Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce local pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

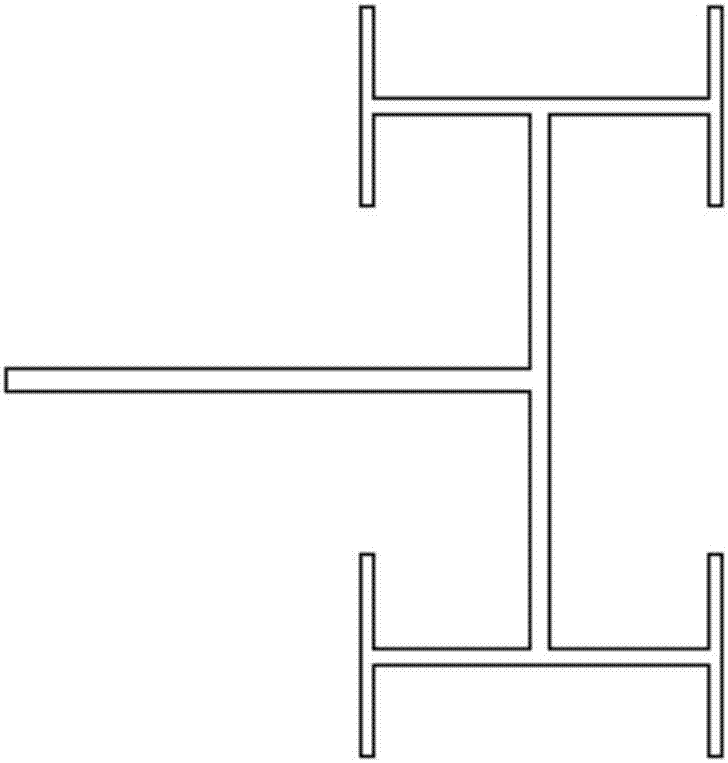

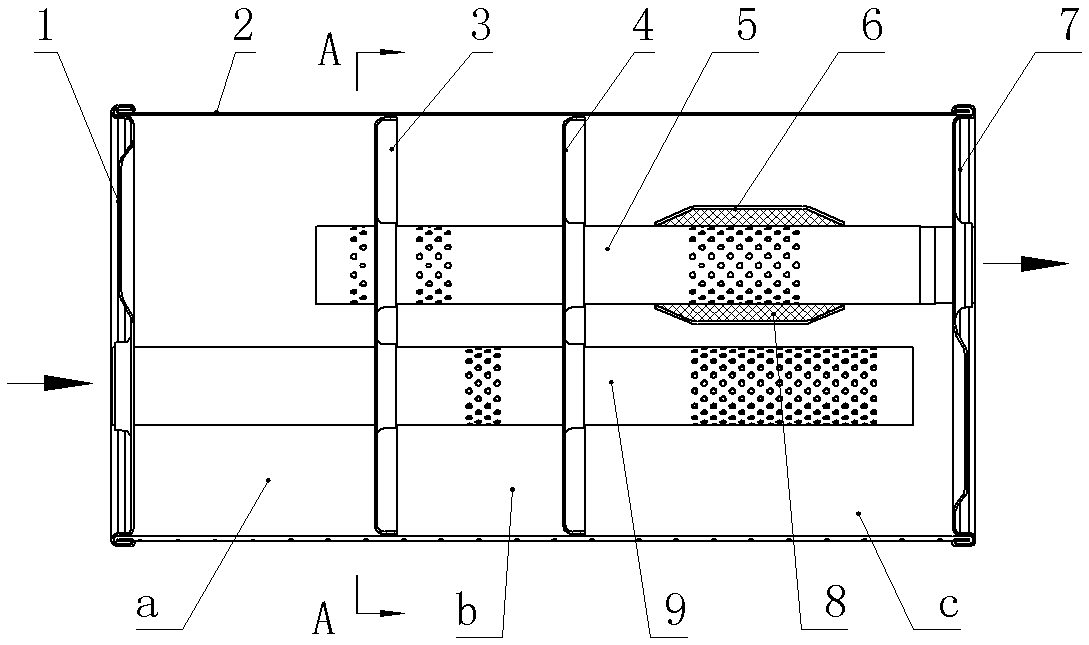

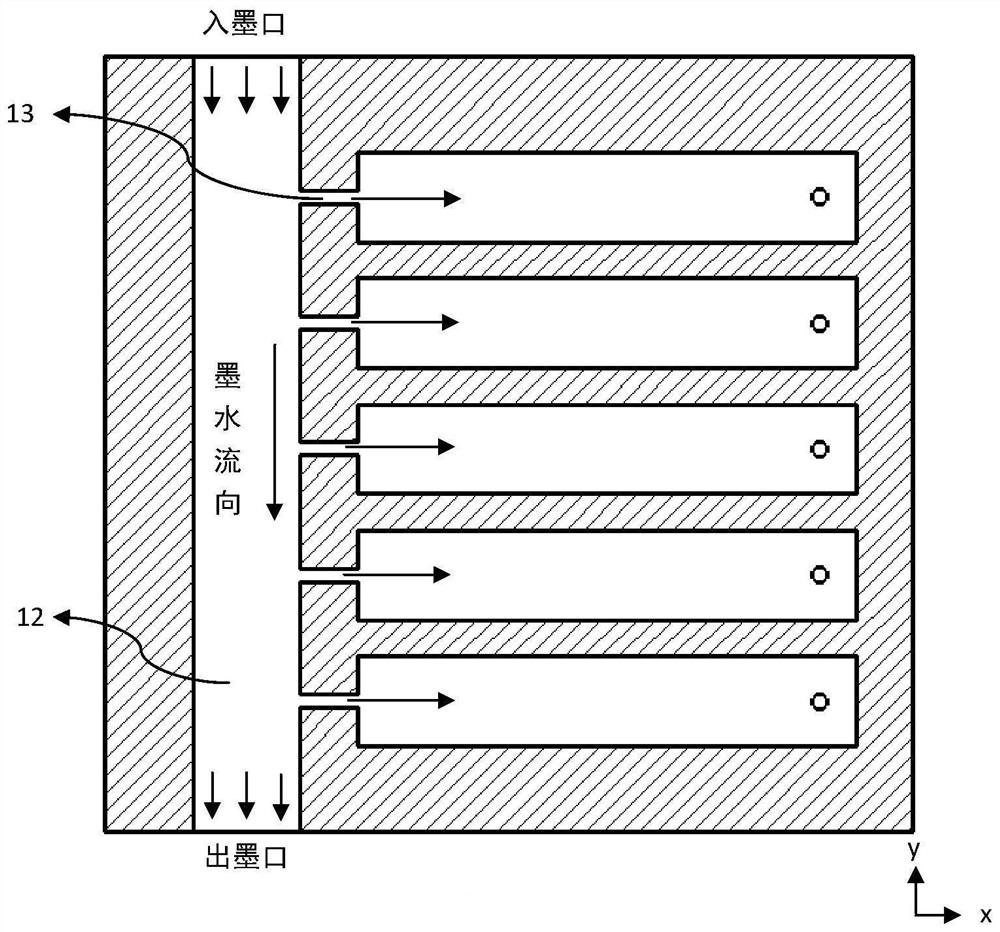

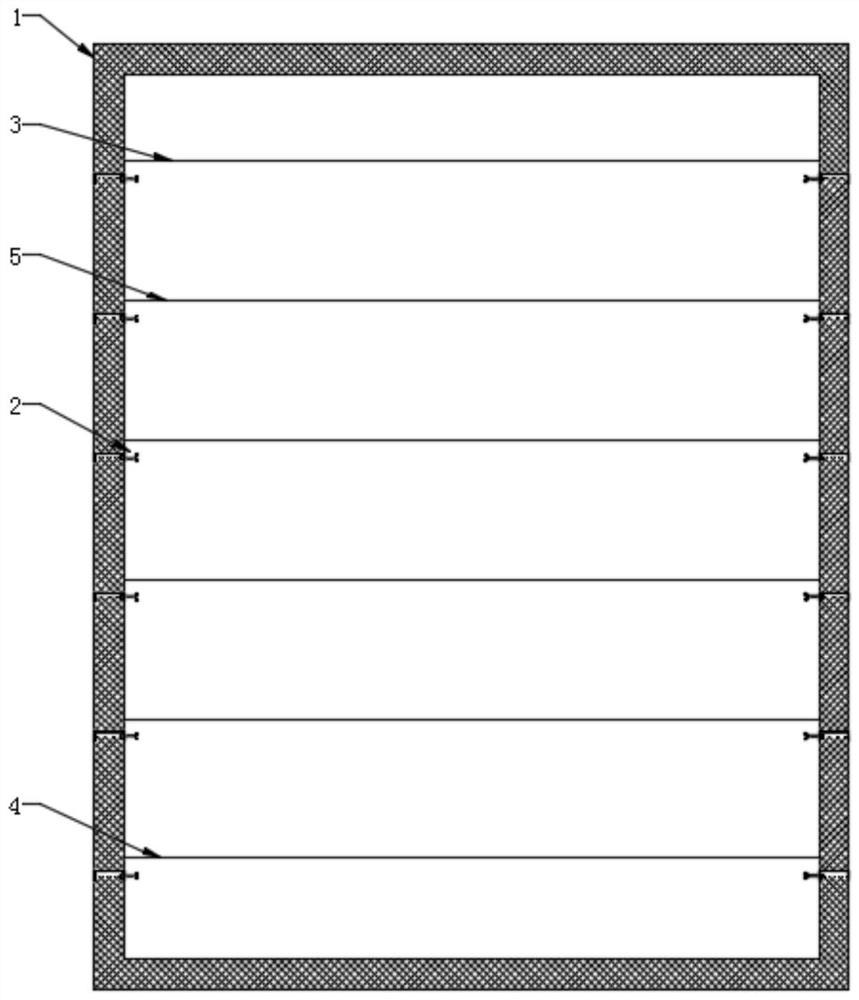

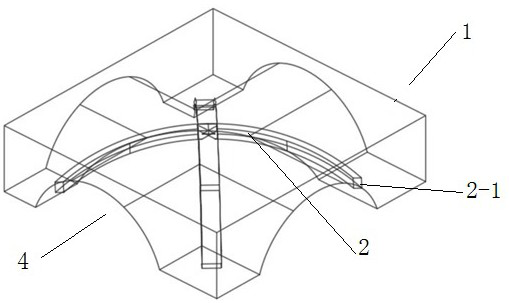

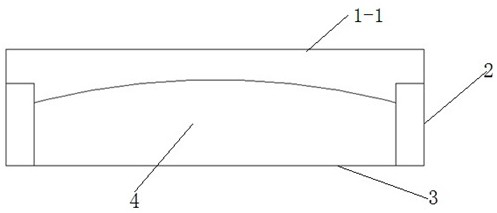

Micro-channel cold plate structure

InactiveCN107146938ASpeed up the flowImprove temperature consistencyDe-icing/drying-out arrangementsChannel networkEngineering

The invention discloses a micro-channel cold plate structure. The micro-channel cold plate structure comprises a substrate and a micro-flowing-channel network processed on the substrate; and the micro-flowing-channel network comprises a shunting structure, a partial micro-channel network and a confluence structure in a combined manner. The micro-channel cold plate structure has the beneficial effects as follows: reasonable flow deploying of a cooling working medium is realized through T-shaped flowing channels, and then heat transfer is strengthened by tree-like and parallel micro channels; finally, energy re-confluence is realized through inverse Y-shaped two-furcation flowing channels, so that high channel distribution uniformity is realized, and the network can be uniformly distributed in the whole to-be-dissipated region; the overall micro-fluid network is in all-parallel-connection way, so that high temperature consistency is achieved; the cooling working medium flows smoothly in the flowing channels, so that low flowing resistance is formed; and furthermore, the micro channels in each group of the partial micro-channel network are arranged in parallel, and the channels are more in branches and high in span, so that the process can be realized conveniently, partial pressure loss can be lowered, and the heat dissipation performance of the micro-channel cold plate can be further improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

