Active mixed acid plugging removal solution applicable to low permeability reservoir

A low-permeability reservoir, mixed acid technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of short validity period, poor effect of plugging removal and injection enhancement, etc., achieve good effect, inhibit clay expansion, improve Effect of Water Phase Permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Weigh 9g of acetic acid, 5g of formic acid, 2g of ammonium difluoride, 2g of boric acid, 1.0g of corrosion inhibitor, 2.0g of mutual solvent, 2.0g of clay stabilizer, 0.5g of anti-wetting active agent and 76.5g of water to prepare acid hydrolysis Blockage.

Embodiment 2

[0013] Weigh 10g of acetic acid, 7g of formic acid, 3g of ammonium difluoride, 4g of boric acid, 2.0g of corrosion inhibitor, 4.0g of mutual solvent, 2.0g of clay stabilizer, 1.0g of anti-wetting active agent and 67.0g of water to prepare acid hydrolysis Blockage.

Embodiment 3

[0015] Weigh 9.5g of acetic acid, 6g of formic acid, 2.5g of ammonium difluoride, 3g of boric acid, 1.5g of corrosion inhibitor, 3.0g of mutual solvent, 2.0g of clay stabilizer, 0.7g of dewetting active agent and 71.8g of water and mix to prepare Acid unblocking fluid.

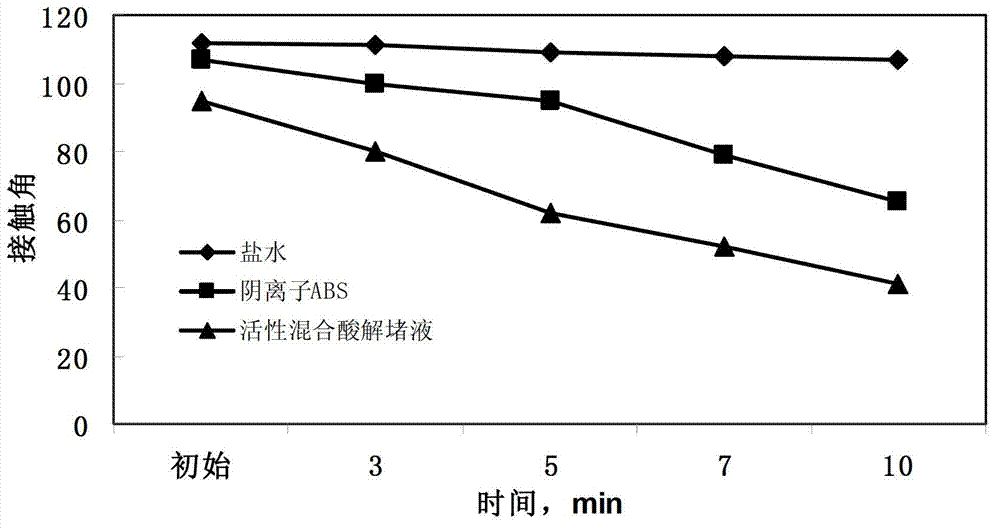

[0016] Performance evaluation of the active mixed acid plugging fluid suitable for low-permeability reservoirs:

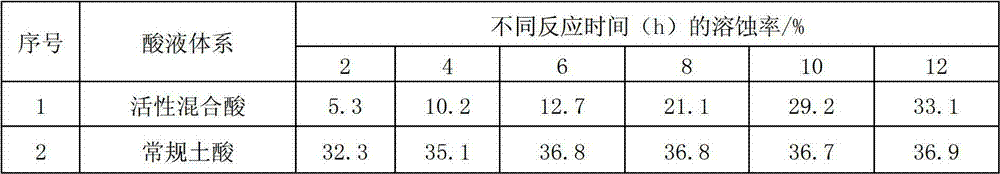

[0017] 1. Evaluation of corrosion ability and retarding performance

[0018] A certain weight (1g) of rock cuttings is ground into a powder of 100 meshes, and placed in a certain amount (10ml) of acid solution, and its dissolution rate is measured at 65°C and at different times. Table 1 lists the comparison between the active mixed acid of the present invention and conventional earth acid in corrosion inhibition performance and dissolution ability.

[0019] Table 1 Dissolution experiment data

[0020]

[0021] It can be seen from Table 1 that after 4 hours of reaction, the reaction between so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com