Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce membrane area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

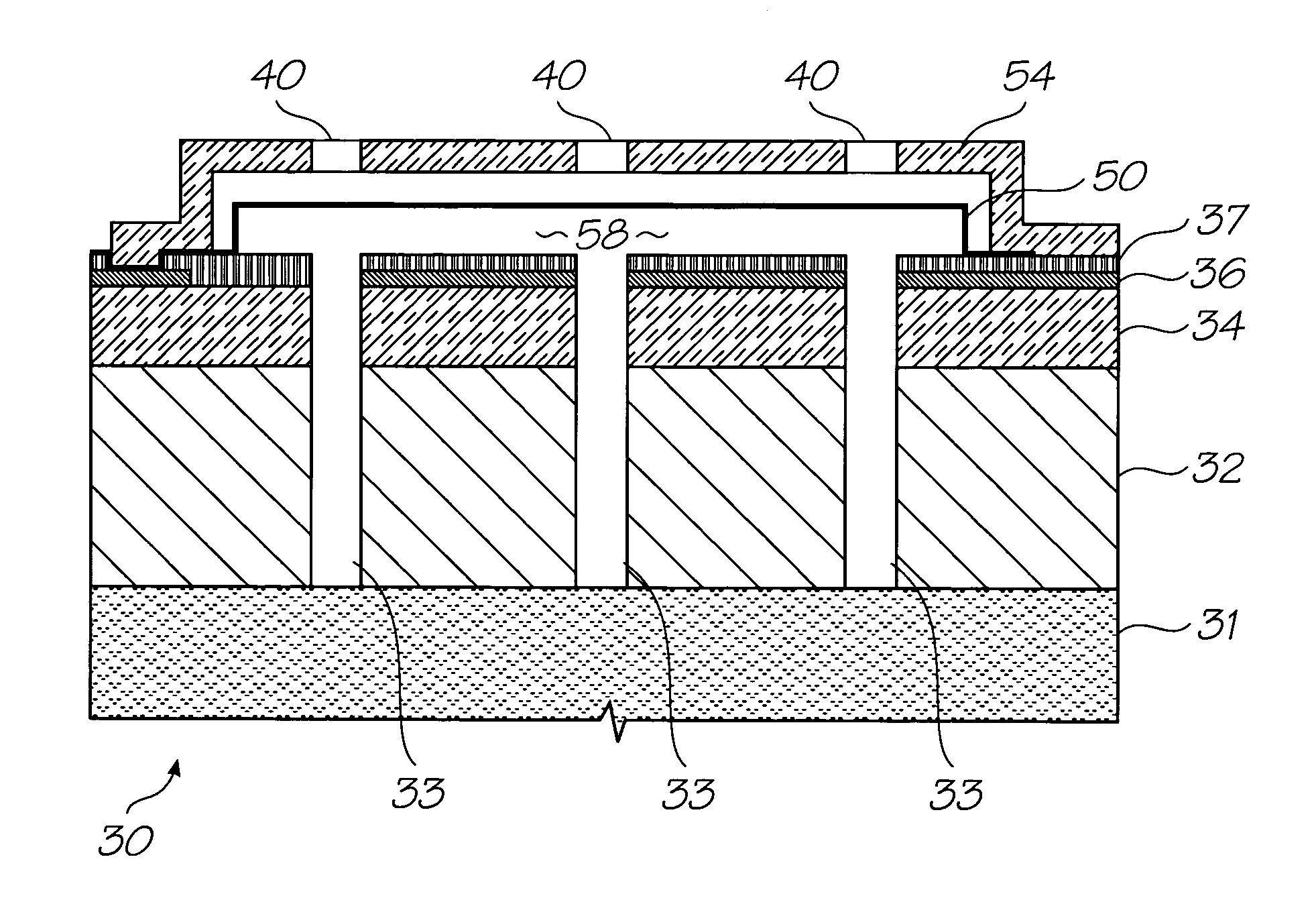

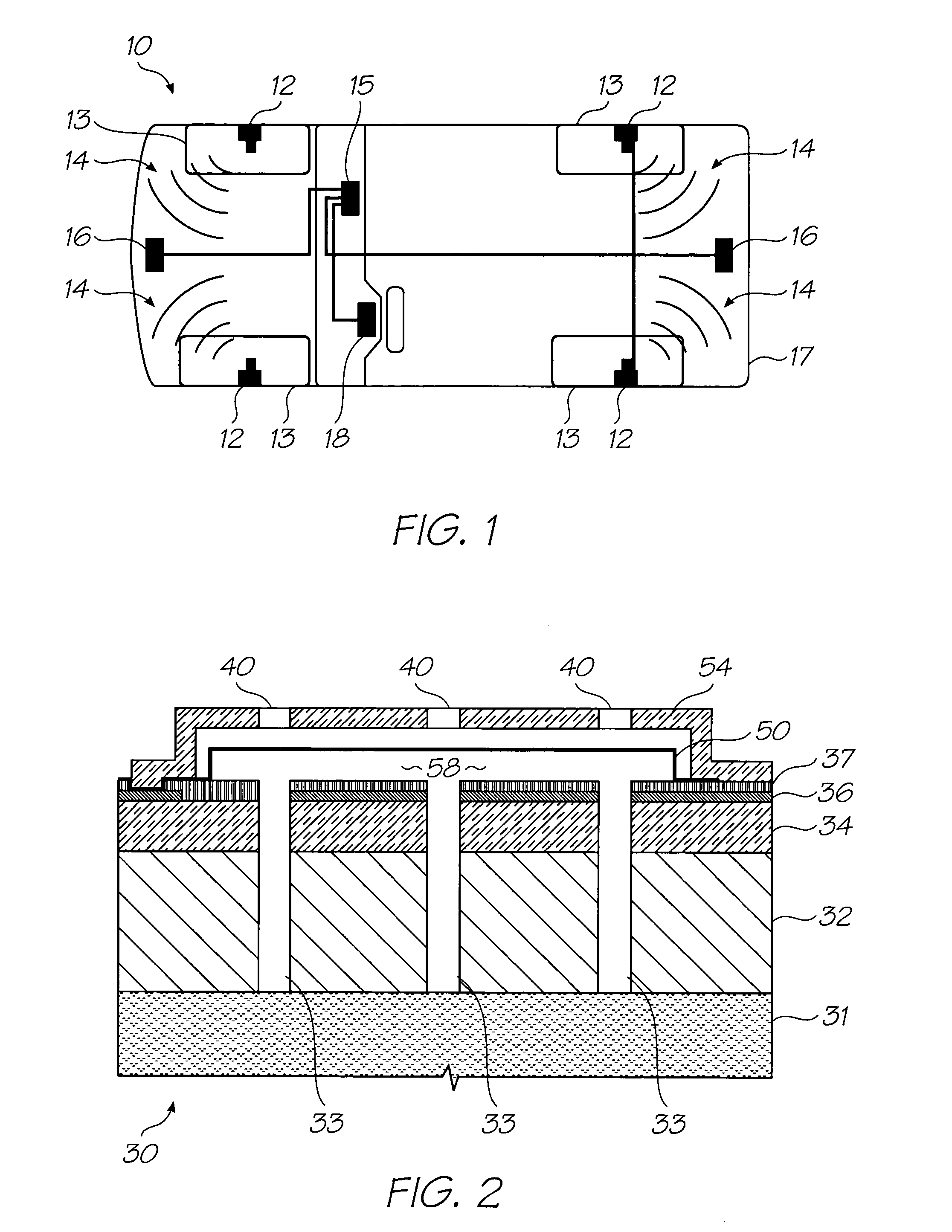

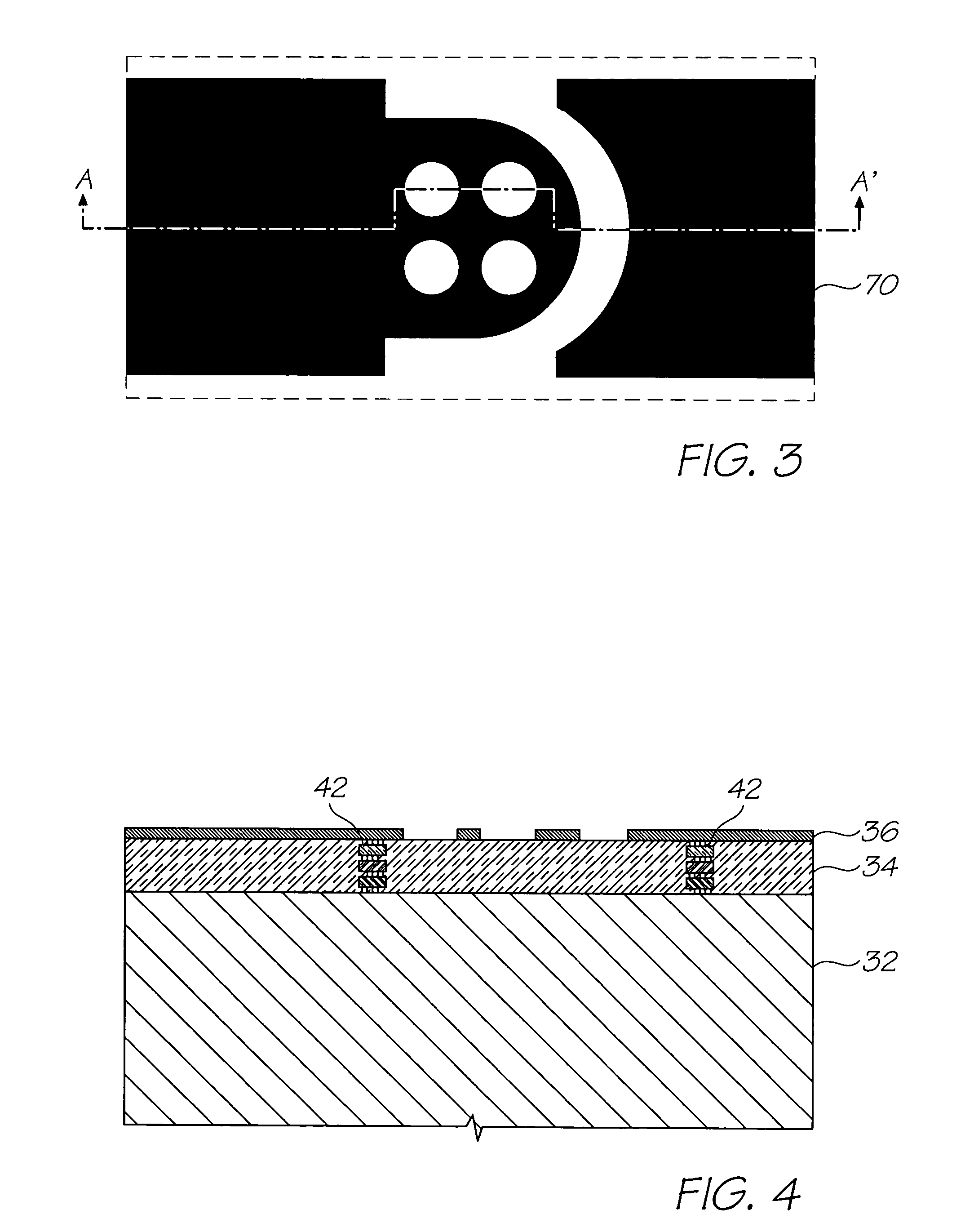

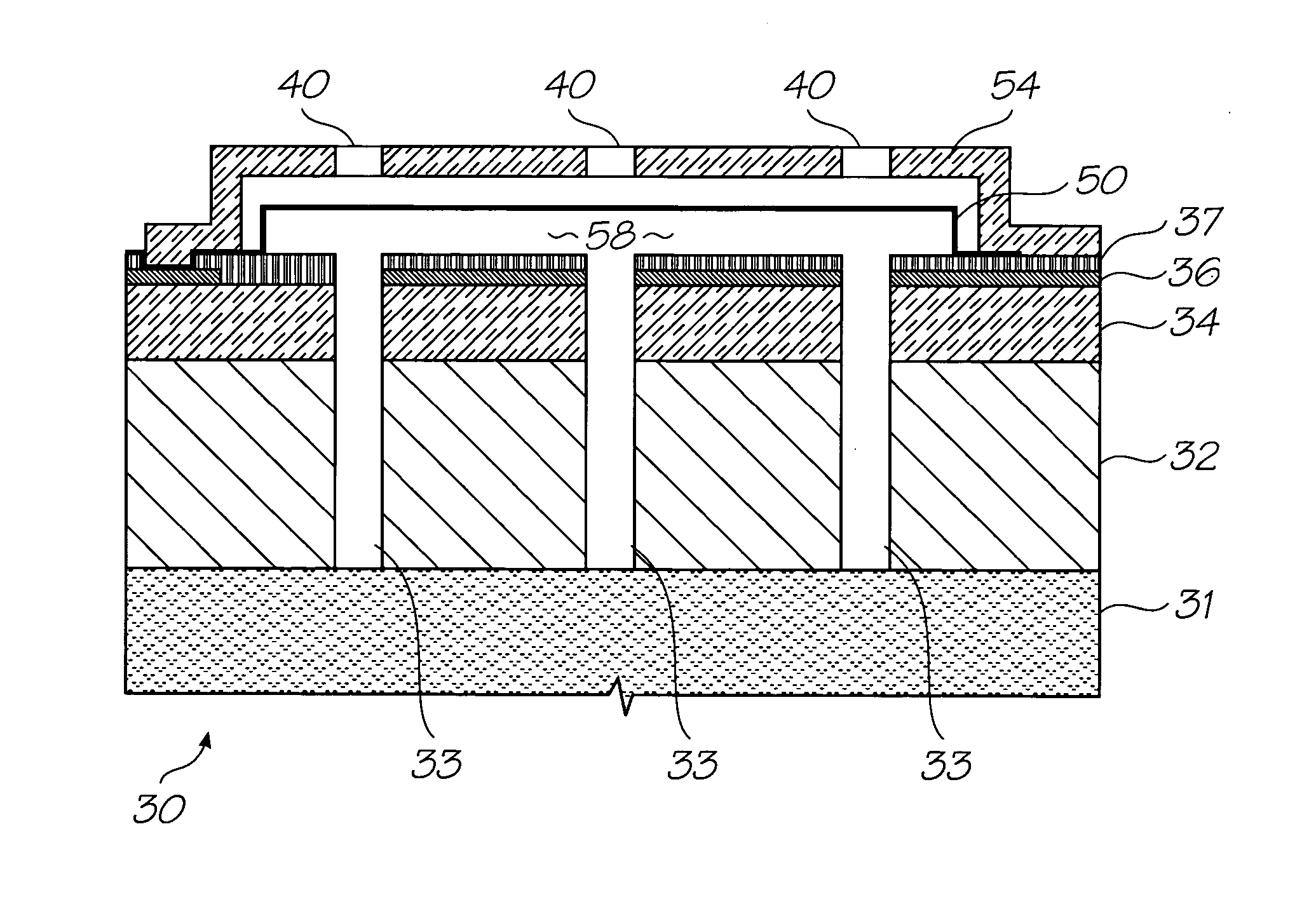

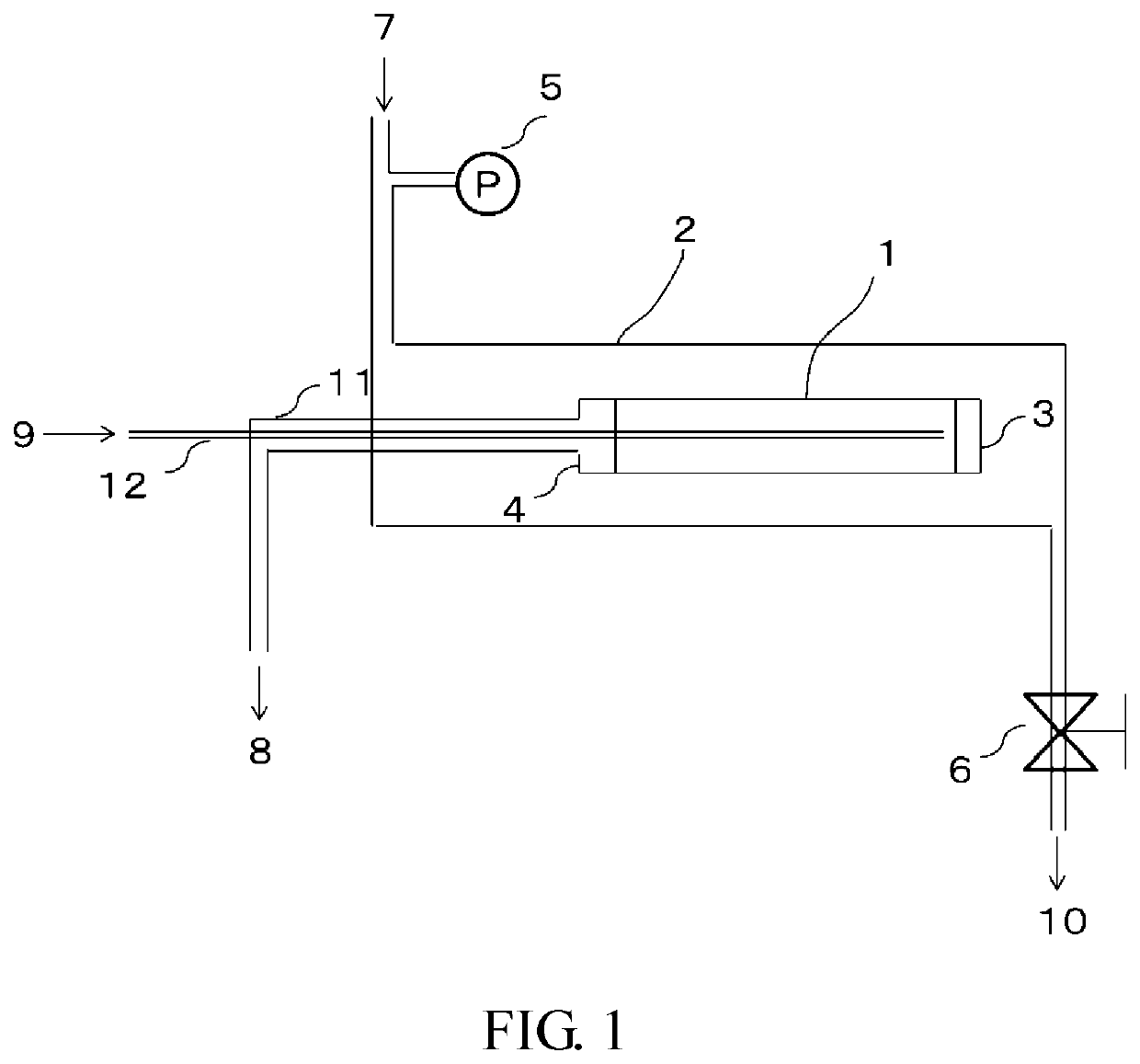

Pressure sensor with thin membrane

InactiveUS7089798B2Thickness minimizationHigh yield strengthFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsThin membraneConductive materials