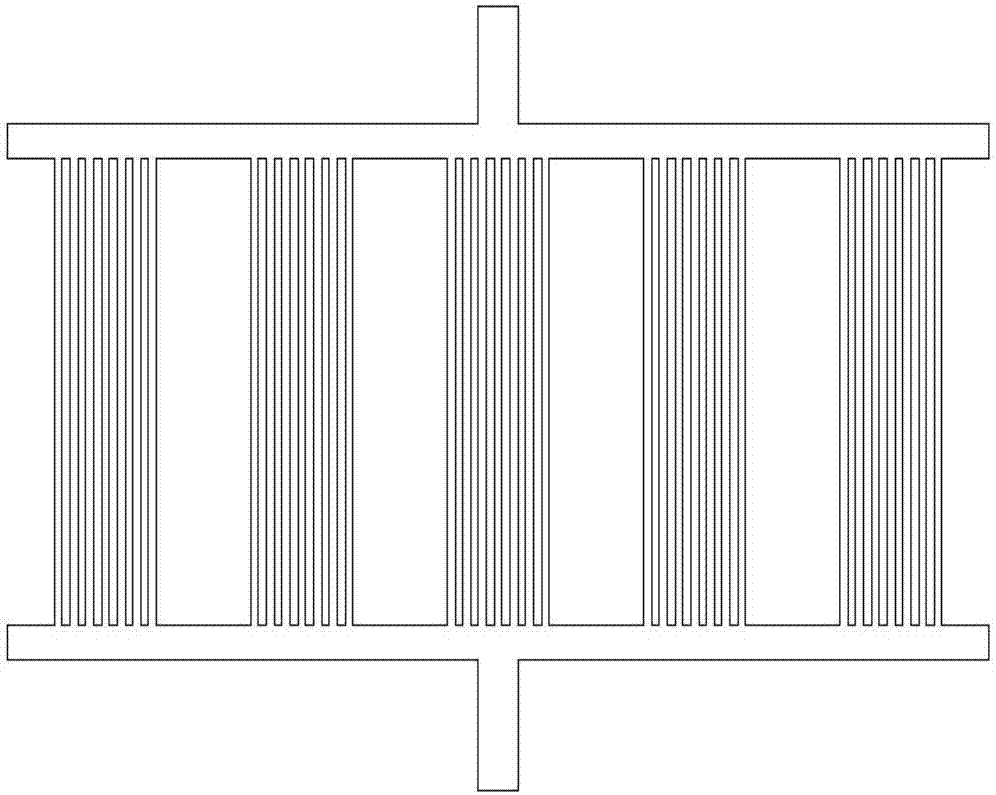

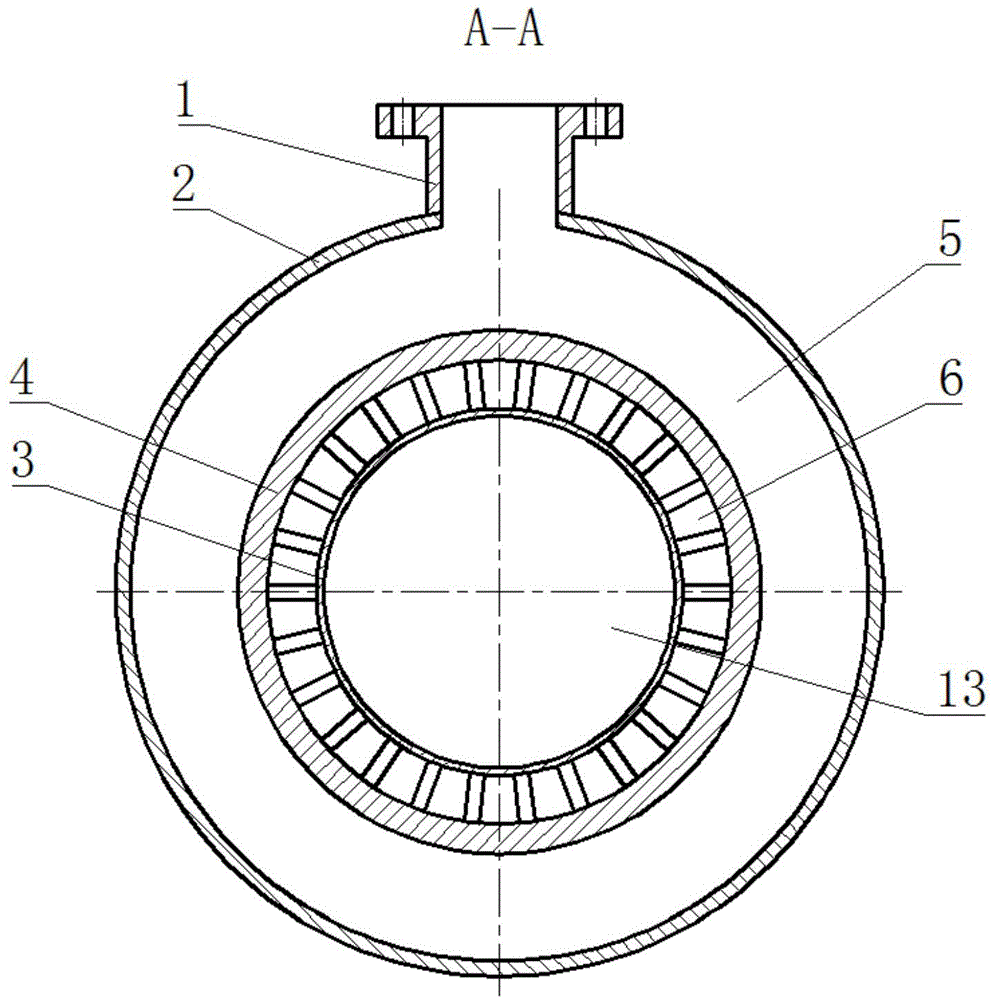

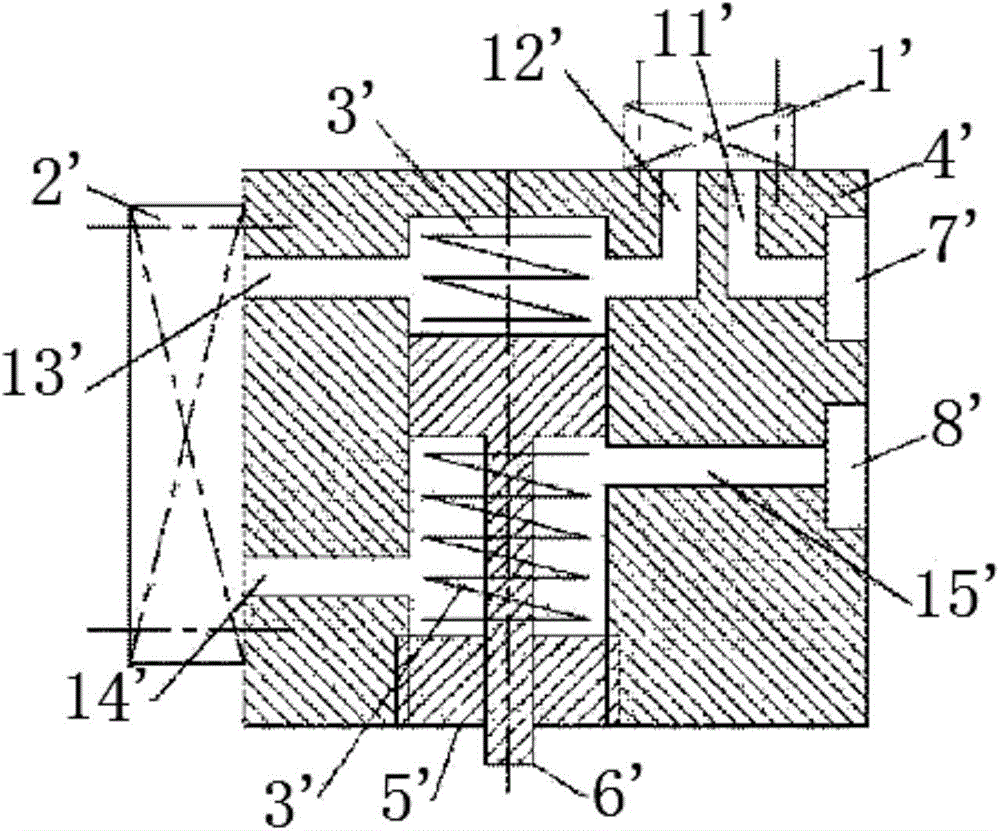

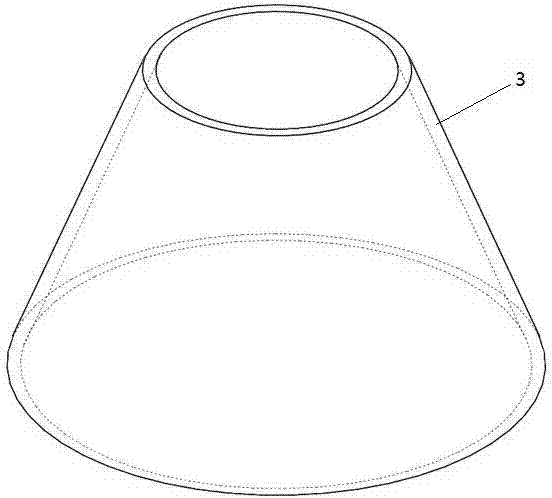

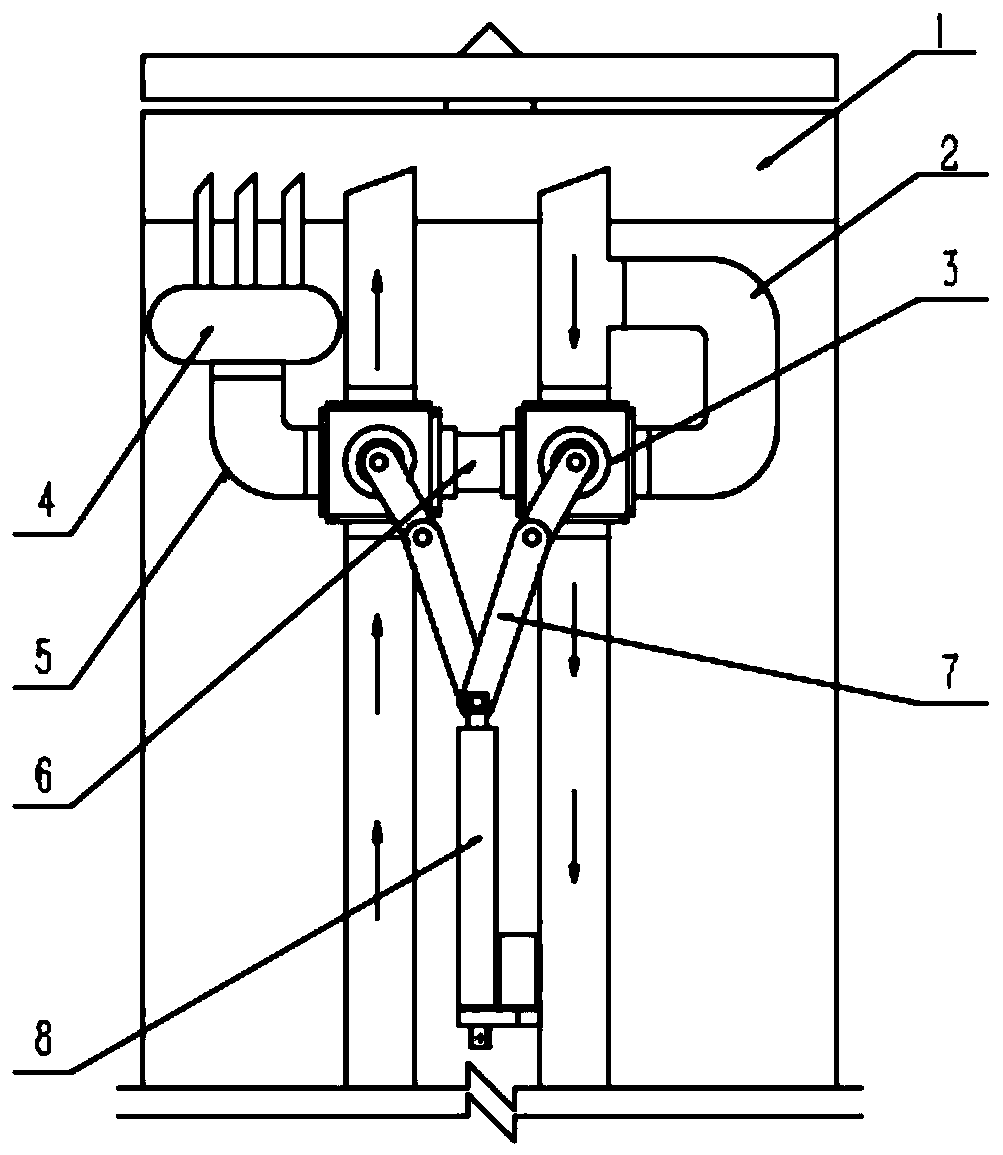

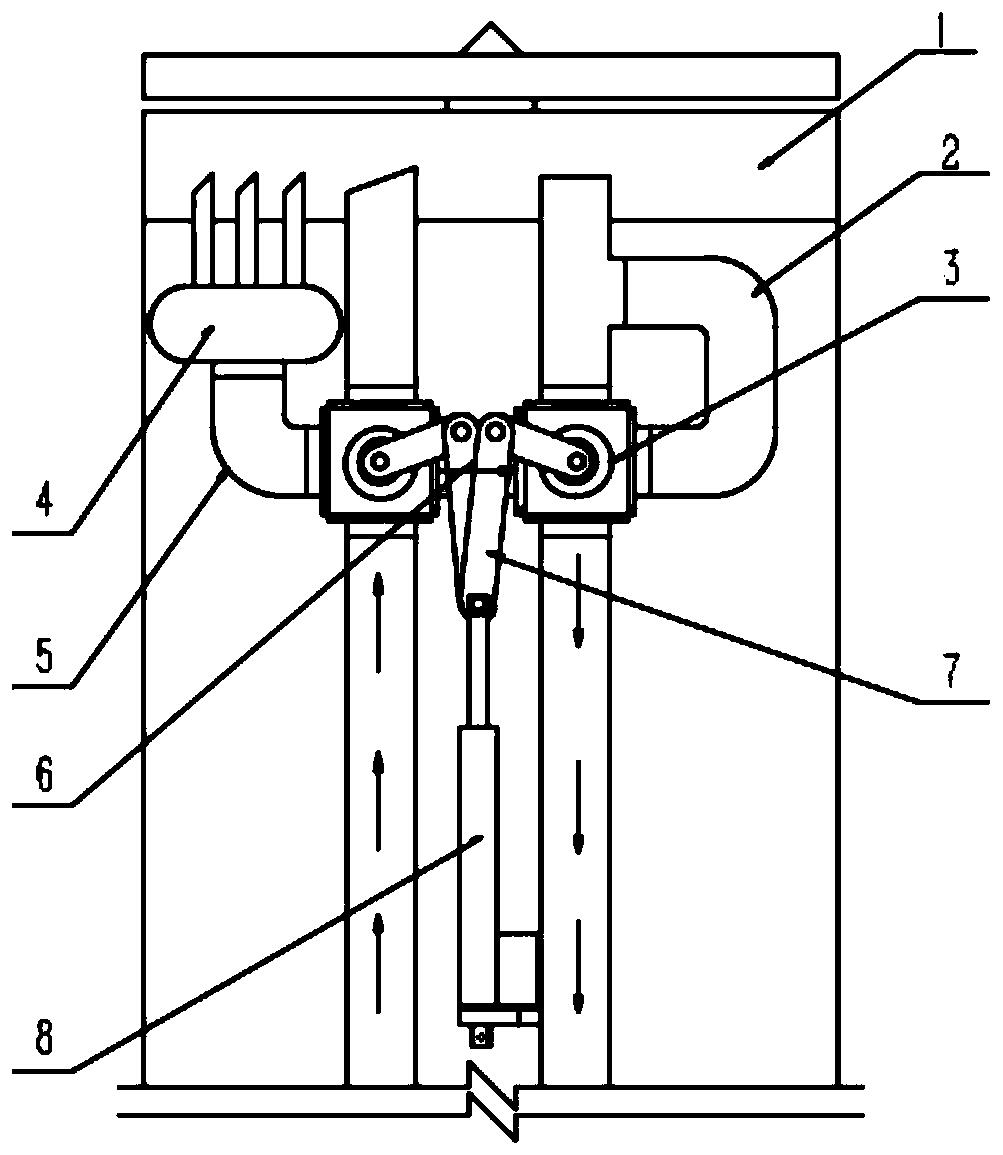

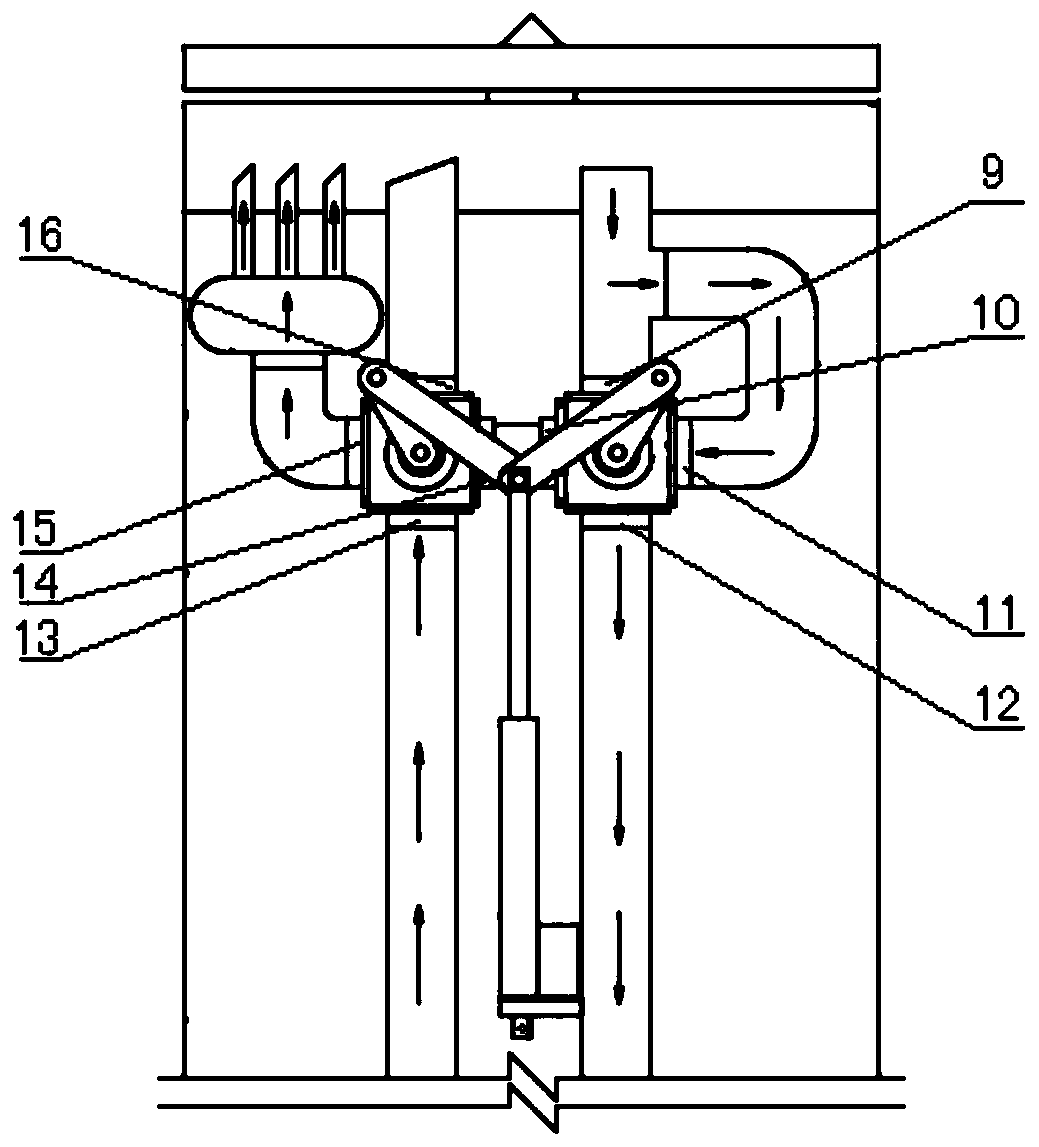

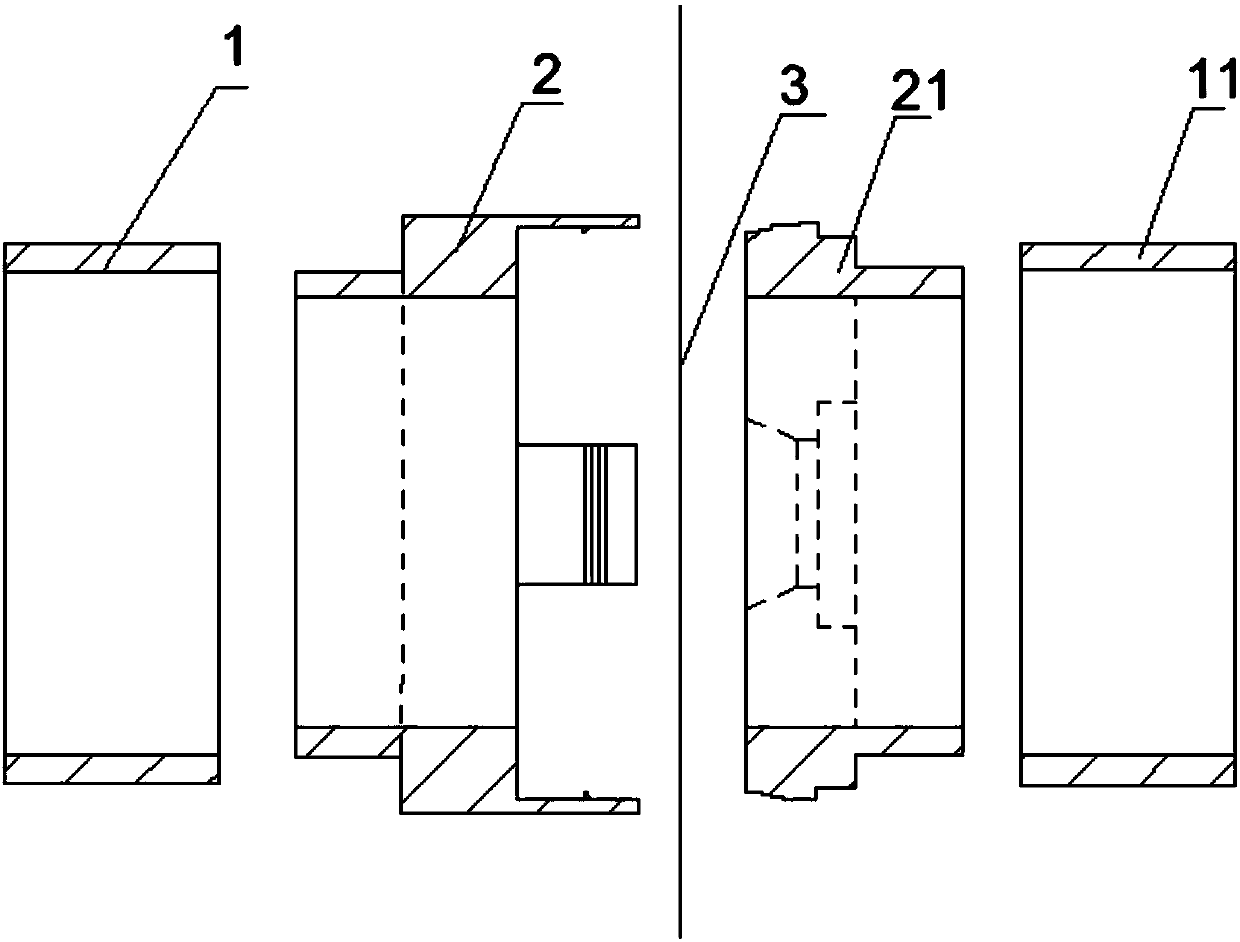

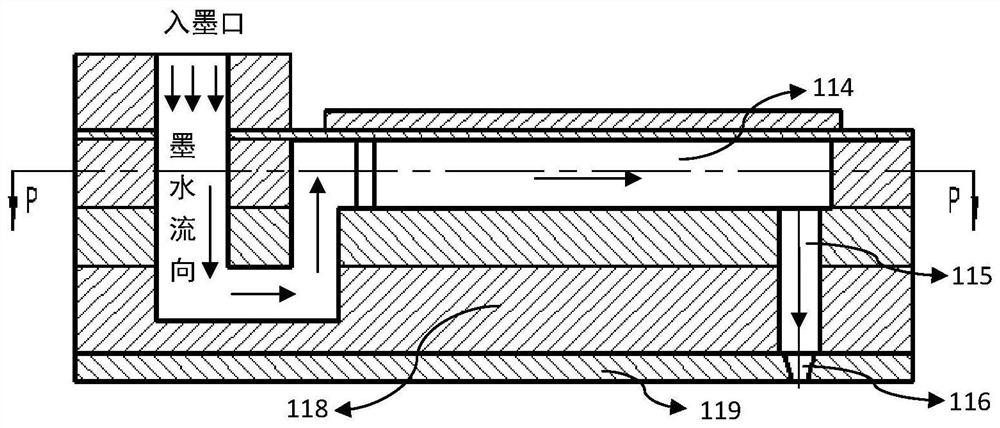

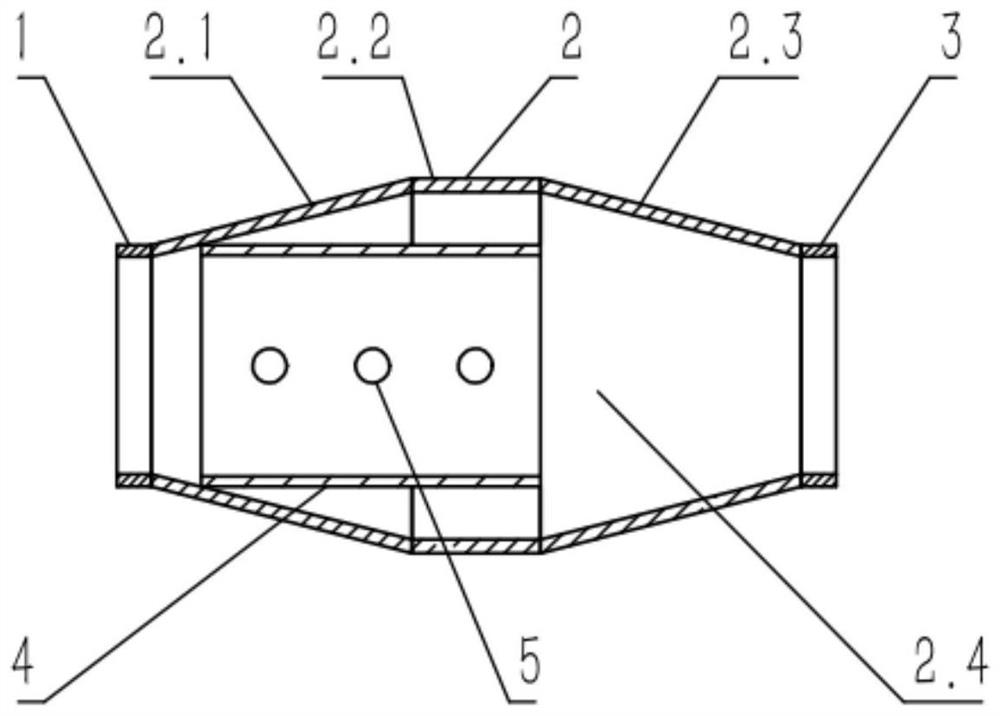

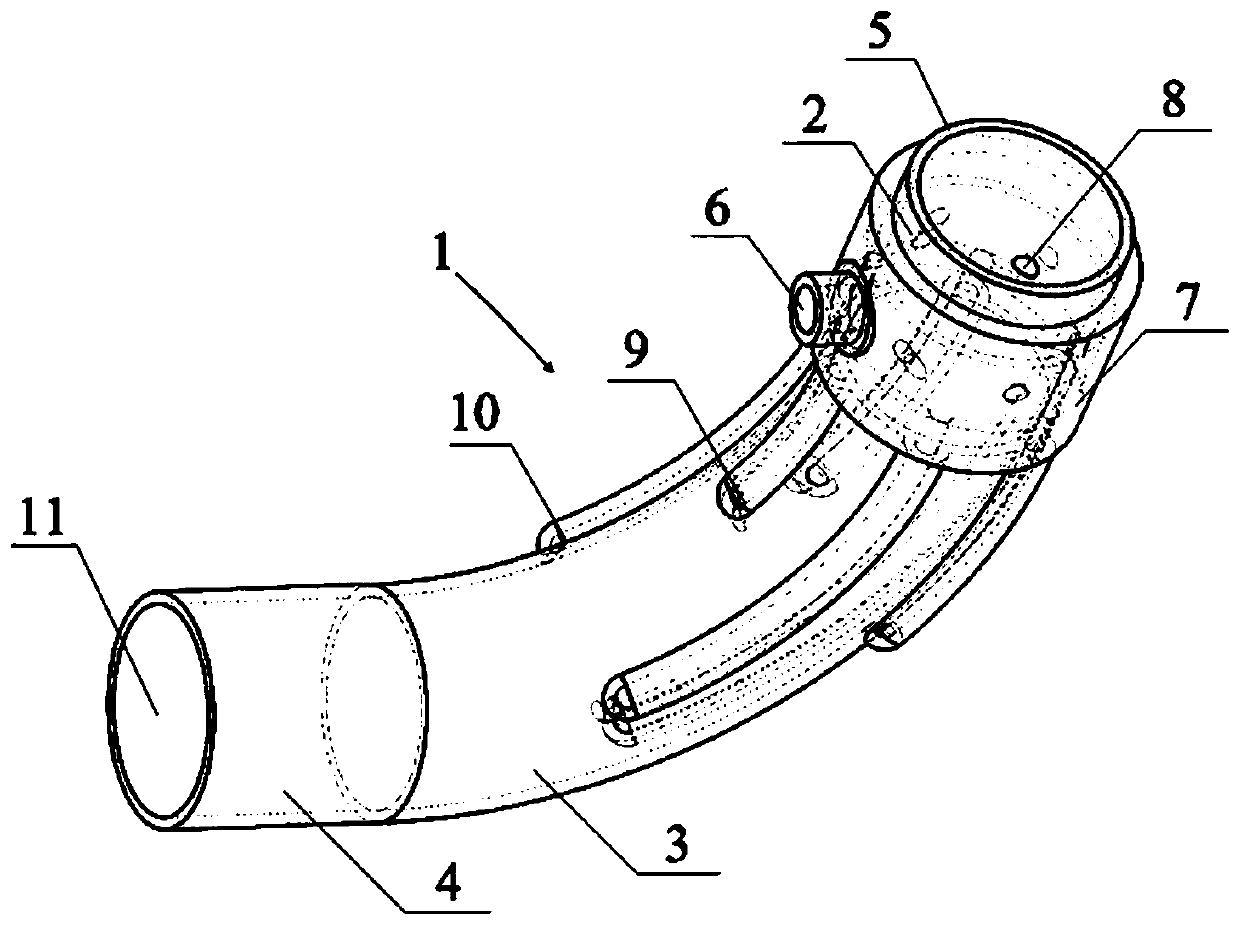

Thrust chamber collector with flow uniformizing function

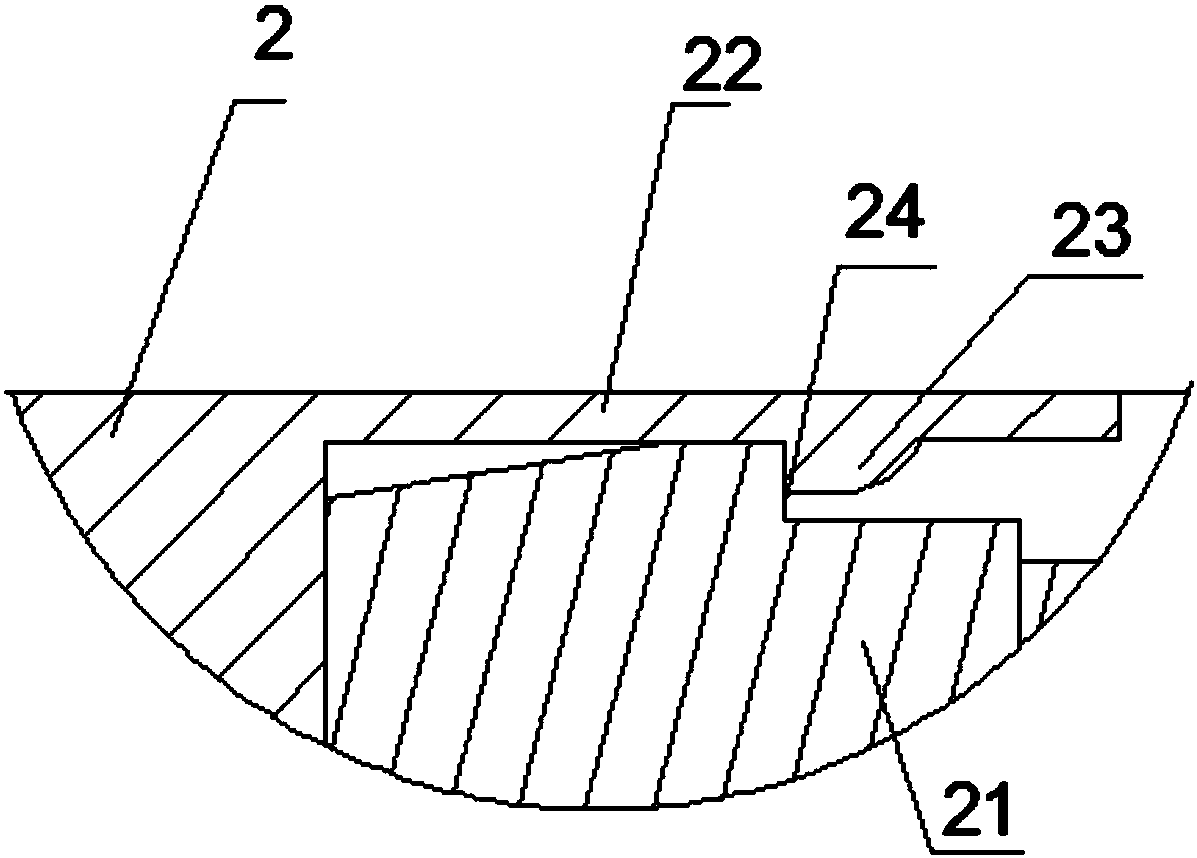

ActiveCN104948347ARealize secondary current sharingUniform pressureRocket engine plantsCombustion chamberThrust chamber

The invention relates to the liquid rocket propulsion technology, and particularly discloses a thrust chamber collector with a flow uniformizing function. A body shell is composed of an inner wall and an outer wall together. A cylinder formed when the inner wall is closed serves as a combustion chamber. An interlayer between the inner wall and the outer wall forms a cooling passageway. Annular grooves are formed in the inlet and the outlet of the cooling passageway. A bent pipe of the collector is welded and connected to the body shell at the annular groove in the inlet of the cooling passageway. A collector cavity is formed by the bent pipe and the body shell. The opening of the collector cavity is welded and connected to an inlet flange to form a collector inlet. Due to the double-collection-cavity structure, fluid is secondarily uniformized before entering the cooling passageway; by means of a horn-shaped expansion inlet with a reverse-Y-shaped diversion piece, fluid can more stably turn at the collector inlet, pressure fluctuation at the inlet and the two sides is reduced, local pressure loss can be reduced, and the diversion piece can play a role in reinforcing structure supporting.

Owner:BEIJING AEROSPACE PROPULSION INST

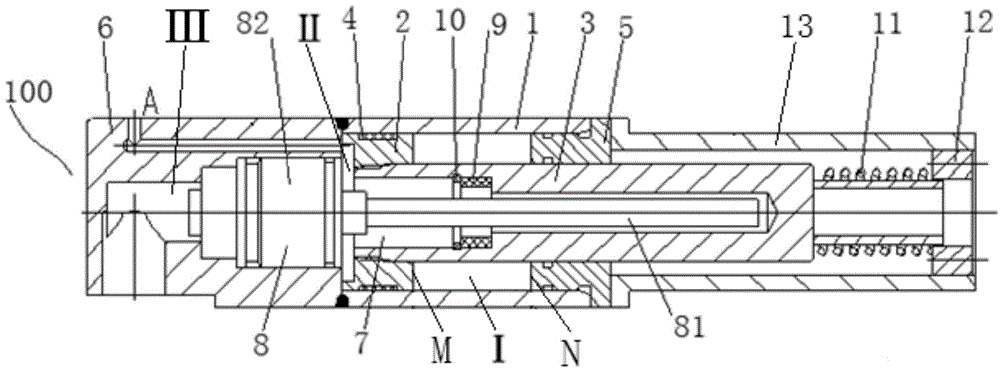

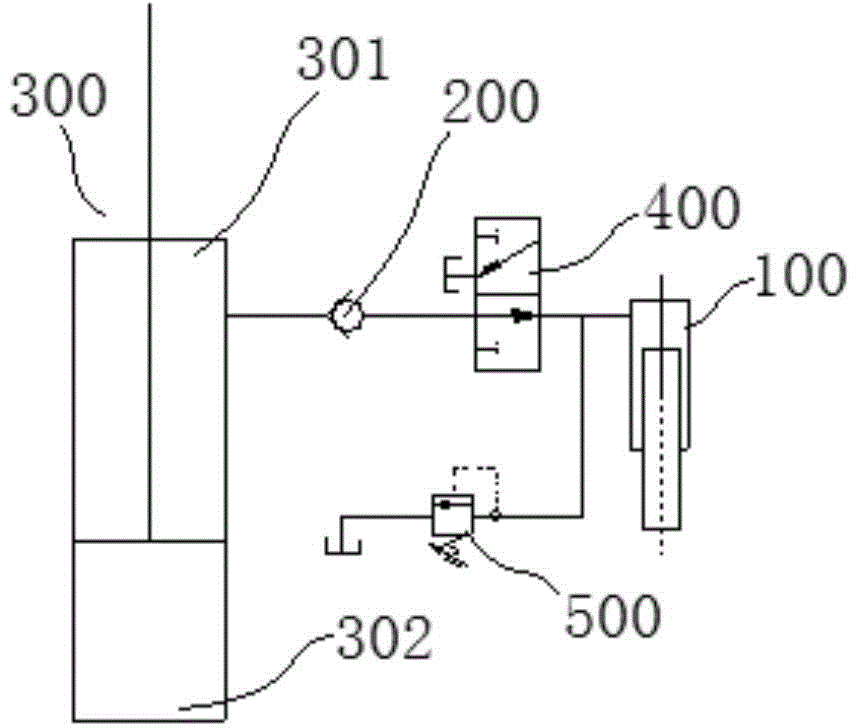

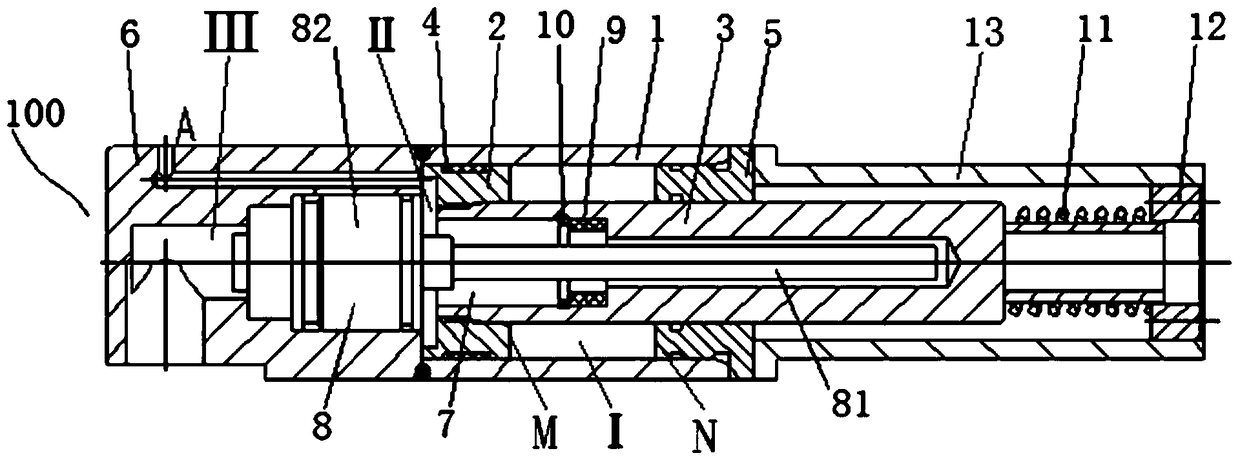

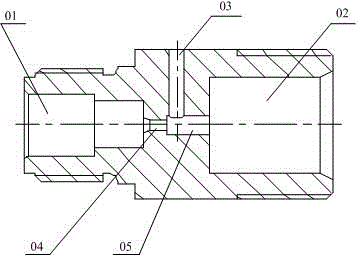

Internal leakage detection equipment and device for hydraulic oil cylinder

ActiveCN105465101AThere are few abrupt changes in the oil passage sectionReduce local pressure lossFluid-pressure actuator testingHydraulic cylinderPiston rod

The invention relates to a piece of internal leakage detection equipment and device for a hydraulic oil cylinder. The internal leakage detection equipment for the hydraulic oil cylinder at least comprises a cylinder barrel, a piston rod assembly installed inside the cylinder barrel in a matched mode, and a speed detection mechanism fixedly installed in the cylinder barrel and used for sensing the movement speed of the piston rod assembly. By the adoption of the internal leakage detection equipment and device, accurate judgment data are provided for internal leakage of the hydraulic oil cylinder.

