Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154 results about "Zeolite membranes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

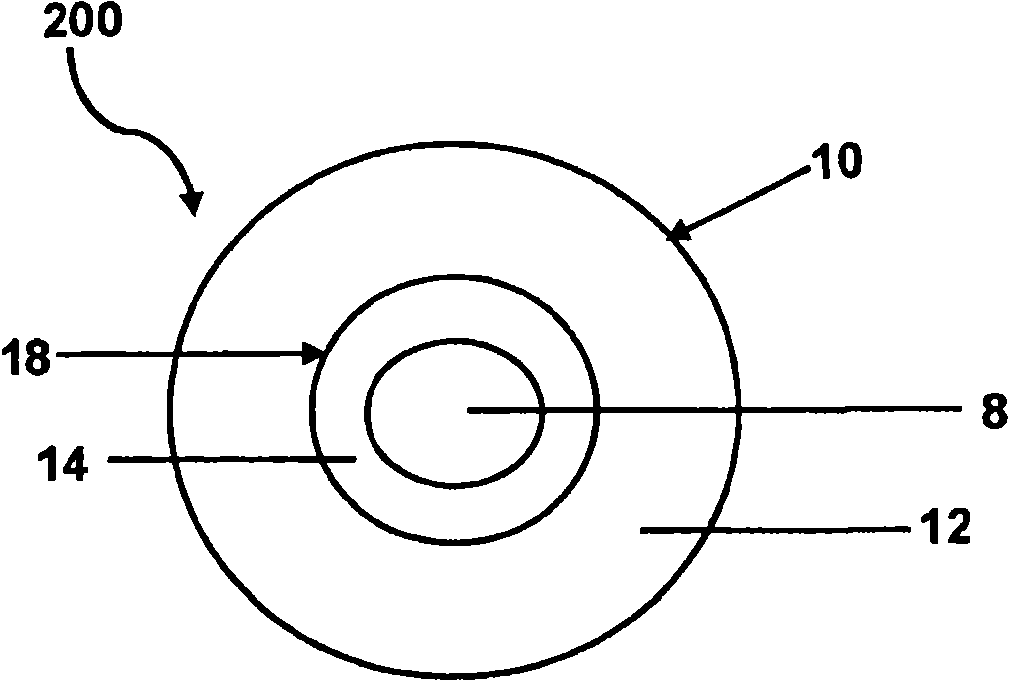

Zeolite membrane structures and methods of making zeolite membrane structures

InactiveUS20090000475A1High energyEnhanced capital efficiencyMembranesSemi-permeable membranesFiltrationHoneycomb

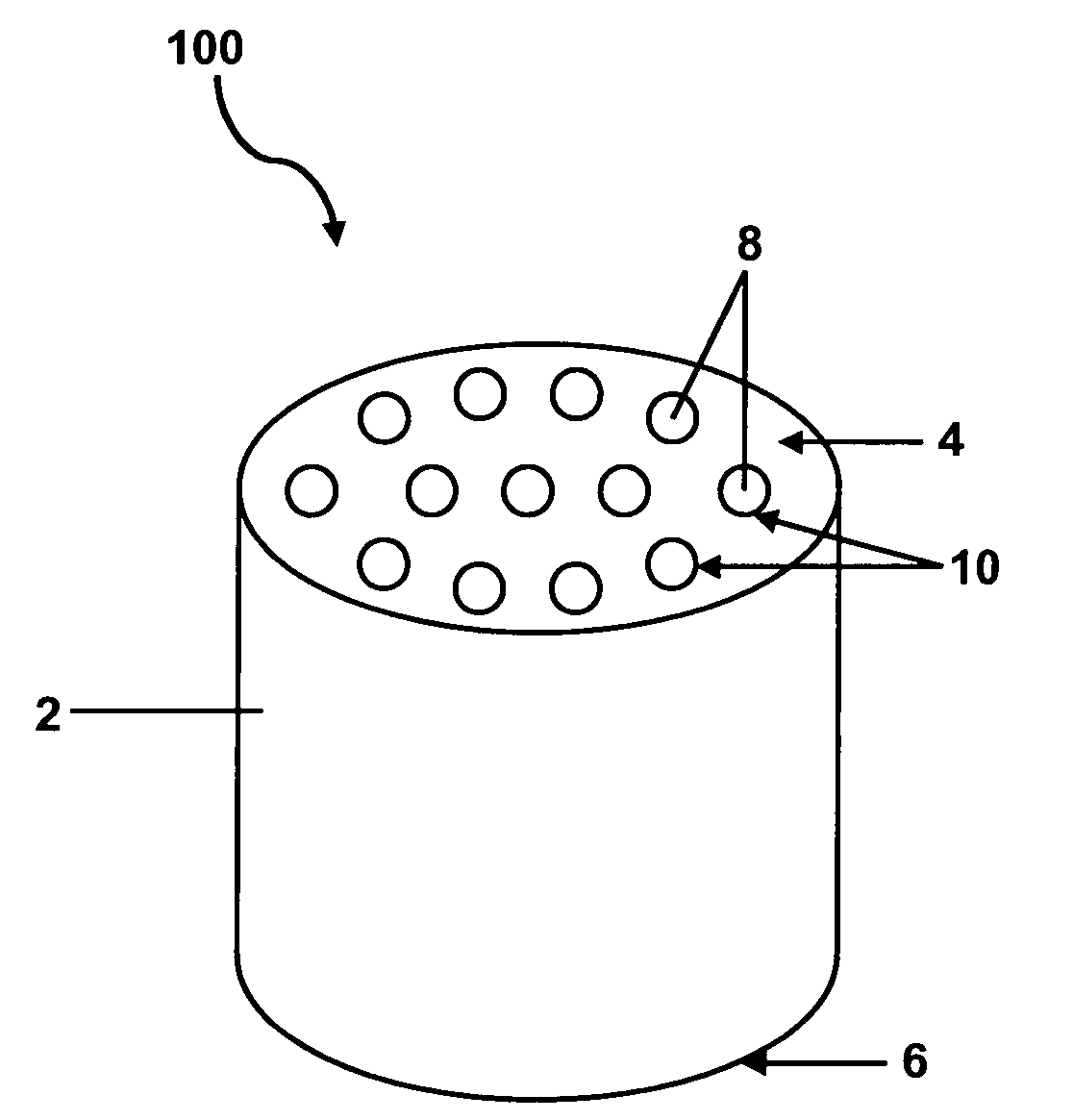

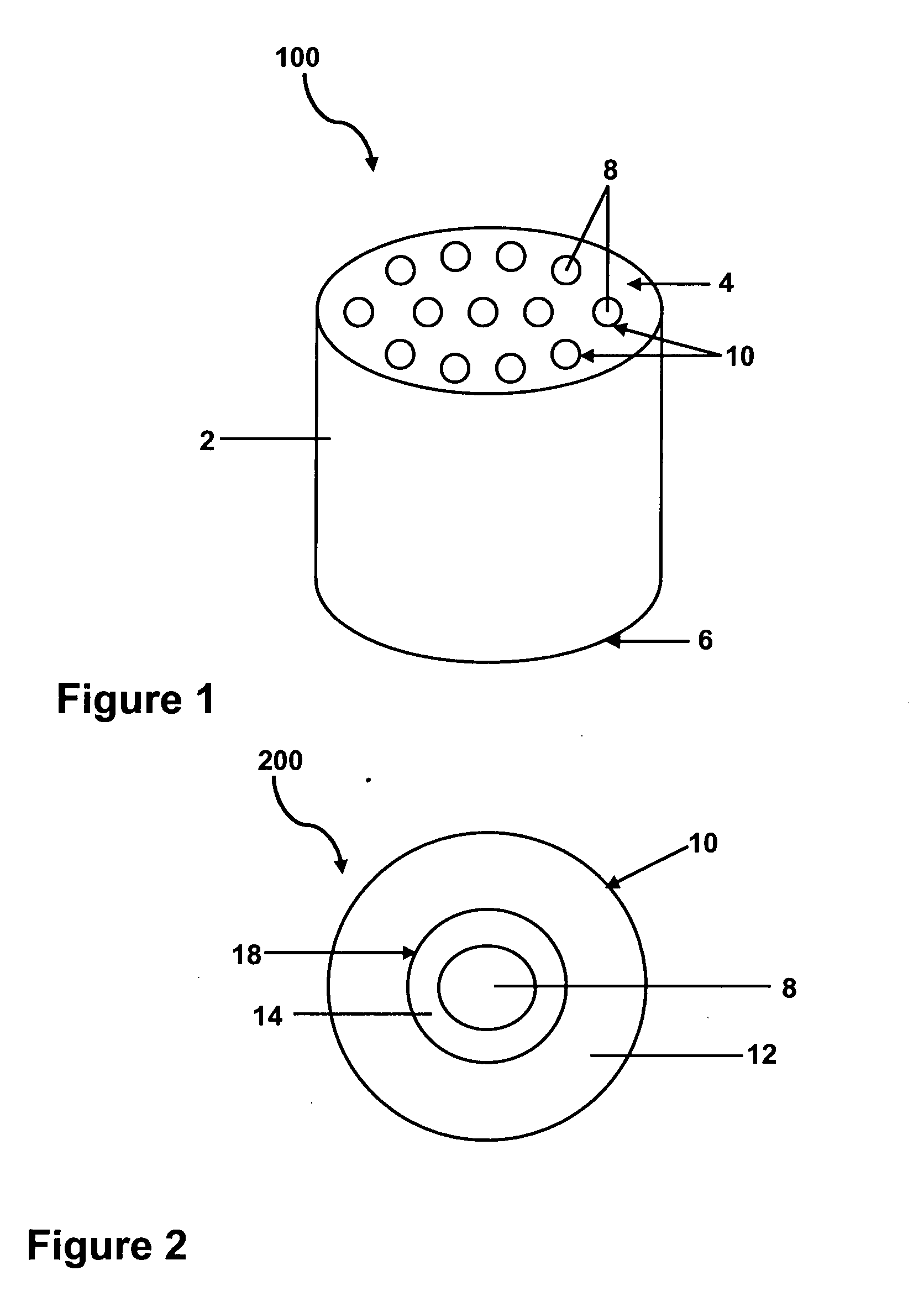

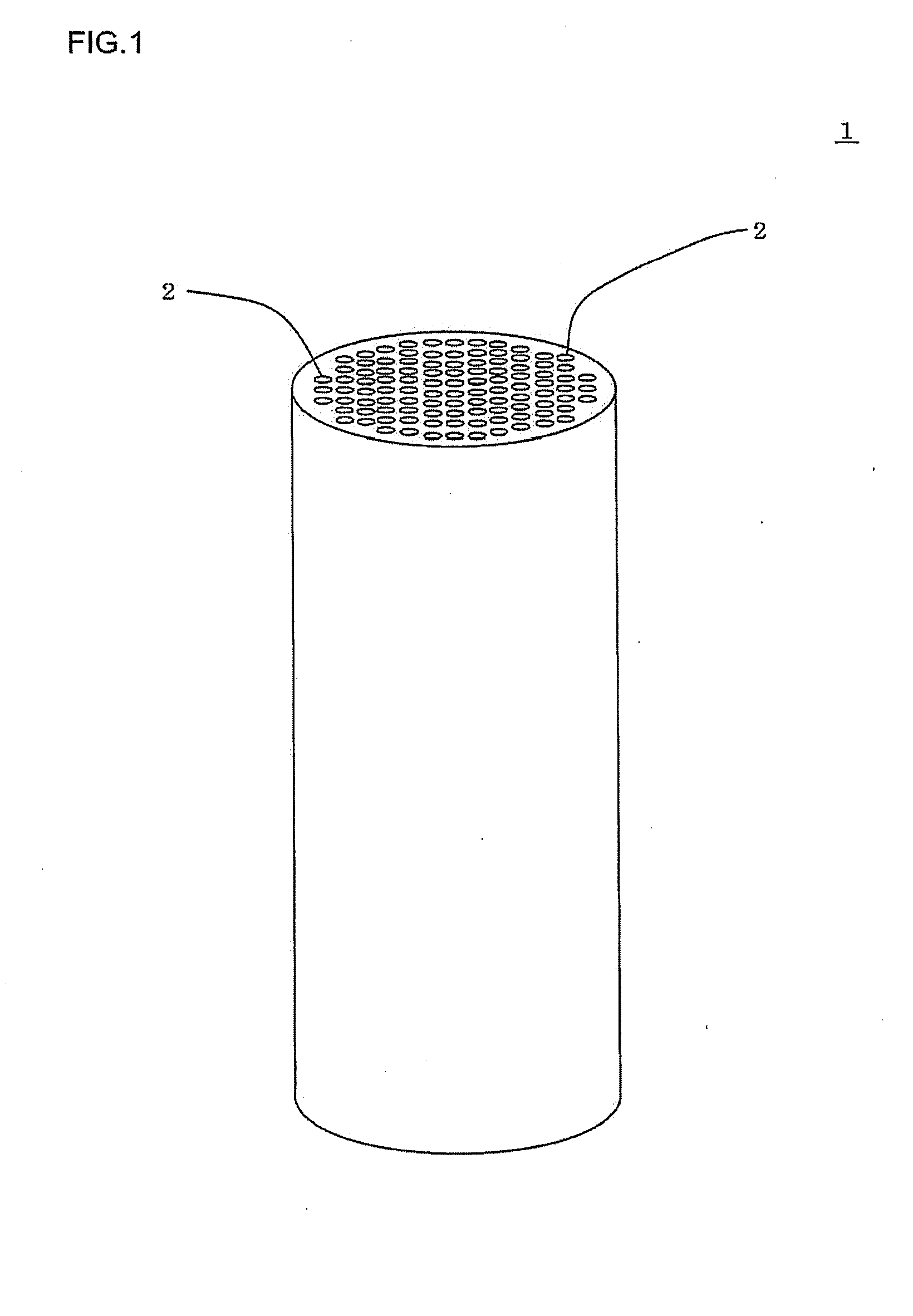

Inorganic membrane structures of high stability, high permeability, and large surface area. Zeolite membranes can be disposed onto an intermediate pore size modification layer which reduces the pore size of the inorganic porous support. The intermediate pore size modification layer minimizes the defects in the zeolite membrane and provides a more continuous and uniform zeolite membrane. The inorganic membrane structure can be in the form of a honeycomb monolith. The applications for the zeolite membranes include, for example, membrane ultra-filtration of gas or liquid fluids, biological assays and cell culture surfaces.

Owner:CORNING INC

Zeolite Membranes for Separation of Mixtures Containing Water, Alcohols, or Organics

InactiveUS20100304953A1High selectivityMechanical strengthSemi-permeable membranesMembranesAlcoholZeolite membranes

Zeolite membrane sheets for separation of mixtures containing water, alcohols, or organics are provided, as well as methods for making the same. Thin, but robust, zeolite membrane sheets having a zeolite membrane layer formed directly on a thin porous metal support sheet provide improved separations performance. The zeolite membrane layers have a thickness less than 3 μm and are formed on a thin porous metal support sheet having a thickness less than or equal to approximately 200 μm. The porous metal support sheet comprises an average pore size of less than 3 μm, a porosity between 25% and 75%, and a thickness of less than or equal to 200 μm.

