Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Reduce seepage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-stage temporary plugging depth network acid fracturing method

The invention discloses a multi-stage temporary plugging depth network acid fracturing method, and belongs to the technical field of oil and gas well production increment and improvement. The method comprises the steps that bridge plugging is formed in an artificial fracture through fracture interior temporary plugging material liquid, the artificial fracture is forced to form multiple branch fractures, and main acid is used for etching the fracture; bridge plugging is formed in an artificial fracture opening through fracture opening temporary plugging material liquid, the fracture is forced to be cracked at the new position of a well wall, and interlayer steering is achieved. The multi-stage temporary plugging depth network acid fracturing method has the advantages of being simple in technology, convenient to operate and the like, a complex fracture network is formed in different permeability zones in carbonatite multi-layer, thick-layer or horizontal well long well sections through the principle of combining fluid power self serching and manual control, the oil and gas region communication probability is increased, the oil and gas percolating resistance is reduced, the single-well yield is improved, and a carbonate reservoir is efficiently and economically developed.

Owner:SOUTHWEST PETROLEUM UNIV +2

Method for increasing petroleum production rate of low-permeability oil reservoir through air and microorganism flooding

ActiveCN105239977AReduce seepage resistanceReduce oxygen contentMicroorganismsFluid removalThroatMicroorganism metabolism

The invention discloses a method for increasing petroleum production rate of a low-permeability oil reservoir through air and microorganism flooding. The method includes that microorganisms, nutritional agents and air are provided, and the microorganisms are endogenous microorganisms in the oil reservoir; an air-microorganism composite injection mode refers to injecting the microorganisms and the nutritional agents into the oil reservoir by means of a slug and then injecting an air slug into the oil reservoir in a form a small slug. The microorganisms utilize the nutritional agents and the air for quick fermentation and consuming oxygen in the air, oxygen content is reduced to be below 3% which is a safe value, and microorganism metabolism surfactant emulsifies crude oil, emulsified particles expand wave and size while lowering flow seepage resistance; rock pore and throat radius of the low-permeability oil reservoir are small, microbial thalluses have wave and size expanding effect, and crude oil recovery rate is increased further.

Owner:NANKAI UNIV

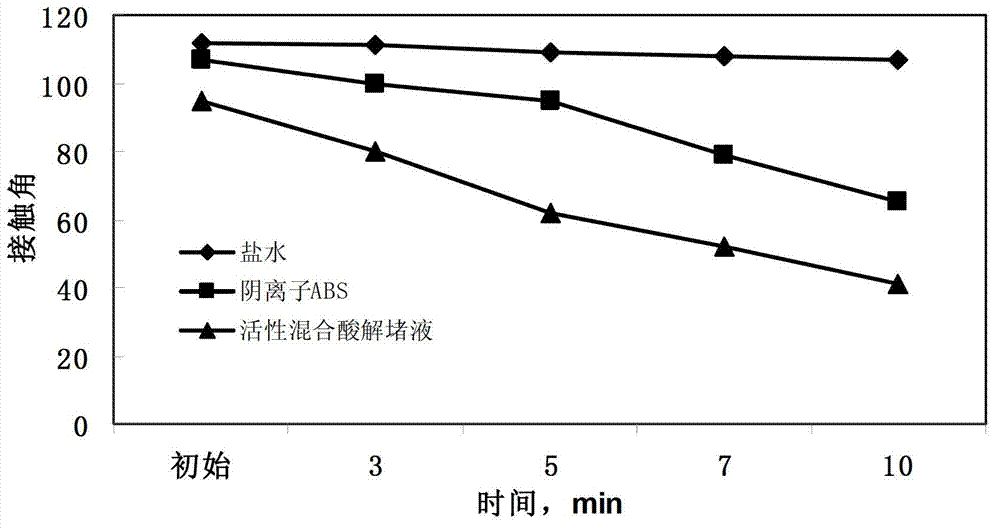

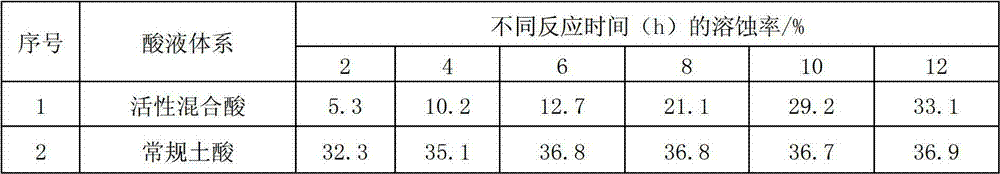

Active mixed acid plugging removal solution applicable to low permeability reservoir

ActiveCN102775974AChange wettabilityProlong the action timeDrilling compositionReaction rateEffective action

The invention relates to active mixed acid plugging removal solution applicable to a low permeability reservoir and mainly solves the problems of short period of validity and poor plugging removal and augmented injection effects when conventional mud acid and composite acid methods are adopted for plugging removal treatment on low permeability formation. The active mixed acid plugging removal solution consists of the following components in proportions according to weight percent: 9-10% of acetic acid, 5-7% of formic acid, 2%-3% of bifluorid acid ammonium, 2%-4% of boric acid, 1.0-2.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 2.0% of clay stabilizer, 0.5-1.0% of dewetting active agent and 67.0-76.5% of water. The active mixed acid plugging removal solution applicable to the low permeability reservoir can delay the reaction rate of acid rock, increase the effective operating distance of acid solution, and realize the acidification of deep formation, and simultaneously can improve the oil and water seepage characteristics and increase the water phase permeability.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

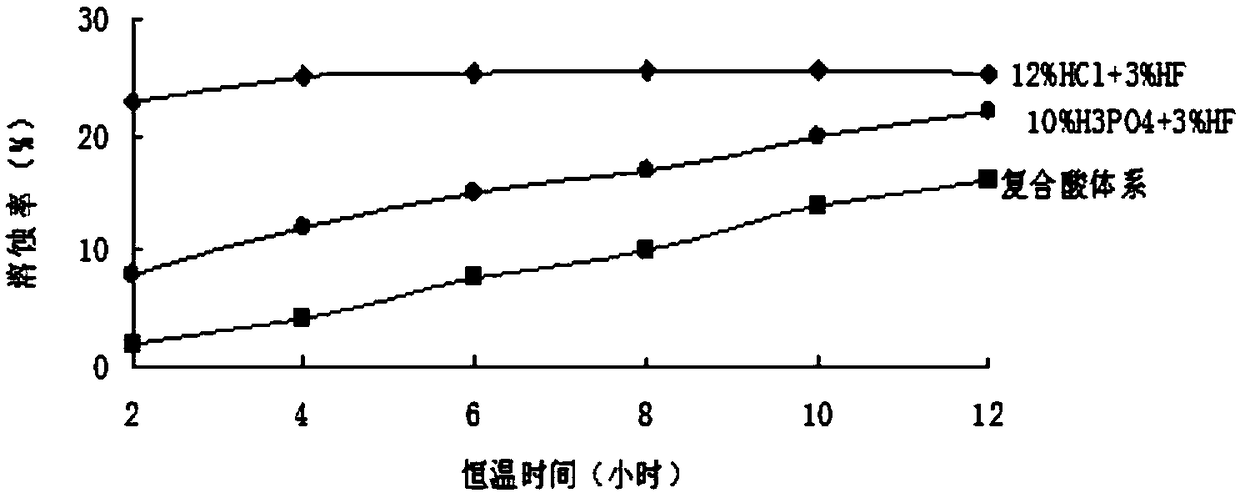

Compound acid blockage removing fluid for oil-water wells of ultralow-permeability oil fields

InactiveCN108822819ASlow reaction speedStrong penetrating abilityDrilling compositionEnvironmental chemistryCorrosion

The invention discloses a compound acid blockage removing fluid. The blockage removing fluid is prepared from raw materials in parts by weight as follows: 4-6 parts of a foam flushing fluid, 20-30 parts of a prepad fluid, 70-100 parts of main acid and 10-20 parts of postpad fluid. The acid fluid has higher capacity of removing organic sediment pollution and high acid residue and emulsifying resistance. The acid fluid has low corrosion speed and good swelling inhibition and does not change the original water wetting characteristic of the stratum.

Owner:兰州凯宏中原石油科技有限公司

Fireflooding huff and puff and fireflooding linkage thickened oil exploitation method

InactiveCN104196507AReduce seepage resistanceThe fire drive process continuesFluid removalInjection airInjection well

The invention provides a fireflooding huff and puff and fireflooding linkage thickened oil exploitation method. The method comprises the steps of conducting well spacing in an area well pattern mode, wherein the distance between a deployment central well and the nearest producing well around the central well is smaller than or equal to 100 m; conducting fireflooding huff and puff on all wells of a deployment well pattern synchronously or sequentially; conducting area fireflooding with the central well of the area well pattern serving as a continuous gas-injection well and surrounding wells serving as producing wells after fireflooding huff and puff is conducted on all the wells for three to five periods averagely. According to the method, by means of fireflooding huff and puff and fireflooding linkage, air injection fireflooding exploitation of extra-heavy oil reservoirs and super-heavy oil reservoirs with viscosity over 10000 mPa.s under the formation condition is made possible.