Owner:XUZHOU HEAVY MASCH CO LTD

Cleaning machine and water outlet device of plunger/piston pump

ActiveCN103244401AIncrease outlet pressureReduce local pressure lossPositive displacement pump componentsLiquid fuel engine componentsEngineeringLocal pressure

The invention provides a water outlet device of a plunger / piston pump. A flow passage switching pipeline structure is added between a water inlet passage and a water outlet passage, a first slider which is fixedly connected with a Venturi pipe device and slides synchronously is arranged in the flow passage switching pipeline structure, an elastic return device guiding along a guide slideway in the return direction and a liquid suction pipeline are arranged between the first slider and the guide slideway, and a second slider which is butted against the Venturi pipe device is arranged at the other end of a flow passage switching pipeline and is in sliding seal with the guide slideway. In a liquid suction working condition, a passage of the Venturi pipe device is communicated with the water inlet passage and the water outlet passage; and in a normal working condition, the Venturi pipe device is pushed to a stagger position of the water inlet passage and the water outlet passage, passage area between the water inlet passage and the water outlet passage is enlarged, local pressure loss of constant-pressure working media flowing through the position between the water inlet passage and the water outlet passage is reduced greatly, and accordingly water outlet pressure is increased with wasted work not increased. The invention further provides a cleaning machine.

Owner:苏州黑猫清捷科技有限公司

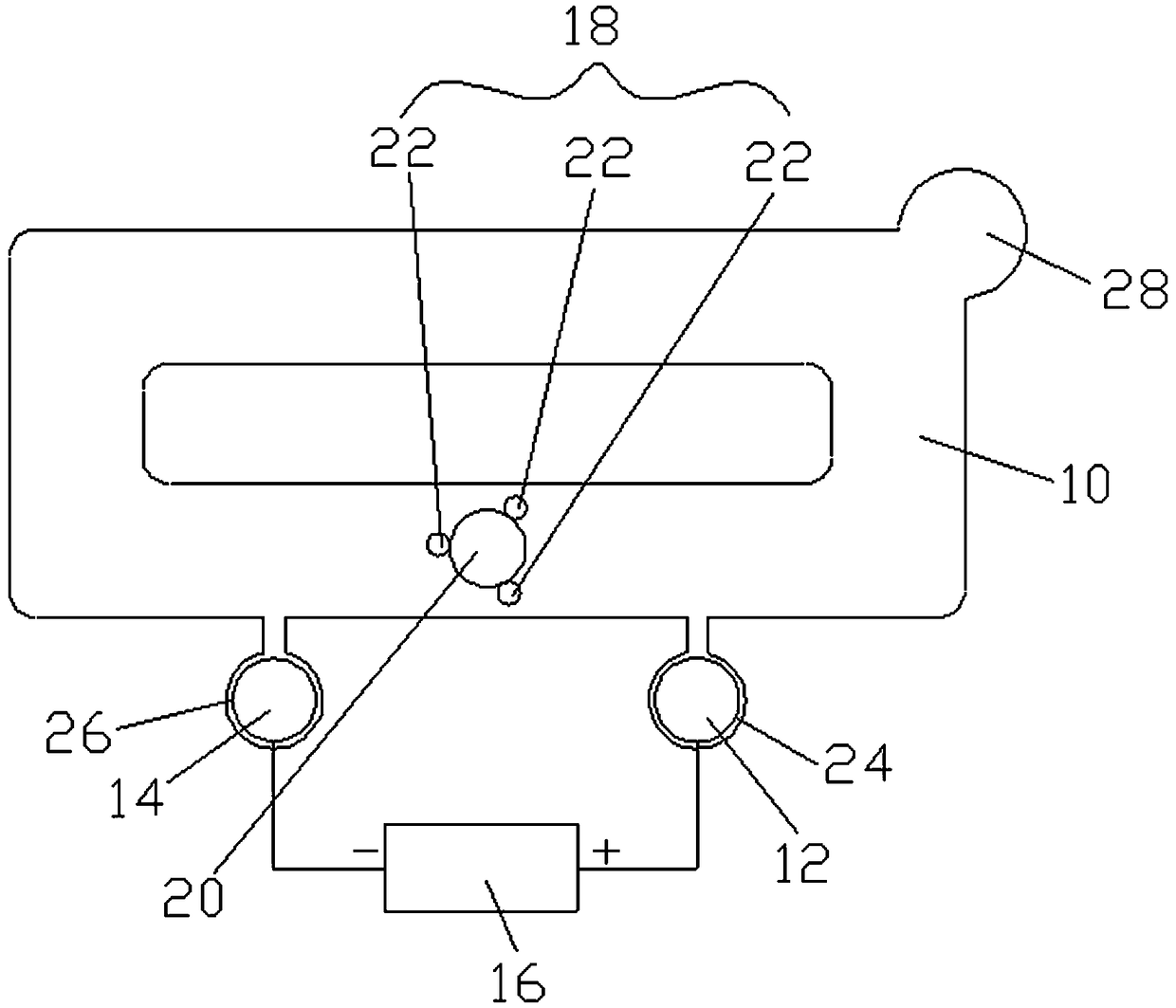

Micropump structure based on liquid metal at room temperature

InactiveCN109231148AReduce local pressure lossAvoid heat lossSemi-permeable membranesFixed microstructural devicesRoom temperatureLiquid metal

The invention relates to a micropump structure based on liquid metal at room temperature, the micropump structure including a channel, a first electrode, a second electrode and a power generator. An open chamber is arranged in the channel, a liquid metal droplet is contained in the open chamber, an electrolyte solution is filled in the channel, one end of the first electrode and one end of the second electrode are in contact with the electrolyte solution, and the other end of the first electrode and the other end of the second electrode are connected with the power generator. The structure does not contain any mechanical moving parts, greatly reduces the local pressure loss caused by the micro pump structure itself in the fluid, and simultaneously avoids the heat loss caused by the heatingof the parts, at the same time, the structure can generate a larger flow rate under relatively small power consumption, the structure is simple and efficient, and the pumping effect is greatly improved.

