Preparation process of 5754 aluminum alloy plate with high formability

A technology of aluminum alloy plate and preparation process, which is applied in the direction of manufacturing tools, metal rolling, heat treatment equipment, etc., can solve the problems of insufficient formability and cracking of finished materials, achieve uniform structure and composition of ingots, reduce stamping costs, reduce Effects of non-equilibrium and eutectic phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

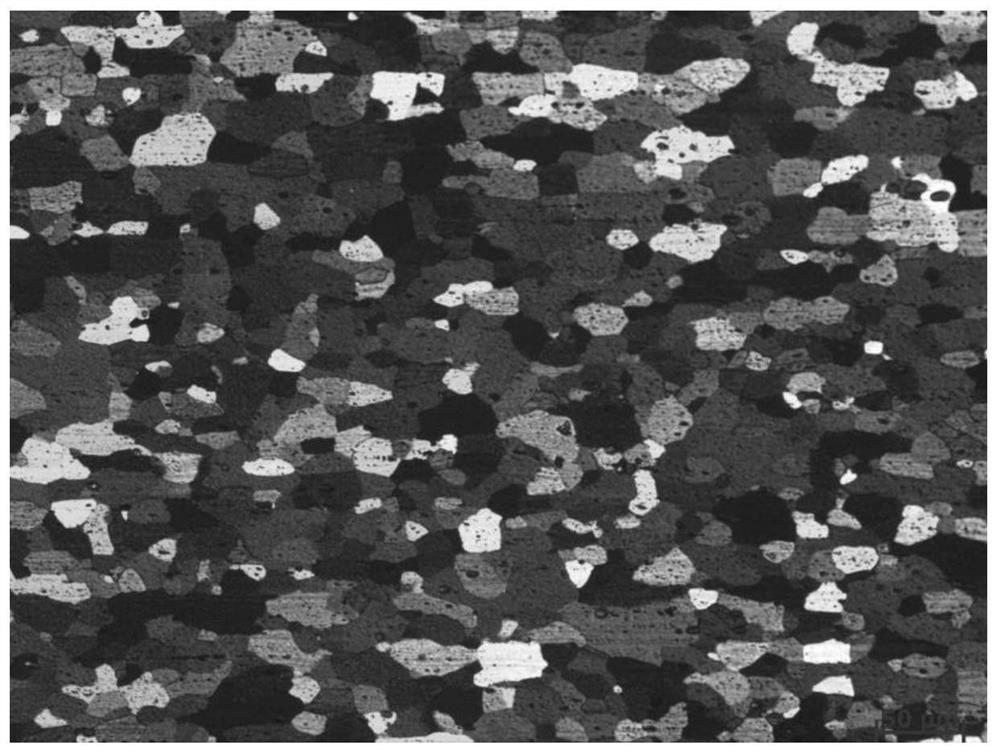

Image

Examples

Embodiment

[0029] A preparation process of high formability 5754 aluminum alloy plate, comprising the following steps:

[0030] A. Ingredients: 5754 aluminum alloy raw materials are mixed according to weight percentage, namely Si: 0.15%, Fe: 0.35%, Cu: 0.10%, Mn: 0.30%, Mg: 3.10%, Cr: 0.12%, Zn: 0.08% , Ti: 0.03%, impurity ≤ 0.05%, the balance is Al;

[0031] B. Melting and casting: Add the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt them into liquid aluminum alloys. After standing still, refining, slag removal, online degassing, and filtering processes, the liquid aluminum alloys are melted and cast into aluminum alloys. Ingot casting, aluminum alloy ingots are cast by electromagnetic stirring, and the furnace top temperature control mode is selected for smelting. The temperature of the molten aluminum is controlled at 720-760°C during the smelting process. During the casting process, the dummy head is used for traction casting, and the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com