Owner:PRECISION MECHATRONICS

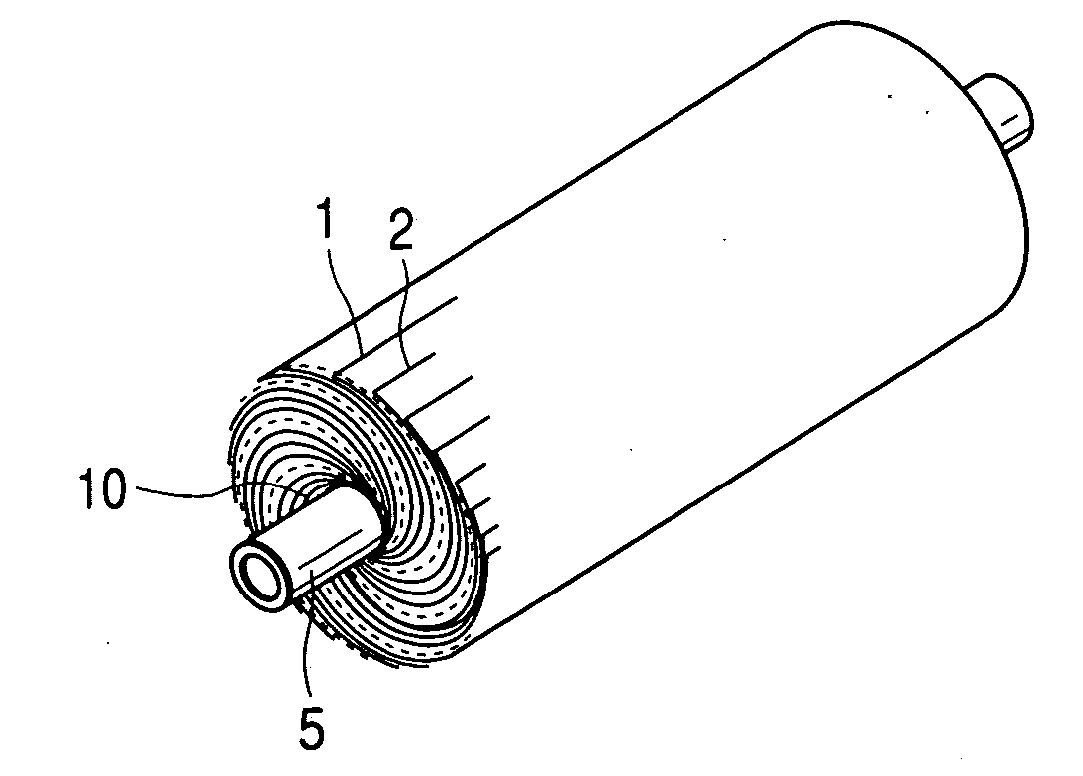

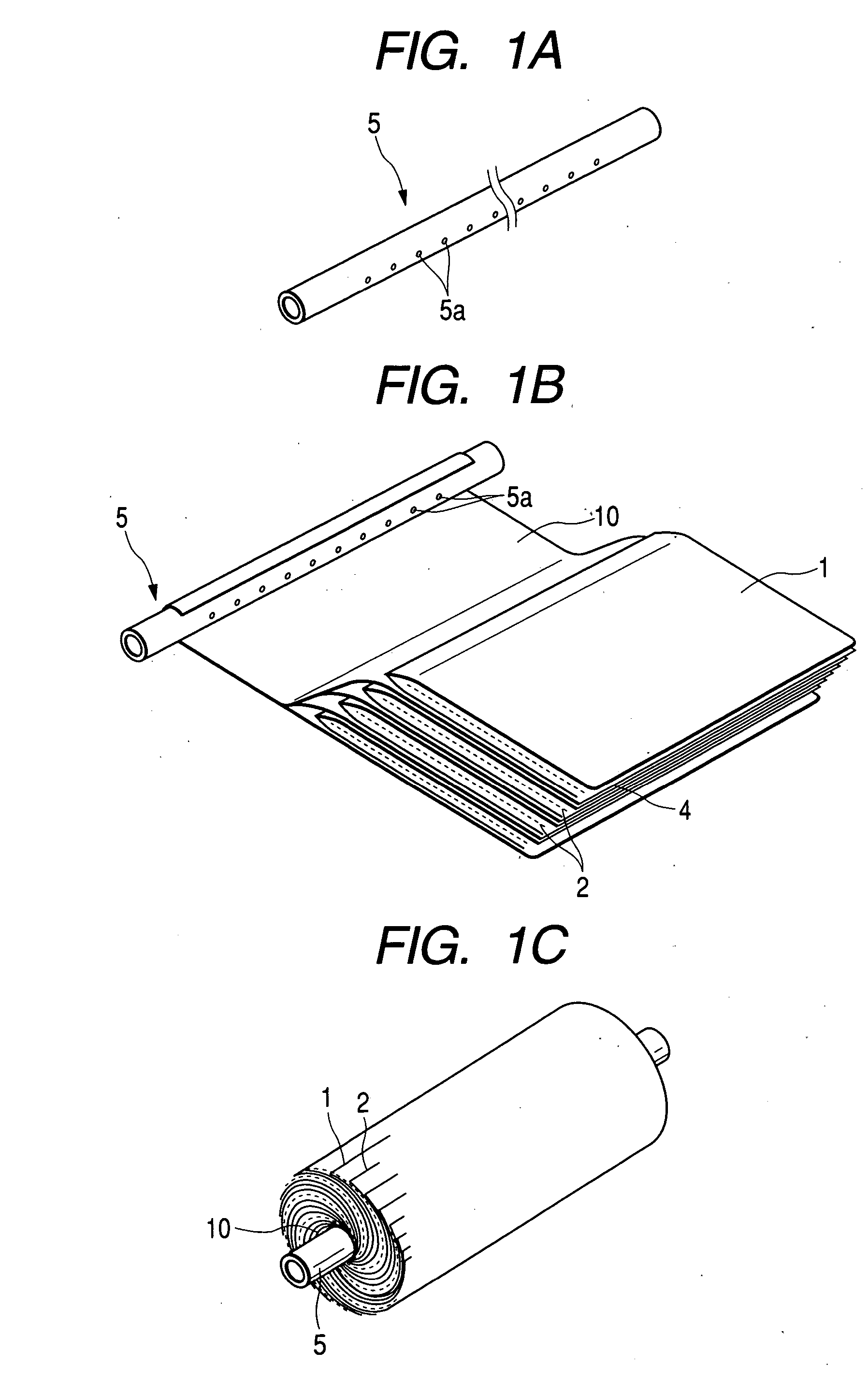

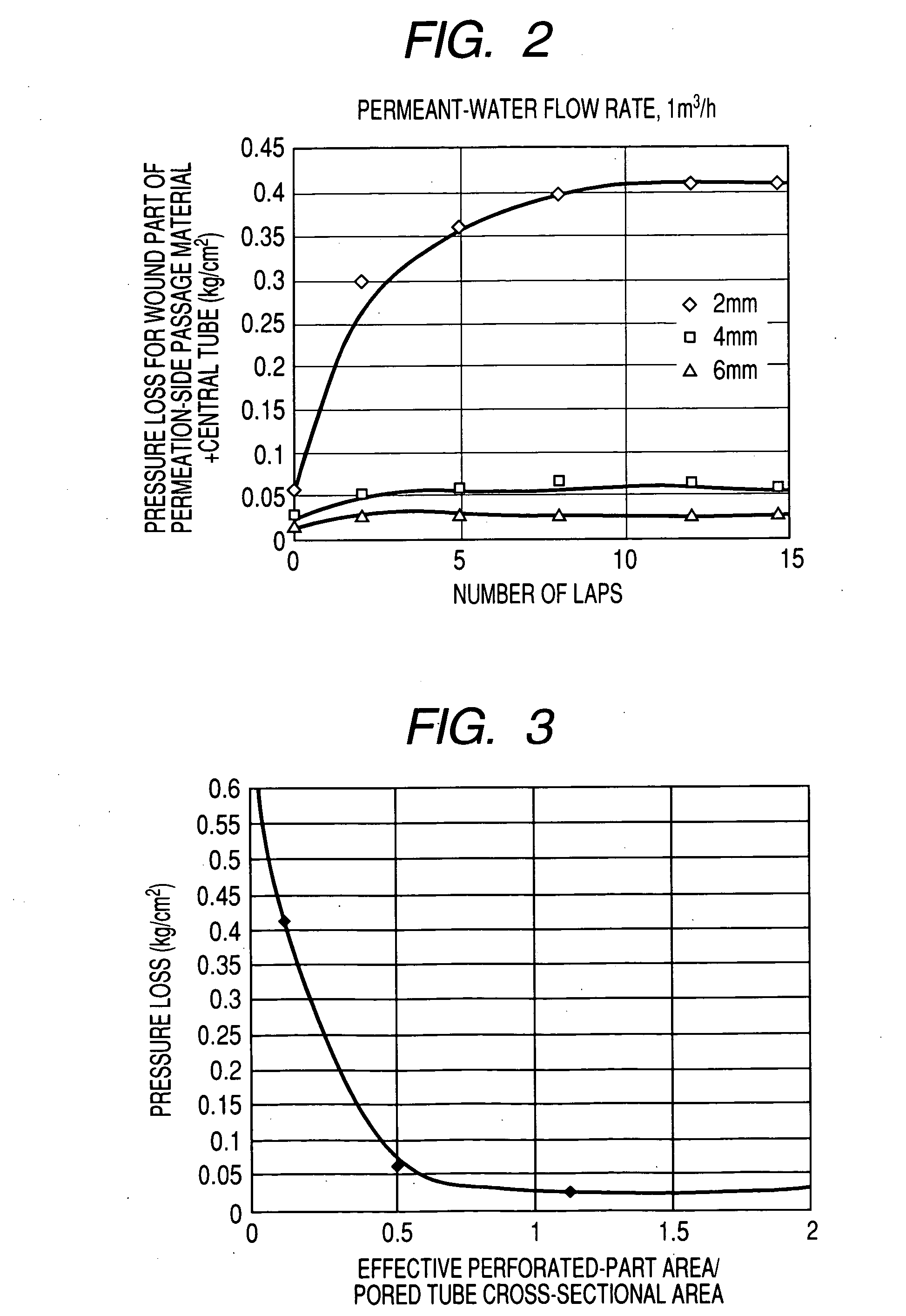

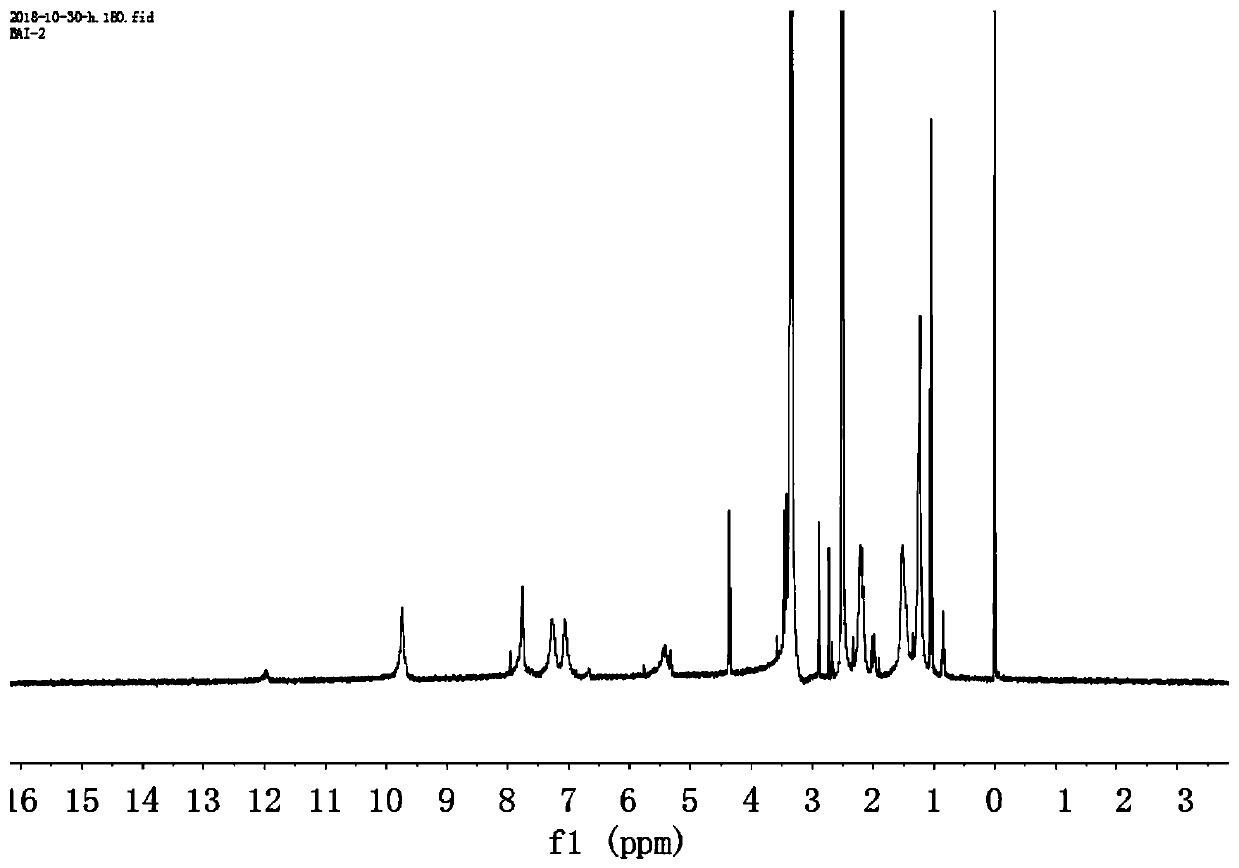

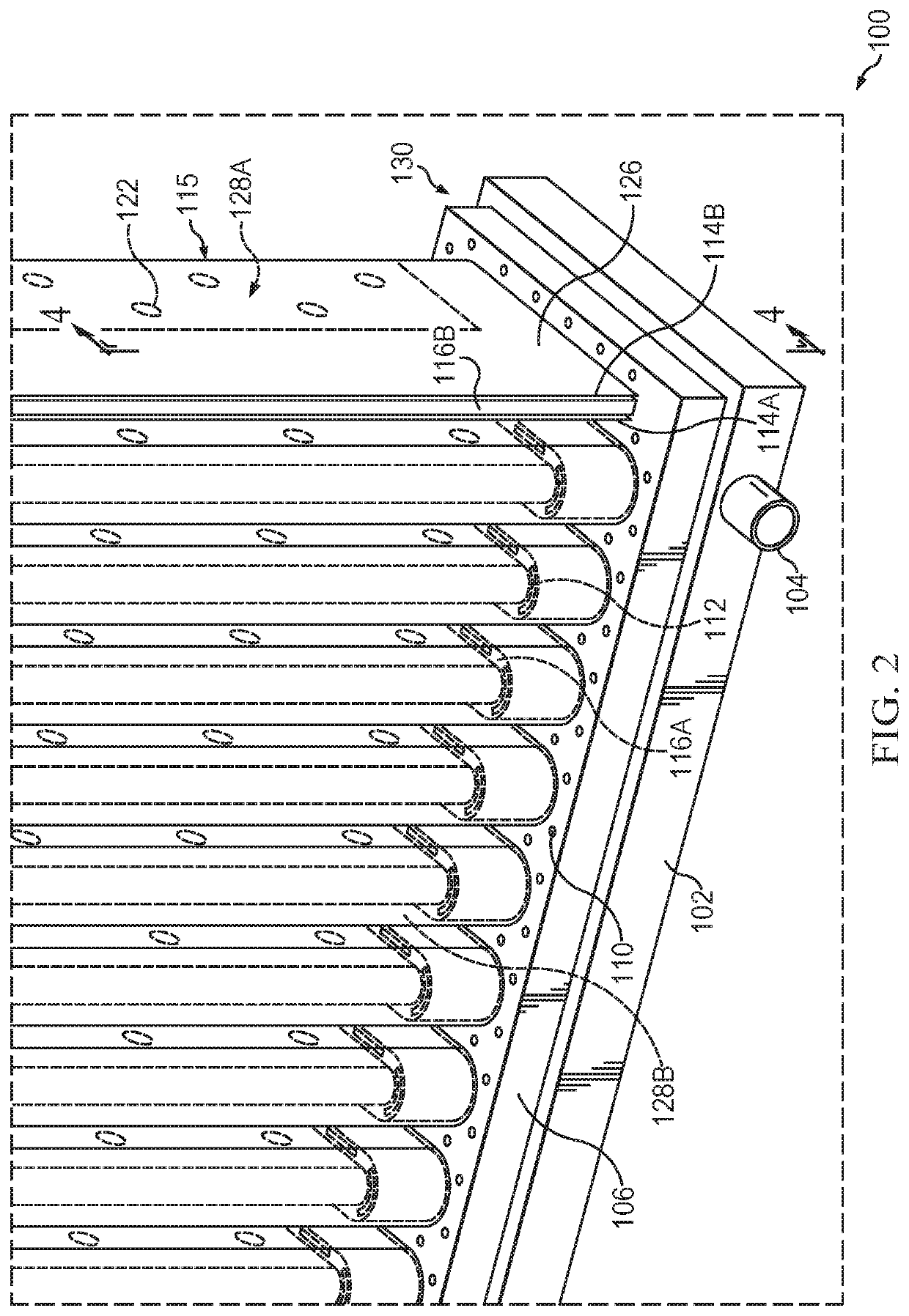

Spiral separation membrane element

InactiveUS20040195164A1Increase the areaReduce membrane areaUltrafiltrationReverse osmosisChemistryMembrane configuration

A spiral separation membrane element effective in reducing the pressure loss around core tube perforated parts, which is problematic especially in low-pressure operations. The spiral separation membrane element comprises a perforated cored tube 5 and, spirally wound therearound, separation membranes 1, feed-side passage materials 2, and permeation-side passage materials 4, the separation membranes 1 and the passage materials 2 and 4 being wound around the cored tube 5 so that the feed-side passage materials 2 and the permeation-side passage materials 4 are disposed respectively on the feed side and permeation side of the separation membranes 1 and that a permeation-side passage material 10 which is the same as or different from the permeation-side passage materials 4 is interposed at the periphery of the perforated cored tube 5, wherein the effective perforated-part area as calculated by multiplying the total area of the perforated parts in the core tube 5 by the percentage of openings of one layer of the permeation-side passage material surrounding the core tube 5 is at least 1.0 time the inner cross-sectional area of the core tube 5.

