Continuous production die for automobile activated carbon canister support parts

A technology of activated carbon and parts, which is applied in the field of continuous production molds for automobile activated carbon canister bracket parts, which can solve the problems of potential safety hazards and increased production costs, and achieve the effects of long service life, extended service life and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

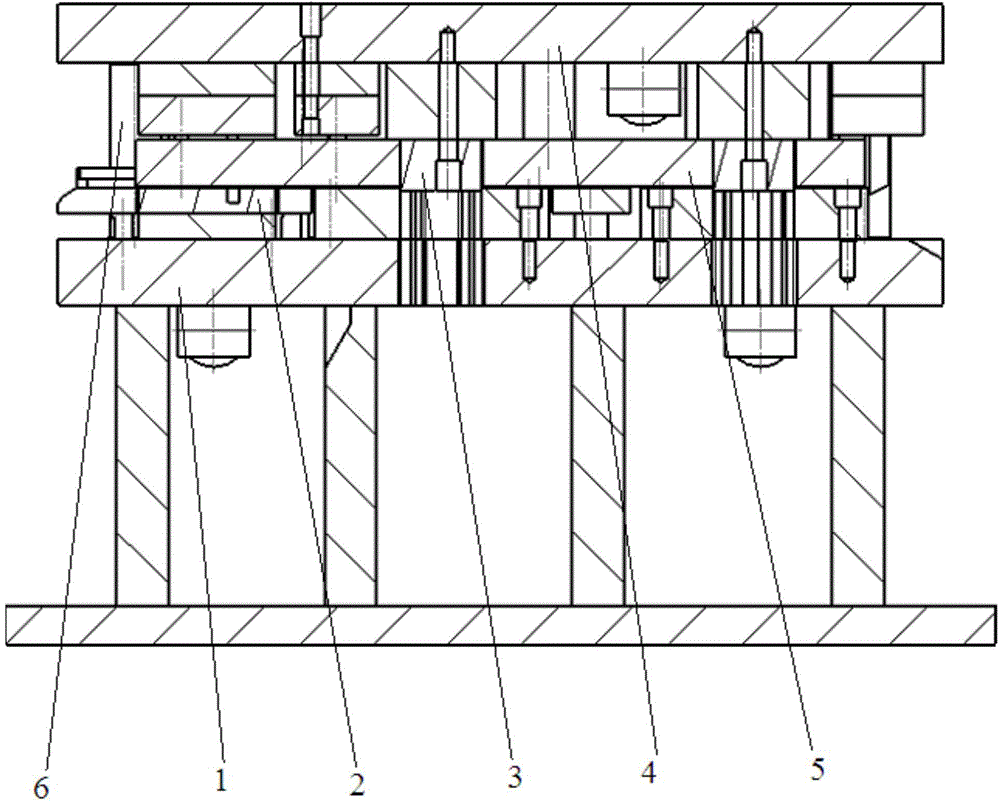

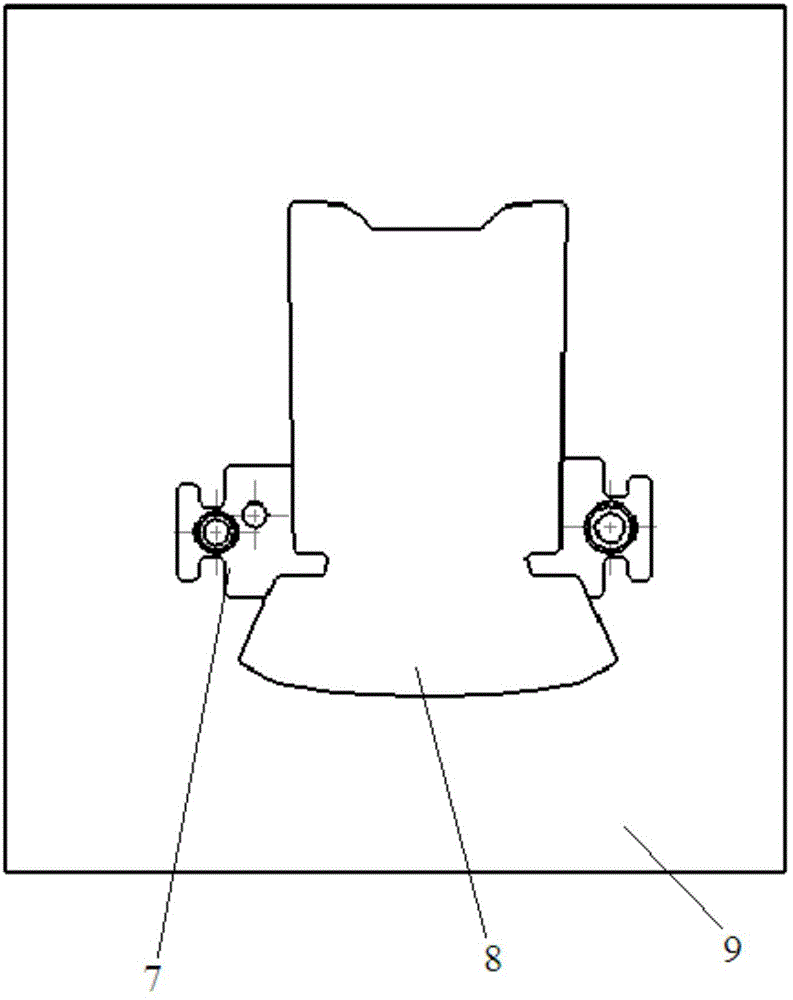

[0025] like figure 1 As shown, a continuous production mold for automotive activated carbon canister bracket parts includes an upper mold part, a lower mold part and a guide post; the lower mold part includes a lower mold base 1 and a punching recess fixed on the upper surface of the lower mold base 1 The die cutter 2 and the lower die trimming cutter block 3; the upper die part includes an upper die base 4 and a pressing plate 5 fixed on the lower surface of the upper die base 4, a punch and an upper die trimming cutter block, so The above-mentioned pressing plate 5 is arranged on the upper die trimming cutter block and is connected with the upper die trimming cutter block, and the described punch is arranged on the pressing plate; the described upper die seat 4 is connected to the lower die through a guide post. Seat 5 connection;

[0026] When working, the upper die base 4 is pressed against the lower die base 1, the parts to be processed are pressed by the pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com