Owner:BATTELLE MEMORIAL INST

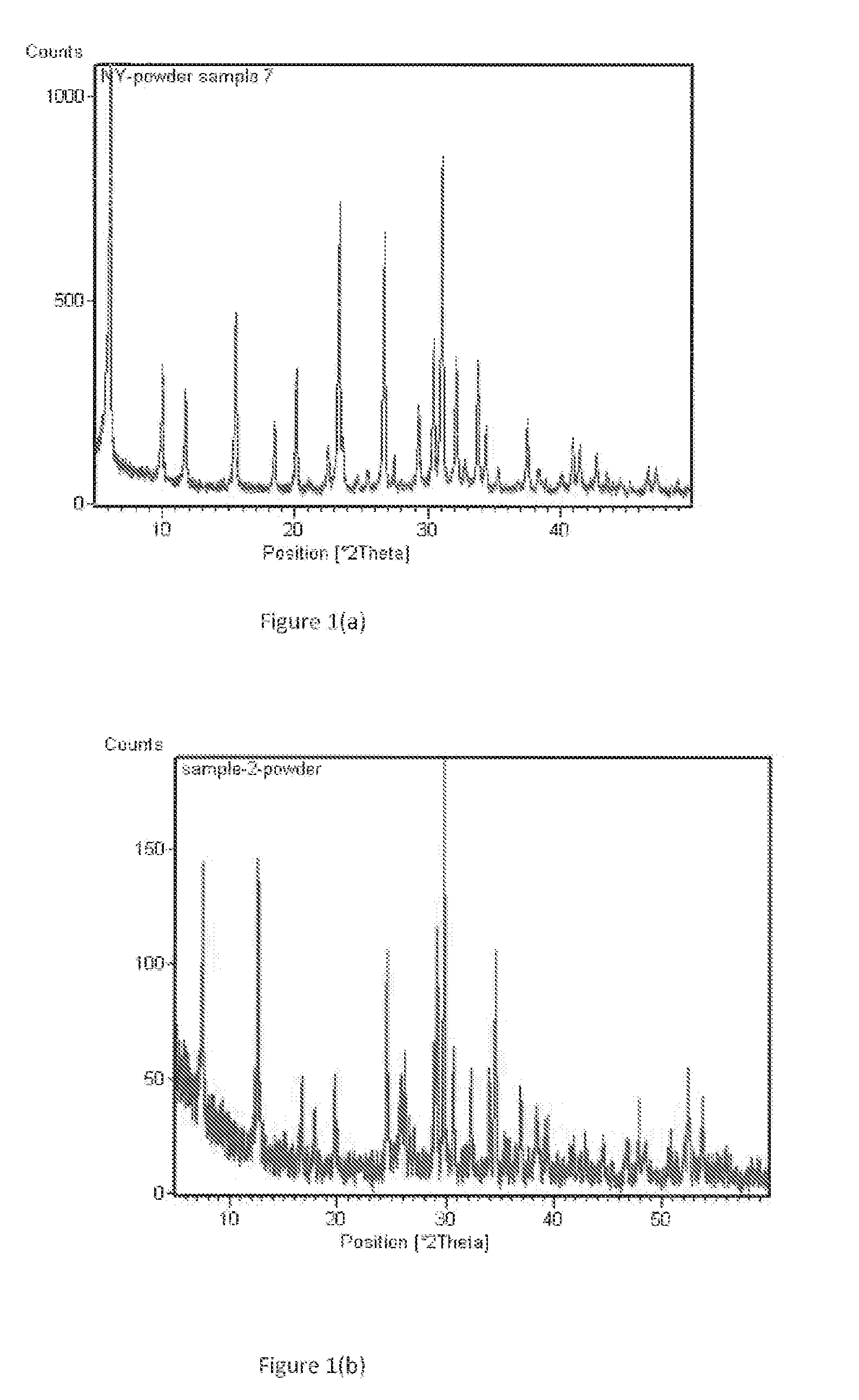

Zeolite DDR membranes

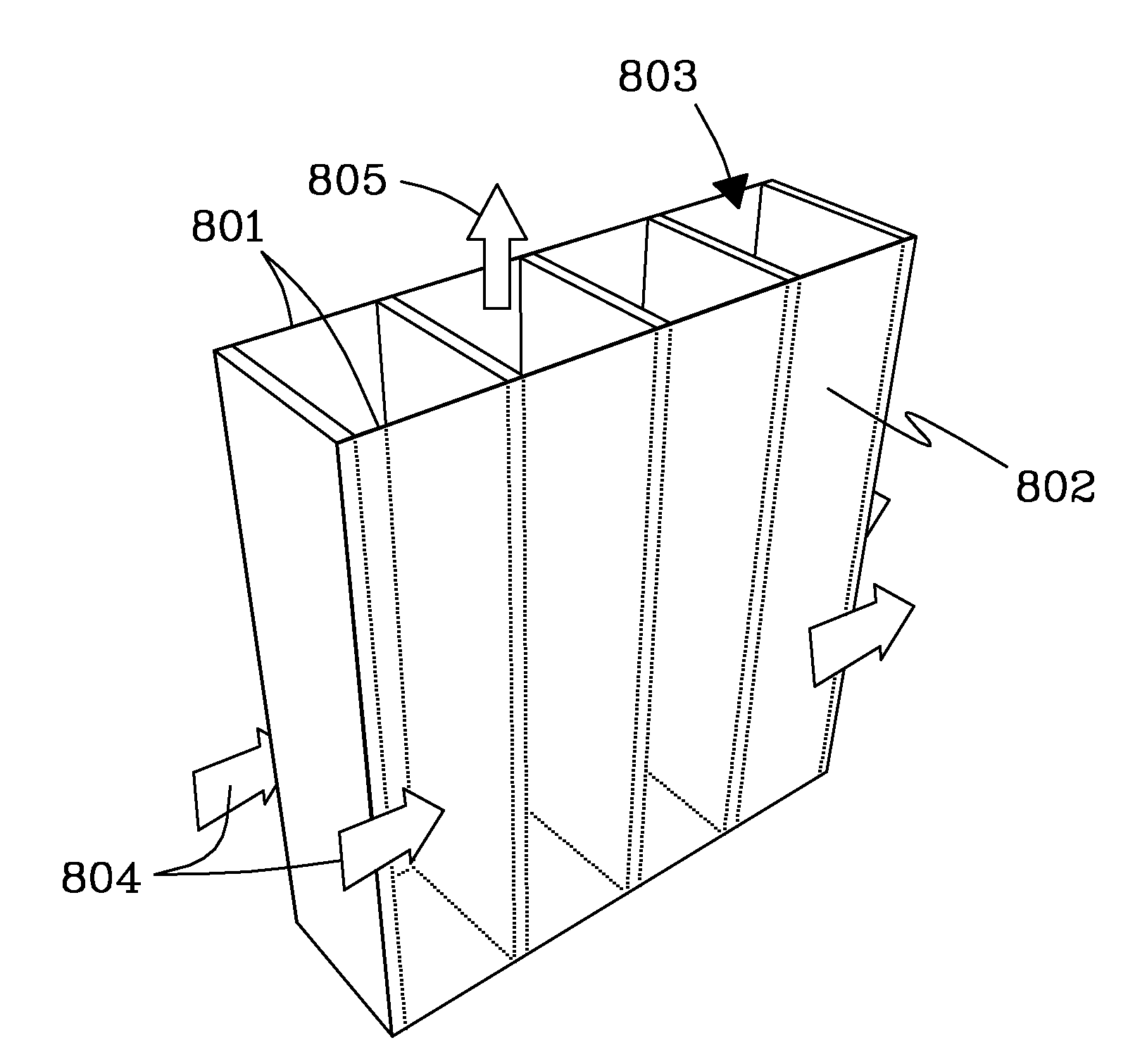

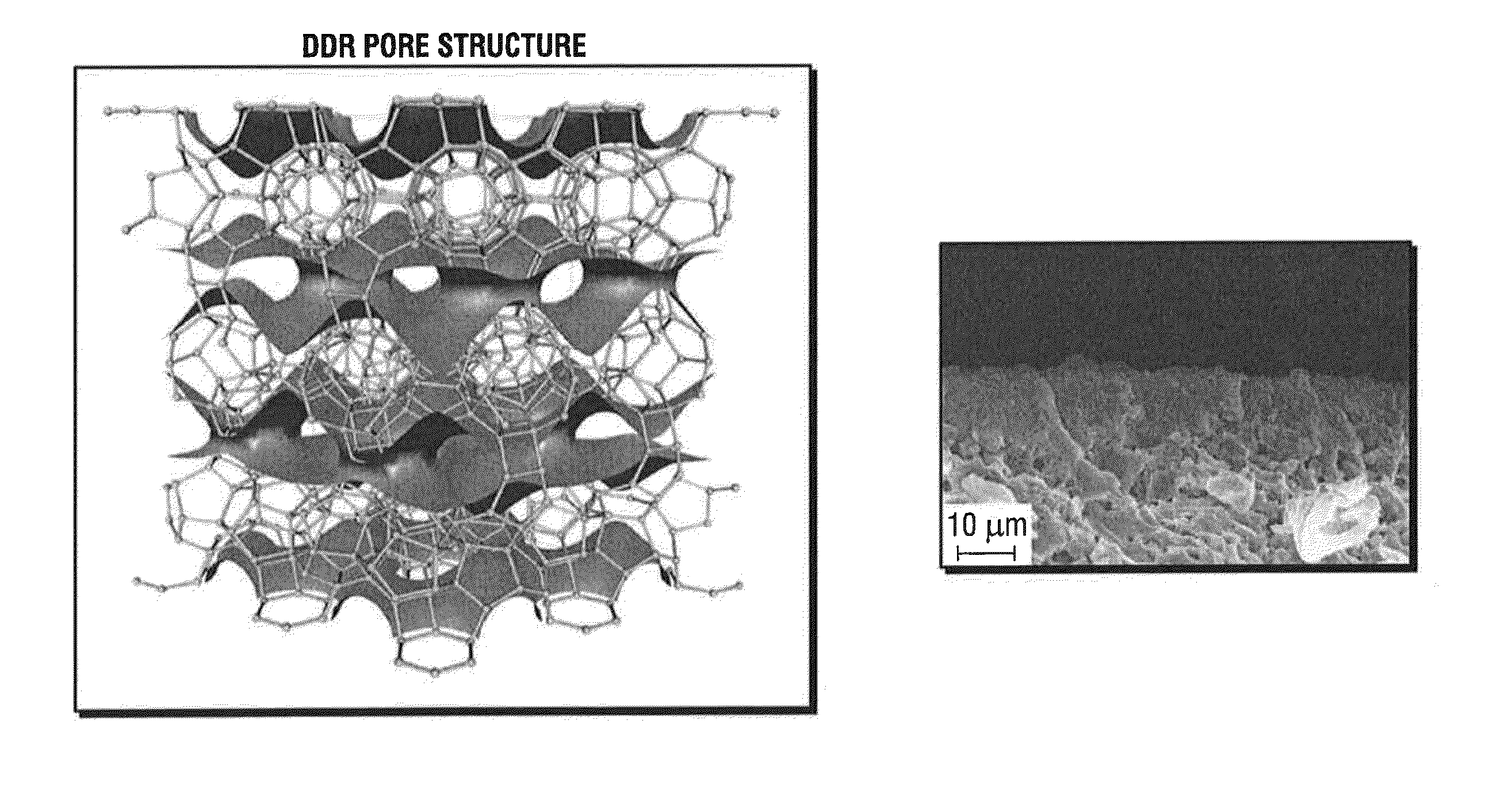

DDR nanocrystals of uniform size and structure were synthesized using hydrothermal secondary growth and then used to make DDR zeolite membranes and for any other use where uniform, small DDR zeolite crystals are beneficial.

Owner:GEORGIA TECH RES CORP

Apparatus for concentrating water-soluble organic material

ActiveUS7699961B2Easy to operateReduce energy consumptionEvaporators/condensersDistillation in boilers/stillsDistillationDistilled water

A water-soluble organic material condensation apparatus equipped with a distillation column for distilling an aqueous solution of a water-soluble organic material, wherein a vapor generated at the top of the distillation column or a condensed liquid from the vapor is introduced to a device other than the distillation column which has the function to separate water from the water-soluble organic material to thereby condense the water-soluble organic material through separating water and then the condensed water-soluble organic material is recycled to the distillation column. The device other than the distillation column is desirably a separating film such as a zeolite film. The apparatus is improved in the operation of the upper portion of the condensation section of the distillation column and allows energy savings during distillation.

Owner:MITSUBISHI CHEM CORP

Zeolite membrane structures and methods of making zeolite membrane structures

Inorganic membrane structures of high stability, high permeability, and large surface area. Zeolite membranes can be disposed onto an intermediate pore size modification layer which reduces the pore size of the inorganic porous support. The intermediate pore size modification layer minimizes the defects in the zeolite membrane and provides a more continuous and uniform zeolite membrane. The inorganic membrane structure can be in the form of a honeycomb monolith. The applications for the zeolite membranes include, for example, membrane ultra-filtration of gas or liquid fluids, biological assays and cell culture surfaces.

Owner:CORNING INC

Uniformly b-oriented mfi zeolite membrane with variable thickness supported on substrate and preparation method thereof

InactiveUS20090291046A1Film thickness controllableSemi-permeable membranesMembranesMolecular sieveVariable thickness

A b-oriented MFI zeolite membrane with variable thickness is provided. The MFI zeolite membrane is composed of zeolite crystals whose b-axes are all uniformly oriented perpendicular to a substrate. Further provided is a method for preparing the MFI zeolite membrane. The method comprises forming zeolite or zeotype molecular sieve seeds with different thicknesses on a substrate and adding the seeded substrate to a gel for the synthesis of an MFI zeolite containing a structure-directing agent to grow zeolite or zeotype molecular sieve crystals thereon. The MFI zeolite membrane overcomes the limitations of prior art zeolite membranes to maximize its applicability.