Owner:NITTO DENKO CORP

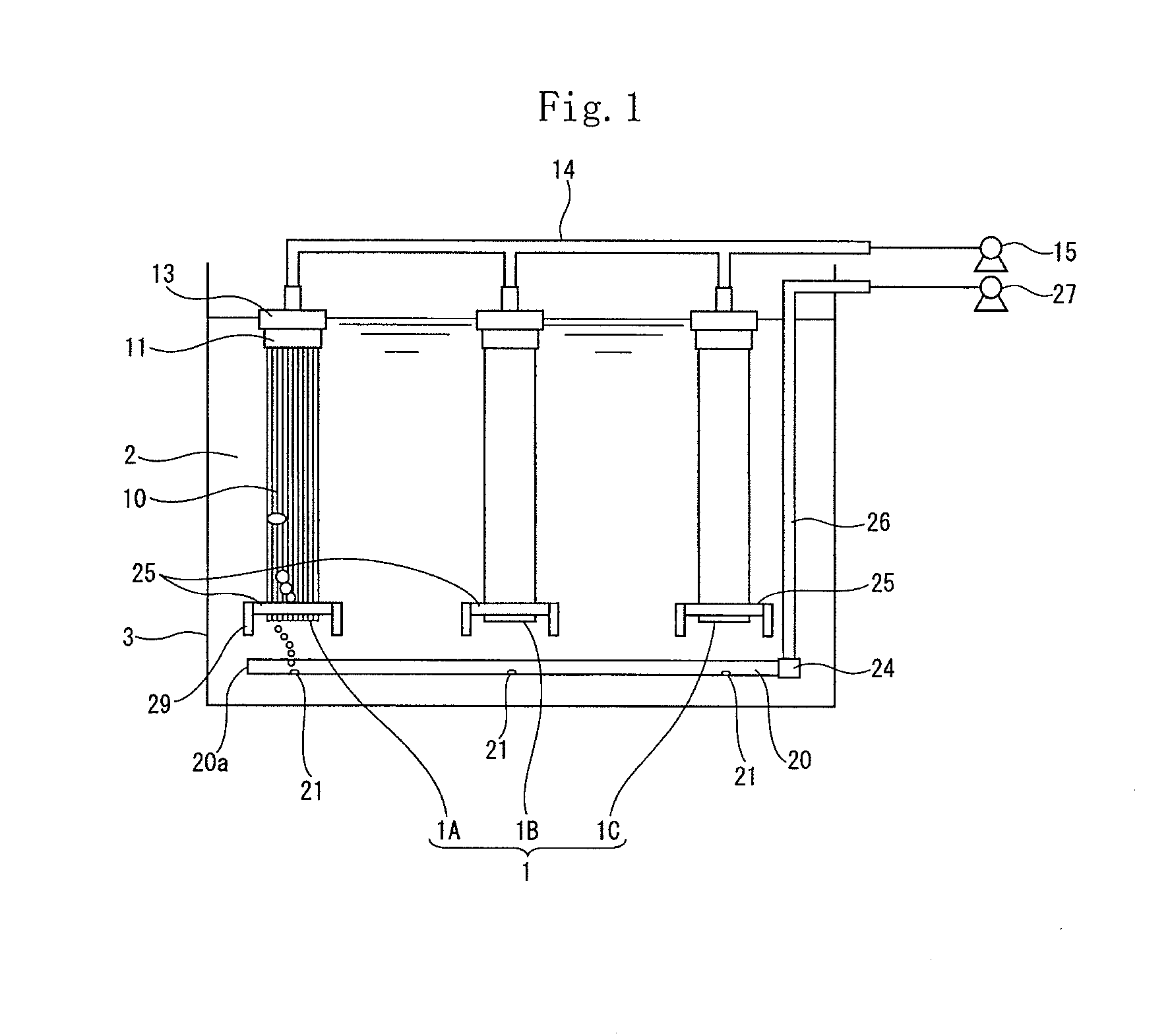

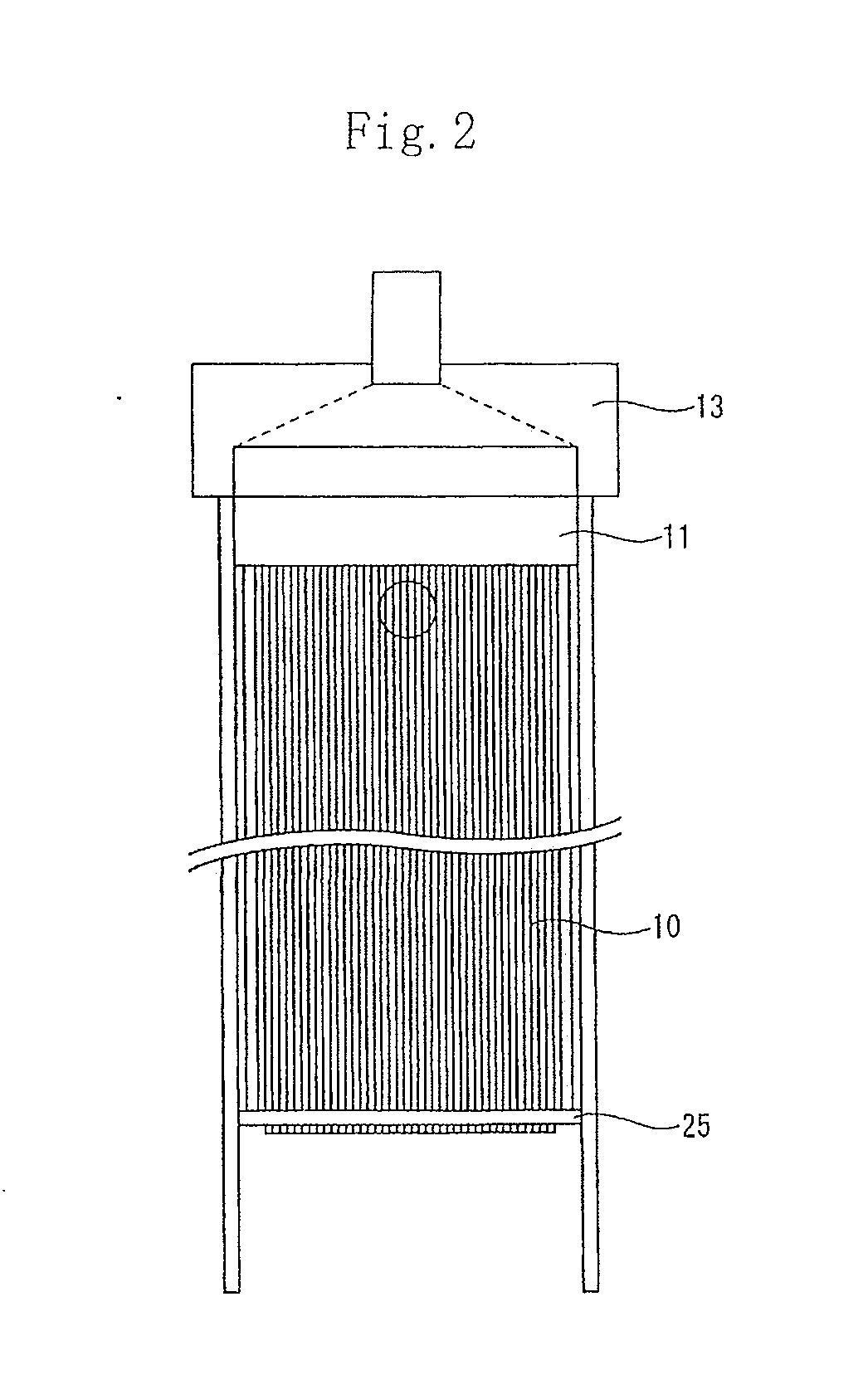

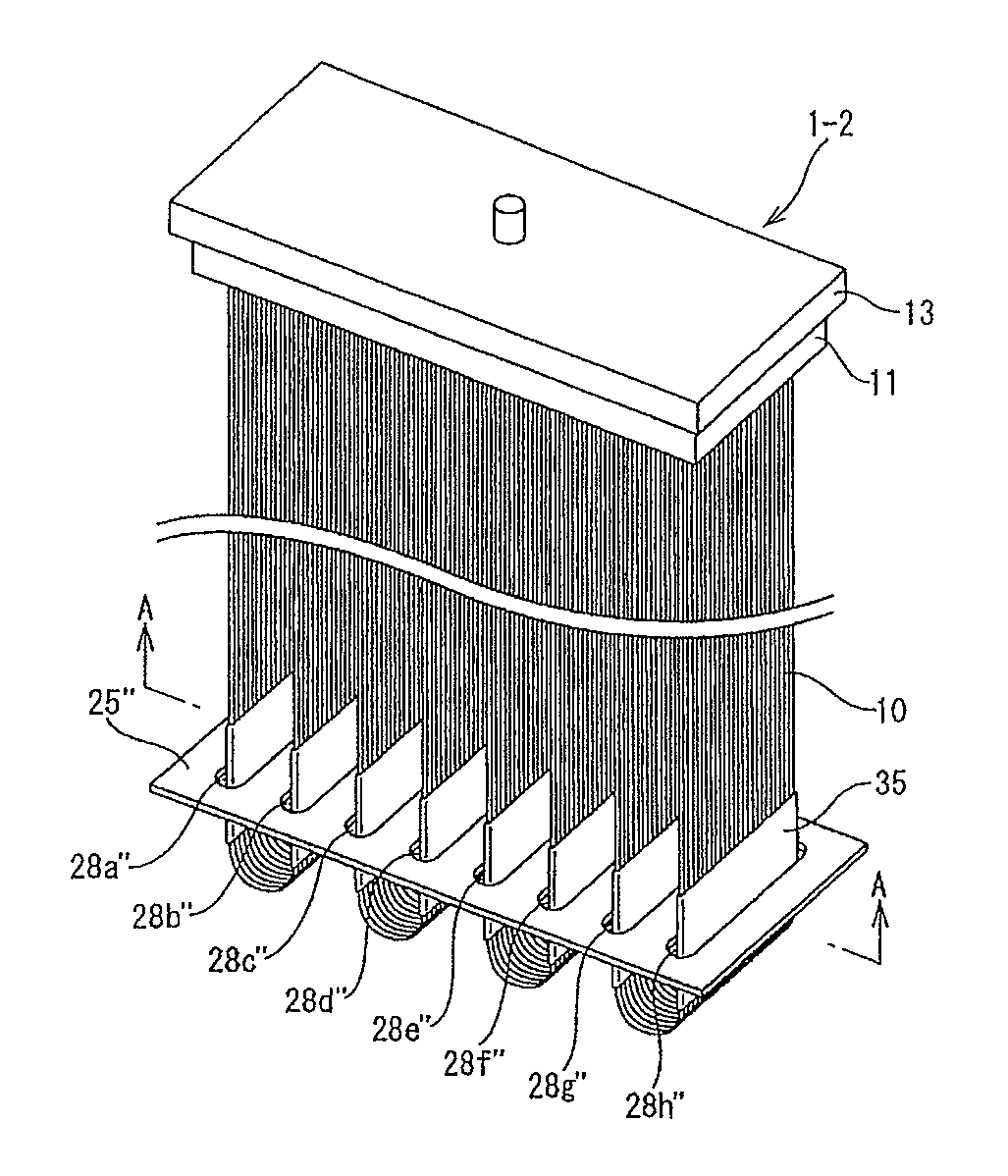

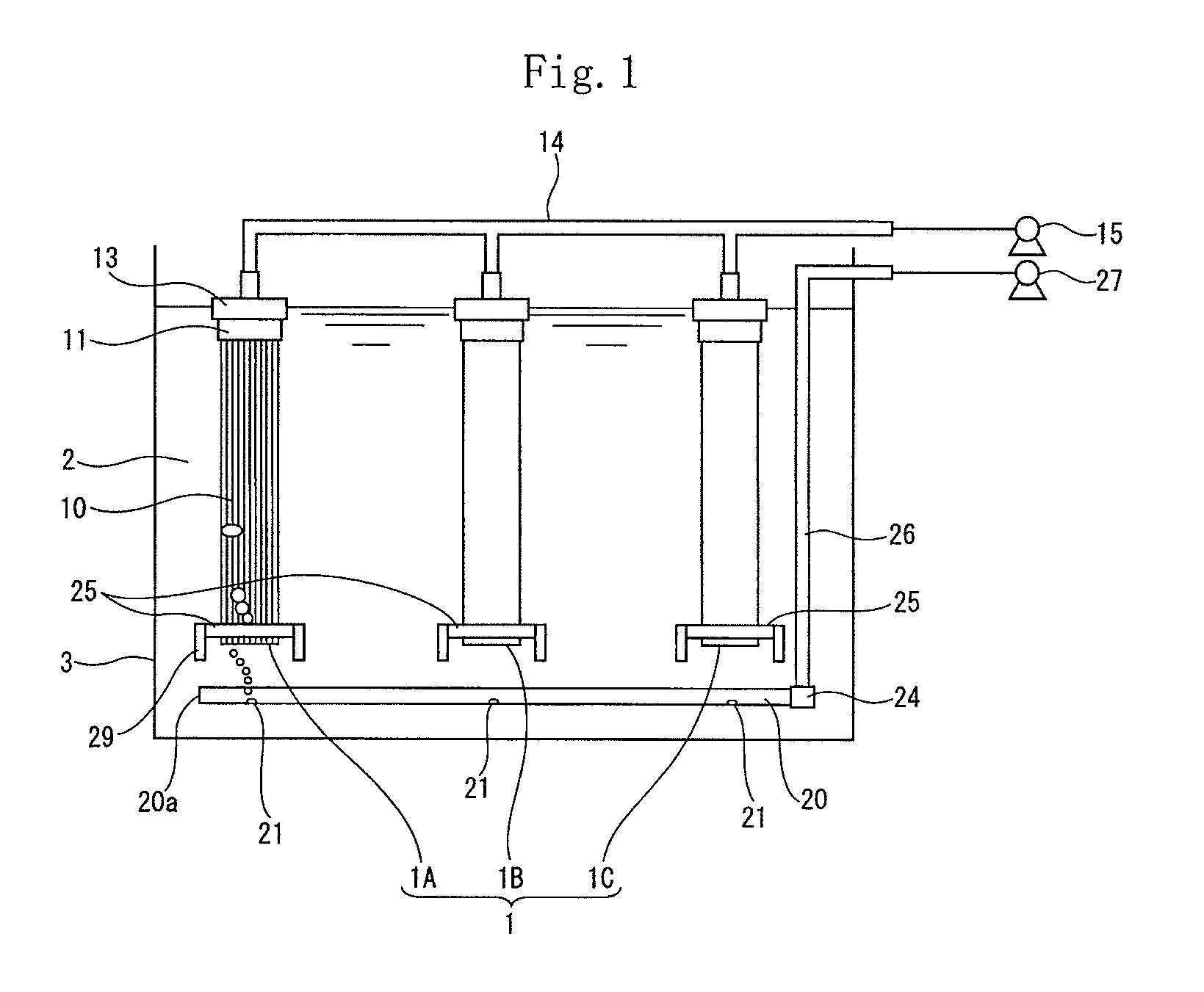

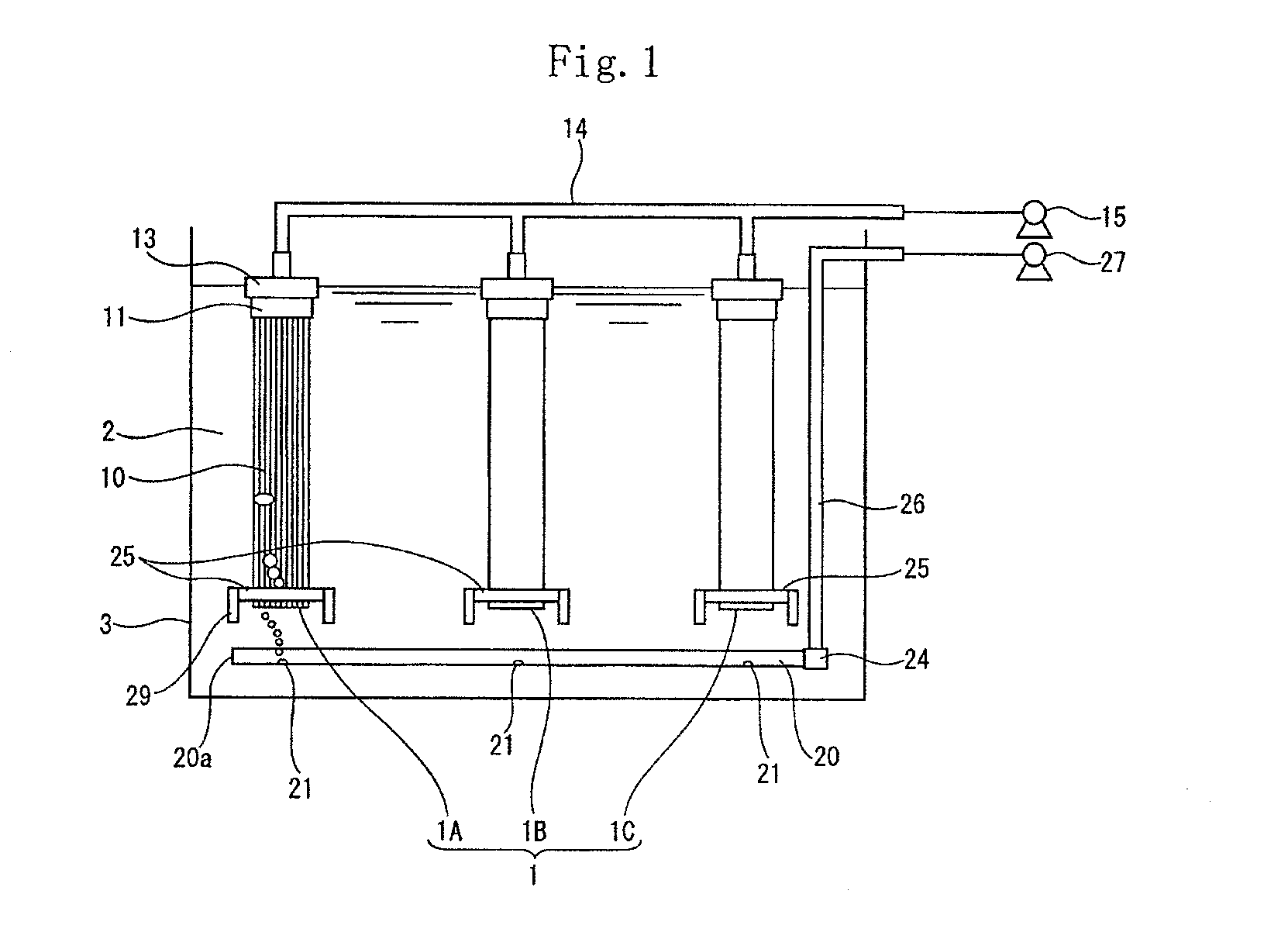

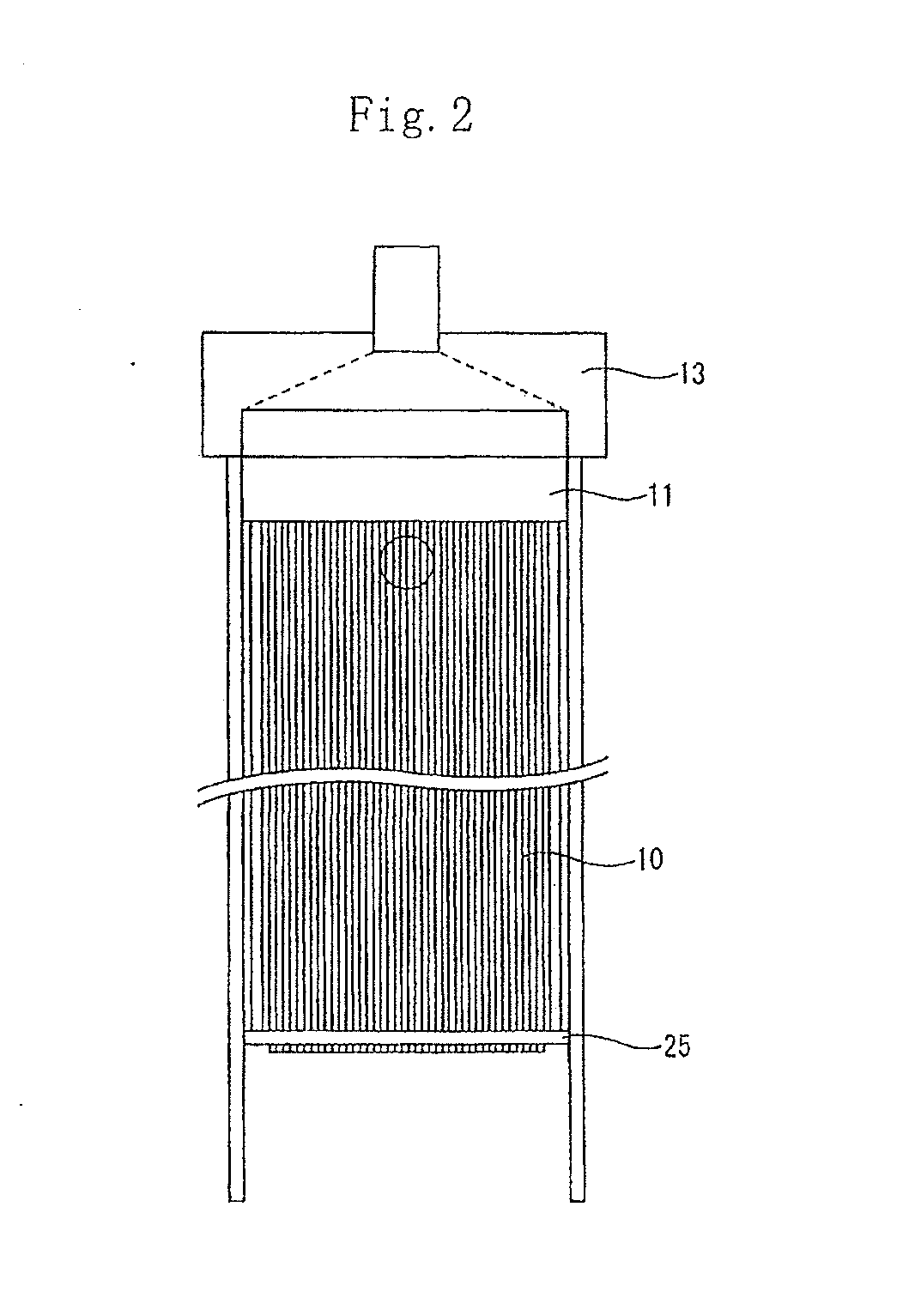

Filtration apparatus

ActiveUS20090236280A1Reliably membrane surfaceStable filtration functionMembranesWaste water treatment from animal husbandryFiltrationProduct gas

A filtration apparatus for performing solid-liquid separation by immersing a plurality of hollow fiber membranes in a to-be-treated liquid containing a suspended component includes the hollow fiber membranes folded double, a treated liquid collection means communicated with an open end of each of the hollow fiber membranes, a holding member for holding a bent portion of each of the hollow fiber membranes with a gap formed between the bent portion and the holding member, and a gas-jetting means for jetting a cleaning gas from the bent side of each of the hollow fiber membranes to a side of the open end. A gap for flowing the gas jetted by the gas-jetting means is formed between the hollow fiber membranes and the holding member or / and in at least one part of gaps between the hollow fiber membranes.

Owner:SUMITOMO ELECTRIC IND LTD

Pressure sensor with thin membrane

InactiveUS20060081058A1The material is lowAvoids high surface cleanlinessFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsThin membraneConductive materials

A pressure sensor (30) for harsh environments such as vehicle tires, formed from a chamber (58) partially defined by a flexible membrane (50), the chamber (58) containing a fluid at a reference pressure. In use, the flexible membrane (50) deflects from any pressure difference between the reference pressure and the fluid pressure. The membrane (50) being at least partially formed from conductive material so that associated circuitry (34) converts the deflection of the flexible membrane (50) into an output signal indicative of the fluid pressure. The flexible membrane is less than 3 microns thick to allow the use of a high yield strength membrane material. A thinner membrane also allows the area of the membrane to be reduced. Reducing the area of the membrane reduces the power consumption and the overall size of the sensor. A high yield strength material is better able to withstand the extreme conditions within the tire and a compact design can be installed in restricted spaces such as the valve stem.

Owner:PRECISION MECHATRONICS

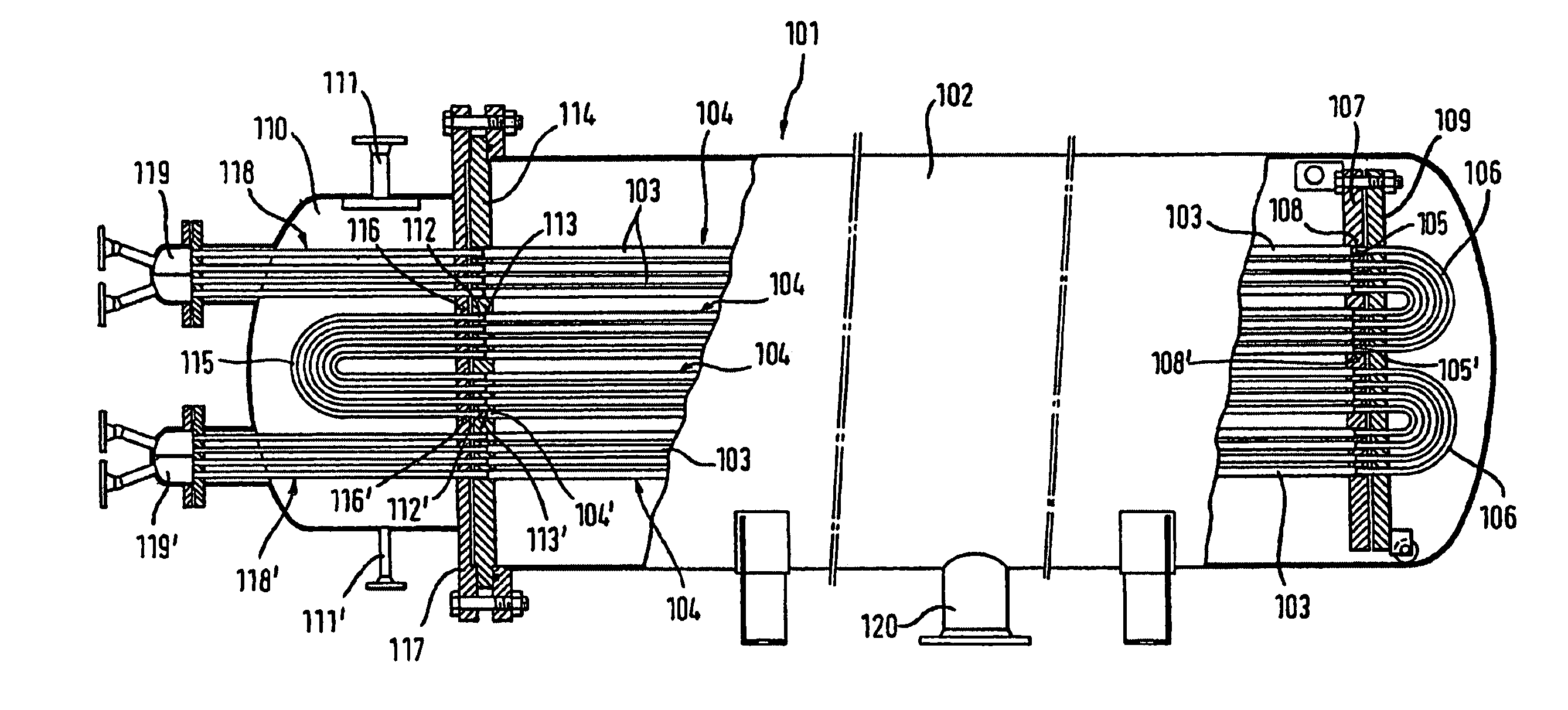

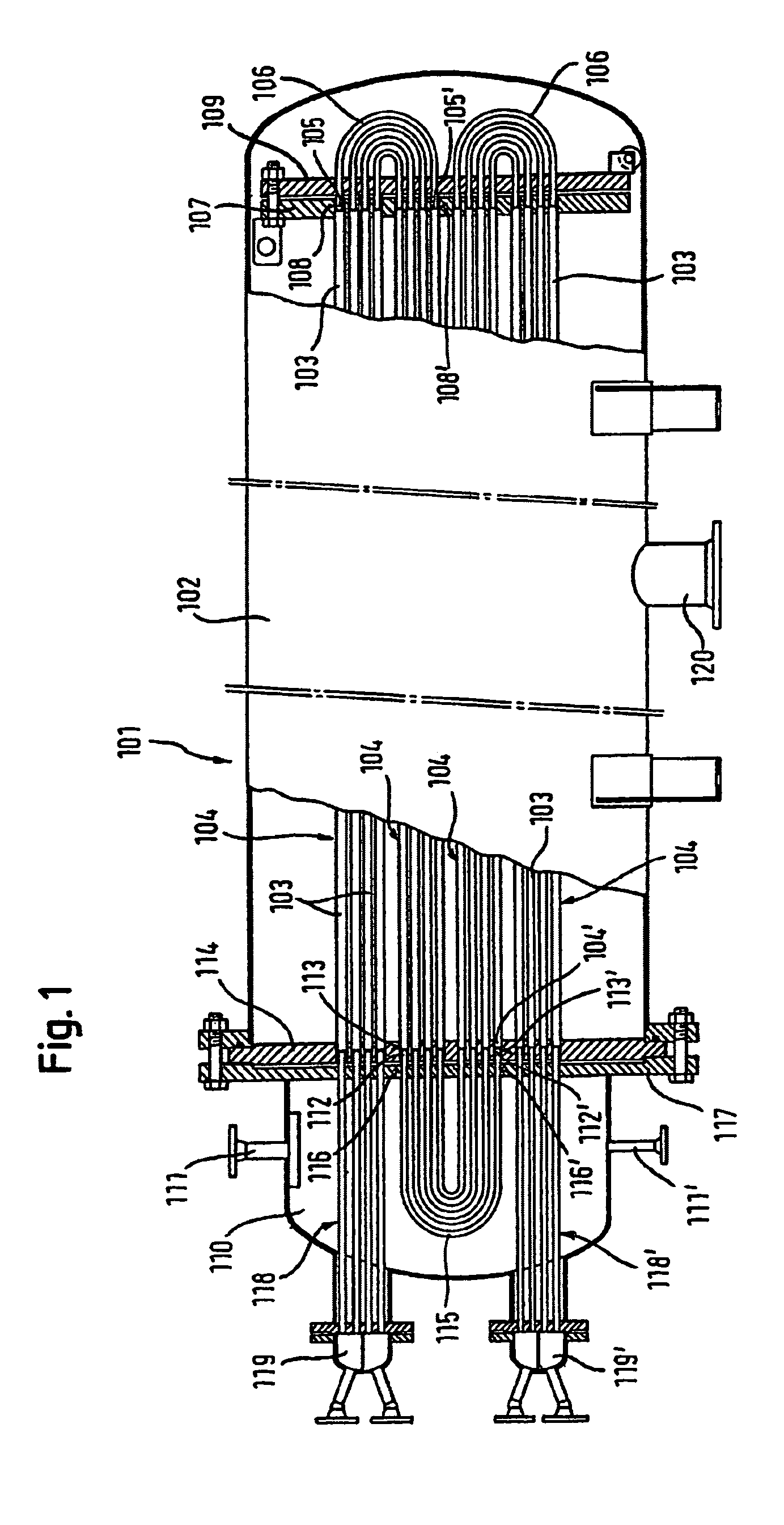

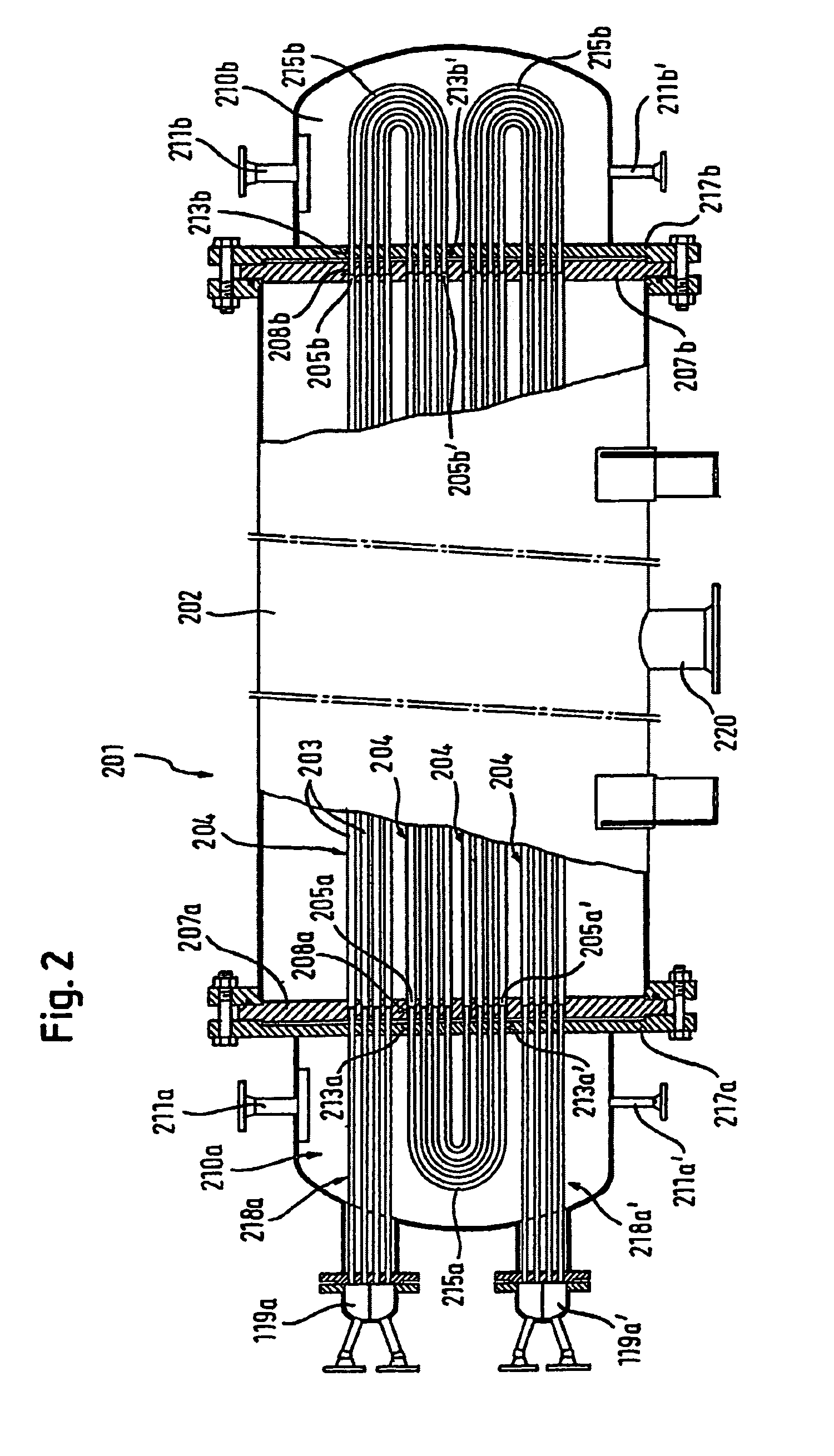

Membrane pipe module

InactiveUS7655141B2Large reduction of the fluxOptimal high fluxesMembranesSolid sorbent liquid separationMembrane configurationTubular membrane

The invention relates to a membrane pipe module, said module comprising a cylindrical housing containing a plurality of tubular membrane sections which extend in the axial direction and are interconnected at the ends thereof, forming longer tubular membrane sections. Said cylindrical housing comprises a heatable chamber, on one or both sides, comprising U-shaped connection pipes which are arranged therein and are guided through a separating wall between the chamber and the housing, with the two open ends thereof, and respectively connect two adjacent open tubular membrane sections, forming a membrane loop.

