Stimulation method and system for enhancing oil production

a technology of oil production and stimulation method, applied in the direction of survey, drilling pipe, borehole/well accessories, etc., can solve the problems of increasing reservoir contact with the production well, substantial pressure drop through the well, fluids cannot effectively transport or place proppant deep in the formation, etc., to achieve the effect of altering the wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will now be described with reference to the accompanying drawings.

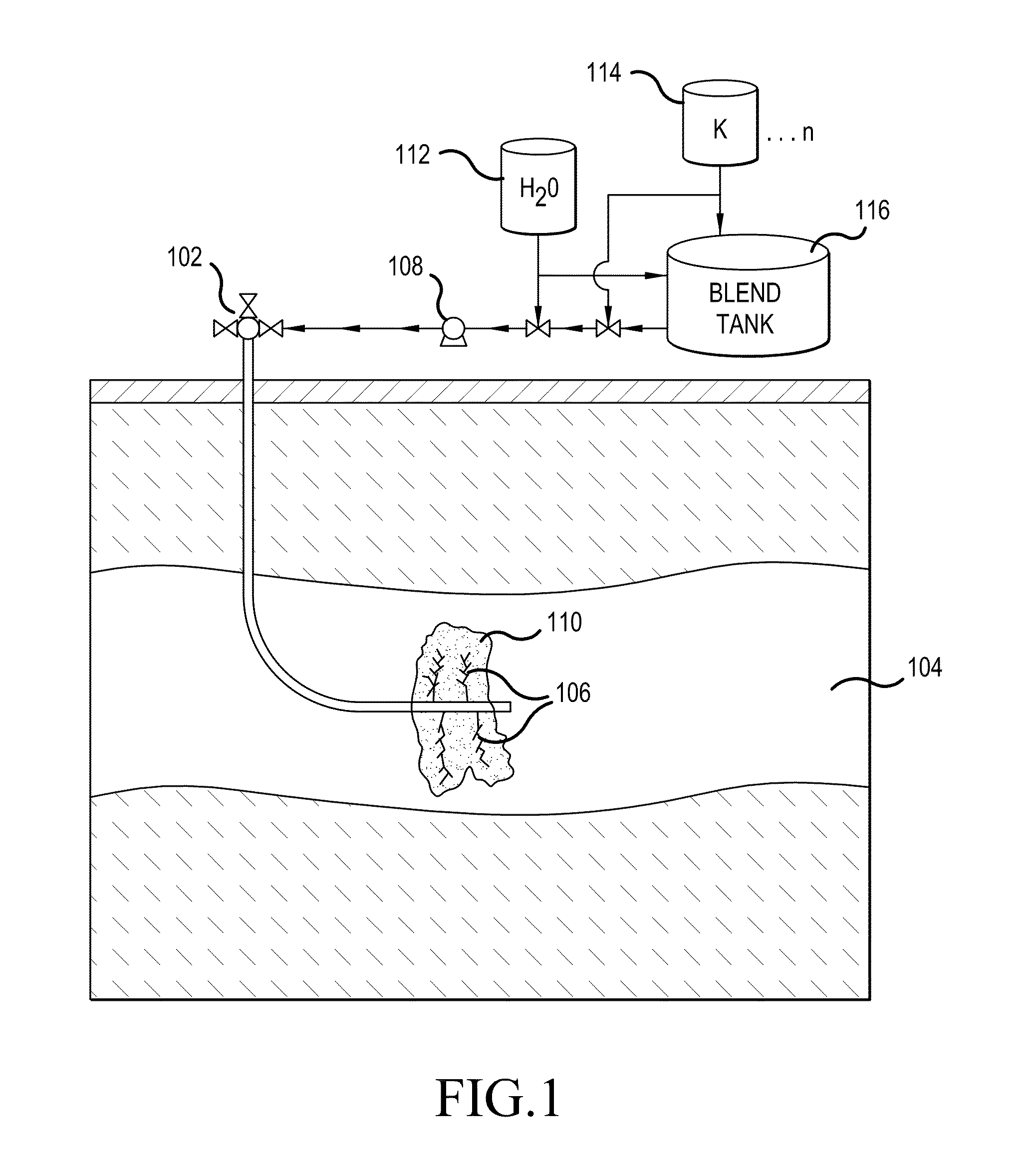

[0027]FIG. 1 is an example of a ketone supply, injection, and production system for hydrocarbon recovery from a hydrocarbon bearing subterranean formation. A well (102) is drilled in a hydrocarbon-bearing subterranean formation (104). Alternatively, an existing well (102) can be utilized. The well (102) can be a single well, operational as both an injection and production well, or alternatively the well can be distinct injection and production wells. The well (102) may be conventional or directionally drilled, thereby reaching the formation (104), as is well known to one having ordinary skill in the art.

[0028]The formation (104) can be hydraulically stimulated using conventional hydraulic fracturing methods, thereby creating fractures (106) in the formation. During injection, or during a cyclic injection phase, the production of hydrocarbons is stimulated by injecting via an injection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com