Owner:SUZHOU UNIV

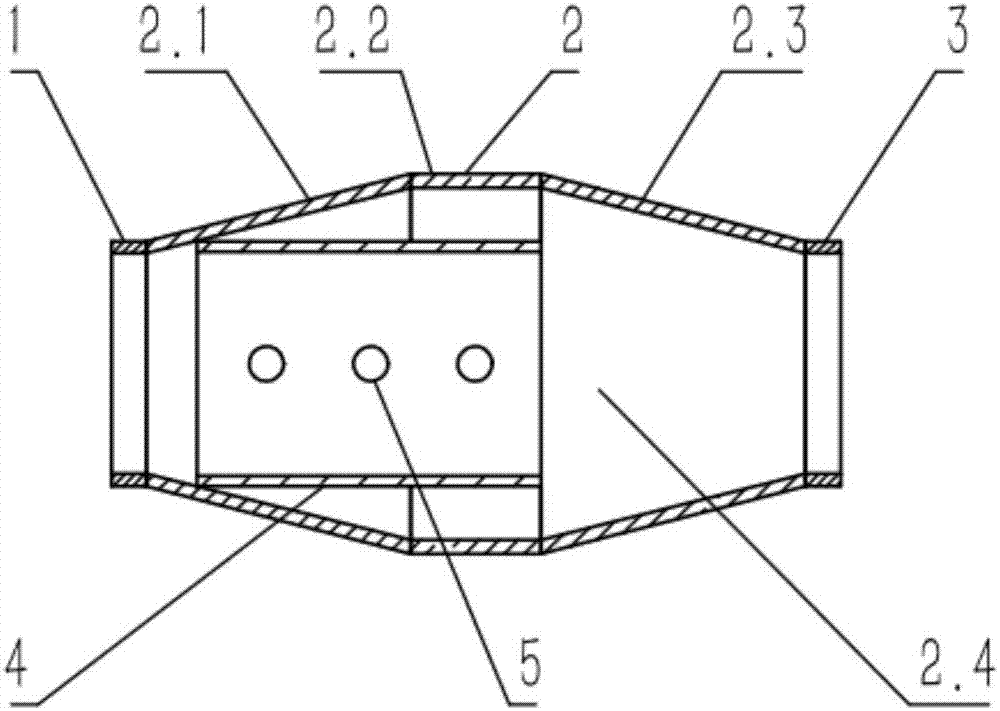

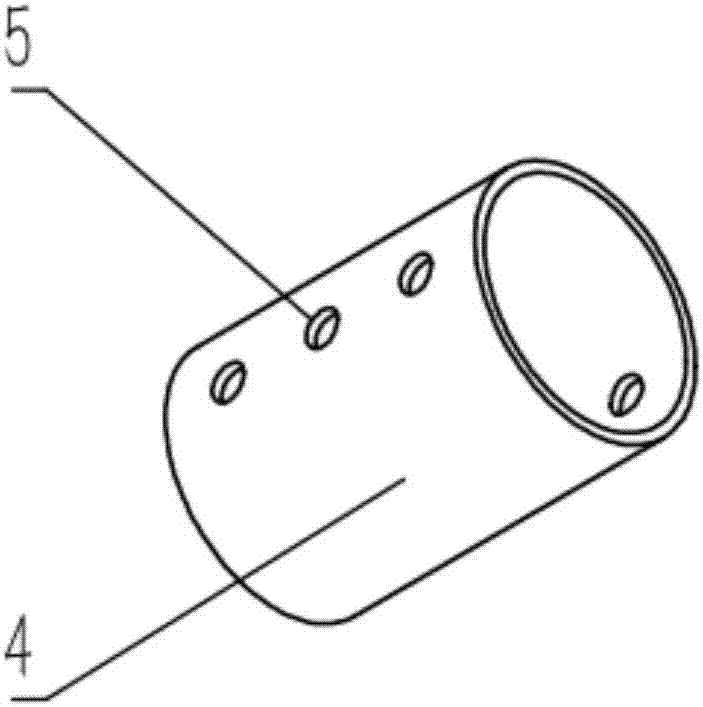

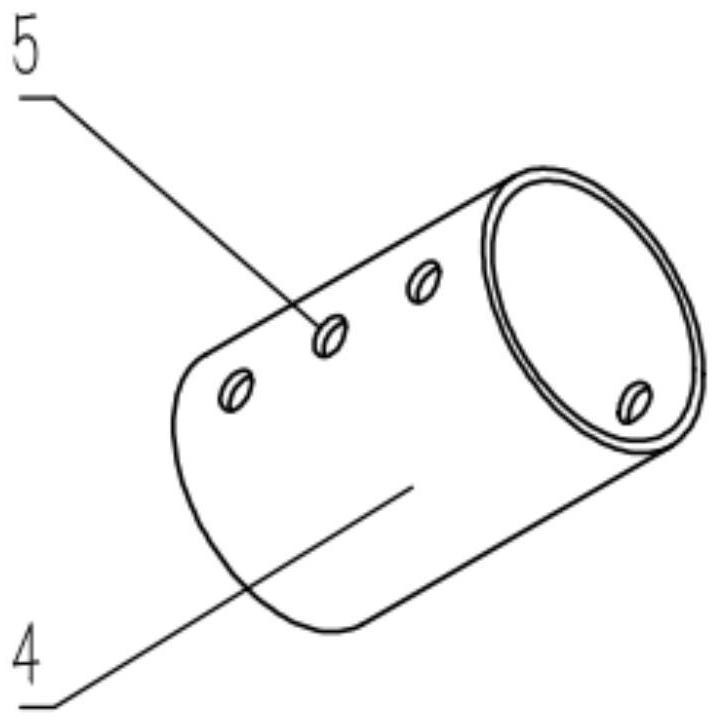

Exhaust silencer for screw type machine set

ActiveCN107120288ASmall pressure lossReduce total pressure lossRotary/oscillating piston pump componentsLiquid fuel engine componentsStraight tubeGyration

The invention relates to an exhaust silencer for a screw type machine set. The exhaust silencer comprises an air inlet pipe, a silencer shell body and an air outlet pipe which communicate with each other sequentially and straightly; and the silencer shell body is composed of a diverging tube, a straight tube and a converging tube in the flow direction of a refrigerant, and gyration spaces which are sequentially combined in the silencer shell body form a silencer cavity. The exhaust silencer is characterized in that an insert-pipe is fixedly arranged in at least one of the diverging tube and the converging tube; the insert-pipe is inserted into the silencer cavity through the joint of the insert-pipe and the diverging tube or the insert-pipe and the converging tube; through-hole type air vents are formed in the pipe wall of the insert-pipe; and the gyration center of the silencer shell body coincides with the gyration centers of the air inlet pipe and the air outlet pipe. According to the exhaust silencer for the screw type machine set, on the premise of ensuring noise elimination, the pressure loss of the silencer is lower, the structure is simper, and moreover, the silencer can be applied to a variable-frequency screw type machine set with great noise-frequency change.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

Cyclone separator overflow pipe with horn-mouth-shaped flow guide plates and cyclone separator

InactiveCN104492613AReasonable structureEasy to manufactureReversed direction vortexEngineeringPhencyclone

The invention discloses a cyclone separator overflow pipe with horn-mouth-shaped flow guide plates. The cyclone separator overflow pipe comprises a straight pipe section and a horn-mouth-shaped pipe with a small upper part and a large lower part, wherein the small mouth end of the horn-mouth-shaped pipe is connected with the lower end of the straight pipe section; the inner wall of the horn-mouth-shaped pipe is uniformly provided with flow guide plates; the flow guide plates comprise circular arc plates and straight plates which are connected with each other and are tangent. The invention also discloses a cyclone separator using the overflow pipe structure. The cyclone separator is relatively stable in inner flow path, basically eliminates the short-circuit current effect, and reduces the pressure loss greatly, so that the integral running performance is improved obviously.

Owner:SUZHOU AINAJIE INTELLIGENT TECH

Compressor five-cavity air suction muffler and compressor

ActiveCN112901453AConsider performanceAnechoic peak frequency increasedInternal combustion piston enginesPositive displacement pump componentsEngineeringMuffler

The invention discloses a compressor five-cavity air suction muffler and a compressor. The compressor five-cavity air suction muffler comprises a container and a filter screen, wherein the container is provided with an opening; the filter screen is mounted at the opening of a shell; the area of the filter screen is equal to that of the opening; a cavity is formed in the container; a plurality of partition plates are mounted in the container and divide the cavity in the container into a first cavity, a second cavity, a third cavity, a fourth cavity and a fifth cavity which are communicated with each other; and the first cavity is communicated with the opening of the container.

Owner:QINGDAO WANBAO COMPRESSOR

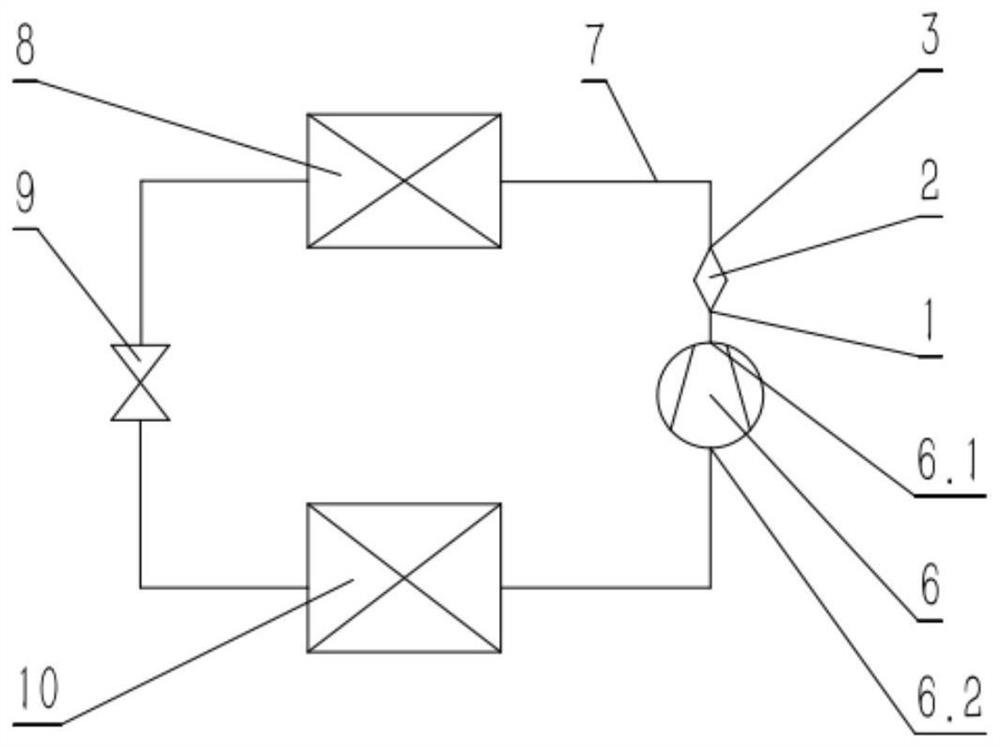

Muddy water bypass device for miniature pipe jacking machine

PendingCN111594641ACombination structure is simple and feasibleEasy to installPipe laying and repairOperating means/releasing devices for valvesFour-way valveOutfall

The invention relates to the technical field of construction equipment, in particular to a muddy water bypass device for a miniature pipe jacking machine. A water inlet pipeline and a water outlet pipeline are arranged on the lower side of a muddy water bin of the pipe jacking machine, a first four-way valve is arranged in the water inlet pipeline, a second four-way valve is arranged in the wateroutlet pipeline, wherein the first four-way valve is provided with a first water inlet, a first water outlet, a pressurizing opening and a first connecting opening, the pressurizing opening communicates to the muddy water bin of the pipe jacking machine through a pressurizing pipeline, a pressurizing valve is arranged at the pressurizing pipeline, and the second four-way valve is provided with a second water inlet A, a second water inlet B, a second water outlet and a second connecting opening. According to the muddy water bypass device, the structure size of the device can be reduced, and thein-machine space is saved; the universality and adaptability of the device are improved, the use is reliable, the manual labor amount is reduced, the occupational hazards are reduced, the structure is simple, a four-way ball valve is adopted for replacement to complete switching of three loops of a mud feeding and discharging mode, a bypass mode and a flushing mode, and the structural size of thedevice is greatly reduced.

Owner:中铁市政环境建设有限公司

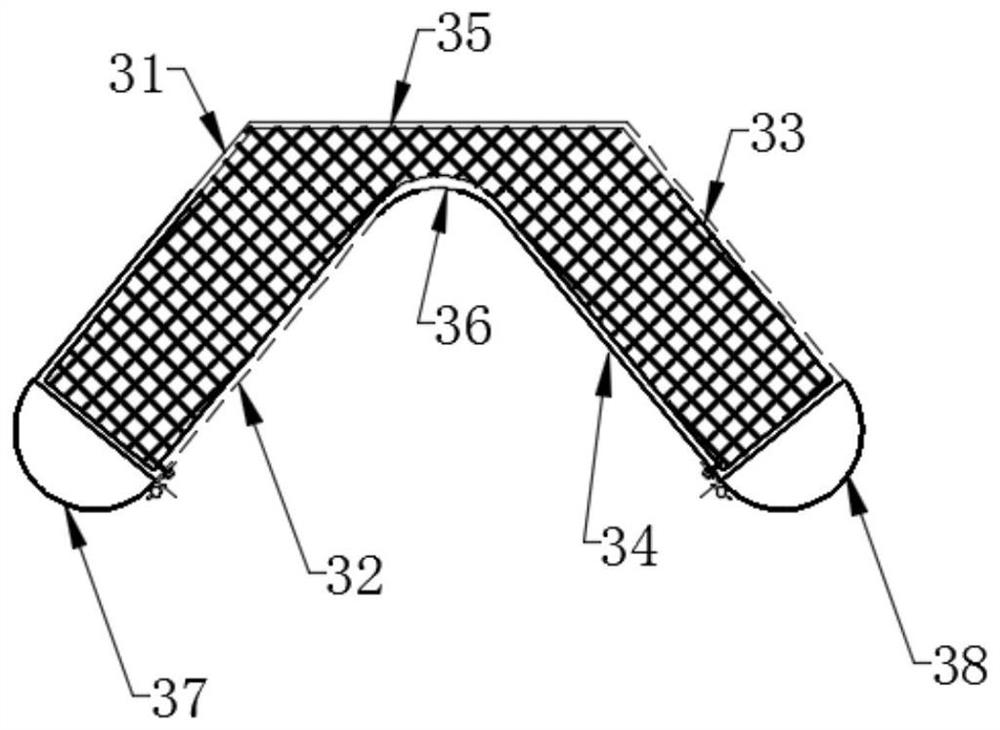

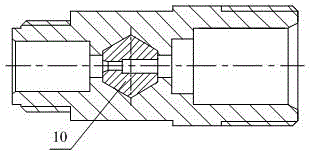

Composite pneumatic transport rotational flow elbow pipe

Provided is a composite pneumatic transport rotational flow elbow pipe. The composite pneumatic transport rotational flow elbow pipe includes a pipe body for transporting fluid; the pipe body includesan inlet straight pipe part, an elbow pipe part and an outlet straight pipe part. The inlet straight pipe part includes an inlet straight pipe segment, a gas-solid mixture inlet, a rotational flow gas inlet, a rotational flow gas mixing chamber and a rotational flow generation hole; the elbow pipe part includes an elbow pipe segment, a primary rotational flow generation pipe and a secondary rotational flow generation pipe; the outlet straight pipe part includes an outlet straight pipe segment and a gas-solid mixture outlet which is formed in the end portion of the outlet straight pipe segment. By adopting the composite pneumatic transport rotational flow elbow pipe, adequate rotational flow gas can be generated, rotational flow transportation is achieved, collision and friction between particles and a pipe wall are effectively reduced, the material transport quality is improved, the service life of the composite pneumatic transport rotational flow elbow pipe is effectively prolonged,meanwhile, local pressure loss is reduced, and the working efficiency of a pneumatic transport system is improved.

Owner:CHINA UNIV OF MINING & TECH

Test system for filter screen life and testing method thereof

PendingCN109100277ASimplify the installation processMeet the requirements of single person disassembly and assemblyPermeability/surface area analysisEngineeringLife testing

The invention provides a test system for filter screen life and a testing method thereof, and relates to the field of filter screen life testing. The device comprises an air inlet drive pipe, a clamping device connected with the air inlet drive pipe and an air outlet drive pipe connected with one side of the clamping device remote from the air inlet drive pipe, the clamping device comprises a first clamping pipe in threaded connection with the air inlet drive pipe, a second clamping pipe in threaded connection with the air outlet drive pipe, and a clamping part arranged on the first clamping pipe for fixing with the second clamping pipe, the filter screen is arranged between the first clamping pipe and the second clamping pipe; a static pressure test point 1, a static pressure test point 2and a static pressure test point 3 are respectively arranged on inner walls of the air inlet drive pipe, the first clamping pipe and the second clamping pipe; and pressure testing devices are arranged at each of the static pressure test point 1, the static pressure test point 2 and the static pressure test point 3. The system has the advantages that disassembly and installation process of test assemblies can be effectively simplified in the life testing process of the filter screen, the disassembly and the assembly of the single person can be realized, and working efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

Motor Vehicle Muffler

ActiveCN104948267BImprove buffering effectRelieve stressSilencing apparatusMachines/enginesInterior spaceEngineering

