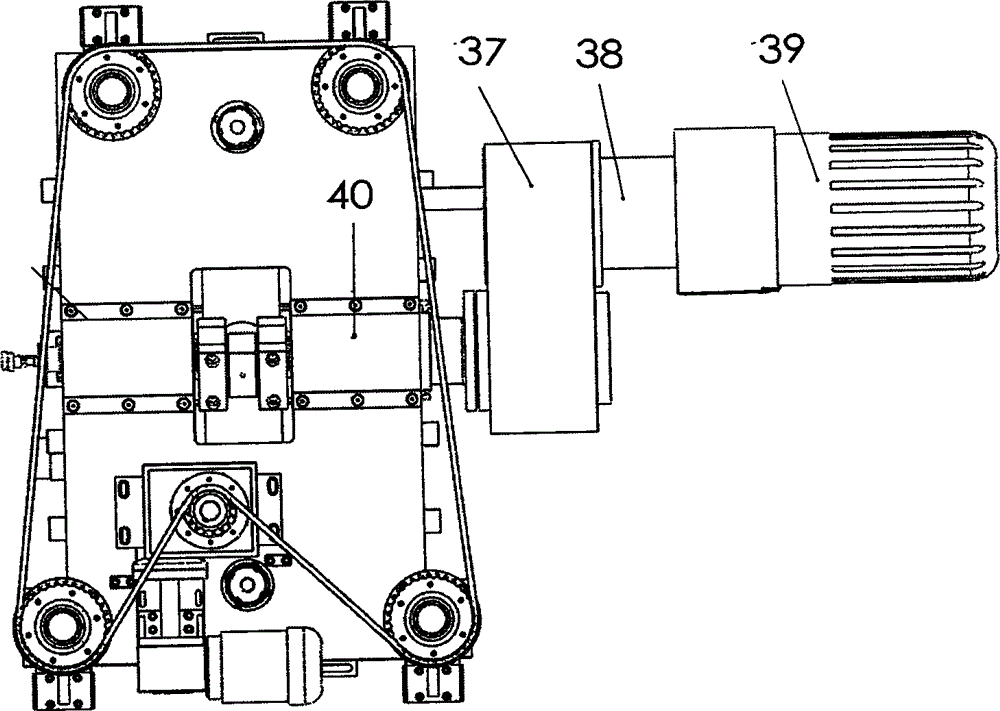

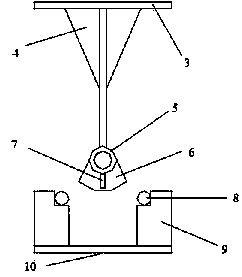

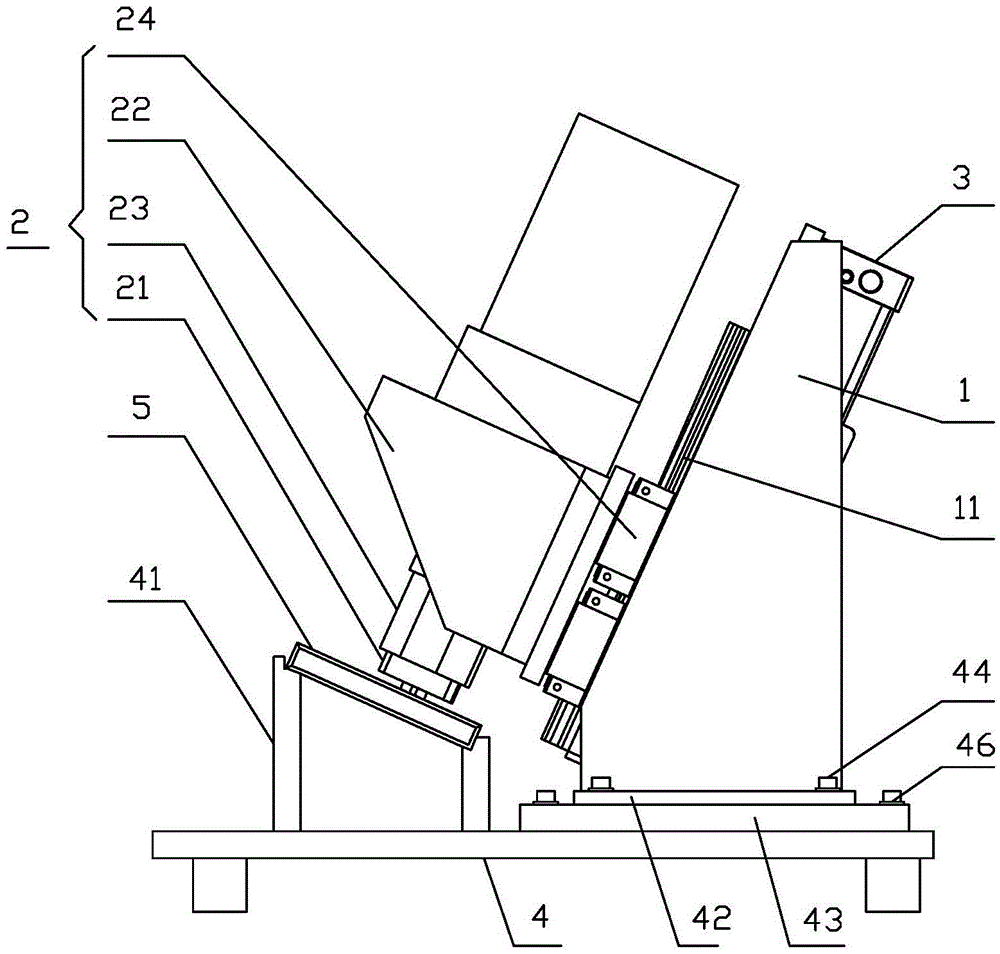

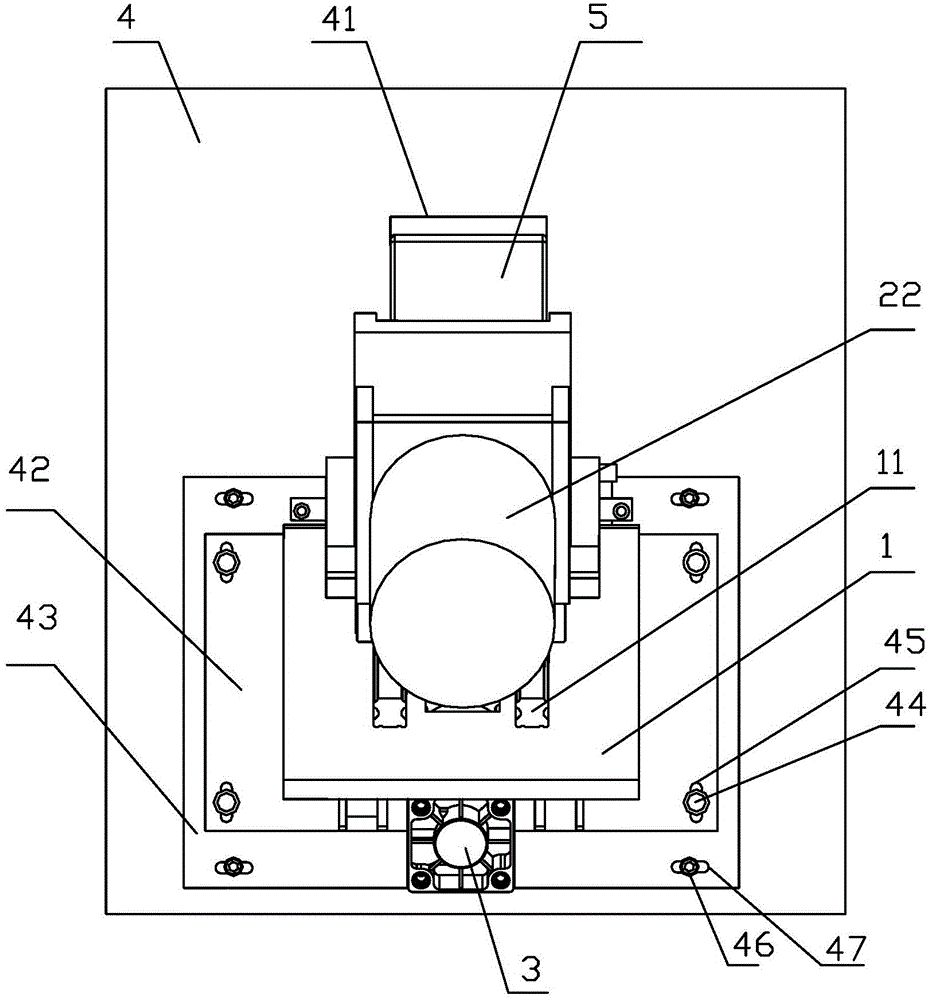

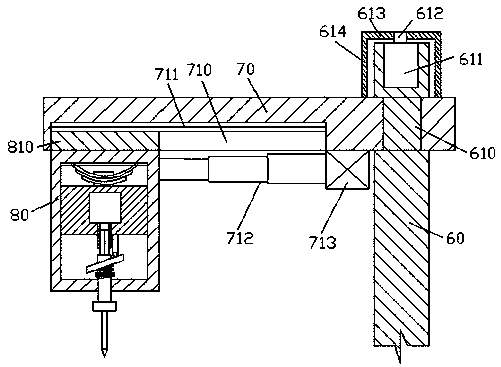

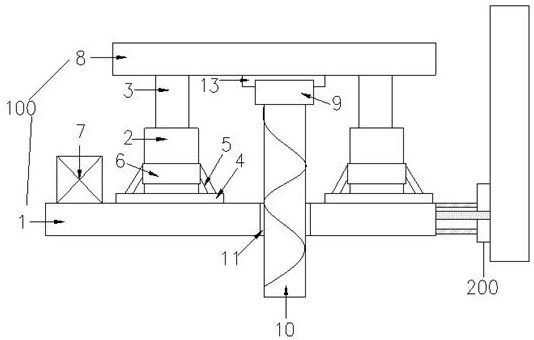

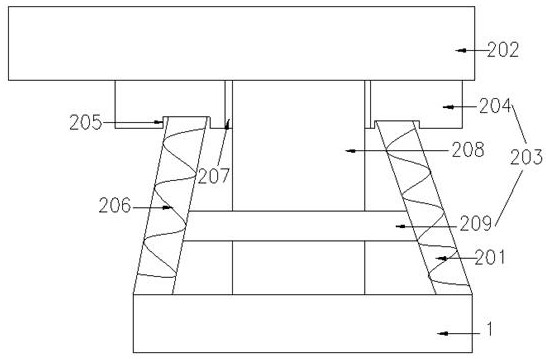

Biomass solidified fuel forming machine

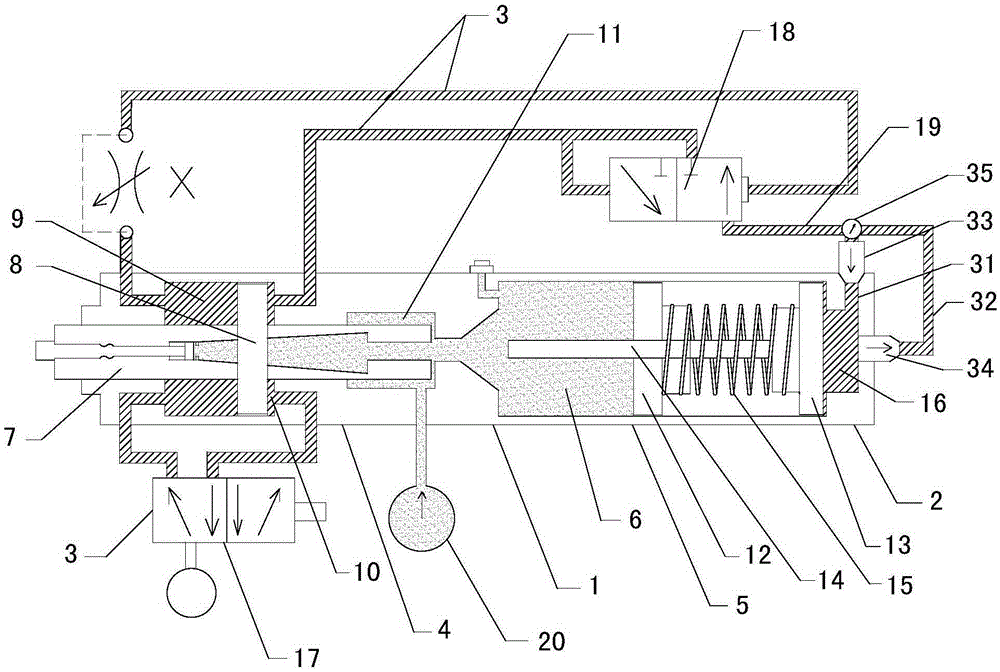

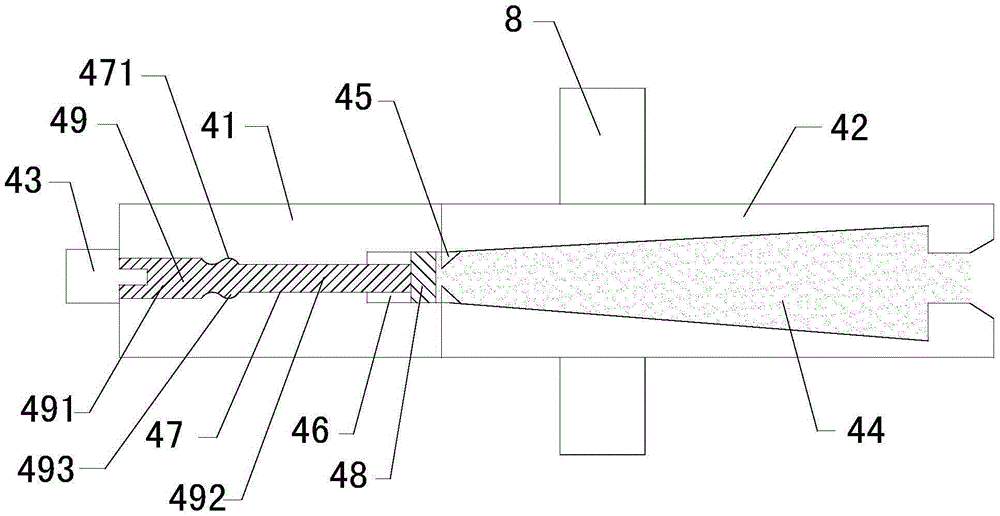

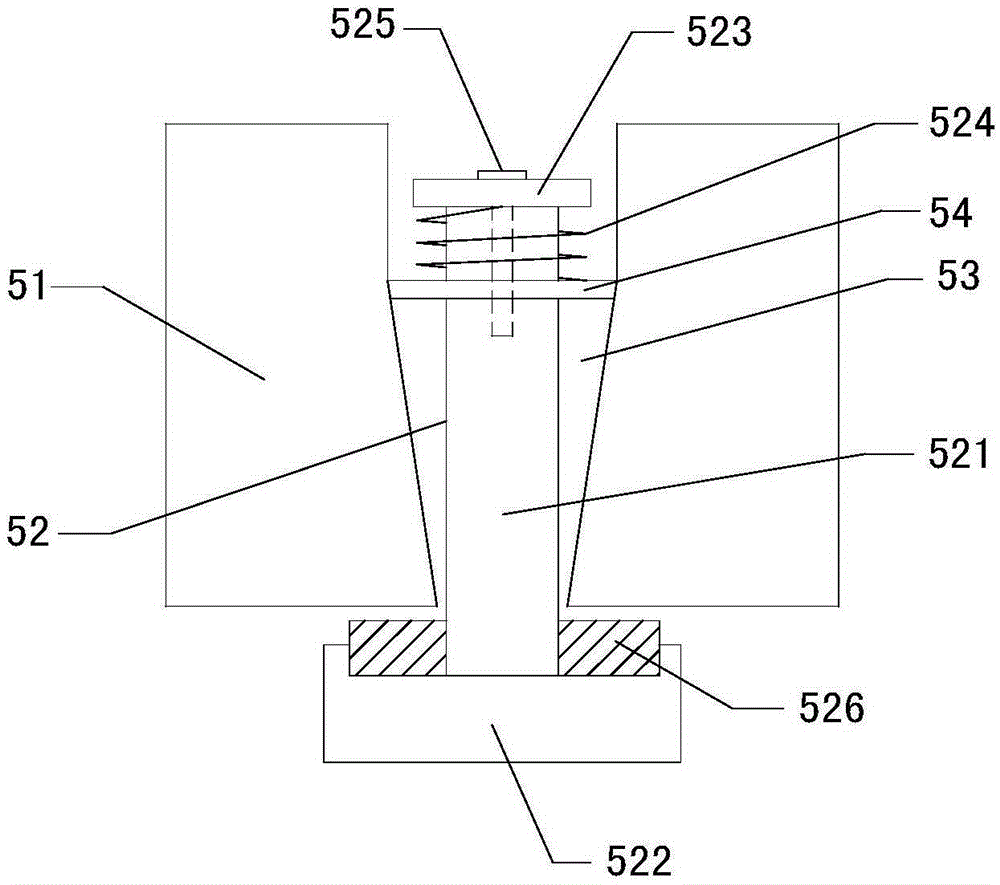

InactiveCN103496189AIncrease punching forceIncrease the number ofShaping pressEngineeringMechanical engineering

A biomass solidified fuel forming machine is mainly composed of a base, a machine case and a crankshaft piston connecting rod stamping mechanism. The crankshaft piston connecting rod stamping mechanism is composed of a stamping motor, a crankshaft connecting rod mechanism, a stamping piston rod and a plurality of stamping rods, the machine base is provided with a stamping bin, a feeding bin is arranged above the stamping bin, a discharge mold is provided with a plurality of discharge holes corresponding to the stamping rods on the stamping piston rod, and a feeding auger is vertically arranged in the feeding bin. The auger is vertically arranged in the feeding bin, vertical feeding of biomass raw materials falling in a following mode is achieved, the raw material feeding of large materials and flocculent materials is facilitated, the problem of raw material blocking is solved, meanwhile, the stamping rods connected with the front portion of the piston rod in the crankshaft piston connecting rod stamping mechanism directly correspond to the discharge holes in the discharge mold, the ineffective contact area of the stamping rods and the discharge mold is eliminated, the stamping force of each stamping rod is improved, and the biomass solidified fuel forming machine has the advantages of being long in maintenance period, high in production efficiency and low in energy consumption.

Owner:德州大河生物燃料机械有限公司

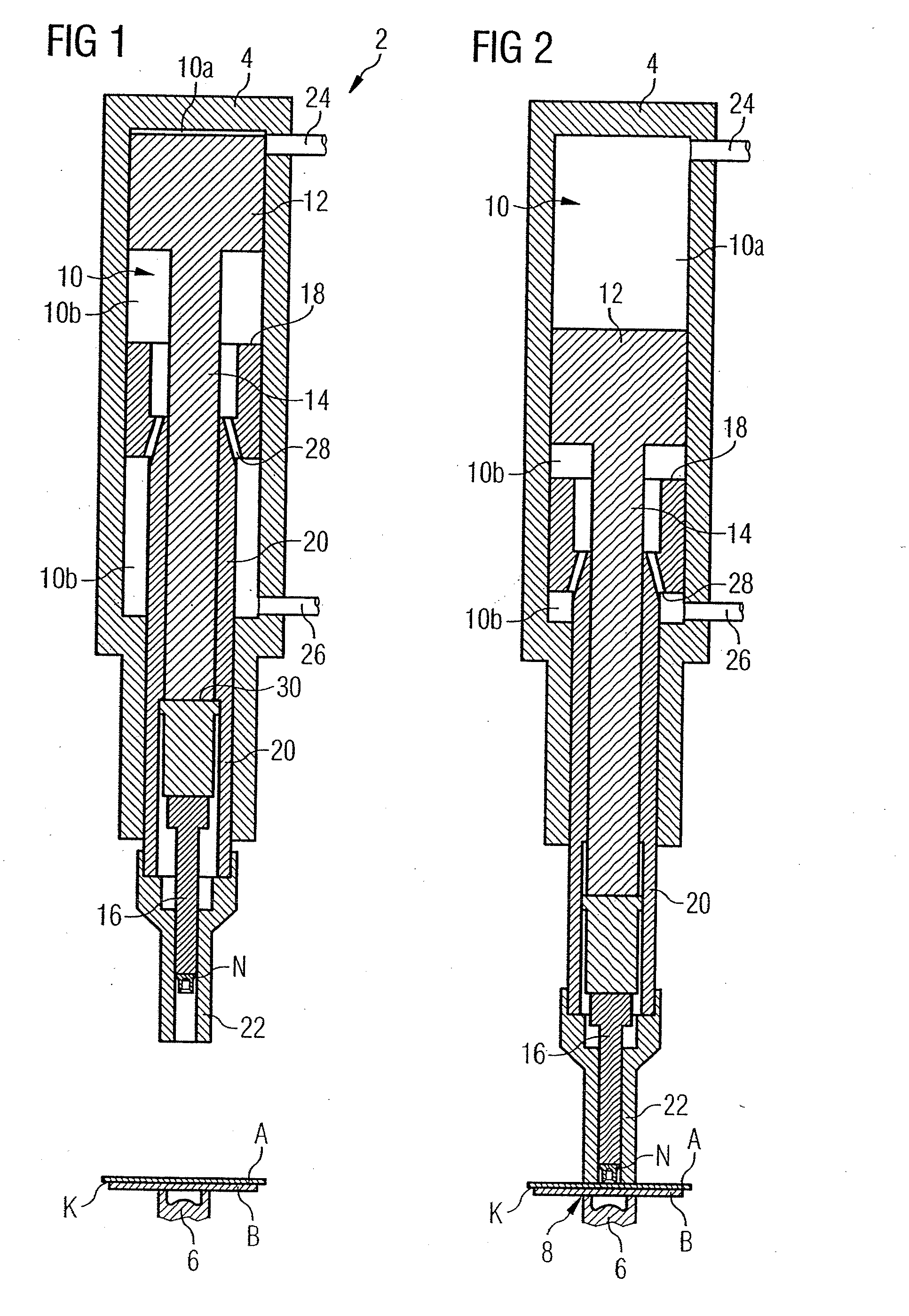

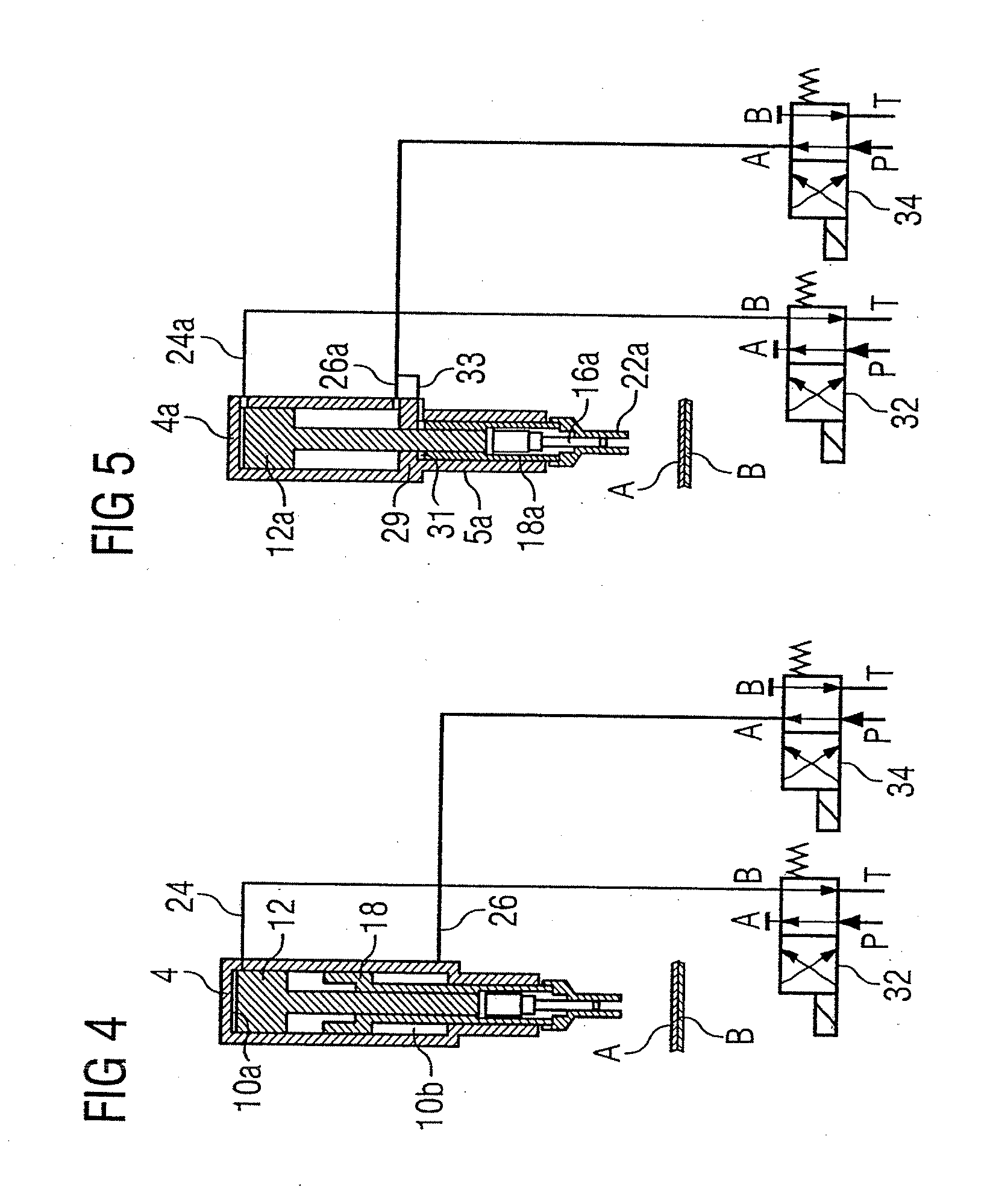

Joining Method and a Device for Operating a Fastening Tool

InactiveUS20070124911A1Quality improvementSufficient final strength of jointMetal working apparatusConnectionsEngineeringRivet

