Suction muffler, compressor, refrigerator

A muffler and compressor technology, applied in the fields of compressors, refrigerators, and suction mufflers, can solve the problems of reducing the performance of the compressor and the heat transfer efficiency of the system, increasing the compression power consumption of the compressor, and the large amount of oil in the suction. , to achieve the effect of improving compressor performance, reducing suction resistance and smooth airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

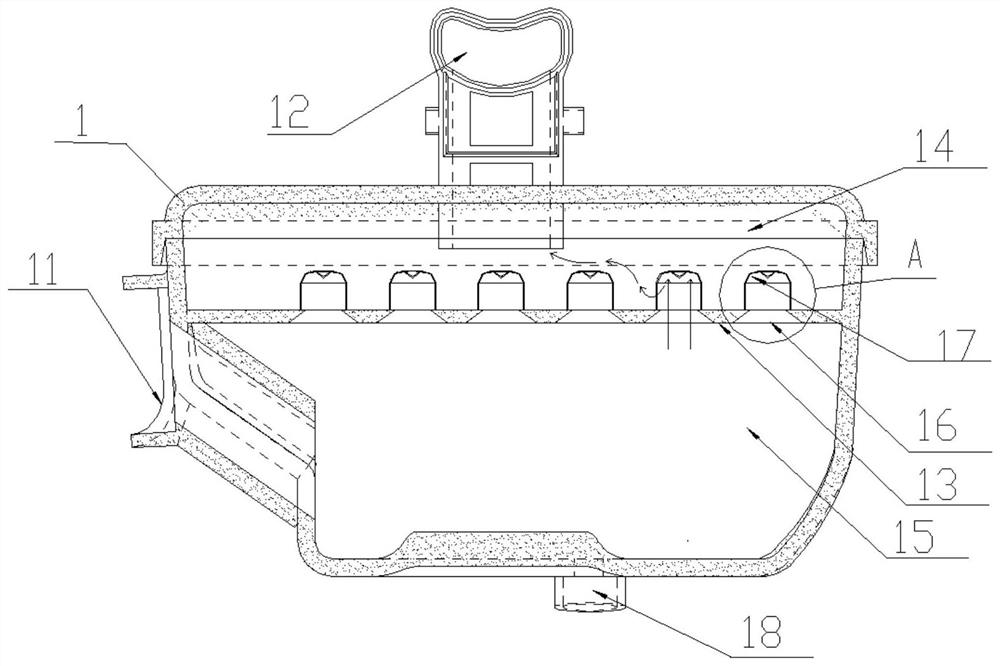

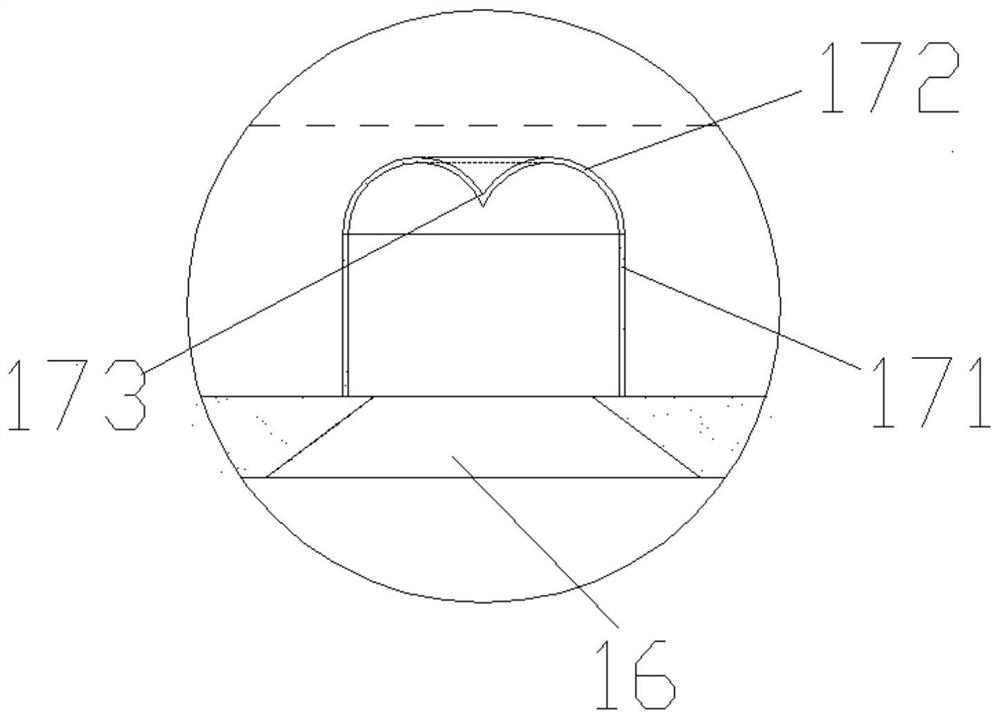

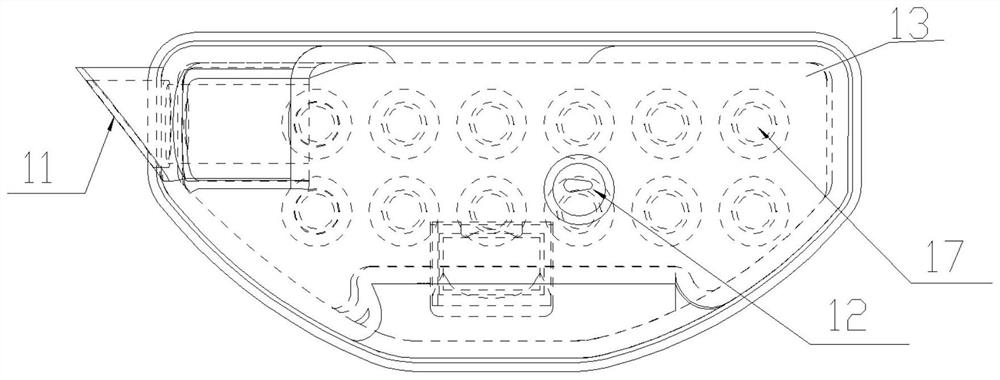

[0023] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, a suction muffler 2 is provided, which includes a housing 1 on which an air inlet 11 and an exhaust port 12 are configured, and the inner cavity of the housing 1 A partition 13 is arranged in the middle, and the partition 13 divides the inner chamber into an upper chamber 14 corresponding to the exhaust port 12 and a lower chamber 15 corresponding to the air inlet 11. The partition 13 The upper structure has a plurality of through holes 16 passing through the upper chamber 14 and the lower chamber 15, and also includes a plurality of oil-gas separation covers 17, and the plurality of oil-gas separation covers 17 are respectively one-to-one correspondingly arranged on the plurality of through-holes. On the hole 16 and on the side of the partition plate 13 facing the upper chamber 14 , the oil-gas separation cover 17 has a flow hole (not shown in the figure) to pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com