Owner:BEIJING PUXIN PETROLEUM TECH DEV

Low-filtration-loss blockage relieving fluid for acidification oilfield well and preparation method thereof

InactiveCN108559481AGood dispersionGood filter loss reduction effectDrilling compositionOrganic acidClay minerals

The invention discloses low-filtration-loss blockage relieving fluid for acidification oilfield well. The blockage relieving fluid is prepared from the following raw materials in parts by weight: 20-40 parts of organic acid, 110-130 parts of composite acid body, 2-4 parts of corrosion inhibitor, 30-40 parts of micellar acid stabilizer solution, 1-2 parts of surfactant and 1-3 parts of sodium tripolyphosphate. The reaction speed of the blockage relieving fluid with quartz and feldspar minerals is higher than that of the blockage relieving fluid with clay minerals, so that acid liquid not only can eliminate the formation pollution, but also can well improve the original permeability of the formation; the acid liquor system has good adaptability with the formation, and secondary precipitatedacid slag is not produced in a formation treatment process, so that new pollution is not caused.

Owner:兰州凯宏中原石油科技有限公司

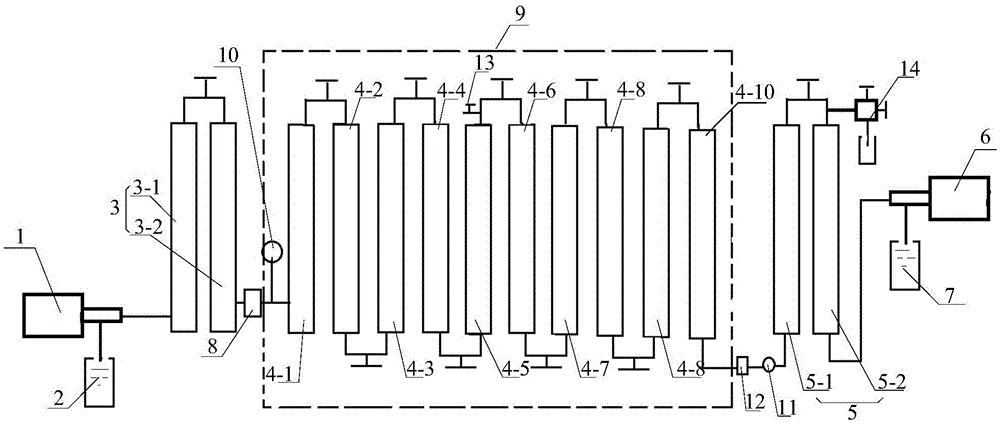

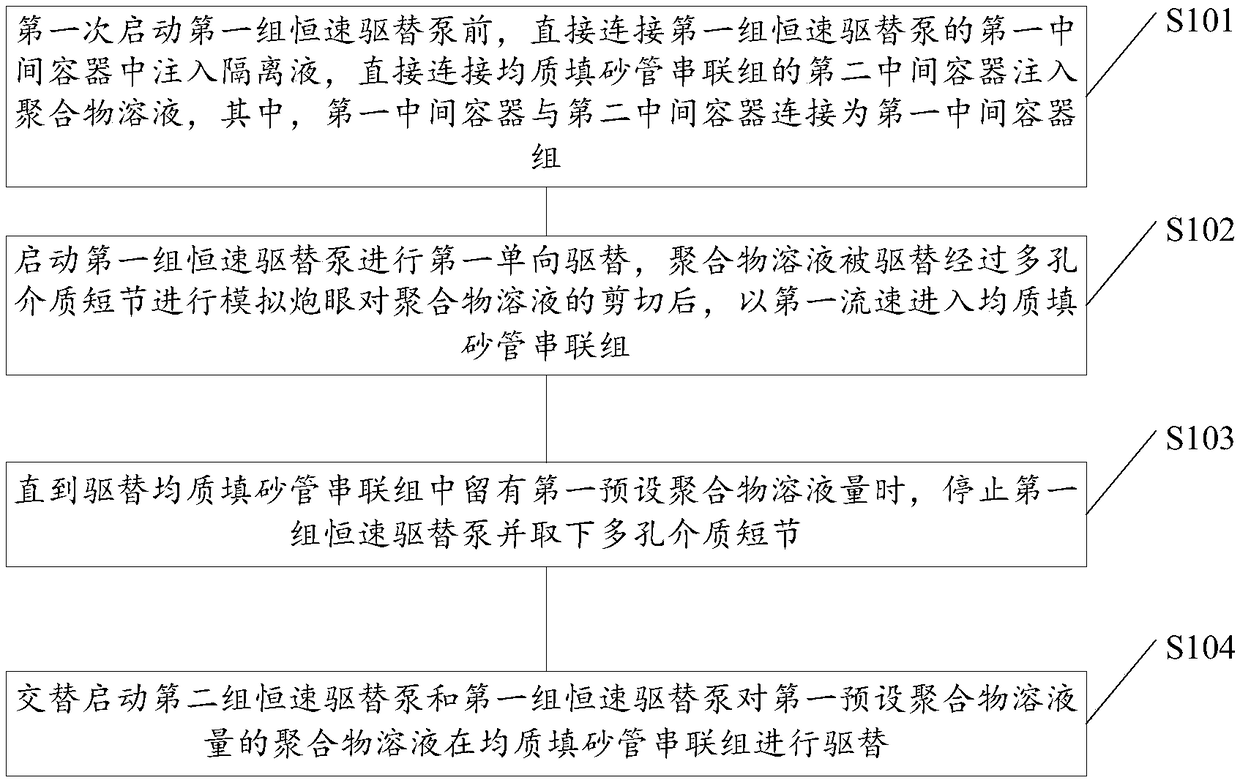

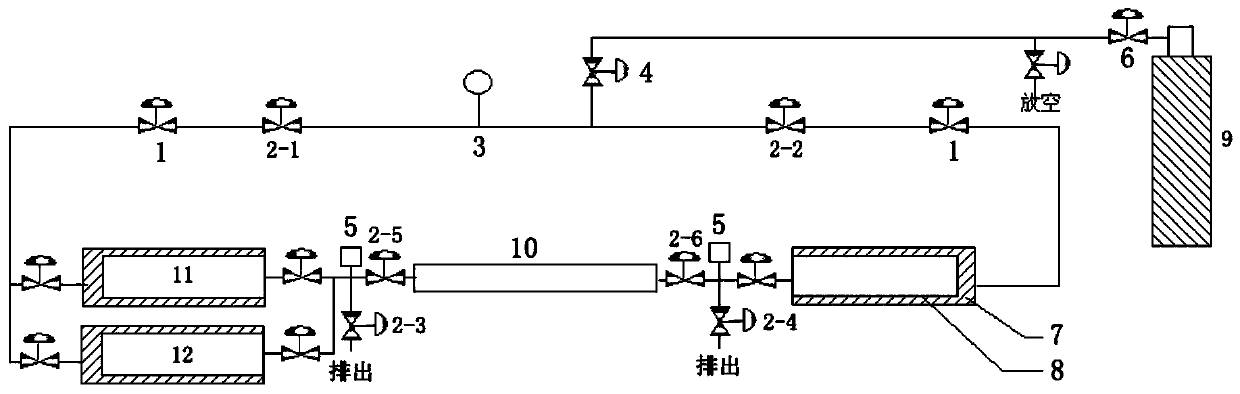

Polymer thermal stability detecting equipment and detecting method

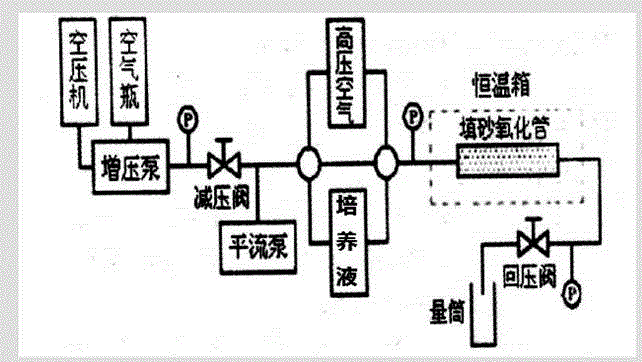

ActiveCN105571988ARealization of thermal stability detectionAddresses the lack of assessment of the impact of multiple conditions combined with realityFlow propertiesPorous mediumEngineering

The invention discloses polymer thermal stability detecting equipment and a polymer thermal stability detecting method. The inlet of a first group of constant speed displacement pump is connected to a first displacing fluid storage device; the outlet of the first group of constant speed displacement pump is connected to the inlet of a first intermediate container group; the outlet of the first intermediate container group is connected to the inlet of a homogeneous sand-filled pipe series group; the outlet of the homogeneous sand-filled pipe series group is connected to the inlet of a second intermediate container group; the outlet of the second intermediate container group is connected to the outlet of a second group of constant speed displacement pump; the inlet of the second group of constant speed displacement pump is connected to a second displacing fluid storage device; the homogeneous sand-filled pipe series group is placed in a temperature constant box; a porous medium short section is mounted between the inlet of the homogeneous sand-filled pipe series group and the outlet of the first intermediate container group. According to the polymer thermal stability detecting equipment and the polymer thermal stability detecting method, the influence on the assessment of polymer stability caused by the lack of combination of a plurality of actual conditions in the prior art is effectively solved, and the dynamic stability detection of a polymer solution is realized.