Owner:INTELLECTUAL DISCOVERY CO LTD

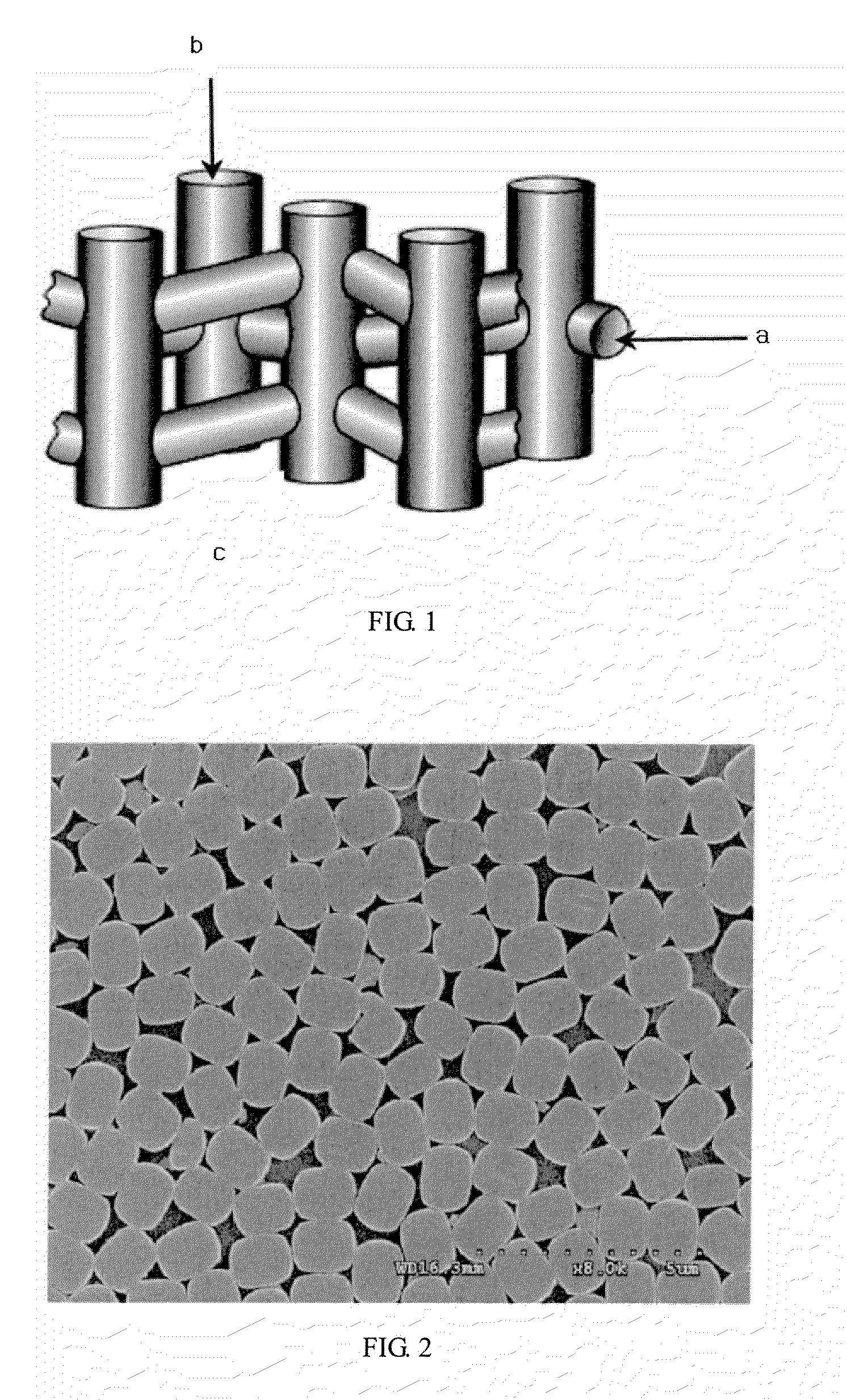

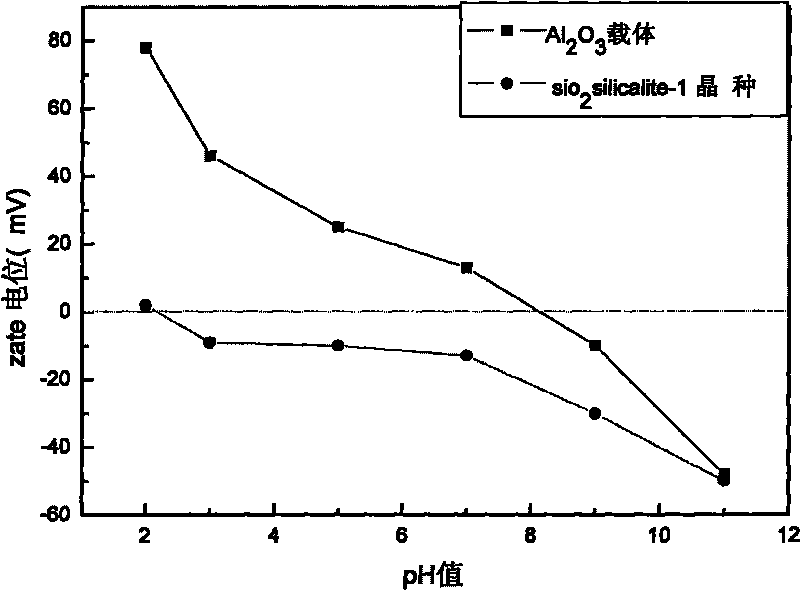

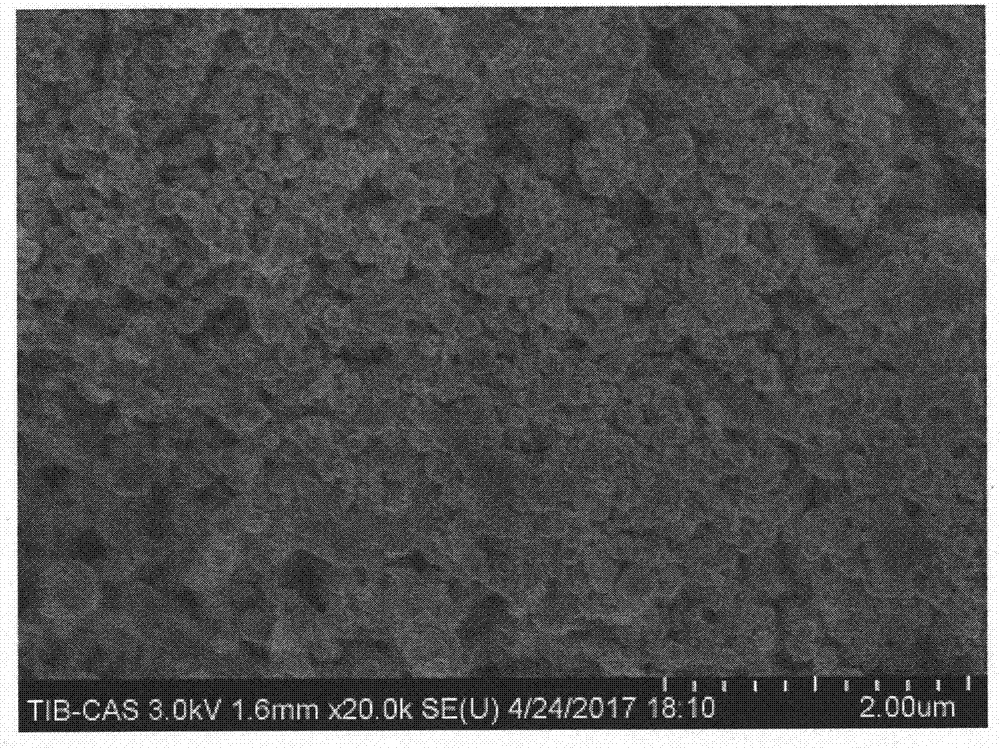

Method for synthesizing silicalite-1 zeolite membranes

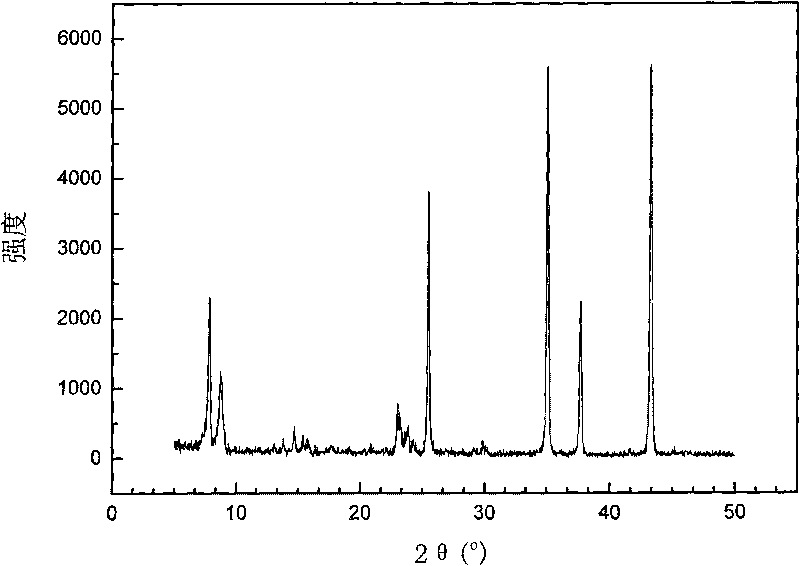

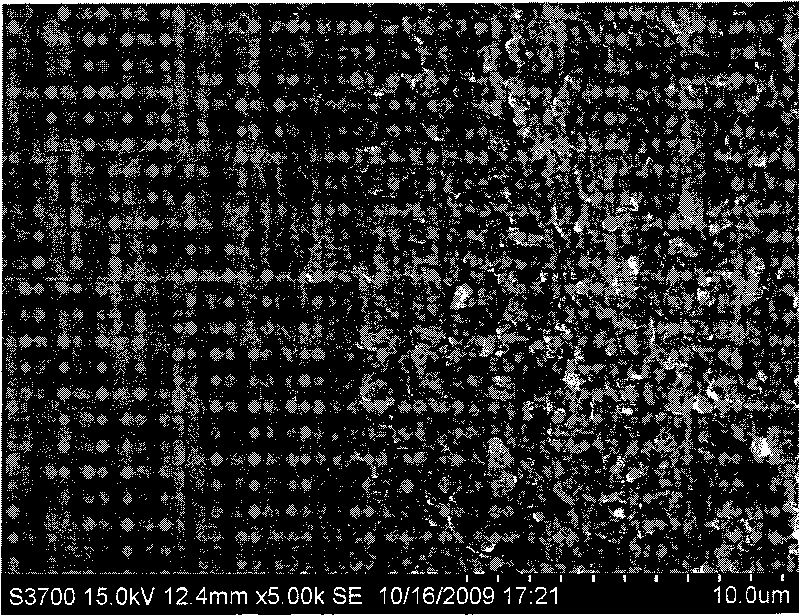

InactiveCN101696018AGood repeatabilityNo crystallizationMolecular-sieve and base-exchange compoundsMolecular-sieve compoundsHydrothermal synthesisZeolite membranes

The invention discloses a method for synthesizing silicalite-1 zeolite membranes. The method comprises: preparing synthetic fluid of crystal seeds, performing hydrothermal synthesis for 0.5 to 3 days, obtaining crystal seeds uniform in particle size and preparing a crystal-seed solution; impregnating a carrier with the crystal-seed solution for 5 to 10 seconds, drying and roasting the obtained product; preparing template-free zeolite membrane mother liquor, placing diaphragms containing crystal-seed layers in the mother liquor and performing hydrothermal reaction in a reaction kettle for 4 to 8 hours; and washing and drying membranes. As the synthetic fluid has no template, roasting is not needed after secondary growth, so that defect-free pure silicon zeolite membranes can be obtained. The zeolite membranes are resistant to heat and chemicals, have good stability, and can be applied to the permeation and separation of gas and liquid steam at high temperature and other aspects.

Owner:SOUTH CHINA UNIV OF TECH

Membrane structures and their production and use

InactiveUS20100006503A1The process is compact and efficientKeep the same performanceMembranesSemi-permeable membranesPorous substratePolymer science