Owner:SULZER CHEMTECH - MEMBRANTECHN

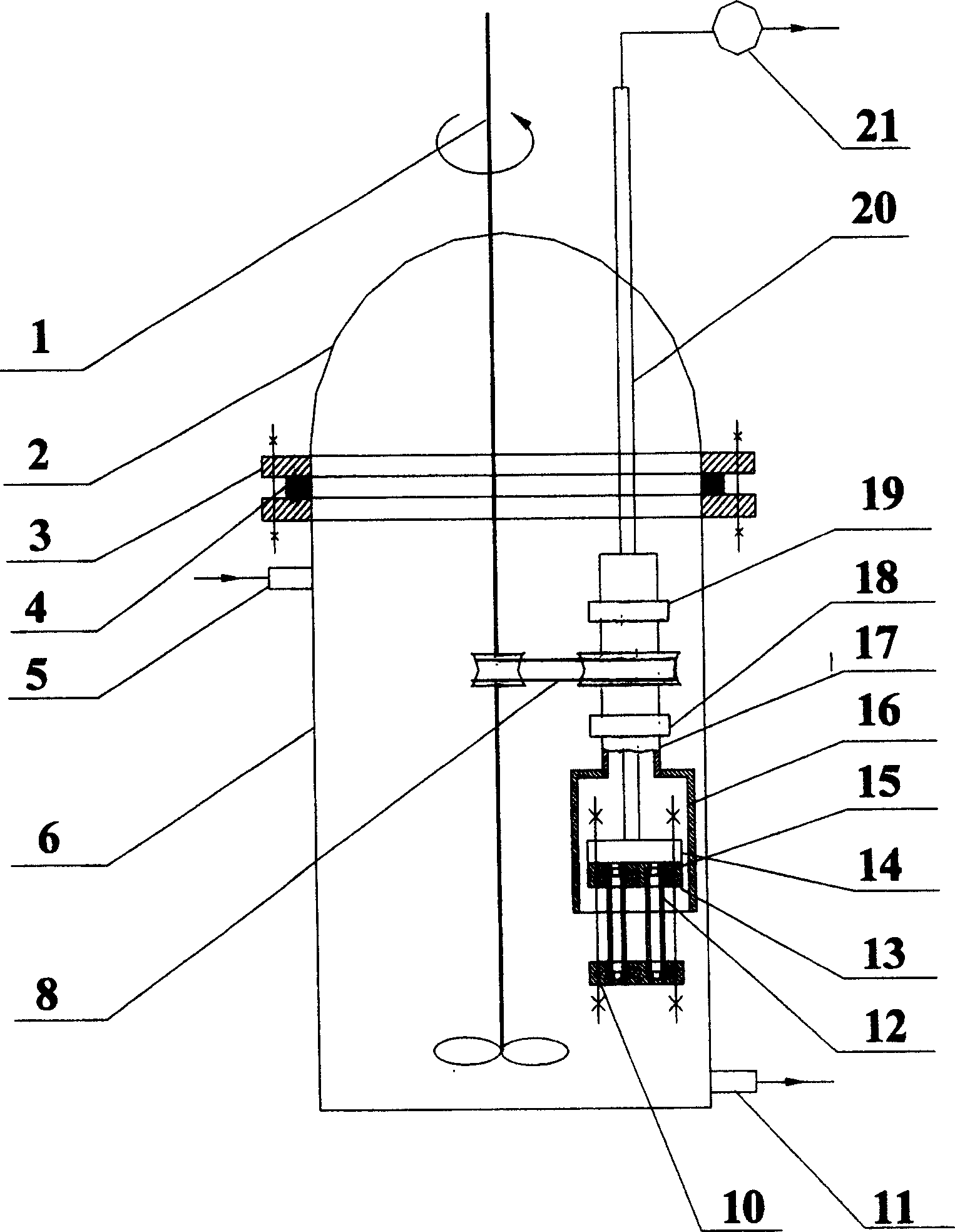

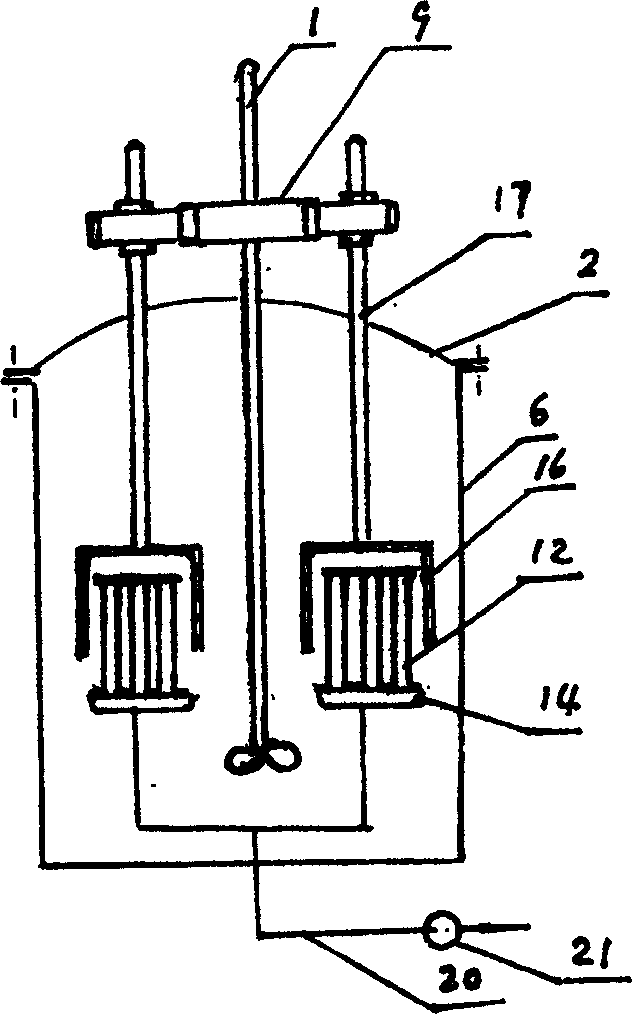

Integrated suspension bed inorganic mambrane reactor

ActiveCN1597082AImprove sealingEasy to separateChemical/physical processesEngineeringSmall footprint

An integrated suspension-bed reactor with inorganic membrane for the reaction between multiple phases of material and the solid-liquid separation features that its reaction still has internal stirrer and inorganic membrane as the separating unit with several membrane tubes which has a closed end and an open end communicated with filtrate outlet tube. A turbulence promoter with a rotary axle is arranged outside said separating unit.

Owner:NANJING TECH UNIV

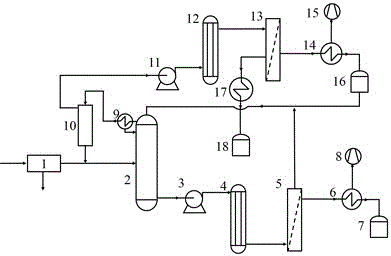

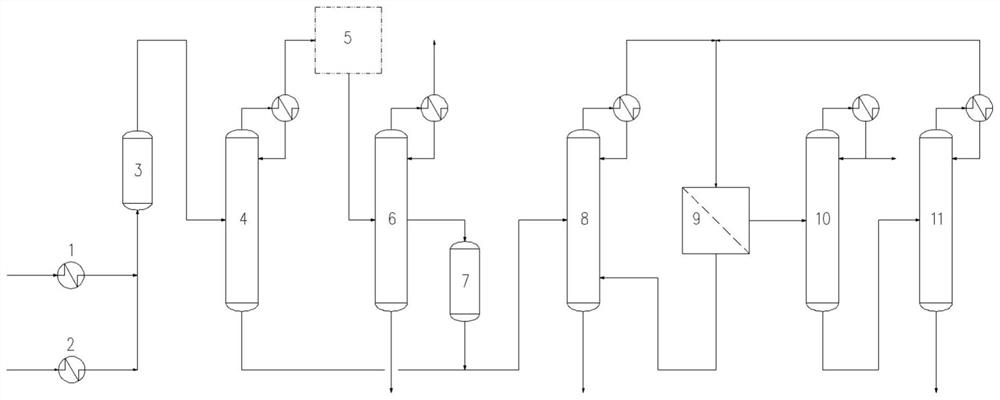

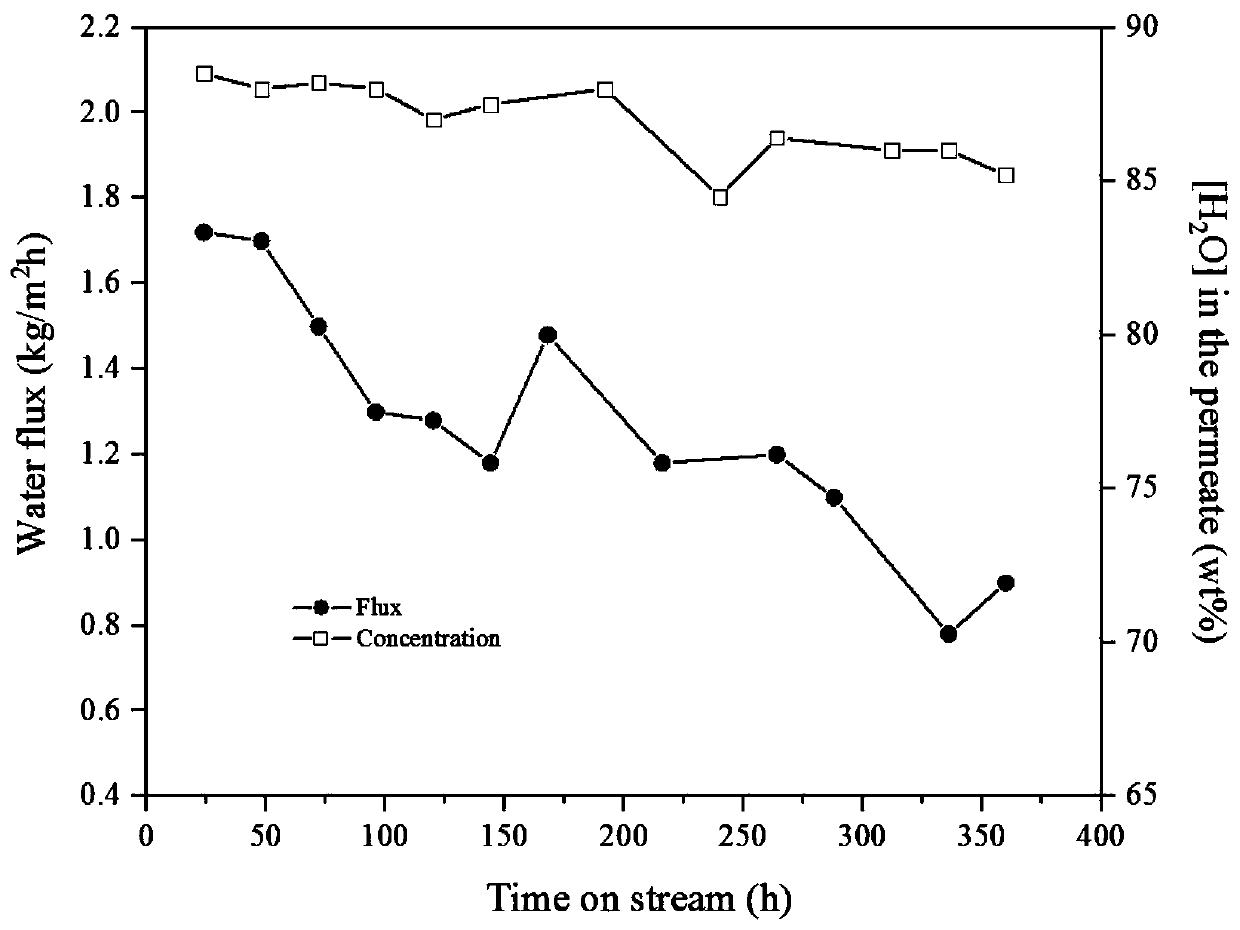

Process and device for recycling dimethyl carbonate through steam permeation method

InactiveCN105949061AReduce processing loadReduce membrane areaCarbonic/haloformic acid esters purification/separationHigh concentrationAlcohol

The invention relates to a process and device for recycling dimethyl carbonate through a steam permeation method. The process comprises the specific steps that some byproducts are removed after a reaction solution is subjected to primary distillation, and a methanol-dimethyl carbonate azeotrope enters an extractive distillation tower from the middle and makes contact with spraying water on the top of the tower for extractive separation; methyl alcohol is separated out of liquid at the bottom of the extractive tower through a steam permeable membrane, water and trace dimethyl carbonate are retuned to the top of the extractive tower after being subjected to heat exchange, distillate on the top of the extractive tower is separated through a separator, the water layer at the bottom of the separator returns to the extractive tower, the organic matter layer on the upper portion of the separator is further heated to enter the steam permeable membrane, high-concentration dimethyl carbonate is separated out through the separator, the dimethyl carbonate enters a dimethyl carbonate storage pot after being condensed through a condenser, and permeable water returns to the top of the tower after being subjected to heat exchange. The process and device have the advantages that the technological process is simple, the safety coefficient is high, equipment investment is low, the energy utilization rate is high, and the recycling rate is high.