In a method for joining at least two plate-shaped workpieces by a fastening tool and a device for operating the fastening tool, the fastening tool comprises a punch for exerting a punch force to perform a joining operation and a clamp for exerting a clamping force upon the workpieces at the joining area. During the joining operation the punch exerts a high punch force to perform the joining operation and the clamp exerts substantially no clamping force to allow for free material deformation in the joining area. After the joining operation both the punch and the clamp exert high forces at the same time to reduce any material deformations of the workpieces and to provide for compression of the workpieces in the joining area. Preferably the invention is used in a riveting tool for setting self-piercing rivets; as an alternative it may be used in a clinching tool.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Press-forming tool with tolerance compensation

ActiveCN105382098AReduce manufacturing costLow costShaping toolsPressesEngineeringMechanical engineering

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Hardware stamping component capable of discharging rapidly

ActiveCN107838261AImprove stamping qualityFast punching speedShaping toolsMetal-working feeding devicesHydraulic cylinderControl system

The invention discloses a hardware stamping component capable of discharging rapidly. The hardware stamping component comprises a stamping device and a discharging device, and the discharging device is arranged beside the stamping device; the stamping device consists of a base, a rear box body, a rotary worktable, a stepping motor, a lower mold, an upper mold, a hydraulic cylinder and a telescopicair cylinder; the discharging device consists of a base body, a supporting vertical plate, a swing air cylinder, a connecting rod, an electromagnet, a low-speed motor, a discharging pipeline, a material receiving trolley and a power supply; and the stamping component further comprises a control system. According to the stamping component, a form of combining the hydraulic cylinder with the telescopic cylinder is adopted, forming can be achieved by one-time stamping, so that the stamping speed is improved; and the discharging device adopts a mode that the electromagnet swings along with the swinging air cylinder, the electromagnet is electrified and sucks a stamped hardware from the lower mold, the control system controls the electromagnet to be powered off so that the hardware on the electromagnet can automatically falls into the discharging pipeline, then slides into a material receiving box, and therefore, automatic discharging is realized, and the discharging strength is greatly reduced.

