Device for stamping with adjustable distance between the rolls

A technology of stamping equipment and rollers, which is applied to cardboard articles, rotary printing machines, printing and other directions, can solve problems such as laborious processing, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

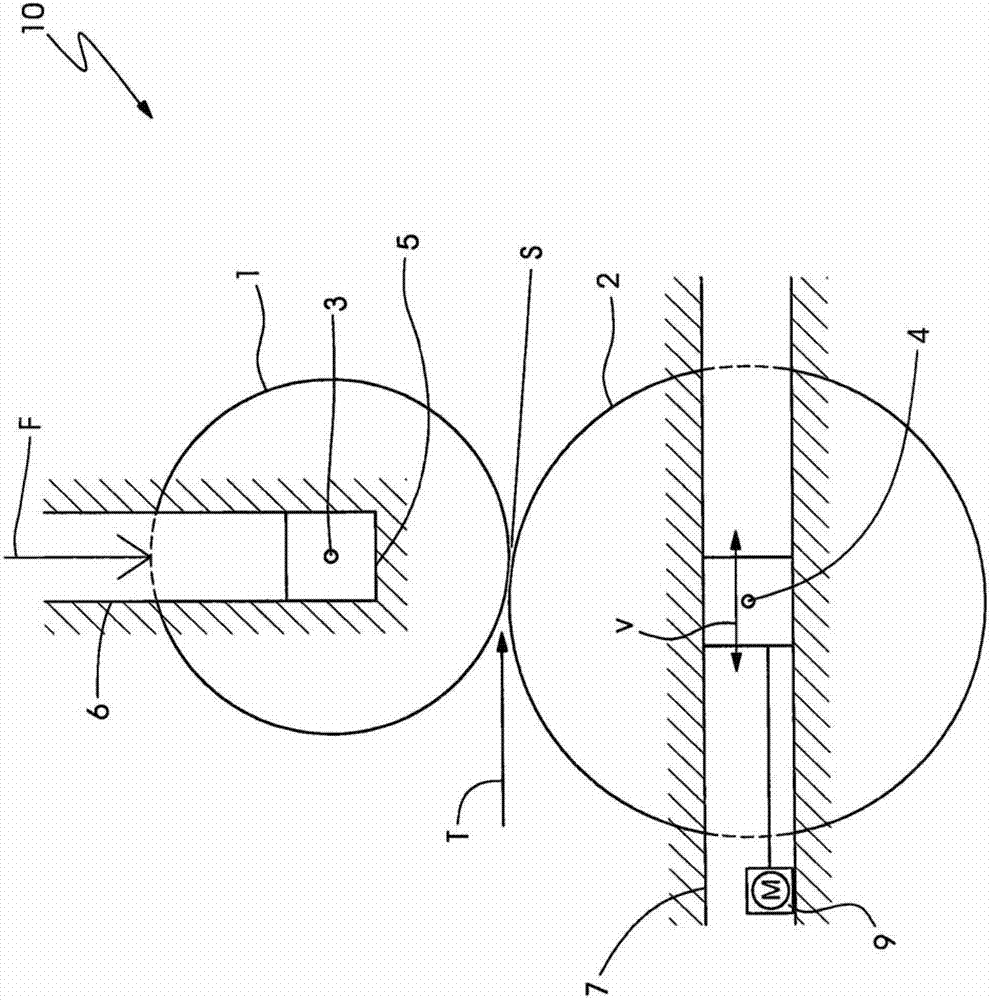

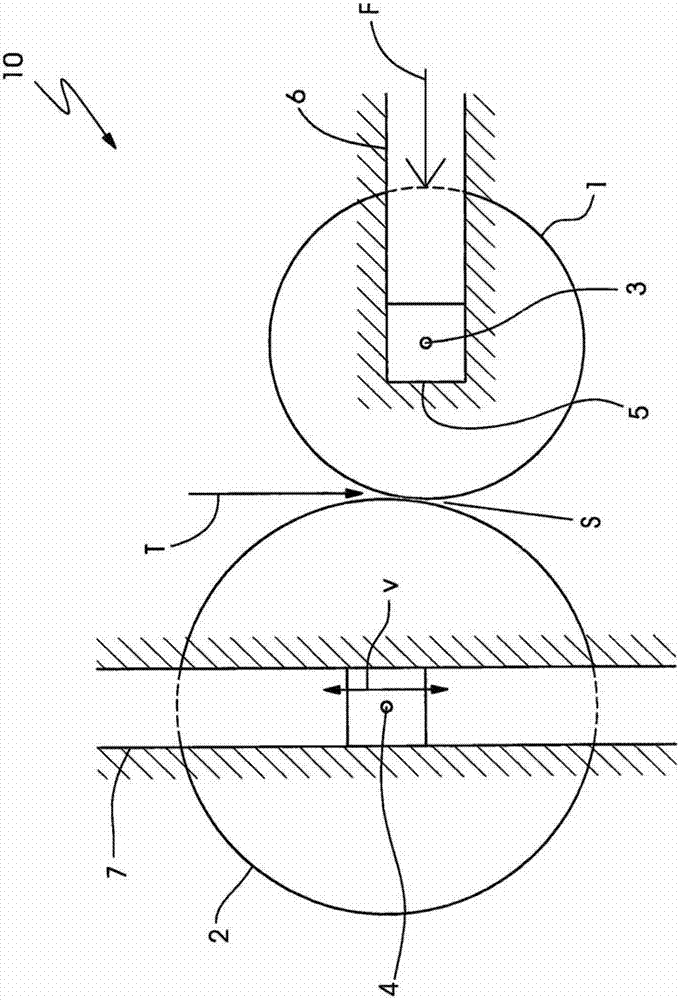

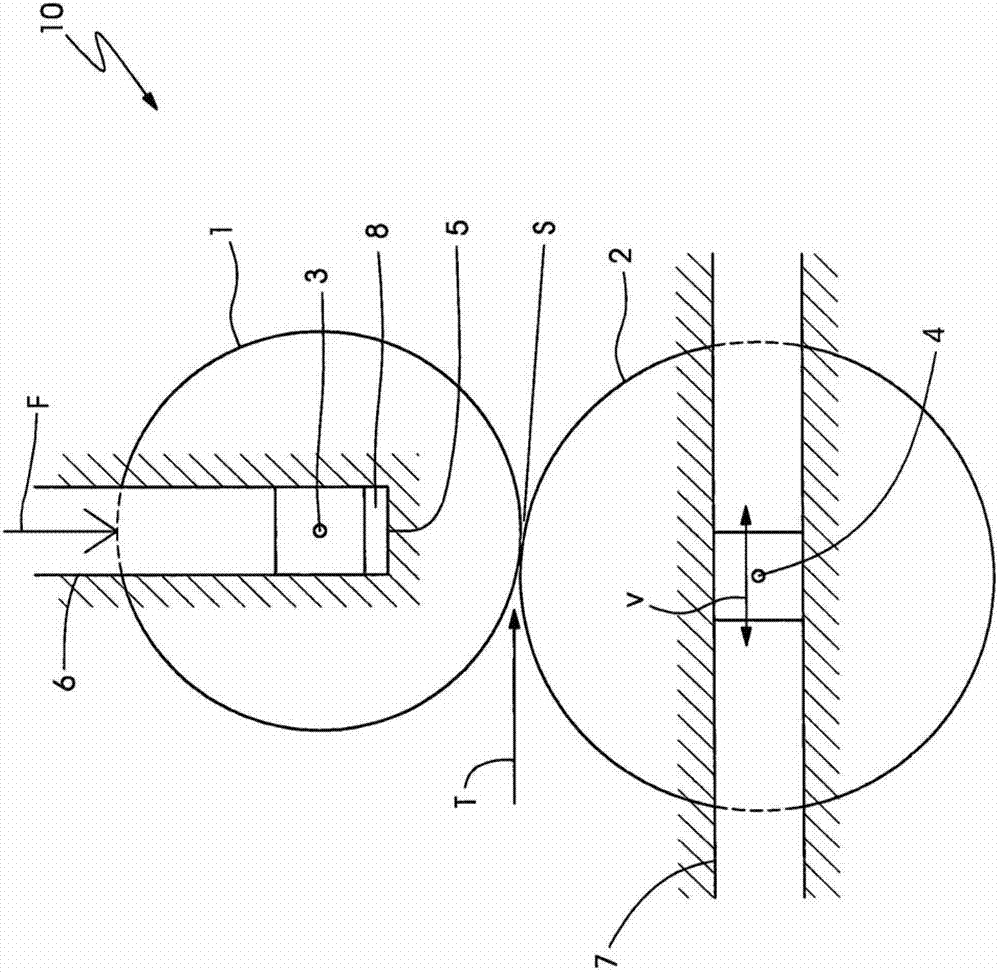

[0025] figure 1 A first embodiment of a punching device 10 according to the invention is shown with a punching cylinder 1 and a counter punching cylinder 2 which interact as tools and bring about the processing of a strip-shaped material 144 (not shown) conveyed in the conveying direction T . There is a gap S between the stamping cylinder 1 and the counterpressing cylinder 2 , that is to say, the stamping cylinder 1 and the counterpressing cylinder 2 are spaced apart from each other. In order to vary the effect of the stamping cylinder 1 on the sheet-shaped sheet 144 to be processed, the distance between the cylinders 1 , 2 , that is to say the gap S, can be varied. For this purpose, the counterpress cylinder 2 is mounted displaceably in a guide 7 , as indicated by the double arrow v. The counter punching cylinder 2 is thus displaceable in the horizontal direction along guides 7 . The movement can either be done manually or as figure 1 This is done by means of a drive 9 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com