Micropump structure based on liquid metal at room temperature

A liquid metal and micropump technology, applied in the field of microfluidics, can solve problems such as slow development and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

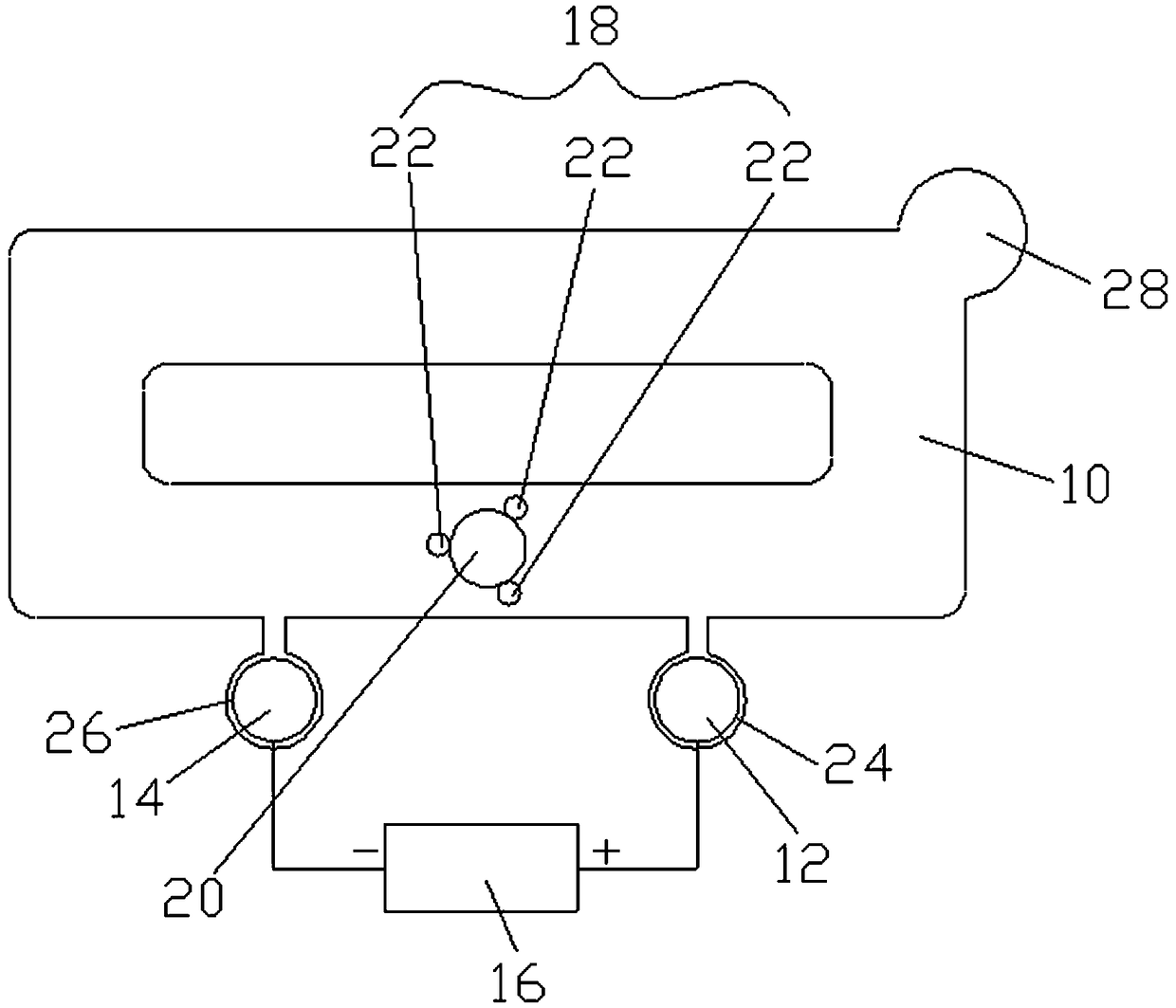

[0019] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0020] Such as figure 1 As shown, a micropump structure based on liquid metal at room temperature includes a channel 10, a first electrode 12, a second electrode 14 and a power generator 16, an open chamber 18 is arranged in the channel 10, and the open chamber 18 contains The liquid metal droplet 20 is used to limit the movement of the liquid metal droplet 20 through the setting of the open chamber 18, so as to maintain the relative position of the liquid metal droplet 20, and at the same time ensure that the liquid metal droplet 20 does not undergo large deformation, and the channel 10 Filled with electrolyte solution (not shown in the figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com