Owner:HAIYAN HONGQIANG HARDWARE MFG CO LTD

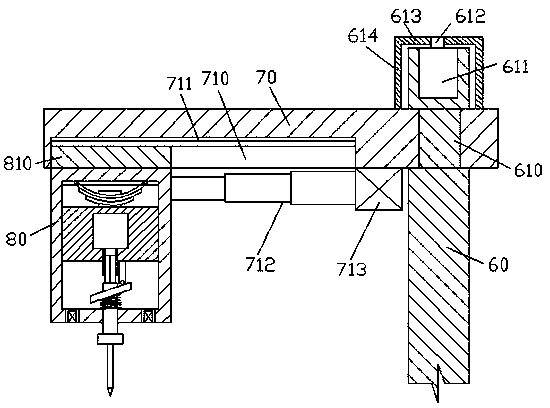

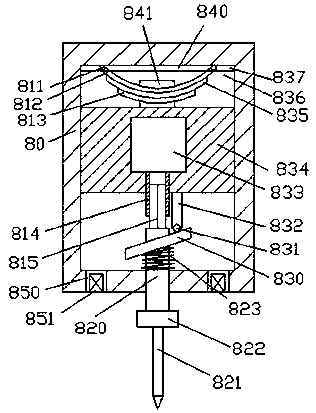

Arc drilling device

ActiveCN108031888ASimple structureEasy to operateBoring/drilling componentsBoring/drilling machinesEngineeringDrilling force

The invention discloses an arc drilling device, comprising a lifting support post, and a support frame and a drilling unit movably mounted on the lifting support post; a first rotary motor is fixedlymounted in the top end of the lifting support post; an output shaft of the first rotary motor is extended out of the end face of the lifting support post; fixing cross rods are fixedly mounted on theleft and right end faces of the output shaft; fixing vertical rods are symmetrically mounted on the left and right of the fixing cross rods; the fixing vertical rods are fixedly connected with the lower end faces of the fixing cross rods and the upper end face of the support frame respectively; a dovetail groove is arranged in the lower end face of the support frame on the left of the lifting support post, and slide rails extended to left and right are fitted to the inner top wall of the dovetail groove. The arc drilling device can drill holes, in arc distribution and having difference radians, in a workpiece, radian adjusting is convenient, drilling force is great, and drilling speed is high.

Owner:ANHUI SANZHI BRAKE CO LTD

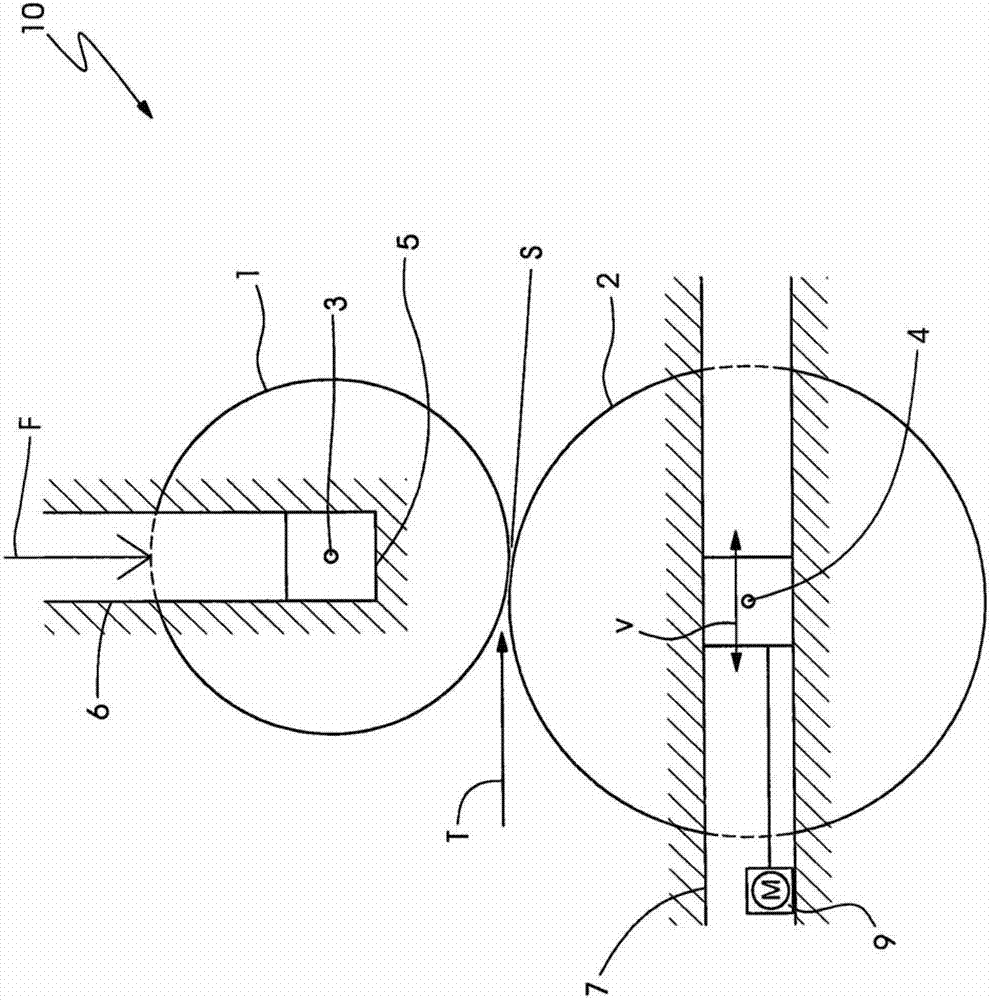

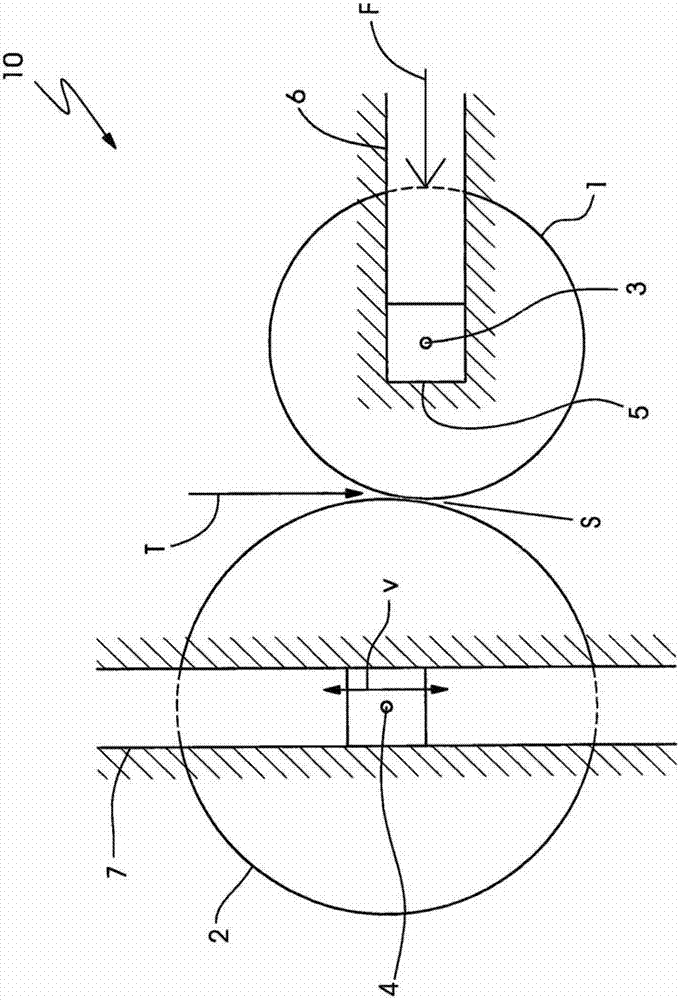

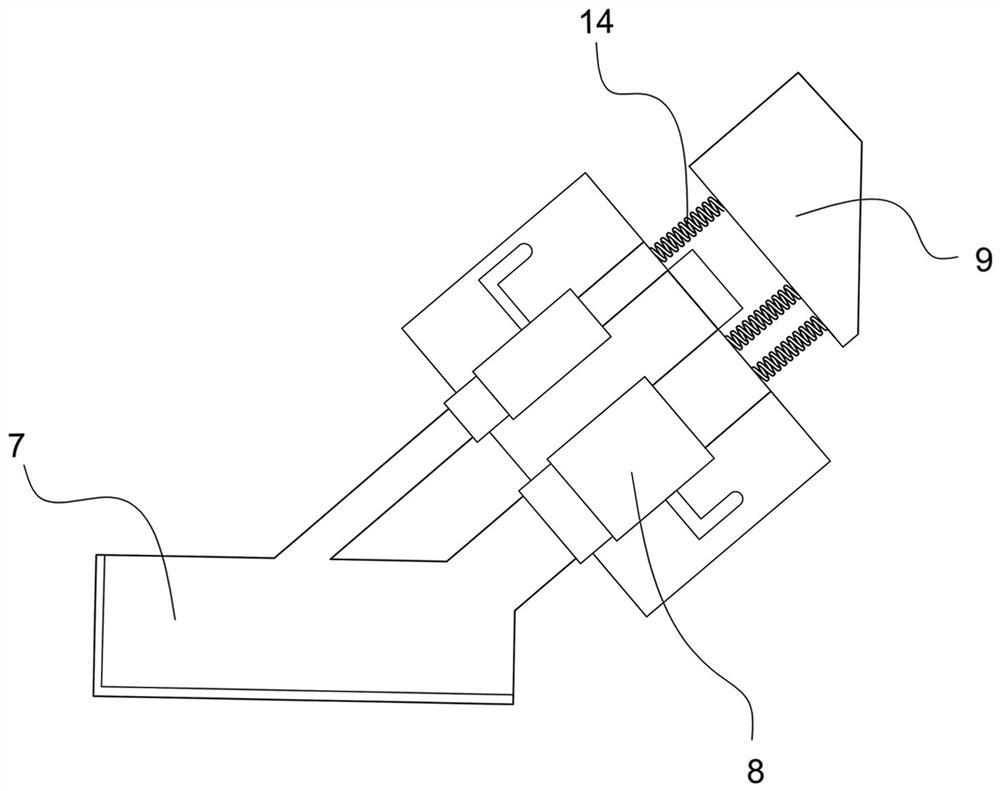

Device for stamping with adjustable distance between the rolls

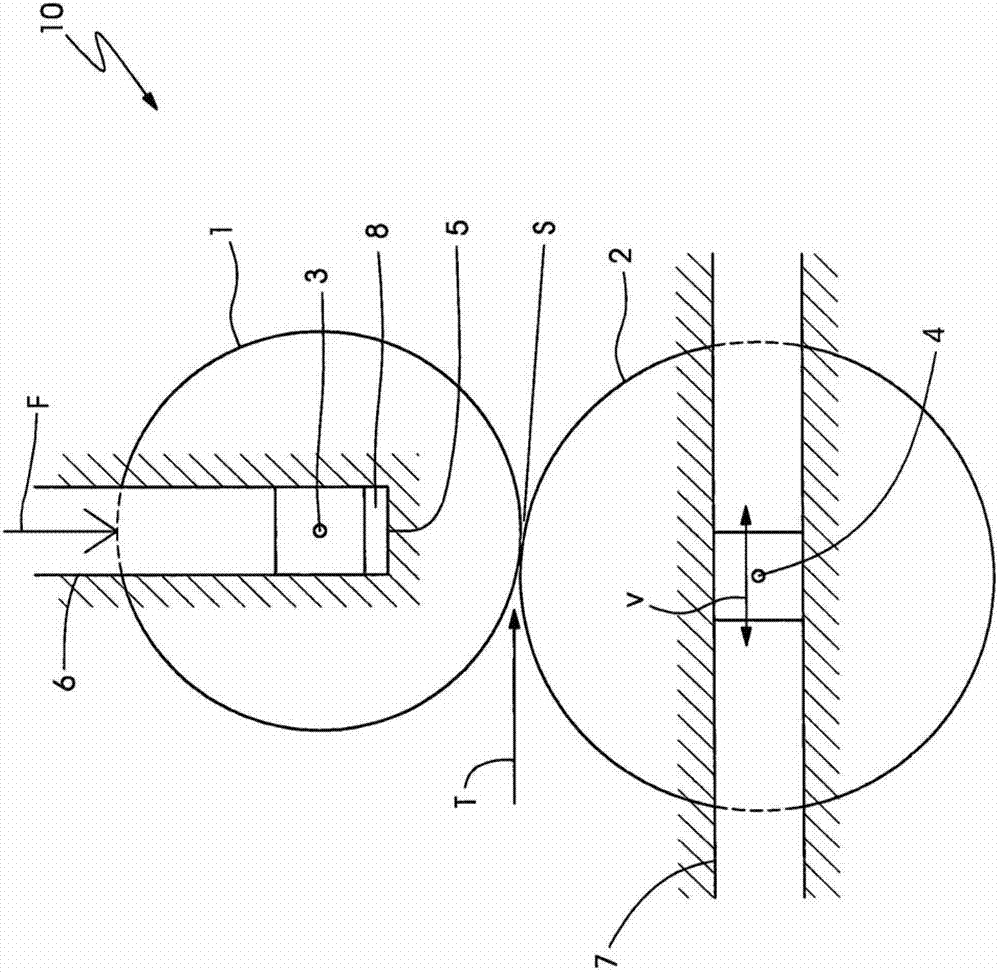

InactiveCN102896888ASimple structureIncrease punching forcePaper/cardboard articlesMetal working apparatusRotational axisPunching

The punching apparatus (10) has a rotatable punching cylinder (1) about a rotational axis (3) and a rotatable cylindrical object (2) parallel to another rotational axis (4) of the punching cylinder, where a distance (S) between the punching cylinder and the cylindrical object is adjustable. The cylindrical object is slidably mounted in a guide (7). The clamping force (F) and the guide are aligned perpendicular to each other. In addition, the invention further relates to a narrow-width printer equipped with the device for stamping.