Owner:柳州利和排气控制系统有限公司

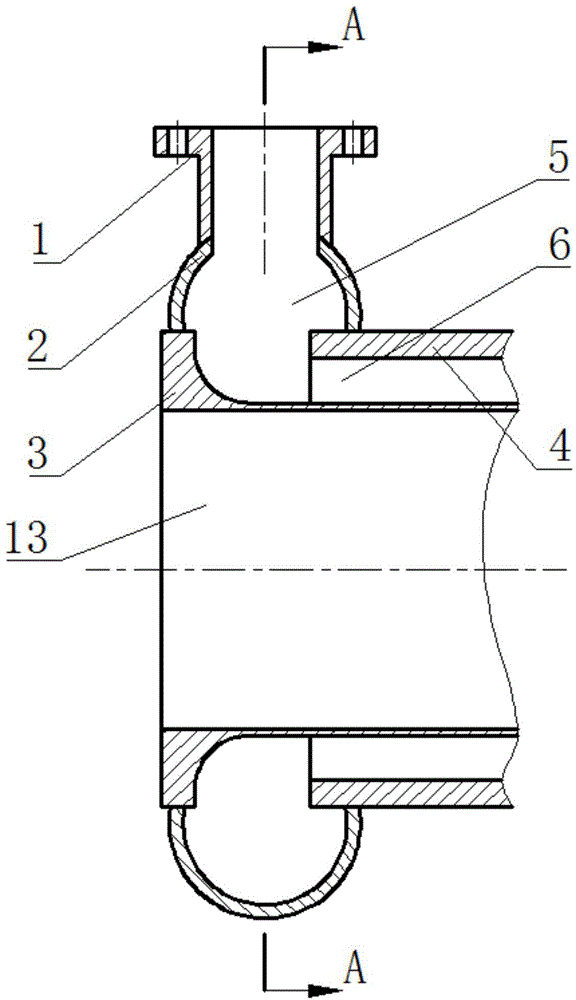

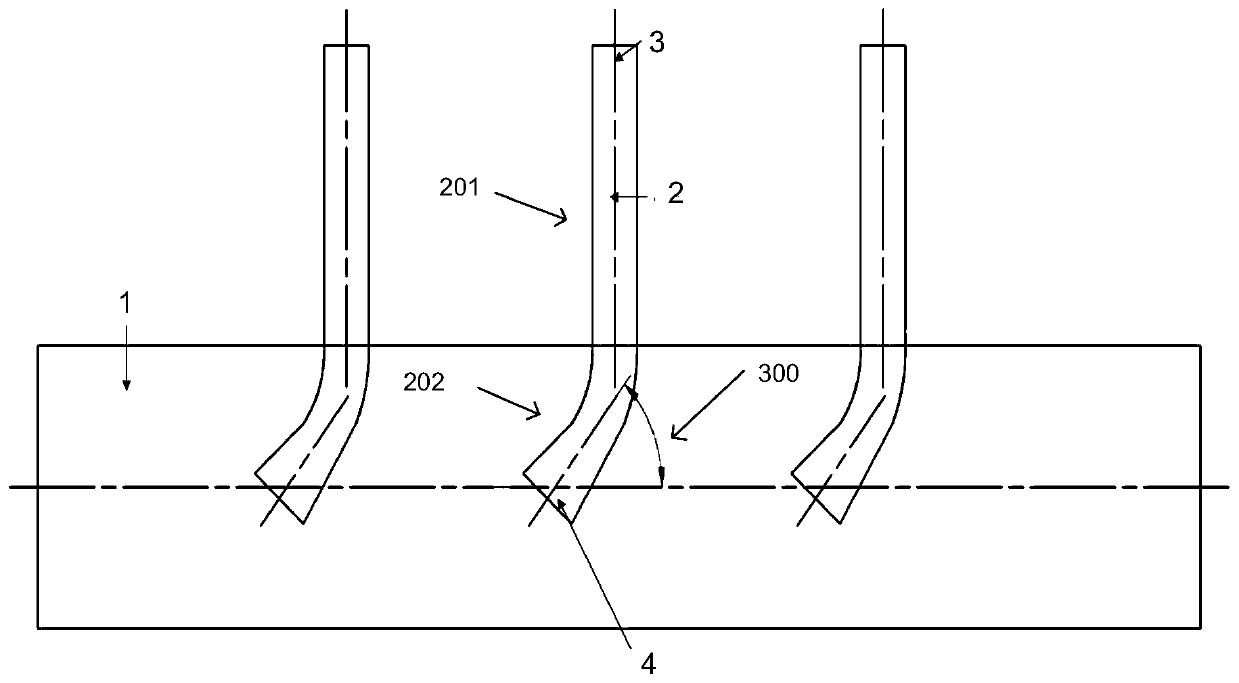

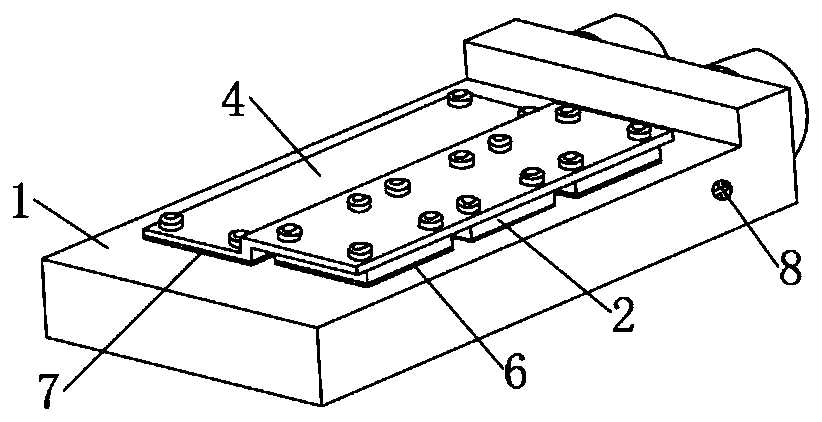

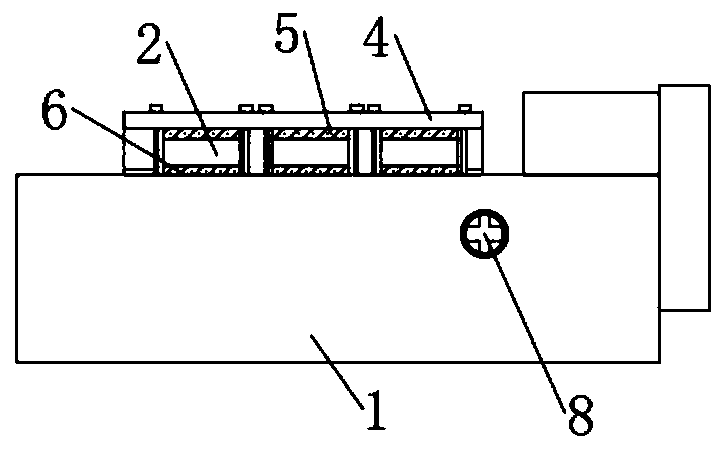

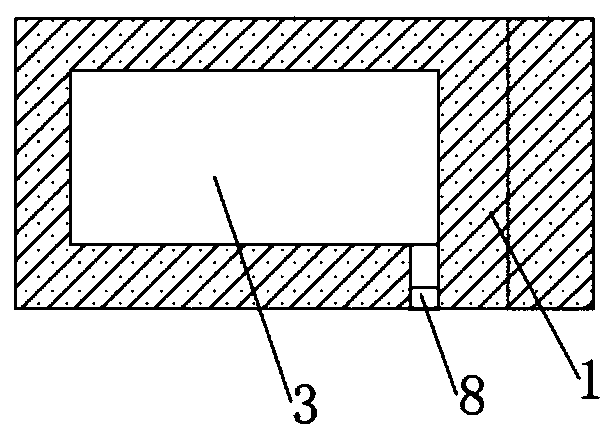

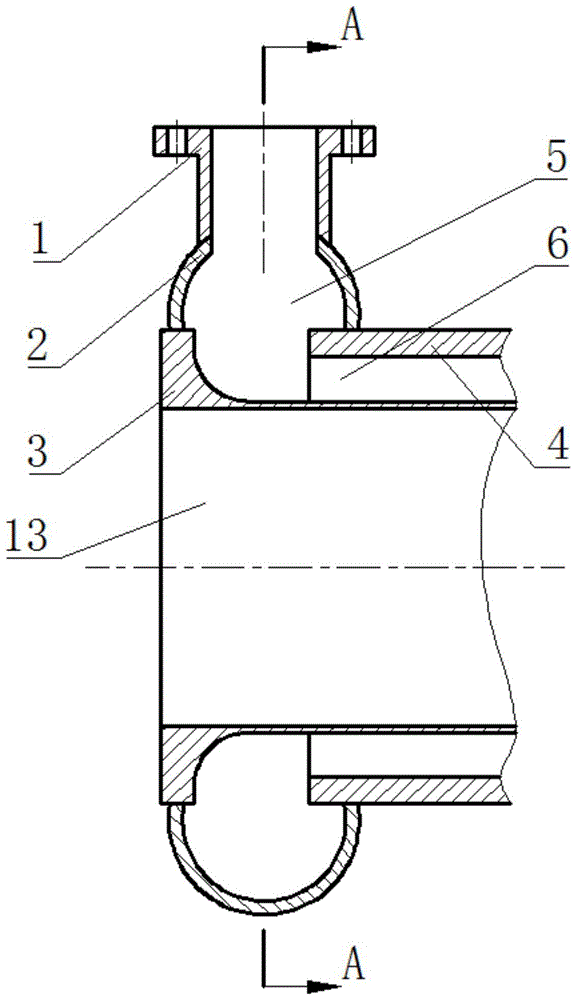

Inclined penetrating type two-stroke diesel engine pipe joint suitable for ship

InactiveCN110374731AReasonable structureReduce local pressure lossExhaust apparatusSilencing apparatusLow speedLocal pressure

The invention provides an inclined penetrating type two-stroke diesel engine pipe joint suitable for a ship. The pipe joint comprises an exhaust manifold (1) and a penetrating type exhaust branch (2).The penetrating type exhaust branch (2) communicates to the exhaust manifold (1), the penetrating type exhaust branch outlet (4) penetrates into the exhaust manifold (1) to form a penetrating type structure; the penetrating type exhaust branch (2) comprises a straight pipe section (201) and a bended pipe section (202); the axis of the bended pipe section (202) and the axis of the exhaust manifold(1) form a first included angle (300); the penetrating type exhaust branch outlet (4) is deviated to the downstream side of the exhaust manifold (1); and the straight pipe section (201) and the bended pipe section (202) are integrally formed. The inclined penetrating type two-stroke diesel engine pipe joint is reasonable in structure and can reduce local pressure loss of exhaust of a low speed two-stroke diesel engine for the ship effectively.

Owner:SHANGHAI JIAO TONG UNIV

Double-sided cooling structure for vehicle-mounted inverter

InactiveCN110518814ASmall sizeIncreased installation difficultyConversion constructional detailsCooling/ventilation/heating modificationsLocal pressureWater cooling

The invention discloses a double-sided cooling structure for a vehicle-mounted inverter, comprising an inverter shell and a double-sided cooling channel power module. A water channel is formed in theinverter shell. The double-sided cooling channel power module is clamped to the surface of the inverter shell. The other side of the upper end of the inverter shell is connected with a heat conductionplate through bolts, and the heat conduction plate is of a bent structure. The other end of the heat conduction plate is clamped at the upper end of the double-sided cooling channel power module, andthe other end of the heat conduction plate is also connected with the side wall of the inverter shell through bolts. An upper heat conduction interface material is adhered to the upper end face of the double-sided cooling channel power module. Improvement is made on the basis of the original single-sided water cooling structure. The water channel is constructed on the machine shell, a heat dissipation channel does not need to be independently arranged for other heating devices, and the original single-sided water cooling structure is inherited. The technology is mature, and the reliability ishigh. There is only one flow channel cavity, and local pressure loss caused by a communicated structure is greatly reduced.

Owner:江西精骏电控技术有限公司

A piezoelectric inkjet print head

The invention belongs to the technical field of droplet jetting printing, and in particular relates to a piezoelectric inkjet printing head, which solves the problem of poor printing quality caused by insufficient ink supply or uneven ink supply in the traditional piezoelectric inkjet printing head. The pressure difference channel is used to connect the main ink channel and each pressure chamber, so that there is a certain hydraulic pressure difference between the main ink channel and each pressure chamber, and the ink is promoted to enter each chamber under the action of hydraulic pressure, ensuring the ink supply of each chamber. Unobstructed and sufficient, effectively improving printing efficiency; and adding a meandering restrictor structure between the pressure chamber and the main ink channel, reducing the liquid backflow in the pressure chamber, reducing the pressure loss in the pressure chamber, improving the jetting performance of the print head, and reducing the pressure at the same time Pressure crosstalk between chambers. At the same time, a transition channel plate is added between the pressure chamber and the nozzle plate, that is, the strength of the nozzle plate is increased. When the piezoelectric ceramic is driven by deformation and the pressure in the pressure chamber increases, the pressure loss in the pressure chamber caused by the deformation of the nozzle plate is reduced, and the print head is improved. Jetting performance.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

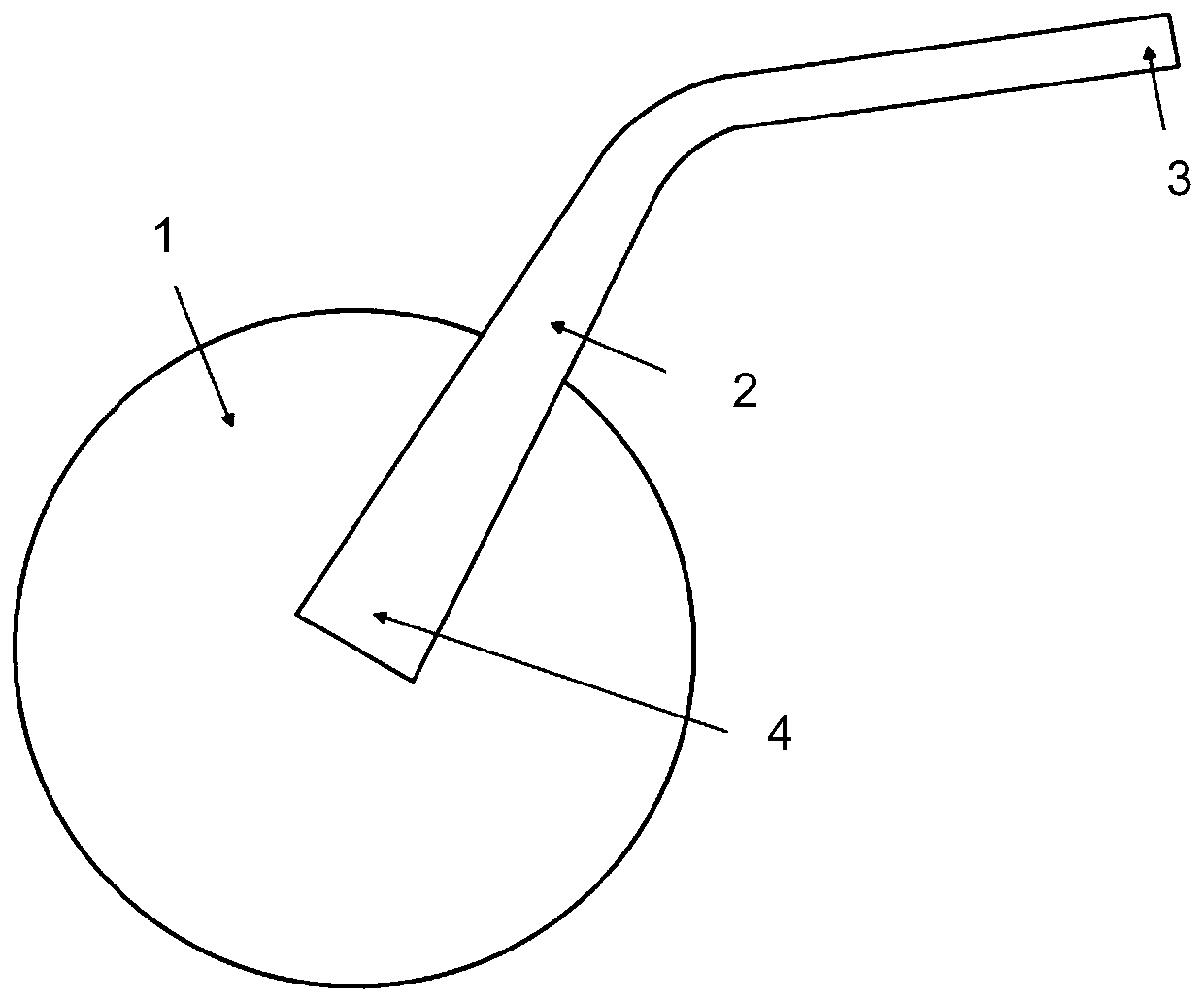

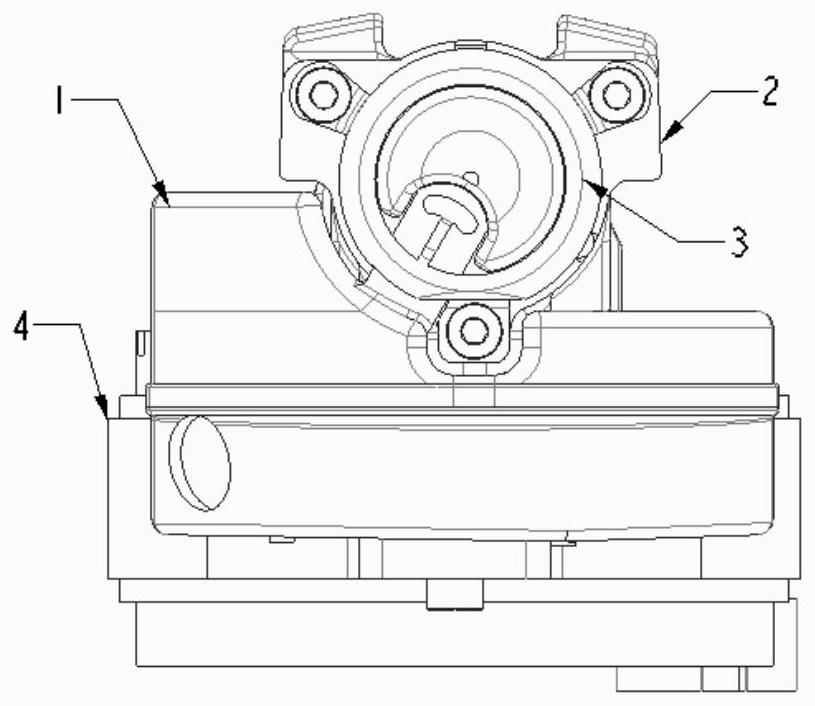

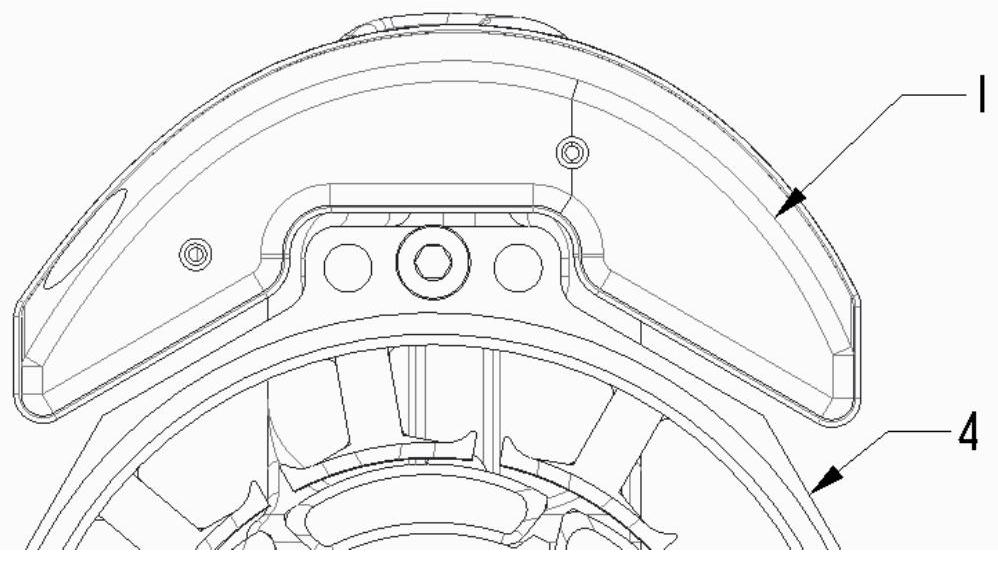

Dishwasher washing pump and dishwasher

ActiveCN109247895BImprove work efficiencyReduce local pressure lossTableware washing/rinsing machine detailsWater trapWater flow

The invention discloses a dishwasher washing pump and a dishwasher. The dishwasher includes a spray arm. The washing pump includes a pump housing with an inner cavity. In communication, a guide part is provided in the inner cavity of the pump casing, and part of the structure of the guide part is located in the projection of the opening on the inner cavity, and the guide part is used to guide the water flow in the pump casing to change. The direction of movement breaks up the vortex and reduces the local pressure loss of the water flow. The present invention eliminates the energy loss caused by "dead water area" or "vortex area" in the washing pump, thus improving the working efficiency of the washing pump.