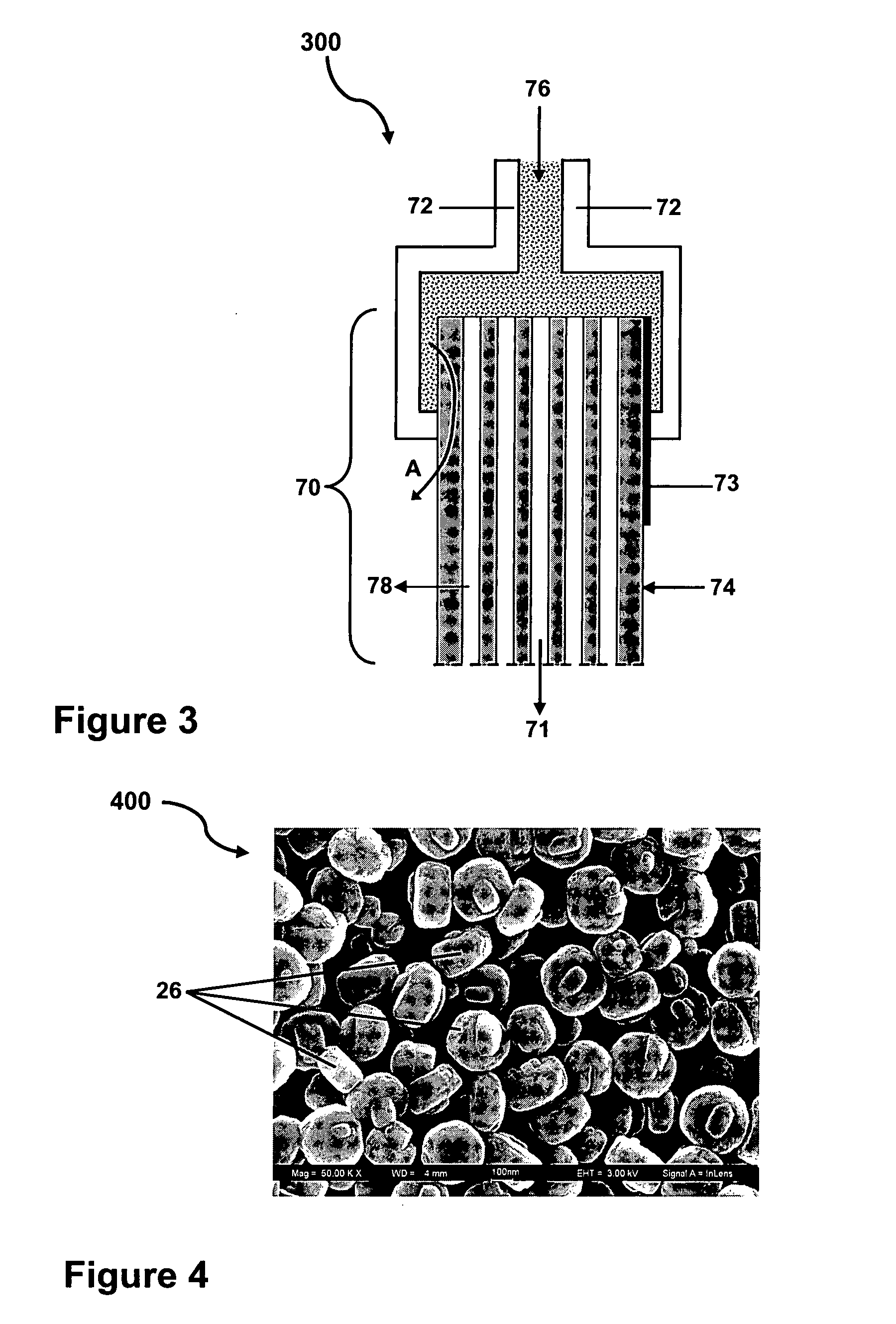

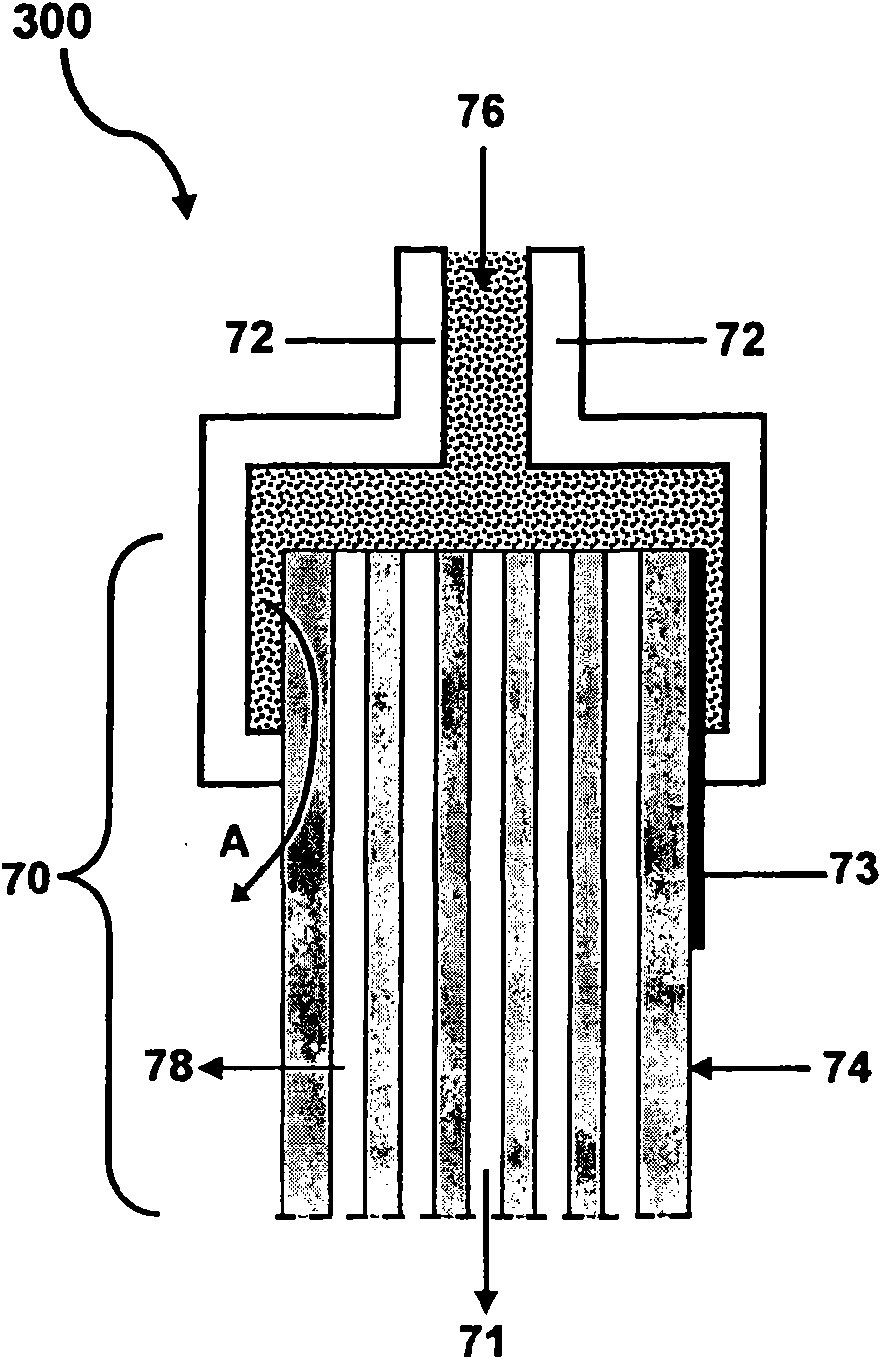

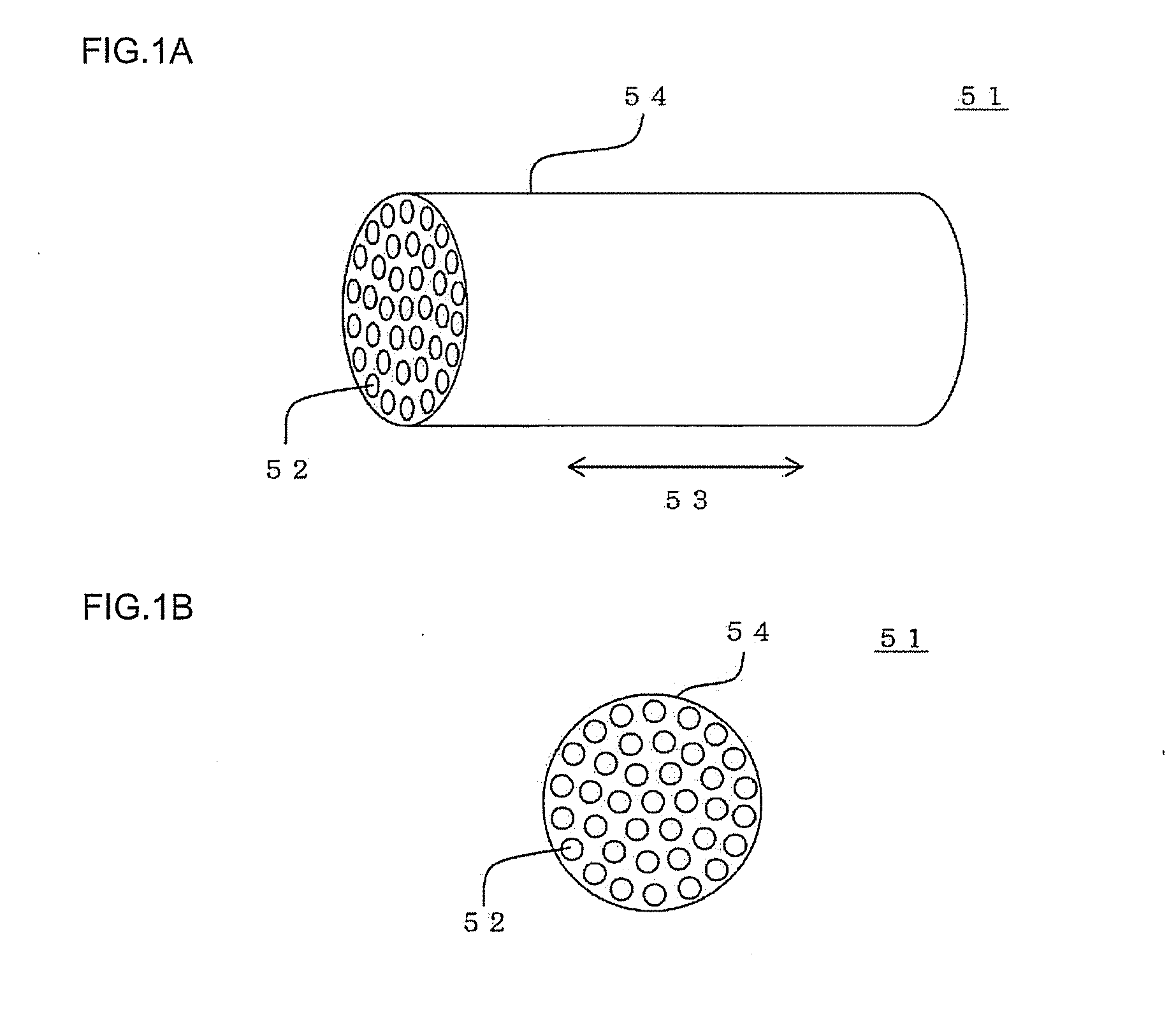

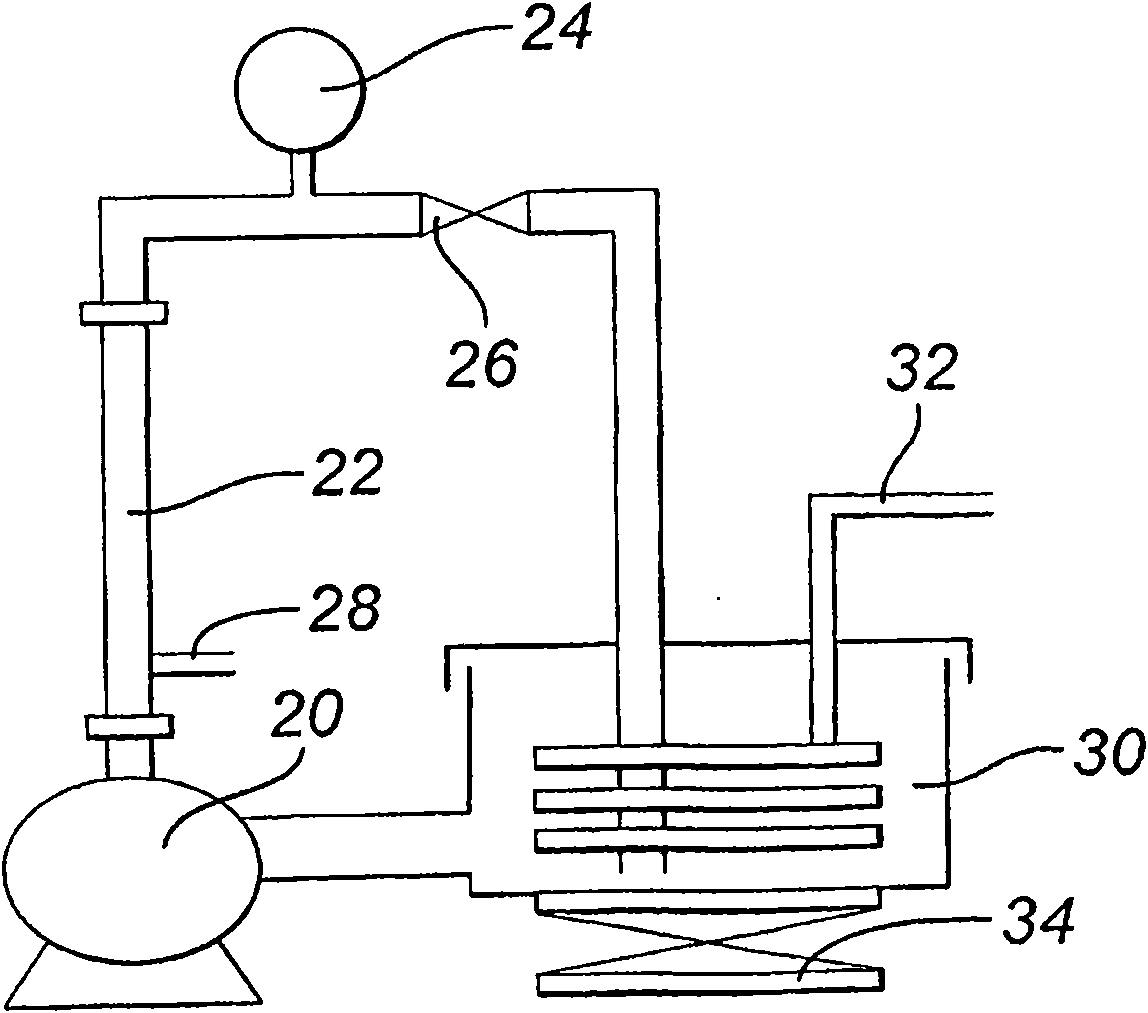

A method is provided for forming zeolite membranes in internal surfaces of a plurality of conduits in a cylindrical porous ceramic monolith, the conduits extending from one end of the monolith to the other, said method including a step of: flowing a pre-treatment liquid including a zeolite initiating agent into the conduits; causing at least part of a carrier liquid component of the treatment liquid to flow from the conduits into and through the body of the monolith to the exterior; and causing zeolite crystals to be deposited in the porous internal surfaces of the conduits as the carrier liquid component flows into the monolith. The substrates may be pre-conditioned for membrane formation by a method which comprises: (a) forming an aqueous suspension of zeolite particles; and (b) passing the suspension alternately (i) through the tubular conduits and (ii) out through the walls of the tubular conduits so as to deposit a layer of zeolite particles on the inner surfaces of the tubular conduits; wherein the porous substrates are treated in chambers arranged e.g in annularly and the suspension is supplied to the chambers from a first common manifold via respective delivery tubes and is recovered via recovery tubes leading to a second common manifold, the first and second manifolds and the supply and recovery tubes being configured so that the branch path to and from each chamber is substantially the same. After pre-conditioning, formation of membranes may be by depositing or crystallizing a zeolite membrane on the zeolite particles by gel crystallization. A membrane structure is also provided which comprises a tubular porous ceramic monolith having tubular conduits each having an internal diameter of (5) to (9) mm formed within the monolith with a zeolite membrane formed on the internal surface of each of the conduits, wherein either there are four conduits and the monolith is longer than 600 mm or there are five or more conduits. The invention also provides methods for removal of water from organic liquids and methods for the purification of water using the above membrane structures e.g. to remove residual water from ethanol or butanol or to produce high purity water.

Owner:PHOENIX IPR LTD

Zeolite membranes for selective oxidation on carbon monoxide in mixed hydrogen gas source

InactiveUS20070110649A1High strengthImprove stabilityUsing liquid separation agentIsotope separationPlatinumPore diameter