Owner:GALLUS DRUCKMASCHINEN GMBH

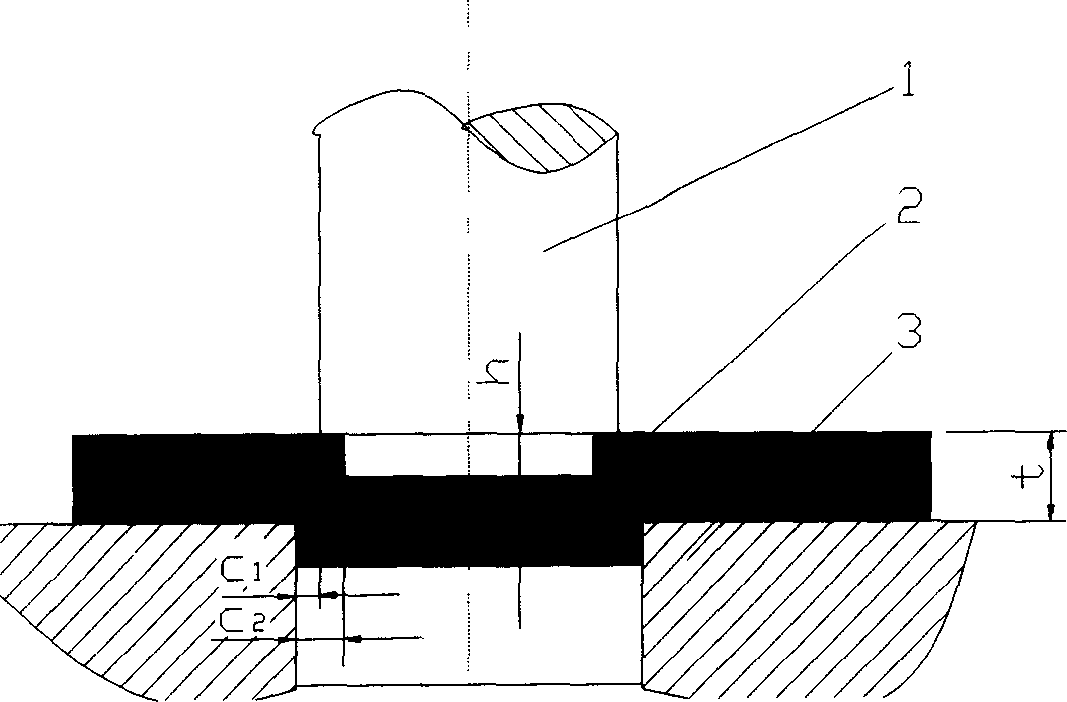

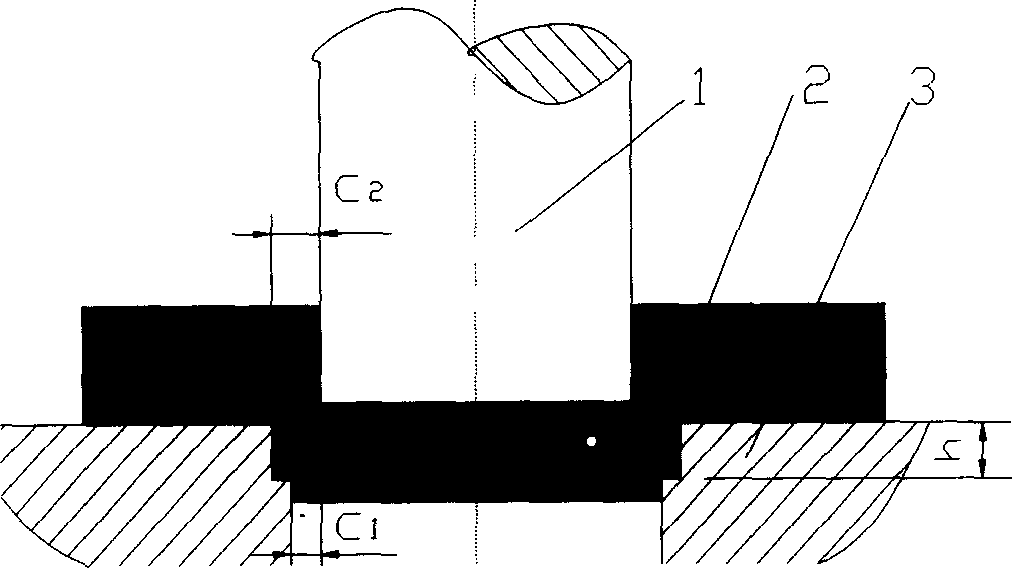

Dual positive clearance blanking method

InactiveCN1775406AManufacturing difficulty is not increasedIncrease manufacturing difficultyEngineeringMachine press

The present invention relates to a double forward clearance blanking method. The male die or female die of said die equipment can be made into continuous step form, and its is characterized by that the height h of the step is 1 / 3-1 / 2 of the thickness t of material to be blanked, between male die and female die the double forward clearances are formed, clearance C1=(0.125-0.20)t, and the clearance C2=(0.02-1.10)t. Under the condition of general blanking die, general blanking clearance and general pressing machine said invention can raise shearing surface height of blanking piece section in once blanking stroke.

Owner:NANCHANG UNIV

Hydraulic punching machine for flange plate machining

InactiveCN111659798AEasy to punch and shapeImprove concentrationShaping toolsEjection devicesPunchingPipe fitting

The invention relates to the technical field of mechanical equipment, and discloses a hydraulic punching machine for flange plate machining. The hydraulic punching machine comprises a base, the upperend of the base is fixedly connected with a supporting column, the upper end of the supporting column is fixedly connected with a fixing plate, the middle of the fixing plate is movably sleeved with asliding rod, the bottom of the sliding rod is fixedly connected with a sleeve, and a vertical rod fixedly connected with the base is movably sleeved with the sleeve. According to the hydraulic punching machine, through the arrangement of oil distribution pipe fittings and a stamping device, stamping heads of corresponding sizes can be selected for stamping according to switches of opened valves,meanwhile, when an annular stamping part needs to be stamped, only the valves on the two corresponding sides can be opened, and the stamping heads on the two sides can stamp the annular stamping part,so that stamping force can be conveniently increased in a centralized mode, and the stamping effect is improved; and by controlling the opening time difference of all the corresponding valves, all the stamping heads are in a step shape so that people can conveniently stamp and shape stepped parts.

Owner:喻贞烈

Novel arc drilling equipment

ActiveCN108031895ASimple structureEasy to operateFeeding apparatusBoring/drilling componentsEngineeringDrilling machines

The invention discloses novel arc drilling equipment which comprises a lifting support column and a support frame and a drilling machine which are movably mounted on the lifting support column. A first rotating motor is fixedly mounted in the top end face of the support column, the output shaft of the first rotating shaft extends out of the end face of the lifting support column, a fixing transverse rod is fixedly mounted on left and right end faces of the output shaft, fixing vertical rods are symmetrically mounted on the fixing transverse rod on the left and right sides and are respectivelyand fixedly connected with the lower end face of the fixing transverse rod and the upper end face of the support frame, a dovetail groove is arranged in the lower end face of the support body arrangedon the left side of the lifting support column, and a slide rail extending leftwards and rightwards is mounted in the top wall of the dovetail groove. By the arrangement, a workpiece can be shaped with curved distribution and different radian holes, radians are convenient to adjust, and high drilling strength and rapid drilling speed are achieved.

Owner:绍兴伊司特家具有限公司

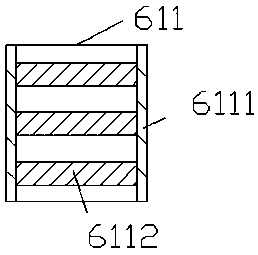

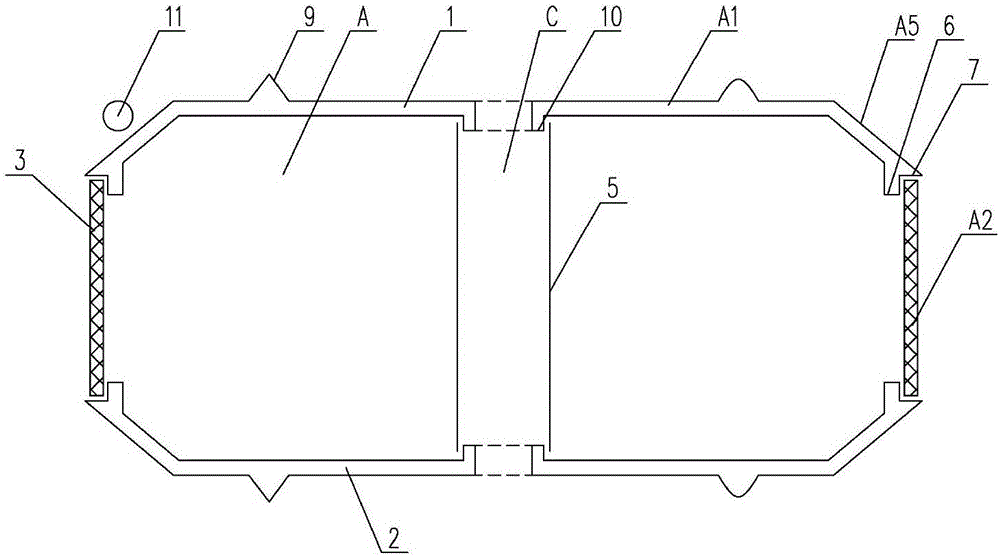

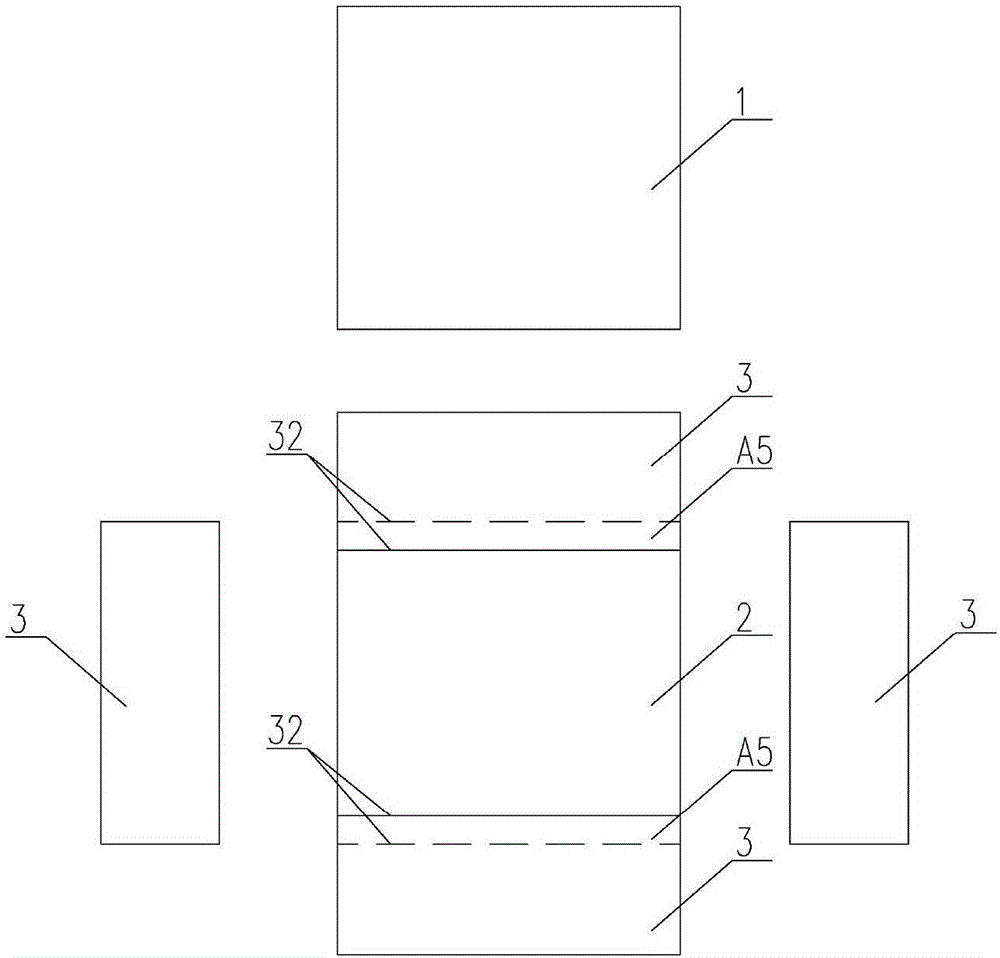

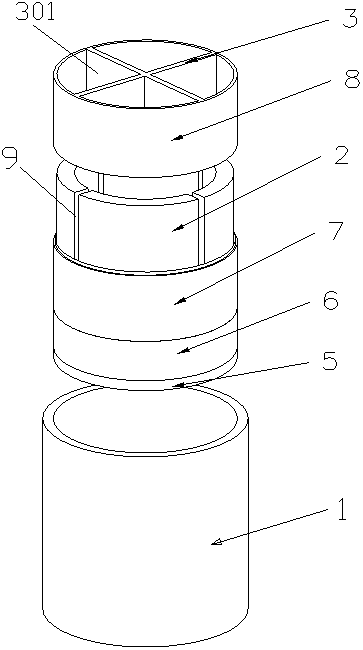

Cast-in-situ hollow floor with pores formed by combined reticular box-shaped component

InactiveCN104314214AHigh degree of mechanizationIncrease productivityFloorsReinforced concreteEngineering

The invention provides a cast-in-situ hollow floor with pores formed by a combined reticular box-shaped component. The cast-in-situ hollow floor comprises a reinforced concrete girder or a profile steel concrete girder, a reinforced concrete ribbed beam, an upper flange plate, a lower flange plate and the combined reticular box-shaped component, wherein the combined reticular box-shaped component comprises a box roof, a box body and a box bottom; the box body and the box bottom are made of reticular bodies; reinforcing ribs of the reticular bodies are vertically placed; each reticular body comprises a reticular plate, the reinforcing rib and a connecting piece, which constitute an integral structure; the lower flange plate is directly compounded with the reticular bodies at the box bottom of the combined reticular box-shaped component. The cast-in-situ hollow floor with the pores formed by the combined reticular box-shaped component adopts the unsealed combined reticular box-shaped component to substitute the existing fully-sealed hollow fillers and solid fillers as the cast-in-situ hollow floor pore-forming technology. The cast-in-situ hollow floor with the pores formed by the combined reticular box-shaped component is beneficial to realization of energy conservation integration of a building and the multifunctional use of hollow floor.

