Low-resistance rainproof noise reduction device for air inlet

An air inlet and windward side technology, applied in the field of noise reduction, can solve the problems of poor noise reduction and ventilation, large volume, difficult to disassemble and replace, and reduce volume, etc., to achieve good sound insulation, good rainproof effect, and reduce pressure. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

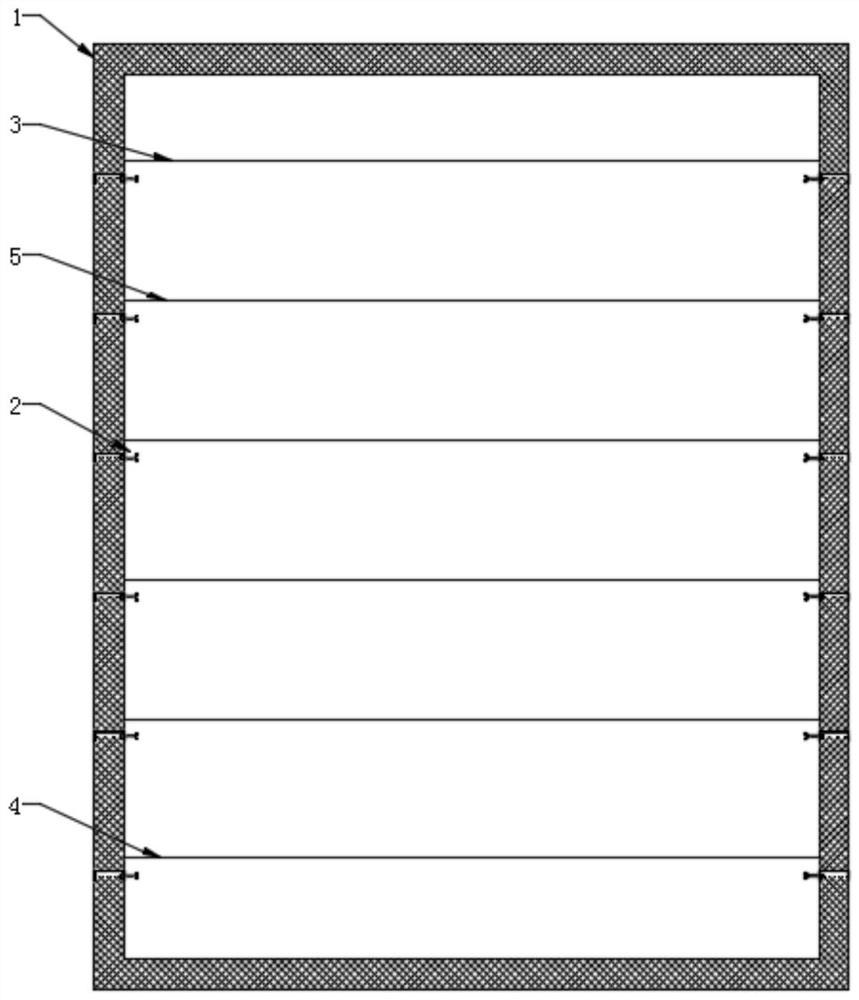

[0045] Such as figure 1 As shown, a low-resistance rain-proof and noise-reducing device for air inlets includes an outer frame 1, a first sound-absorbing sheet 3 detachably fixed on the upper part of the outer frame 1 through a fixing assembly 2, and a first sound-absorbing sheet 3 fixed in the outer frame 1 The second sound-absorbing sheet 4 at the bottom and the third sound-absorbing sheet 4 arranged between the first sound-absorbing sheet 3 and the second sound-insulating sheet 4 are detachably fixed inside the outer frame 1 through the fixing assembly 2 and evenly spaced. Sound insulation sheet 5.

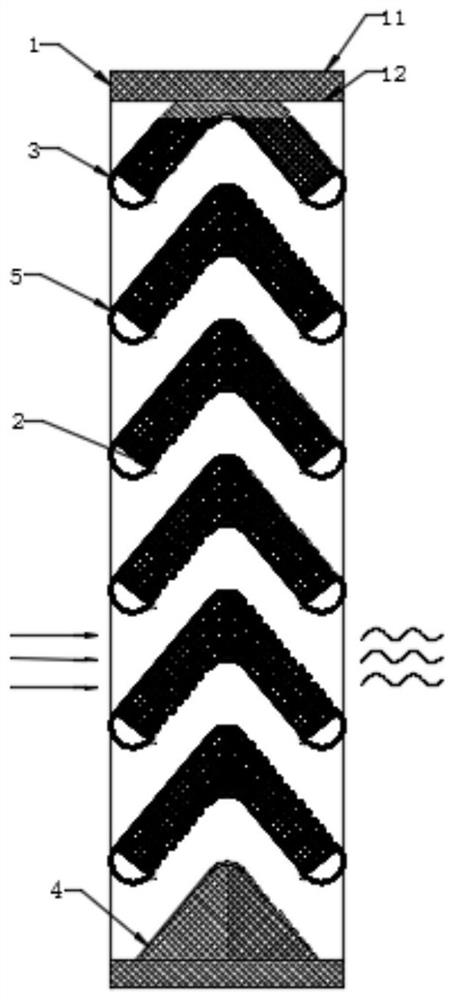

[0046] Such as figure 2 As shown, the outer frame 1 includes an outer surface 11 and an inner surface 12 with through holes, a cavity is formed between the outer surface 11 and the inner surface 12, and the interior is filled with sound-absorbing materials.