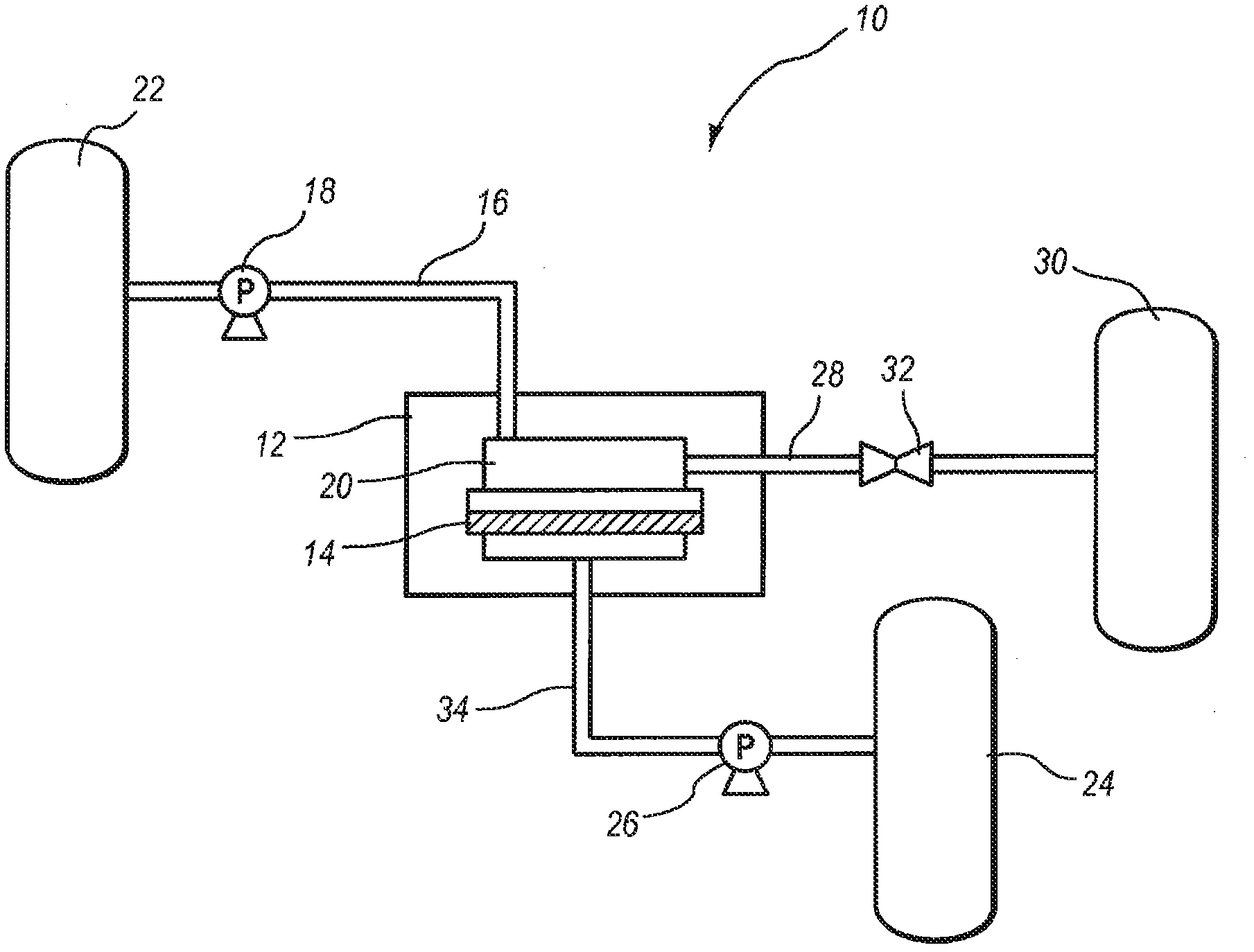

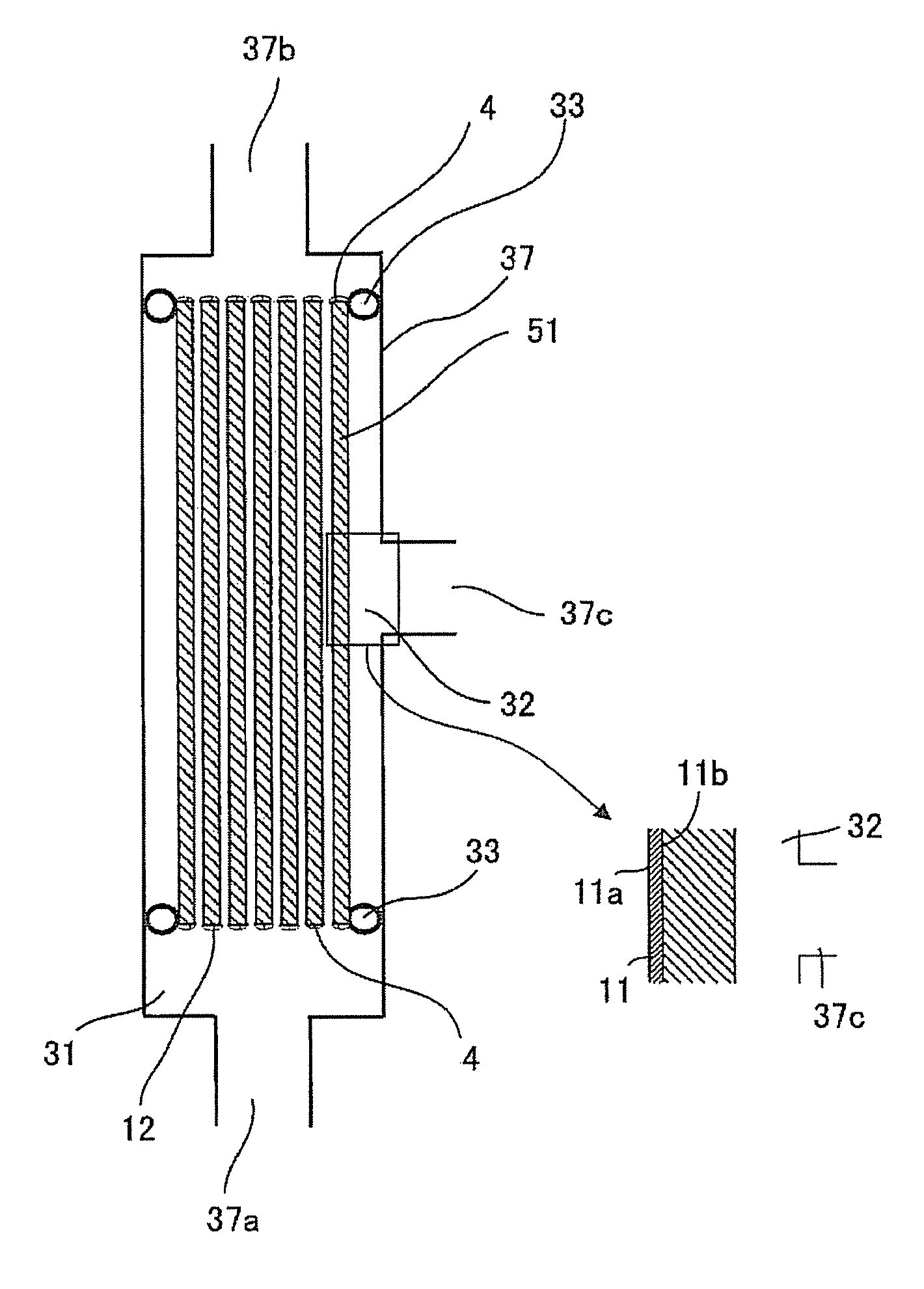

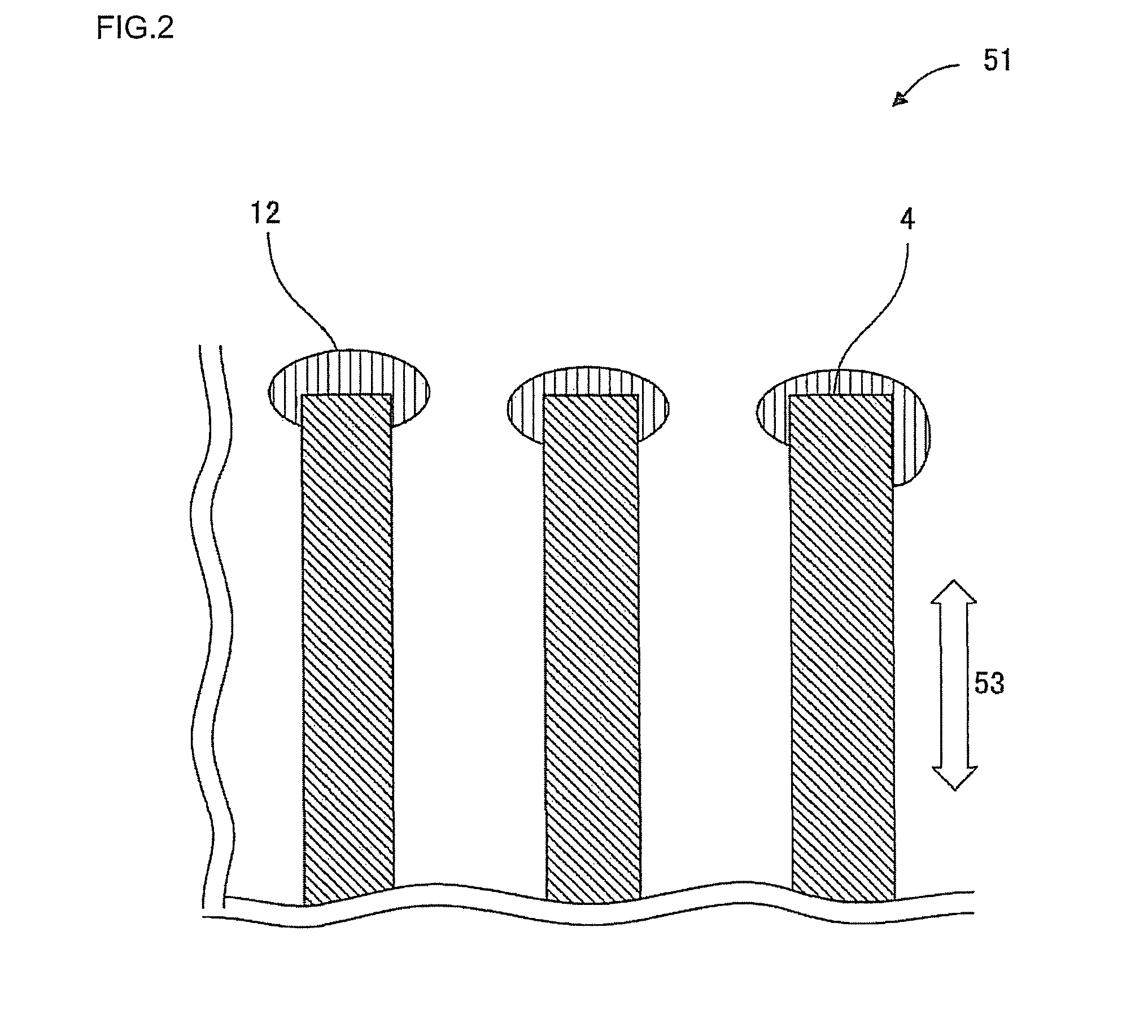

Methods and apparatus are taught for selectively oxidizing carbon monoxide in a source of gas containing carbon monoxide and hydrogen. A gas containing carbon monoxide and hydrogen is fed into a membrane reactor (10, 50, 60) capable of selectively absorbing the carbon monoxide. Preferably, the reactor comprises a substantially defect-free zeolite membrane (4) having at one metal that acts as an oxidation catalyst. The zeolite membrane (4) may be supported on a porous ceramic support (2, 52, 61) and the average pore diameter is preferably between about 0.3 nm and about 1.0 nm. Moreover, the substantially defect-free zeolite membrane (4) preferably has a thickness between about 0.1 micron and about 50.0 microns. The at least one metal is preferably capable of selectively oxidizing the carbon monoxide and is preferably platinum. Preferably, the temperature of reactor housing is maintained at about 200-300° C.

Owner:NORITAKE CO LTD

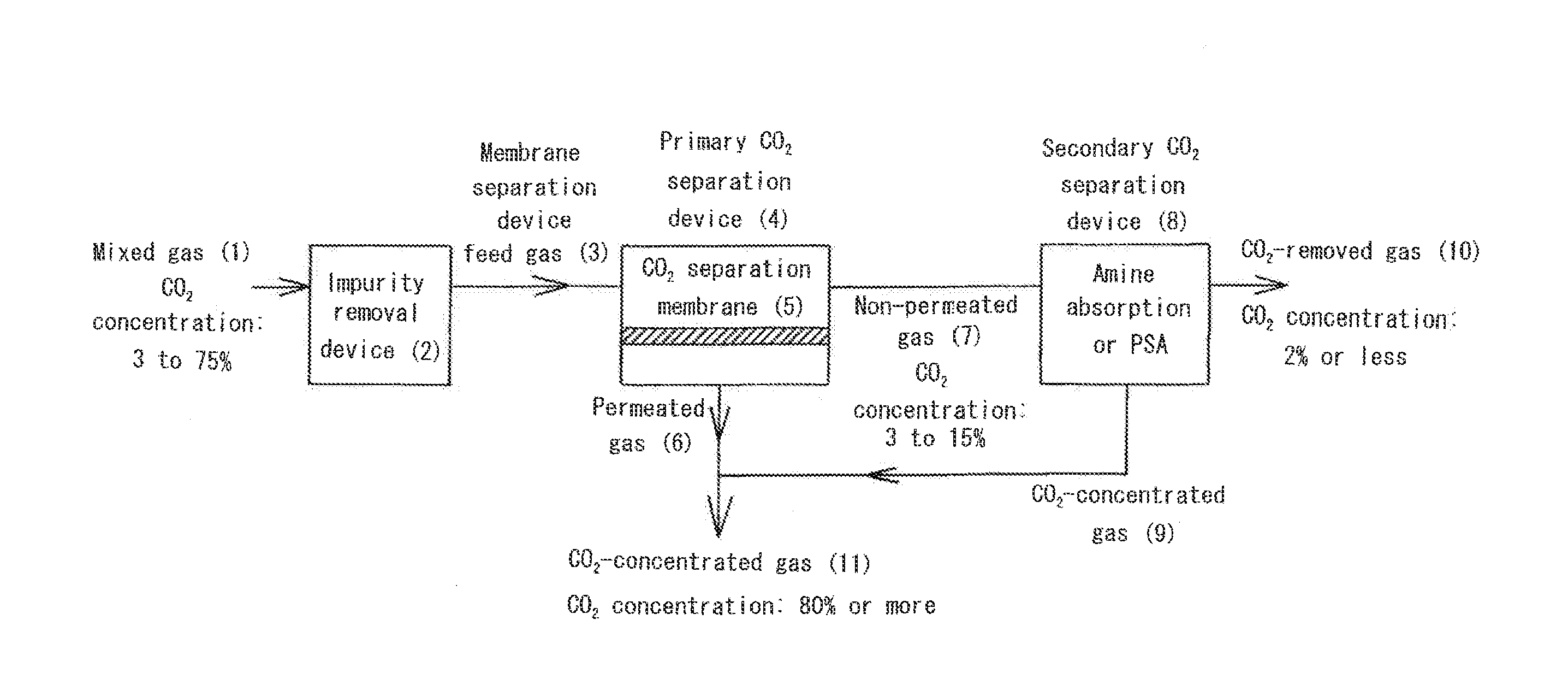

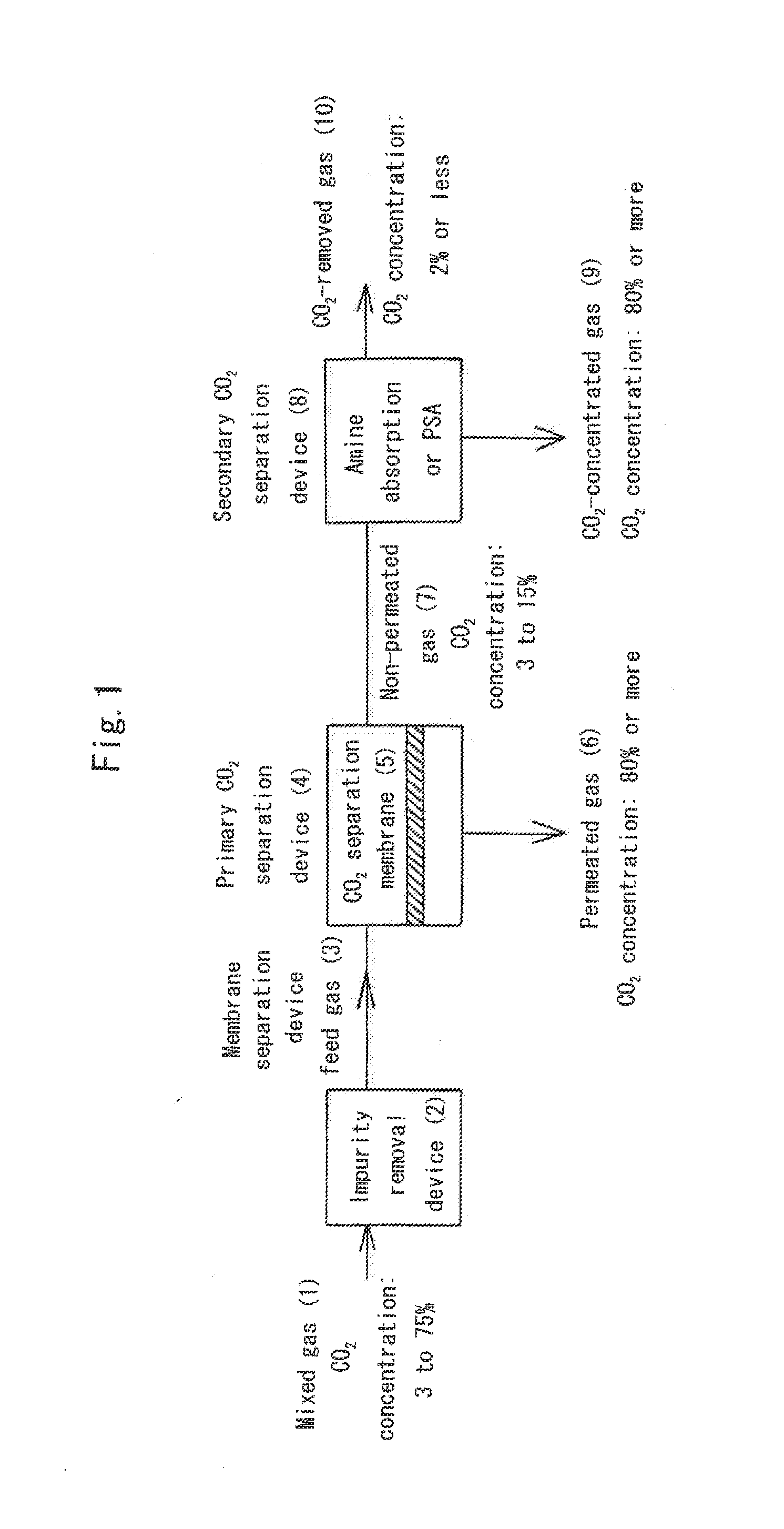

Carbon dioxide separation system

ActiveUS20140144321A1Efficient separationReduce carbon dioxide concentrationSemi-permeable membranesGas treatmentMixed gasSeparation system

In the carbon dioxide separation system, a mixed gas having a carbon dioxide concentration of 3 to 75% is introduced into a primary carbon dioxide separation device equipped with a zeolite membrane for carbon dioxide separation to produce a primary permeated gas having a carbon dioxide concentration of 80% or more on the permeate side of the zeolite membrane and also reduce the carbon dioxide concentration of a primary gas on the non-permeate side of the zeolite membrane to 3 to 15%. Next, the primary gas on the non-permeate side is introduced into a secondary carbon dioxide separation device that employs an amine absorption method or a pressure swing adsorption (PSA) method to produce a secondary separated gas having a carbon dioxide concentration of 80% or more separated by the separation device and also produce a carbon-dioxide-removed gas having a carbon dioxide concentration of 2% or less.

Owner:HITACHI ZOSEN CORP

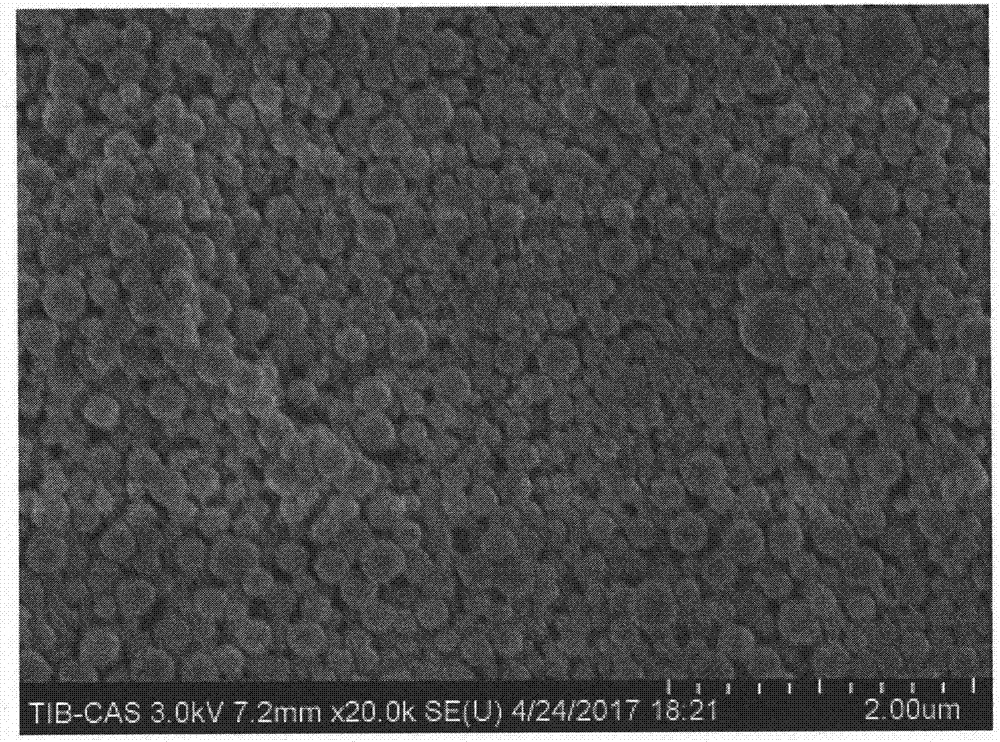

Method for preparing NaA type zeolite membrane for ethanol dehydration

InactiveCN104548953AHigh mechanical strengthExtended service lifeSemi-permeable membranesAluminosilicate zeolite type-AReaction temperatureDip-coating

The invention discloses a method for preparing a NaA type zeolite membrane for ethanol dehydration. NaA type molecular sieves are taken as seed crystals, an ultra-thin uniform seed crystal layer is directly introduced into the surface of a porous support tube, and high-performance NaA type zeolite membranes with different silica-alumina ratios are synthesized by hydrothermal crystallization. The preparation method is implemented by the following steps of introducing a layer of NaA type molecular sieve into the surface of the porous support tube by adopting a hot dipping method, and then introducing a second layer of NaA type molecular sieve to form a dense ultra-thin seed crystal layer by adopting a dip coating method; preparing crystallization mother liquid from silica sol, sodium hydroxide, sodium metaaluminate and de-ionized water; adding the prepared crystallization mother liquid into a stainless steel reaction kettle containing polytetrafluoroethylene, placing the porous support tube pre-planted with seed crystals, and performing hydrothermal synthesis for 4 to 10h at the reaction temperature of 60 to 80 DEG C; taking out the support tube after reaction, washing the support tube with de-ionized water, and drying the support tube at 80 DEG C.