Owner:NANJING UNIV OF TECH

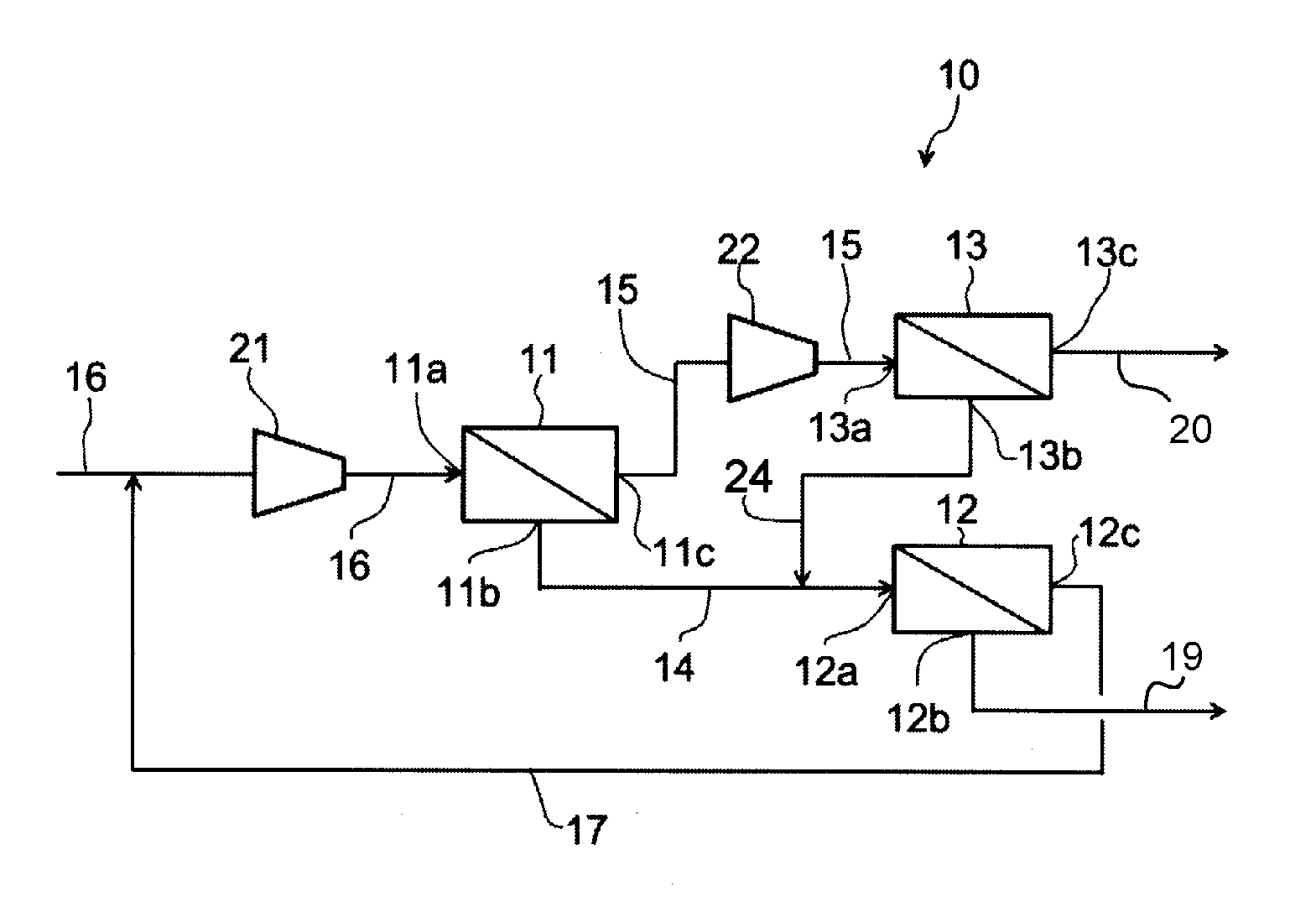

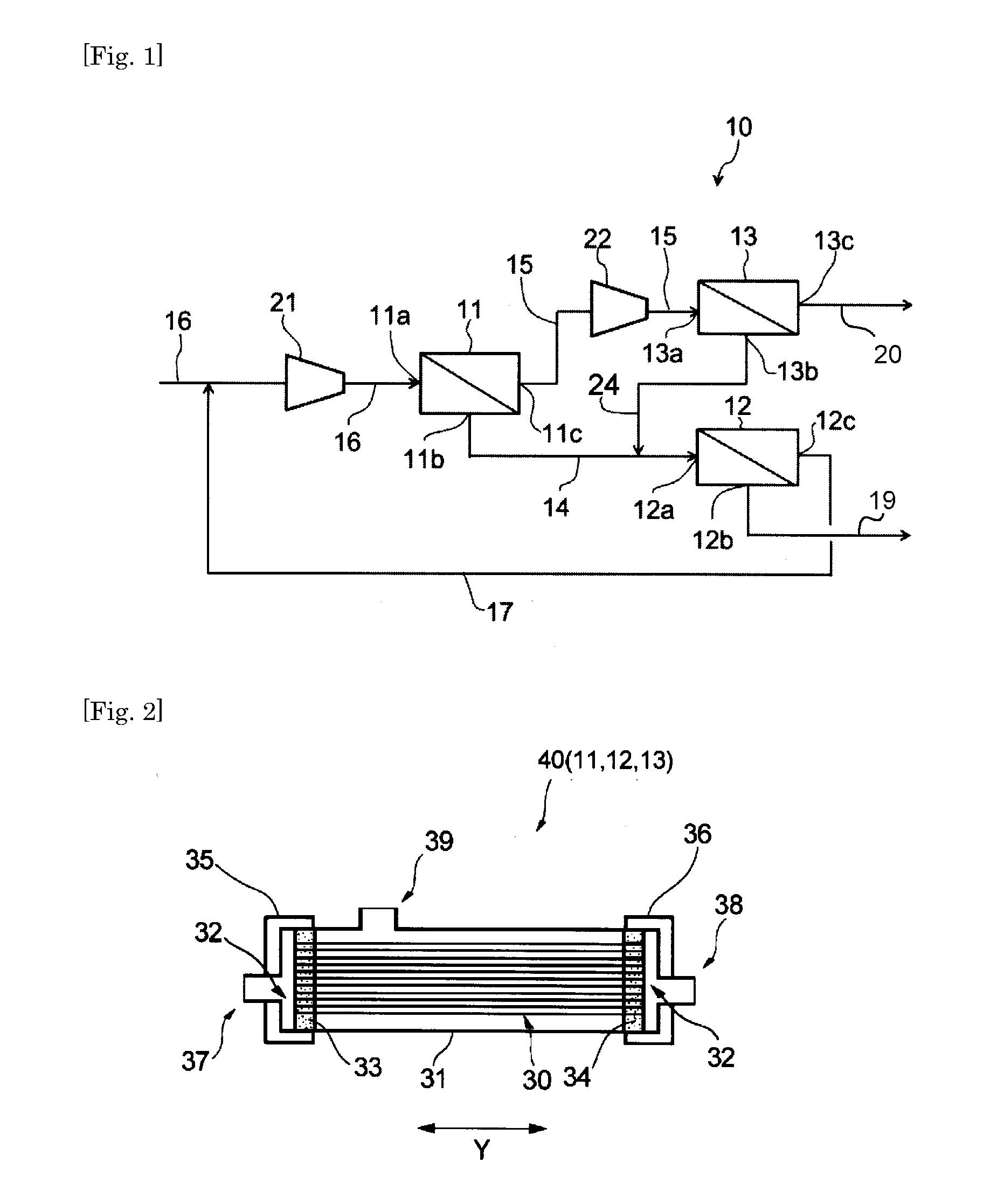

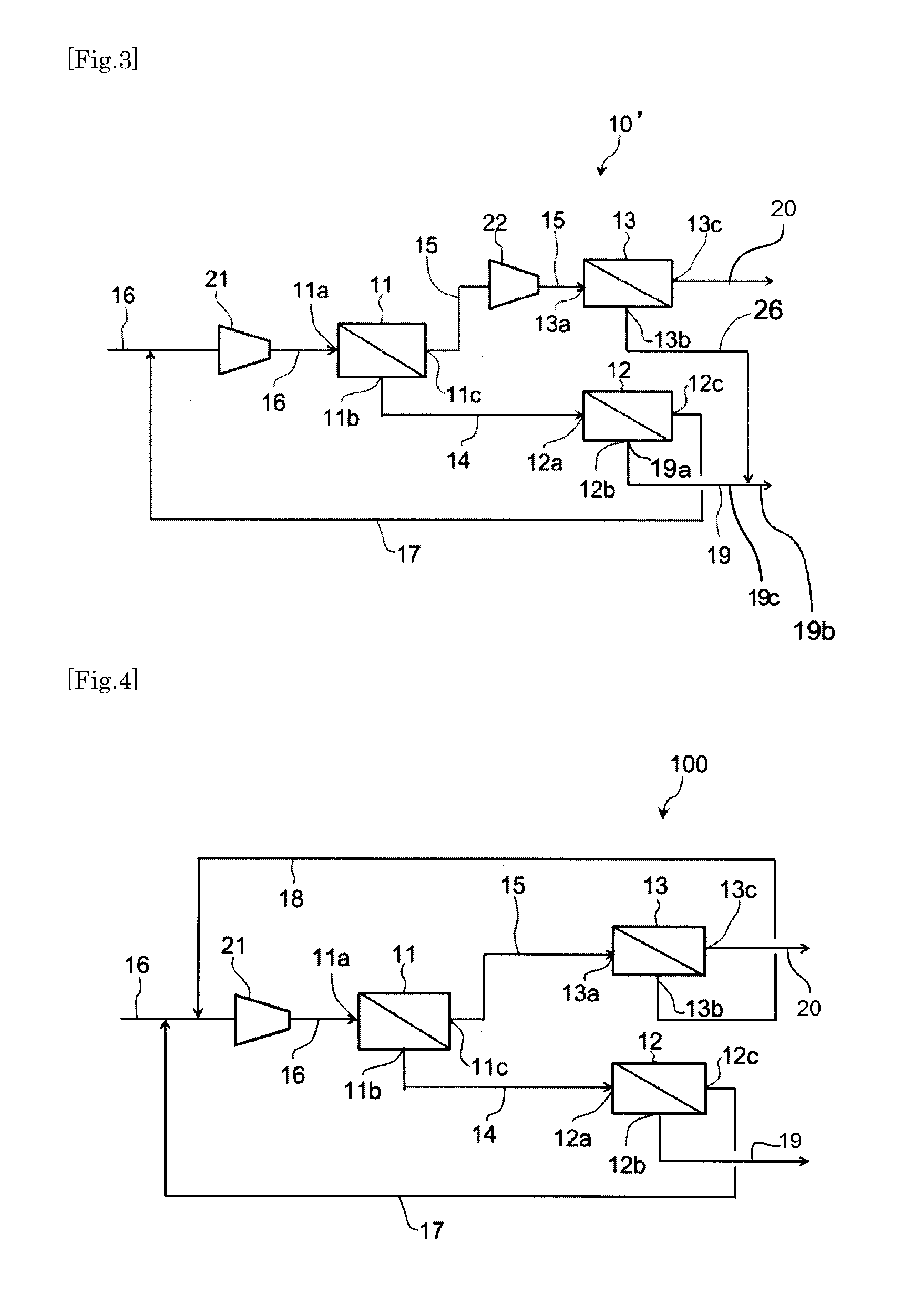

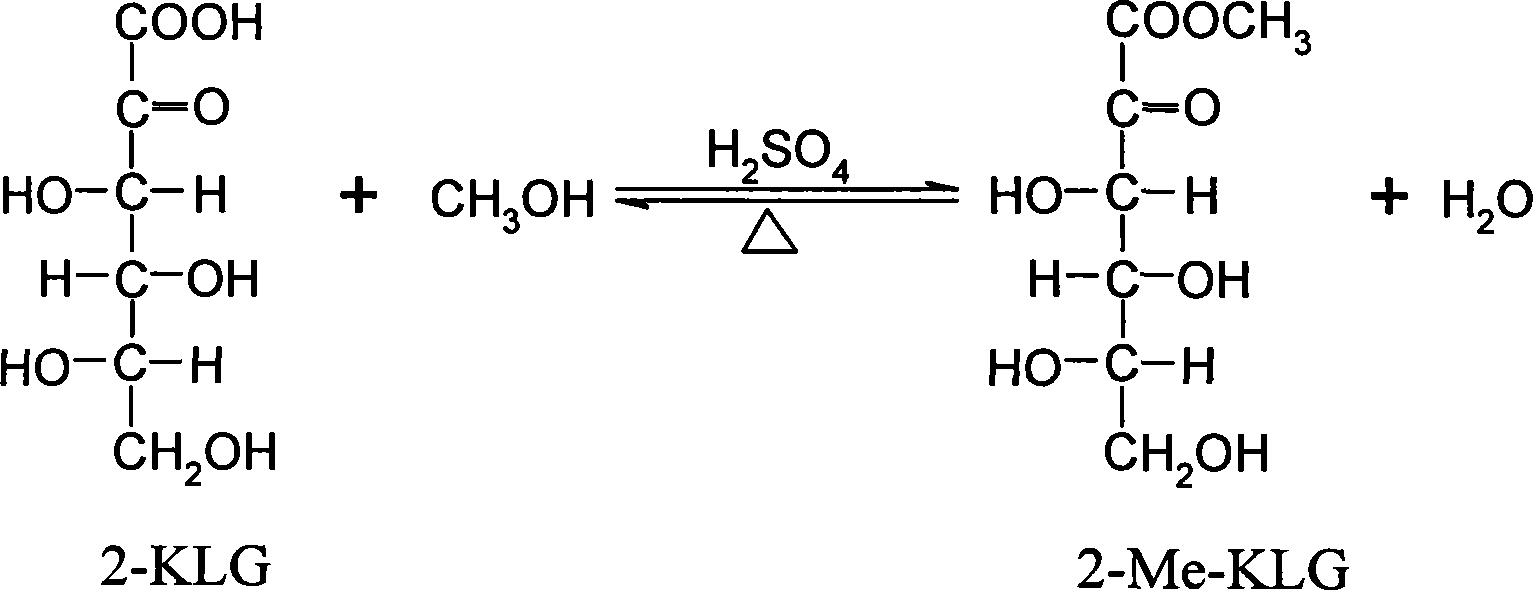

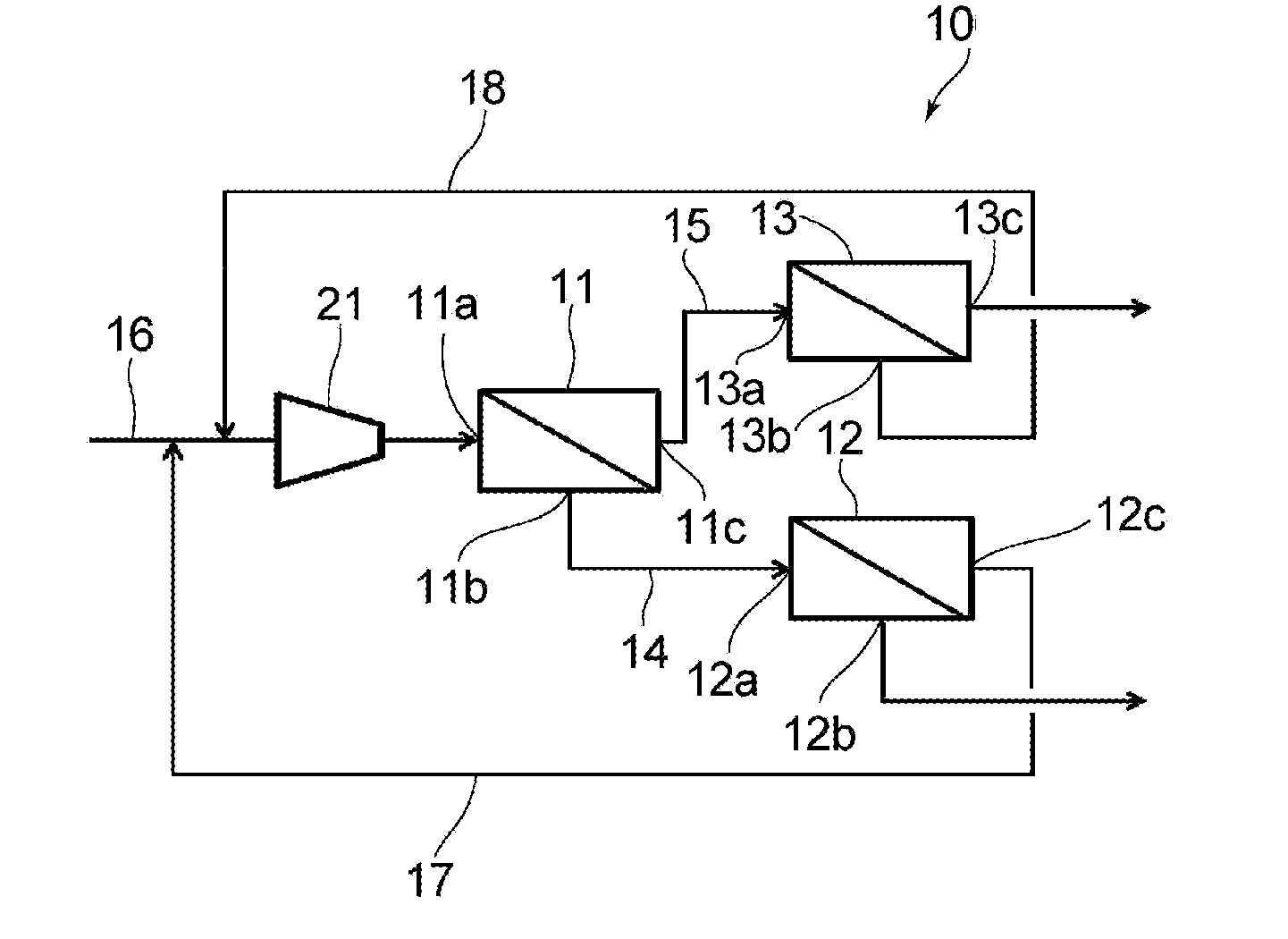

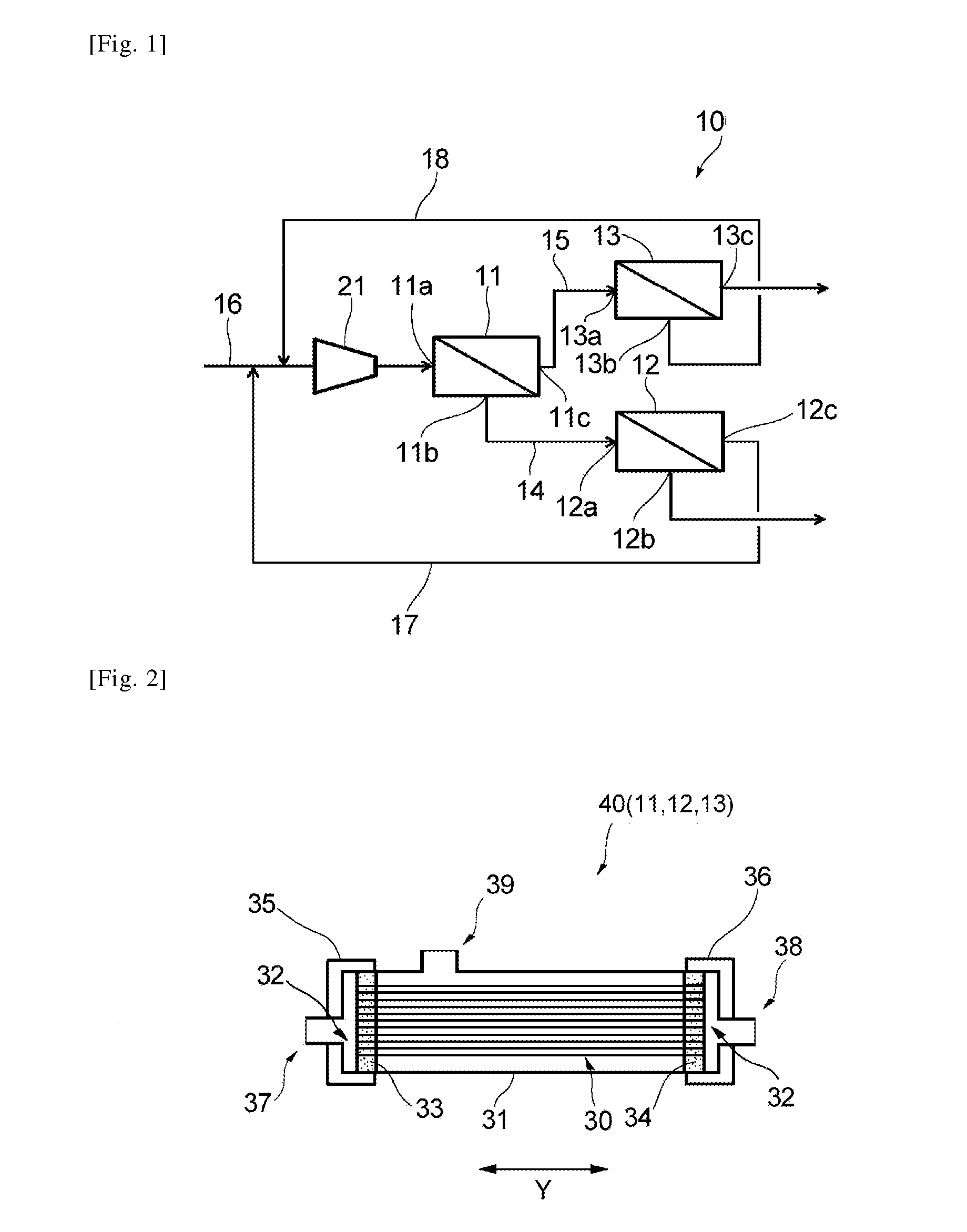

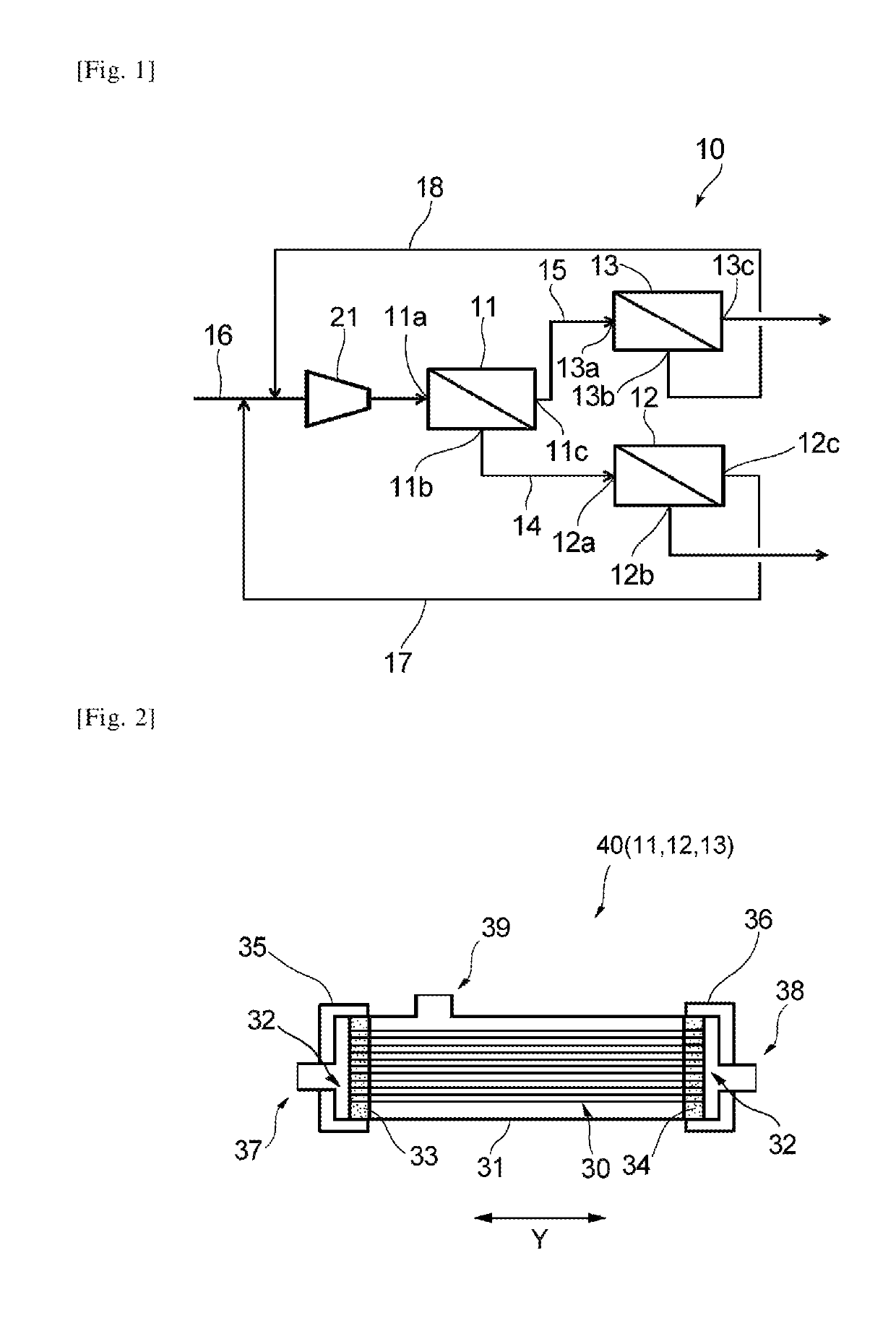

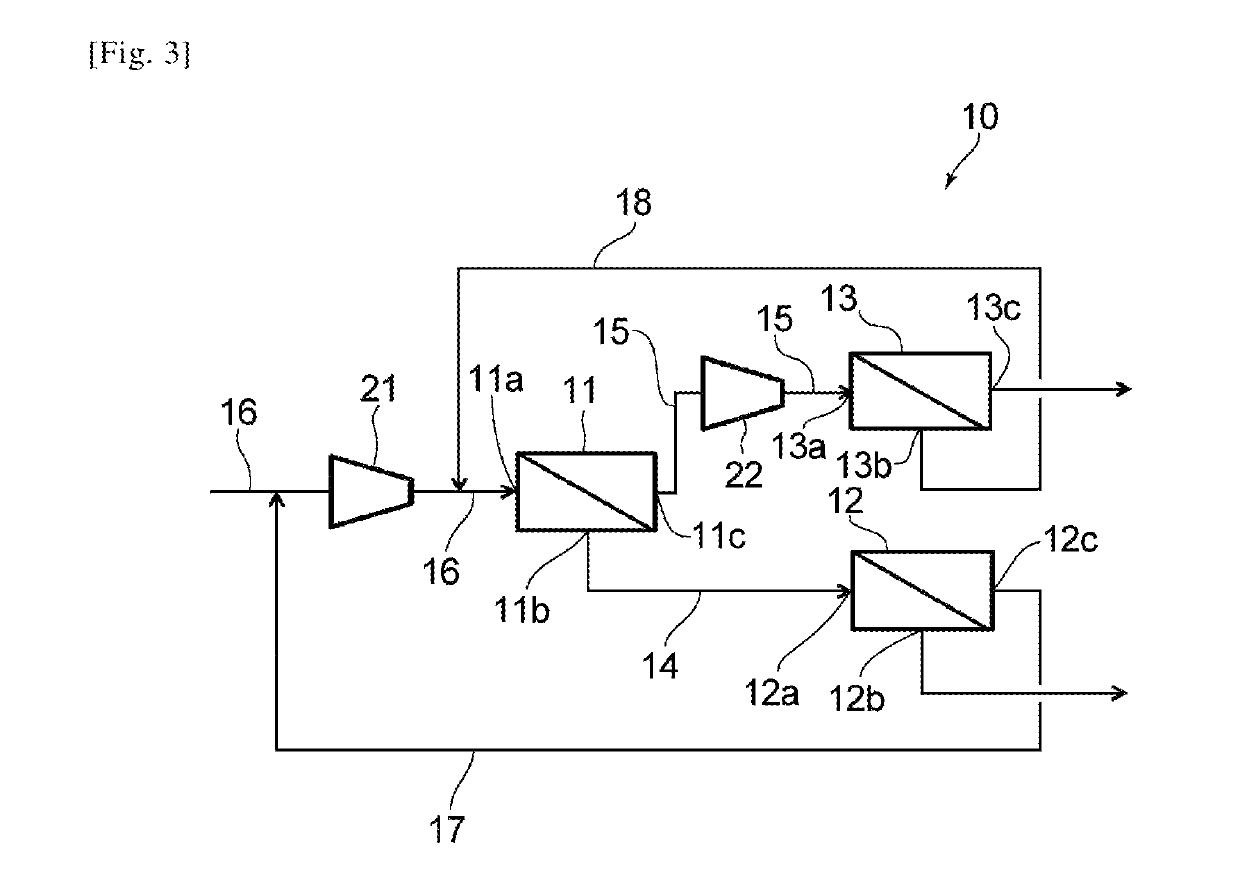

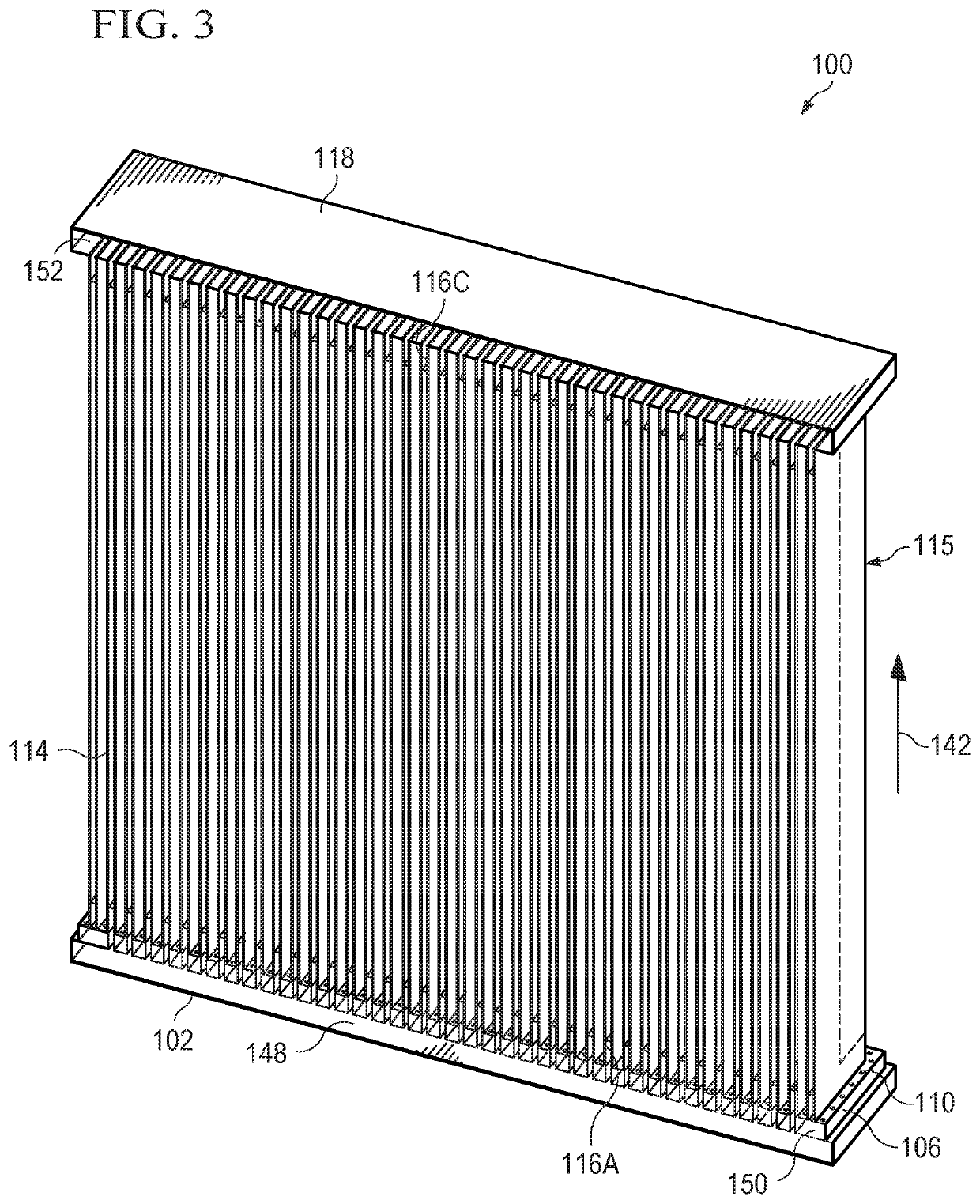

Gas separation system and enriched gas production method

ActiveUS20160288047A1Reduce compression powerIncrease choiceSemi-permeable membranesMembranesProduct gasProcess engineering

A gas separation system includes: first, second, and third gas separation membrane units. A first retentate gas line connects a retentate gas discharge port of the first unit and gas inlet port of the second unit. A first permeate gas line connects a permeate gas discharge port of the first unit and gas inlet port of the third unit. A feed gas mixture supply line is connected to a gas inlet port of the first unit, and provided with first compression elements. The first permeate gas line is provided with second compression elements. The permeate gas discharge port of the second unit is connected by a second permeate gas line to the suction side of the first compression elements in the feed gas mixture supply line. A retentate gas discharge port of the third unit is connected by a third retentate gas line to the first retentate gas line.

Owner:UBE CORP

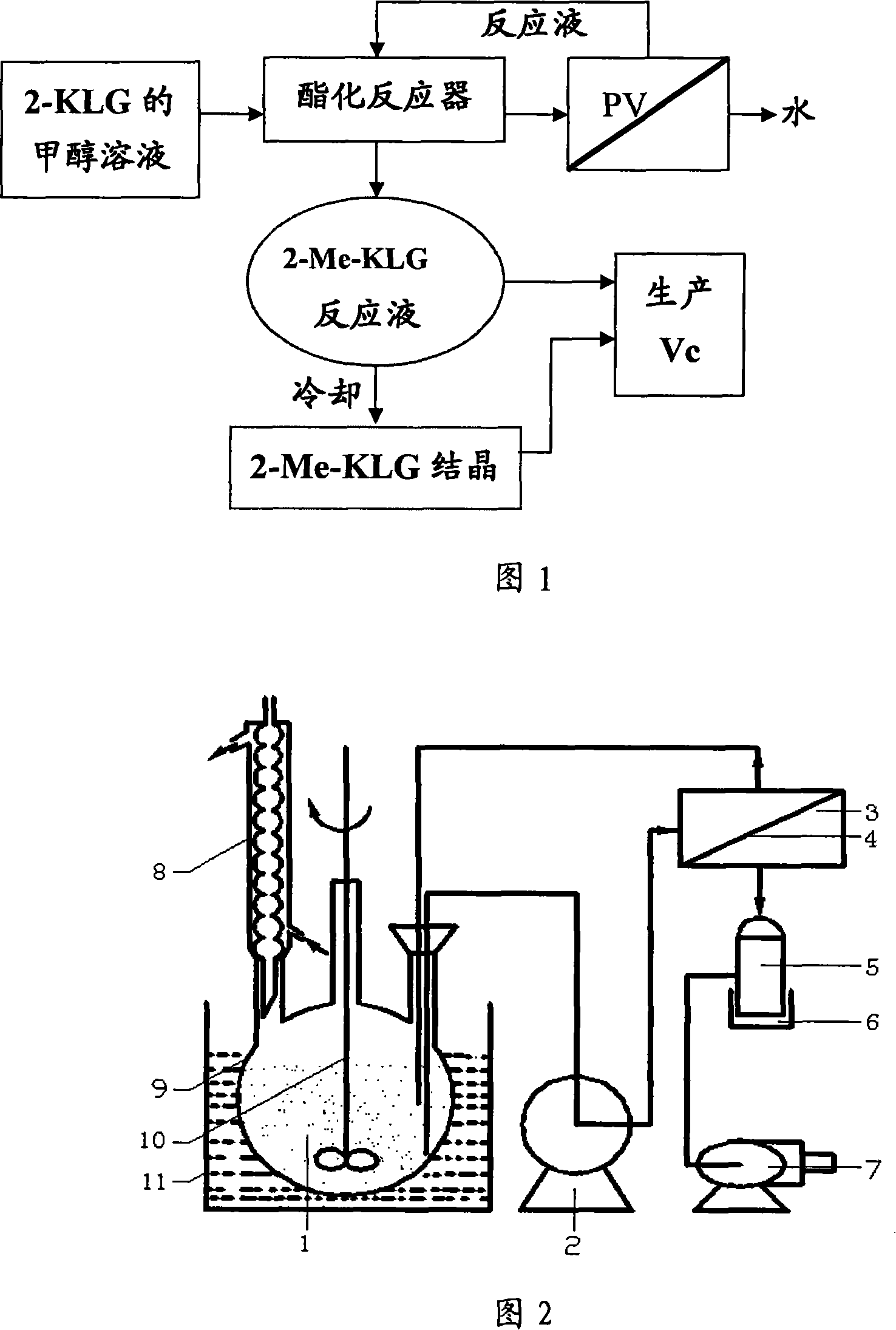

Method for producing vitamin C by esterification reaction-infiltration evaporation barrier separation integral process

InactiveCN101139290AStable production processSimple production processOrganic compound preparationCarboxylic acid esters preparationProduction lineVitamin C

The present invention provides a method of synthesizing the vitamin C (V C ) through the esterification, the pervaporation (PV) membrane separation and integration technology, comprising the process of the methyl esterification between the methanol and the 2-ketone-L-gulonic acid (2-KLG) to produce the 2-ketone-L-gulonic methyl ester (2-Me-KLG). The process comprises the following steps: (1) the solid or liquid 2-KLG is dissolved in the methanol; the temperature is then raised and the catalyst is added; (2) the reaction solution prepared in the first step is pumped into the PV membrane separation device; the reaction solution after the membrane dehydration circulates into the esterification reactor; (3) the product 2-Me-KLG or the reaction solution is directly provided for the later production of the VC. In the method of the present invention, the area of the used membrane is small; the ratio between the alcohol and acid of the raw material liquid and the reaction temperature are relatively low; the invention greatly improves the purity and collection rate of the 2-Me-KLG; the technology is simple and the process is stable; the present invention is suitable for the industrial production-line.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

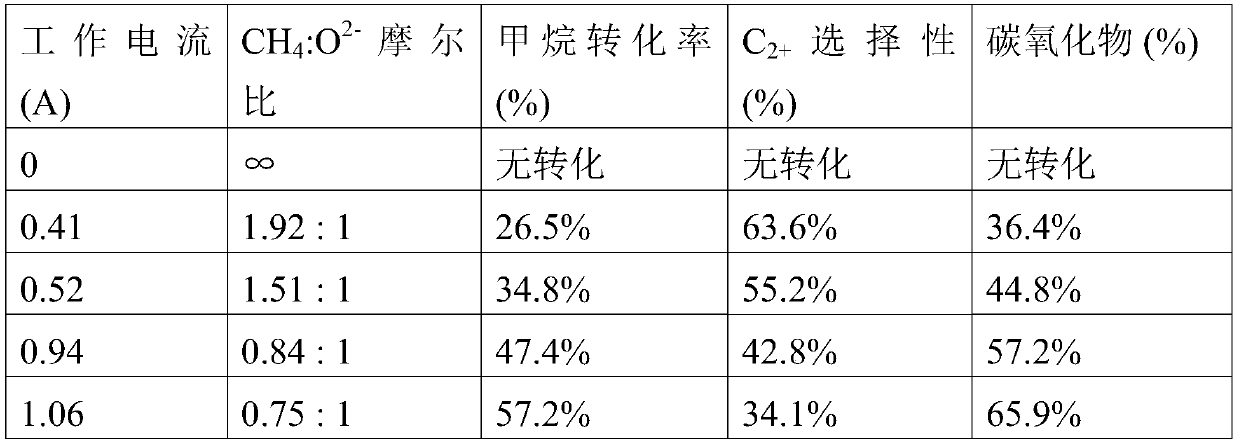

Gas separation system and enriched gas production method

InactiveUS20150273388A1Reduce membrane areaHigh target-gas recovery rateIsotope separationGas blendingChemistry

In a gas separation system, a retentate gas discharge port of a first unit U1 and a gas inlet port of a second unit U2 are connected by a retentate gas discharge line. A permeate gas discharge port of U1 and a gas inlet port of a third unit U3 are connected by a permeate gas discharge line. A feed gas mixture supply line is connected to a gas inlet port of U1. A permeate gas discharge port of U2 and the feed gas mixture supply line are connected by a permeate gas return line. A retentate gas discharge port of U3 and the feed gas mixture supply line are connected by a retentate gas return line. At least in operation, the gas permeability of U2 is higher than that of U3, and the gas selectivity of U3 is higher than that of U2.

