Stamping die for discharge chute of mixer truck

A stamping die and discharge trough technology, applied in the field of stamping dies, can solve the problems of large volume, inability to adapt to the rapid response mechanism, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

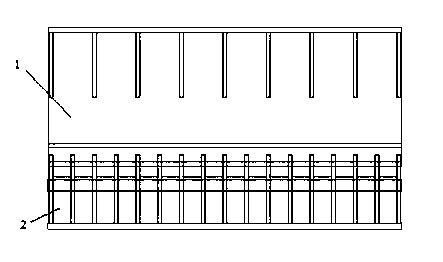

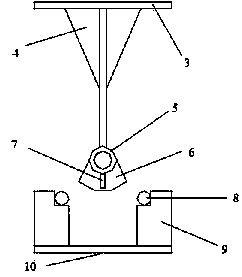

[0015] Such as figure 1 As shown, it is a schematic diagram of the longitudinal section structure of the mold of the present invention, and the mold is composed of an upper mold 1 and a lower mold 2 corresponding to the upper mold 1; figure 2 is a schematic diagram of the cross-sectional structure of the mold, from figure 2 It can be seen that the upper mold 1 includes a base plate 3, the base plate 3 is also provided with upper mold reinforcing ribs 4, the base plate 3 is connected with an upper mold beam 5, and the upper mold beam 5 is provided with 9 upper mold blades 6 (such as figure 1 ), the upper mold support plate 7 is arranged between the upper mold blades 6, the upper mold blades 6 are axially vertical and evenly distributed on the upper mold beam 5; the lower mold 2 includes a lower mold bottom plate 10 and a lower mold beam 8 , the lower mold bottom plate 10 is vertically provided with a lower mold reinforcement rib 9, the number of the lower mold reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com