Owner:HUNAN BDF ENERGY SAVING TECH

Automotive upholstery production device

ActiveCN103753641AIncrease flexibilityIncrease punching frequencyMetal working apparatusPunchingEngineering

The invention discloses an automotive upholstery production device. The device is characterized by comprising a rack and a punching unit which is arranged on the rack movably. According to the device, a punching guide rail is added on the rack, so that offset of a device head on the rack during moving is prevented, the device head can fall in the preset hole position on a to-be-punched upholstery support accurately, the punching stability and the punching accuracy are improved, the punching quality is improved, and the punching efficiency is enhanced.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

Double-hole shielding cover progressive die

The invention relates to the technical field of dies, in particular to a double-hole shielding cover progressive die. The double-hole shielding cover progressive die comprises an upper die holder, an upper die, a stripper plate, a lower die, a lower die holder, and a punching pilot hole station, a half sectioning station, a stretching station and a shielding cover punching-off station which are assembled correspondingly, wherein the upper die, the stripper plate and the lower die are correspondingly assembled with the punching pilot hole station, the half sectioning station, the stretching station, a double-side punching station, a bilateral hole turnup station, a first turnup flattening station, a second turnup flattening station, a punching side notch station and the shielding cover punching-off station which are formed sequentially. During actual production, production can be performed only by placing a material belt on the lower die, all the procedures are finished in the die, andfull automation of the whole flow is realized, so labor cost is reduced, the defective rate of the shielding covers is low, production efficiency is high, and the double-hole shielding cover progressive die is suitable for production of the shielding cover with side holes on the two sides.

Owner:DONGGUAN DAZHONG ELECTRONICS

Electronic detonator control chip slitting equipment

The invention discloses electronic detonator control chip slitting equipment. The electronic detonator control chip slitting equipment comprises a conveying box; the conveying box is internally provided with a conveying cavity with an upward opening; the conveying cavity is internally provided with a conveying device for conveying control chips; the upper end surface of the rear side of the conveying cavity is fixedly connected with two left and right symmetrical fixing plates; the front side end faces of the fixing plates on the left side and the right side are each provided with one power device; the front side end faces of the fixing plates are provided with quick-release cutters which are positioned on the lower sides of the power devices and used for cutting the chips; trigger devicespositioned on the right sides of the power devices are arranged on the front side end faces of the fixing plates; and the trigger devices are used for triggering the power devices to move downwards.According to the electronic detonator control chip slitting equipment, the cutters can be quickly replaced by a quick-release cutter set, the quick-release cutter set can adapt to processing of different chips by adjusting the distance between the cutters in a sliding mode, so that the electronic detonator control chip slitting equipment is strong in processing applicability, high in production efficiency and low in equipment cost.

Owner:永泰山水生态农场

Improved arc-shaped drilling device

InactiveCN108856777ASimple structureEasy to operateFeeding apparatusLarge fixed membersPunchingEngineering

The invention discloses an improved arc-shaped drilling device. The device comprises a lifting supporting column body, a supporting frame body and a drilling machine body, wherein the supporting framebody and the drilling machine body are movably installed on the lifting supporting column body; a first rotating motor is fixedly installed in the end surface of the top of the supporting column body, an output shaft of the first rotating motor extends out of the end surface of the lifting supporting column body, and a fixed cross rod is fixedly installed on the end surfaces of the left side andthe right side of the output shaft; and fixed vertical rods are symmetrically arranged on the left side and the right side of the fixed cross rod, the fixed vertical rods are fixedly connected to thelower end surface of the fixed cross rod and the upper end surface of the support frame body, a dovetail groove is formed in the lower side end surface of the supporting frame body on the left side ofthe lifting supporting column body, and a sliding rail which extends leftwards and rightwards is arranged on the inner top wall of the dovetail groove. According to the improved arc-shaped drilling device, holes with different radian and distributed in an arc shape can be formed in the workpiece, the radian is convenient to adjust, the punching force is high, and the punching speed is high.

Owner:沈立峰

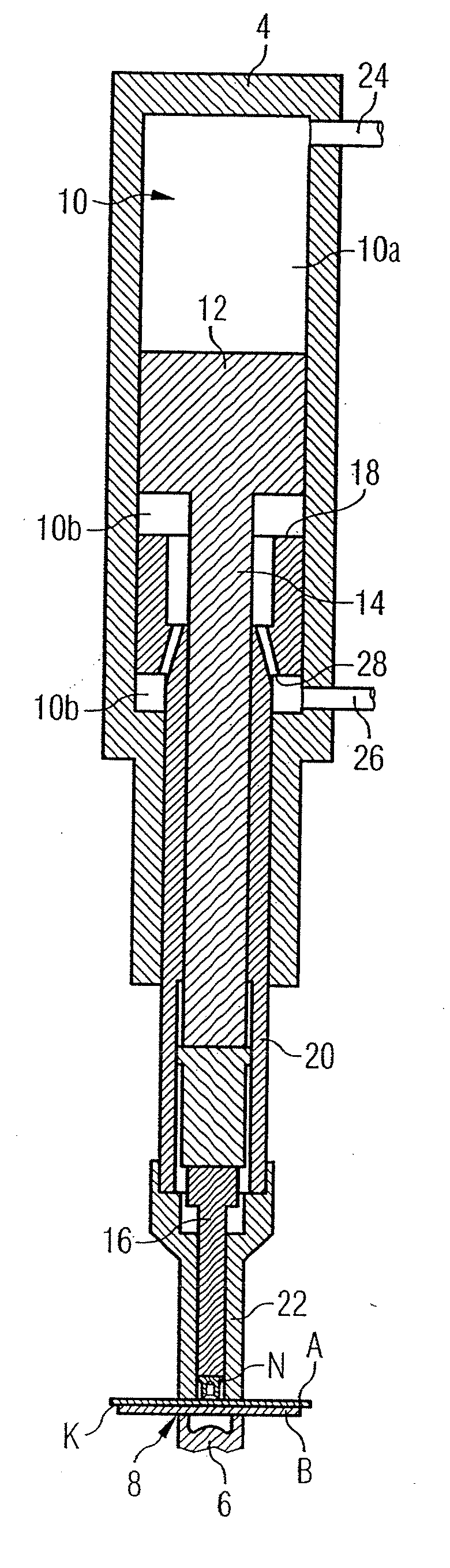

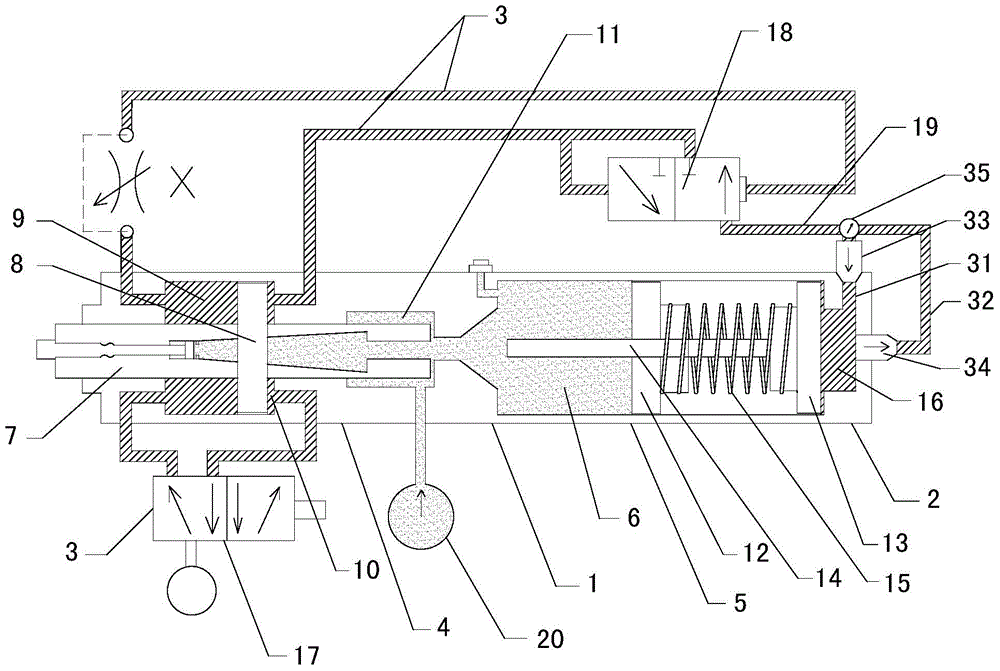

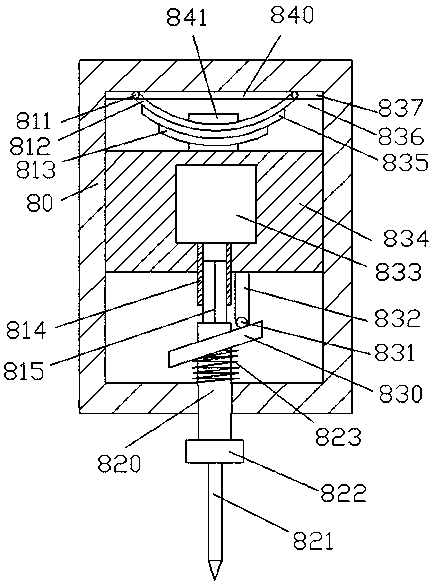

Novel pressurized oil-air cylinder

The invention relates to a novel pressurized oil-air cylinder which is capable of further improving the stamping force in the condition of the same equipment size through a two-section stroke mode. Work air channels comprise an air inlet channel and an air outlet channel, a high-pressure one-way air valve and a large-flow one-way air valve are arranged on the air inlet channel and the air outlet channel respectively, and a switching valve is arranged at the air inlet channel and air outlet channel connection position. A stamping rod comprises a front rod body, a rear rod body and a stamping head. A secondary stamping oil cavity is formed in the rear rod body, the inner diameter of the secondary stamping oil cavity is decreased from the rear end to the front end, and a piston retaining block is arranged at the front end of the secondary stamping oil cavity. A piston cavity is formed in the rear end of the front rod, a sliding rod cavity is formed in the middle section and the front section of the front rod, a secondary stamping piston is arranged in the piston cavity, an ejection rod is arranged in the sliding rod cavity, and a stamping head is connected with the front end of the ejection rod. The ejection rod comprises a front ejection rod body and a rear ejection rod body, and a clamping block is arranged on the rear ejection rod body. The sliding rod cavity comprises a front sliding rod cavity body and a rear sliding rod cavity body, and a clamping groove is formed in the inner wall of the rear sliding rod cavity body.