Owner:UBE IND LTD

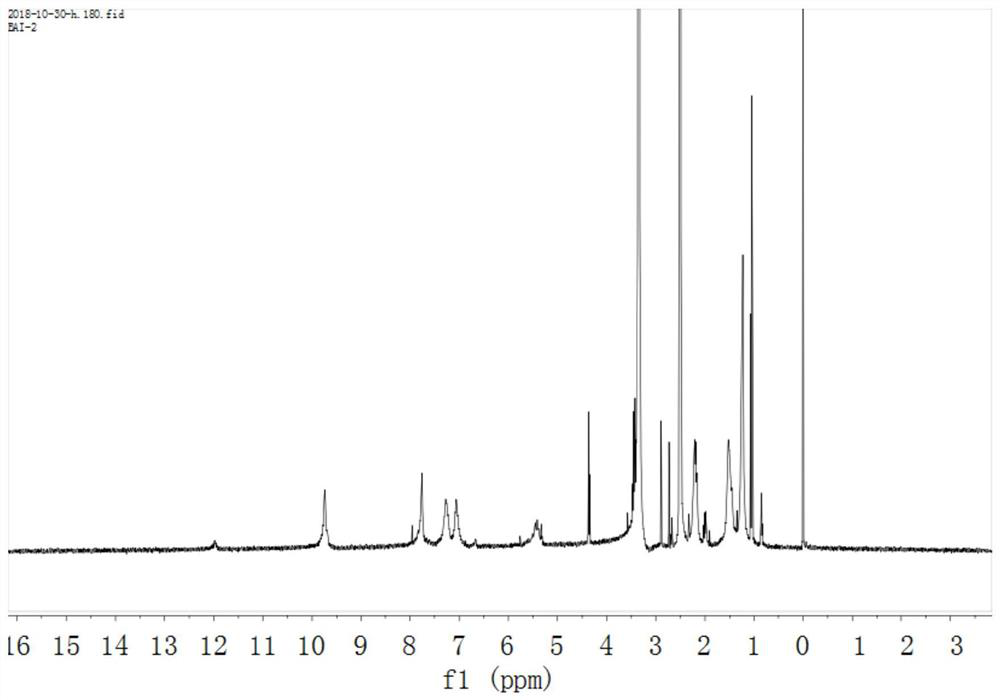

Preparation method of graphene oxide modified triptycenyl polyamide separation membrane

ActiveCN111111475AImprove mechanical propertiesImprove thermal stabilitySemi-permeable membranesGas treatmentOrganic solventPolyamide

The invention discloses a preparation method of a graphene oxide modified triptycenyl polyamide separation membrane. The method comprises the following steps: carrying out polymerization reaction in an organic solvent in the presence of an acid-binding agent by using a triptycenyl compound containing an active group, a diacyl chloride compound and a graphene oxide compound as monomers; pouring a polymer solution obtained by the reaction into deionized water for precipitation, filtering out precipitates, respectively washing the precipitates with methanol and deionized water, and performing drying to obtain a graphene oxide modified triptycenyl polymer; dissolving the graphene oxide modified triptycenyl polymer in an organic solvent to prepare a membrane casting solution, coating a supportbody with the membrane casting solution, and performing drying to obtain the graphene oxide modified triptycenyl polyamide separation membrane. The triptycenyl polyamide separation membrane solves theproblem of close packing of macromolecules of a net structure, and breaks through the limitation of small flux of a traditional triptycenyl polyamide separation membrane.

Owner:NANJING UNIV OF TECH

Filtration apparatus

ActiveUS7972510B2Reliably membrane surfaceEfficiently and reliably remove the suspended componentMembranesWaste water treatment from animal husbandryHollow fibreFiltration

A filtration apparatus for performing solid-liquid separation by immersing a plurality of hollow fiber membranes in a to-be-treated liquid containing a suspended component includes the hollow fiber membranes folded double, a treated liquid collection means communicated with an open end of each of the hollow fiber membranes, a holding member for holding a bent portion of each of the hollow fiber membranes with a gap formed between the bent portion and the holding member, and a gas-jetting means for jetting a cleaning gas from the bent side of each of the hollow fiber membranes to a side of the open end. A gap for flowing the gas jetted by the gas-jetting means is formed between the hollow fiber membranes and the holding member or / and in at least one part of gaps between the hollow fiber membranes.

Owner:SUMITOMO ELECTRIC IND LTD

Acetonitrile refining method

PendingCN113501770AAvoid it happening againImprove separation efficiencyOrganic compound preparationCarboxylic acid amides preparationAcetic acidPhysical chemistry

The invention provides an acetonitrile refining method which comprises the following steps: recovering unreacted ammonia gas discharged by an ammoniation reactor through an ammonia recovery tower, introducing the ammonia gas recovered by the ammonia recovery tower into an acrylonitrile device, carrying out a propylene ammoxidation reaction to obtain an acetonitrile crude product, carrying out decyanation on the acetonitrile crude product through a decyanation tower, and concentrating and rectifying the decyanated acetonitrile crude product, to obtain an acetonitrile finished product. According to the acetonitrile refining method disclosed by the invention, the unreacted ammonia gas after the acetic acid ammoniation reaction is recovered by the ammonia recovery tower and is used as a raw material of an acrylonitrile device, and a cryogenic reflux deamination technology is adopted, so that a large amount of ammonium salt wastewater generated by absorbing the ammonia gas by using acid liquor is avoided.

Owner:CHINA TIANCHEN ENG

Ammonia separation method and zeolite

ActiveUS10946333B2High selectivityEasy to useMembranesSemi-permeable membranesPhysical chemistryZeolite membranes

Provided is a method for separating ammonia gas using zeolite membrane having excellent separation stability at a high temperature capable of separating ammonia gas from a mixed gas composed of multiple components including ammonia gas, hydrogen gas, and nitrogen gas to the permeation side with high selectivity and high permeability. Also provided is a method for separating ammonia by selectively permeating ammonia gas from a mixed gas containing at least ammonia gas, hydrogen gas, and nitrogen gas using a zeolite membrane, wherein the ammonia gas concentration in the mixed gas is 1.0% by volume or more.

Owner:MITSUBISHI CHEM CORP

Filtration apparatus

InactiveUS20110198277A1Reliably membrane surfaceEfficiently and reliably remove the suspended componentMembranesUltrafiltrationFiberHollow fibre membrane

A filtration apparatus for performing solid-liquid separation by immersing a plurality of hollow fiber membranes in a to-be-treated liquid containing a suspended component so that the treated liquid permeates the hollow fiber membranes. The filtration apparatus includes the hollow fiber membranes folded double; a treated liquid collection means communicated with an open-side end of each of the hollow fiber membranes; a holding member for holding a bent portion at an other-end side of each of the hollow fiber membranes with a gap formed between the bent portion of each of the hollow fiber membranes and the holding member; and a gas-jetting means for jetting a cleaning gas from the other-end side of each of the hollow fiber membranes to the open-side end of each of the hollow fiber membranes. A gap for flowing the gas jetted by the gas-jetting means is formed between the hollow fiber membranes held by the holding member and the holding member or / and on at least one part of gaps between the hollow fiber membranes.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

A kind of preparation method of graphene oxide modified triptycene-based polyamide separation membrane

ActiveCN111111475BImprove mechanical propertiesImprove thermal stabilitySemi-permeable membranesGas treatmentPolyamideOrganosolv

The invention discloses a preparation method of a graphene oxide modified triptycene-based polyamide separation membrane. The method comprises the following preparation steps: using a triptycene compound containing an active group, a diacid chloride compound and a graphene oxide compound as The monomer is polymerized in an organic solvent in the presence of an acid-binding agent; the polymer solution obtained by the reaction is poured into deionized water for precipitation, and the filtered precipitate is washed with methanol and deionized water respectively, and dried to obtain Graphene oxide-modified triptycene-based polymer; graphene oxide-modified triptycene-based polymer is dissolved in an organic solvent to make a casting solution, coated on a support and dried to obtain a graphene oxide-modified Triptyl polyamide separation membrane. The invention solves the feature of close packing of network structure macromolecules and breaks the limitation of small flux of traditional triptylenyl polyamide separation membrane.