Owner:PETROCHINA CO LTD

Fracturing method of cluster-type horizontal wall

InactiveCN106481327AEnhanced overall recoveryReduce seepage resistanceFluid removalCluster typeEnvironmental geology

The invention relates to a fracturing method of a cluster-type horizontal wall. The cluster-type horizontal wall comprises multiple horizontal sections located in the same storage layer and parallel mutually. The fracturing method includes the steps: selecting two lines of opposite fracturing point groups on the horizontal sections, wherein the fracturing point groups are formed by multiple fracturing points partitioned along the horizontal and the fracturing points of the neighboring horizontal sections are staggered mutually; implementing fracture on the storage layers on the fracturing points to form multiple cracks. With the method, recovery efficiency of the cluster-type horizontal wall can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

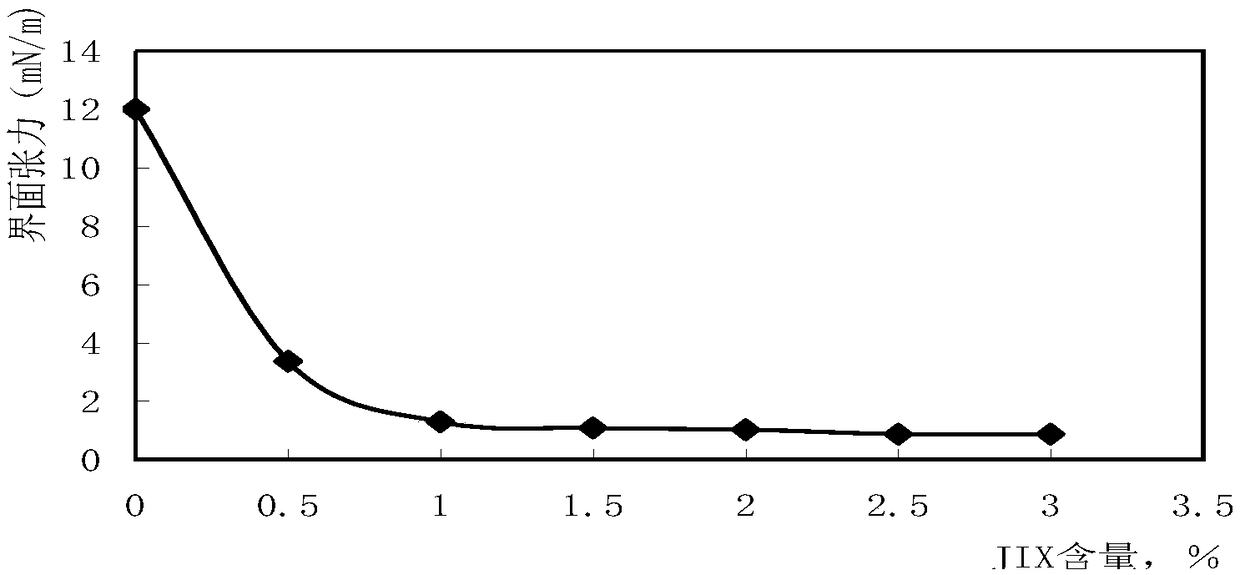

Chelating augmented injection agent for water injection well and preparation method thereof

PendingCN111961456ARealize normal water injectionFacilitated ionizationDrilling compositionActive agentCarboxylic acid

The invention provides a chelating augmented injection agent for a water injection well and a preparation method of the chelating augmented injection agent. The chelating augmented injection agent isprepared from the following raw materials in percentage by mass: 26%-35% of an amino cartankylic acid chelating agent, 10%-14% of a penetrating agent, 12%-16% of an ampholytic surfactant, 14%-18% of anonionic surfactant, 18%-22% of a mutual solvent and the balance of water. The chelating augmented injection agent for the water injection well can be used for treating water injection wells with poor injection water quality, stratum scaling and high residual oil saturation and water injection wells with long-term produced water reinjection, resulting in high water injection pressure and seriousunder-injection of the water injection wells or long-term water injection under-injection wells. The crude oil stripped from the rock surface is dispersed into small oil drops under the action of thesurfactant, and the flowing capacity of the crude oil passing through the throat is improved, so that the reservoir permeability is improved, the stratum is dredged, the oil well liquid supply capacity is recovered, and normal water injection of a water well is realized.

Owner:PETROCHINA CO LTD

Synergist for soil acid acidification, and preparation method and use method thereof

InactiveCN111560242AIncrease the solubility productAchieve dissolutionDrilling compositionFerric hydroxideSoil science

The invention discloses a synergist for soil acid acidification, and a preparation method and a use method thereof. The synergist is prepared from, by mass, 25-38% of a barium sulfate strontium scalesolubilizer, 18-25% of a polycarboxylic acid dispersant, 5-15% of a penetrant, 12-20% of a mutual solvent, and the balance of water. The raw materials in the formula are environment-friendly, non-toxic and harmless, and a small amount of synergist for soil acid acidification is added to a conventional solonic acid solution system to quickly complex with calcium ions, barium ions, iron ions and thelike after an acid liquid reaction, so the solubility product of barium sulfate is improved, dissolution of barium sulfate is achieved, the inhibition performance of acid liquor on secondary precipitation of calcium fluoride, fluoroaluminate, ferric hydroxide and the like is effectively improved, expanded clay mineral crystal lattices are distorted and dehydrated, and blocked stratum pores are recovered. The synergist for soil acid acidification can effectively solve the damage of secondary precipitation caused in the conventional soil acid acidification process to stratums.

Owner:西安长庆化工集团有限公司 +1

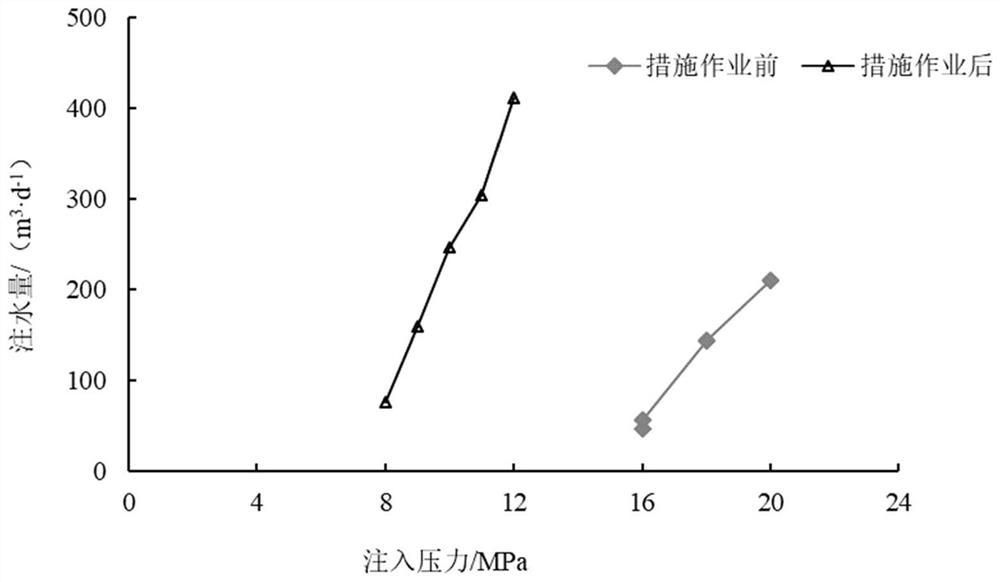

Method for determining lowering of fluid seepage resistance based on nanotechnology

ActiveCN108756873AReduce seepage resistanceMake sure the results are accurate and reliableSurveyFluid removalInjection pressureRelative magnitude

The invention provides a method for determining lowering of fluid seepage resistance based on a nanotechnology. The method comprises the steps that first, according to different injection fluids and injection times of an actual working area, the injection process is divided into three stages, namely, the initial injection stage, the nano-solution injection stage and the replacement liquid injection stage; second, according to the seepage Darcy law and the injection times, the total cumulative injection amount of the fluids in a reservoir under the condition of the different injection times ineach of the three phases is determined; third, according to the linear relation between the total cumulative injection amount of the fluids and the injection pressure time integral, the slope of injection resistance curves of the three stages is determined; fourth, the resistance coefficient of the fluid in the reservoir in the nano-solution injection stage and the residual resistance coefficientof the fluid in the reservoir in the replacement liquid injection stage are determined correspondingly; and fifth, according to the relative magnitude relation of the two resistance coefficients in the fourth step, the effects of resistance lowering and injection increasing of the nanotechnology are evaluated. The determining method is accurate, reliable and high in practicability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