Owner:QINGDAO HAIER DISHWASHER

An exhaust muffler for a screw unit

ActiveCN107120288BSmall pressure lossReduce total pressure lossRotary/oscillating piston pump componentsLiquid fuel engine componentsStraight tubeEngineering

The invention relates to an exhaust muffler for a screw-type unit, which comprises an intake pipe, a muffler shell, and an air outlet pipe connected linearly in sequence; the muffler shell is composed of an expanding pipe, a straight pipe, and a tapering pipe according to the flow direction of the refrigerant , the turning space combined sequentially in the muffler shell is the muffler cavity; it is characterized in that: at least one of the expander and the reducer is fixed with an inner insert; the inner insert is formed with the expander or the The joint of the shrinking tube is inserted into the muffler cavity; the wall of the inner tube is provided with through-hole air holes; the center of rotation of the muffler shell coincides with the centers of rotation of the inlet pipe and the outlet pipe. On the premise of ensuring the noise reduction capacity, the pressure loss of the muffler is smaller and the structure is simpler, and the muffler can be applied to the frequency conversion screw type unit with a large change in noise frequency.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

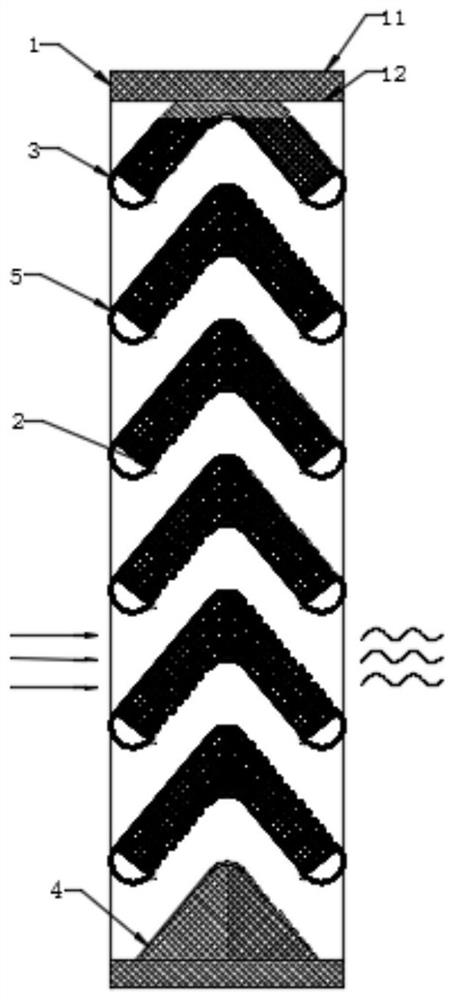

Low-resistance rainproof noise reduction device for air inlet

PendingCN111706990AReduce frictional pressure lossReduce local pressure lossLighting and heating apparatusNoise suppressionEngineeringSecond sound

The invention provides a low-resistance rainproof noise reduction device for an air inlet. The device comprises an outer frame, a first sound absorption and insulation sheet, a second sound absorptionand insulation sheet and third sound absorption and insulation sheets, wherein the first sound absorption and insulation sheet is detachably fixed on the inner upper part of the outer frame through fixing assemblies; the second sound absorption and insulation sheet is fixed on the inner bottom of the outer frame; the third sound absorption and insulation sheets are detachably fixed in the outer frame through fixing assemblies and uniformly arranged between the first sound absorption and insulation sheet and the second sound absorption and insulation sheet in a gap mode; and the first sound absorption and insulation sheet and the third sound absorption and insulation sheets are designed to be in an arc shape. According to the low-resistance rainproof noise reduction device for the air inlet, the sound absorption and insulation sheets of the device are arch, so that the size is reduced; a rainproof shutter is not needed, a windward surface is a metal non-perforated protective panel, sothat rain and snow are prevented from entering; a noise facing surface is a metal perforated protective panel to absorb and consume sound energy; flow guide circular arcs are arranged at the abrupt change positions of airflow, so that local pressure loss is reduced; the sound absorption and insulation sheets adopt the fixing assemblies convenient to disassemble, thereby being convenient to disassemble, clean and replace; and under the condition that the noise reduction amount is determined, the size can be effectively reduced, so that the pressure loss is reduced, and the disassembly and the assembly are facilitated.

Owner:国能朗新明环保科技有限公司

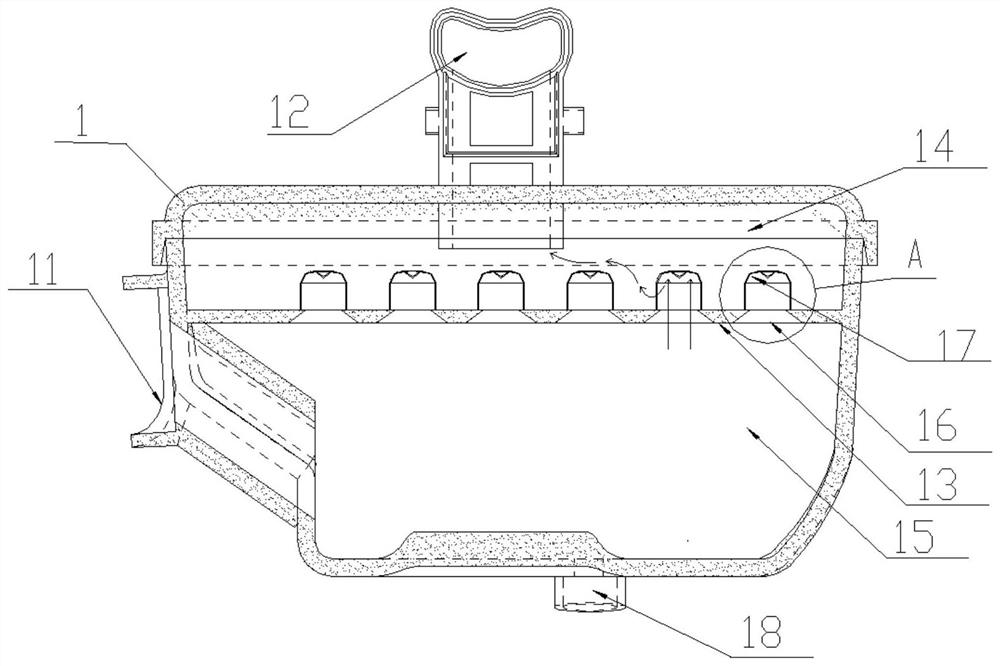

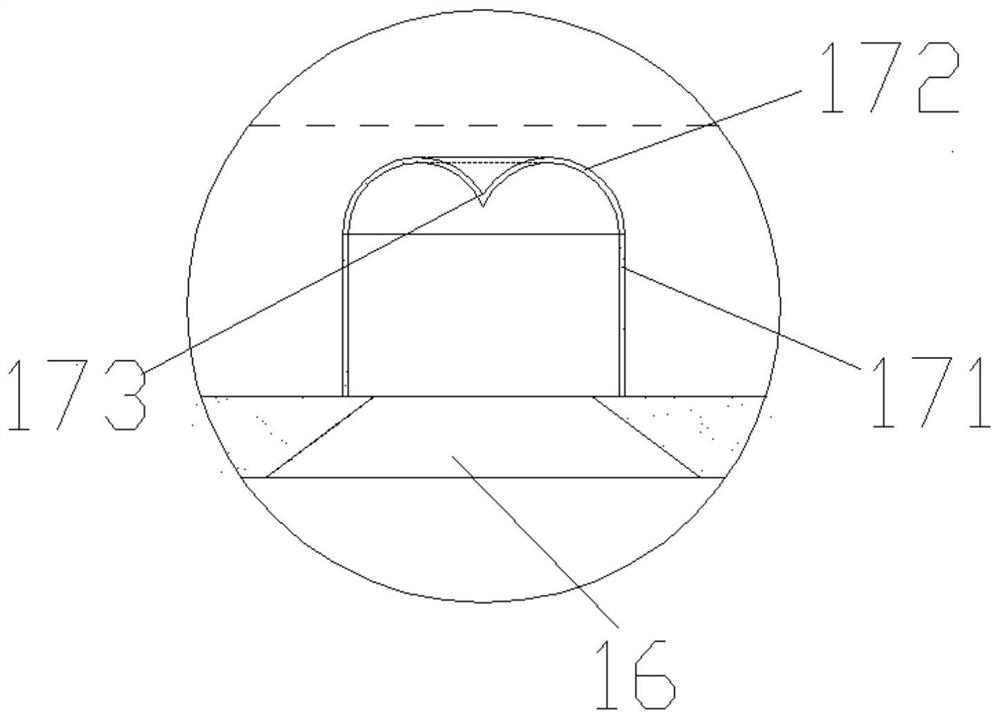

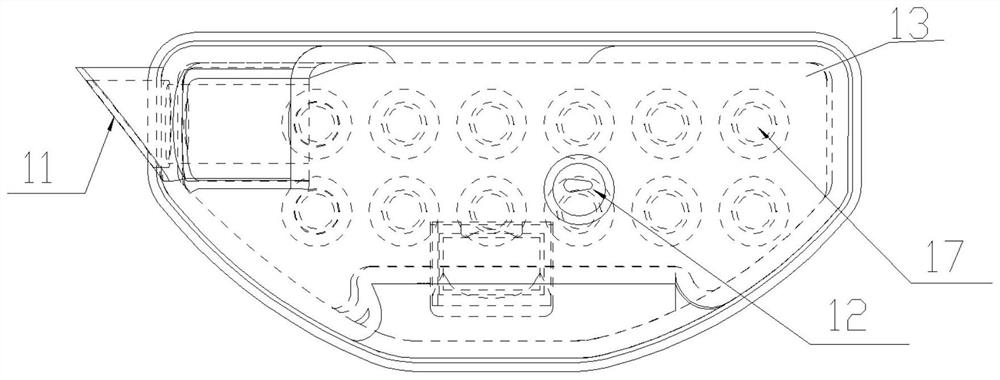

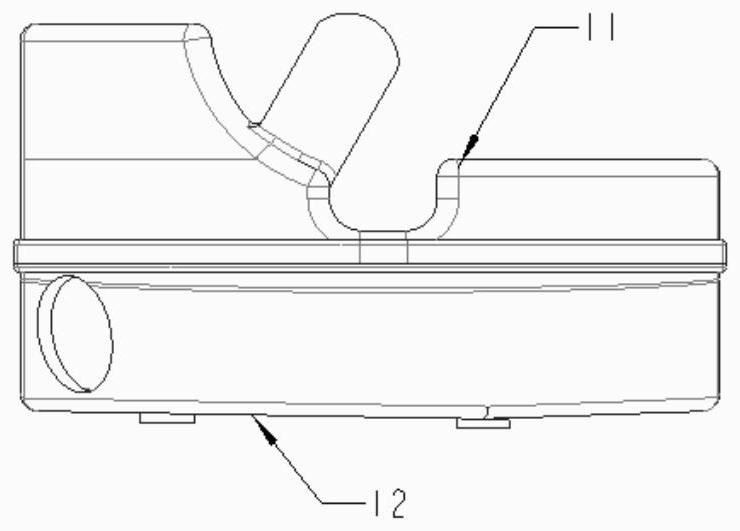

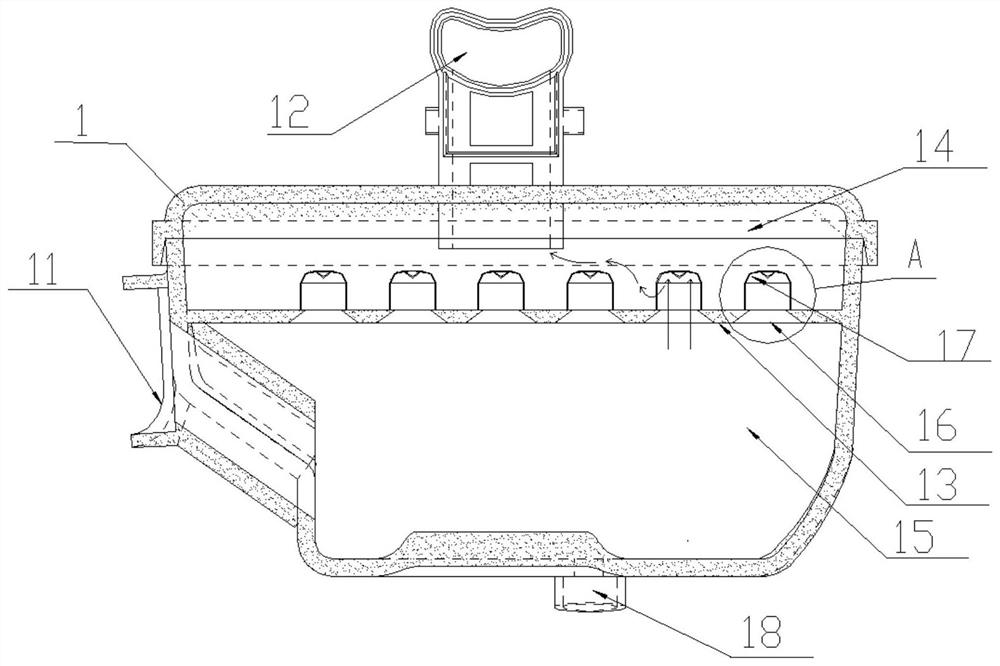

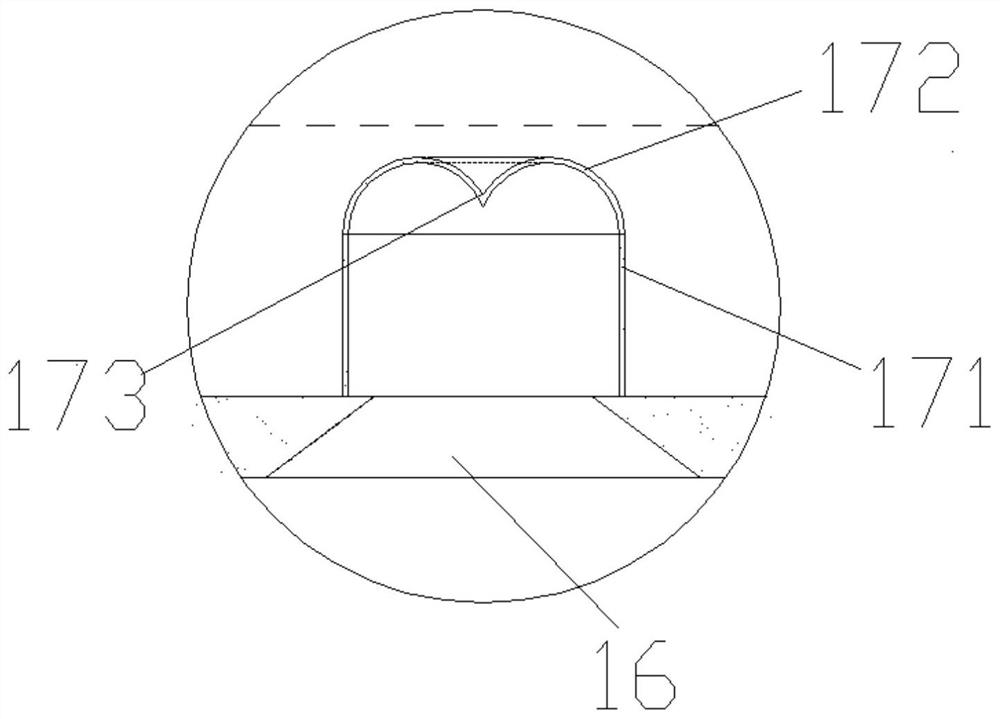

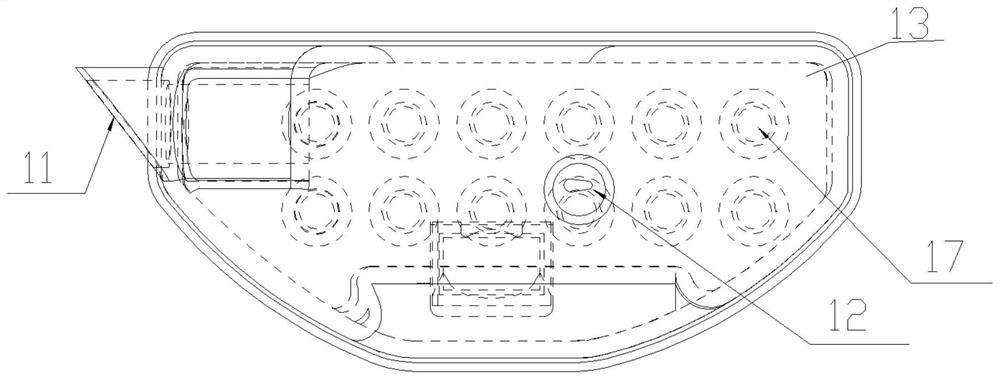

Suction muffler, compressor, refrigerator

ActiveCN111894832BReduce suction noiseReduce local pressure lossPositive displacement pump componentsPositive-displacement liquid enginesIceboxMuffler

The invention provides a suction muffler, a compressor, and a refrigerator, wherein the suction muffler includes a casing, the casing is configured with an air inlet and an exhaust port, and the inner cavity of the casing is provided with A baffle, the baffle divides the inner cavity into an upper cavity corresponding to the exhaust port and a lower cavity corresponding to the air inlet, and the baffle is configured with a The multiple through holes of the cavity also include multiple oil-gas separation covers, and the multiple oil-gas separation covers are respectively one-to-one covered on the multiple through holes and are located on the side of the partition facing the upper chamber. On the side, the oil-gas separation cover has a flow hole to pass through the upper chamber and the lower chamber. According to the suction muffler, compressor, and refrigerator of the present invention, the amount of oil carried by the suction of the cylinder can be reduced, and at the same time, the resistance of the suction air flow and the noise of suction can be reduced, so that the suction is more uniform and smooth.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