Owner:SUZHOU ICOOLMACH EQUIP MFG

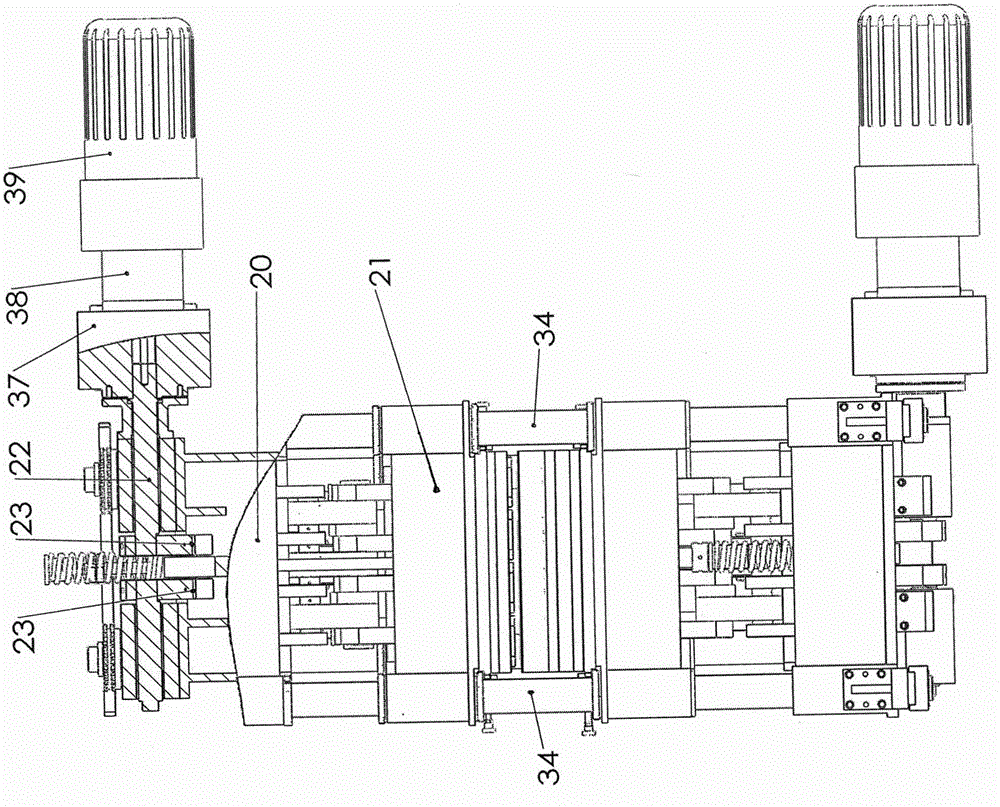

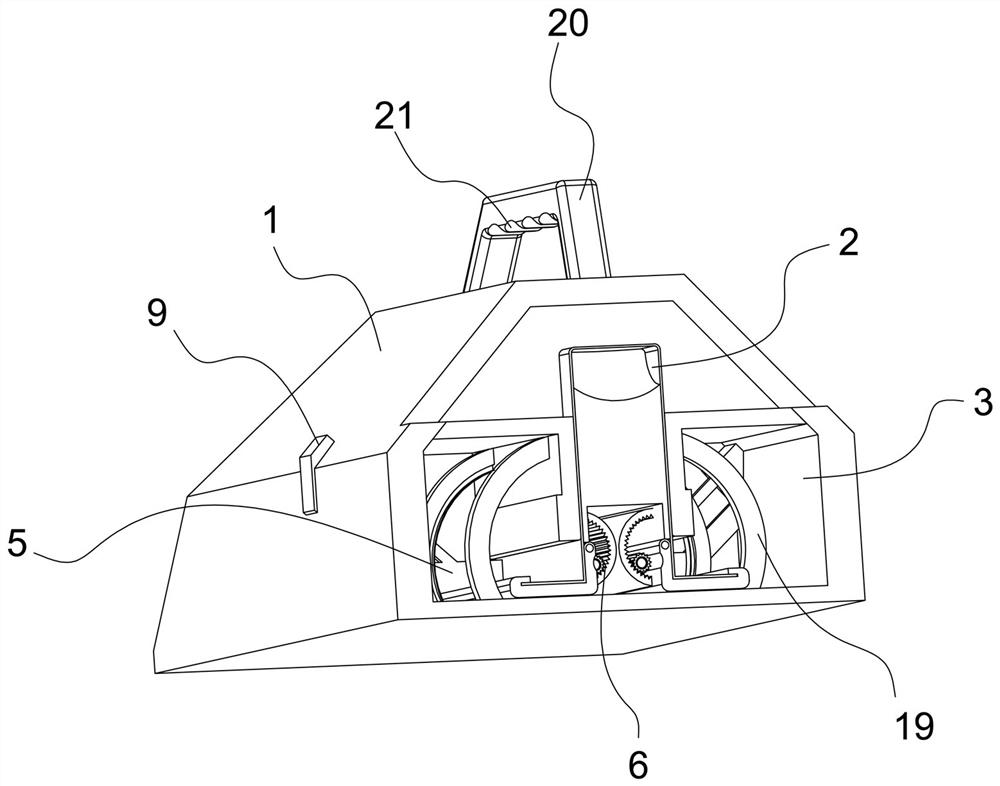

Anti-sliding punching transmission mechanism for sheet hot forming machine

The invention discloses an anti-sliding punching transmission mechanism for a sheet hot forming machine. The anti-sliding punching transmission mechanism comprises a punching motor, a punching speed reducer, a punching upper beam, a punching movable formwork and a column. The punching speed reducer is provided with an output shaft, and a bi-directional backstop is installed between the punching motor and the punching speed reducer. The output shaft is connected with a die-opening and die-assembly pull rod through a rotating swing arm, the die-opening and die-assembly pull rod is connected with a cross connecting rod, two ends of the cross connecting rod are connected with the punching movable formwork respectively through joint connecting rod modules, and the lower portion of the cross connecting rod is connected with the punching movable formwork through a guide rod. According to the anti-sliding punching transmission mechanism, the bi-directional backstop is installed to replace an original electromagnetic brake, the motor rotates in one direction, slippage of a movable forming seat and a forming upper die in the suspension process is avoided, and the anti-sliding punching transmission mechanism has safety; and a connecting mode of the cross connecting rod and the joint connecting rod modules increases punching force and improves hot forming and punching efficiency.

Owner:ZHEJIANG FUXINLONG MACHINERY

Keel cutting and bending equipment and using method thereof

PendingCN112571078AGuaranteed stabilityExtended service lifeMetal-working feeding devicesOther manufacturing equipments/toolsElectric machineryLap joint

The invention discloses keel cutting and bending equipment, and relates to the technical field of keel machining. The keel cutting and bending equipment comprises a containing body, an inserting channel for allowing an n-shaped keel to be inserted is formed in the containing body, and containing cavities are further formed in the two sides of the inserting channel in the containing body; the keelcutting and bending equipment further comprises a cutting mechanism and a bending mechanism which are sequentially arranged in the containing cavities in the inserting direction of the n-shaped keel;the cutting mechanism comprises a cutting tool, a hydraulic telescopic rod for controlling the cutting tool to move and a cutting controller for controlling the hydraulic telescopic rod to work; the bending mechanism comprises a bending motor and a bending clamp driven by the bending motor to rotate; and the bending clamp comprises a clamping plate piece of an L-shaped structure and a clamping part which is arranged on the end edge of the clamping plate piece and provided with a clamping groove. The invention further discloses a using method of the keel cutting and bending equipment, the usingmethod is used for guiding and implementing cutting and bending operation at the end of the n-shaped keel so as to directly manufacture the lap joint end at the end of the n-shaped keel, convenienceand rapidness are achieved, and the effect is remarkable.

Owner:ZHEJIANG YASHA DECORATION

A combined netted box-shaped component for forming holes in cast-in-place hollow floors

The invention provides a combined netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The combined netlike box-shaped component comprises a box roof, a box bottom and a box body, and consists of functional fabricated boards and netlike bodies, wherein the functional fabricated boards are manufactured from concrete mortar and a reinforcing material under the action of a mould or is compounded by superposing adhesive on the netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting sheets; the netlike board, the reinforcing ribs and the connecting sheets form an entirety; the area of a grid in the netlike board is smaller than 120 mm<2>; the netlike bodies are at least applied to the box body of the combined netlike box-shaped component; two structural inclined planes are arranged at corners of the box bottom and the box body. The combined netlike box-shaped component can form holes in the hollow floor; by virtue of surface tension of concrete, the unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the existing cast-in-situ hollow floor, so that integration of building energy conservation and multifunctional utilization of the floor can be easily implemented.

Owner:王本淼 +2

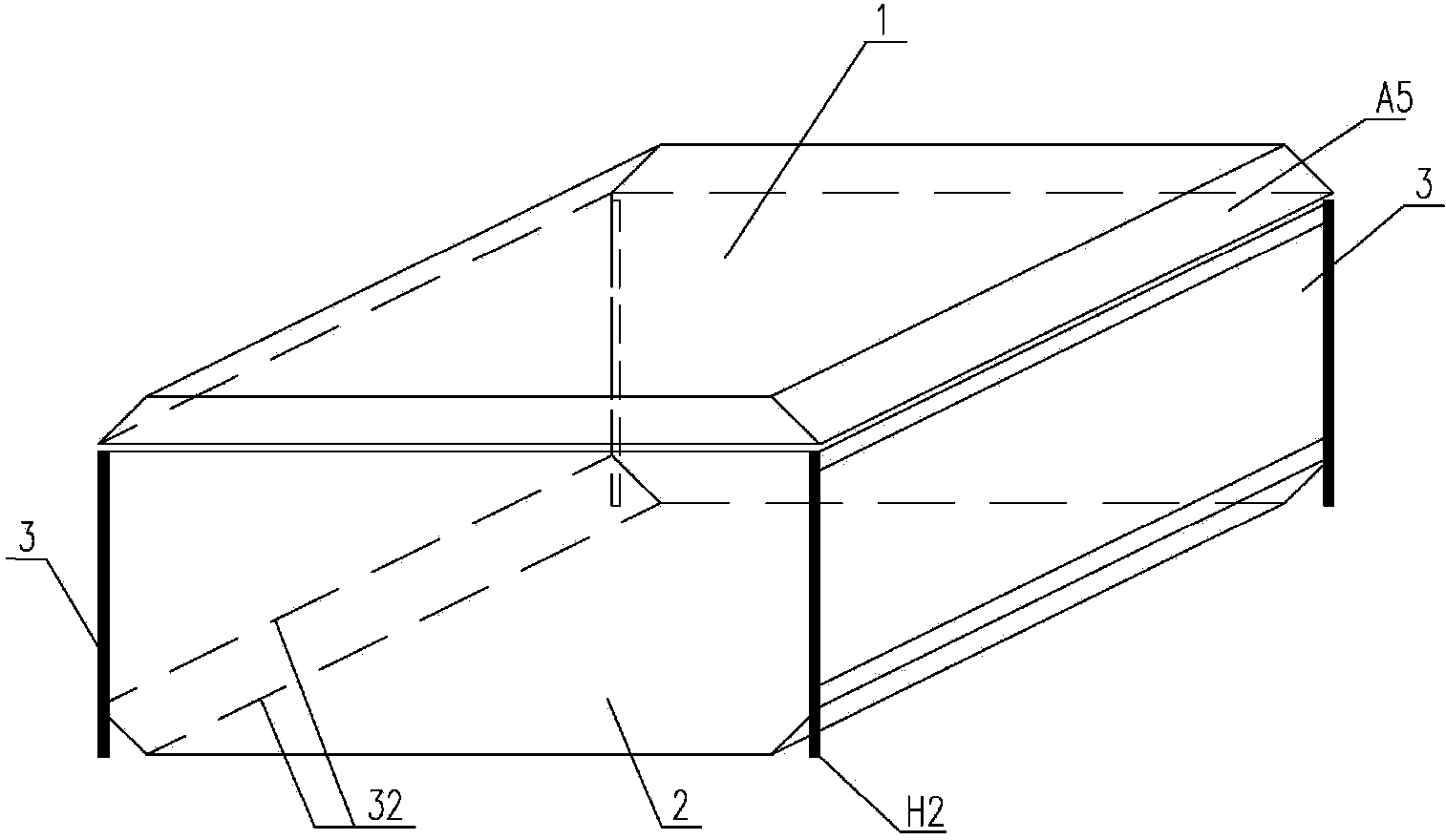

A new steel-concrete composite cast-in-place hollow floor

The invention provides a novel steel-concrete combined cast-in-situ hollow floor. The novel steel-concrete combined cast-in-situ hollow floor consists of a sectional steel column, a sectional steel main beam, a concrete ribbed beam, an upper flange plate, a lower flange plate and a netlike box-shaped component, wherein the lower end of the sectional steel main beam adopts a special steel mould; the netlike box-shaped component is formed by combining a box roof, a box bottom and a box body; the box roof is manufactured from concrete mortar and a reinforcing material under the action of a mould or is formed by compounding the netlike bodies and an adhesive; the box bottom is manufactured from the netlike body; the box body is manufactured from the netlike body; the reinforcing ribs of the netlike bodies are required to be vertically arranged; each netlike body comprises a netlike board, reinforcing ribs and connecting sheets; the netlike board, the reinforcing ribs and the connecting sheets form an entirety; at least two structural inclined planes are arranged at corners of the box bottom and the box body; the netlike body of the box bottom of the netlike box-shaped component is directly compounded in the lower flange plate. By virtue of surface tension of concrete, the unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the steel-concrete combined cast-in-situ hollow floor.

Owner:HUNAN BDF ENERGY SAVING TECH

Stamping die for discharge chute of mixer truck

The invention discloses a stamping die for a discharge chute of a mixer truck. The stamping die for the discharge chute of the mixer truck is composed of an upper die and a lower die corresponding to the upper die, wherein the upper die comprises a base plate, an upper die cross beam is connected to the base plate, upper die blades are arranged on the upper die cross beam, upper die supporting plates are arranged between the upper die cross beams, and the lower die comprises a lower die base plate and a lower die cross beam. The stamping die for the discharge chute of the mixer truck has the advantages that the structure is simple, cost is saved, the trial-manufacturing cycle is short, and discharge chutes which are attractive in appearance can be machined. According to a preferable technical scheme, lower die reinforcing ribs are vertically arranged on the lower die base plate, the lower reinforcing ribs are provided with steps, and the lower die cross beam is arranged on the steps and is connected with the lower die reinforcing ribs. Due to the fact that the lower die cross beam is arranged on the steps of the lower die reinforcing ribs, the lower die cross beam can be effectively protected; meanwhile, due to the arrangement of the steps, pushing impact force exerted on the upper die is buffered.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

Motor-driven implement having improved carburettor preheating apparatus

InactiveCN102486140AIncrease intake ram pressureIncrease punching forceInternal combustion piston enginesAir coolingImpellerMotor drive

The present invention relates to a motor-driven IMPLEMENT HAVING an IMPROVED CARBURETTOR PREHEATING apparatus, wherein motor-driven implement such as a hand-held tool or device for garden and landscape maintenance, includes an internal combustion engine having at least one cylinder and at least one carburettor, which is disposed in a carburettor chamber, is separated by an intermediate wall from an engine compartment. A housing is provided which at least partially encloses the engine compartment so that an upper part of the cylinder extends in the direction of the housing, and a fan wheel is further provided by which means air from the engine compartment can be introduced through a warm air opening in the intermediate wall into the carburettor chamber. For the motor-driven implement to have an improved carburettor pre-heating which enables easier operation, it is proposed that the warm air opening is disposed in the area of the intermediate wall which is disposed adjacently to the upper part of the cylinder.