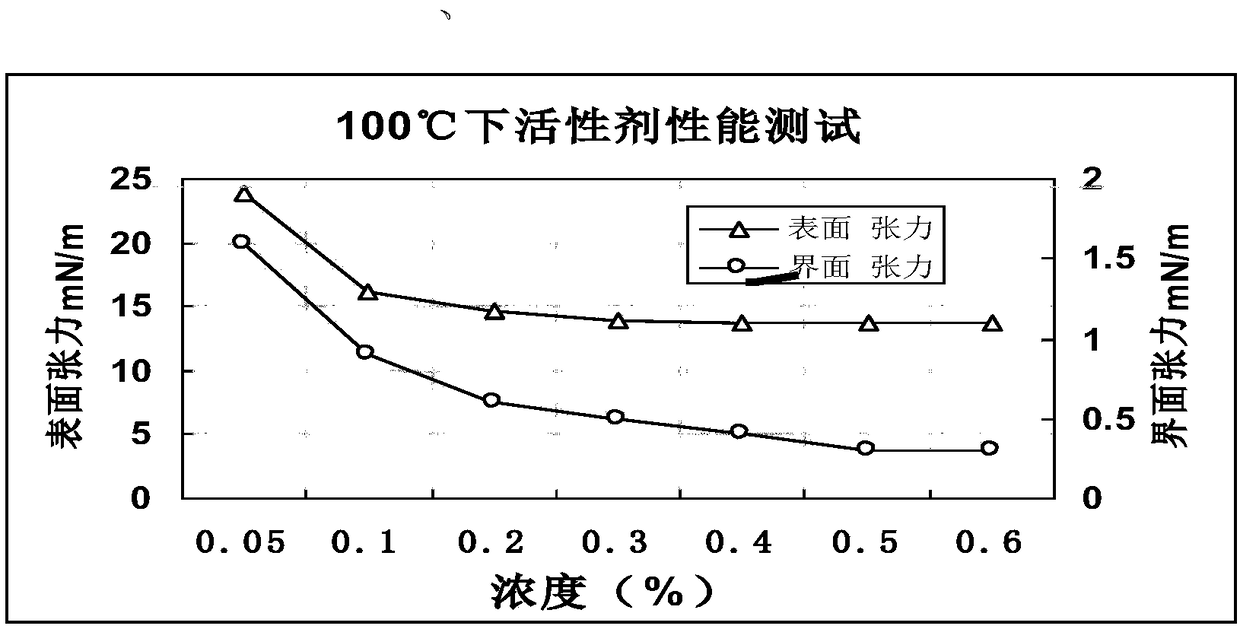

Surfactant for improving water injection efficiency of low-permeability oil reservoir as well as preparation method and application

ActiveCN113897190AReduce water injection pressureReduce interfacial tensionFluid removalDrilling compositionCapillary pressureActive agent

The invention discloses a surfactant for improving the water injection efficiency of a low-permeability reservoir as well as a preparation method and application of the surfactant, and belongs to the technical field of surfactants for oil and gas field exploitation. The surfactant is prepared from the following components in parts by weight: 1 to 5 parts of a nonionic surfactant and 25 to 50 parts of a cationic surfactant. The surfactant can effectively reduce the water injection pressure of a water injection well, avoid water injection pressure rise caused by a large amount of emulsification of crude oil, improve the water injection capacity of the water injection well, change rock wettability, reduce capillary pressure and inhibit damage of precipitation of carbonates such as calcium carbonate to stratums; and meanwhile, the oil-water interfacial tension can be effectively reduced, excellent surface performance is achieved, and improvement of the crude oil recovery rate is facilitated.

Owner:SHANDONG DESHI CHEM IND CO LTD +1

Augmented injection liquid, preparation method and application thereof

ActiveCN112852395AReduce seepage resistanceIncrease the validity period of measuresFluid removalDrilling compositionNano siliconMetabolite

The invention discloses an augmented injection liquid, a preparation method and application thereof. The augmented injection liquid comprises a carrying liquid and a nanometer silicon material, wherein the carrying liquid comprises the following components by weight: 0.1-1% of a biological surfactant, 0.1-2% of a biological enzyme, 0.5-2% of a cosolvent, 0.01-0.1% of microbial polysaccharide, and the balance of water, wherein the weight ratio of the carrying liquid to the nano silicon material is 100: (0.01-10). According to the augmented injection liquid, microbial metabolites are used as a dispersion system, synthesis and performance of a nano resistance-reducing augmented injection material are utilized, and technical mechanisms such as wetting reversal, adsorption, scouring resistance and pore and permeability increase of a nano material are comprehensively applied to reduce seepage resistance near a shaft, so that the validity period of measures is greatly prolonged.

Owner:CHINA OILFIELD SERVICES

Shale gas front complex seam net constructing and fracturing technology

ActiveCN111706310ASave fracturing timeAvoid pollutionOther gas emission reduction technologiesFluid removalPre treatmentShale gas

The invention discloses a shale gas front complex seam net constructing and fracturing technology. The technology comprises the flows that a fracturing channel is opened; front seam making pretreatment liquid is pumped; micro cracks are made; main branch cracks are made; the front seam making pretreatment liquid is pumped; the micro cracks are made; the main branch cracks are made; main cracks aremade; and displacing liquid is pumped. By pumping the front seam making pretreatment liquid to reservoir stratums, the seam net complexity of the reservoir stratums is enlarged, thus a seam nut is complicated in advance, and the gas producing rate and the accumulative output are increased. Along with the front seam making pretreatment liquid pushed into the deep portions of the stratums, as shaleof the reservoir stratums is hydrophilic, the displacement effect is generated on associated gas and adsorbed gas among the reservoir stratums and seams, and the gas production rate and the yield arefurther increased. After the front seam making pretreatment liquid is pumped, cracking is carried out in time, the situation that a high-pressure liquid shielding area formed by pumping the front seam making pretreatment liquid disappears due to permeation and dispersion of the liquid can be prevented, the cracking time of each reservoir stratum is saved, in addition, excessive hydration expansion can be prevented, and pollution to the reservoir stratums is avoided.

Owner:JEREH ENERGY SERVICES

A polymer thermal stability detection equipment and detection method

ActiveCN105571988BRealization of thermal stability detectionAddresses the lack of assessment of the impact of multiple conditions combined with realityFlow propertiesPorous mediumEngineering

The invention discloses polymer thermal stability detecting equipment and a polymer thermal stability detecting method. The inlet of a first group of constant speed displacement pump is connected to a first displacing fluid storage device; the outlet of the first group of constant speed displacement pump is connected to the inlet of a first intermediate container group; the outlet of the first intermediate container group is connected to the inlet of a homogeneous sand-filled pipe series group; the outlet of the homogeneous sand-filled pipe series group is connected to the inlet of a second intermediate container group; the outlet of the second intermediate container group is connected to the outlet of a second group of constant speed displacement pump; the inlet of the second group of constant speed displacement pump is connected to a second displacing fluid storage device; the homogeneous sand-filled pipe series group is placed in a temperature constant box; a porous medium short section is mounted between the inlet of the homogeneous sand-filled pipe series group and the outlet of the first intermediate container group. According to the polymer thermal stability detecting equipment and the polymer thermal stability detecting method, the influence on the assessment of polymer stability caused by the lack of combination of a plurality of actual conditions in the prior art is effectively solved, and the dynamic stability detection of a polymer solution is realized.

Owner:PETROCHINA CO LTD

Micro packed bed bionic reactor

ActiveCN105727843AHigh mechanical strengthReduce seepage resistanceChemical/physical processesProcess engineeringHeat transfer

The invention discloses a micro packed bed bionic reactor.The micro packed bed bionic reactor comprises a reactor body.Artery channels for air inflow, vein channels for air outflow and catalyst packed bed layers between the artery channels and the vein channels are formed in the reactor body.The reactor body is of a porous structure with a permeable wall.The artery channels and the vein channels are spaced and staggered and each occupy at least one single-end-closed pore channel.The two ends of pore channels in the catalyst packed bed layers are closed, and the closed pores are packed with catalyst granules.The micro packed bed bionic reactor has the advantages of being small in pressure drop, good in heat transfer property, high in catalyst effectiveness coefficient and the like and is very suitable for being applied to a rapid gas-solid catalytic reaction.

Owner:ZHEJIANG UNIV

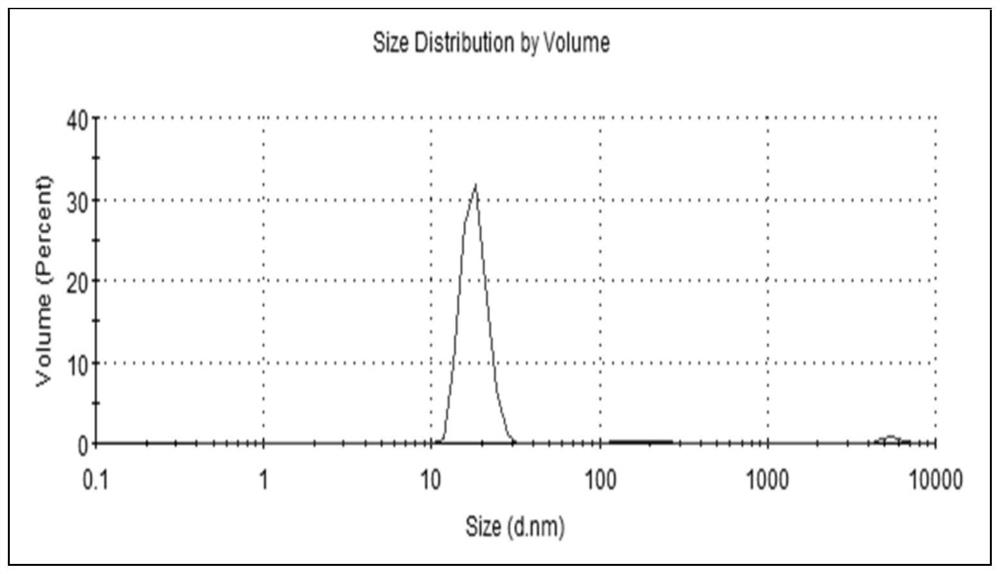

Method for improving oil well productivity through nano system composite CO2 huff and puff

PendingCN113882841AIncrease production capacitySolving the problem of declining oil productionFluid removalDrilling compositionAsphaltene precipitationLipophilicity

