Low-filtration-loss blockage relieving fluid for acidification oilfield well and preparation method thereof

A technology for oilfield wells and fluid loss, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low illite content, low porosity and permeability, and difficulty in removing blockages in the Yanchang Formation oil layer, and achieves the Good adaptability and technical promotion value, strong active penetration ability, and the effect of reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

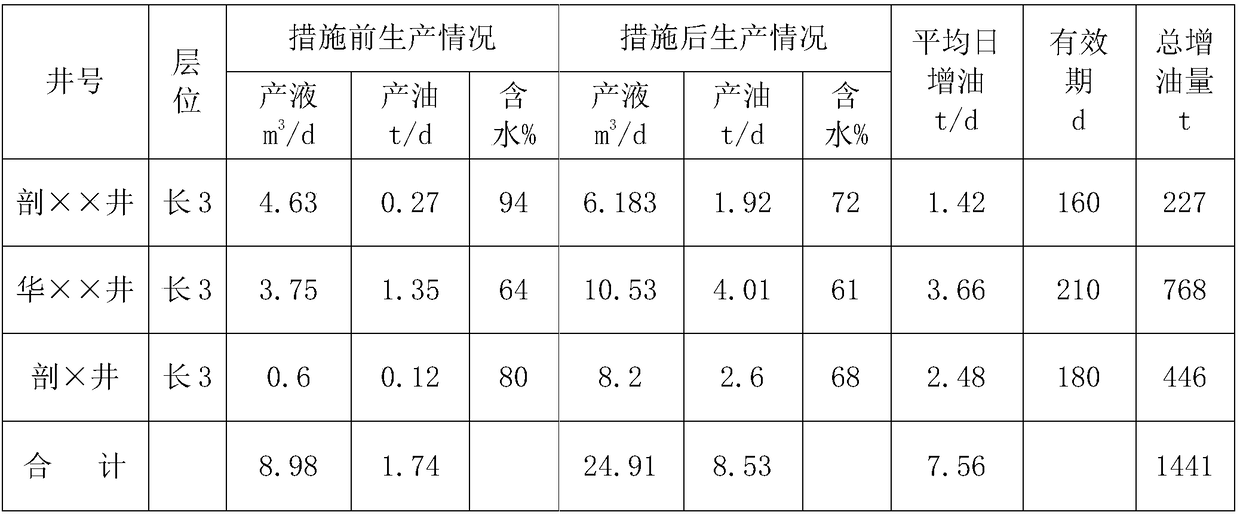

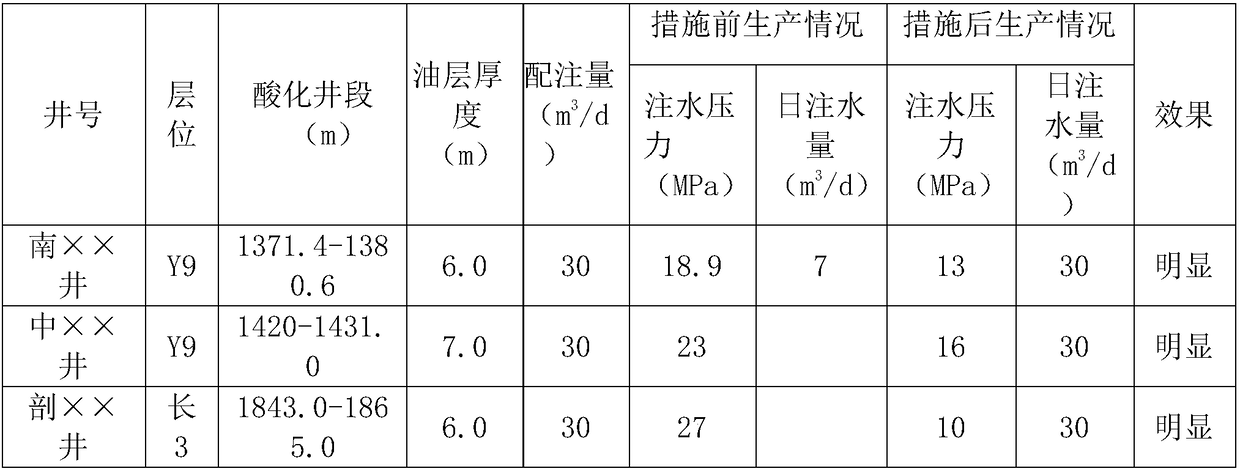

Examples

Embodiment 1

[0054] A kind of plug-removing fluid for acidizing oil field with low fluid loss, it is made up of the raw material of following parts by weight:

[0055] Organic acid 30, compound acid main body 120, corrosion inhibitor 3, micellar acid stabilizer solution 35, surfactant 1.5, sodium tripolyphosphate 2.

[0056] Described composite acid body is made up of the raw material of following weight part:

[0057] Nitrilotriacetic acid 1.8, aluminum ammonium sulfate 1.5, 31% hydrochloric acid 45, calcium acetylacetonate 1.5, 95% acetic acid 20, hydrofluoric acid 2.5, thiodipropionic acid 0.2, sorbitan laurate 0.1, Xylene 0.2, ethylene glycol butyl ether 2.4, ethanol 0.9, water 110.

[0058] The organic acid is a mixture of sulfamic acid and chloroacetic acid in a weight ratio of 15:3.5.

[0059] Described corrosion inhibitor is sodium myristate soap.

[0060] The surfactant is fatty alcohol polyoxyethylene ether sodium sulfate.

[0061] Described micellar acid stabilizer solution ...

Embodiment 2

[0069] A kind of plug-removing fluid for acidizing oil field with low fluid loss, it is made up of the raw material of following parts by weight:

[0070] Organic acid 40, compound acid main body 130, corrosion inhibitor 4, micellar acid stabilizer solution 40, surfactant 2, sodium tripolyphosphate 3.

[0071] Described composite acid body is made up of the raw material of following weight part:

[0072] Nitrilotriacetic acid 2, aluminum ammonium sulfate 2, 31% hydrochloric acid 50, calcium acetylacetonate 2, 97% acetic acid 15, hydrofluoric acid 3, thiodipropionic acid 0.4, sorbitan laurate 0.2, Xylene 0.2, ethylene glycol butyl ether 3, ethanol 1, water 120.

[0073] The organic acid described is a mixture of sulfamic acid and chloroacetic acid in a weight ratio of 20:4.

[0074] Described corrosion inhibitor is sodium myristate soap.

[0075] Described surfactant is alkyl sulfonate.

[0076] Described micellar acid stabilizer solution is made up of the raw material of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com