Owner:MAKITA CORP

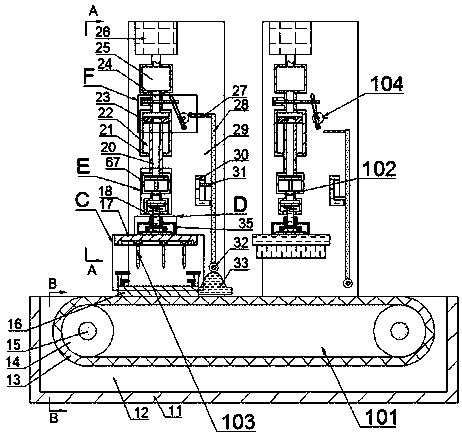

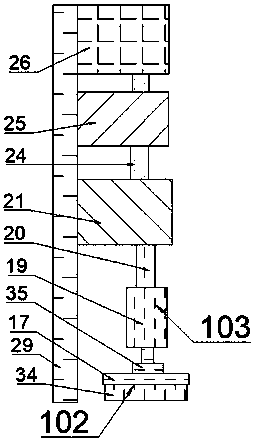

Automobile interior parts processing device

ActiveCN103753641BIncrease flexibilityIncrease punching frequencyMetal working apparatusPunchingEngineering

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

A New Type of Arc Drilling Equipment

ActiveCN108031895BSimple structureEasy to operateFeeding apparatusBoring/drilling componentsEngineeringDrilling machines

The invention discloses novel arc drilling equipment which comprises a lifting support column and a support frame and a drilling machine which are movably mounted on the lifting support column. A first rotating motor is fixedly mounted in the top end face of the support column, the output shaft of the first rotating shaft extends out of the end face of the lifting support column, a fixing transverse rod is fixedly mounted on left and right end faces of the output shaft, fixing vertical rods are symmetrically mounted on the fixing transverse rod on the left and right sides and are respectivelyand fixedly connected with the lower end face of the fixing transverse rod and the upper end face of the support frame, a dovetail groove is arranged in the lower end face of the support body arrangedon the left side of the lifting support column, and a slide rail extending leftwards and rightwards is mounted in the top wall of the dovetail groove. By the arrangement, a workpiece can be shaped with curved distribution and different radian holes, radians are convenient to adjust, and high drilling strength and rapid drilling speed are achieved.

Owner:绍兴伊司特家具有限公司

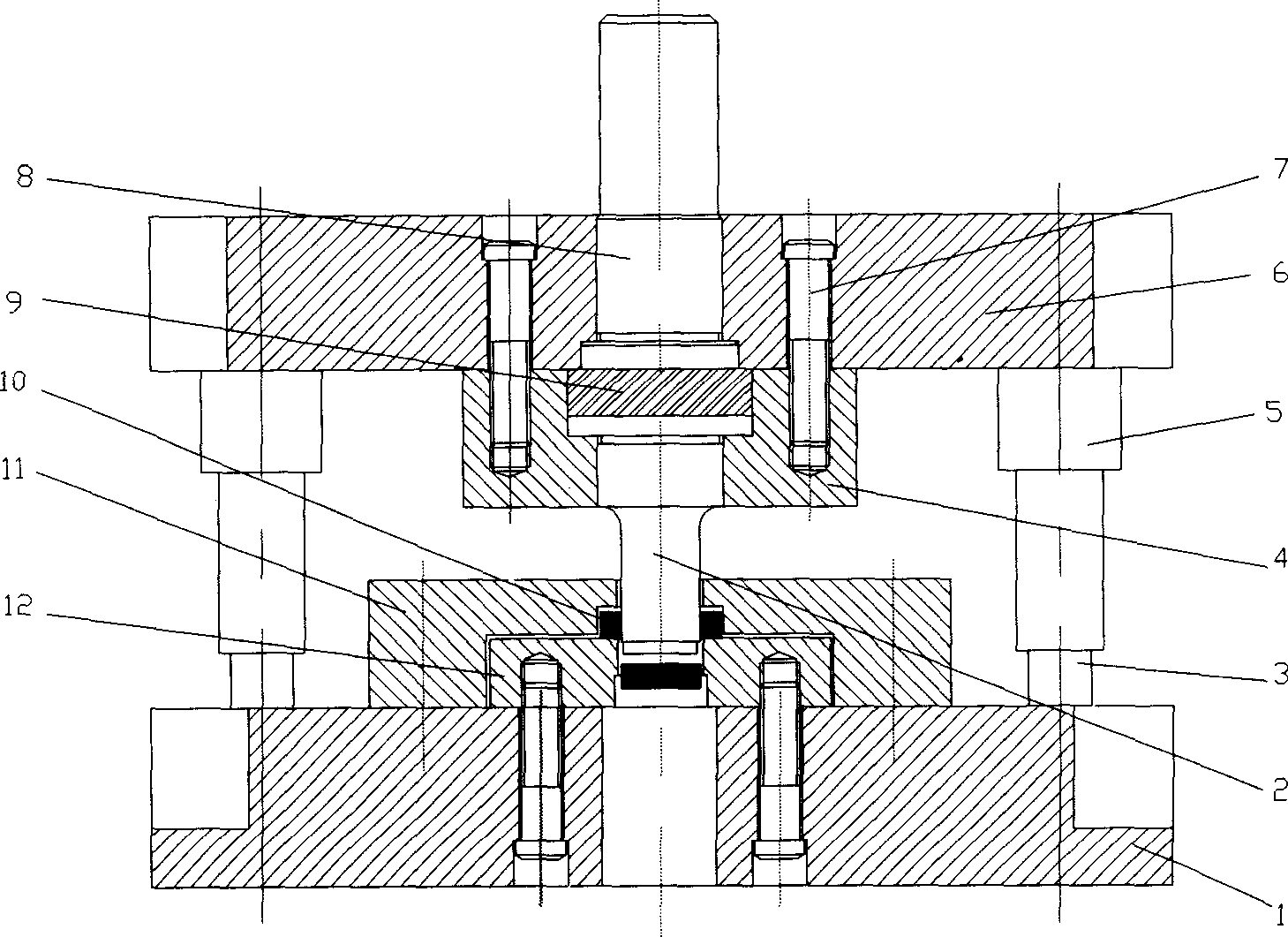

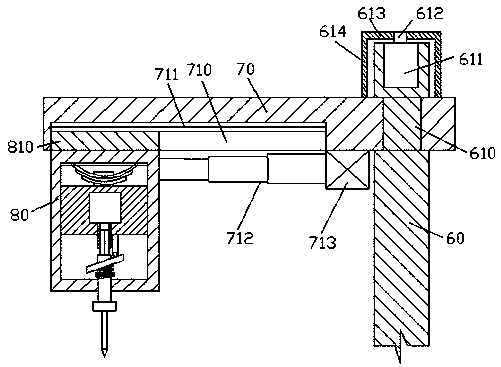

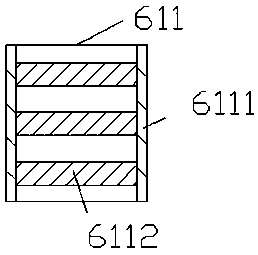

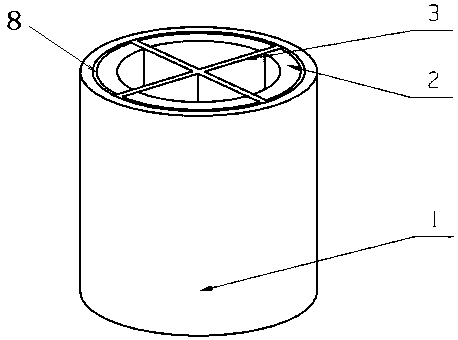

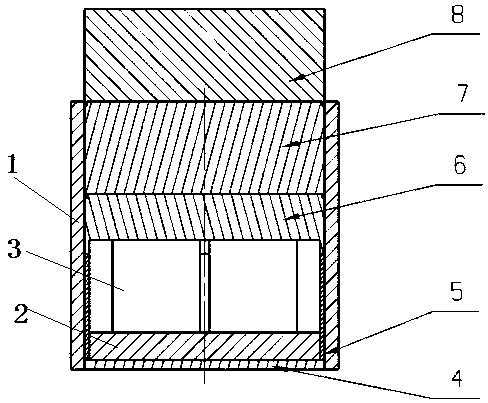

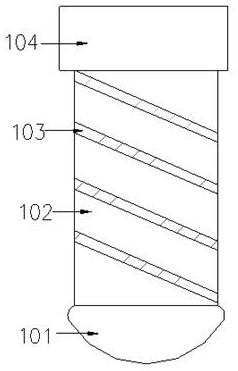

Combined tower type thin-wall ring-shaped metal rubber part stamping die with inner reinforcement rib plates and operation method thereof

The invention provides a combined tower type thin-wall ring-shaped metal rubber part stamping die with inner reinforcement rib plates and an operation method thereof. The stamping die comprises a cylindrical female die and a cushion block fixedly arranged on the bottom surface of the female die; a cylindrical core shaft is arranged in a female die body in a sleeving mode and is located above the cushion block; a spiral coiled metal wire blank is wound on the periphery of the cylindrical core shaft; four sunken grooves are uniformly formed in the cylinder wall of the cylindrical core shaft; a plurality of cylindrical male dies capable of moving in the axial direction of the cylindrical core shaft are sleeved between the periphery of the cylindrical core shaft and the inner wall of the female die; crossed reinforcement rib plates are fixedly arranged on the inner walls of the cylindrical male dies; the reinforcement rib plates are limited in the sunken grooves and are capable of moving along the axial direction of the cylindrical core shaft. Through the combined tower type thin-wall ring-shaped metal rubber part stamping die with the inner reinforcement rib plates, the problem that the male dies are damaged when the thin-wall ring-shaped metal rubber is stamped and molded can be effectively solved; the deformation of the male dies caused by low rigidity of the male dies in the stamping process can be avoided so as to ensure that the stamping die is not damaged under the condition that the thin-wall ring-shaped metal rubber parts are stamped and molded.