The invention discloses a method for improving oil well productivity through nano system composite CO2 huff and puff. The method comprises the following steps of (1) injecting a nano solution slug: preparing a water-based nano solution with the solid content of 0.005-0.01%, and injecting the water-based nano solution into a stratum from an oil well oil jacket annulus; (2) injecting a liquid CO2 slug: injecting the liquid CO2 slug into a stratum from the oil well oil jacket annulus, wherein the mass ratio of the injected CO2 to the water-based nano solution is (1.5-2.2): 1; and (3) stopping injection and soaking the well, specifically, after injection of the liquid CO2 is completed, closing the well for soaking, and the soaking time is 10-20 days. According to the method, nano-particles can be adsorbed on the surface of rock, the lipophilicity of the nano-particles is changed into lipophobicity, the deposition of asphaltene is effectively prevented, the damage of asphaltene precipitation to a reservoir in the CO2 spitting process is greatly reduced, and the fluidity of crude oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

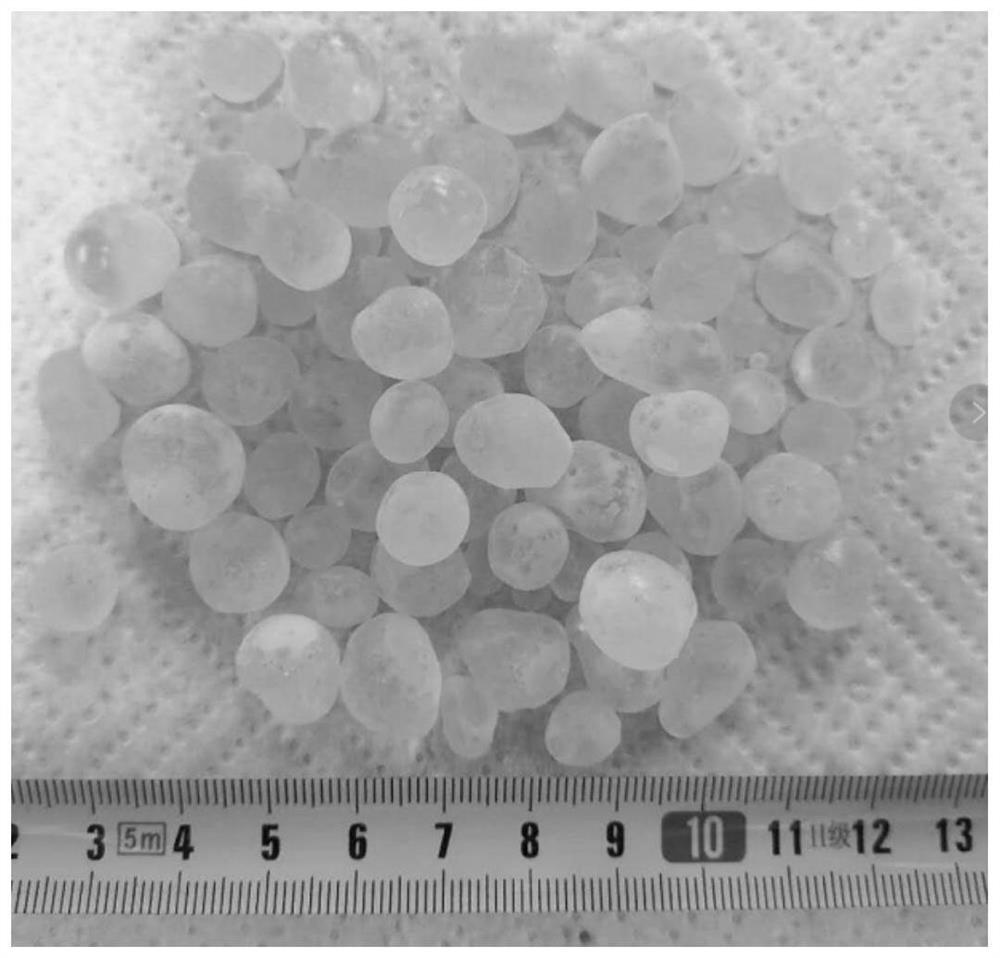

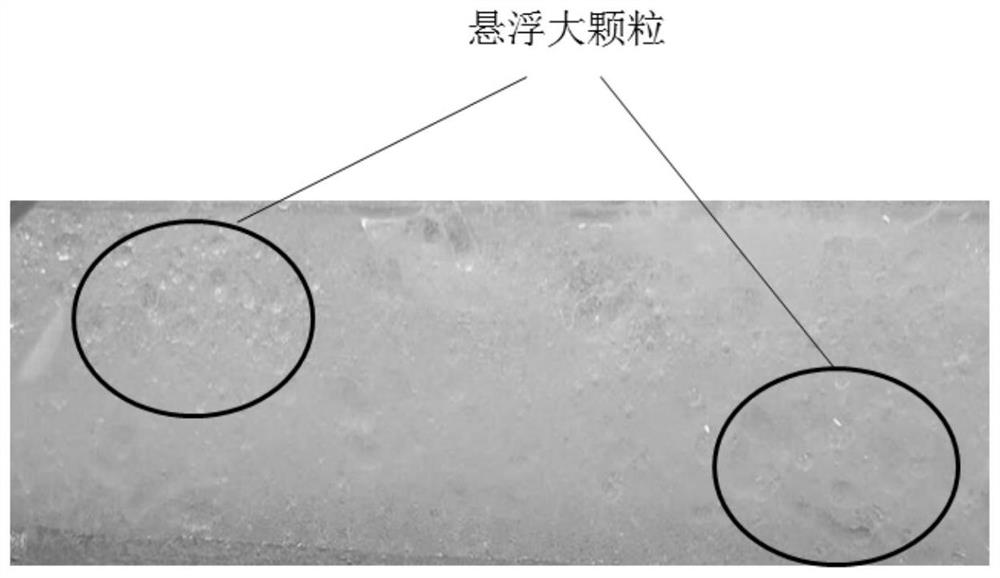

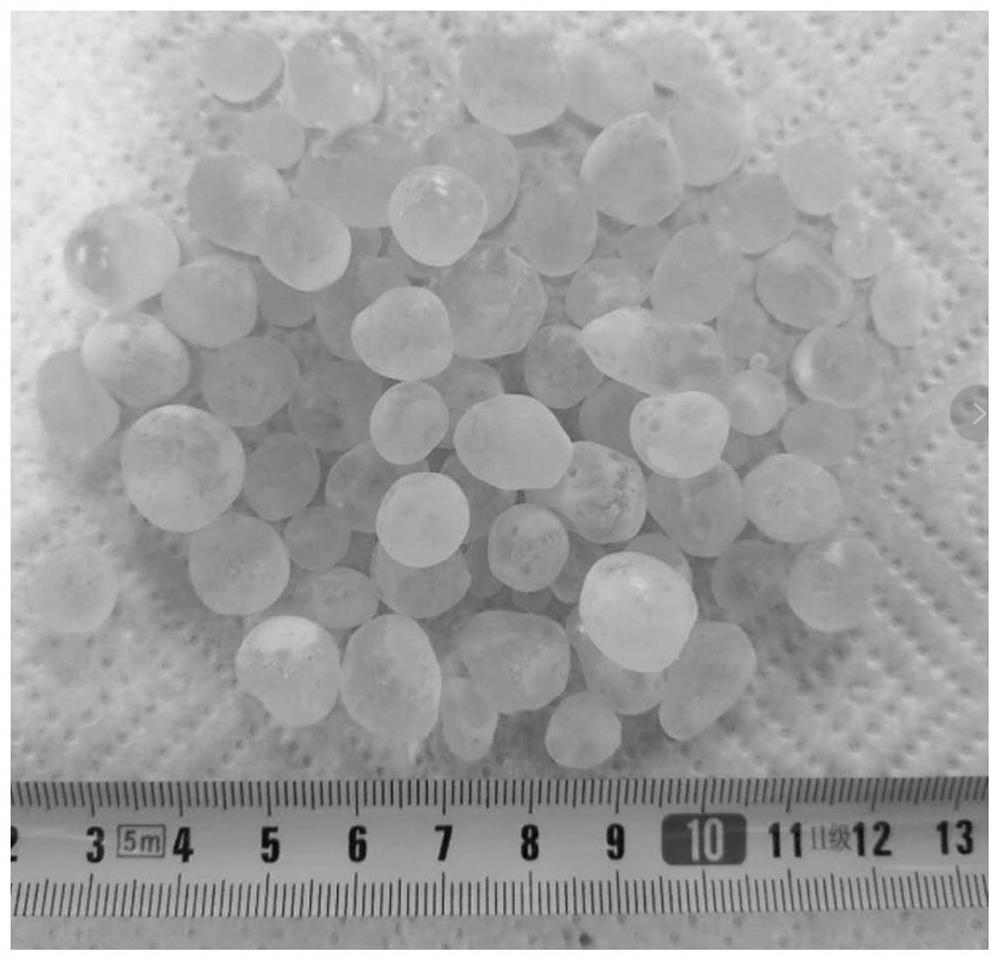

Liquid self-supporting high-speed channel fracturing fluid and experimental method