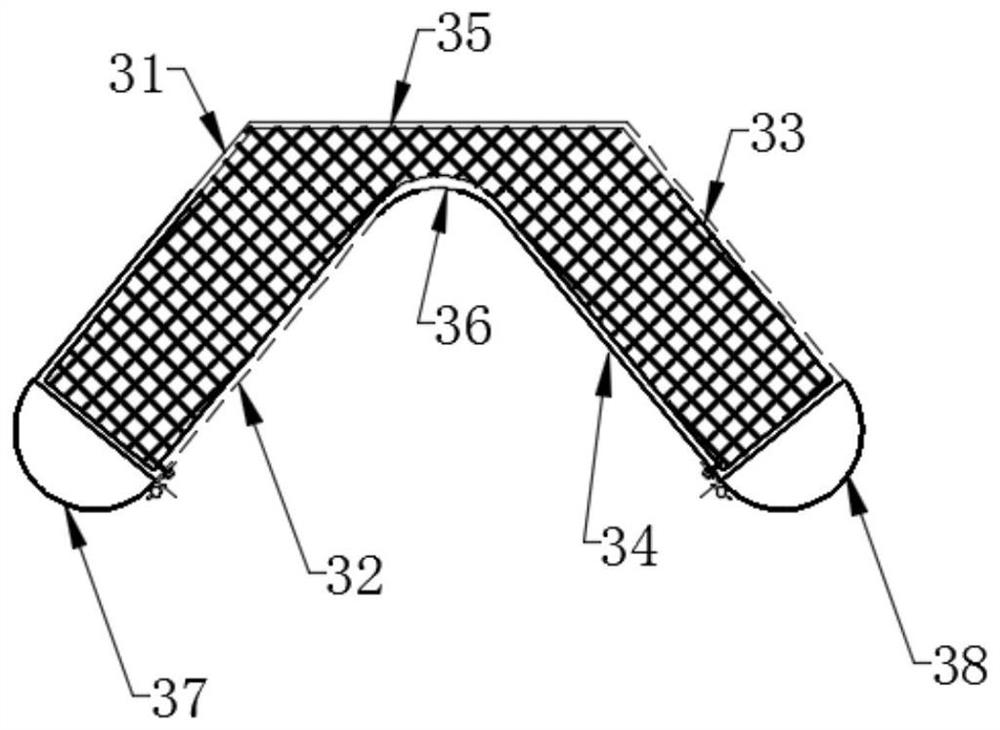

[0047] Such as image 3 As shown, the first sound-absorbing and insulating sheet 3 includes a first upper windward s...

Embodiment 2

[0051] Such as figure 1 As shown, a low-resistance rain-proof and noise-reducing device for air inlets includes an outer frame 1, a first sound-absorbing sheet 3 detachably fixed on the upper part of the outer frame 1 through a fixing assembly 2, and a first sound-absorbing sheet 3 fixed in the outer frame 1 The second sound-absorbing sheet 4 at the bottom and the third sound-absorbing sheet 4 arranged between the first sound-absorbing sheet 3 and the second sound-insulating sheet 4 are detachably fixed inside the outer frame 1 through the fixing assembly 2 and evenly spaced. Sound insulation sheet 5.

[0052] Such as figure 2 As shown, the outer frame 1 includes an outer surface 11 and an inner surface 12 with through holes, a cavity is formed between the outer surface 11 and the inner surface 12, and the interior is filled with sound-absorbing materials.

[0053] Such as Figure 6 As shown, several frame-shaped internal skeletons 13 corresponding to the positions of the ...

Embodiment 3

[0059] Such as figure 1 As shown, a low-resistance rain-proof and noise-reducing device for air inlets includes an outer frame 1, a first sound-absorbing sheet 3 detachably fixed on the upper part of the outer frame 1 through a fixing assembly 2, and a first sound-absorbing sheet 3 fixed in the outer frame 1 The second sound-absorbing sheet 4 at the bottom and the third sound-absorbing sheet 4 arranged between the first sound-absorbing sheet 3 and the second sound-insulating sheet 4 are detachably fixed inside the outer frame 1 through the fixing assembly 2 and evenly spaced. Sound insulation sheet 5; the distance between the third sound absorption sheet 5 is 80mm, the distance between the third sound absorption sheet 5 and the first sound absorption sheet 3 is 80mm, the third absorption sound insulation sheet 5 and the first sound insulation sheet The distance between the two sound insulation sheets 4 is 80mm.

[0060] Such as figure 2 As shown, the outer frame 1 includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com