Owner:NANJING TECH UNIV

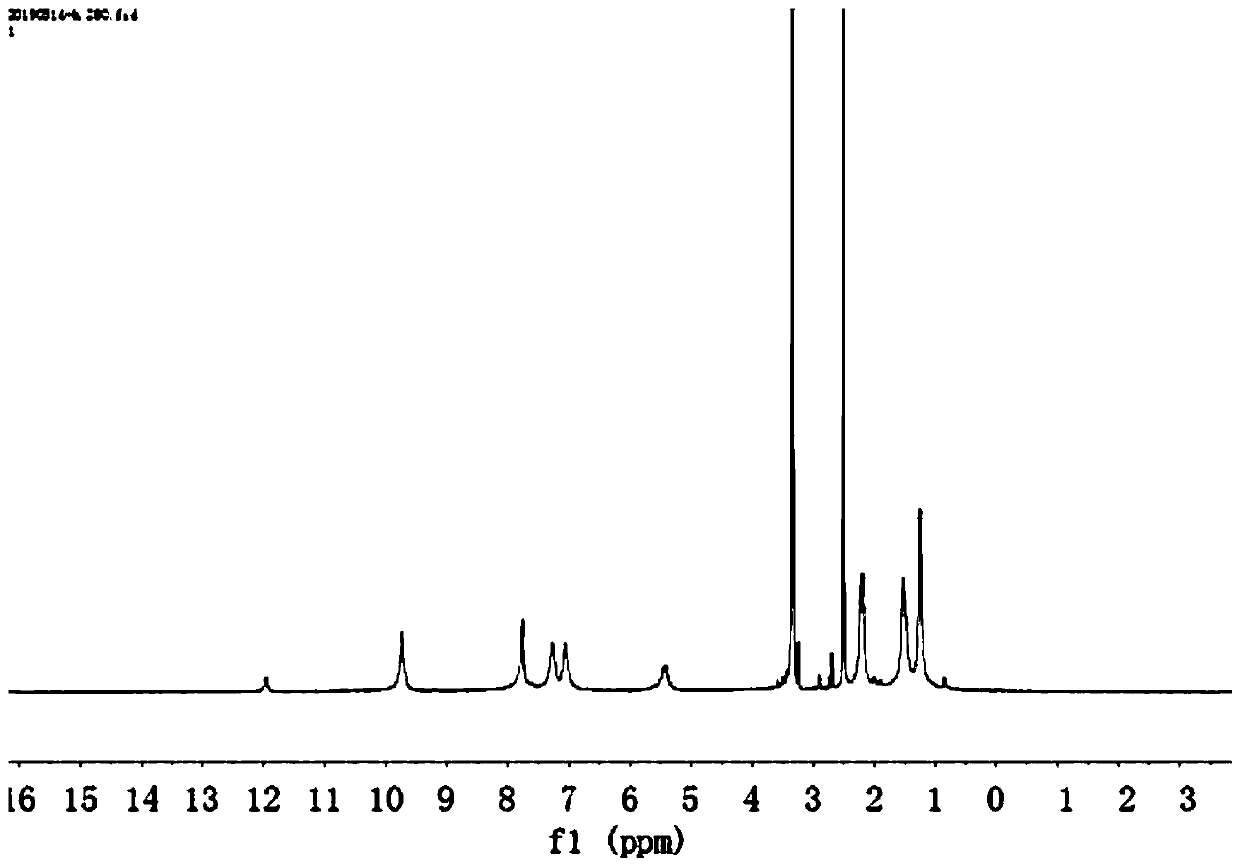

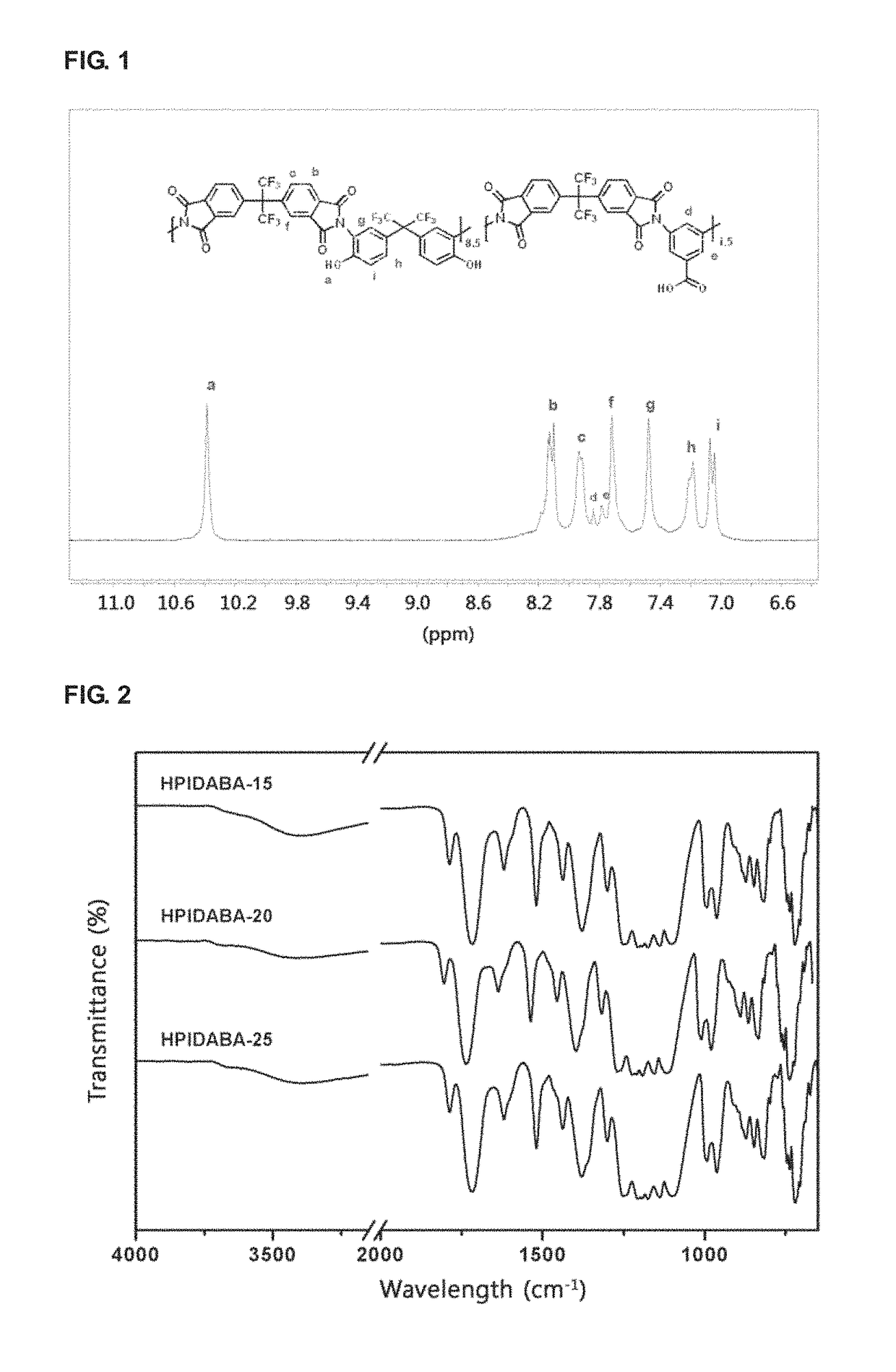

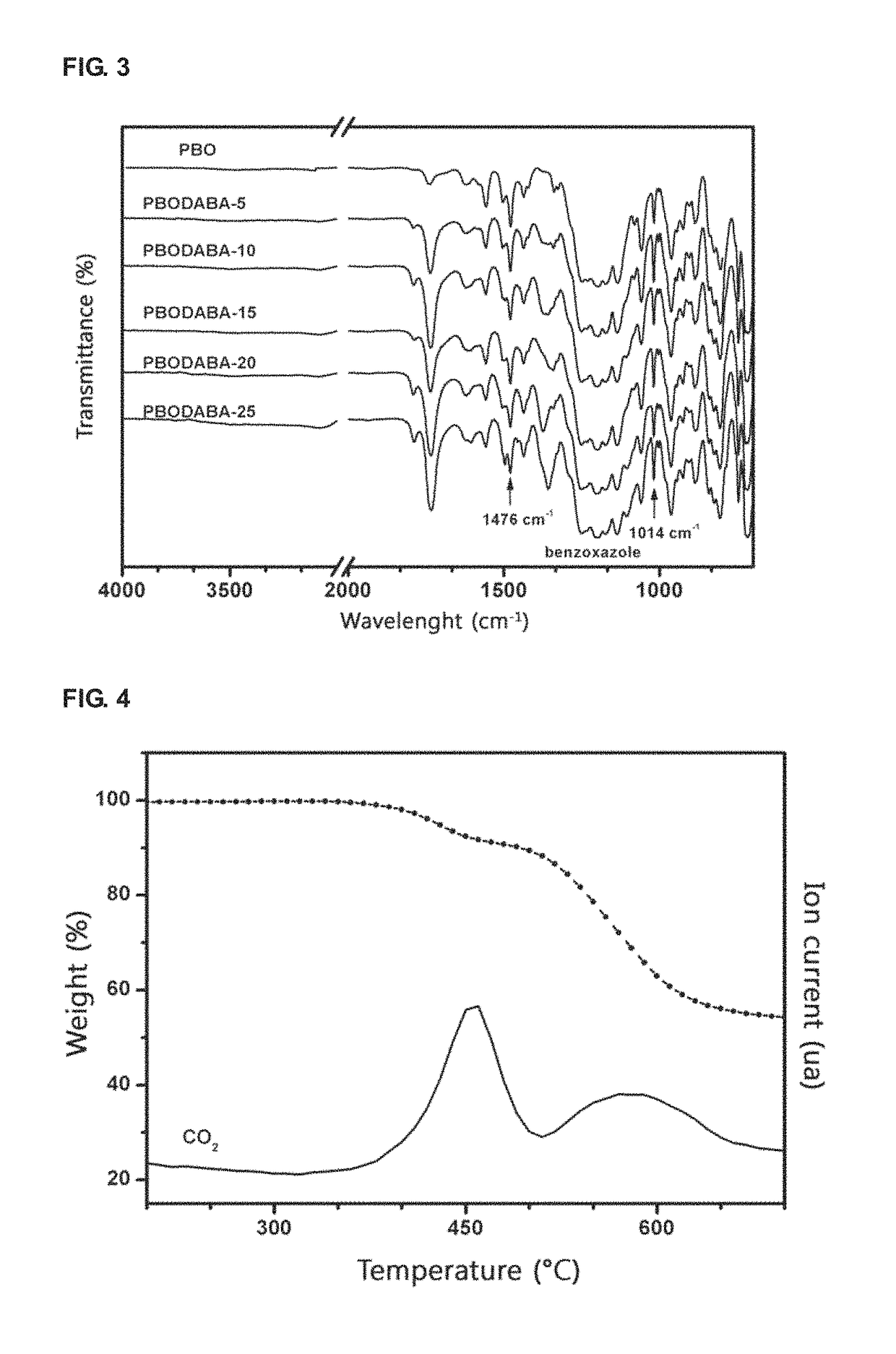

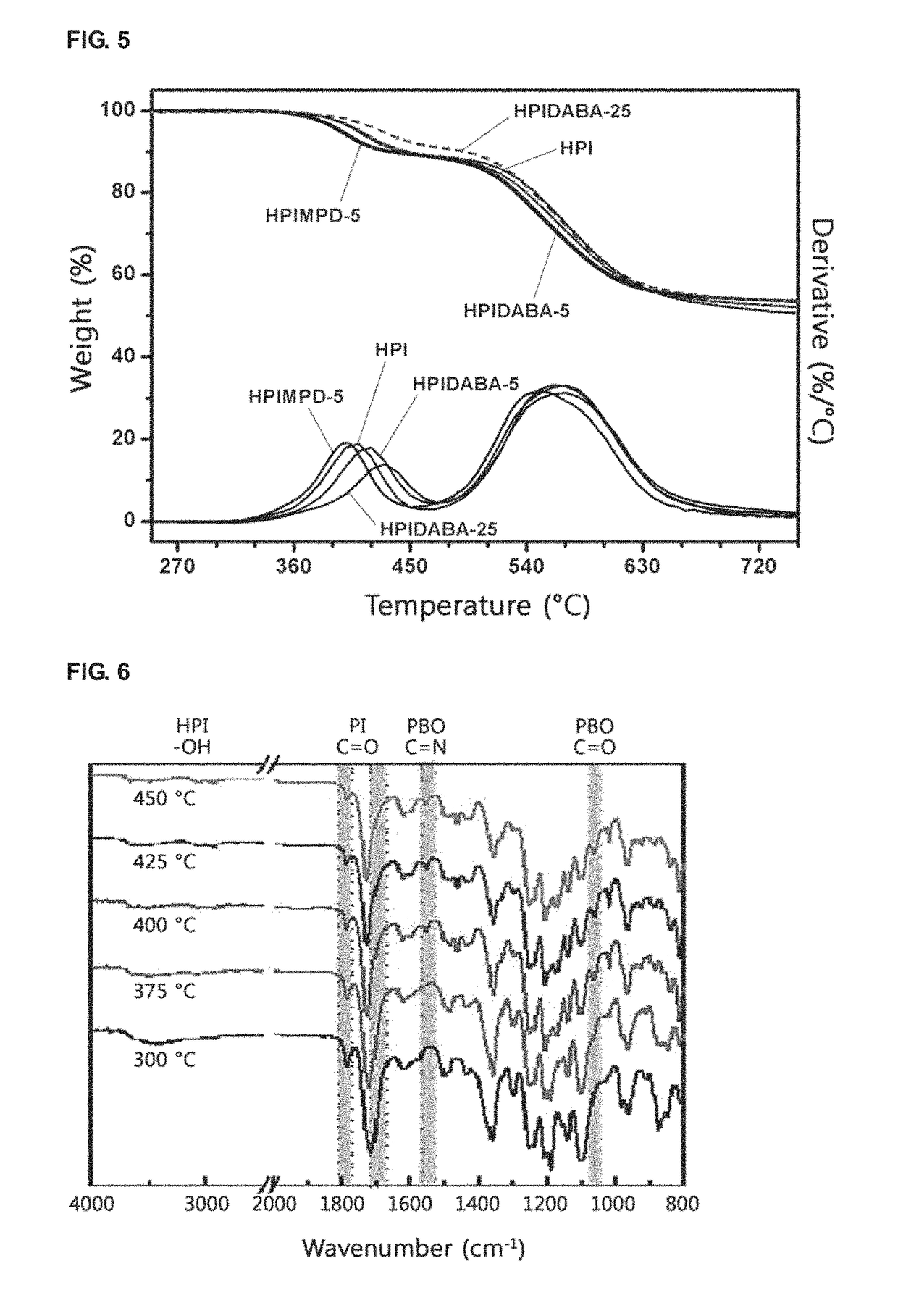

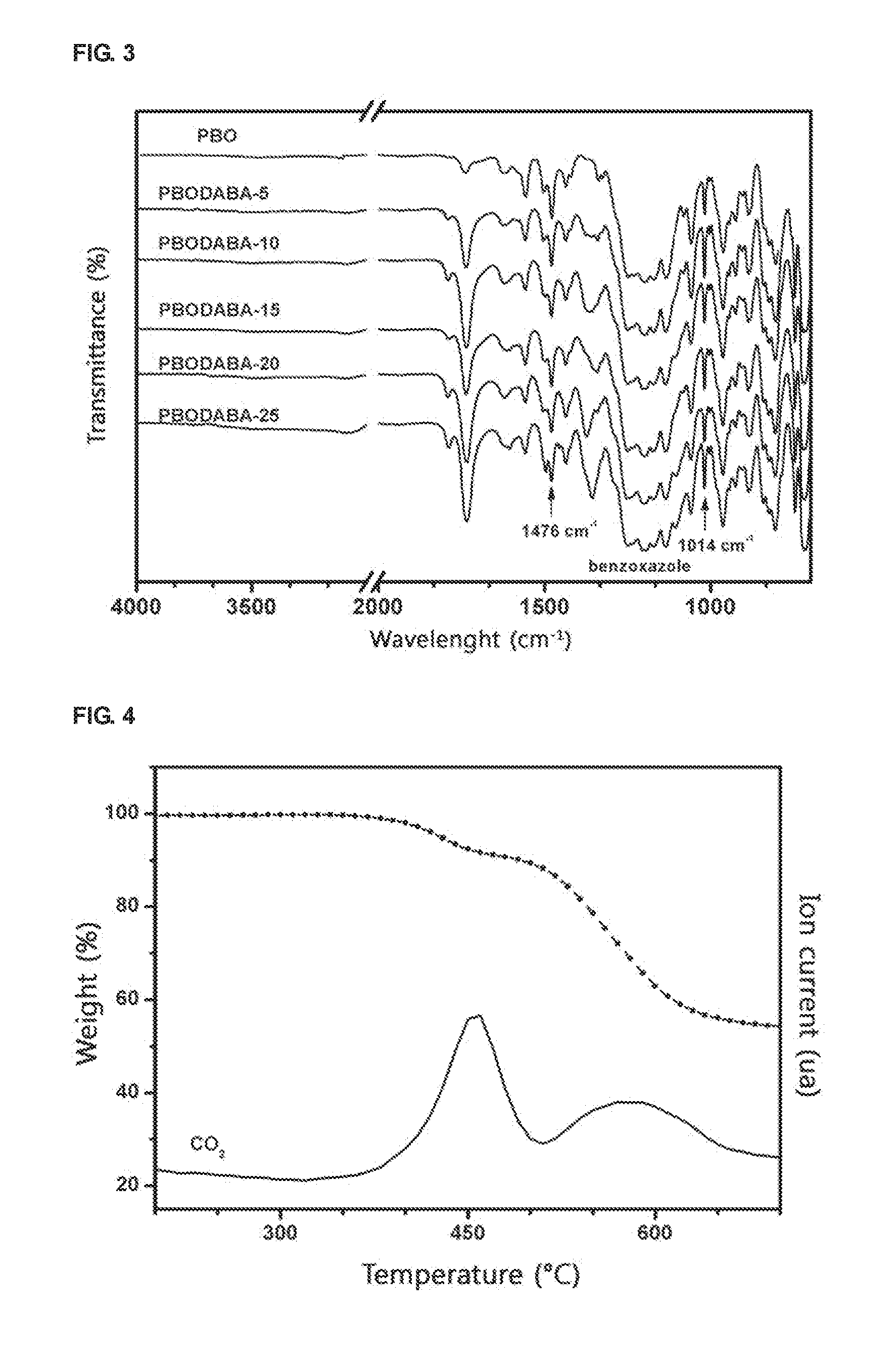

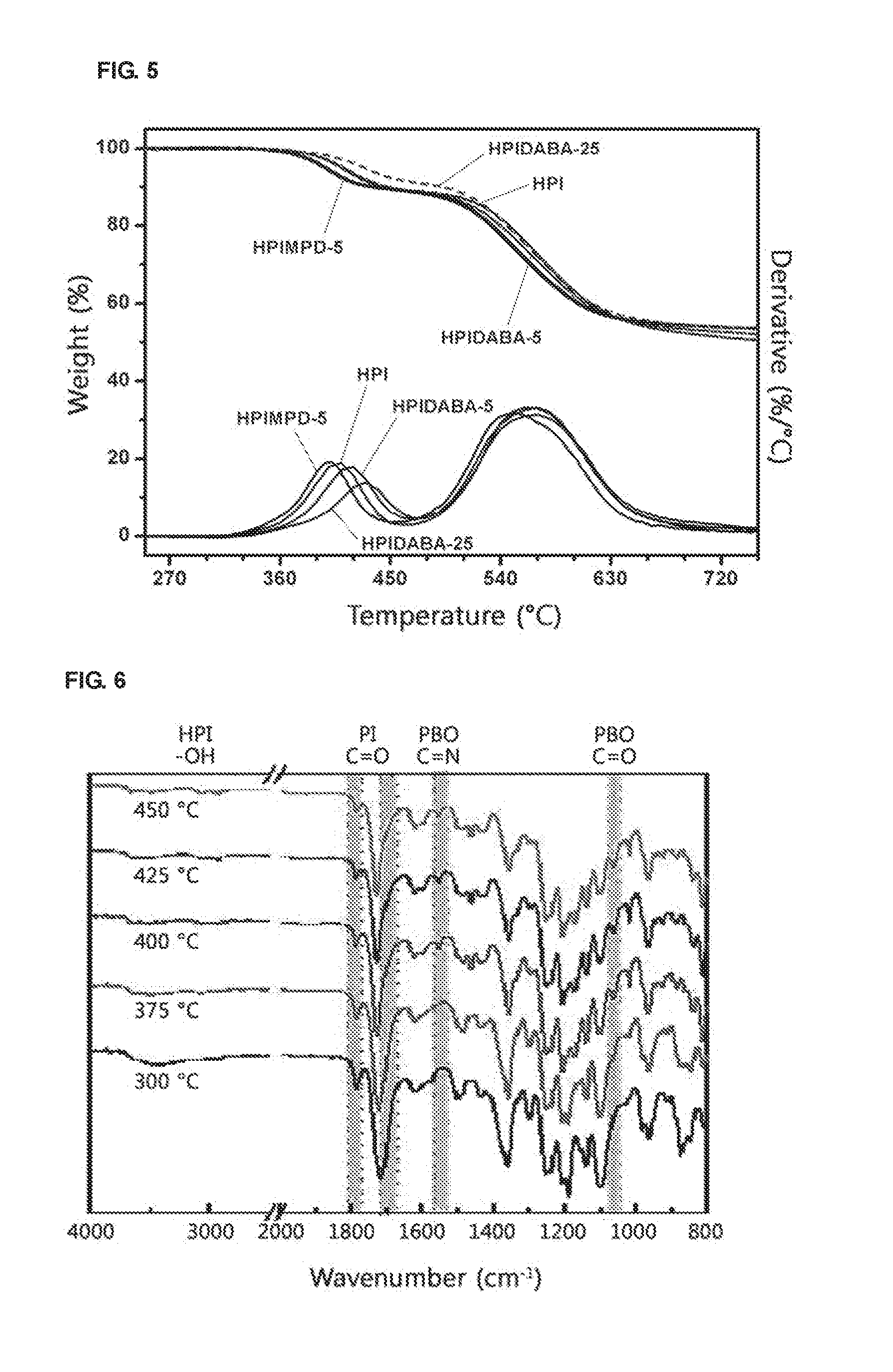

Crosslinked, thermally rearranged poly(benzoxazole-co-imide), gas separation membranes comprising the same and preparation method thereof

InactiveUS10035109B2Improve permeabilityHigh selectivitySemi-permeable membranesMembranesBenzoxazoleCarboxylic acid

The present disclosure relates to a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane prepared simply by heat-treating a membrane prepared from an o-hydroxypolyimide copolymer having carboxylic acid groups such that thermal crosslinking and thermal rearrangement occur simultaneously or a gas separation membrane containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer having a benzoxazole group content of less than 80% in the polymer chain, prepared from transesterification crosslinking of an o-hydroxypolyimide copolymer having carboxylic acid groups and a diol-based compound followed by thermal rearrangement, and a method for preparing the same (a membrane for flue gas separation is excluded).In accordance with the present disclosure, a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane for gas separation can be prepared simply through heat treatment without requiring a complicated process such as chemical crosslinking, UV irradiation, etc. for forming a crosslinked structure and a gas separation membrane (a membrane for flue gas separation is excluded) prepared therefrom exhibits superior permeability and selectivity. Also, the method is applicable to commercial-scale production because the preparation process is simple.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

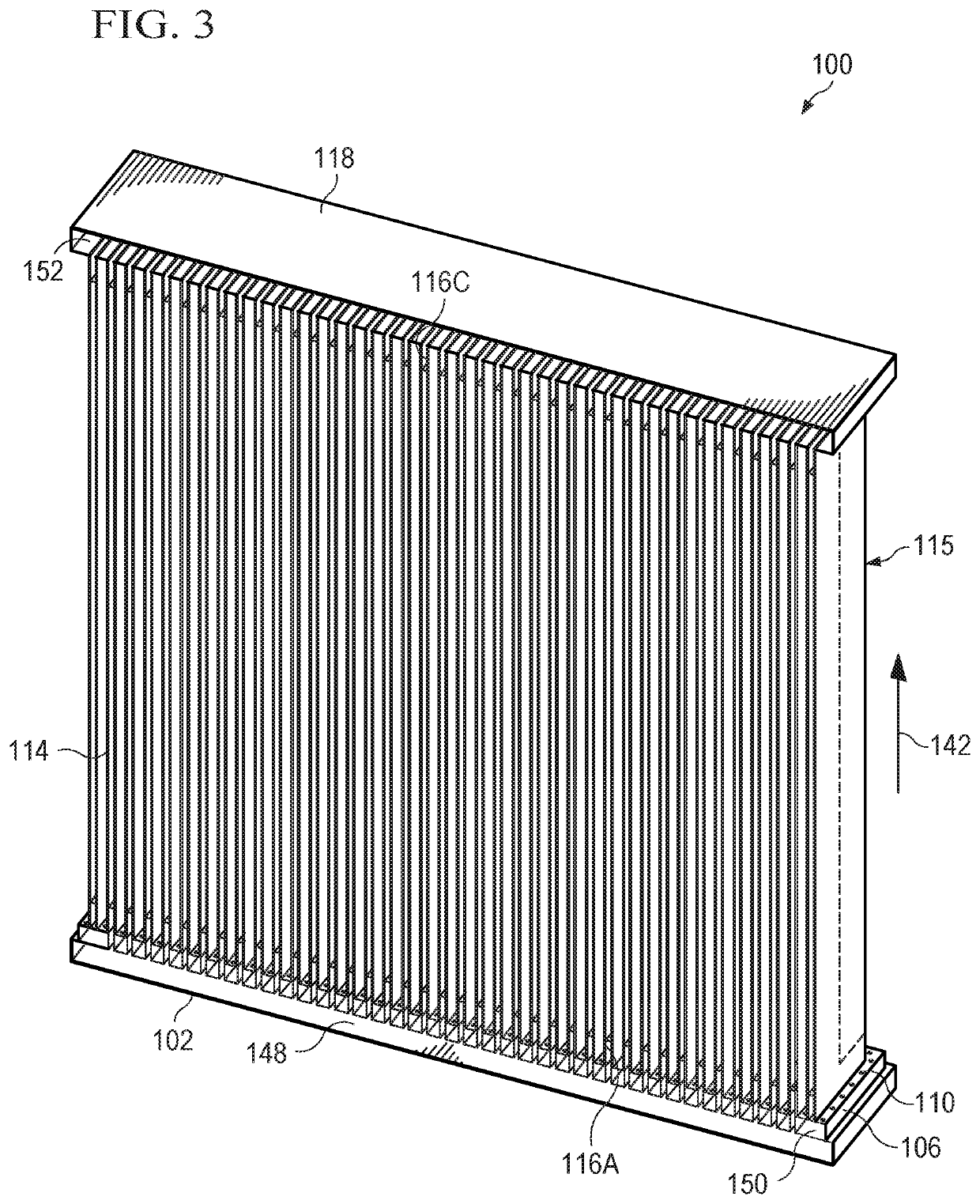

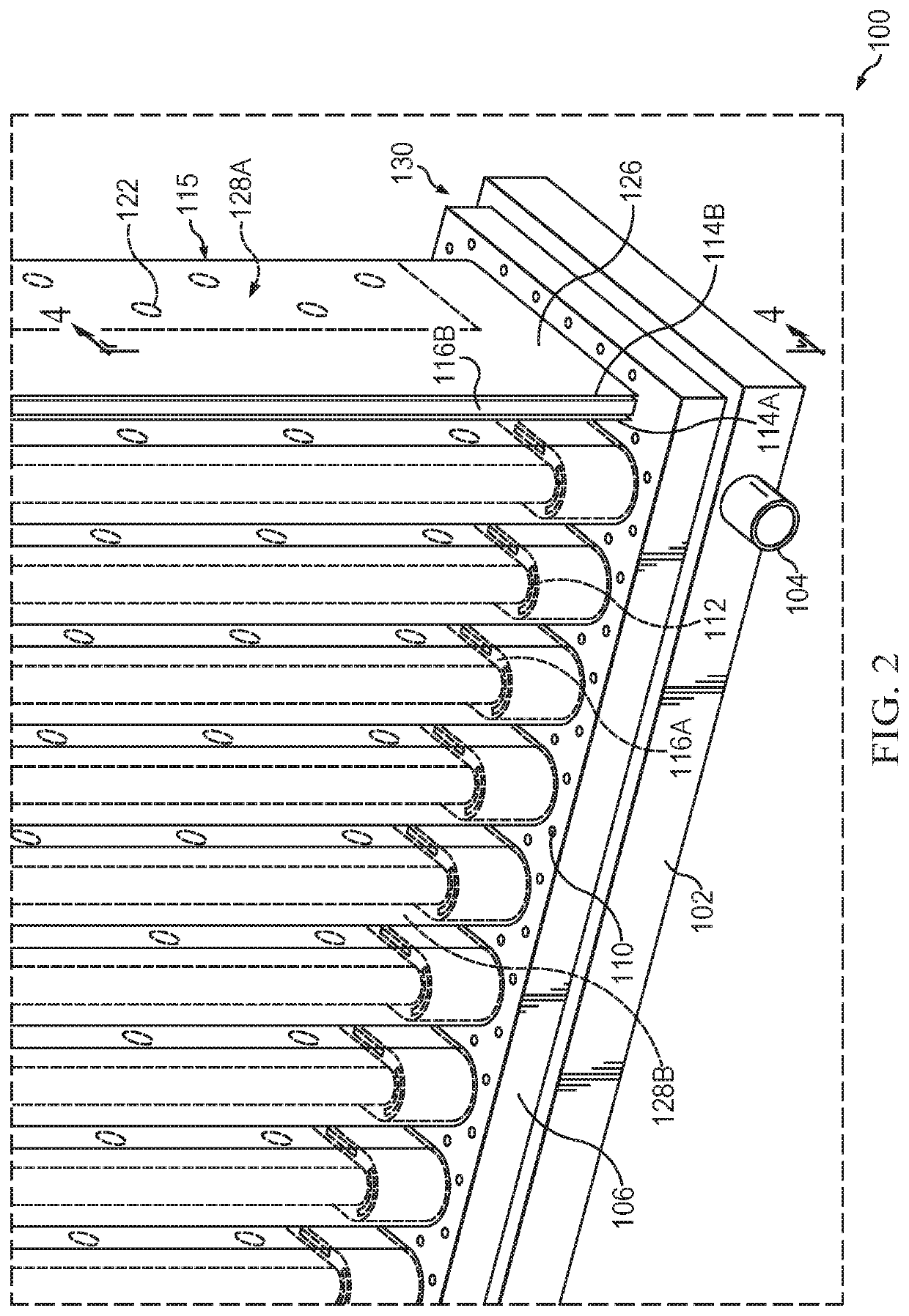

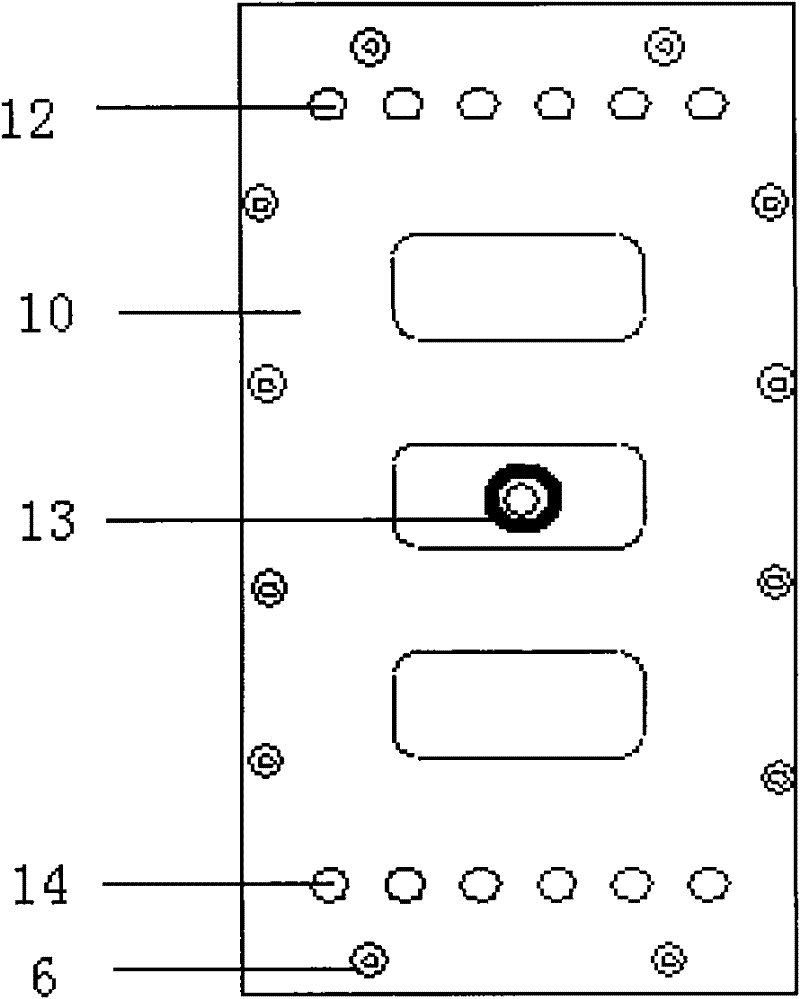

Compact high-throughput device for water treatment

ActiveUS11083998B2Increase capacityReduce membrane areaMembranesWater/sewage treatment bu osmosis/dialysisChemical physicsEngineering

Owner:KING ABDULLAH UNIV OF SCI & TECH

Membranes for flue gas separation comprising crosslinked, thermally rearranged poly(benzoxazole-co-imide) and preparation method thereof

InactiveUS20160296893A1Improve permeabilityHigh selectivityMembranesSemi-permeable membranesBenzoxazoleImide

The present disclosure relates to a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer prepared simply by heat-treating a membrane prepared from an o-hydroxypolyimide copolymer having carboxylic acid groups such that thermal crosslinking and thermal rearrangement occur simultaneously or a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer having a benzoxazole group content of less than 80% in the polymer chain, prepared from transesterification crosslinking of an o-hydroxypolyimide copolymer having carboxylic acid groups and a diol-based compound followed by thermal rearrangement, and a method for preparing the same.In accordance with the present disclosure, a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane for flue gas separation can be prepared simply through heat treatment without requiring a complicated process such as chemical crosslinking, UV irradiation, etc. for forming a crosslinked structure and a membrane for flue gas separation prepared therefrom exhibits superior permeability and selectivity. Also, the method is applicable to commercial-scale production because the preparation process is simple.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

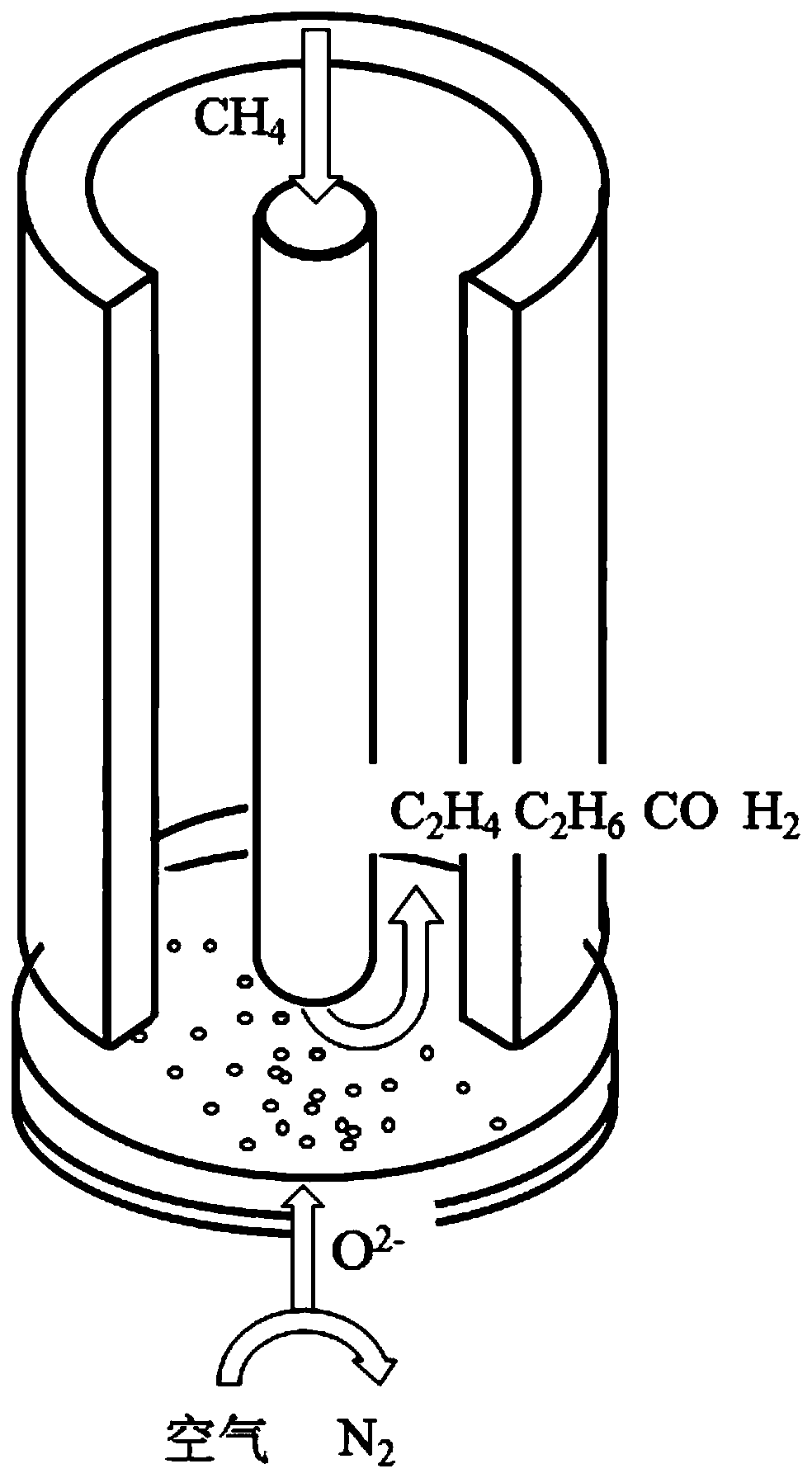

Method for converting methane into aliphatic hydrocarbons, fuel cell and fuel cell preparation method

ActiveCN109385643BRealize integrationAvoid demandElectrolysis componentsCell electrodesPtru catalystFuel cells

Owner:PETROCHINA CO LTD

Gas separation system and enriched gas production method

ActiveUS10258921B2Reduce membrane areaReduce in quantityDispersed particle separationThermodynamicsPetroleum engineering

In a gas separation system, a retentate gas discharge port of a first unit U1 and a gas inlet port of a second unit U2 are connected by a retentate gas discharge line. A permeate gas discharge port of U1 and a gas inlet port of a third unit U3 are connected by a permeate gas discharge line. A feed gas mixture supply line is connected to a gas inlet port of U1. A permeate gas discharge port of U2 and the feed gas mixture supply line are connected by a permeate gas return line. A retentate gas discharge port of U3 and the feed gas mixture supply line are connected by a retentate gas return line. At least in operation, the gas permeability of U2 is higher than that of U3, and the gas selectivity of U3 is higher than that of U2.