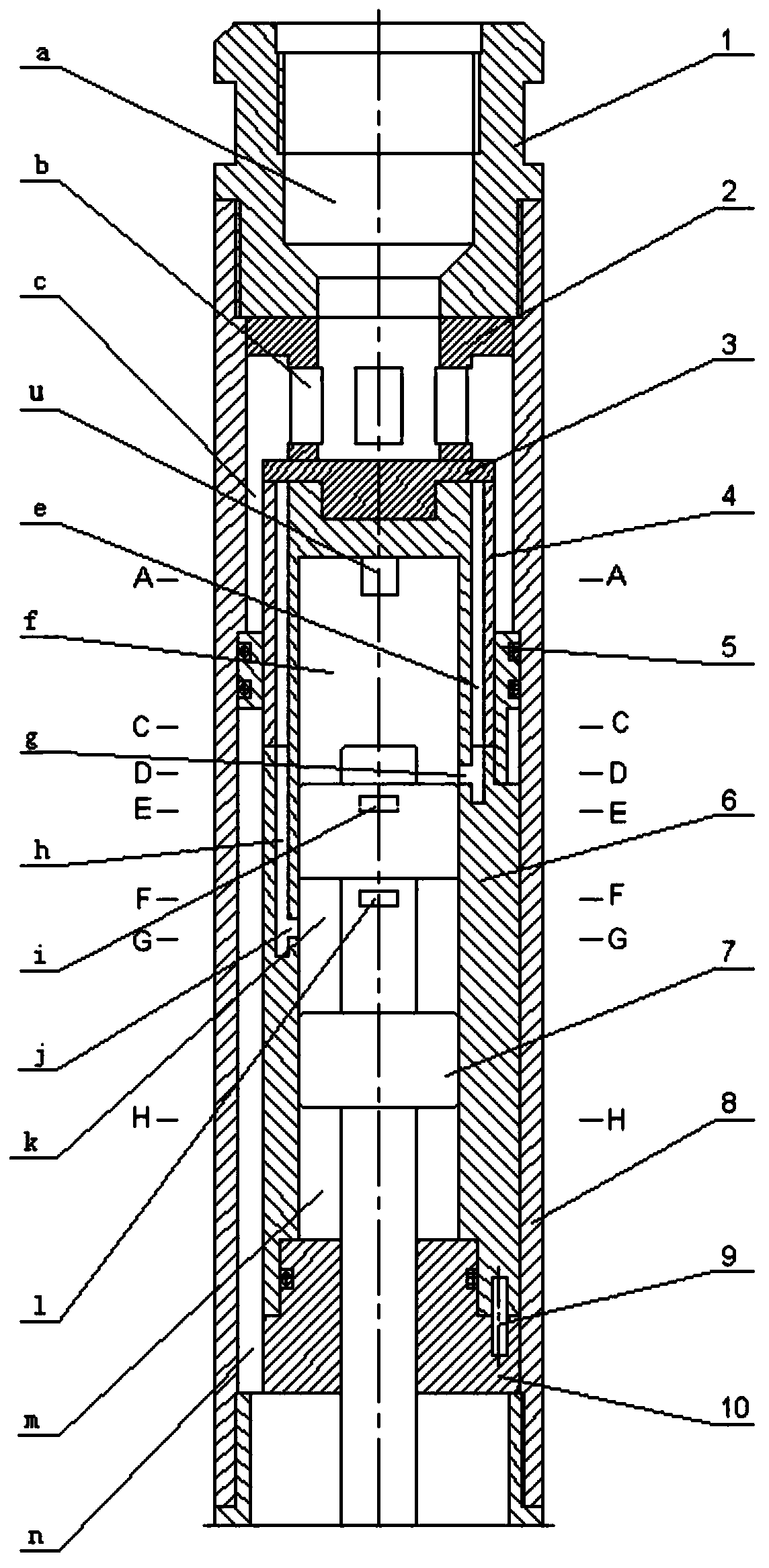

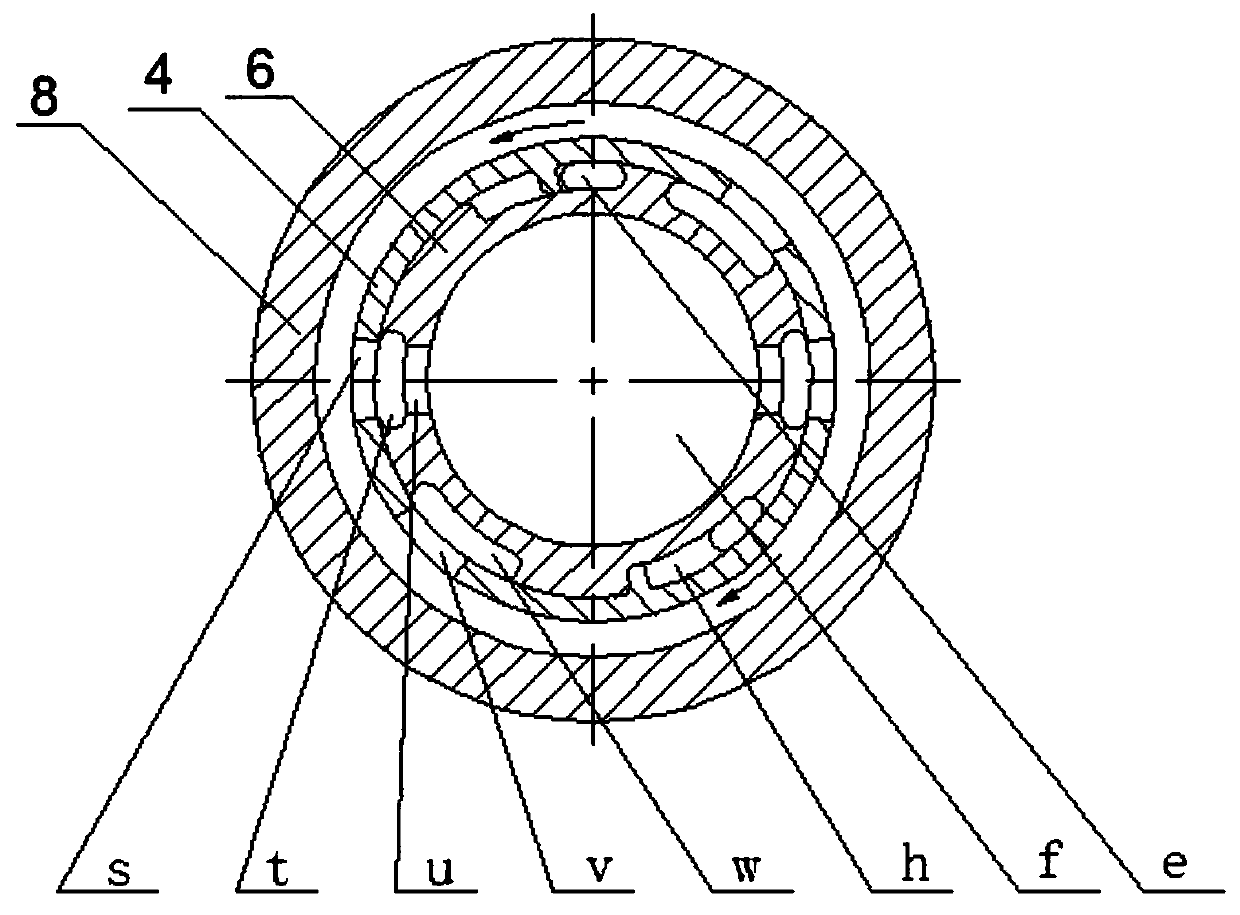

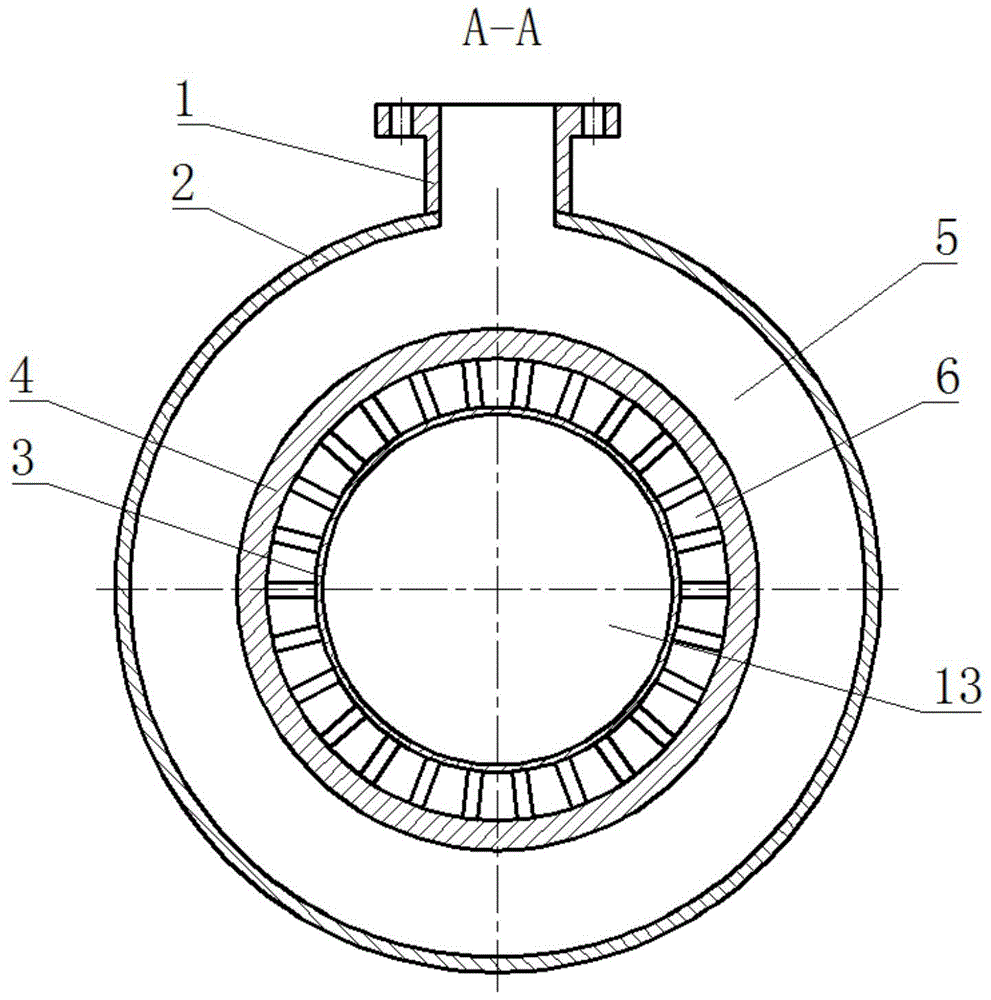

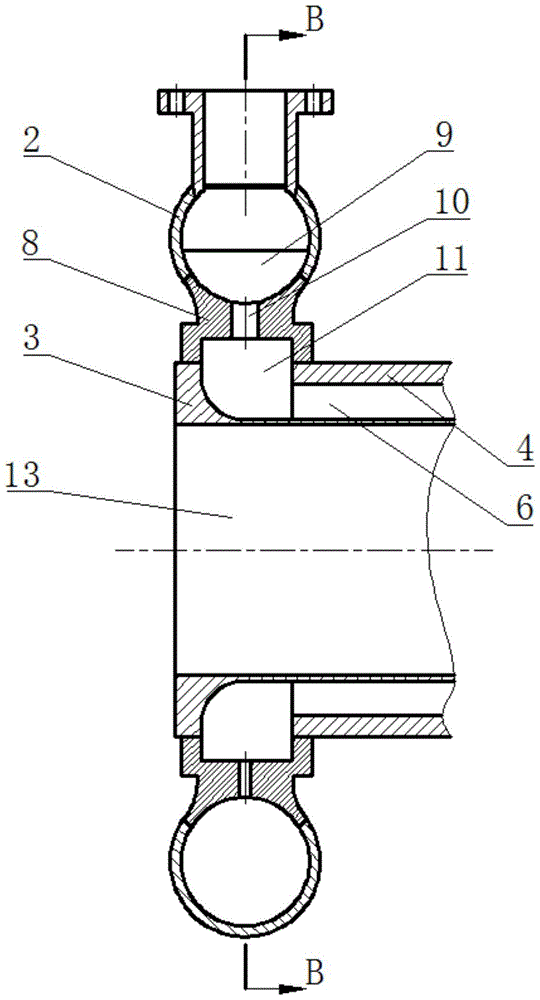

A rotary valve type hydraulic impactor

ActiveCN108316855BReduce local pressure lossImprove energy efficiencyBorehole drivesRotary valveEngineering

The invention discloses a rotating-valve-type hydrodynamic impactor. An upper connector of the rotating-valve-type hydrodynamic impactor is connected with an upper outer pipe through a thread, a glandand a valve cover are sequentially fixed to the upper end face of a cylinder body through the upper connector, the cylinder body is sleeved with the upper outer pipe, and the periphery of the upper end of the cylinder body is sleeved with a freely-rotating rotor sleeve. Various vertical and radial fluid channels are formed in the cylinder body, a piston is formed by means of the method that an upper piston head and a lower piston head are connected to a piston rod in series, and according to the piston, the upper piston head and the lower piston head are machined on the piston rod. An end cover is inserted into the lower end of the cylinder body and positioned by a positioning pin, a middle connector is connected with an upper outer pipe and a lower outer pipe through threads, and the piston rod penetrates through the end cover to be connected with a hammer body to form a movement whole. A spline sleeve is connected with the lower outer pipe through a thread, a spline on a drill bit body is matched with a spline groove in the spline sleeve, an assembled body capable of axially moving is formed, and the lower bottom face of the hammer body makes contact with the top face of a drillbit. The rotating-valve-type hydrodynamic impactor has the advantages that the clamp-blocking problem caused by a slide valve is avoided, the structure is simple, impacting energy is large, and the service life is long.

Owner:CHONGQING UNIV

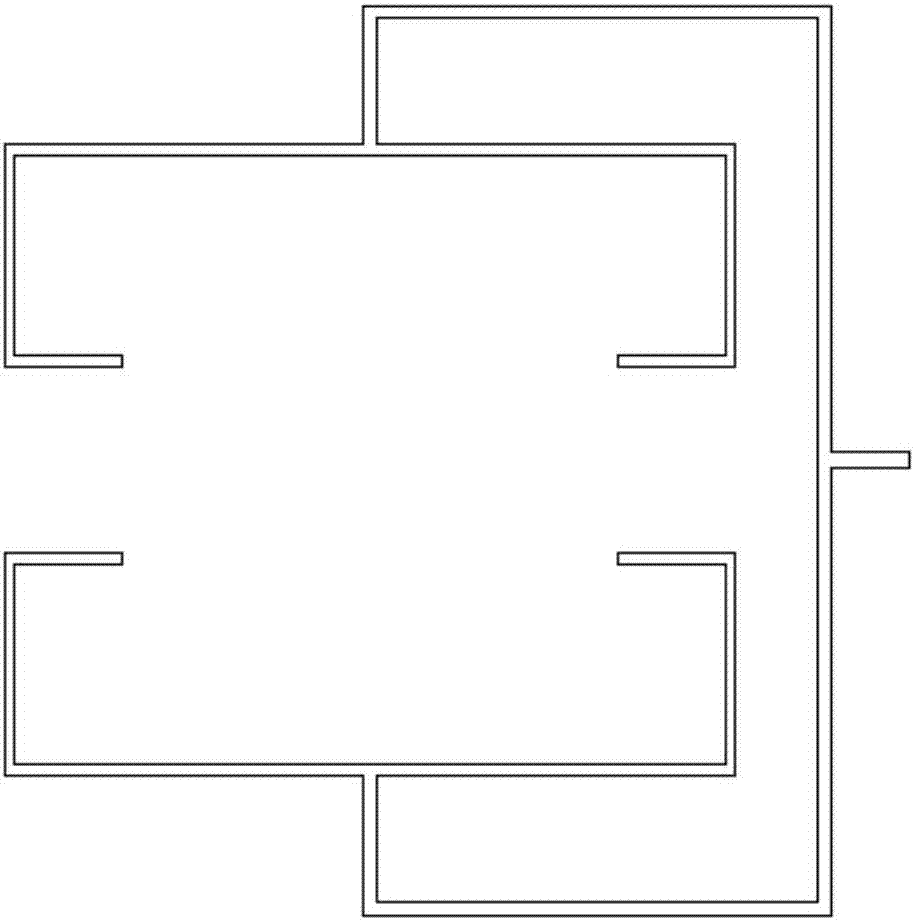

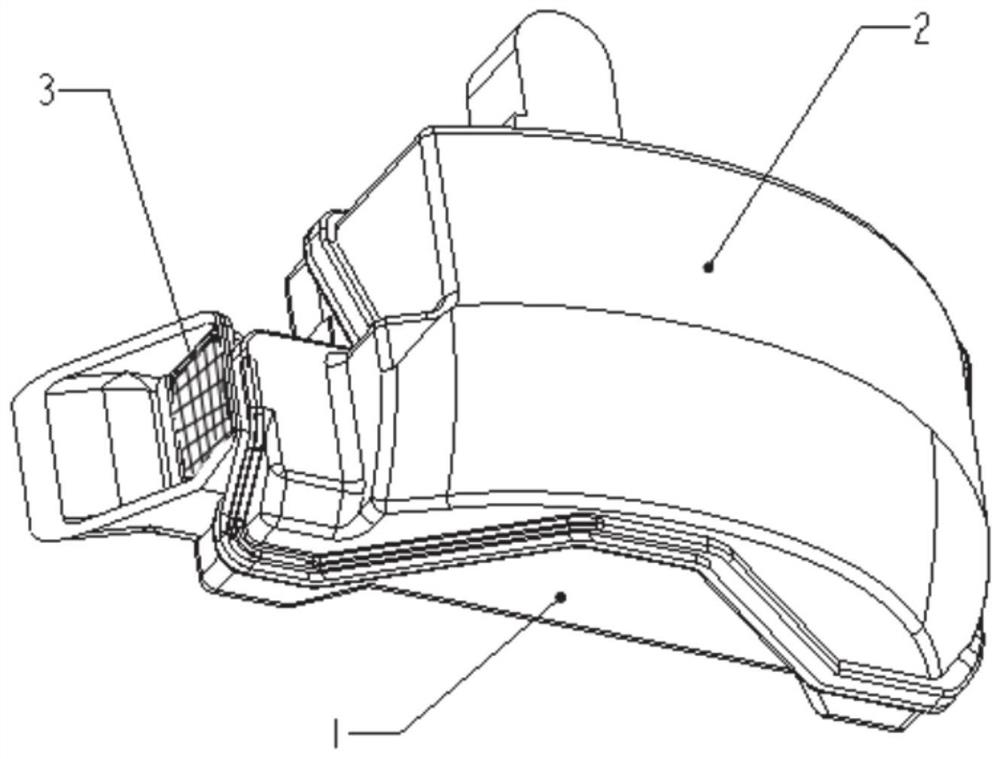

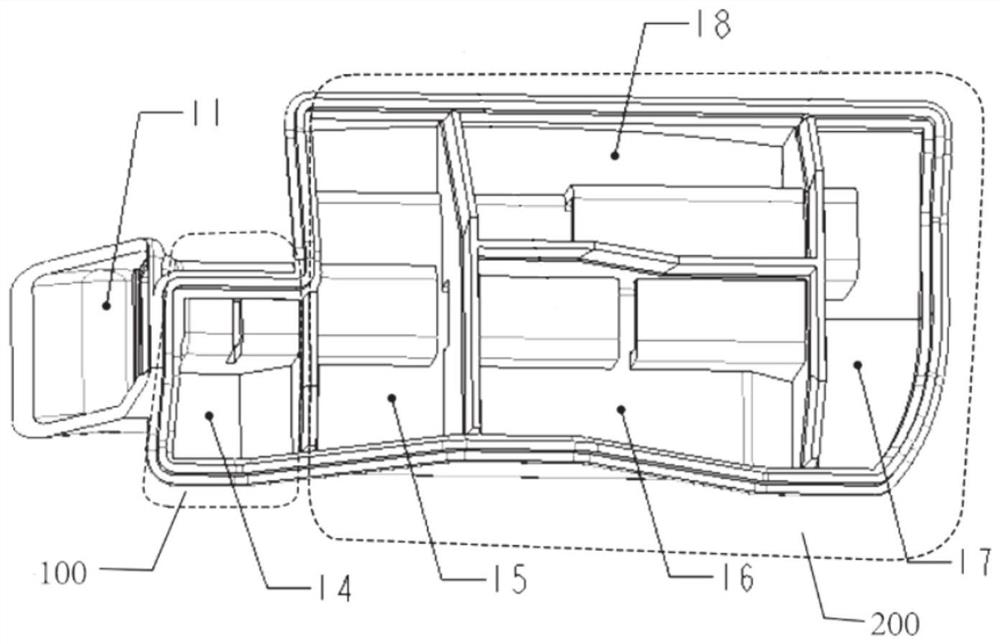

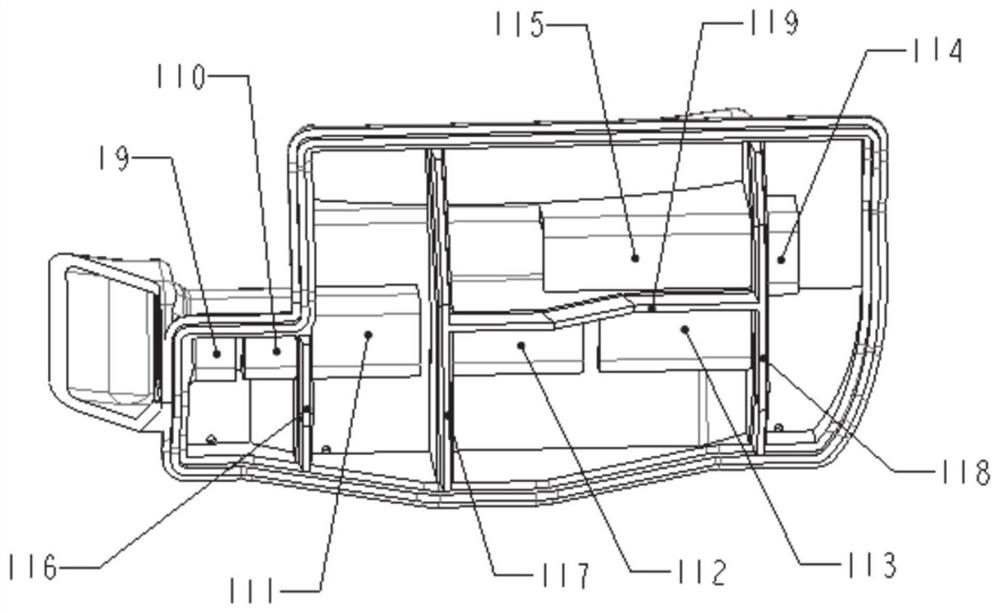

A three-cavity profiling suction muffler and compressor

ActiveCN110469486BSmall volumeReduce local pressure lossPositive displacement pump componentsPiston pumpsCylinder headNoise

The invention discloses a three-cavity profiling suction muffler and a compressor, which solves the problems of the existing muffler, such as poor muffler effect on middle and low frequency noise, insufficient muffler capacity, easy resonance, large leakage, etc., and has the advantages of Enhance the noise reduction effect on middle and low frequency noise, increase the noise reduction volume, and avoid vibration; the technical solution is: including a first casing and a second casing, and the first casing is inserted above the second casing; the second casing The upper surface of a casing has a first curved surface adapted to the cylinder seat, and the first curved surface is offset and inclined to be provided with an air outlet connection section for matching the cylinder head; the first casing and the second casing The side surfaces of the body respectively have second curved surfaces adapted to the motor; the inside of the first housing and the second housing are divided into a resonance cavity and a first expansion cavity and a second expansion cavity connected in series, wherein the first The second expansion cavity inside the second housing is connected in series with the resonance cavity.

Owner:QINGDAO WANBAO COMPRESSOR

A hydraulic cylinder internal leakage detection equipment and device

ActiveCN105465101BThere are few abrupt changes in the oil passage sectionReduce local pressure lossFluid-pressure actuator testingHydraulic cylinderPiston rod

The invention relates to a piece of internal leakage detection equipment and device for a hydraulic oil cylinder. The internal leakage detection equipment for the hydraulic oil cylinder at least comprises a cylinder barrel, a piston rod assembly installed inside the cylinder barrel in a matched mode, and a speed detection mechanism fixedly installed in the cylinder barrel and used for sensing the movement speed of the piston rod assembly. By the adoption of the internal leakage detection equipment and device, accurate judgment data are provided for internal leakage of the hydraulic oil cylinder.

