Biomass solidified fuel forming machine

A technology for solidifying fuel and molding machine, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve problems such as equipment damage, low processing efficiency, pipeline blockage, etc., to solve raw material blockage and improve production efficiency. , Improve the effect of punching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

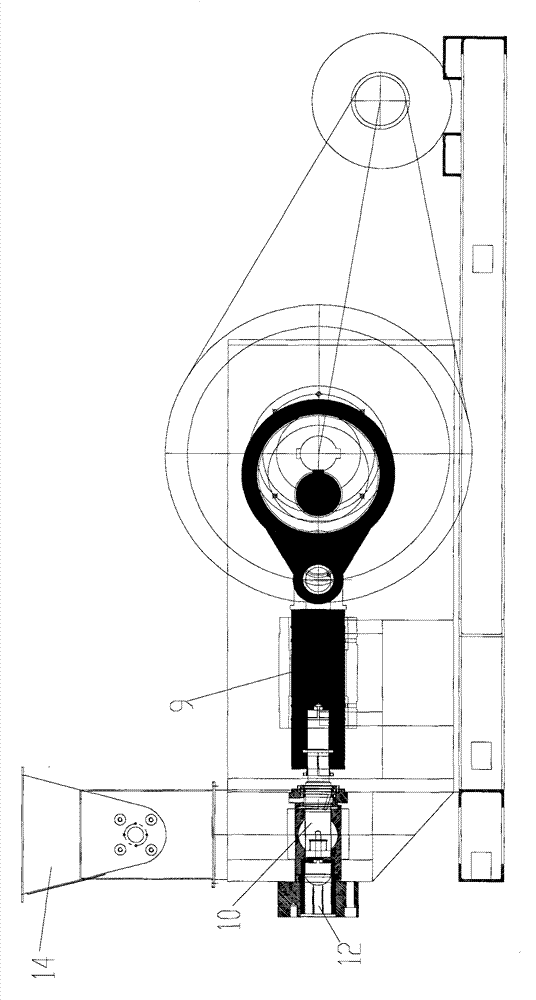

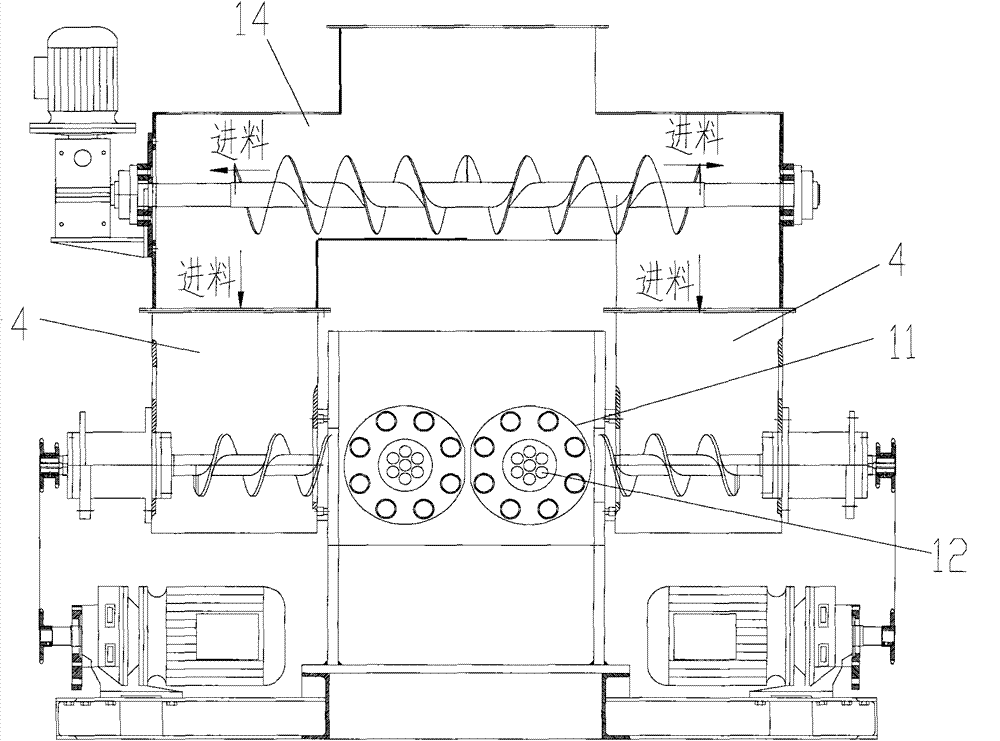

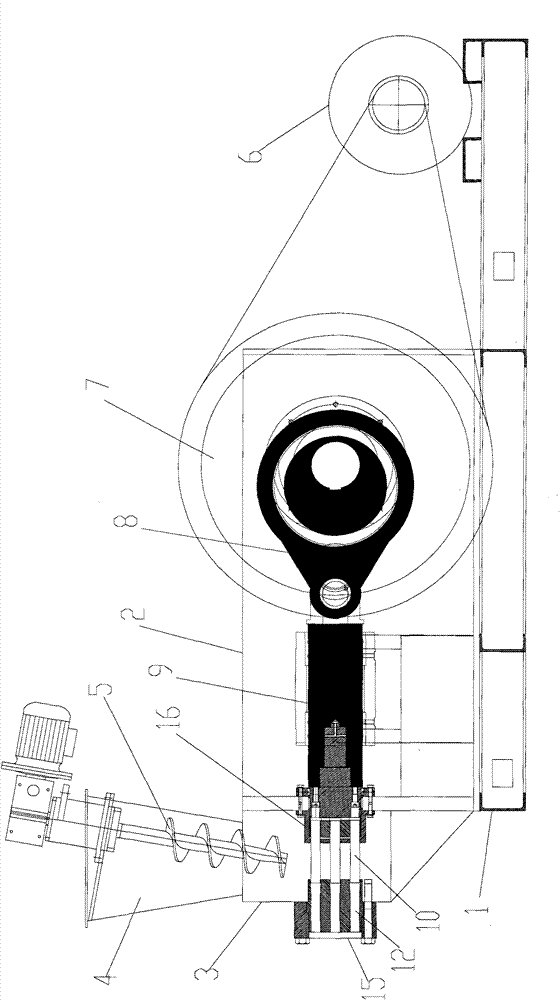

[0024] like image 3 and Figure 4 As shown, a biomass solidified fuel molding machine is mainly composed of a base 1, a chassis 2 and a crank piston stamping mechanism. The chassis 2 and the crank piston stamping mechanism are installed on the base 1. The crank piston stamping mechanism consists of a stamping motor 6 A crankshaft connecting rod mechanism 8, two punching piston rods 9 and several small punching rods 10 are formed, and several small punching rods 10 are installed on the punching piston rod 9, and the two crankshaft connecting rod mechanisms 8 are axially connected to the transmission of the punching motor 6 On the wheel 7, two stamping piston rods 9 are respectively installed on the two crankshaft linkages 8, and several small stamping rods 10 on the stamping piston rod 9 perform a reciprocating stamping movement in the guide sleeve 16, and a stamping chamber is arranged in front of the chassis 2. 3. The feeding bin 4 is set above the punching bin 3, and two d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com