A kind of preparation method and application of acid-resistant psq composite membrane

A composite membrane, acid-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex membrane-forming mechanism, high carrier requirements, and large performance fluctuations of zeolite membranes, achieving good Effects of hydrothermal stability, membrane area reduction, and tunable surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

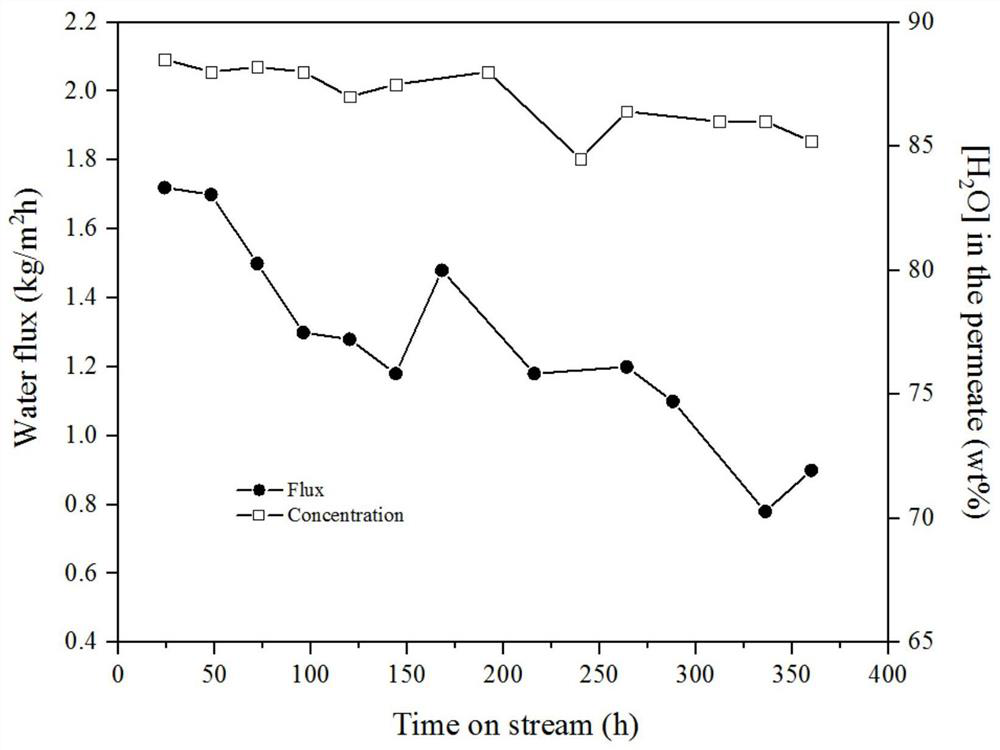

Image

Examples

Embodiment 1

[0025] (1) Dissolve 1,2-(triethoxysilyl)ethylene (BTESEthy) in an alcohol solvent with a mass fraction of 5wt%, add deionized water and 2wt% hydrochloric acid, and stir continuously for 30min in a water bath at 50°C , wherein the molar ratio of BTESM, water, and hydrochloric acid is 1:80:0.1.

[0026] (2) step (1) after acid catalyzed reaction, add ammoniacal liquor and carry out alkali catalyzed reaction, add the ammoniacal liquor that massfraction is 5wt% in molar ratio ammoniacal liquor: hydrochloric acid (the hydrochloric acid that is step (1)) is the ratio of 9:1, 50 ℃ Stir continuously in a water bath for 60 minutes to carry out alkali-catalyzed reaction, so that the particle size of the sol increases.

[0027] (3) add hydrochloric acid to carry out acid-catalyzed reaction after alkali catalysis, according to molar ratio hydrochloric acid: the ratio of ammoniacal liquor is 1.2:1 adding mass fraction is the hydrochloric acid of 2wt% to stop the alkali-catalyzed reaction o...

Embodiment 2

[0030] (1) Dissolve 1,2-bis(triethoxysilyl)methane (BTESM) in an alcohol solvent at 5 wt% by mass fraction, add deionized water and 2 wt% hydrochloric acid, and continuously stir in a water bath at 50°C 30min, wherein the molar ratio of BTESM, water and hydrochloric acid is 1:60:0.1.

[0031] (2) Add ammonia water with a mass fraction of 5wt% at a ratio of 10:1 to hydrochloric acid, and stir continuously in a water bath at 50°C for 60 minutes to carry out alkali-catalyzed reaction to increase the particle size of the sol.

[0032] (3) Molar ratio hydrochloric acid: ammoniacal liquor is the ratio of 1.5:1 to add the hydrochloric acid that the mass fraction is 2wt% to stop the alkali-catalyzed reaction of step (2), the reaction time is 45min, and reaction temperature is 45 ℃, generates stable under acidic environment BTESM Sol.

[0033] (4) Coating silica-zirconia sol on the ceramic support to form a transition layer, the transition layer is 0.5 wt% silica-zirconia sol. The tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com