Owner:DALIAN CITY SHAHEKOU DISTRICT SMALL MEDIUM & MICRO ENTERPRISES SERVICE CENT

Process for the production of ddr-type zeolite membranes

ActiveUS20110301017A1High densityGood effectMembranesSemi-permeable membranesPorous substrateHydrothermal synthesis

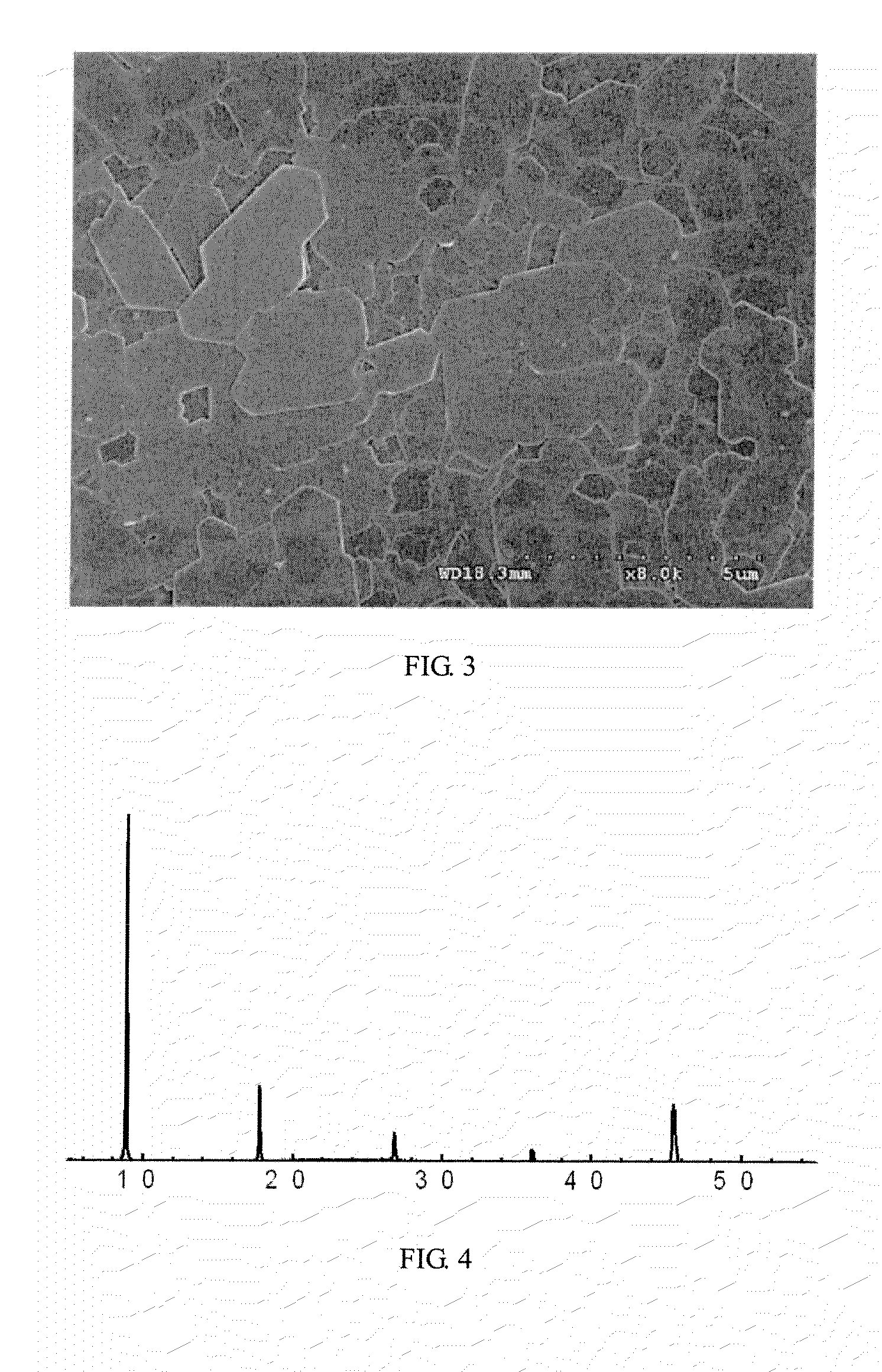

A process for production of a DDR-type zeolite membrane, which comprises: both a seed crystal-forming step of immersing a porous substrate in a seed crystal-forming raw material solution which contains a DDR-type zeolite powder dispersed therein and performing hydrothermal synthesis to form plural DDR-type zeolite crystal particles on surface of the porous substrate, and a membrane-forming step of immersing the resulting porous substrate with DDR-type zeolite crystal particles on the surface in a membrane-forming raw material solution which is free from DDR-type zeolite powder and performing hydrothermal synthesis to form a DDR-type zeolite membrane on the surface of the porous substrate. According to the process, a dense DDR-type zeolite membrane can be formed, and the vessel used in the synthesis can be prevented from being damaged.

Owner:NGK INSULATORS LTD

Zeolite DDR membranes

Owner:GEORGIA TECH RES CORP

Structure provided with zeolite separation membrane, method for producing same, method for separating mixed fluids and device for separating mixed fluids

InactiveUS20120000358A1Improve permeabilityEasy to separateMembranesSemi-permeable membranesRoom temperatureProduct gas

There is provided a zeolite separation membrane-provided article having gaps or pores larger than pores inherent to zeolite crystals and controlled within an appropriate range and being capable of achieving both high permeability and high separability for components with small difference in adsorption properties or a component having a smaller molecular diameter than the diameter of the pores, a method for producing the same, a method for separating mixed fluids, and a device for separating mixed fluids. The zeolite separation membrane-provided article is provided with a zeolite membrane having an N2 gas permeation speed at room temperature of 1.0×10−6 mol·m−2·s−1·Pa−1 or more and a permeation speed ratio of 1,3,5-trimethylbenzene / N2 at room temperature of 0.17 or more and being free from dyeing caused by the impregnation with Rhodamine B.

Owner:NGK INSULATORS LTD

Zeolite membrane and methods of making and using same for water desalination

InactiveCN102438736ARich knowledgeMembranesGeneral water supply conservationWater desalinationReverse osmosis

A novel zeolite membrane is manufactured using zeolite seeds that are deposited on a support material. The seeds are then further grown in a secondary growth step to form a membrane with inter-grown particles. The pore size of the zeolite membrane is in a range between 3 angstrom and 8 angstrom, which allows water to flow through the membrane at a relatively high flux rate while excluding dissolved ions. The novel zeolite membrane is surprisingly efficient for desalinating sea water using reverse osmosis. The zeolite membrane is capable of high rates of water flux rate and high percentage of ion rejection.

Owner:HEADWATERS NANOKINETIX INC

Uniformly b-oriented MFI zeolite membrane with variable thickness supported on substrate and preparation method thereof

InactiveUS8153099B2Film thickness controllableMembranesSemi-permeable membranesMolecular sievePhysical chemistry

A b-oriented MFI zeolite membrane with variable thickness is provided. The MFI zeolite membrane is composed of zeolite crystals whose b-axes are all uniformly oriented perpendicular to a substrate. Further provided is a method for preparing the MFI zeolite membrane. The method comprises forming zeolite or zeotype molecular sieve seeds with different thicknesses on a substrate and adding the seeded substrate to a gel for the synthesis of an MFI zeolite containing a structure-directing agent to grow zeolite or zeotype molecular sieve crystals thereon. The MFI zeolite membrane overcomes the limitations of prior art zeolite membranes to maximize its applicability.

Owner:INTELLECTUAL DISCOVERY CO LTD

Membrane structures and their production and use

InactiveCN101657249AReduced Quantity RequirementsReduce inventoryMembranesDistillationPorous substratePre-condition

A method is provided for forming zeolite membranes in internal surfaces of a plurality of conduits in a cylindrical porous ceramic monolith, the conduits extending from one end of the monolith to theother, said method including a step of: flowing a pre-treatment liquid including a zeolite initiating agent into the conduits; causing at least part of a carrier liquid component of the treatment liquid to flow from the conduits into and through the body of the monolith to the exterior;andcausing zeolite crystals to be deposited in the porous internal surfaces of the conduits as the carrier liquidcomponent flows into the monolith. The substrates may be pre-conditioned for membrane formation by a method which comprises: (a) forming an aqueous suspension ofzeolite particles; and (b) passing thesuspension alternately(i)through the tubular conduits and(ii)out through the walls of the tubular conduits so as to deposit a layer of zeolite particles on the inner surfaces ofthe tubular conduits;wherein the porous substrates are treated in chambers arranged e.g in annularly and the suspension is supplied to the chambers from a first common manifold via respective delivery tubes and is recovered via recovery tubes leading to a second common manifold, the first and second manifolds and the supply and recovery tubes being configured so that the branch path to and from each chamber is substantially the same. After pre-conditioning, formation of membranes may be by depositing or crystallizingazeolite membrane on the zeolite particles by gel crystallization.A membrane structureis also provided which comprisesa tubular porous ceramic monolith having tubular conduitseach having an internal diameter of (5) to (9) mmformed within the monolithwitha zeolite membrane formed on the internal surface ofeach of theconduits, wherein either there are four conduits and the monolith is longer than 600 mm or there are five or more conduits.