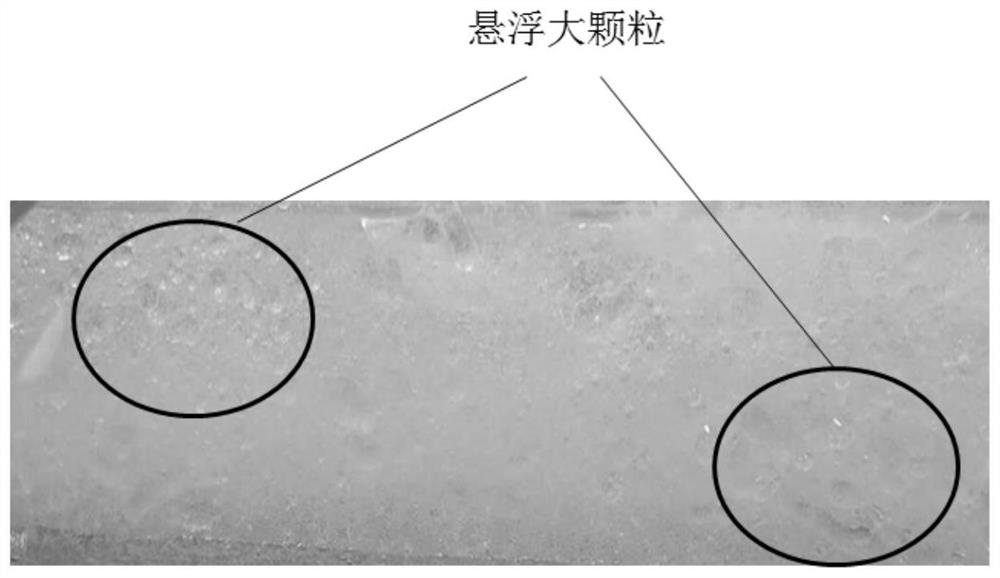

ActiveCN111718703ALow costAvoid the risk of sand pluggingFluid removalDrilling compositionFracturing fluidEconomic benefits

The invention provides a liquid self-supporting high-speed channel fracturing fluid and an experimental method. The mass ratio of a fluid A to a fluid B in the fracturing fluid is 1: (3-19), wherein the liquid A comprises resin, a curing agent and a suspension dispersing agent; the liquid B comprises conventional fracturing liquid, a density regulator and a suspension dispersing agent, and the liquid A is suspended and dispersed in the liquid B; the liquid self-supporting fracturing fluid does not need a solid-phase propping agent, an existing conventional fracturing mode is changed, the costof the solid-phase propping agent is saved, the construction process is reduced, and the sand blocking risk caused by the solid-phase propping agent is avoided. Centimeter-level cured particles can beformed, the compressive strength is high, and the defect that a traditional low-density proppant is prone to being compacted is overcome. And the solid-phase system A liquid accounts for less ratio,so that the fracturing cost can be reduced, and economic benefits can be obtained. Uniformly suspended and dispersed centimeter-level solid particles formed by the liquid self-supporting fracturing fluid can form a seepage channel with high flow conductivity, reduce the seepage resistance, enlarge the crack control area and improve the yield.