Owner:UBE CORP

Gas separation system and enriched gas production method

ActiveUS20180339264A1Reduce membrane areaReduce in quantityDispersed particle separationChemistryGas separation

In a gas separation system, a retentate gas discharge port of a first unit U1 and a gas inlet port of a second unit U2 are connected by a retentate gas discharge line. A permeate gas discharge port of U1 and a gas inlet port of a third unit U3 are connected by a permeate gas discharge line. A feed gas mixture supply line is connected to a gas inlet port of U1. A permeate gas discharge port of U2 and the feed gas mixture supply line are connected by a permeate gas return line. A retentate gas discharge port of U3 and the feed gas mixture supply line are connected by a retentate gas return line. At least in operation, the gas permeability of U2 is higher than that of U3, and the gas selectivity of U3 is higher than that of U2.

Owner:UBE CORP

Integrated suspension bed inorganic membrane reactor

ActiveCN1289179CImprove sealingEasy to separateChemical/physical processesSmall footprintMembrane reactor

An integrated suspension-bed reactor with inorganic membrane for the reaction between multiple phases of material and the solid-liquid separation features that its reaction still has internal stirrer and inorganic membrane as the separating unit with several membrane tubes which has a closed end and an open end communicated with filtrate outlet tube. A turbulence promoter with a rotary axle is arranged outside said separating unit.

Owner:NANJING TECH UNIV

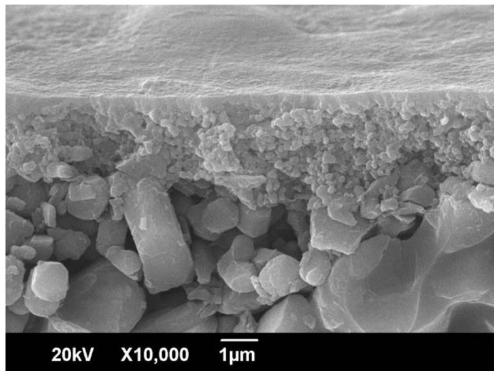

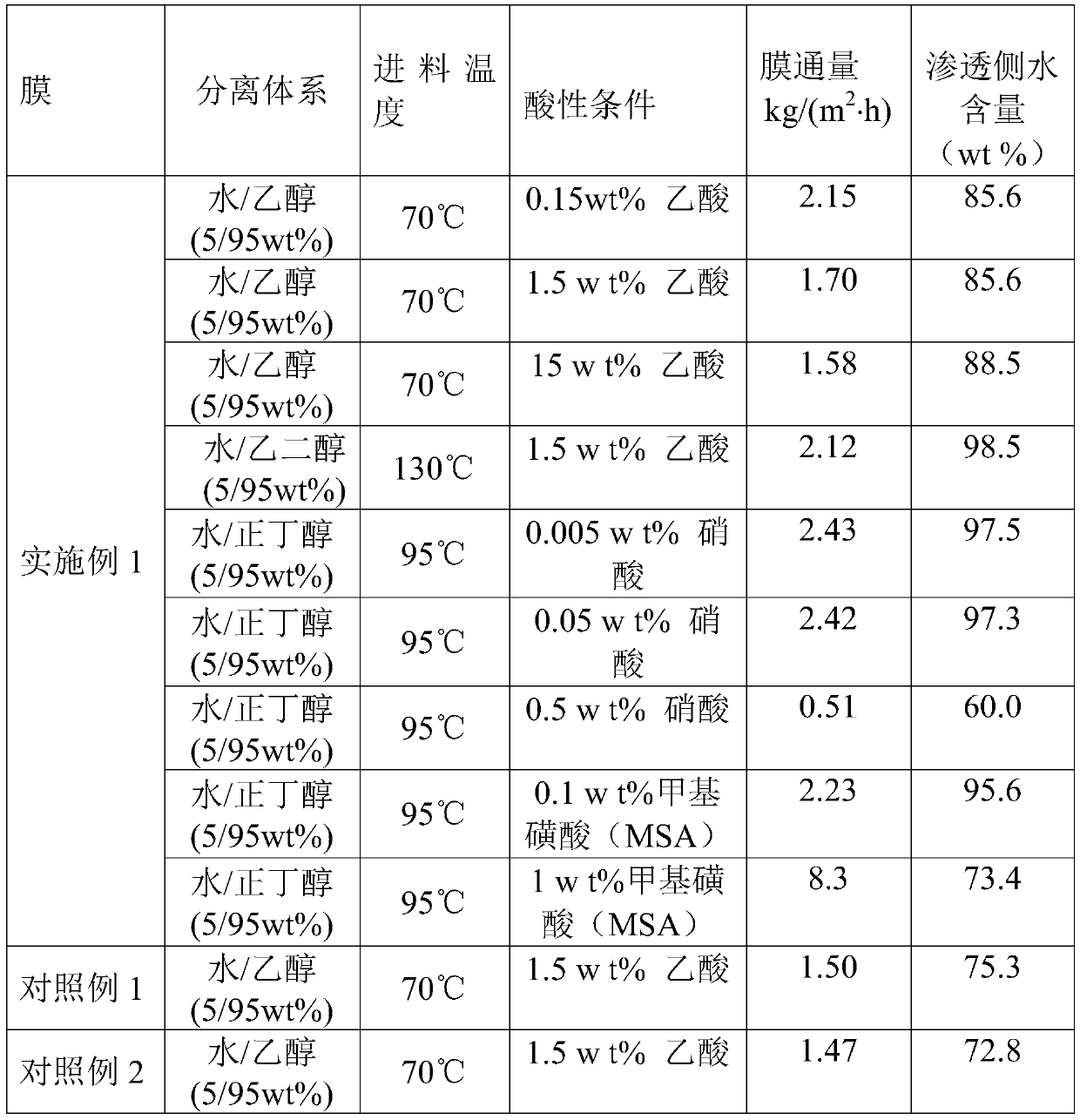

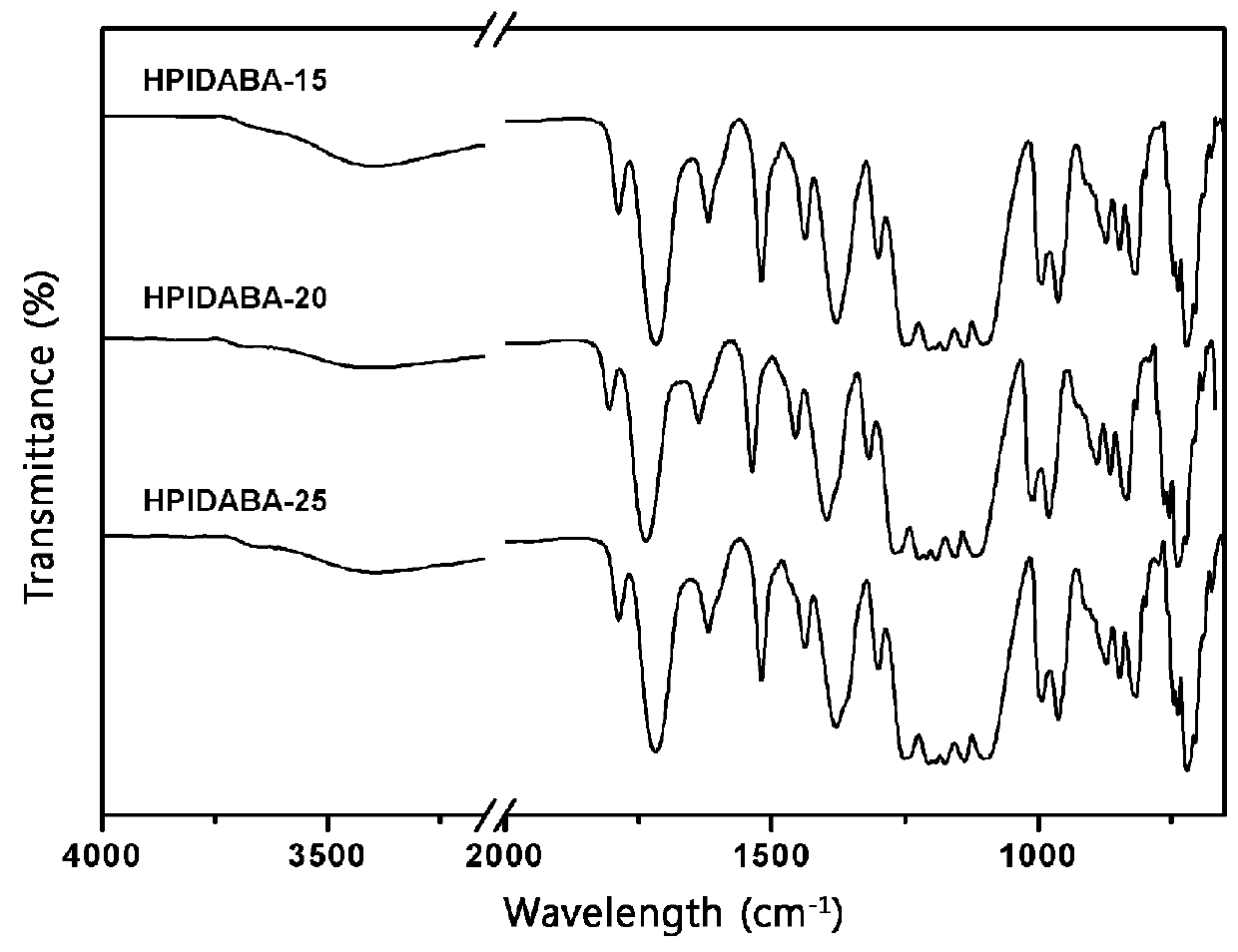

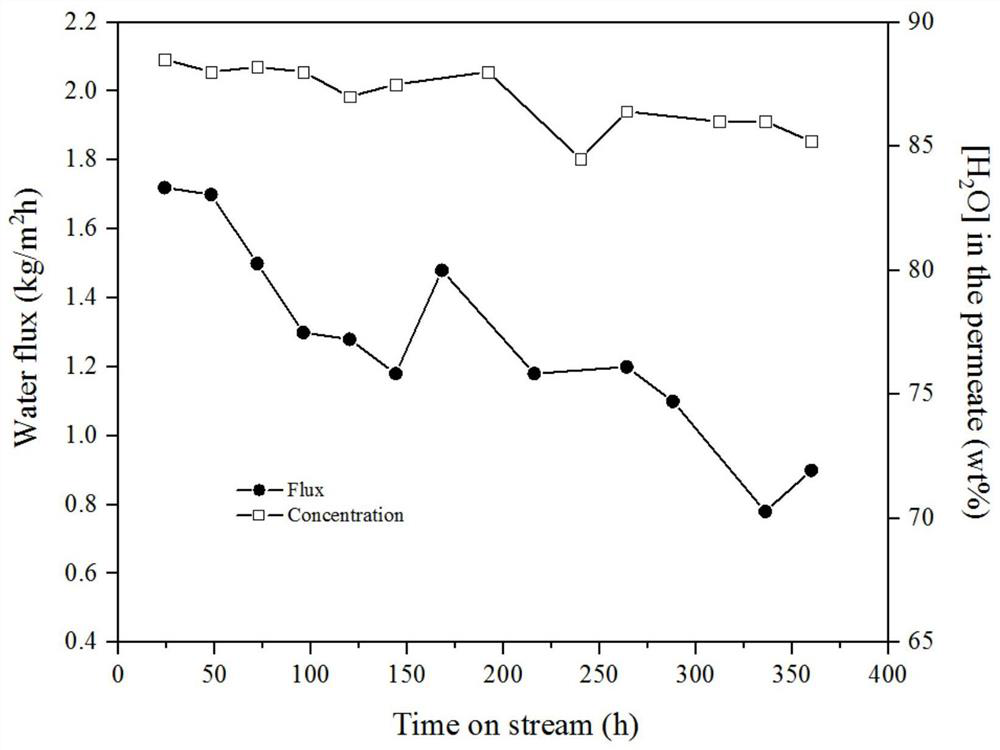

Preparation method and application of acid-resistant PSQ composite membrane

ActiveCN111359446AGood solvent resistanceImprove mechanical stabilityReverse osmosisDistillationOrganic solventPhysical chemistry

The invention discloses a preparation method and an application of an acid-resistant PSQ composite membrane, and belongs to the technical field of membrane separation preparation. The preparation method comprises the following steps: (1) dissolving a PSQ precursor in an alcohol solvent, sequentially adding hydrochloric acid, ammonia water and hydrochloric acid, and carrying out an acid-base-acid alternate catalytic reaction to obtain PSQ sol; (2) coating a ceramic support body with a silicon dioxide-zirconium oxide sol to generate a transition layer; and (3) coating the surface of the transition layer with the PSQ sol to serve as a separation layer, and dipping-pulling to prepare the PSQ composite membrane with a supporting layer, the transition layer and a separation layer structure . ThePSQ composite membrane provided by the invention has good acid resistance, high flux and high selectivity, meets the current industrial requirements and expectations, and is widely applied to organicsolvent dehydration and organic solvent separation of an acidic system.

Owner:CHANGZHOU UNIV

Membranes for flue gas separation comprising crosslinked, thermally rearranged poly(benzoxazole-co-imide) and preparation method thereof

InactiveUS10040034B2Improve permeabilityHigh selectivityMembranesSemi-permeable membranesBenzoxazoleImide

The present disclosure relates to a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer prepared simply by heat-treating a membrane prepared from an o-hydroxypolyimide copolymer having carboxylic acid groups such that thermal crosslinking and thermal rearrangement occur simultaneously or a membrane for flue gas separation containing a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer having a benzoxazole group content of less than 80% in the polymer chain, prepared from transesterification crosslinking of an o-hydroxypolyimide copolymer having carboxylic acid groups and a diol-based compound followed by thermal rearrangement, and a method for preparing the same.In accordance with the present disclosure, a crosslinked, thermally rearranged poly(benzoxazole-co-imide) copolymer membrane for flue gas separation can be prepared simply through heat treatment without requiring a complicated process such as chemical crosslinking, UV irradiation, etc. for forming a crosslinked structure and a membrane for flue gas separation prepared therefrom exhibits superior permeability and selectivity. Also, the method is applicable to commercial-scale production because the preparation process is simple.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

A kind of preparation method and application of acid-resistant psq composite membrane

ActiveCN111359446BGood solvent resistanceImprove mechanical stabilityReverse osmosisDistillationOrganosolvSilicon oxide

The invention discloses a preparation method and application of an acid-resistant PSQ composite membrane, and belongs to the technical field of membrane separation preparation. The preparation method includes the following steps: (1) dissolving a PSQ precursor in an alcohol solvent, and sequentially adding hydrochloric acid, ammonia water and hydrochloric acid to perform an acid-base-acid alternating catalytic reaction to obtain PSQ sol. (2) Coating silica-zirconia sol on the ceramic support to form a transition layer. (3) Coating PSQ sol on the surface of the transition layer as a separation layer, and dipping-pulling to obtain a PSQ composite membrane having a structure of a support layer, a transition layer and a separation layer. The PSQ composite membrane provided by the present invention has good acid resistance, high flux and high selectivity, meets current industrial needs and expectations, and is widely used in organic solvent dehydration and organic solvent separation in acidic systems.

Owner:CHANGZHOU UNIV

Compact high-throughput device for water treatment

ActiveUS20200101421A1Increase capacityReduce membrane areaMembranesWater/sewage treatment bu osmosis/dialysisChemical physicsEngineering

Owner:KING ABDULLAH UNIV OF SCI & TECH

Gas separation system and enriched gas production method

ActiveUS9981221B2Reduce compression powerIncrease choiceMembranesSemi-permeable membranesProcess engineeringProduct gas

A gas separation system includes: first, second, and third gas separation membrane units. A first retentate gas line connects a retentate gas discharge port of the first unit and gas inlet port of the second unit. A first permeate gas line connects a permeate gas discharge port of the first unit and gas inlet port of the third unit. A feed gas mixture supply line is connected to a gas inlet port of the first unit, and provided with first compression elements. The first permeate gas line is provided with second compression elements. The permeate gas discharge port of the second unit is connected by a second permeate gas line to the suction side of the first compression elements in the feed gas mixture supply line. A retentate gas discharge port of the third unit is connected by a third retentate gas line to the first retentate gas line.

Owner:UBE CORP

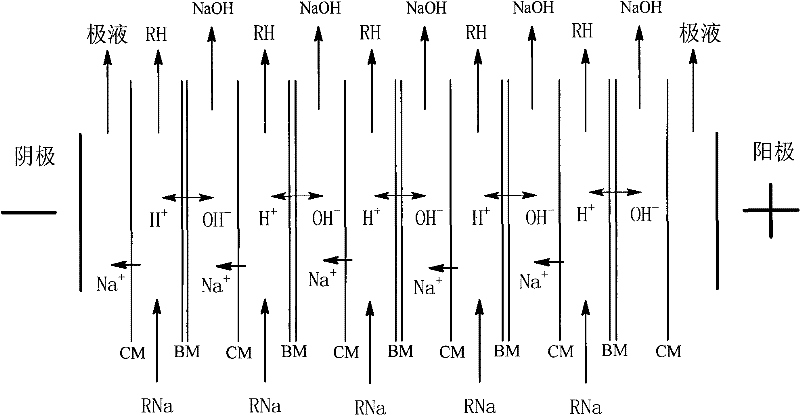

Bipolar membrane device for producing gluconic acid

ActiveCN102002725BReduce contact resistancePrevent leakageElectrolytic organic productionDiaphragmsPlatinumGluconic acid

The invention discloses a mechanical device, and in particular relates to a device for producing gluconic acid. The device comprises a clamping steel plate, a polar liquid flow channel plate, a platinum electrode, a bipolar membrane, an elastic partition plate, a hydroxyl difficult penetrating homogeneous phase cationic membrane, and the like, wherein the electrode adopts a titanium alloy or platinum electrode with higher efficiency; an elastic coating is coated on the elastic partition plate for sealing; a material liquid inlet, a material liquid outlet, a sodium hydroxide liquid outlet and a sodium hydroxide inlet are arranged on the clamping steel plate, which is beneficial to the safety in the transportation process; and a liquid guide hole is improved and adopts an elliptic liquid guide hole. The invention has the advantages of high yield, no pollution, low running cost, convenience for transportation, and the like and can be widely applied to a glucose producing enterprise.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

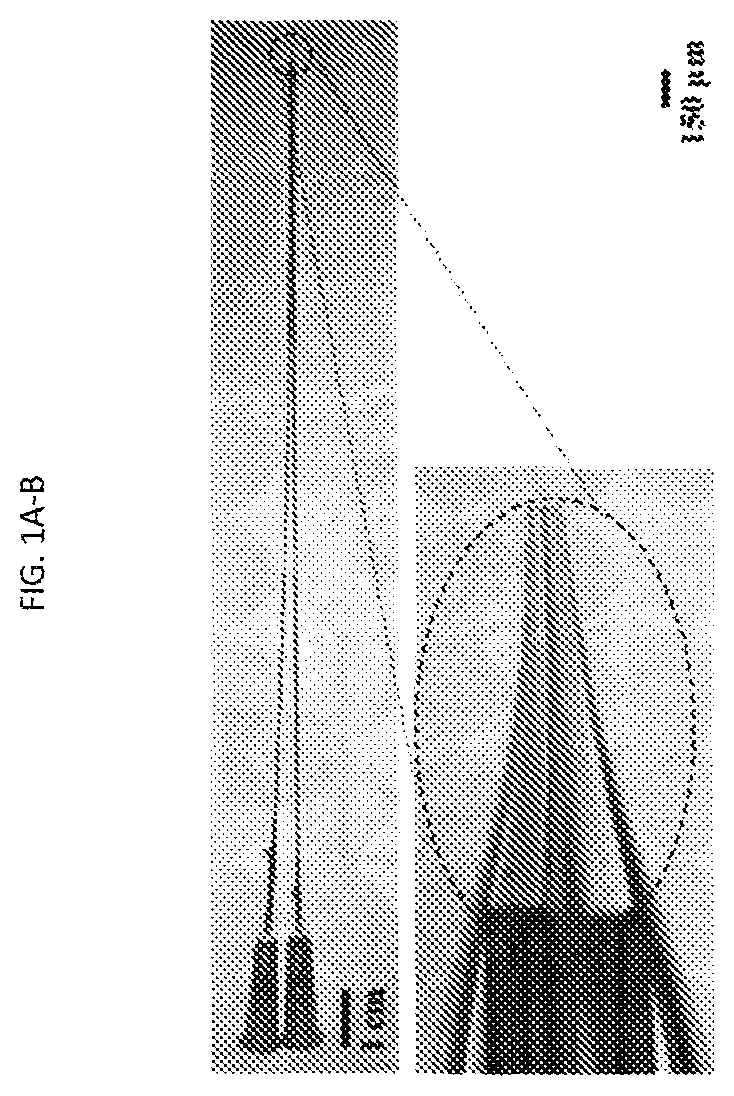

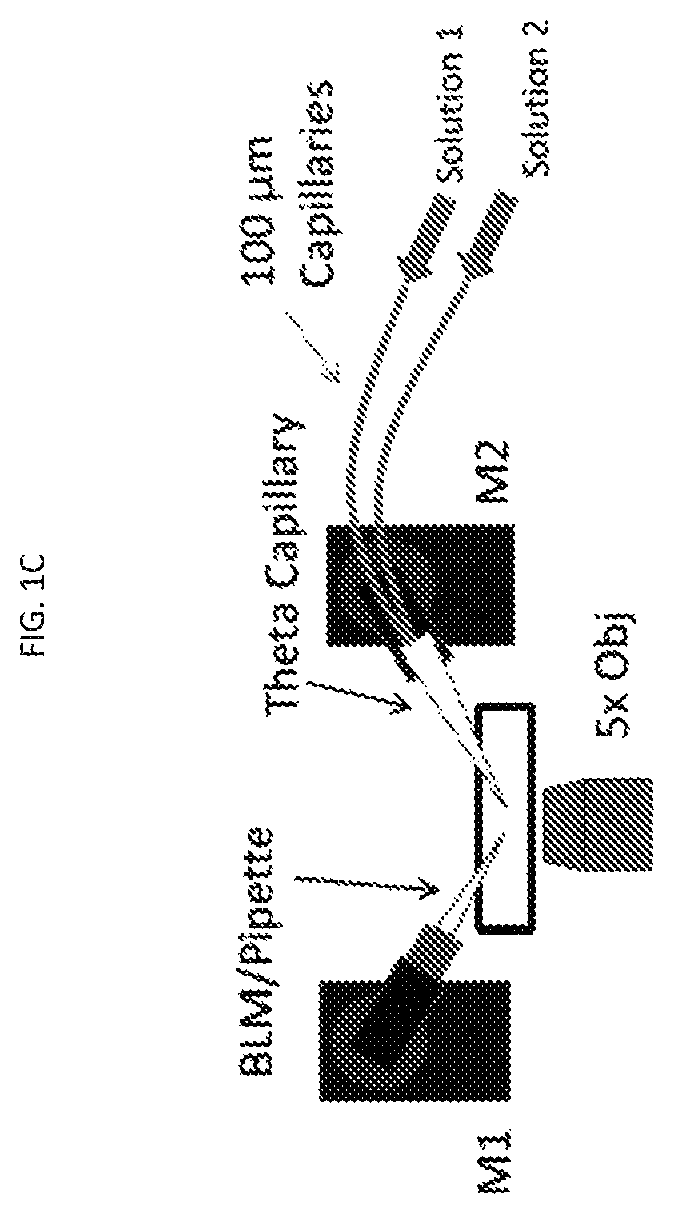

Rapid conductance based ion channel analysis

ActiveUS11073508B2Quick responseHigh sensitivityIndividual particle analysisIonic ChannelsBiochemistry

Ligand-ion channel interactions are analyzed via electrophysiological methods having rapid temporal response and high sensitivity, thereby reducing the collection time and enabling monitoring of dynamic processes. This protocol allows quantification of ligand concentrations in the sub-millisecond to ms range, as compared to s-min for traditional approaches. Moreover, the method can be easily integrated into existing patch clamp analysis packages and allow for monitoring of rapid, dynamic chemical processes in a feasible manner.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com