Method for increasing petroleum production rate of low-permeability oil reservoir through air and microorganism flooding

A technology of air microorganisms and microorganisms, applied in the fields of biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of oil well shutdown and affecting normal production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

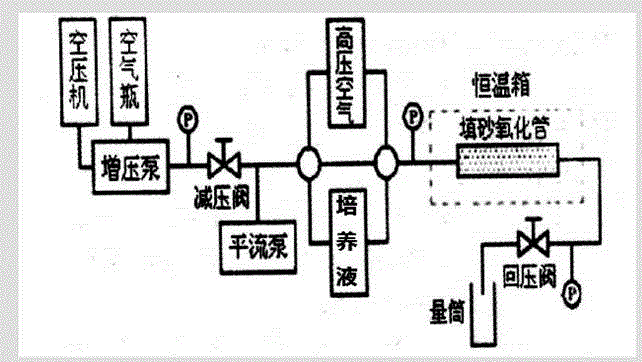

Image

Examples

Embodiment 1

[0032] One, microbial nutrient solution, composition counts by weight percentage: diammonium hydrogen phosphate (industrial product), 0.3%; Yeast powder (industrial product) 0.05%, icing sugar (industrial product) 0.3%, all the other are water.

[0033] 2. The oil well output fluid is deoiled, and the microorganisms in it are used to make the concentration 1×10 7 individual / mL.

[0034] 3. Air.

[0035] 2. Experimental method

[0036] 1. Add the above-mentioned nutrient solution to the production solution to prepare the nutrient solution, and mix it with air during the experiment to investigate the oxygen content of the air injected into the core at the output end under the action of microorganisms.

[0037] 2. Inject air and nutrient solution into the artificial core (40°C) in the form of a slug of 1.5:1, with an injection volume of 0.5 PV (pore volume). After 5 days of storage, water flooding is resumed, and gas is collected at the outlet of the core for gas phase Chromat...

Embodiment 2

[0044] One, microbial nutrient solution, composition counts by weight percentage: diammonium hydrogen phosphate (industrial product), 0.5%; Yeast powder (industrial product) 0.1%, icing sugar (industrial product) 0.5%, all the other are water.

[0045] 2. The oil well output fluid is deoiled, and the microorganisms in it are used to make the concentration 1×10 7 individual / mL.

[0046]3. Air.

[0047] 2. Experimental method

[0048] 1. The nutrient solution is added to the output solution to prepare the nutrient solution, which can be mixed with air during the experiment to investigate the oxygen content of the air injected into the core at the output end under the action of microorganisms.

[0049] 2. Inject air and nutrient solution into the artificial core (40°C) in the form of a slug of 1.5:1, with an injection volume of 0.5 PV (pore volume). After 5 days of storage, water flooding is resumed, and gas is collected at the outlet of the core for gas phase Chromatographic ...

Embodiment 3

[0056] One, microbial nutrient solution, composition counts by weight percentage: diammonium hydrogen phosphate (industrial product), 0.5%; Yeast powder (industrial product) 0.1%, icing sugar (industrial product) 0.5%, all the other are water.

[0057] 2. The oil well output fluid is deoiled, and the microorganisms in it are used to make the concentration 1×10 7 individual / mL.

[0058] 3. Air.

[0059] 2. Experimental method

[0060] 1. Add the nutrient solution to the output solution to prepare the nutrient solution, add crude oil to the nutrient solution at a ratio of 5%, add a rubber stopper to the shaker bottle, put it in a shaker to simulate the reservoir conditions for oxygen-limited experiments, and investigate microorganisms Effect of metabolites on emulsifying crude oil.

[0061] 2. The experimental temperature is 40°C. The shaker rotates at 100 revolutions per minute.

[0062] 3. Experimental results

[0063] After 5 days of cultivation, microorganisms and thei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com