Owner:XUZHOU HEAVY MASCH CO LTD

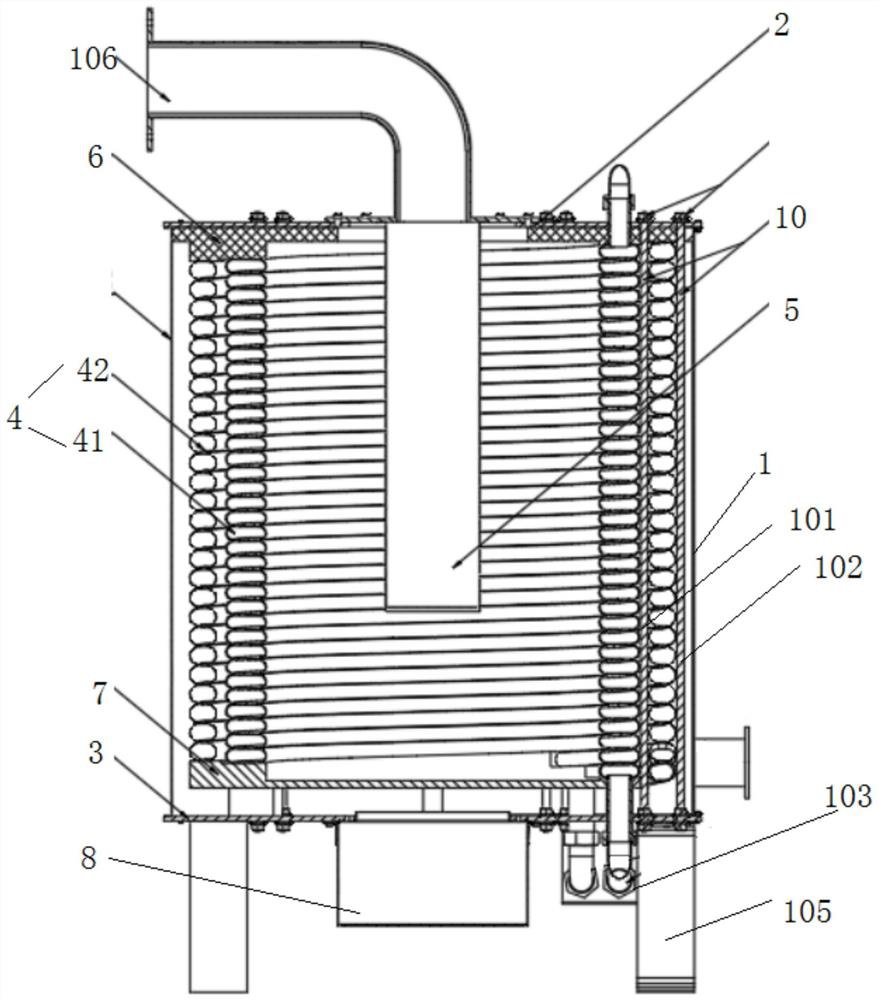

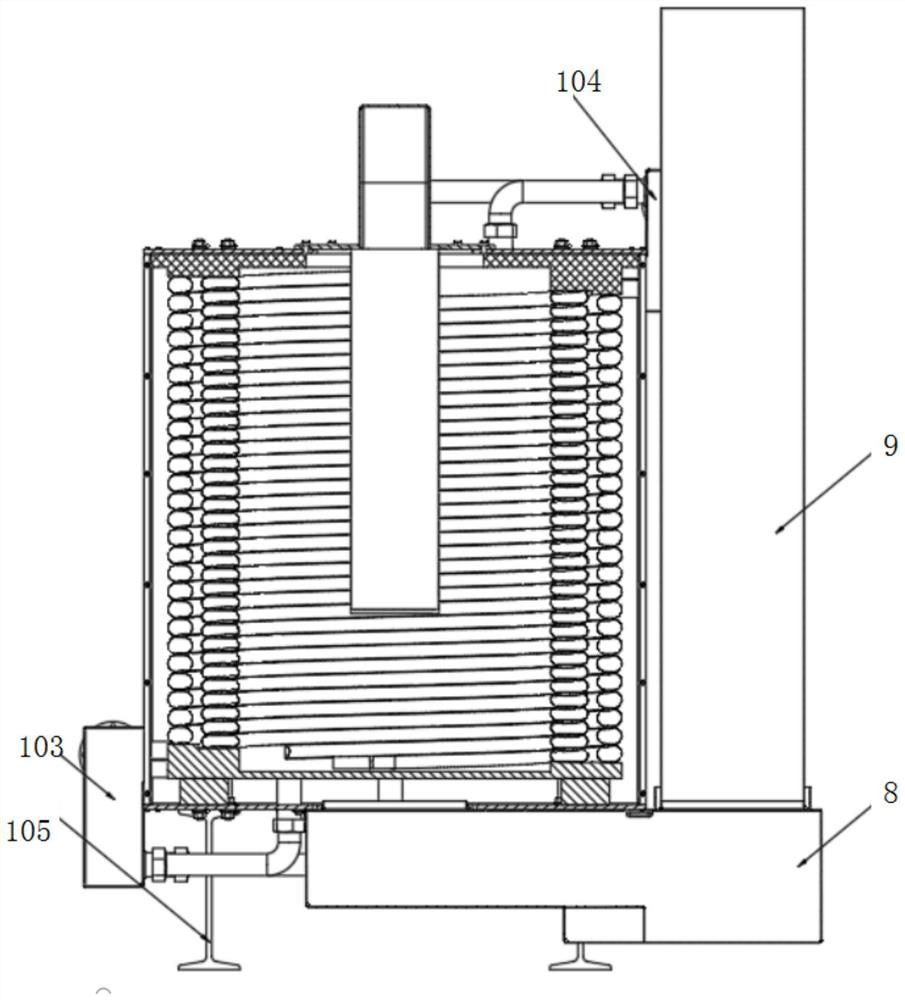

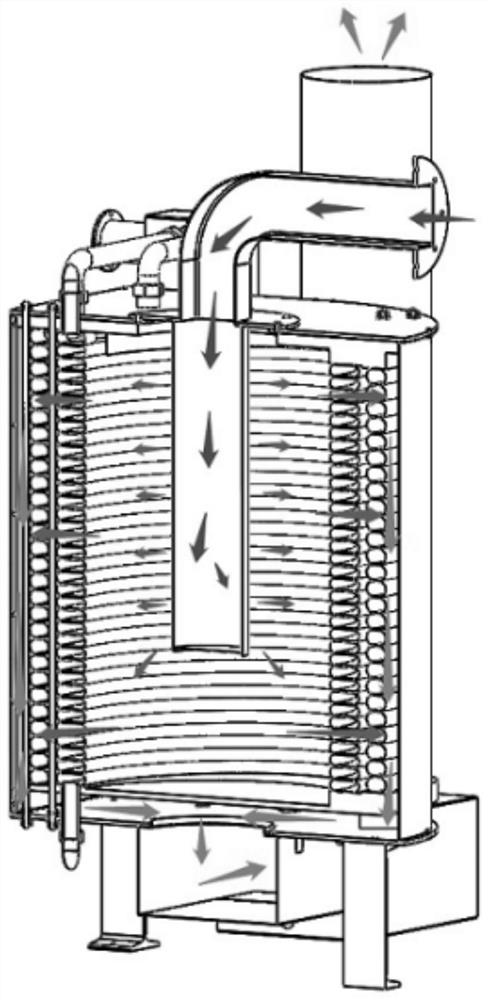

Vertical low-carbon condensation energy saver

PendingCN113916021AReduce weldingReduce water leakageAir heatersSteam/vapor condensersThermodynamicsFlue gas

The invention discloses a vertical low-carbon condensation energy saver. The energy saver comprises a housing, a front cover plate, a rear cover plate, a heat exchange coil pipe and a combustion assembly; the whole housing is of a cavity structure with two open ends, the front cover plate and the rear cover plate are arranged on the two sides of the housing respectively, and the heat exchange coil pipe is arranged in the housing; and the combustion assembly is arranged in the heat exchange coil pipe, and the heat exchange coil pipe is of a double-circle coil pipe structure. According to the energy saver, through the arrangement of various structures, flue gas multiply flows around, such that the flowing time of high-temperature flue gas can be effectively shortened, and the retention time of the high-temperature flue gas in the cavity is longer; and meanwhile, the high-temperature flue gas can be in contact with an inner-circle coil pipe and an outer-circle coil pipe as much as possible, such that a temperature difference of liquid in the inner-circle coil pipe and the outer-circle coil pipe is smaller, and the temperature of the liquid finally converged into a water outlet box is more constant.

Owner:成都双流积利热能科技股份有限公司

Water outlet device for cleaning machine and column/piston pump

ActiveCN103244401BIncrease outlet pressureReduce local pressure lossPositive displacement pump componentsLiquid fuel engine componentsEngineeringLocal pressure

The invention provides a water outlet device of a plunger / piston pump. A flow passage switching pipeline structure is added between a water inlet passage and a water outlet passage, a first slider which is fixedly connected with a Venturi pipe device and slides synchronously is arranged in the flow passage switching pipeline structure, an elastic return device guiding along a guide slideway in the return direction and a liquid suction pipeline are arranged between the first slider and the guide slideway, and a second slider which is butted against the Venturi pipe device is arranged at the other end of a flow passage switching pipeline and is in sliding seal with the guide slideway. In a liquid suction working condition, a passage of the Venturi pipe device is communicated with the water inlet passage and the water outlet passage; and in a normal working condition, the Venturi pipe device is pushed to a stagger position of the water inlet passage and the water outlet passage, passage area between the water inlet passage and the water outlet passage is enlarged, local pressure loss of constant-pressure working media flowing through the position between the water inlet passage and the water outlet passage is reduced greatly, and accordingly water outlet pressure is increased with wasted work not increased. The invention further provides a cleaning machine.

Owner:苏州黑猫清捷科技有限公司

A Composite Pneumatic Conveying Swirl Elbow

Provided is a composite pneumatic transport rotational flow elbow pipe. The composite pneumatic transport rotational flow elbow pipe includes a pipe body for transporting fluid; the pipe body includesan inlet straight pipe part, an elbow pipe part and an outlet straight pipe part. The inlet straight pipe part includes an inlet straight pipe segment, a gas-solid mixture inlet, a rotational flow gas inlet, a rotational flow gas mixing chamber and a rotational flow generation hole; the elbow pipe part includes an elbow pipe segment, a primary rotational flow generation pipe and a secondary rotational flow generation pipe; the outlet straight pipe part includes an outlet straight pipe segment and a gas-solid mixture outlet which is formed in the end portion of the outlet straight pipe segment. By adopting the composite pneumatic transport rotational flow elbow pipe, adequate rotational flow gas can be generated, rotational flow transportation is achieved, collision and friction between particles and a pipe wall are effectively reduced, the material transport quality is improved, the service life of the composite pneumatic transport rotational flow elbow pipe is effectively prolonged,meanwhile, local pressure loss is reduced, and the working efficiency of a pneumatic transport system is improved.

Owner:CHINA UNIV OF MINING & TECH

Gas suction silencer, compressor and refrigerator

ActiveCN111894832AReduce suction noiseReduce local pressure lossPositive displacement pump componentsPositive-displacement liquid enginesIceboxEngineering

The invention provides a gas suction silencer, a compressor and a refrigerator. The gas suction silencer comprises a shell. A gas inlet and an exhaust port are formed in the shell. A partition plate is arranged in an inner cavity of the shell. The inner cavity is divided into an upper cavity corresponding to the exhaust port and a lower cavity corresponding to the gas inlet through the partition plate. Multiple through holes penetrating through the upper cavity and the lower cavity are formed in the partition plate. The gas suction silencer further comprises multiple oil-gas separation covers.The multiple oil-gas separation covers are arranged on the multiple through holes in a one-to-one correspondence and covering manner and are located on the side, facing the upper cavity, of the partition plate. Each oil-gas separation cover is provided with a flow hole so that the upper cavity and the lower cavity can communicate. According to the gas suction silencer, the compressor and the refrigerator, the cylinder gas suction oil carrying amount can be decreased, and meanwhile the gas suction gas flow resistance and the gas suction noise can be reduced and gas suction can be more uniformand smoother.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Arched cavity fluid flowing floor slab, manufacturing method and flowing pipe

ActiveCN114704015AReduce dosageImprove bearing capacityDischarging arrangementFloorsFloor slabWater flow

The invention relates to the field of buildings, and discloses an arch-shaped cavity fluid flowing floor slab, an arc-shaped groove is formed in the bottom surface of the floor slab, a groove enabling the groove to be communicated with the outer side of the floor slab is formed in the side part of the arc-shaped groove, the depth of the groove is close to that of the groove, and a supporting surface is arranged at the bottom of the floor slab. A groove is formed in the floor, the floor and the supporting face form a box body structure, a cavity and a pipeline are arranged in the box body structure, two arched beam plates which are arranged in a crossed mode are arranged in the groove, the bending degree of the arched beam plates is consistent with the radian of the groove, and beam feet at the two ends of the arched beam plates are fixedly connected with the supporting face. The concrete consumption is reduced, the bearing capacity of the whole structure is improved, reinforcing steel bars do not need to be embedded into the floor slab for reinforcement, the flowing pipe formed by arranging the floor slabs has no obvious sudden expansion and sudden shrinkage structures, local pressure loss in the flowing process of airflow or water flow is effectively reduced, and the efficiency of fluid flowing work such as smoke exhaust, ventilation and water drainage is remarkably improved.

Owner:CHINA UNIV OF MINING & TECH

Washing pump of dishwasher and dishwasher

ActiveCN109247895AImprove work efficiencyReduce local pressure lossTableware washing/rinsing machine detailsWater flowEngineering

The invention discloses a washing pump of a dishwasher and the dishwasher. The dishwasher includes spray arms, the washing pump includes a pump shell with an inner chamber, openings are arranged in the pump shell and communicate with the spray arms, a diversion piece is arranged in the inner chamber of the pump shell, and parts of structures of the diversion piece are located within projection ofthe openings in the inner cavity; and the diversion piece is used for guiding water flows in the pump shell to change moving directions to break up a vortex and reduce local pressure loss of the waterflows. By using of the washing pump and the dishwasher, energy loss caused by "dead water zones" or "vortex zones" in the washing pump can be eliminated, and therefore working efficiency of the washing pump is improved.

Owner:QINGDAO HAIER DISHWASHER

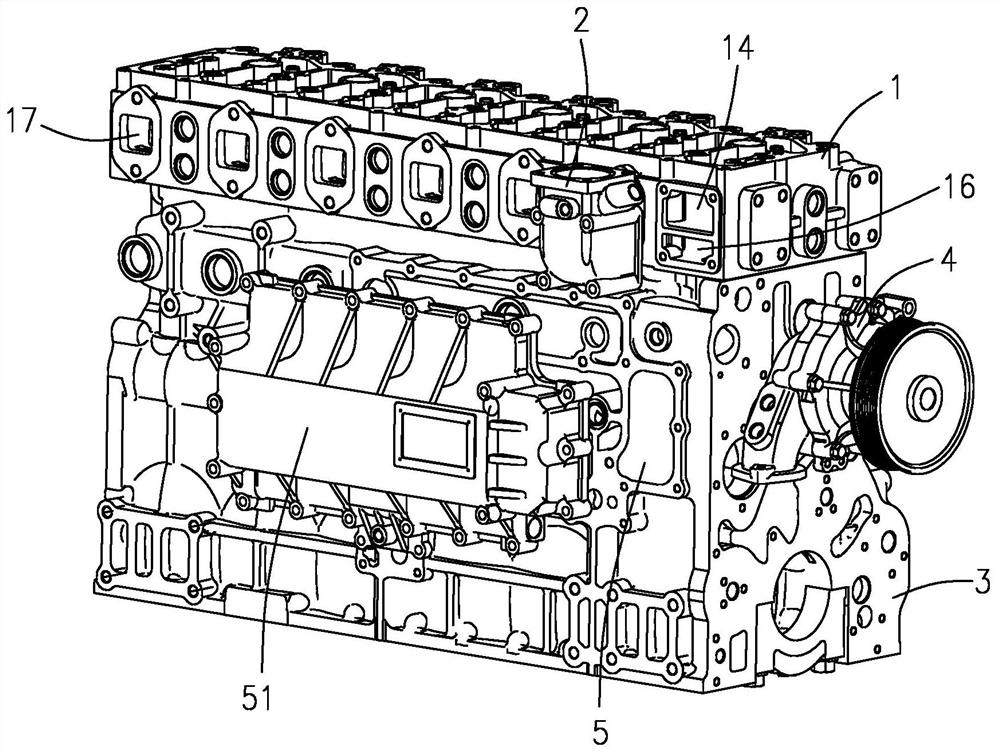

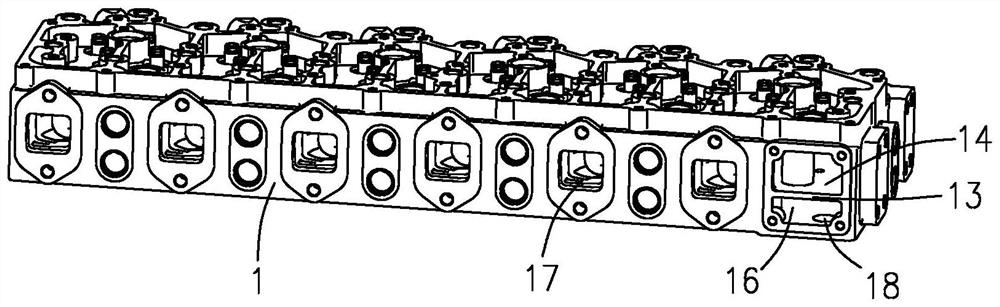

Cylinder cover and engine

PendingCN114837844AMeet the needs of the jobReduce resistanceLiquid coolingCoolant flow controlMarine engineeringStructural engineering

The invention provides a cylinder cover which comprises an upper-layer water jacket, a lower-layer water jacket, a partition plate and a first cavity, the upper-layer water jacket is provided with a first water outlet, the first cavity comprises a second water outlet and a first water inlet, and the first water outlet is formed above the first water inlet. The invention further provides an engine which comprises an engine body, a thermostat shell and the cylinder cover, the second water outlet is formed in the bottom of the cylinder cover, an engine body water return opening is formed in the top of the engine body, the second water outlet is communicated with the engine body water return opening, and the first water outlet and the first water inlet are both communicated with the thermostat shell. The cylinder cover, the engine body and the thermostat shell are directly connected, the circulating water paths are all arranged in the engine, external pipelines of the engine body are omitted, pressure loss is small, and efficiency is high.

Owner:JIANGSU CHANGFA AGRI EQUIP

A thrust chamber collector with flow sharing function

ActiveCN104948347BRealize secondary current sharingUniform pressureRocket engine plantsCombustion chamberThrust chamber

The invention relates to the liquid rocket propulsion technology, and particularly discloses a thrust chamber collector with a flow uniformizing function. A body shell is composed of an inner wall and an outer wall together. A cylinder formed when the inner wall is closed serves as a combustion chamber. An interlayer between the inner wall and the outer wall forms a cooling passageway. Annular grooves are formed in the inlet and the outlet of the cooling passageway. A bent pipe of the collector is welded and connected to the body shell at the annular groove in the inlet of the cooling passageway. A collector cavity is formed by the bent pipe and the body shell. The opening of the collector cavity is welded and connected to an inlet flange to form a collector inlet. Due to the double-collection-cavity structure, fluid is secondarily uniformized before entering the cooling passageway; by means of a horn-shaped expansion inlet with a reverse-Y-shaped diversion piece, fluid can more stably turn at the collector inlet, pressure fluctuation at the inlet and the two sides is reduced, local pressure loss can be reduced, and the diversion piece can play a role in reinforcing structure supporting.

Owner:BEIJING AEROSPACE PROPULSION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com