Owner:PHOENIX IPR GB

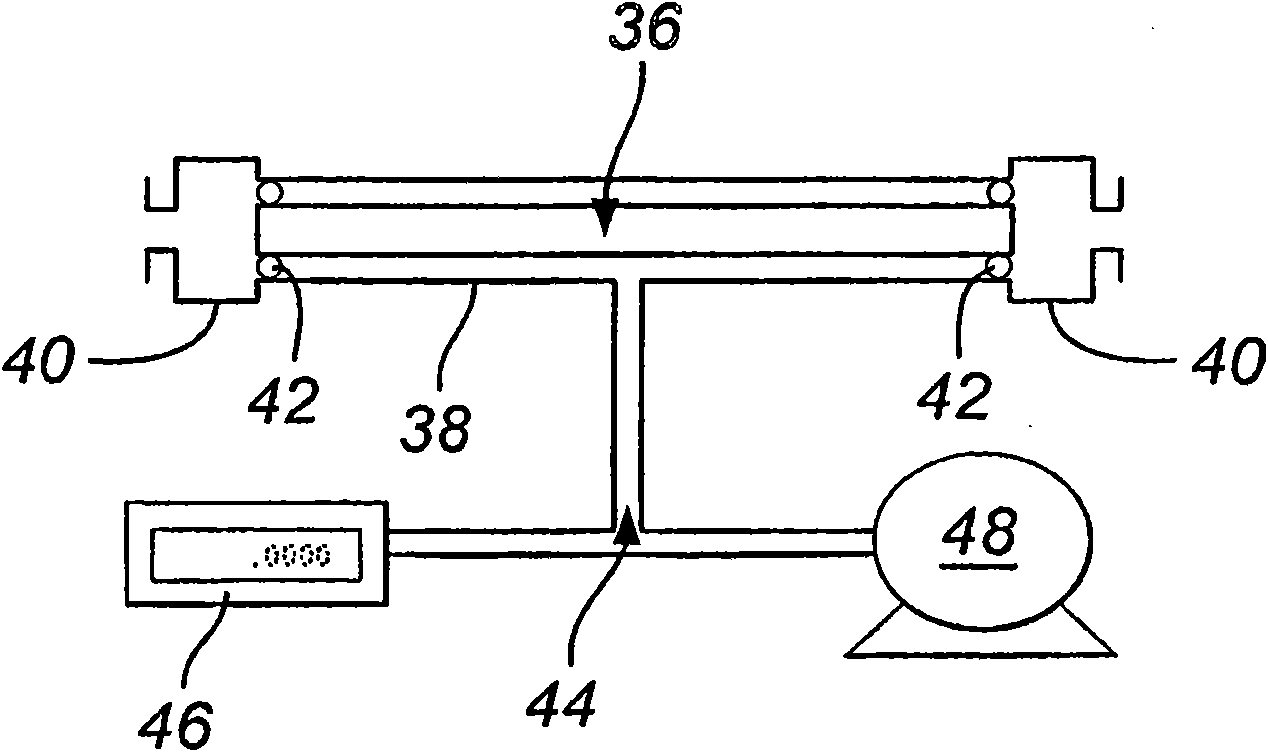

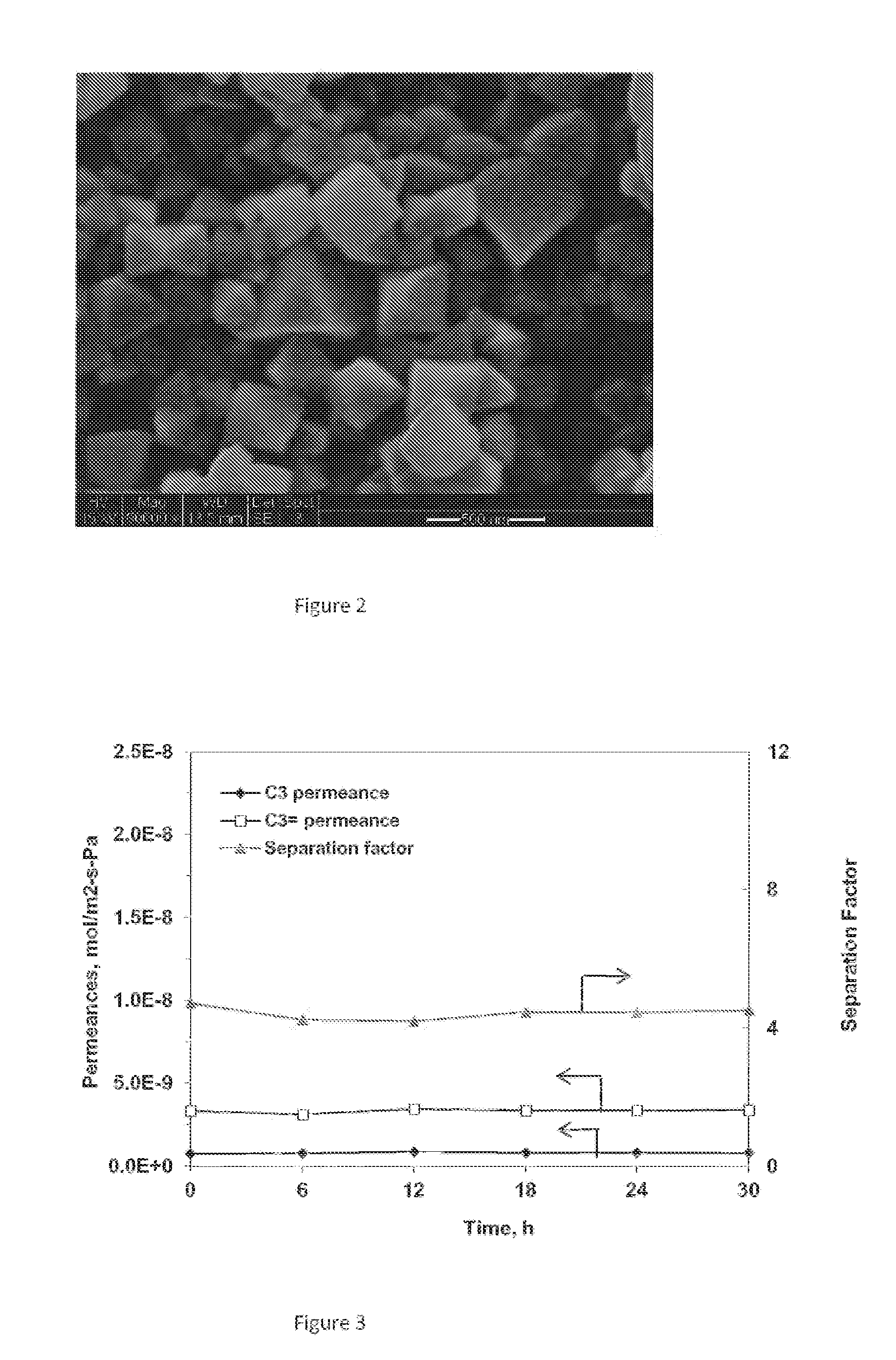

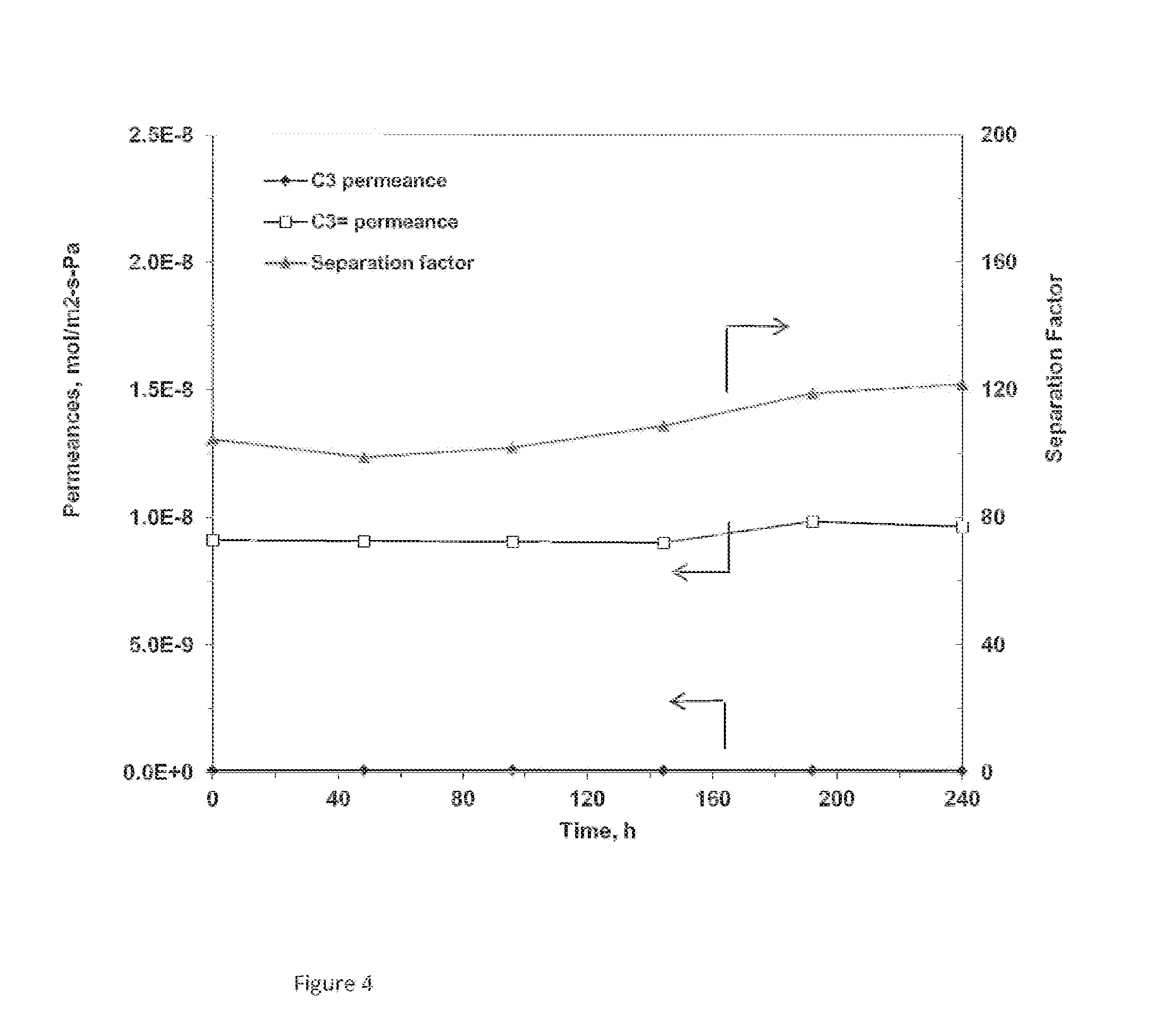

Composite membranes for olefin/paraffin separation

ActiveUS20150321141A1Improve olefin selectivityStrong ion exchange performanceSemi-permeable membranesMembranesPorous substrateMolecular sieve

This invention presents a metal-doped zeolite membrane-based apparatus containing molecular sieving zeolite thin film on the seeded porous substrate. The metal-doped zeolite membrane exhibits high selectivity to olefin over paraffins. The membrane is synthesized by seed coating and secondary growth method, followed by metal doping and post treatment processes.

Owner:BETTERGY

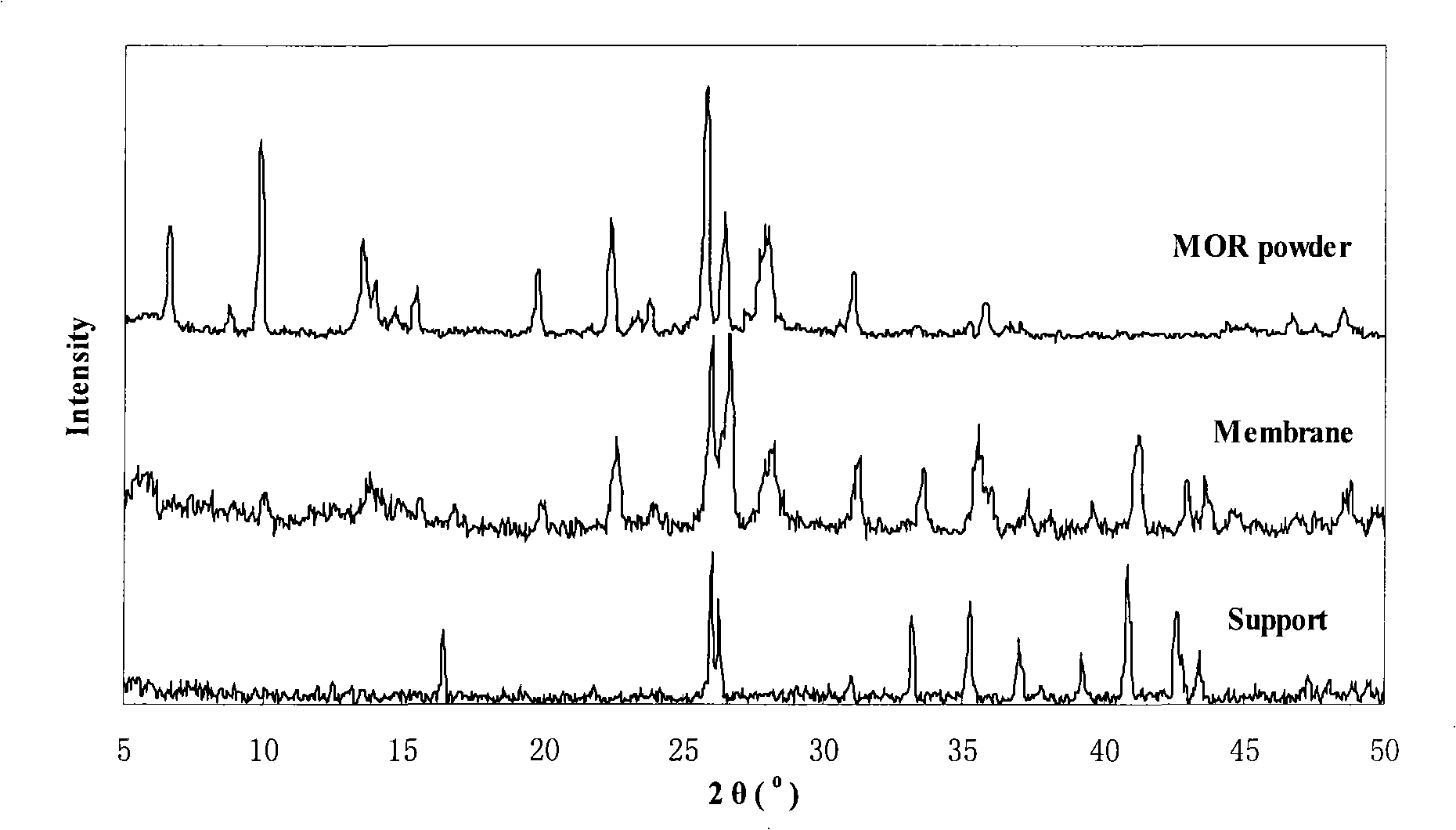

Method for preparing highly-acidproof mordenite molecular sieve membrane

InactiveCN101293658AEvenly distributedAchieve separationMordenite aluminosilicate zeoliteMulliteMembrane reactor

The invention provides a preparation method for mordenite zeolite molecular sieve membranes with high acid resistance. The method directly synthesizes mordenite crystals, and then takes the crystals as crystal seeds, and takes silica sol and aluminum isopropoxide as the source of silicon and aluminum to synthesize dense mordenite zeolite molecular sieve membranes on a porous carrier. The method adopts a tubular support body made of various materials and prepares the mordenite zeolite membranes on a mullite support body. The flux of the membranes prepared on a stainless steel support body is twice higher than that of the membranes prepared on the mullite support body. The synthesized membranes show better stability in the studied acidic media under the different acidity conditions of organic acid and inorganic acid. The method can be widely applied to the pervaporation separation process of an acid system and a reactor for pervaporation membranes.

Owner:JIANGXI NORMAL UNIV

FAU-structural-type supported zeolite membranes, their process for preparation and their applications

InactiveUS20090029845A1Improve mechanical stabilityImprove thermal stabilitySemi-permeable membranesMembranesPorous substrateZeolite membranes

The invention relates to a FAU-type zeolite membrane that comprises a FAU-type zeolite crystal layer incorporated in the surface porosity of at least one selected face of a porous substrate, in which the ratio between the thickness of said zeolite layer incorporated in the surface porosity of said selected face of the substrate and the total thickness of said zeolite layer is at least 70%. It also relates to processes for preparation and application of these membranes.

Owner:INST FR DU PETROLE

Process for preparing nano silver zeolite film catalyst for 1,2-propylene glycol gas phase dehydrogenation and oxidation to synthesize pyruvic aldehyde

InactiveCN1586719AImprove conversion rateHigh selectivityMolecular sieve catalystsCarbonyl compound preparation by oxidationElectrolysisGas phase

The present invention belongs to the field of chemical technology, and is especially one kind of nano silver zeolite film catalyst for gas phase dehydrogenation and oxidation of 1, 2-propylene glycol to synthesize pyruvic aldehyde and its preparation process. The catalyst has nanometer electrolytic silver particle carried onto metal net coated with superthin zeolite film, and is prepared through lamination electrolysis process to deposite electrolytic silver onto zeolite film. The catalyst has low temperature catalytic effect superior to traditional electrolytic silver catalyst and features the continuous catalytic dehydrogenation in the conversion rate up to 96.1 % and selectivity up to 75.6 %.

Owner:FUDAN UNIV

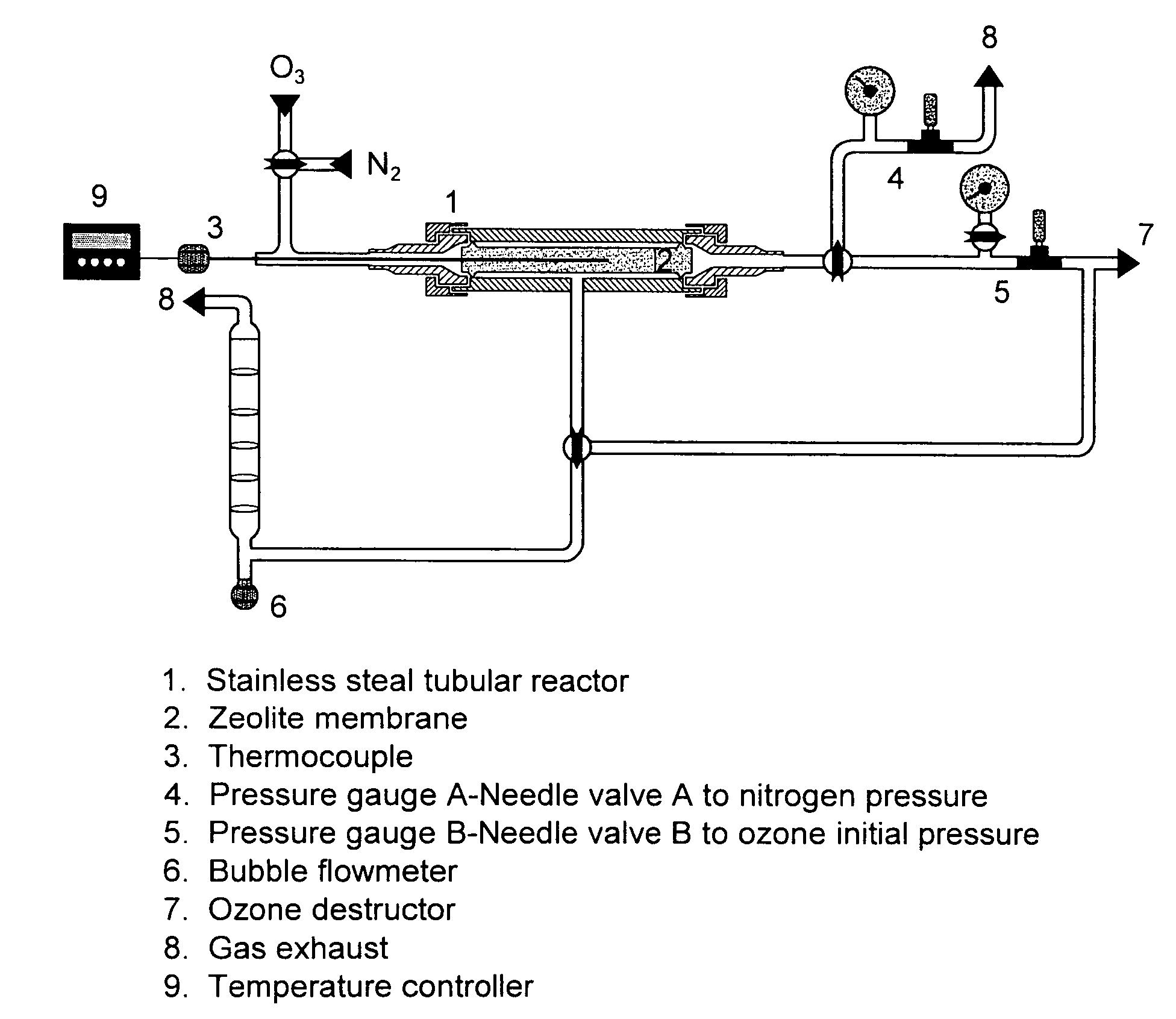

Methods for fabricating zeolite micromembranes

ActiveUS7494610B2Less aggregation and irreversible bondingAluminium compoundsIon-exchanger regenerationPhysical chemistryZeolite membranes

A method of activating a zeolite membrane comprising a step of placing the membrane in contact with a fluid mixture containing ozone, wherein when the fluid mixture is a gaseous mixture, the fluid mixture has a temperature of at least 423K, and wherein when the fluid mixture is a liquid mixture, the fluid mixture has a temperature of 353K.