Owner:青岛大地新能源技术研究院

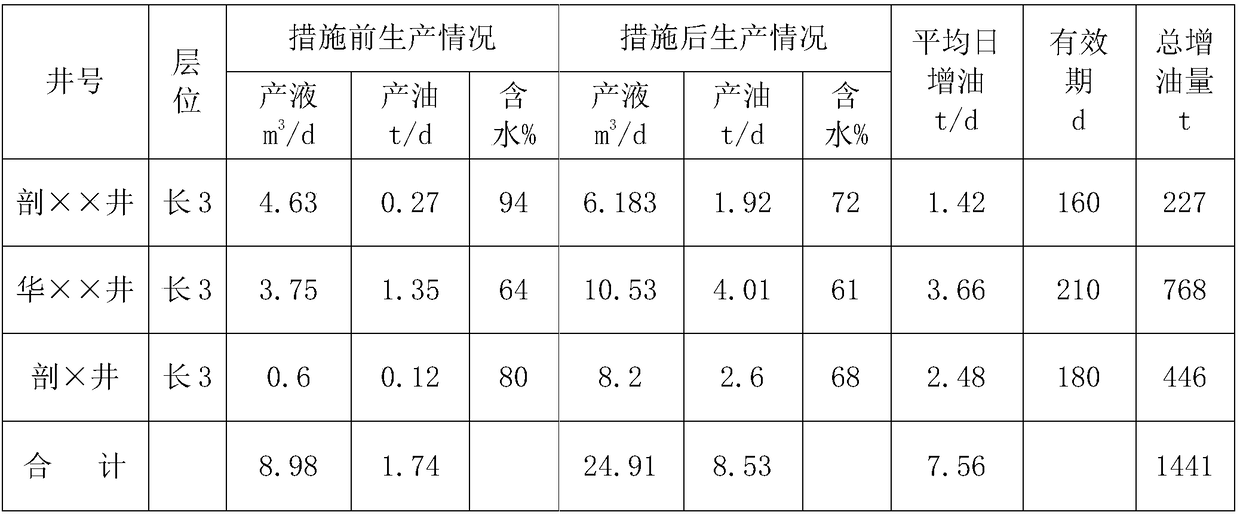

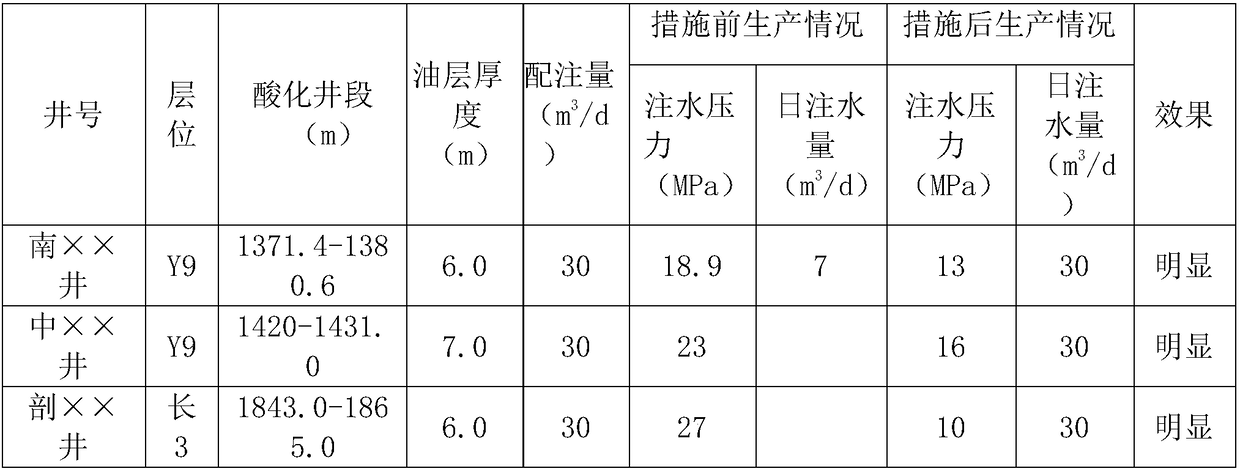

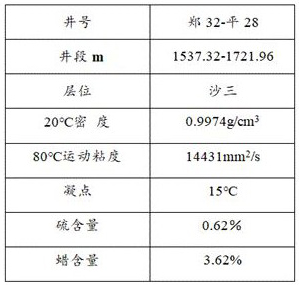

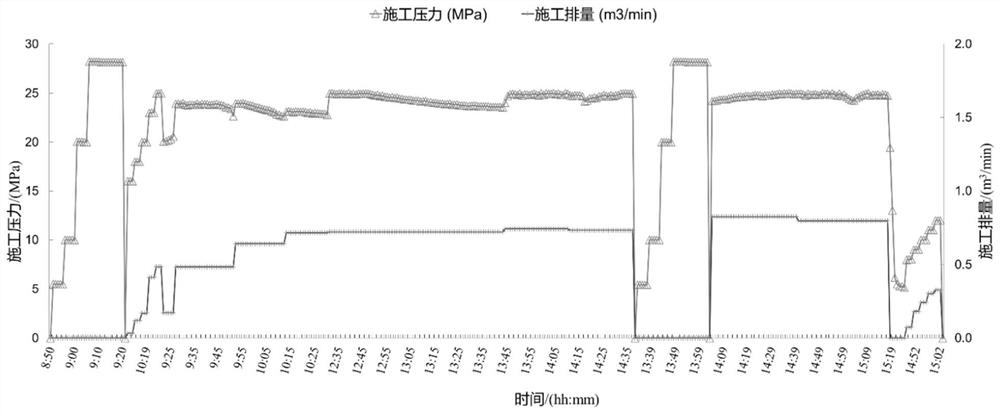

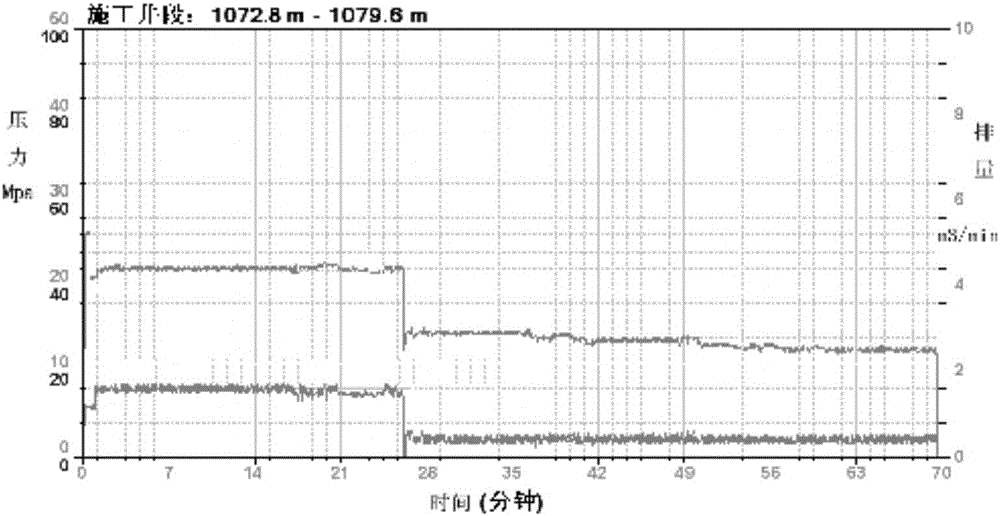

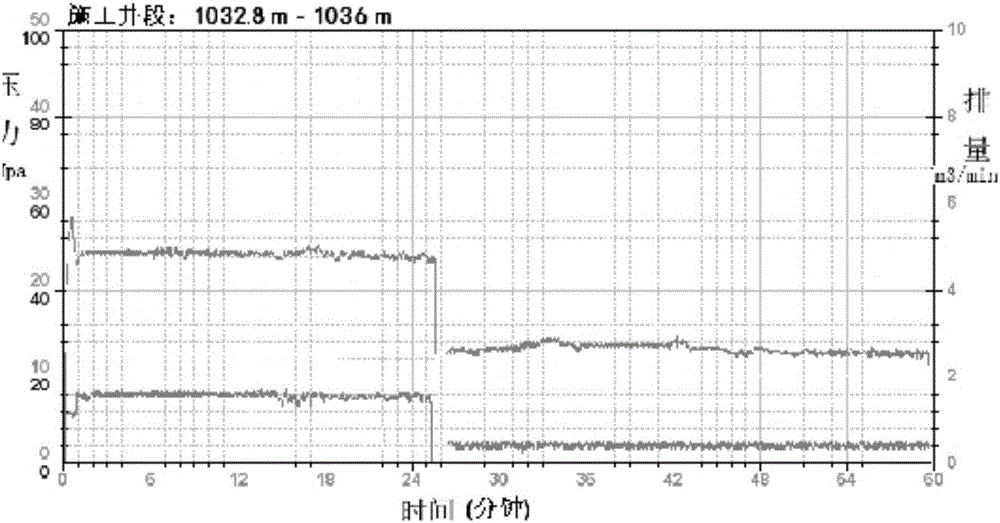

Hydraulic plug removal acidizing technology

The invention provides a hydraulic plug removal acidizing technology. The technology includes the following steps that firstly, a wellhead is detached; secondly, an original well pipe column is lifted out; thirdly, a hydraulic plug removal acidizing pipe column is put down; fourthly, magnetic positioning is conducted; fifthly, high-pressure hydraulic plug removal acidification is conducted; sixthly, a ground pressure test is conducted, wherein the ground pressure test is exerted at 55 Mpa for 10 min, and the test is passed if no puncture or leakage exists; seventhly, a first layer is subjected to hydraulic plug removal acidification; eighthly, steel balls are thrown to hit a sliding sleeve; ninthly, a second layer is subjected to hydraulic plug removal acidification; tenthly, the steel balls are thrown to hit the sliding sleeve; eleventhly, a third layer is subjected to hydraulic plug removal acidification; twelfthly, a well is closed, a reaction is conducted for 12 hours, and then liquid is reversely drained; thirteenthly, the plug removal acidizing pipe column is lifted up; fourteenthly, puncturing washing and measuring are conducted; and fifteenthly, a completion pipe string is put down, wherein a layered water distribution tool and an anti-corrosion oil pipe are put down, and sealing grease is painted; and the wellhead is mounted, and the technology is ended. By the adoption of the technology, a physical method is fully used for increasing the effective penetrating distance of acid liquid in a stratum, the stratum seeping performance is improved within a relatively large range, and therefore the purposes of yield increase and injection increase are achieved.

Owner:DAQING XINZHIHE TECH

Pulse type fracturing construction process for liquid self-supporting highway

ActiveCN111827950ALow costAvoid the risk of sand pluggingCleaning apparatusFluid removalHigh densityPulsed mode

The invention provides a pulse type fracturing construction process for a liquid self-supporting highway. The process includes the following steps of preparing curable liquid A, low-density carrying liquid B and high-density middle-roof liquid B' on site when fractures are made, mixing the liquid A with the liquid B immediately after the fractures are made, injecting the A / B mixed liquid and the liquid B' into a stratum in a pulse mode until fracturing ends, injecting displacing liquid into a shaft to replace the A / B mixed liquid and the liquid B' in the stratum, and then stopping a pump, closing a well and holding the pressure for 40-180 min. A mixing method of the liquid A and the liquid B includes the step of jetting the liquid A into the liquid B, wherein a jet port is located below the liquid surface of the liquid B, and the liquid A forms evenly-distributed centimeter-level liquid particles in the liquid B. The process can reduce the consumption of the liquid A, further improvesthe suspension property and carrying property of the liquid B, further enhances the flow guide capacity, is beneficial for cleaning a well wall or an oil tube, omits the wall hanging property, and reduces the construction risk.

Owner:青岛大地新能源技术研究院

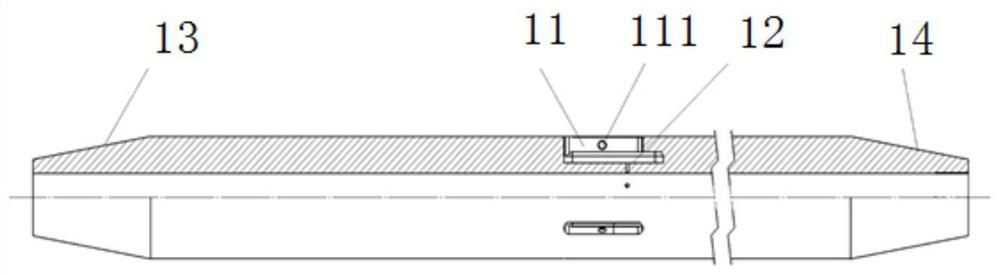

Hole positioning and cleaning assembly and unconventional reservoir hole positioning and spraying tool and method

ActiveCN112502647ARealize hole location cleaning methodReduce seepage resistanceFluid removalFlushingPhysicsField development

The invention relates to the technical field of oil and gas field development, and discloses a hole positioning and cleaning assembly and an unconventional reservoir hole positioning and spraying tooland method. The hole positioning and cleaning assembly comprises a rack and a positioning piece, wherein the rack is used for being arranged in an axial groove in the outer surface of a tubular column in an axial moving mode, a first jet hole and a second jet hole are formed in the length direction of the rack at an interval, the positioning piece is used for being rotationally arranged on the outer surface of the tubular column and comprises a tooth part meshed with the rack and an extension arm rotating along with the tooth part, and when the positioning piece rotates, the rack can be driven to move, so that the first jet hole or the second jet hole communicates with a through hole in the bottom wall of the axial groove. The unconventional reservoir hole positioning and jetting tool using the hole positioning and cleaning assembly is accurate in perforation positioning and capable of thoroughly removing blockages in perforations, secondary transformation of the perforations can be achieved, the near-wellbore-zone seepage resistance of wellbores is effectively reduced, and therefore the productivity of the wellbores is recovered, the structure is simple, and the working efficiency is high.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A multi-stage temporary plugging deep network acid fracturing method

The invention discloses a multi-stage temporary plugging depth network acid fracturing method, and belongs to the technical field of oil and gas well production increment and improvement. The method comprises the steps that bridge plugging is formed in an artificial fracture through fracture interior temporary plugging material liquid, the artificial fracture is forced to form multiple branch fractures, and main acid is used for etching the fracture; bridge plugging is formed in an artificial fracture opening through fracture opening temporary plugging material liquid, the fracture is forced to be cracked at the new position of a well wall, and interlayer steering is achieved. The multi-stage temporary plugging depth network acid fracturing method has the advantages of being simple in technology, convenient to operate and the like, a complex fracture network is formed in different permeability zones in carbonatite multi-layer, thick-layer or horizontal well long well sections through the principle of combining fluid power self serching and manual control, the oil and gas region communication probability is increased, the oil and gas percolating resistance is reduced, the single-well yield is improved, and a carbonate reservoir is efficiently and economically developed.

