Motor Vehicle Muffler

A muffler and motor vehicle technology, which is applied in the direction of machines/engines, mufflers, mechanical equipment, etc., can solve the problems of short service life and high production cost of the muffler, and achieve the effect of improving muffler volume and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

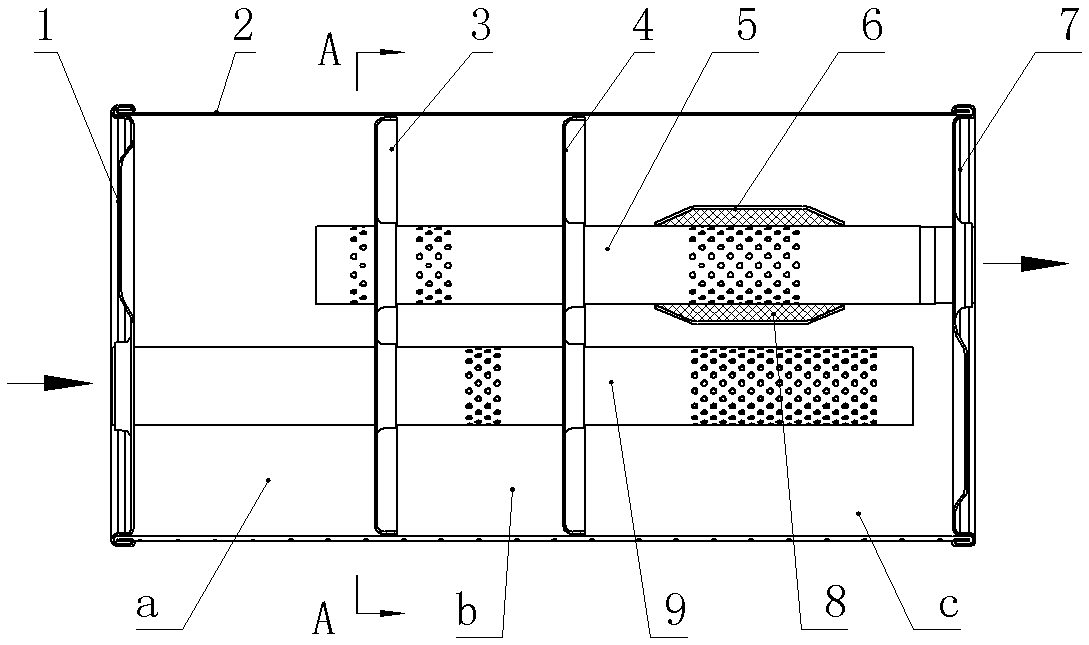

[0013] like figure 1 and figure 2 The motor vehicle muffler shown includes a casing provided with an air intake pipe 9 and an air outlet pipe 5. The casing is formed by connecting the front end cover 1, the rear end cover 7 and the cylinder body 2, and the cylinder body 2 is formed by two layers of overlapping steel plate locking seams. Enclosed, the thickness of the two layers of steel plates is the same and both are 0.6 mm. The connection between the cylinder body and the front end cover 1 and the rear end cover 7 is the end cover crimping connection, and the edge of the rear end cover 7 is provided with a drainage through hole; The inner space is divided into a first chamber a, a second chamber b and a third chamber c by the first baffle plate 3 and the second baffle plate 4 with holes along the intake direction. The edge of the partition plate 4 is provided with a drainage gap, and the first partition plate 3 and the second partition plate 4 are provided with a plurality...

Embodiment 2

[0015] The number of through holes on the perforated pipe section of the third chamber c of the intake pipe 9 is 5 times that of the number of through holes on the perforated pipe section of the second chamber b; The third chamber c is respectively provided with a perforated pipe section on which a plurality of through holes are distributed, and the sum of the equivalent areas of the holes on the two perforated pipe sections of the intake pipe 9 is the hole in the second chamber b of the exhaust pipe 5 2.1 times the sum of the flow area of the through hole on the pipe section and the hole on the first partition; the first partition 3 and the second partition 4 are provided with a plurality of holes with a diameter of 4 mm and a diameter of 20 mm. The large holes 10, the plurality of 4 mm holes 11 on the first separator 3 and the second separator 4 are evenly distributed; other features are the same as those in Embodiment 1.

[0016] During operation, the airflow enters from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com