Owner:THE HONG KONG UNIV OF SCI & TECH

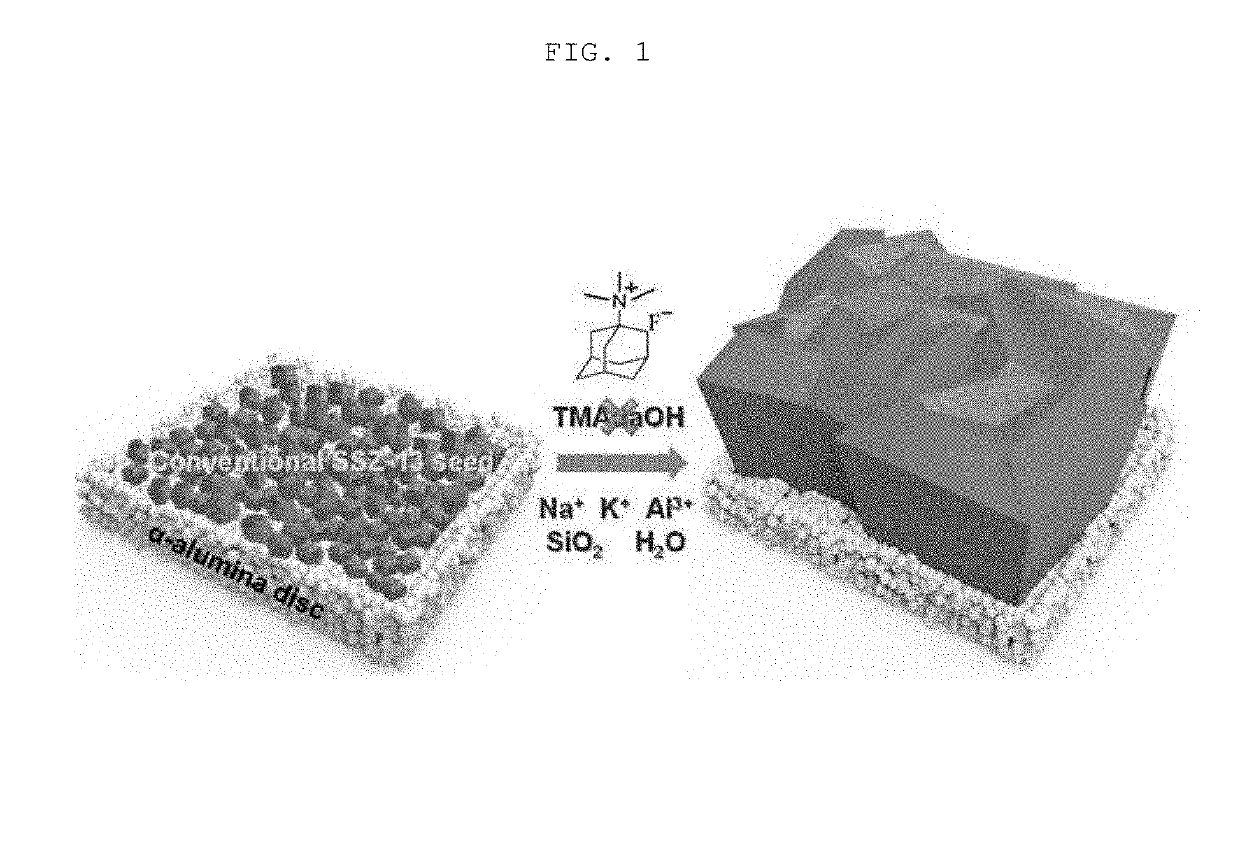

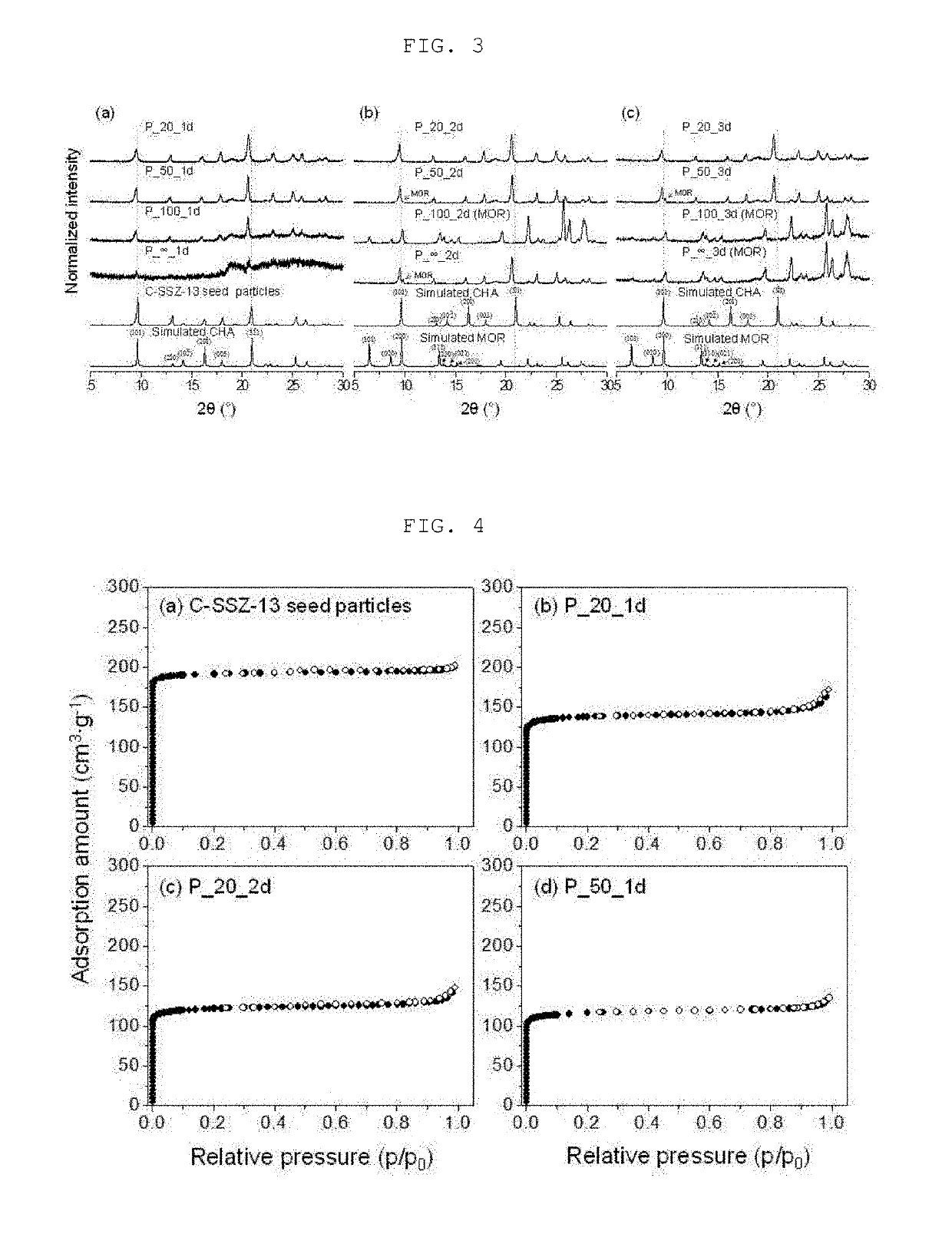

Method of fabricating organic structure directing agent-free cha type zeolite membrane and membrane fabricated thereby

ActiveUS20190143296A1Cost-effectiveMembranesSemi-permeable membranesOrganic structureAlkali hydroxide

The present invention relates to a method of fabricating an organic structure directing agent-free CHA type zeolite membrane and a membrane fabricated thereby, and more particularly to a method of fabricating a continuous CHA type zeolite membrane, which exhibits CO2 / N2 and CO2 / CH4 separation performances comparable with those of conventional membranes, in a cost-effective manner without a calcination process by hydrothermal synthesis using an alkali metal hydroxide without using an organic structure directing agent, and to a membrane fabricated thereby.

Owner:KOREA UNIV RES & BUSINESS FOUND

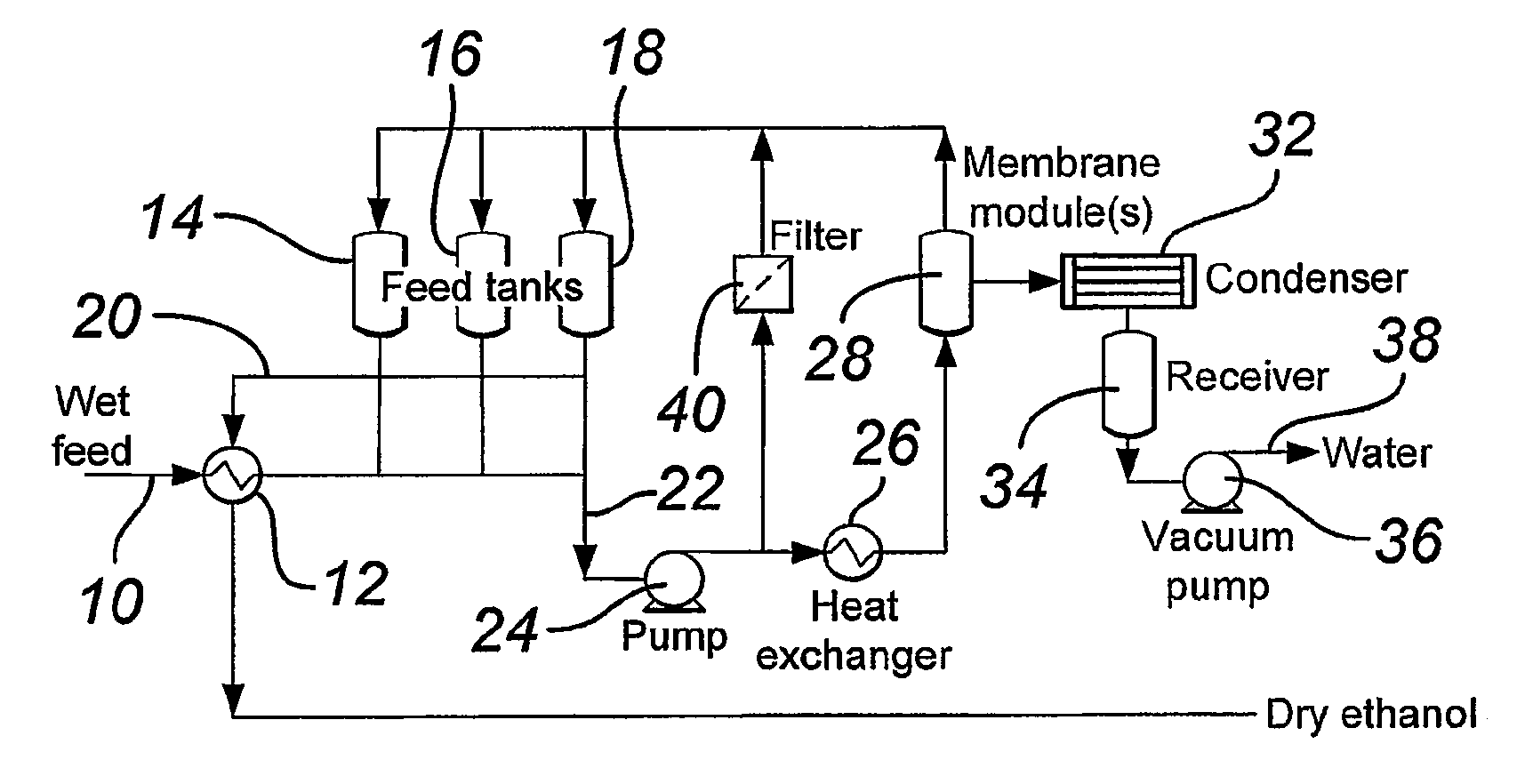

Process and apparatus for treatment of organic solvents

InactiveUS20100090165A1Trend downImprove sealingFermented solutions distillation/rectificationSemi-permeable membranesOrganic solventMembrane surface

A method is provided for separating water from an organic solvent which comprises: passing the solvent through at least one conduit within a porous ceramic with a zeolite membrane formed on the internal surface of the conduit; recovering solvent of reduced water content from the conduit; and recovering water which has passed via the membrane through the ceramic to the exterior thereof. The velocity at which the solvent is passed through the conduit induces turbulent flow for scouring solids from the surface of the membrane and reducing or preventing concentration of the organic solvent on the membrane surface e.g. at 1-6 m / s The invention also provides a method of separating water from an organic solvent which comprises: supplying the solvent to first, second and third tanks; circulating solvent between the first tank and zeolite membranes to separate water therefrom; recovering separated water from the membranes; supplying fresh solvent to the second tank; recovering solvent separated of water from the third tank in heat-exchange relationship with solvent supplied to the second tank; and on completion of water separation initiating at least a first new processing cycle in which recovery is from the first tank, circulation is from the second tank and supply is to the third tank. On completion of said first new processing cycle at least a second cycle may be initiated in which supply is to the first tank, recovery is from the second tank and circulation is from the third tank. Apparatus is also provided for separating first and second fluids, comprising: a multiplicity of tubular porous ceramic monoliths having tubular conduits formed within the monolith with a zeolite membrane formed on the internal surface of each of the conduits; first and second support plates each formed with a multiplicity of holes for receiving the ends of the monoliths for supporting said monoliths in spaced parallel relationship, the holes where they open to outer faces of the support plates being formed with counterbores; O-rings in the counterbores for supporting the monoliths in the apertures each at a small clearance from its respective hole; first and second cover plates attached to the first and second support plates and formed with holes corresponding to the holes in the support plate leading to enlarged inwardly facing regions in which ends of the monoliths are received, attachment of the cover plate compressing the O-rings to seal against the monolith; and a housing having a flow passage in which the first and second support Phoenix,002-PCT26 plates are welded; wherein the support plates have outer surfaces machined flat after the support plates have been welded in position.

Owner:PHOENIX IPR LTD

Method of preparing heterogeneous zeolite membranes

Disclosed are a heterogeneous zeolite membrane and a method of preparing the same, and more particularly a heterogeneous zeolite membrane that has CHA and DDR zeolite structures by growing seed particles into a crystal structure different from that of the zeolite membrane and can thus separate CO2 / N2 and CO2 / CH4 even under wet conditions, a method of preparing the same, and a method of capturing and removing carbon dioxide using the membrane.

Owner:KOREA UNIV RES & BUSINESS FOUND

Method of preparing decadodecasil 3r type zeolite membranes and membranes prepared thereby

The present invention relates to a method of preparing a decadodecasil 3R (DDR) type zeolite membrane and a membrane prepared thereby, and more particularly, to a method of preparing a hydrophobic decadodecasil 3R (DDR) type zeolite membrane having a continuous out-of-plane orientation by adding a substrate on which a seed layer is formed to a silica source synthetic precursor containing a methyltropinium salt and performing a hydrothermal synthesis, and a method of capturing and removing carbon dioxide using a membrane prepared thereby.

Owner:KOREA UNIV RES & BUSINESS FOUND

A preparation method of tubular zeolite membrane applied to reverse osmosis water treatment

ActiveCN110523296BHydrophilicHigh desalination rateGeneral water supply conservationSeawater treatmentDesalinationReverse osmosis

The invention provides a method for preparing a tubular zeolite membrane applied to reverse osmosis water treatment. The method prepares a tubular zeolite membrane through a traditional secondary growth method, and repairs it after high-temperature roasting. The repair is The aqueous phase solution containing polyamine and the organic phase solution containing acyl chloride are successively passed through the inner and outer sides of the tubular membrane, so that the two-phase solution reflects cross-linking at the defect hole to form polyamide to repair the defect hole. The repair method provided by the invention combines the advantages of the zeolite membrane and the polyamide membrane, improves the desalination rate of the membrane, and keeps the water flux in a relatively high range.

Owner:四川林奥科技有限公司

Preparation method of separation-purification film for deicing waste liquid of airplane

InactiveCN106984200ASimple processLow costSemi-permeable membranesWater contaminantsLiquid wasteAlcohol

The invention belongs to the technical fields of wastewater treatment and alcohol-water separation and particularly relates to a preparation method of a separation-purification film for deicing waste liquid of an airplane. The preparation method comprises the following four steps: preprocessing a support body; preparing crystal seeds; depositing the crystal seeds; and synthesizing a zeolite film. According to the preparation method, a layer of dense zeolite film is generated on the surface of a ceramic matrix and is capable of separating the deicing waste liquid. The preparation method is simple in operation, a prepared zeolite coating layer is compact and environment-friendly and has a good binding force, so that the popularization of the preparation method has good social, environmental and economic benefits.

Owner:CIVIL AVIATION UNIV OF CHINA

Supported zeolite membranes

ActiveCN110913979AIncrease the effective permeable areaFlexible Design ConfigurationMembranesDistillationOsmolyteAlcohol ethyl

An asymmetric membrane having a layer containing a zeolite supported on a geopolymer substrate and methods for making an asymmetric membrane having a layer containing a zeolite supported on a geopolymer substrate. A cross-flow membrane separation method for increasing the concentration of ethanol from a feed mixture comprising water and ethanol, comprising: cross-flowing a feed mixture comprisingwater and ethanol across the layer comprising a zeolite of the asymmetric membrane of the instant invention to produce a permeate having an ethanol concentration less than the ethanol concentration ofthe feed mixture and a retentate having an ethanol concentration greater than the ethanol concentration of the feed mixture, the pressure of the feed mixture being greater than the pressure of the permeate.

Owner:NOVO RUICHI TECH CO LTD

Structure provided with zeolite separation membrane, method for producing same, method for separating mixed fluids and device for separating mixed fluids

InactiveUS8361197B2Improve permeabilityEasy to separateSemi-permeable membranesMembranesRoom temperatureProduct gas

There is provided a zeolite separation membrane-provided article having gaps or pores larger than pores inherent to zeolite crystals and controlled within an appropriate range and being capable of achieving both high permeability and high separability for components with small difference in adsorption properties or a component having a smaller molecular diameter than the diameter of the pores, a method for producing the same, a method for separating mixed fluids, and a device for separating mixed fluids. The zeolite separation membrane-provided article is provided with a zeolite membrane having an N2 gas permeation speed at room temperature of 1.0×10−6 mol·m−2·s−1·Pa−1 or more and a permeation speed ratio of 1,3,5-trimethylbenzene / N2 at room temperature of 0.17 or more and being free from dyeing caused by the impregnation with Rhodamine B.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com