Owner:SOUTHWEST PETROLEUM UNIV +2

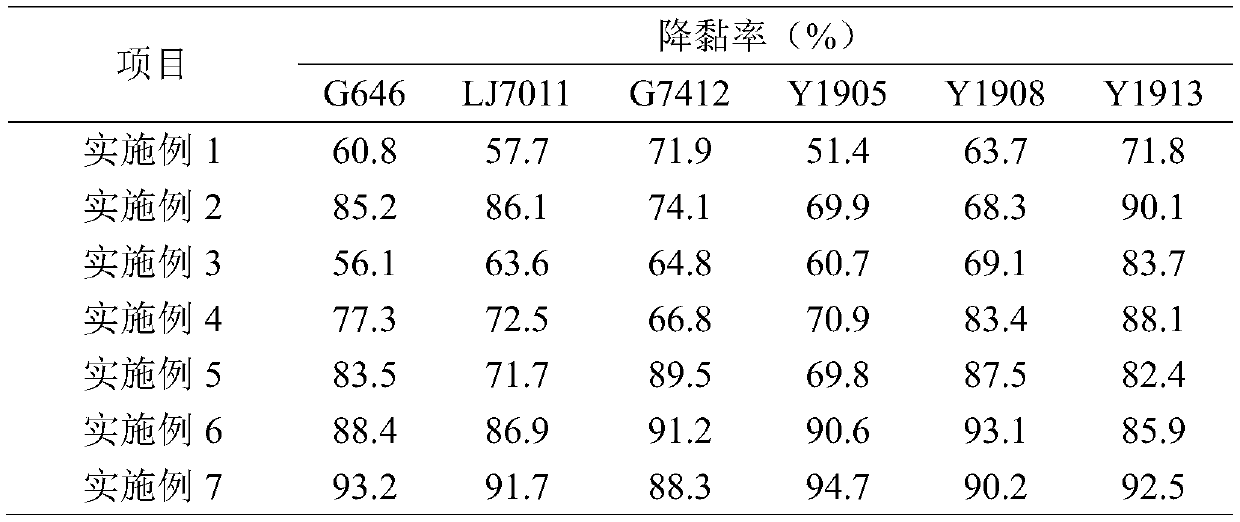

Viscosity-reducing and drainage-aiding composition for heavy oil, viscosity-reducing and drainage-aiding agent, preparation method and application

ActiveCN106967404BLower dynamic viscosityImprove wettabilityFluid removalDrilling compositionSulfonateRock core

The invention discloses a viscosity-reducing and cleanup composition for thickened oil, and a viscosity-reducing and cleanup additive and a preparation method and application thereof, belonging to the technical field of oil exploitation. The viscosity-reducing and cleanup composition comprises, by mass, 0.1 to 2 parts of a fluorocarbon surfactant, 0.5 to 1 part of a hydrocarbon surfactant, 0.25 to 1 part of an auxiliary agent and 0.05 to 0.3 part of the cleanup additive, wherein the fluorocarbon surfactant is one or more selected from a group consisting of FC-01, FC-02, FC-04-1, FC-06, FC-08 and FC-11; the hydrocarbon surfactant is one or more selected from a group consisting of sodium alpha-olefin sulfonate, SYHSY, SDBS and YN; and the cleanup additive is one or more selected from a group consisting of F370, F633 and SH6. The viscosity-reducing and cleanup composition has low surface and interfacial tension, can effectively reduce the dynamic viscosity of thickened oil, improves surface wettability of a rock core and enhances water recovery rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graded displacement oil extraction method for conglomerate oil reservoir chemical flooding reservoir

ActiveCN112780242AReduce concentrationRealize graded displacementFluid removalCapillary pressureCapillary Tubing

The invention provides a graded displacement oil extraction method for a conglomerate oil reservoir chemical flooding reservoir. The graded displacement oil extraction method comprises the following steps that the pore throat radius of each pervious bed is obtained to obtain a plurality of pore throat radiuses; residual resistance coefficients, corresponding to the multiple pore throat radiuses, of a displacement medium are obtained, and seepage resistance corresponding to each pore throat radius is determined according to capillary pressure of the pore throat radiuses; a displacement pressure gradient is determined according to the parameters of an oil reservoir injection-production system; injection parameters of the displacement medium are determined according to the displacement pressure gradient and the seepage resistances of a plurality of permeable layers; and according to the injection parameters of the displacement medium, the displacement medium is injected into the multiple permeable layers through an injection well, and crude oil in the multiple permeable layers is displaced into an oil producing well to be produced. According to the technical scheme, the problems that in the related technology, chemical agents in the conglomerate oil reservoir easily enter the large pore throats to form high-permeability layer agent channeling and difficultly enter the medium and small pore throats to displace crude oil in medium and low permeability layers are effectively solved.

Owner:PETROCHINA CO LTD

Liquid self-supporting highway fracturing construction process

The invention provides a liquid self-supporting highway fracturing construction process, comprising the following steps: (1) preparing liquid B1 from conventional fracturing liquid and a density adjusting agent according to a certain weight ratio; (2) manufacturing cracks by using the liquid B1; (3) preparing liquid A and liquid B during the manufacturing of the cracks: mixing resin or a resin diluent with a suspension dispersant, adding a curing agent, and performing uniform mixing to obtain the liquid A; uniformly mixing the liquid B1 with the suspension dispersant or uniformly mixing the liquid B1 with the suspension dispersant and a crosslinking agent to obtain the liquid B; (4) after crack manufacturing is completed, jetting the liquid A immediately into the liquid B through a plurality of jet orifices, the jet orifices being located below the liquid surface of the liquid B, and injecting the A and B mixed liquid into a stratum; and (5) displacing all the A and B mixed liquid intothe stratum by using displacement liquid, and building the pressure for 40 to 180 min. The process solves the problem, in the prior art, that the stratum is easily damaged because the liquid A is distributed in blocks and pieces, and can achieve comprehensive crack self-supporting and highway fracturing effects.

Owner:青岛大地新能源技术研究院

A determination method for reducing fluid seepage resistance based on nanotechnology

ActiveCN108756873BReduce seepage resistanceMake sure the results are accurate and reliableSurveyFluid removalEngineeringNanotechnology Techniques

The present invention provides a method for determining fluid seepage resistance based on nanotechnology, including step 1, dividing the injection process into three stages according to the injection fluid and injection time of the actual work area, namely the initial injection stage, nano solution injection stage and replacement fluid injection stage; step 2, according to seepage Darcy's law and injection time, determine the total cumulative injection volume of fluid in the reservoir under the condition of different injection time in each stage in each of the three stages; step 3, according to The linear relationship between the total cumulative injection volume of the fluid and the time integral of the injection pressure determines the slope of the injection resistance curve in the three stages; Step 4, respectively determines the resistance coefficient of the fluid in the reservoir during the nano-solution injection stage and the replacement fluid injection stage The residual resistance coefficient of the fluid in the reservoir; step five, according to the relative size relationship between the two resistance coefficients described in step four, evaluate the effect of nanotechnology on reducing resistance and increasing injection. The determination method is accurate, reliable and practical.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Well pattern system and construction process of well pattern system

PendingCN114075964AReduce seepage resistanceImprove displacement efficiencyFluid removalMultiple injectionMining engineering

The embodiment of the invention discloses a well pattern system and a construction process of the well pattern system and belongs to the technical field of oil and gas exploitation. The well pattern system comprises a production well penetrating through a plurality of to-be-developed layers of a reservoir and multiple injection wells, wherein a polygon is defined by the multiple injection wells, the production well is located in an area defined by the multiple injection wells, each injection well is a vertical well, each injection well penetrates through at least one to-be-developed layer, and each injection well extends in the penetrating to-be-developed layer to form a first crack section; and the distance from each injection well to the production well in the layer to be developed is greater than the minimum distance from the first crack section of the corresponding injection well to the production well. The well pattern system is advantaged in that when the gas is injected through the injection well, the gas can be diffused in a large range in the to-be-developed layer based on the first crack section, so seepage resistance of the gas in the to-be-developed layer is remarkably reduced, displacement efficiency of the gas to petroleum is improved, and the oil and gas exploitation efficiency is improved.

Owner:PETROCHINA CO LTD

Method for controlling bottom water coning by foam

The invention discloses a method for controlling oil well bottom water coning by foam. In the method, a mass of foam is injected at the oil-water boundary of an oil well so that a foam plugging area is formed. In the technical technology of controlling oil well bottom water coning by foam in the invention, a mass of foam is injected at the oil-water boundary of the oil well so that a stable foam plugging band is formed. The injected foam has the characteristic of selective water plugging that the foam is broken when meeting oil and is stable when meeting water, so that the foam is comparatively stable at the oil-water boundary and is not easy to be broken and raising of bottom water can be efficiently plugged; and at an oil reservoir, the foam stability becomes weakened due to damage of the oil to the foam, and the foam is easy to be broken, but the output of crude oil in the oil layer is not influenced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A pulse fracturing construction technology for realizing liquid self-supporting high-speed channel

ActiveCN111827950BLow costAvoid the risk of sand pluggingCleaning apparatusFluid removalHigh densityInjection port

Owner:青岛大地新能源技术研究院

Shale gas pre-complex fracture network construction fracturing technology

ActiveCN111706310BSave fracturing timeAvoid pollutionOther gas emission reduction technologiesFluid removalShale gasNetwork construction

The invention discloses a fracturing technology for shale gas pre-complex fracture network construction. Place fracture-forming pretreatment fluid-create micro-fractures-create main branch fractures-create main fractures-pump displacement fluid, and by pumping pre-fracture-forming pretreatment fluid into the reservoir, expand the complexity of the fracture network of the reservoir and make the reservoir more complex. The fracture network is complicated in advance, which increases the gas production rate and cumulative production. As the pre-fracture pretreatment fluid is pushed into the deep formation, because the shale in the reservoir is hydrophilic, it will affect the associated gas and the interlayer fractures. Adsorbed gas produces displacement, which further improves gas production rate and production; after pumping pre-fracture pretreatment fluid, fracturing in time can prevent the high-pressure liquid barrier area formed by pre-fracture pretreatment fluid from being pumped. It disappears due to permeation and diffusion, saving the fracturing time of each layer of the reservoir; in addition, it can prevent excessive hydration expansion and avoid reservoir pollution.

Owner:JEREH ENERGY SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com