Owner:FUZHOU UNIVERSITY

A special movable mechanism for a drilling machine

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

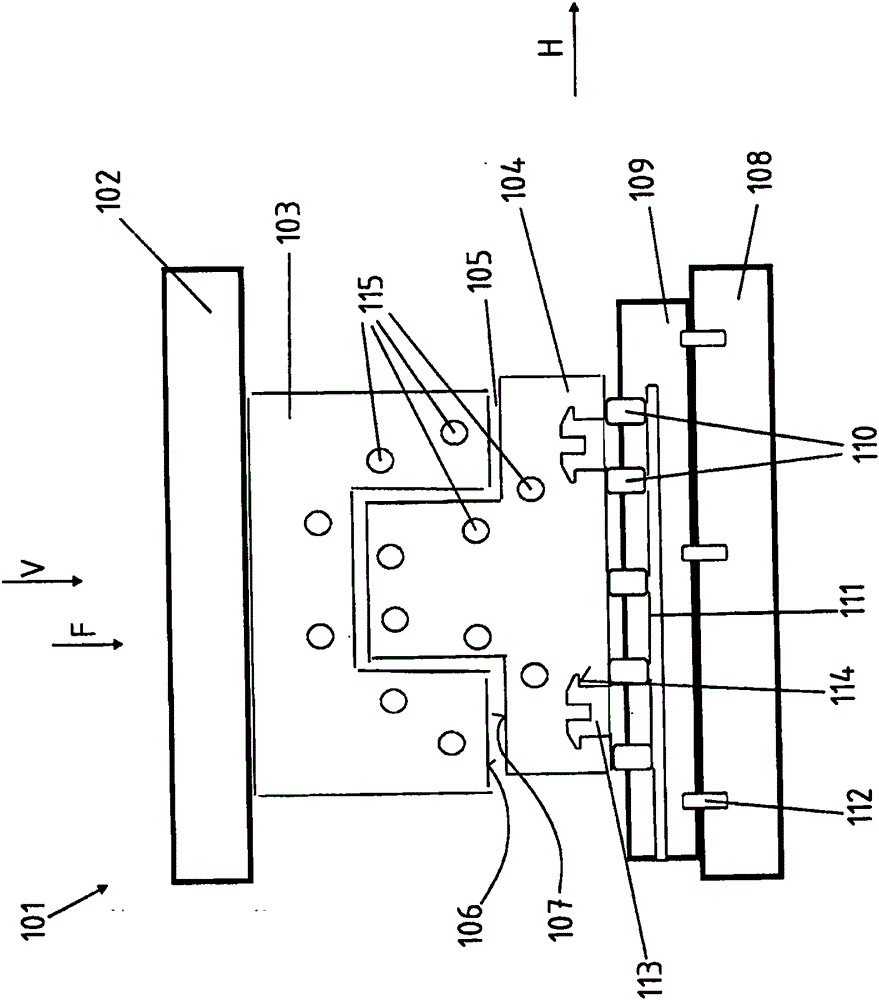

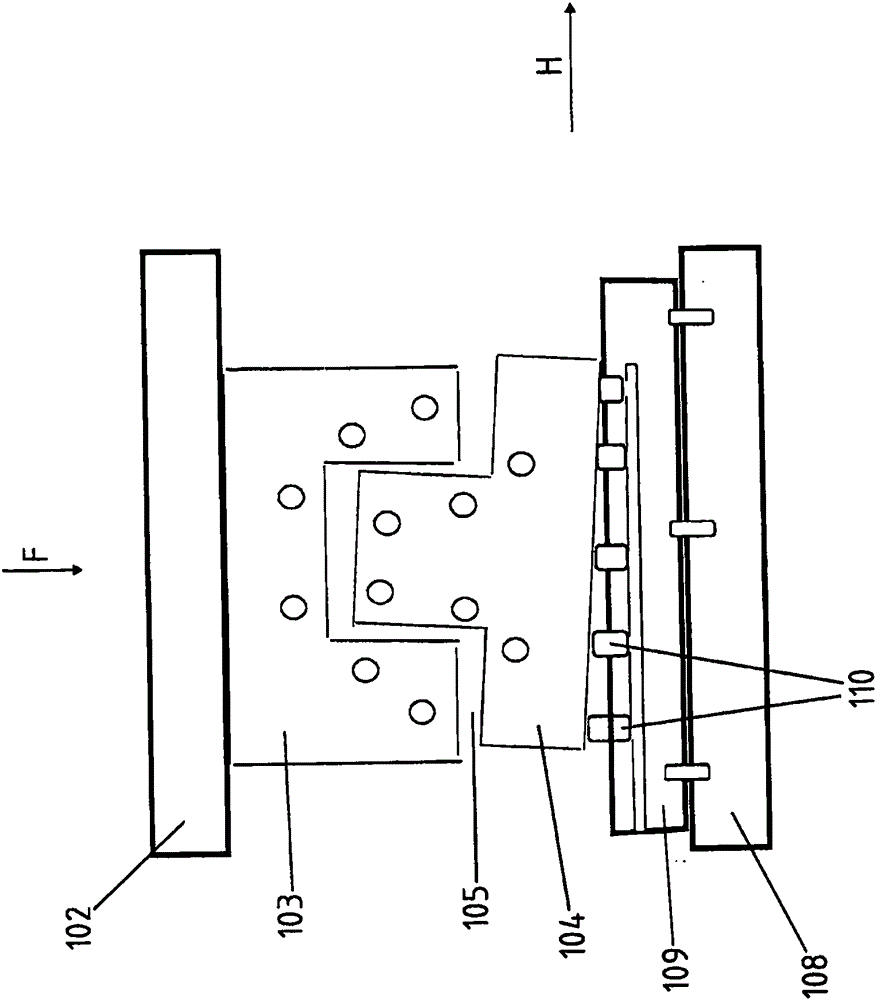

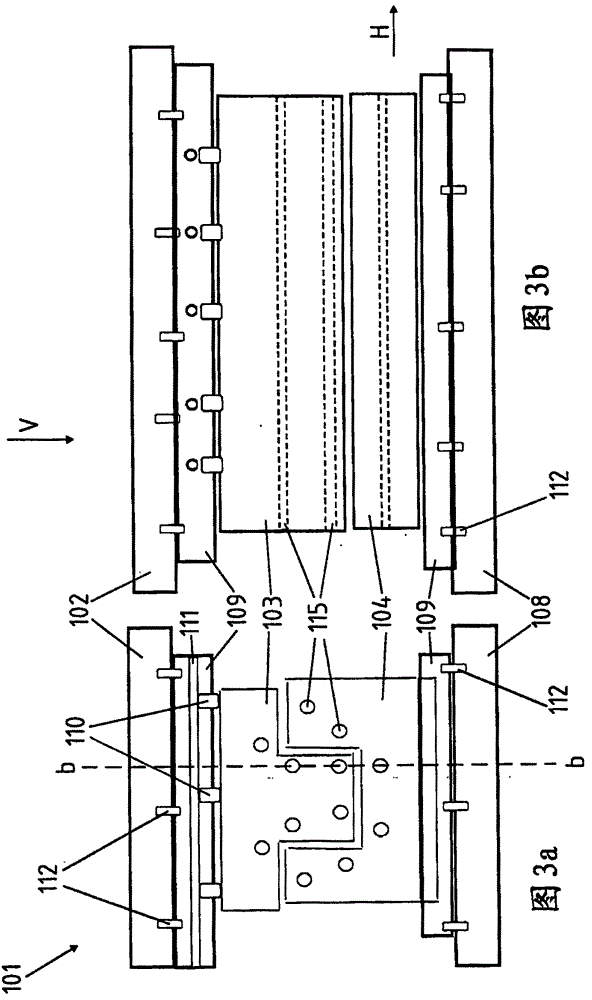

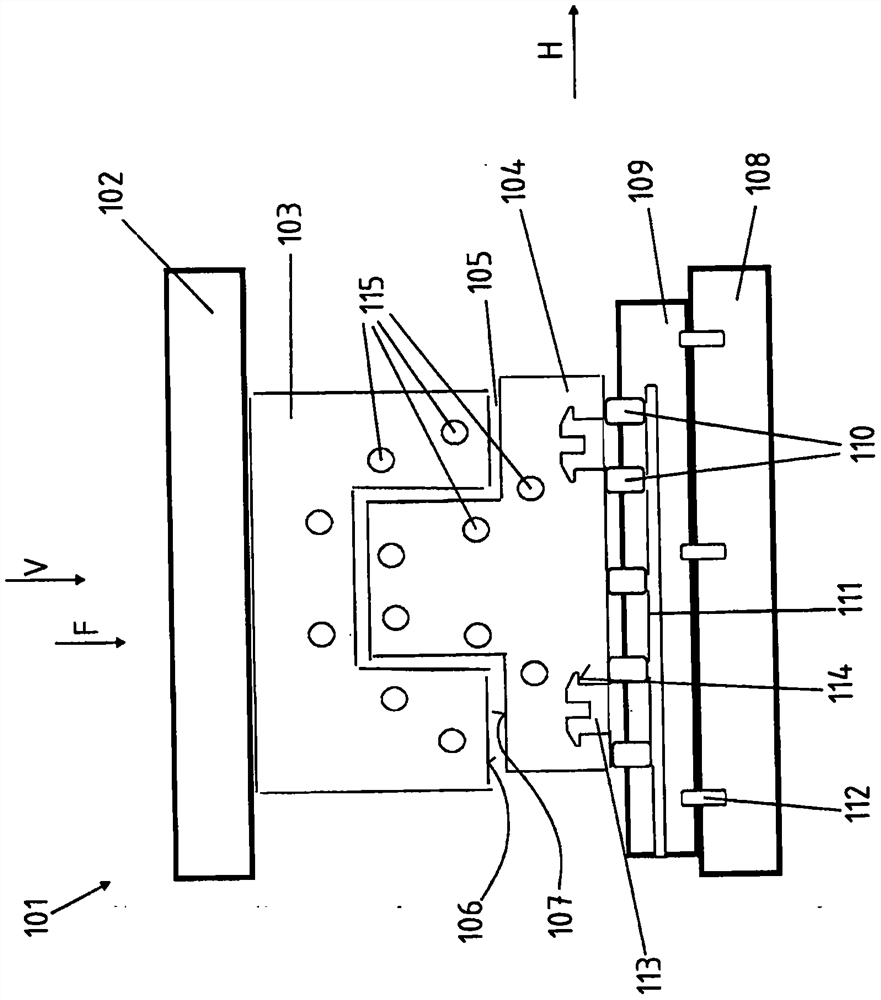

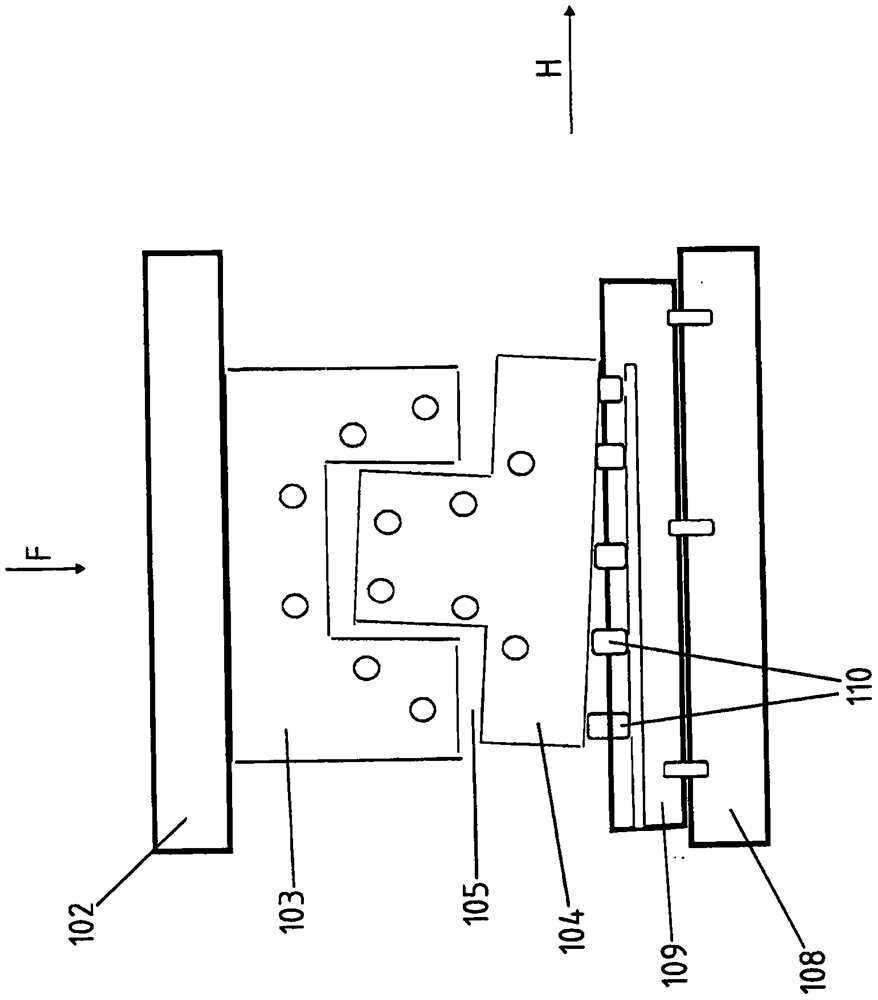

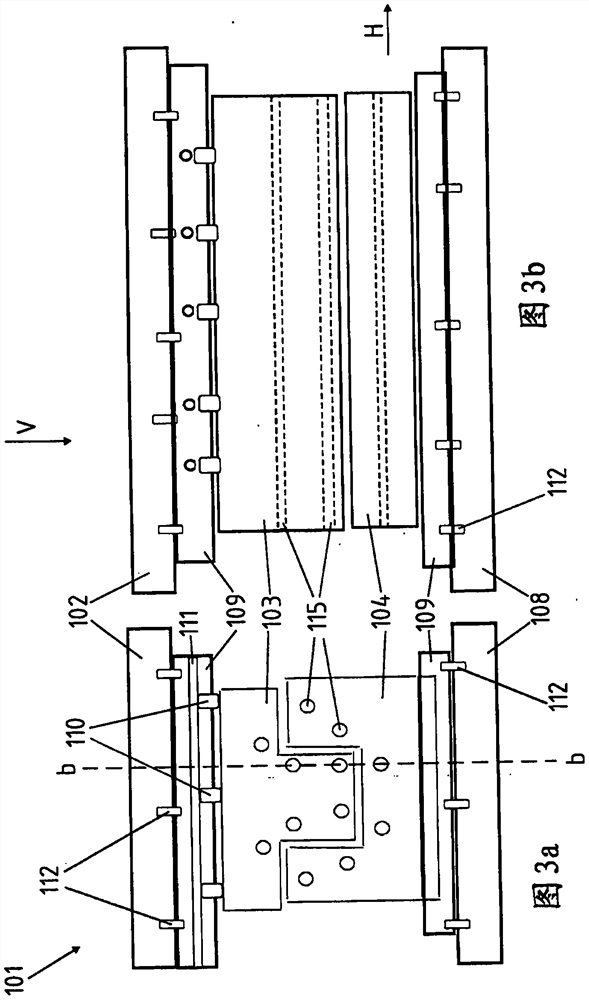

Stamping dies with tolerance compensation

ActiveCN105382098BIncrease punching forceAvoid collisionShaping toolsPressesEngineeringMechanical engineering

The invention relates to a stamping mold (101), which has an upper mold (103) and a lower mold (104), the upper mold and the lower mold can move relatively, and when the stamping mold (101) is closed Between the die (103) and the lower die (104) there is an inter-mold gap (105), characterized in that a die clamping plate (109) is provided on the pressure punch (102) and / or the stamping table (108) An upper mold (103) or a lower mold (104) capable of relative movement relative to the mold clamping plate (109) is supported on the mold clamping plate by inserting at least one elastic adjustment element (110).

Owner:BENTELER AUTOMOBILTECHNIK GMBH

New gas-hydraulic booster cylinder

The invention relates to a novel pressurized oil-air cylinder which is capable of further improving the stamping force in the condition of the same equipment size through a two-section stroke mode. Work air channels comprise an air inlet channel and an air outlet channel, a high-pressure one-way air valve and a large-flow one-way air valve are arranged on the air inlet channel and the air outlet channel respectively, and a switching valve is arranged at the air inlet channel and air outlet channel connection position. A stamping rod comprises a front rod body, a rear rod body and a stamping head. A secondary stamping oil cavity is formed in the rear rod body, the inner diameter of the secondary stamping oil cavity is decreased from the rear end to the front end, and a piston retaining block is arranged at the front end of the secondary stamping oil cavity. A piston cavity is formed in the rear end of the front rod, a sliding rod cavity is formed in the middle section and the front section of the front rod, a secondary stamping piston is arranged in the piston cavity, an ejection rod is arranged in the sliding rod cavity, and a stamping head is connected with the front end of the ejection rod. The ejection rod comprises a front ejection rod body and a rear ejection rod body, and a clamping block is arranged on the rear ejection rod body. The sliding rod cavity comprises a front sliding rod cavity body and a rear sliding rod cavity body, and a clamping groove is formed in the inner wall of the rear sliding rod cavity body.

Owner:SUZHOU ICOOLMACH EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com